WO2025147390A1 - Entangled hydrogel network - Google Patents

Entangled hydrogel networkDownload PDFInfo

- Publication number

- WO2025147390A1 WO2025147390A1PCT/US2024/060731US2024060731WWO2025147390A1WO 2025147390 A1WO2025147390 A1WO 2025147390A1US 2024060731 WUS2024060731 WUS 2024060731WWO 2025147390 A1WO2025147390 A1WO 2025147390A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- formula

- null

- polymer

- ionically charged

- hydrocarbyl group

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Classifications

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L27/00—Materials for grafts or prostheses or for coating grafts or prostheses

- A61L27/28—Materials for coating prostheses

- A61L27/34—Macromolecular materials

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L27/00—Materials for grafts or prostheses or for coating grafts or prostheses

- A61L27/50—Materials characterised by their function or physical properties, e.g. injectable or lubricating compositions, shape-memory materials, surface modified materials

- A61L27/52—Hydrogels or hydrocolloids

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L2430/00—Materials or treatment for tissue regeneration

- A61L2430/20—Materials or treatment for tissue regeneration for reconstruction of the heart, e.g. heart valves

Definitions

- ENTANGLED HYDROGEL NETWORKS CROSS-REFERENCE TO RELATED APPLICATION[0001] This application claims the benefit of U.S. Application No.63/617,620, filed December 4, 2024, the entire disclosure which is incorporated by reference for all purposes.

- FIELD[0002] The present application concerns aspects of chemical compositions that can be used in implantable medical devices. More specifically, the present application relates to entangled hydrogel networks for implantable medical devices to reduce or prevent tissue overgrowth and/or biofouling in implantable medical devices.

- BACKGROUND[0003] The heart can suffer from various valvular diseases or malformations that result in significant malfunctioning of the heart and ultimately require the replacement of the native heart valve with an artificial valve.

- Human heart valveswhich include the aortic, pulmonary, mitral, and tricuspid valves, function essentially as one-way valves operating in synchronization with the pumping heart.

- the valvesallow blood to flow downstream but block blood from flowing upstream.

- Diseased heart valvesexhibit impairments such as narrowing of the valve or regurgitation, which inhibits the valves’ ability to control blood flow.

- Such impairmentsreduce the heart’s blood-pumping efficiency and can be a debilitating and life-threatening condition.

- valve insufficiencycan lead to conditions such as heart hypertrophy and dilation of the ventricle.

- extensive effortshave been made to develop methods and apparatuses to repair or replace impaired heart valves.

- Prosthesesexist to correct problems associated with impaired heart valves.

- mechanical and tissue-based heart valve prosthesescan be used to replace impaired native heart valves.

- substantial efforthas been dedicated to developing replacement heart valves, particularly tissue-based replacement heart valves that can be delivered with less trauma to the patient than through open-heart surgery.

- Replacement valvesare being designed to be delivered through minimally invasive procedures and even percutaneous procedures.

- Such replacement valvesoften include a tissue-based valve body that is connected to an expandable frame that is then delivered to the native valve’s annulus.

- a replacement valvee.g., any foreign body

- different surfaces of the valvecan adsorb various proteins and ultimately elicit a foreign body response leading to cellular accumulation and tissue growth around the valve.

- the overgrowth of various tissuescan lead to structural valve deterioration and reduced implant effectiveness.

- transcatheter valvesexhibit faster leaflet encapsulation and tissue overgrowth.

- surface chemistrycontrols cell adhesion, modulates cell- cell interaction and cellular functions.

- Non-hemolytic polymer coatingscan be used to encourage endothelialization and promote anticoagulation which will lead to less tissue overgrowth over time.

- alkylis a subset of “alkyl” and refers to an alkyl group substituted by an aryl group, wherein the point of attachment is on the alkyl moiety.

- heteroarylrefers to a radical of a 5–14 membered monocyclic or polycyclic (e.g., bicyclic, tricyclic) 4n+2 aromatic ring system (e.g., having 6, 10, or 14 ⁇ electrons shared in a cyclic array) having ring carbon atoms and 1–4 ring heteroatoms provided in the aromatic ring system, wherein each heteroatom is independently selected from nitrogen, oxygen, and sulfur (“5–14 membered heteroaryl”).

- R 1ais O-CH2CH2N(CH3)2. In other implementations R 1a is O-(2-ethylhexyl).

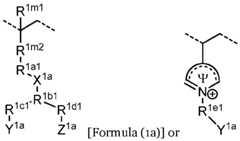

- the first ionically charged polymerincludes repeating units of formula (1a), optionally in combination with repeating units of formula (1e) and/or formula (1f). In some implementations the first ionically charged polymer includes repeating units of formula (1b), optionally in combination with repeating units of formula (1e) and/or formula (1f). In certain implementations the first ionically charged polymer includes repeating units of formula (1a) and formula (1b), optionally in combination with repeating units of formula (1e) and/or formula (1f).

- the first ionically charged polymerincludes repeating units of formula (1a) and formula (1c), optionally in combination with repeating units of formula (1e) and/or formula (1f).

- the first ionically charged polymerincludes repeating units having the formula: wherein R 1a1 is (CH 2 CH 2 O) n , R 1d1 is null, and Z 1a is N + (CH 3 ) 3 , in combination with 2- units, N,N-dimethylaminoethyl methacrylate units, poly(ethylene)glycol methacrylate units, 2-hydroxyethyl methacrylate units, vinylpyrrolidone units, or a combination thereof.

- the first ionically charged polymercontains units having the above formula in combination with 2-ethylhexyl methacrylate units and N,N- dimethylaminoethyl methacrylate units.

- the first ionically charged polymerincludes 2- methacryloyloxyethyl phosphorylcholine (MPC) units, sulfobetaine methacrylate (SBMA) units, carboxybetaine methacrylate (CBMA) units, or any combination thereof, optionally in combination with 2-ethylhexyl methacrylate units, N,N-dimethylaminoethyl methacrylate units, poly(ethylene)glycol methacrylate units, 2-hydroxyethyl methacrylate units, vinylpyrrolidone units, or a combination thereof.

- MPC2- methacryloyloxyethyl phosphorylcholine

- SBMAsulfobetaine methacrylate

- CBMAcarboxybetaine methacrylate

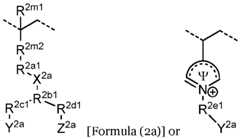

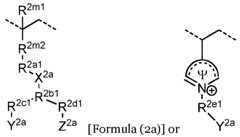

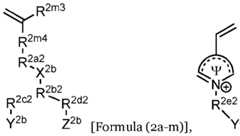

- the repeating unit of formula (2d)may include repeating units having the formula: , or a [0128]

- X 2bis N + (CH3)2, and Y 2b is not H.

- X 2bis -O-PO 2 – -O-, and Y 2b is H.

- the repeating unit of formula (2c)includes units having the formula: , R 2f2 is O or NH; Y 2b is carboxylate; sulfonate, or phosphonate; and Z 2b is H or -N + (R n1 ) 3 .

- the repeating unit of formula (2c)includes units having the formula: , or a implementations n is 2.

- the second ionically charged polymercan include neutral repeating units of vinyl alcohol, formula (2e), formula (2f), or a combination thereof: [ Formula (1f)], wherein R 2m5 is H or CH3; R 2m6 is H or CH3; and R 2a is OR 2b or N(R 2b ) 2 , wherein R 2b is in each case independently selected from H, C 1– 12 hydrocarbyl, wherein R 2b may be substituted one or more times by OH, OC1–6 alkyl, NH 2 , NH(C 1–6 alkyl), or N(C 1–6 alkyl) 2 .

- R 2ais O-CH2CH2N(CH3)2. In other implementations R 2a is O-(2-ethylhexyl).

- the second ionically charged polymerincludes repeating units of formula (2a), optionally in combination with repeating units of formula (2e) and/or formula (2f). In some implementations the second ionically charged polymer includes repeating units of formula (2b), optionally in combination with repeating units of formula (2e) and/or formula (2f). In certain implementations the second ionically charged polymer includes repeating units of formula (2a) and formula (2b), optionally in combination with repeating units of formula (2e) and/or formula (2f).

- the second ionically charged polymerincludes repeating units of formula (2a) and formula (2c), optionally in combination with repeating units of formula (2e) and/or formula (2f).

- the second ionically charged polymerincludes repeating units having the formula: wherein R 2a2 is (CH2CH2O)n, R 2c2 is null, and Y 2b is sulfonate, carboxylate or phosphonate, with 2-ethylhexyl methacrylate units, N,N-dimethylaminoethyl methacrylate units, poly(ethylene)glycol methacrylate units, 2-hydroxyethyl methacrylate units, vinylpyrrolidone units, or a combination thereof.

- the repeating unit of formula (Xd)may include repeating units having the formula: , or a [0150]

- X Ybis N + (CH 3 ) 2 , and Y Yb is not H.

- X Ybis -O-PO2 – -O-, and Y Yb is H.

- the repeating unit of formula (Xc)includes units having the formula: , R Yf2 is O or NH; Y Yb is carboxylate; sulfonate, or phosphonate; and Z Yb is H or -N + (R n1 ) 3 .

- the repeating unit of formula (Xc)includes units having the formula: , or a implementations n is 2.

- the brush polymercan include neutral repeating units of vinyl alcohol, formula (Xe), formula (Xf), or a combination thereof: [Formula (Xf)], wherein R Ym5 is H or CH 3 ; R Ym6 is H or CH3; and R Ya is OR Yb or N(R Yb )2, wherein R Yb is in each case independently selected from H, C1– 12 hydrocarbyl, wherein R Yb may be substituted one or more times by OH, OC1–6 alkyl, NH 2 , NH(C 1–6 alkyl), or N(C 1–6 alkyl) 2 .

- R Yais O-CH 2 CH 2 N(CH 3 ) 2 . In other implementations R Ya is O-(2-ethylhexyl).

- the brush polymeris a poly(2-acrylamido-2-methyl- 1-propanesulfonic acid) (“PAAMPS”).

- PAAMPSpoly(2-acrylamido-2-methyl- 1-propanesulfonic acid)

- the first ionically charged polymeris a copolymer of (2-acrylamido-2-methyl-1-propanesulfonic acid) and vinyl alcohol (“PAAMPS-PVA”).

- the second ionically charged polymerincludes repeating units of formula (Xa) and formula (Xb), optionally in combination with repeating units of formula (Xe) and/or formula (Xf). In some implementations the second ionically charged polymer includes repeating units of formula (Xa) and formula (2c), optionally in combination with repeating units of formula (Xe) and/or formula (Xf). In certain implementations, the brush polymer includes repeating units of formula (Xe) and/or formula (Xf), and does not include repeating units of (Xa), (Xb), (Xc), or (Xd).

- the first ionically charged polymeris one of poly(lysine acrylamide), poly(2-methacryloyloxyethyl phosphorylcholine), poly[2- (methacryloyloxy)ethyl dimethyl-(3-sulfopropyl)ammonium hydroxide)], poly(sulfobetaine vinyl imidazole), poly(sulfobetaine acrylamide), poly(carboxybetaine methacrylate), a combination thereof, or a copolymer thereof.

- the first ionically charged polymeris a copolymer including the aforementioned ionic component in combination with polyvinyl alcohol, polyvinylpyrrolidone, or a combination thereof.

- the second ionically charged polymeris one of poly(lysine acrylamide), poly(2-methacryloyloxyethyl phosphorylcholine), poly[2- (methacryloyloxy)ethyl dimethyl-(3-sulfopropyl)ammonium hydroxide)], poly(sulfobetaine vinyl imidazole), poly(sulfobetaine acrylamide), poly(carboxybetaine methacrylate), a combination thereof, or a copolymer thereof.

- the brush charged polymeris a copolymer including the aforementioned ionic component in combination with polyvinyl alcohol, polyvinylpyrrolidone, or a combination thereof.

- the first ionically charged polymeris poly(lysine acrylamide), poly(2-methacryloyloxyethyl phosphorylcholine), poly[2- (methacryloyloxy)ethyl dimethyl-(3-sulfopropyl)ammonium hydroxide)],

- the second ionically charged polymeris poly(sulfobetaine vinyl imidazole), poly(sulfobetaine acrylamide), poly(carboxybetaine methacrylate), and the brush polymer is poly(sulfobetaine vinyl imidazole), poly(sulfobetaine acrylamide), poly(carboxybetaine methacrylate).

- the entangled hydrogel networkcan be prepared by forming the second ionically charged polymer in the presence of the first ionically charged polymer, wherein the first ionically charged polymer can be crosslinked.

- the first ionically charged polymeris combined with second ionically charged polymer-precursor(s) in an aqeuous solvent.

- the compound of formula 2a-m, formula 2b-m, or combination thereofis polymerized in the presence of a crosslinker.

- exemplary crosslinkinersinclude bis(meth)acrylates, bis(meth)acrylamides, diimides, and divinyl compounds.

- the compound of formula 2a-m, formula 2b-m, or combination thereofis polymerized in the absence of a crosslinker, and then crosslinked in a separate step following formation of the second ionically charged polymer.

- the compound of formula 2a-m, formula 2b-m, or combination thereofis polymerized in the presence of an initiator.

- the initiatorcan be a photoinitiator or a thermal initiator.

- photoinitiatorsinclude: acetophenone, 2- phenylacetophenone, 2-hydroxy-2-methylpro piophenone, 4-hydroxybenzophenone, 4,4- dihydroxybenzophenone, 4-(dimethylamino) benzophenone 4-ethoxyacetophenone, 4- phenoxyacetophenone, hexafluorophosphate, anthraquinone, anthraquinone-2-sulfonic acid, sodium salt monohydrate; tricarbonylchromium, benzoin based initiators, benzoin methyl ether, benzoin isobutyl ether, 2-hydroxy-4-(2-hydroxy ethoxy )-2- methylpropiophenone, benzil ketal based initiators dialkoxyacetophenone, hydroxyphenone, phenyl ketone, aminoalkylphenone, acylphosphine oxide, benzophenone, thioxanthone, azobisisobutyronitrile, lithium phenyl

- the initiator in the prepolymer solutionranges between 0.01 wt % to 10 wt %.

- the compound of formula 2a-m, formula 2b-m, or combination thereofis polymerized by exposure to actinic radiation, for example UV irradiation.

- the polymerizationcan be carried out in solution with a 100 to 300:1:1 mol ratio between the monomer(s), initiator and the catalyst, respectively. In a typical synthesis, a flask can be charged with catalyst, then monomer and solvent. In some implementations, the solution is degassed and second monomer is added. In some implementations the molar ratio of the different monomers is from 1:5 to 1:3.

- the reaction mixturemaintained at a temperature between 50–100 °C for 1–24 hours.

- the final polymeris poured into different solvent, filtered and finally purified through column chromatography/filtration (e.g., through Florisil® magnesium silicate) with another solvent.

- the first ionically charged polymer (whether crosslinked or not) and compound of formula 2a-m, formula 2b-m, or combination thereofcan be provided in a reaction media (e.g., a solution or suspension with one or more solvents), or the first ionically charged polymer and compound of formula 2a-m, formula 2b-m, or combination thereof (and optional crosslinking agent) is disposed as a film on the surface of valve component, and then polymerized.

- a reaction mediae.g., a solution or suspension with one or more solvents

- the resulting entangled hydrogelmay then be disposed on the surface of a valve component.

- the second ionically charged polymermay be crosslinked prior to disposition on the valve surface.

- the second ionically charged polymermay be crosslinked subsequent to disposition on the valve surface.

- the second ionically charged polymeris not crosslinked.

- the compound of formula 1a-m, formula 1b-m, or combination thereofis polymerized in the presence of a crosslinker, as defined above.

- the compound of formula 1a-m, formula 1b-m, or combination thereofis polymerized in the presence of an initiator, as defined above.

- compound of formula 1a-m, formula 1b-m, or combination thereofcan be provided in a reaction media (e.g., a solution or suspension with one or more solvents), or the compound of formula 1a-m, formula 1b-m, or combination thereof (and optional crosslinking agent) is disposed as a film on the surface of valve components, and then polymerized.

- the resulting first ionically charged polymermay then be disposed on the surface of a valve component.

- the first ionically charged polymermay be crosslinked prior to disposition on the valve surface.

- the first ionically charged polymermay be crosslinked subsequent to disposition on the valve surface.

- the first ionically charged polymeris not crosslinked.

- the entangled hydrogel networkis applied to a surface of a valve component by grafting the entangled hydrogel to the surface or coating the entangled hydrogel on the surface.

- conjugationsmay be accomplished using nucleophile/electrophile chemistry or cycloaddition chemistry (including click-cycloaddition chemistry).

- the conjugationis accomplished using a reaction between a first functional group selected from an alcohol, thiol, amine, or carboxylate and a second functional group selected from an isocyanate, epoxide, activated carboxylate (e.g., acid chloride, NHS ester), and a Michael acceptor (e.g., an alkene or alkyne or acetylene directly bonded to an electron withdrawing group like a ketone, ester, cyano, nitro, sulfone, or sulfonyl).

- a first functional groupselected from an alcohol, thiol, amine, or carboxylate

- a second functional groupselected from an isocyanate, epoxide, activated carboxylate (e.g., acid chloride, NHS ester)

- a Michael acceptore.g

- the conjugationis accomplished using a click chemistry: Cu(I)-catalyzed azide-alkyne click chemistry reaction, strain-promoted azide-alkyne click chemistry reaction (SPAAC), cycloaddition between tetrazine and alkene (trans-cyclooctene).

- the alkyneis a cyclooctyne like a dibenzocyclooctyne or bicyclo[6.1.0]nonyne.

- the prerequisite reactive groupmay be included in the entangled hydrogel by including the relevant monomer in the polymerization reaction.

- a brush polymercan be directly formed on the entangled hydrogel network.

- the entangled hydrogelis first functionalized with an anchor compound using the chemistries disclosed above.

- the anchor compoundinclude a polymerizable group, for example a radically labile group such as a (meth)acrylate or meth(acrylamide).

- the entangled hydrogelis functionalized with the radically labile group it can be combined with one or more appropriate monomers (e.g., (meth)acrylates, (meth)acylamides, and/or vinyl compounds) and subjected to conditions suitable to polymerize the monomers.

- the brush polymeris not covalently conjugated to the entangled hydrogel, but rather mechanically conjugated.

- a portion of the brush polymeris physically entangled with the entangled network.

- the entangled hydrogelmay be swelled in a solution including the brush polymer. A portion of the brush polymer will penetrate the hydrogel.

- various surfactants, plasticizers, and the likemay be included in the solvent to facilitate penetration (a penetration aid) of the brush polymer.

- the penetration aidcan include polyethylene glycol, polypropylene oxide, pectin, carrageenan, polylysine, gelatins (including gelatin type A), agarose, PEO-PPO-PEO copolymers (Pluronics® polymers), poly(phosphazene), hyaluronans, chitosans, agar, heparin, sulfate, cellulose, alginates (including alginate sulfate), collagen, dextrans (including dextran sulfate), poly(hydroxyethyl methacrylate), (poly(methyl methacrylate, poly(N-isopropylacrylamide), poly(lactic acid), poly(lactic-co-glycolic acid), poly(N- vinylpyrrolidone), PL(G)A-PEO-PL(G)

- the exemplary implantable medical devicecan comprise a frame 1000, as shown in FIG.1.

- the frame 1000is shown in an expanded configuration.

- the frame 1000can include a frame portion 1002.

- frame portion 1002will include an entangled hydrogel network.

- Frame portion 1002can include an inner frame side 1002a and an outer frame side 1002b.

- inner frame side 1002acan include an entangled hydrogel network, while outer frame side 1002b does not.

- outer frame side 1002bcan include an entangled hydrogel network, while inner frame side 1002a does not.

- both inner frame side 1002a and outer frame side 1002bcan include an entangled hydrogel network.

- inner frame side 1002a and outer frame side 1002bcan include the same entangled hydrogel network, while in other implementations inner frame side 1002a will include a different entangled hydrogel network than outer frame side 1002b.

- inner skirt 2016includes an entangled hydrogel network.

- Inner skirt 2016can have an inner side 2016a and an outer side 2016b.

- inner skirt, inner side 2016aincludes an entangled hydrogel network.

- inner skirt, outer side 2016bincludes an entangled hydrogel network.

- both inner skirt, inner side 2016a and inner skirt, outer side 2016bcan include an entangled hydrogel network.

- inner skirt, inner side 2016a and inner skirt, outer side 2016bcan include the same entangled hydrogel network.

- inner skirt, inner side 2016a and inner skirt, outer side 2016bcan include different entangled hydrogel networks.

- the implantable medical devices disclosed hereincan comprise a mitral replacement valve or a tricuspid replacement valve, among other forms of valves (e.g., aortic replacement valves, pulmonary replacement valves, or other valves).

- the implantable medical devices disclosed hereincan include prosthetic heart valves or other forms of implants, such as stents or filters or diagnostic devices, among others.

- the implantable medical devicescan be expandable implants configured to move from a compressed or undeployed state to an expanded or deployed state.

- the implantable medical devicescan be compressible implants configured to be compressed inward to have a reduced outer profile and to move the implant to the compressed or undeployed state.

- Various forms of delivery apparatusescan be utilized with the examples disclosed herein.

- Example 13The device of any example herein, particularly Examples 1–12, wherein the outer surface of the inner skirt comprises the entangled hydrogel network, and the inner surface of the inner skirt does not comprise the entangled hydrogel network.

- Example 14The device of any example herein, particularly Examples 1–13, wherein the inner surface and outer surface of the inner skirt comprise the entangled hydrogel network.

- Example 15The device of any example herein, particularly Examples 1–14, wherein the inner surface of the frame comprises the entangled hydrogel network.

- Example 16The device of any example herein, particularly Examples 1–15, wherein the inner surface of the frame comprises the entangled hydrogel network, and the outer surface of the frame does not comprise the entangled hydrogel network.

- Example 17The device of any example herein, particularly Examples 1–16, wherein the outer surface of the frame comprises the entangled hydrogel network.

- Example 18The device of any example herein, particularly Examples 1–17, wherein the outer surface of the frame comprises the entangled hydrogel network, and the inner surface of the frame does not comprise the entangled hydrogel network.

- Example 19The device of any example herein, particularly Examples 1–18, wherein the inner surface and outer surface of the frame comprise the entangled hydrogel network.

- Example 23The device of any example herein, particularly Examples 1–22, wherein the outer surface of the outer skirt comprises the entangled hydrogel network, and the inner surface of the outer skirt does not comprise the entangled hydrogel network.

- Example 24The device of any example herein, particularly Examples 1–23, wherein the inner surface and outer surface of the outer skirt comprise the entangled hydrogel network.

- Example 25The device of any example herein, particularly Examples 1–24, wherein the outer surface of the frame comprises a covered portion covered by the outer skirt, and an exposed portion that is not covered by the outer skirt.

- Example 26The device of any example herein, particularly Examples 1–25, wherein the exposed portion of the outer surface of the frame comprises the entangled hydrogel network.

- Example 27The device of any example herein, particularly Examples 1–26, wherein the inner surface of the frame comprises the entangled hydrogel network, and the outer surface of the frame does not comprise the entangled hydrogel network.

- Example 28The device of any example herein, particularly Examples 1–27, wherein each leaflet comprises the entangled hydrogel network.

- Example 29The device of any example herein, particularly Examples 1–28, wherein the leaflet structure comprises two or three leaflets.

- Example 30The device of any example herein, particularly Examples 1–29, wherein the leaflet structure comprises pericardial tissue (e.g., bovine pericardial tissue), biocompatible synthetic polymers (e.g., polyurethane, polyethylene terephthalate), or a combination thereof.

- pericardial tissuee.g., bovine pericardial tissue

- biocompatible synthetic polymerse.g., polyurethane, polyethylene terephthalate

- Example 31The device of any example herein, particularly Examples 1–30, wherein the frame comprise a metal (pure titanium, cobalt–chromium-nickel or molybdenum alloys such as Elgiloy® alloy, stainless steel (316L), nickel ⁇ titanium alloy (nitinol), platinum, and tantalum alloys or magnesium alloys, a metal-based frame with ceramic-coated, or a combination thereof.

- metalpure titanium, cobalt–chromium-nickel or molybdenum alloys such as

- Example 32The device of any example herein, particularly Examples 1–31, wherein the frame comprises nickel-titanium alloy, cobalt-chromium alloy, nickel-cobalt- chromium alloy, nickel-cobalt-chromium-molybdenum alloy, stainless steel, [0230]

- Example 33The device of any example herein, particularly Examples 1–32, wherein the skirt comprises of the following polymer yarns that can be constructed into textile (wovens or knit warps) such as polyhydroxyalkanoates (PHAs) and polyethylene furanoate (PEF) polyethylene terephthalate (PET) polyamides of high molecular weight such as Nylon 6, 6,6, 12, 610, 1010.

- PHAspolyhydroxyalkanoates

- PEFpolyethylene furanoate

- PETpolyethylene terephthalate

- Example 34The device of any example herein, particularly Examples 1–33, wherein the inner skirt is sutured to the frame with sutures, wherein said sutures comprise an ionically charged polymer coating.

- Example 35The device of any example herein, particularly Examples 1–34, comprising a first entangled hydrogel network and a second entangled hydrogel network, wherein the inner surface of the frame comprises the first entangled hydrogel network, and the inner skirt comprises the second entangled hydrogel network.

- Example 36The device of any example herein, particularly Examples 1–35, wherein the first entangled hydrogel network is mechanically bonded to the frame, and the second entangled hydrogel network is covalently bonded to the inner skirt.

- Example 37The device of any example herein, particularly Examples 1–36, wherein the entangled hydrogel network is covalently incorporated into the polymeric structure or attached to the surface.

- Example 38The device of any example herein, particularly Examples 1–37, wherein the entangled hydrogel network is mechanically bonded to the surface.

- Example 39The device of any example herein, particularly Examples 1–38, wherein the entangled hydrogel network has a thickness from 10 nm – 100 ⁇ m, from 10 nm – 1,000 nm, from 10 nm – 500 nm, from 50 nm – 500 nm, from 50 nm – 250 nm, from 250 nm – 500 nm, from 500 nm – 2,500 nm, from 500 nm – 1,500 nm, from 1 ⁇ m – 100 ⁇ m, from 1 ⁇ m – 5 ⁇ m, from 1 ⁇ m – 10 ⁇ m, from 5 ⁇ m – 15 ⁇ m, from 10 ⁇ m – 25 ⁇ m, from 10 ⁇ m – 50 ⁇ m, from 25 ⁇ m – 50 ⁇ m, from 50 ⁇ m – 75 ⁇ m, or from 75 ⁇ m – 100 ⁇ m.

- Example 40The device of any example herein, particularly Examples 1–39, wherein the entangled hydrogel network comprises a first ionically charged polymer and a second ionically charged polymer.

- Example 41The device of any example herein, particularly Examples 1–40, wherein the entangled hydrogel network comprises a first ionically charged polymer, a second ionically charged polymer, and a third ionically charged polymer.

- Example 42The device of any example herein, particularly Examples 1–41, wherein the first ionically charged polymer is a crosslinked polymer or is not a crosslinked polymer.

- Example 43The device of any example herein, particularly Examples 1–42, wherein the first ionically charged polymer comprises a backbone and one or more side chains.

- Example 44The device of any example herein, particularly Examples 1–43, wherein the first ionically charged polymer is a homopolymer or copolymer.

- Example 45The device of any example herein, particularly Examples 1–44, wherein the first ionically charged polymer is a cationic polymer, anionic polymer, or zwitterionic polymer.

- Example 46The device of any example herein, particularly Examples 1–45, wherein the first ionically charged polymer has an ionically charged polymer backbone.

- Example 47The device of any example herein, particularly Examples 1–46, wherein the backbone of the first ionically charged polymer comprises quaternary ammonium groups.

- Example 48The device of any example herein, particularly Examples 1–47, wherein the backbone of the first ionically charged polymer comprises phosphoryl choline groups, carboxybetaine groups, sulfobetaine groups, or a combination thereof.

- Example 49The device of any example herein, particularly Examples 1–48, wherein the first ionically charged polymer comprises a polyalkylene backbone, a polyether backbone, a polyurethane backbone, or combination thereof.

- Example 50The device of any example herein, particularly Examples 1–49, wherein the first ionically charged polymer comprises a neutral polymer backbone and ionically charged side chains.

- Example 51The device of any example herein, particularly Examples 1–50, wherein the first ionically charged polymer comprises a neutral polymer backbone and a combination of ionically charged side chains and neutral side chains.

- Example 52The device of any example herein, particularly Examples 1–51, wherein the first ionically charged polymer is a random copolymer.

- Example 53The device of any example herein, particularly Examples 1–52, wherein the first ionically charged polymer comprises a zwitterionic side chains and neutral side chains.

- Example 54The device of any example herein, particularly Examples 1–53, wherein the first ionically charged polymer comprises cationic side chains and anionic side chains.

- Example 55The device of any example herein, particularly Examples 1–54, wherein the first ionically charged polymer comprises a poly(meth)acrylate, a poly(meth)acrylamide, a polyolefin, or a combination thereof.

- Example 56The device of any example herein, particularly Examples 1–55, wherein the first ionically charged polymer comprises side chains comprising phosphoryl choline groups, carboxybetaine groups, sulfobetaine groups, or a combination thereof.

- Example 58The device of any example herein, particularly Examples 1–57, wherein the first repeating unit in the first ionically charged polymer includes units having the formula: , or a [0256]

- Example 59The device of any example herein, particularly Examples 1–58, X 1a is N + (CH3)2, and Y 1a is not H.

- Example 60The device of any example herein, particularly Examples 1–58, X 1a is -O-PO2 – -O-, and Y 1a is H.

- Example 61The device of any example herein, particularly Examples 1–60, wherein the first repeating unit in the first ionically charged polymer includes units having the formula:

- Example 62The device of any example herein, particularly Examples 1–61, wherein the first repeating unit in the first ionically charged polymer includes units having the formula: , wherein R 1f1 is O

- Example 64The device of any example herein, particularly Examples 1–63, wherein the second repeating unit in the first ionically charged polymer includes units having the formula: , or a combination

- Example 65The device of any example herein, particularly Examples 1–64, X 1b is N + (CH3)2, and Y 1b is not H.

- Example 66The device of any example herein, particularly Examples 1–64, X 1b is -O-PO 2 – -O-, and Y 1b is H.

- Example 69The device of any example herein, particularly Examples 1–68, wherein the first ionically charged polymer further comprises neutral repeating units of formula (1e), formula (1f), or a combination thereof: [Formula (1f)], wherein, R 1m5 is H or CH3; R 1m6 is H or CH 3 ; and R 1a is OR 1b or N(R 1b )2, wherein R 1b is in each case independently selected from H, C1–12 hydrocarbyl, wherein R 1b may be substituted one or more times by OH, OC 1–6 alkyl, NH2, NH(C1–6 alkyl), or N(C1–6 alkyl)2.

- Example 84The device of any example herein, particularly Examples 1–83, wherein the second ionically charged polymer comprises a neutral polymer backbone and ionically charged side chains.

- Example 85The device of any example herein, particularly Examples 1–84, wherein the second ionically charged polymer comprises a neutral polymer backbone and a combination of ionically charged side chains and neutral side chains.

- Example 86The device of any example herein, particularly Examples 1–85, wherein the second ionically charged polymer is a random copolymer.

- Example 147The method of any example herein, particularly Examples 145–146, wherein the mixture comprising a compound of formula (2a-m), formula (2b-m), or a combination thereof further comprises a crosslinker, or does not include a crosslinker.

- Example 148The method of any example herein, particularly Examples 145–147, wherein the mixture comprising a compound of formula (2a-m), formula (2b-m), or a combination thereof further comprises a crosslinker.

- Example 149The method of any example herein, particularly Examples 145–148, wherein the mixture comprising a compound of formula (2a-m), formula (2b-m), or a combination thereof comprises an initiator.

- Example 160The method of any example herein, particularly Examples 145–159, further comprising forming a brush polymer conjugated to the entangled hydrogel network.

- Example 161The method of any example herein, particularly Examples 145–160, wherein forming a brush polymer comprises: conjugating a polymer to the entangled hydrogel network; polymerizing a brush polymer precursor in the presence of the entangled hydrogel network; or a combination thereof.

- Example 162The method of any example herein, particularly Examples 145–161, wherein the entangled polymer network comprises initiator groups that are reactive with the brush polymer precursor.

- Example 163The method of any example herein, particularly Examples 145–162, wherein the initiator group comprises a radically transferrable atom, an isocyanate, a carboxylic acid, a primary amine, a thiol, a Michael acceptor, or a combination thereof.

- Example 164The method of any example herein, particularly Examples 145–163, further comprising reacting the entangled polymer network with an anchor compound comprising an initiator group or masked initiator group.

- Example 165A device prepared according to the method of any example herein, particularly Examples 145–164.

Landscapes

- Health & Medical Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Transplantation (AREA)

- Dermatology (AREA)

- Medicinal Chemistry (AREA)

- Oral & Maxillofacial Surgery (AREA)

- Epidemiology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Dispersion Chemistry (AREA)

- Materials For Medical Uses (AREA)

Abstract

Description