WO2025045767A1 - Stabilized lipid and lipidoid nanoparticle formulations with specific surfactant properties for enhanced pharmaceutical applications - Google Patents

Stabilized lipid and lipidoid nanoparticle formulations with specific surfactant properties for enhanced pharmaceutical applicationsDownload PDFInfo

- Publication number

- WO2025045767A1 WO2025045767A1PCT/EP2024/073691EP2024073691WWO2025045767A1WO 2025045767 A1WO2025045767 A1WO 2025045767A1EP 2024073691 WEP2024073691 WEP 2024073691WWO 2025045767 A1WO2025045767 A1WO 2025045767A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- lipid

- surfactant

- lipidoid

- formulation

- nanoparticle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Classifications

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/48—Preparations in capsules, e.g. of gelatin, of chocolate

- A61K9/50—Microcapsules having a gas, liquid or semi-solid filling; Solid microparticles or pellets surrounded by a distinct coating layer, e.g. coated microspheres, coated drug crystals

- A61K9/51—Nanocapsules; Nanoparticles

- A61K9/5107—Excipients; Inactive ingredients

- A61K9/5123—Organic compounds, e.g. fats, sugars

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/70—Carbohydrates; Sugars; Derivatives thereof

- A61K31/7088—Compounds having three or more nucleosides or nucleotides

- A61K31/7125—Nucleic acids or oligonucleotides having modified internucleoside linkage, i.e. other than 3'-5' phosphodiesters

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K47/00—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient

- A61K47/06—Organic compounds, e.g. natural or synthetic hydrocarbons, polyolefins, mineral oil, petrolatum or ozokerite

- A61K47/08—Organic compounds, e.g. natural or synthetic hydrocarbons, polyolefins, mineral oil, petrolatum or ozokerite containing oxygen, e.g. ethers, acetals, ketones, quinones, aldehydes, peroxides

- A61K47/10—Alcohols; Phenols; Salts thereof, e.g. glycerol; Polyethylene glycols [PEG]; Poloxamers; PEG/POE alkyl ethers

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/0012—Galenical forms characterised by the site of application

- A61K9/0019—Injectable compositions; Intramuscular, intravenous, arterial, subcutaneous administration; Compositions to be administered through the skin in an invasive manner

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/10—Dispersions; Emulsions

- A61K9/127—Synthetic bilayered vehicles, e.g. liposomes or liposomes with cholesterol as the only non-phosphatidyl surfactant

- A61K9/1271—Non-conventional liposomes, e.g. PEGylated liposomes or liposomes coated or grafted with polymers

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/10—Dispersions; Emulsions

- A61K9/127—Synthetic bilayered vehicles, e.g. liposomes or liposomes with cholesterol as the only non-phosphatidyl surfactant

- A61K9/1271—Non-conventional liposomes, e.g. PEGylated liposomes or liposomes coated or grafted with polymers

- A61K9/1272—Non-conventional liposomes, e.g. PEGylated liposomes or liposomes coated or grafted with polymers comprising non-phosphatidyl surfactants as bilayer-forming substances, e.g. cationic lipids or non-phosphatidyl liposomes coated or grafted with polymers

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12N—MICROORGANISMS OR ENZYMES; COMPOSITIONS THEREOF; PROPAGATING, PRESERVING, OR MAINTAINING MICROORGANISMS; MUTATION OR GENETIC ENGINEERING; CULTURE MEDIA

- C12N15/00—Mutation or genetic engineering; DNA or RNA concerning genetic engineering, vectors, e.g. plasmids, or their isolation, preparation or purification; Use of hosts therefor

- C12N15/09—Recombinant DNA-technology

- C12N15/87—Introduction of foreign genetic material using processes not otherwise provided for, e.g. co-transformation

- C12N15/88—Introduction of foreign genetic material using processes not otherwise provided for, e.g. co-transformation using microencapsulation, e.g. using amphiphile liposome vesicle

Definitions

- the present inventionrelates to stabilized lipid and/or lipidoid formulations comprising lipid nanoparticles or lipidoid nanoparticles and one or more surfactants with specific properties for the delivery of nucleic acids and enhanced pharmaceutical applications.

- Lipid or lipidoid nanoparticlesare frequently used for the delivery of active pharmaceutical ingredients in patients.

- lipid or lipidoid formulations of nucleic acidsare extremely useful and efficient for introducing nucleic acids into cells.

- This advantageous property of lipid or lipidoid formulations of nucleic acidshas been used for decades in biological and medical research and in therapeutic approaches to i) overexpress genes or to complement genetic defects in target cells, or ii) to downregulate or upregulate endogenous gene expression in cells, or iii) to repair genetic defects (mutations).

- mRNA formulations relying on nanoparticlesare now also established as vaccines against COVID- 19.

- the present inventionprovides novel stabilized lipid and lipidoid formulations with specific surfactants that help overcome issues arising during said purification, processing and handling.

- This inventionpresents novel lipid and lipidoid nanoparticle (LNP and LiNP) formulations enhanced with specifically characterized surfactants. These surfactants exhibit unique Langmuir isotherm properties, ensuring optimal stabilization of the nanoparticles.

- the described formulationsimprove the stability, reduce aggregation, and mitigate challenges faced during purification, such as filtration clogging or fouling.

- Integral to the innovationis a method for determining the suitability of surfactants as stabilizers based on predetermined Langmuir surface pressure/area isotherm (also referred to briefly herein as “Langmuir isotherm”) values, or filtration speeds.

- the stabilized nanoparticleswhen formulated with therapeutic agents, have demonstrated potential in medical applications, particularly in the realm of mRNA delivery, vaccination or immunization.

- the inventionprovides a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising a plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs) each comprising a lipid mix or lipidoid mix, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, and wherein the formulation comprises a surfactant characterized by having a Langmuir surface pressure/area isotherm with a maximum surface pressure (Umax) that is equal to or below 4.0 mN/m at a minimum surface area established for a lipid mix or lipidoid mix as comprised by the nanoparticles.

- LNPlipid nanoparticle

- LiNPslipidoid nanoparticle

- the inventionprovides a surfactant for use in a pharmaceutical composition, the surfactant being characterized by having a Langmuir isotherm with a maximum surface pressure (n ma x) that is equal to or below 4.0 mN/m at a minimum surface area established for said pharmaceutical composition.

- the inventionprovides a method for classifying a surfactant as suitable or not suitable for use as a stabilizing agent for a pharmaceutical composition comprising a lipid or lipidoid, wherein the method comprises the steps:

- the inventionprovides a method of mitigating or avoiding clogging or fouling of a filtration system during purification of a pharmaceutical composition in the form of a lipid nanoparticle formulation (LNP) or lipidoid nanoparticle formulation (LiNP), the method comprising adding a stabilizing surfactant to a first LNP or LiNP formulation to form a second LNP or LiNP formulation, optionally before purification, wherein the LNP or LiNP formulation comprises a plurality of LNPs or LiNPs, each comprising a lipid mix or lipidoid mix and a therapeutic agent, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, and wherein the stabilizing surfactant is a surfactant according to the invention, e.g. a surfactant according to the third aspect discussed above or a surfactant classified as being

- the inventionprovides a method of mitigating aggregation of lipid nanoparticles or lipidoid nanoparticles in a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation, preferably a pharmaceutical composition in the form of a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation, the method comprising adding a stabilizing surfactant to a first LNP or LiNP formulation to form a second LNP or LiNP formulation optionally before purification, wherein the LNP or LiNP formulation comprises a plurality of LNPs or LiNPs, each comprising a lipid mix or lipidoid mix, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, and the stabilizing surfactant is a surfactant in accordance with

- the inventionprovides a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation obtained by the method in accordance with the fourth to seventh aspect.

- LNPlipid nanoparticle

- LiNPlipidoid nanoparticle

- the inventionprovides a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation in accordance with the first aspect, the second aspect, or the eighth aspect discussed above for use as a medicament.

- LNPlipid nanoparticle

- LiNPlipidoid nanoparticle

- the inventionprovides a method for classifying a surfactant as suitable or not suitable for use as a stabilizer of a pharmaceutical composition comprising a nucleic acid, optionally as a stabilizer during purification, preferably during TFF purification, the method comprising:

- the inventionprovides a use of a surfactant according to the invention, e.g. the surfactant in accordance with the above third aspect, for stabilizing a suspension of lipid nanoparticles or of lipidoid nanoparticles in an aqueous vehicle solution against particle aggregation under a physical stress condition, preferably shear stress, more preferably shear stress during purification such as TFF, wherein the lipid nanoparticles or lipidoid nanoparticles comprise the following components (a) and (b):

- a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulationcomprising a plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs), each comprising a lipid mix or lipidoid mix, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, and wherein the formulation further comprises a surfactant characterized by having a Langmuir surface pressure/area isotherm (also referred to herein as “Langmuir isotherm”) with a maximum surface pressure (n ma x) that is equal to or below 4.0 mN/m at a minimum surface area established for a lipid mix or lipidoid mix as comprised by the nanoparticles.

- a surfactantcharacterized by having a Langmuir surface pressure

- a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulationcomprising a plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs), each comprising a lipid mix or lipidoid mix, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, wherein the formulation comprises as a stabilizing agent a surfactant, and wherein a representative sample comprising an aqueous solution of the surfactant carrying on its surface a lipid mix or lipidoid mix as comprised by the LNPs or LiNPs is characterized by having a Langmuir isotherm An that is equal to or below 0.60, preferably equal to or below 0.45, at each area point during a Langmuir surface pressure/area isotherm cycle comprising a compression

- a surfactantselected from the list consisting of poloxamer 124 (P124), poloxamer 188 (P188), poloxamer 338 (P338), poloxamer 407 (P407), Tween-20, Tween-80, BRIJ35, tyloxapol, VitE-PEG1000, and Kolliphor EL, or from combinations thereof.

- the surfactantis a block copolymer of ethylene oxide and propylene oxide, more preferably a poloxamer, even more preferably poloxamer selected from the list consisting of poloxamer 124, poloxamer 188, poloxamer 338, and poloxamer 407, or from combinations thereof, most preferably P188.

- lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulationaccording to any one of items 1 to 5, wherein the lipid nanoparticles or lipidoid nanoparticles comprise the lipid mix or lipidoid mix and a therapeutic agent.

- lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulationaccording to any one of items 1 to 9, which is a lipidoid nanoparticle formulation comprising a plurality of lipidoid nanoparticles each comprising a lipidoid mix, wherein the lipidoid mix comprises an ionizable lipidoid of formula (L-1 ): wherein: a is 1 or 2 and b is an integer of 1 to 4 or a is an integer of 1 to 4 and b is 1 or 2, preferably a is 1 and b is an integer of 2 to 4 or a is an integer of 2 to 4 and b is 1 , p is 1 or 2, m is 1 or 2; n is 0 or 1 and m+n is > 2, and

- lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulationaccording to any one of items 1 to 10 which is a suspension formulation, and wherein the vehicle solution of the suspension formulation is an aqueous vehicle solution comprising the surfactant.

- a surfactantselected from the list consisting of poloxamer 124 (P124), poloxamer 188 (P188), poloxamer 338 (P338), poloxamer 407 (P407), Tween-20, Tween-80, BRIJ35, tyloxapol, VitE-PEG1000, and Kolliphor EL, or from combinations thereof.

- the surfactant for use according to item 14,which is a block copolymer of ethylene oxide and propylene oxide, more preferably a poloxamer, even more preferably poloxamer selected from the list consisting of poloxamer 124, poloxamer 188, poloxamer 338, and poloxamer 407, or from combinations thereof, most preferably P188.

- the pharmaceutical compositionis in the form of a lipid nanoparticle (LNP) suspension formulation or lipidoid nanoparticle (LiNP) suspension formulation comprising a plurality of LNPs or LiNPs, each comprising a lipid mix or lipidoid mix and a therapeutic agent, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, and wherein the vehicle solution of the suspension formulation is an aqueous vehicle solution comprising the surfactant

- a method for classifying a surfactant as suitable or not suitable for use as a stabilizing agent for a pharmaceutical compositioncomprising a lipid or lipidoid, optionally during purification of said composition, preferably during tangential flow filtration of said composition, wherein the method comprises the steps:

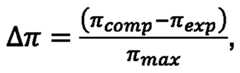

- a Langmuir pressure/area isotherm cycleincluding a compression phase and an expansion phase between a maximum surface area and a minimum surface area on a sample comprising the surfactant in the aqueous solution and carrying on its surface a lipid or lipidoid as comprised by the composition: (c) calculating a Langmuir isotherm An for each area point of the Langmuir pressure/area isotherm cycle, wherein TT is calculated as: wherein n comp is the surface pressure at said area point during the compression phase of the isotherm cycle, wherein it exp is the surface pressure at said area point during the expansion phase of the isotherm cycle, and wherein n max is the maximum surface pressure reached in the isotherm cycle, and

- a method for the preparation of a pharmaceutical compositioncomprising classifying a surfactant as suitable or not suitable for use as a stabilizing agent for a pharmaceutical composition in accordance with the method of item 17 or 18, and, if the surfactant is classified as being suitable for use as a stabilizing agent for the pharmaceutical composition, incorporating the surfactant into the pharmaceutical composition.

- the surfactantis a nonionic surfactant, preferably at least one nonionic surfactant selected from the group of fatty alcohol ethoxylates, fatty acid ethoxylates, block copolymers of ethylene oxide and propylene oxide, alkylphenol ethoxylates or oligomers of alkylphenol ethoxylates, fatty acid esters of sorbitol, ethoxylated fatty acid esters of sorbitol, fatty acid esters of glycerol, ethoxylated castor oil and ethoxylated vitamin E, e.g.

- the surfactantis a nonionic surfactant, preferably at least one nonionic surfactant selected from the group of fatty alcohol ethoxylates, fatty acid ethoxylates, block copolymers of ethylene oxide and propylene oxide, alkylphenol ethoxylates or oligomers of alkylphenol ethoxylates, fatty

- a surfactantselected from the list consisting of poloxamer 124 (P124), poloxamer 188 (P188), poloxamer 338 (P338), poloxamer 407 (P407), Tween-20, Tween-80, BRIJ35, tyloxapol, VitE-PEG1000, and Kolliphor EL, or from combinations thereof.

- the surfactantis a block copolymer of ethylene oxide and propylene oxide, more preferably a poloxamer, even more preferably poloxamer selected from the list consisting of poloxamer 124, poloxamer 188, poloxamer 338, and poloxamer 407, or from combinations thereof, most preferably P188.

- the pharmaceutical compositioncomprises a therapeutic agent comprising a nucleic acid, such as RNA, preferably mRNA.

- the pharmaceutical compositionis a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (Li NP) formulation comprising a plurality of LNPs or LiNPs, each comprising a lipid mix or lipidoid mix and a therapeutic agent, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid.

- LNPlipid nanoparticle

- Li NPlipidoid nanoparticle

- the pharmaceutical compositionis a lipid nanoparticle (LNP) suspension formulation or lipidoid nanoparticle (LiNP) suspension formulation

- the vehicle solution of the suspension formulationis an aqueous vehicle solution comprising the surfactant.

- the pharmaceutical compositionis a lipid nanoparticle (LNP) suspension formulation or lipidoid nanoparticle (LiNP) suspension formulation comprising an aqueous vehicle solution, and wherein the stabilizing surfactant is added to the vehicle solution, optionally wherein the surfactant is essentially absent from the LNPs or LiNPs.

- LNPlipid nanoparticle

- LiNPlipidoid nanoparticle

- a method of mitigating aggregation of lipid or lipidoid nanoparticles in a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulationcomprising adding a stabilizing surfactant to a first LNP or LiNP formulation to form a second LNP or LiNP formulation, optionally before purification, wherein the LNP or LiNP formulation comprises a plurality of LNPs or LiNPs, each comprising a lipid mix or lipidoid mix, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, and wherein the stabilizing surfactant is a surfactant as defined in any of items 12 to 16 or a surfactant classified

- the formulationis a lipid nanoparticle (LNP) suspension formulation or lipidoid nanoparticle (LiNP) suspension formulation comprising an aqueous vehicle solution, and wherein the stabilizing surfactant is added to the vehicle solution, optionally wherein the surfactant is essentially absent from the LNPs or LiNPs.

- LNPlipid nanoparticle

- LiNPlipidoid nanoparticle

- lipid nanoparticles or lipidoid nanoparticlescomprise a therapeutic agent, preferably a nucleic acid such as RNA, more preferably mRNA.

- lipid nanoparticles or lipidoid nanoparticlescomprise a nucleic acid, e.g. RNA, and preferably mRNA

- the methodcomprises the steps of: i) first, combining the nucleic acid and at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid to form LNPs or LiNPs, ii) second, purifying the LNPs or LiNPs, iii) third, adding the stabilizing surfactant before TFF purification and during TFF purification in the exchange buffer, maintaining the surfactant in a steady concentration, iv) optionally wherein the stabilizing surfactant is added to the LNP or LiNP formulation after step (i).

- the lipid mix or lipidoid mixcomprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and a permanently cationic lipid, and further comprises one or more of the following components (c1 ) to (c6):

- the lipid mix or lipidoid mixcomprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and a permanently cationic lipid, and further comprises the components (c1), (c2) and (c3).

- the lipid mix or lipidoid mixcomprises i) 30 to 65 mol% of at least one selected from the ionizable lipid, the ionizable lipidoid and the permanently cationic lipid, and further comprises one or more of the following components (c1 ) to (c6): ii) 10 to 50 mol% of the lipid having a sterol structure (c1 ), iii) 4 to 50 mol% of the phospholipid (c2), iv) 0.5 to 10 mol% of one of the PEG-conjugated lipid (c3), the polysarcosine-conjugated lipid (c4) and the PASylated lipid (c5), or of any combination thereof, v) 0.5 to 10 mol% of a cationic polymer (c6), such that the sum of the amounts of i) and ii) to v) is 100 mol%,

- the lipid mix or lipidoid mixcomprises i) 30 to 65 mol% of at least one selected from the ionizable lipid, the ionizable lipidoid and the permanently cationic lipid, and further comprises ii) 10 to 50 mol% of the lipid having a sterol structure (c1), iii) 4 to 50 mol% of the phospholipid (c2), iv) 0.5 to 10 mol% of a PEG-conjugated lipid (c3), such that the sum of the amounts of i) and ii) to iv) is 100%.

- the formulationis a lipidoid nanoparticle formulation comprising a plurality of lipidoid nanoparticles each comprising a lipidoid mix, wherein the lipidoid mix comprises an ionizable lipidoid of formula (L-1 ): wherein: a is 1 or 2 and b is an integer of 1 to 4 or a is an integer of 1 to 4 and b is 1 or 2, preferably a is 1 and b is an integer of 2 to 4 or a is an integer of 2 to 4 and b is 1 , p is 1 or 2, m is 1 or 2; n is 0 or 1 and m+n is 2; and

- the lipid nanoparticle formulation or lipidoid nanoparticle formulationpreferably a lipid nanoparticle suspension formulation or lipidoid nanoparticle suspension formulation, according to any one of items 1 to 11 or 40 for use as a medicament.

- the lipid nanoparticle formulation or lipidoid nanoparticle formulationpreferably a lipid nanoparticle suspension formulation or lipidoid nanoparticle suspension formulation, according to any one of items 1 to 11 or 40, for use in the treatment or prevention of a disease, preferably a disease selected from Table A, more preferably a disease selected from viral diseases, ciliopathies, autoimmune diseases, and respiratory tract diseases, even more preferably selected from a lung disease, an airway disease or a nasal disease, more preferably a lung viral disease, lung ciliopathies and a lung autoimmune diseases.

- a diseasepreferably a disease selected from Table A, more preferably a disease selected from viral diseases, ciliopathies, autoimmune diseases, and respiratory tract diseases, even more preferably selected from a lung disease, an airway disease or a nasal disease, more preferably a lung viral disease, lung ciliopathies and a lung autoimmune diseases.

- the lipid nanoparticle formulation or lipidoid nanoparticle formulation for use according to item 43wherein the lung disease or lung viral disease is at least one selected from pneumonia and asthma; the airway disease is at least one selected from bronchitis, viral induced asthma, lung fibrosis and COPD; and/or the nasal disease is at least one selected from rhinitis and sinusitis.

- the lipid nanoparticle formulation or lipidoid nanoparticle formulation according to item 41for use in vaccination or immunization.

- a method of avoiding or reducing side effects in a therapy with LNPs or LiNPs carrying at least one therapeutic agentcomprises the steps: i) determine whether LNPs or LiNPs in a pharmaceutical composition comprising LNPs or LiNPs aggregate when subjected to a mechanical stress or a temperature stress, by determining their aggregation level before and after subjecting said pharmaceutical composition is subjected to said mechanical or temperature stress ii) if the LNP or LiNP show aggregation after the test of step (i), then add to the LNP or LiNP formulation a surfactant to obtain a LNP or LiNP suspension with a final surfactant concentration of 0.01 % w/v and up to 10% w/v, preferably between 0.05% w/w surfactant and 5% surfactant, more preferably between 0.33% surfactant and 2.5% surfactant, more preferably between 0.45% and 1 .5% surfactant, most preferably between 0.5% and 1 .5% surfactant, most preferably about

- the nanoparticlescomprise a) 30 to 65 mol% of at least one selected from the ionizable lipid, an ionizable lipidoid and a permanently cationic lipid (b), and one or more of the following components: ii) 10 to 50 mol% of the lipid having a sterol structure (c1 ), iii) 4 to 50 mol% of the phospholipid (c2), iv) 0.5 to 10 mol% of one of the PEG-conjugated lipid (c3), the polysarcosine-conjugated lipid (c4) and the PASylated lipid (c5), or of any combination thereof,

- a cationic polymer (c6)0.5 to 10 mol% of a cationic polymer (c6), such that the sum of (b) and (c1 ) to (c6) amounts to 100 mol%.

- G 1 and G 2are each independently C1-C12 alkylene or C1-C12 alkenylene;

- G 3is C1-C24 alkylene, C1-C24 alkenylene, C3-C8 cycloalkylene, C3-C8 cycloalkenylene, wherein each of alkylene, alkenylene, cycloalkylene, and cyloalkenylene is optionally substituted;

- R ais H or C1-C12 alkyl wherein the alkyl is optionally substituted

- R 1 and R 2are each independently C6-C24 alkyl or C6-C24 alkenyl, wherein each of alkyl and alkenyl is optionally substituted;

- R 4is C1-C12 alkyl, wherein alkyl is optionally substituted;

- R 5is H or Ci-Ce alkyl, wherein alkyl is optionally substituted; and x is 0, 1 or 2.

- the nanoparticlescomprise an ionizable lipidoid (b) of the following formula (L-1 ), wherein: a is 1 or 2 and b is an integer of 1 to 4 or a is an integer of 1 to 4 and b is 1 or 2, preferably a is 1 and b is an integer of 2 to 4; or a is an integer of 2 to 4 and b is 1 , p is 1 or 2, m is 1 or 2; n is 0 or 1 and m+n is > 2; and

- nanoparticlescomprise, as an ionizable lipid (b), (6Z,9Z,28Z,31Z)-heptatriaconta-6,9,28,31- tetraene-19-yl 4-(dimethylamino)butanoate or a protonated form thereof wherein the nitrogen atom of the compound is protonated.

- nanoparticlescomprise, as an ionizable lipid (b), ((4-hydroxybutyl)azanediyl)bis(hexan-6,1- diyl)bis(2-hexyldecanoate) or a protonated form thereof wherein the nitrogen atom of the compound is protonated, and/or (heptadecan -9-yl 8-((2-hydroxyethyl)(6-oxo-6- (undecyloxy)hexyl)amino)octanoate, or a protonated form thereof wherein the nitrogen atom of the compound is protonated.

- nanoparticlescomprise ((4- hydroxybutyl)azanediyl)bis(hexane-6,1-diyl)bis(2-hexyldecanoate) or the protonated form thereof wherein the nitrogen atom of the compound is protonated, and optionally further comprise one or more of the following components (d1 ) to (d8):

- nanoparticlescomprise heptadecan-9-yl 8- ((2-hydroxyethyl)(6-oxo-6-(undecyloxy)hexyl)amino)octanoate or a protonated form thereof wherein the nitrogen atom of the compound is protonated, and further optionally comprise one or more of the following components (e1) to (e7):

- nanoparticlecomprises DLin-MC3-DMA ((6Z,9Z,28Z,31Z)-heptatriaconta-6,9,28,31-tetraen-19-yl-4-(dimethylamino) butanoate) or a protonated form thereof wherein the nitrogen atom of the compound is protonated, and optionally further comprise one or more of the following components (e1 ) to (e7):

- the inventionprovides in a first aspect a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising a plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs), each comprising a lipid mix or lipidoid mix, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, and wherein the formulation further comprises a surfactant characterized by having a Langmuir surface pressure/area isotherm (also referred to herein as “Langmuir isotherm”) with a maximum surface pressure (IT max) that is equal to or below 4.0 mN/m at a minimum surface area established for a lipid mix or lipidoid mix as comprised by the nanoparticles.

- LNPlipid nanoparticle

- TT maxis equal to or below 3.5 mN/m, more preferably equal to or below 3.5 and equal to or above 0.5 mN/m, even more preferably equal to or below 3.0 mN/m and equal to or above 0.5 mN/m, even more preferably equal to or below 2.5 and equal to or above 1.0 mN/m, most preferably equal to or below 2.0 and equal to or above 1 .0 mN/m.

- the maximum surface pressure (TTmax) of the surfactantcan be determined by recording a Langmuir surface pressure/area isotherm of the surfactant in an aqueous solution thereof, e.g. in deionized water.

- the Langmuir isothermis recorded in a Langmuir trough.

- the recording of the Langmuir isotherm of the surfactantinvolves reducing the available surface area in the Langmuir trough at least until the minimum surface area established for the lipid mix or lipidoid mix is reached.

- the surface pressure which is observed at the minimum surface area when recording the Langmuir isotherm of the surfactantis considered as the maximum surface pressure (TT max ) of the surfactant.

- the minimum surface areacan be established, e.g., by compressing a layer, typically a monolayer, of the lipid mix or lipidoid mix (i.e. the lipid mix or lipidoid mix as comprised by the nanoparticles) in the Langmuir trough until a first phase transition is observed in a surface pressure/area isotherm of the lipid mix or lipidoid mix.

- the layercan be conveniently provided on water, e.g. deionized water.

- the surface area at the start of the phase transitionis regarded as the minimum surface area established for the lipid mix or lipidoid mix.

- the start of the phase transition as referred to herein in a pressure/area (TT-A) isotherm plotcan be objectively determined as the point where the slope of the curve (dir/dA) changes significantly, indicating a shift in the molecular organization of the monolayer.

- a step to establish the minimum surface areacan be carried out, e.g., as a calibration step in the Langmuir trough prior to determining the maximum surface pressure of the surfactant as described above.

- a Langmuir surface pressure/area isotherme.g. the maximum area provided by the Langmuir trough can be conveniently used.

- a monolayer of the lipid mix or lipidoid mix on water in a Langmuir troughcan be provided, e.g., by applying the lipid mix or lipidoid mix to the surface until a signal change in the Langmuir trough detector is generated.

- the Langmuir surface pressure/area isotherm of the surfactantcan be recorded, e.g., in the form of a Langmuir surface pressure/area isotherm cycle (also briefly referred to herein as “isotherm cycle”) which includes a compression phase and an expansion phase.

- the maximum surface pressure (n ma x)can be determined, for example, by recording a single isotherm cycle, but preferably results are obtained by recording multiple isotherm cycles in sequence, such as three isotherm cycles, e.g. with a wait time of 5 seconds or less between cycles, such as 3 seconds.

- n ma xis equal to or below 3.5 mN/m, more preferably equal to or below 3.5 and equal to or above 0.5 mN/m, even more preferably equal to or below 3.0 mN/m and equal to or above 0.5 mN/m, even more preferably equal to or below 2.5 and equal to or above 1 .0 mN/m, most preferably equal to or below 2.0 and equal to or above 1.0 mN/m, directly in this single cycle.

- the surfactantshows a Langmuir isotherm with a maximum surface pressure (Umax) as defined herein above in the last, e.g. the third isotherm cycle.

- a Langmuir surface pressure/area isotherm or isotherm cycle as referred to hereinis recorded at about room temperature, e.g. at 22.1 ⁇ 0.2°C.

- a typical concentration of the surfactant in an aqueous solution thereof for the determination of the maximum surface pressureis 1% w/v (corresponding to 1 g of surfactant in 100 ml of the total volume of the solution including the surfactant, generally measured at about room temperature, e.g. at 22.1 ⁇ 0.2°C).

- the lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulationis a suspension formulation comprising a liquid vehicle solution, wherein the LNPs or LiNPs can be dispersed.

- the vehicle solutionis preferably an aqueous vehicle solution. It is preferred that, in such a suspension formulation, the surfactant is comprised in the vehicle solution.

- the surfactantmay favorably act as a stabilizing agent that mitigates aggregation of the LNPs or LiNP or a subpopulation thereof which may be caused by shaking or by shear stress of the suspension during production, purification, handling or transport, preferably during production or purification, more preferably during purification, most preferably during tangential flow filtration (TFF) purification.

- a stabilizing agentthat mitigates aggregation of the LNPs or LiNP or a subpopulation thereof which may be caused by shaking or by shear stress of the suspension during production, purification, handling or transport, preferably during production or purification, more preferably during purification, most preferably during tangential flow filtration (TFF) purification.

- the lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulationis preferably a formulation, e.g. a suspension formulation as discussed above, wherein the LNPs or LiNPs comprise the lipid mix or lipidoid mix and a therapeutic agent, i.e. a pharmaceutical formulation.

- the first aspectalso encompasses the lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising the plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs), each comprising the lipid mix or lipidoid mix and a therapeutic agent, for use as a medicament.

- a preferred therapeutic agentis a nucleic acid, such as RNA, and particularly preferred is mRNA. Details regarding therapeutic agents which may be contained in the LNPs or LiNPs shall likewise be discussed herein below.

- the terms “pharmaceutical formulation” and “pharmaceutical composition”may be used herein as equivalents.

- the lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation in accordance with the first aspectis particularly preferably a lipid nanoparticle (LNP) suspension formulation or lipidoid nanoparticle (LiNP) suspension formulation comprising a plurality of LNPs or LiNPs, each comprising a lipid mix or lipidoid mix and a therapeutic agent, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, and wherein the vehicle solution of the suspension formulation is an aqueous vehicle solution comprising a surfactant characterized by having a Langmuir surface pressure/area isotherm with a maximum surface pressure (n ma x) that is equal to or below 4.0 mN/m at a minimum surface area established for the lipid mix or lipidoid mix as comprised by the nano

- the inventionprovides a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising a plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs), each comprising a lipid mix or lipidoid mix, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, wherein the formulation comprises as a stabilizing agent a surfactant, and wherein a representative sample comprising an aqueous solution of the surfactant carrying on its surface a lipid mix or lipidoid mix as comprised by the LNPs or LiNPs is characterized by having a Langmuir isotherm An that is equal to or below 0.60, preferably equal to or below 0.45, at each area point during a Langmuir surface pressure

- a representative sample used for determining the Langmuir isotherm An valuescomprises an aqueous solution of the surfactant, e.g. a solution in deionized water, carrying on its surface a lipid mix or lipidoid mix as comprised by the LNPs or LiNPs, typically a monolayer of the lipid mix or lipidoid mix.

- the lipid mix or lipidoid mixgenerally has the same composition as the lipid mix or lipidoid mix comprised by the nanoparticles, i.e. it comprises the same lipids and/or lipidoids in the same proportions.

- a Langmuir surface pressure/area isotherm cyclecomprising a compression phase and an expansion phase can be recorded in a Langmuir trough.

- the Langmuir isotherm ATT valuesare calculated for each area point as explained above.

- the Langmuir isotherm An valuesare equal to or below 0.60, preferably equal to or below 0.45, at each area point during a Langmuir surface pressure/area isotherm cycle.

- the Langmuir isotherm ATT values calculated as disclosed aboveare usually above 0.

- the minimum surface areacan be established, e.g., by compressing a layer, typically a monolayer, of the lipid mix or lipidoid mix (i.e.

- the layercan be conveniently provided on water, e.g. on deionized water.

- the surface area at the start of the phase transitionis regarded as the minimum surface area established for the lipid mix or lipidoid mix.

- the start of the phase transition as referred to herein in a pressure/area (TT-A) isotherm plotcan be objectively determined as the point where the slope of the curve (dn/dA) changes significantly.

- a step to establish the minimum surface areacan be carried out, e.g., as a calibration step in the Langmuir trough prior to recording a Langmuir surface pressure/area isotherm cycle on a representative sample as described above.

- the surface area before the start of the compression in a compression phasee.g., the maximum area provided by the Langmuir trough, can be conveniently used.

- a monolayer of the lipid mix or lipidoid mix on water or on an aqueous solution of the surfactant in a Langmuir troughcan be provided, e.g., by applying the lipid mix or lipidoid mix to the surface until a signal change in the Langmuir trough detector is generated.

- a Langmuir surface pressure/area isotherm or isotherm cycle as referred to hereinis recorded at about room temperature, e.g. at 22.1 ⁇ 0.2°C.

- a typical concentration of the surfactant in an aqueous solution thereof in the representative sampleis 1 % w/v (corresponding to 1 g of surfactant in 100 ml of the total volume of the solution including the surfactant, generally measured at about room temperature, e.g. at 22.1 ⁇ 0.2°C).

- a calibration stepwhich may be used to establish the minimum surface area, and the recording of the Langmuir pressure/area isotherm for the calculation of Langmuir isotherm An values are further illustrated in the “Examples” section below.

- the lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulationis a suspension formulation comprising a liquid vehicle solution, wherein the LNPs or LiNPs can be dispersed.

- the vehicle solutionis preferably an aqueous vehicle solution. It is preferred that, in such a suspension formulation, the surfactant is comprised in the vehicle solution.

- the surfactantmay favorably act as a stabilizing agent that mitigates aggregation of the LNPs or LiNP or a subpopulation thereof which may be caused by shaking or by shear stress of the suspension during production, purification, handling or transport, preferably during production or purification, more preferably during purification, most preferably during tangential flow filtration (TFF) purification.

- a stabilizing agentthat mitigates aggregation of the LNPs or LiNP or a subpopulation thereof which may be caused by shaking or by shear stress of the suspension during production, purification, handling or transport, preferably during production or purification, more preferably during purification, most preferably during tangential flow filtration (TFF) purification.

- the lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulationis preferably a formulation, e.g. a suspension formulation as discussed above, wherein the LNPs or LiNPs comprise the lipid mix or lipidoid mix and a therapeutic agent, i.e. a pharmaceutical formulation.

- the second aspectalso encompasses the lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising the plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs), each comprising the lipid mix or lipidoid mix and a therapeutic agent, for use as a medicament.

- a preferred therapeutic agentis a nucleic acid, such as RNA, and particularly preferred is mRNA. Details regarding therapeutic agents which may be contained in the LNPs or LiNPs shall likewise be discussed herein below.

- the terms “pharmaceutical formulation” and “pharmaceutical composition”may be used herein as equivalents.

- the lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation in accordance with the second aspectis particularly preferably a lipid nanoparticle (LNP) suspension formulation or lipidoid nanoparticle (LiNP) suspension formulation comprising a plurality of LNPs or LiNPs, each comprising a lipid mix or lipidoid mix and a therapeutic agent, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, and wherein the vehicle solution of the suspension formulation is an aqueous vehicle solution comprising a surfactant as a stabilizing agent, and wherein a representative sample comprising an aqueous solution of the surfactant carrying on its surface a lipid mix or lipidoid mix as comprised by the LNPs or LiNPs is characterized by having a Langmuir is

- the inventionprovides a surfactant for use in a pharmaceutical composition, the surfactant being characterized by having a Langmuir surface pressure/area isotherm with a maximum surface pressure (IT max) that is equal to or below 4.0 mN/m at a minimum surface area established for said pharmaceutical composition.

- the aspectprovides the use of the surfactant as a component, e.g. as a stabilizing agent, in a pharmaceutical composition.

- Umaxalso in the context of this aspect is equal to or below 3.5 mN/m, more preferably equal to or below 3.5 and equal to or above 0.5 mN/m, even more preferably equal to or below 3.0 mN/m and equal to or above 0.5 mN/m, even more preferably equal to or below 2.5 and equal to or above 1 .0 mN/m, most preferably equal to or below 2.0 and equal to or above 1 .0 mN/m.

- the pharmaceutical compositioncan be a pharmaceutical composition comprising a lipid or a lipidoid, such as a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising a plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs).

- a lipid or a lipidoidsuch as a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising a plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs).

- the pharmaceutical compositionis a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising a plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs), each comprising a lipid mix or lipidoid mix, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid.

- LNPlipid nanoparticle

- LiNPslipidoid nanoparticle

- the pharmaceutical formulationis a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation

- the formulationis a suspension formulation comprising a liquid vehicle solution, wherein the LNPs or LiNPs can be dispersed.

- the vehicle solutionis preferably an aqueous vehicle solution. It is preferred that, in such a suspension formulation, the surfactant as defined in this aspect is comprised in the vehicle solution.

- the surfactantmay favorably act as a stabilizing agent that mitigates aggregation of the LNPs or LiNP or a subpopulation thereof which may be caused by shaking or by shear stress of the suspension during production, purification, handling or transport, preferably during production or purification, more preferably during purification, most preferably during tangential flow filtration (TFF) purification.

- a stabilizing agentthat mitigates aggregation of the LNPs or LiNP or a subpopulation thereof which may be caused by shaking or by shear stress of the suspension during production, purification, handling or transport, preferably during production or purification, more preferably during purification, most preferably during tangential flow filtration (TFF) purification.

- the pharmaceutical compositioncomprises a therapeutic agent, for example a nucleic acid.

- a preferred therapeutic agentis RNA, and particularly preferred is mRNA. Details regarding preferred types of therapeutic agents shall be discussed herein below.

- the pharmaceutical formulationis a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation, e.g. a suspension formulation, the therapeutic agent is typically comprised in the LNPs or LiNPs.

- the surfactant for use in accordance with the third aspectis particularly preferably a surfactant for use in a pharmaceutical composition in the form of a lipid nanoparticle (LNP) suspension formulation or lipidoid nanoparticle (LiNP) suspension formulation comprising a plurality of LNPs or LiNPs, each comprising a lipid mix or lipidoid mix and a therapeutic agent, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, wherein the vehicle solution of the suspension formulation is an aqueous vehicle solution and comprising the surfactant which is characterized by having a Langmuir surface pressure/area isotherm with a maximum surface pressure (n ma x) that is equal to or below 4.0 mN/m at a minimum surface area established for said pharmaceutical composition.

- LNPlipid nanoparticle

- LiNPlipidoid nanoparticle

- the aspectprovides the use of the surfactant as a component, e.g. as a stabilizing agent, in such a pharmaceutical composition.

- the maximum surface pressure (n ma x) of the surfactantcan be determined by recording a Langmuir surface pressure/area isotherm of the surfactant in an aqueous solution thereof, e.g. in deionized water.

- the Langmuir isothermis recorded in a Langmuir trough.

- the recording of the Langmuir isotherm of the surfactantinvolves reducing the available surface area in the Langmuir trough at least until the minimum surface area established for the pharmaceutical composition is reached.

- the surface pressure which is observed at the minimum surface area when recording the Langmuir isotherm of the surfactantis considered as the maximum surface pressure (TT max ) of the surfactant.

- the minimum surface areacan be established for the pharmaceutical composition, e.g., by compressing a layer, typically a monolayer, of the combination of more than one lipid and/or lipidoid as comprised by the pharmaceutical composition in a Langmuir trough until a first phase transition is observed in a surface pressure/area isotherm of the combination.

- the layercan be conveniently provided on water, e.g. deionized water.

- a Langmuir surface pressure/area isotherme.g., the maximum area provided by the Langmuir trough can be conveniently used.

- the inventionprovides a method for classifying a surfactant as suitable or not suitable for use as a stabilizing agent for a pharmaceutical composition, the method comprising:

- the methodcan be used for classifying a surfactant as suitable or not suitable for use as a stabilizing agent for a pharmaceutical composition comprising a lipid or a lipidoid, such as a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising a plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs).

- a surfactantas suitable or not suitable for use as a stabilizing agent for a pharmaceutical composition

- a lipid or a lipidoidsuch as a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising a plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs).

- LNPlipid nanoparticle

- LiNPlipidoid nanoparticle

- the method according to this aspectis a method for classifying a surfactant as suitable or not suitable for use as a stabilizing agent for a pharmaceutical composition

- the pharmaceutical compositionis in the form of a lipid nanoparticle (LNP) suspension formulation or lipidoid nanoparticle (LiNP) suspension formulation comprising a plurality of LNPs or LiNPs, each comprising a lipid mix or lipidoid mix and a therapeutic agent, wherein the lipid mix or lipidoid mix comprises, as a component thereof at least one selected from an ionizable lipid, ionizable lipidoid, and a permanently cationic lipid, and wherein the vehicle solution of the suspension formulation is an aqueous vehicle solution.

- LNPlipid nanoparticle

- LiNPlipidoid nanoparticle

- a surfactantis provided in an aqueous solution, e.g. as a solution in deionized water, at a concentration (C). Details regarding preferred types of surfactants subjected to the method, such as a poloxamer, shall be discussed herein below.

- the concentration of the surfactantis not particularly restricted, exemplary concentrations may be in the range of 0.1 to 10.0 % w/v (i.e. indicated as the weight of surfactant in g in 100 ml of the total volume of the solution, generally measured at about room temperature, e.g. at 22.1 ⁇ 0.2°C)., preferably in the range of 0.5 to 5.0 % w/v. Particularly preferred is a concentration of 1% w/v.

- a Langmuir surface pressure/area isotherm of the surfactant in the solution as provided in step (a)is recorded to determine a maximum surface pressure Umax of the Langmuir surface pressure/area isotherm at a predetermined minimum surface area.

- Umaxof the Langmuir surface pressure/area isotherm at a predetermined minimum surface area.

- the recording of the Langmuir isotherm of the surfactantinvolves reducing the available surface area in the Langmuir trough at least until the predetermined minimum surface area is reached.

- the surface pressure which is observed at the minimum surface area when recording the Langmuir isotherm of the surfactantis considered as the maximum surface pressure (TT ma x) of the surfactant.

- the methodcan be advantageously used, e.g., to differentiate between variants of a single surfactant, each variant nominally identified by the same name and complying with the same quality standards for medicines, to classify each variant as suitable or not suitable for use as a stabilizing agent for a pharmaceutical composition.

- a minimum surface areacan be established, e.g., by compressing a layer, typically a monolayer, of the lipid or lipidoid in a Langmuir trough until a first phase transition is observed in a surface pressure/area isotherm of the lipid or lipidoid.

- the layercan be conveniently provided on water, e.g. deionized water. If the pharmaceutical composition, e.g.

- the minimum surface areacan be established for the pharmaceutical composition, e.g., by compressing a layer, typically a monolayer, comprising at least one lipid or lipidoid of the combination in a Langmuir trough until a first phase transition is observed in a surface pressure/area isotherm of the lipid or lipidoid.

- the layercomprises at least the lipid or lipidoid which accounts for the largest proportion of the components in the combination of more than one lipid and/or lipidoid, in terms of the weight percentage based on the total weight of the combination as 100%.

- the minimum surface areacan be established for the pharmaceutical composition, e.g., by compressing a layer, typically a monolayer, comprising the same combination of more than one lipid and/or lipidoid in the same proportions in a Langmuir trough until a first phase transition is observed in a surface pressure/area isotherm of the combination.

- the layercan be conveniently provided on water, e.g. deionized water.

- a minimum surface areacan be established, e.g., by compressing a layer, typically a monolayer, comprising at least one lipid or lipidoid contained in the lipid mix or lipidoid mix (i.e. the lipid mix or lipidoid mix as comprised by the nanoparticles) in a Langmuir trough until a first phase transition is observed in a surface pressure/area isotherm of the lipid or lipidoid.

- the layercomprises at least the lipid or lipidoid which accounts for the largest proportion of the components in the lipid mix or lipidoid mix, in terms of the weight percentage based on the total weight of the lipid mix or lipidoid mix as 100%.

- a minimum surface areacan be established by compressing a layer, typically a monolayer, of the lipid mix or lipidoid mix (i.e.

- the layercan be conveniently provided on water, e.g. deionized water.

- the surface area at the start of the phase transitioncan then be relied on as the predetermined minimum surface area in step (b) of the method.

- the start of the phase transition as referred to herein in a pressure/area (TT-A) isotherm plotcan be objectively determined as the point where the slope of the curve (dn/dA) changes significantly.

- a step to establish the minimum surface areacan be carried out, e.g., as a calibration step in the Langmuir trough prior to determining the maximum surface pressure of the surfactant as described above.

- the surface area before the start of the compression in a compression phasee.g., the maximum area provided by the Langmuir trough, can be conveniently used.

- a monolayer of a lipid and/or lipidoid on water, or of a lipid mix or lipidoid mix on water, in a Langmuir troughcan be provided, e.g., by applying the lipid and/or lipidoid or the lipid mix or lipidoid mix to the surface until a signal change in the Langmuir trough detector is generated.

- the Langmuir surface pressure/area isotherm of the surfactant in the solution in step (b)can be recorded, e.g., in the form of a Langmuir surface pressure/area isotherm cycle including a compression phase and an expansion phase.

- the maximum surface pressure (n m ax)can be determined, for example, by recording a single isotherm cycle, but preferably results are obtained by recording multiple isotherm cycles in sequence, such as three isotherm cycles, e.g. with a wait time of 5 seconds or less between cycles, such as 3 seconds. If a single isotherm cycle is recorded, it is preferred that Umax is equal to or below 3.5 mN/m.

- the surfactantshows a Langmuir isotherm with a maximum surface pressure (TT ma x) equal to or below the threshold value in the last, e.g. the third isotherm cycle.

- TT ma xmaximum surface pressure

- a Langmuir surface pressure/area isotherm or isotherm cycle as referred to hereincan be recorded at about room temperature, e.g. at 22.1 ⁇ 0.2°C.

- step (c)the maximum surface pressure is subsequently compared to a threshold value. Based on this comparison, a decision can be made on whether the surfactant is suitable for use as a stabilizer.

- a threshold value of the maximum surface pressure TT ma x for comparison and classificationcan be conveniently determined e.g. based on surface pressure data prepared in preliminary tests for a stable composition comprising a surfactant.

- TTmaxcan be equal to or below 4.0 mN/m, or equal to or below 3.5 mN/m.

- a methodfor the preparation of a pharmaceutical composition, said method comprising classifying a surfactant as suitable or not suitable for use as a stabilizing agent for a pharmaceutical composition in accordance with the method as described above, and, if the surfactant is classified as being suitable for use as a stabilizing agent for a pharmaceutical composition, incorporating the surfactant into the pharmaceutical composition, e.g. into a vehicle solution of a pharmaceutical composition which is in the form of a nanoparticle suspension.

- the inventionprovides a method for classifying a surfactant as suitable or not suitable for use as a stabilizing agent for a pharmaceutical composition comprising a lipid or lipidoid, optionally during purification of said composition, preferably during tangential flow filtration of said composition, wherein the method comprises the steps:

- a method for the preparation of a pharmaceutical compositioncomprising classifying a surfactant as suitable or not suitable for use as a stabilizing agent for a pharmaceutical composition comprising a lipid or lipidoid in accordance with the method as described above, and, if the surfactant is classified as being suitable for use as a stabilizing agent, incorporating the surfactant into the pharmaceutical composition.

- the methodcan be used for classifying a surfactant as suitable or not suitable for use as a stabilizing agent in a pharmaceutical composition comprising a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising a plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs).

- a pharmaceutical compositioncomprising a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising a plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs).

- the pharmaceutical compositionis a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising a plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs), each comprising a lipid mix or lipidoid mix, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid.

- LNPlipid nanoparticle

- LiNPslipidoid nanoparticle

- the pharmaceutical formulationis a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation

- the formulationis a suspension formulation comprising a liquid vehicle solution, wherein the LNPs or LiNPs can be dispersed.

- the vehicle solutionis preferably an aqueous vehicle solution. It is preferred that, in such a suspension formulation, a surfactant classified as being suitable for use as a stabilizing agent is incorporated into the vehicle solution.

- the surfactantmay favorably act as a stabilizing agent that mitigates aggregation of the LNPs or LiNP or a subpopulation thereof which may be caused by shaking or by shear stress of the suspension during production, purification, handling or transport, preferably during production or purification, more preferably during purification, most preferably during tangential flow filtration (TFF) purification.

- a stabilizing agentthat mitigates aggregation of the LNPs or LiNP or a subpopulation thereof which may be caused by shaking or by shear stress of the suspension during production, purification, handling or transport, preferably during production or purification, more preferably during purification, most preferably during tangential flow filtration (TFF) purification.

- the pharmaceutical compositioncomprises a therapeutic agent, for example a nucleic acid.

- a preferred therapeutic agentis RNA, and particularly preferred is mRNA. Details regarding preferred types of therapeutic agents shall be discussed herein below.

- the pharmaceutical formulationis a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation, e.g. a suspension formulation, the therapeutic agent is typically comprised in the LNPs or LiNPs.

- the method according to this aspectis a method for classifying a surfactant as suitable or not suitable for use as a stabilizing agent for a pharmaceutical composition

- the pharmaceutical compositionis in the form of a lipid nanoparticle (LNP) suspension formulation or lipidoid nanoparticle (LiNP) suspension formulation comprising a plurality of LNPs or LiNPs, each comprising a lipid mix or lipidoid mix and a therapeutic agent, wherein each of the LNPs or LiNPs comprises, as a component of the lipid mix or lipidoid mix, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, and wherein the vehicle solution of the suspension formulation is an aqueous vehicle solution.

- LNPlipid nanoparticle

- LiNPlipidoid nanoparticle

- a surfactantis provided in an aqueous solution at a concentration (C). Details regarding preferred types of surfactants subjected to the method, such as a poloxamer, shall be discussed herein below.

- the concentration of the surfactantis not particularly restricted, exemplary concentrations may be in the range of 0.1 to 10.0 % w/v (i.e. indicated as the weight of surfactant in g in 100 ml of the combined volumes of the surfactant and aqueous solvent, generally measured at about room temperature, e.g. at 22.1 ⁇ 0.2°C), preferably in the range of 0.5 to 5.0 % w/v. Particularly preferred is a concentration of 1% w/v.

- a Langmuir pressure/area isotherm cycle including a compression phase and an expansion phaseis recorded between a maximum surface area and a minimum surface area.

- the isotherm cycleis recorded on a sample comprising the surfactant in the aqueous solution as provided in step (a), and carrying on its surface a lipid or lipidoid as comprised by the pharmaceutical composition.

- the samplecarries a monolayer of the lipid or lipidoid on its surface.

- recording of the isotherm cyclecan be accomplished using a Langmuir trough containing the sample. If the pharmaceutical composition, e.g.

- the isotherm cyclecan be recorded, e.g., on a sample carrying a layer, typically a monolayer, comprising at least one lipid or lipidoid of the combination.

- the layercomprises at least the lipid or lipidoid which accounts for the largest proportion of the components in the combination of more than one lipid and/or lipidoid in the pharmaceutical composition, in terms of the weight percentage based on the total weight of the combination as 100%.

- the isotherm cyclecan be recorded on a sample carrying a layer, typically a monolayer, comprising the same combination of more than one lipid and/or lipidoid in the same proportions as comprised in the pharmaceutical composition.

- the pharmaceutical compositionis a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising a plurality of lipid nanoparticles (LNPs) or lipidoid nanoparticles (LiNPs), each comprising a lipid mix or lipidoid mix, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid.

- LNPlipid nanoparticle

- LiNPslipidoid nanoparticle

- the isotherm cyclecan be recorded, e.g., on a sample carrying a layer, typically a monolayer, comprising at least one lipid or lipidoid contained in the lipid mix or lipidoid mix (i.e. the lipid mix or lipidoid mix as comprised by the nanoparticles).

- the layercomprises at least the lipid or lipidoid which accounts for the largest proportion of the components in the lipid mix or lipidoid mix, in terms of the weight percentage based on the total weight of the lipid mix or lipidoid mix as 100%.

- the isotherm cycleis recorded on a sample carrying a layer, typically a monolayer, of the lipid mix or lipidoid mix (i.e. the lipid mix or lipidoid mix as comprised by the nanoparticles).

- the minimum surface area to be adopted for recording the isotherm cycleis generally determined by the lipid or lipidoid, or by the combination of more than one lipid/lipidoid contained in the sample used for recording the isotherm cycle.

- the minimum surface area for recording the isotherm cycleis preferably the surface area at which the start of a phase transition can be observed when a layer, typically a monolayer, of the lipid or lipidoid or of the combination of more than one lipid/lipidoid is compressed in a Langmuir trough.

- a step to establish the minimum surface areacan be carried out, e.g., as a calibration step in the Langmuir trough prior to recording the isotherm cycle in step (b).

- a minimum surface areacan be established by compressing a layer, typically a monolayer, of the lipid or lipidoid or of the combination of more than one lipid/lipidoid as it is contained in the sample for recording the isotherm cycle in step (b) in the Langmuir trough until a first phase transition is observed in a surface pressure/area isotherm.

- the layercan be conveniently provided on water, e.g. deionized water.

- the surface area at the start of the phase transitioncan then be relied on as the minimum surface area for recording the isotherm cycle in step (b) of the method.

- the start of the phase transition as referred to herein in a pressure/area (IT -A) isotherm plotcan be objectively determined as the point where the slope of the curve (dn/dA) changes significantly.

- the surface area before the start of the compression in a compression phasee.g., the maximum area provided by the Langmuir trough, can be conveniently used.

- a monolayer of a lipid and/or lipidoid on water, or of a lipid mix or lipidoid mix on water, in a Langmuir troughcan be provided, e.g., by applying the lipid and/or lipidoid or the lipid mix or lipidoid mix to the surface until a signal change in the Langmuir trough detector is generated.

- step (c)it is sufficient if a single isotherm cycle is recorded, and the Langmuir isotherm An values are preferably calculated in step (c) for this isotherm cycle.

- Multiple isotherm cyclescan be recorded in sequence, such as three isotherm cycles, e.g. with a wait time of 5 seconds or less between cycles, such as 3 seconds.

- TT values of the first cyclefulfill the requirements set forth above, the same typically applies also for the subsequent cycles, such that it is preferred to rely on the measurement results of the first cycle for the calculation of the An values even if multiple cycles are recorded.

- a Langmuir surface pressure/area isotherm or isotherm cycle as referred to hereincan be recorded at about room temperature, e.g. at 22.1 ⁇ 0.2°C.

- step (c)a Langmuir isotherm An is calculated for each area point of the Langmuir pressure/area isotherm cycle.

- a method for the preparation of a pharmaceutical compositioncomprising classifying a surfactant as suitable or not suitable for use as a stabilizing agent for a pharmaceutical composition in accordance with the method as described above, and, if the surfactant is classified as being suitable for use as a stabilizing agent, incorporating the surfactant into the pharmaceutical composition, e.g. into a vehicle solution of a pharmaceutical composition which is in the form of a nanoparticle suspension.

- the inventionprovides a method of mitigating or avoiding clogging or fouling of a filtration system during purification of a pharmaceutical composition in the form of a lipid nanoparticle formulation (LNP) or lipidoid nanoparticle formulation (LiNP), the method comprising adding a stabilizing surfactant to a first LNP or LiNP formulation to form a second LNP or LiNP formulation, optionally before purification, wherein the LNP or LiNP formulation comprises a plurality of LNPs or LiNPs, each comprising a lipid mix or lipidoid mix and a therapeutic agent, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, and wherein the stabilizing surfactant is a surfactant according to the invention, e.g. a surfactant as discussed in the third aspect above, or wherein the stabilizing surfact

- the LNP formulation or LiNP formulationcomprises a therapeutic agent, for example a nucleic acid.

- a preferred therapeutic agentis RNA, and particularly preferred is mRNA. Details regarding preferred types of therapeutic agents shall be discussed herein below.

- the LNP formulation or LiNP formulationis a suspension formulation comprising a liquid vehicle solution, wherein the LNPs or LiNPs can be dispersed.

- the vehicle solutionis preferably an aqueous vehicle solution.

- the stabilizing surfactantis added in the context of the above method to the vehicle solution.

- the LNPs or LiNPs dispersed in the liquid vehicleare essentially free of the stabilizing surfactant, e.g. the surfactant is essentially not incorporated into the LNPs or LiNPs.

- the purification of the pharmaceutical compositionincludes tangential flow filtration (TFF) purification.

- the inventionprovides a method of mitigating aggregation of lipid or lipidoid nanoparticles in a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation, the method comprising adding a stabilizing surfactant to a first LNP or LiNP formulation to form a second LNP or LiNP formulation, optionally before purification, wherein the LNP or LiNP formulation comprises a plurality of LNPs or LiNPs, each comprising a lipid mix or lipidoid mix, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid, and wherein the stabilizing surfactant is a surfactant in accordance with invention, e.g. a surfactant as discussed in the third aspect above, or wherein the stabilizing surfactant is a surfactant classified as being suitable

- the methodis a method of mitigating aggregation of lipid or lipidoid nanoparticles in a pharmaceutical formulation in the form of a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation comprising a plurality of LNPs or LiNPs, each comprising a lipid mix or lipidoid mix and a therapeutic agent, for example a nucleic acid.

- LNPlipid nanoparticle

- LiNPlipidoid nanoparticle

- a therapeutic agentfor example a nucleic acid.

- a preferred therapeutic agentis RNA, and particularly preferred is mRNA. Details regarding preferred types of therapeutic agents shall be discussed herein below.

- the LNP formulation or LiNP formulationis a suspension formulation comprising a liquid vehicle solution, wherein the LNPs or LiNPs can be dispersed.

- the vehicle solutionis preferably an aqueous vehicle solution.

- the stabilizing surfactantis added in the context of the above method to the vehicle solution.

- the LNPs or LiNPs dispersed in the liquid vehicleare essentially free of the stabilizing surfactant, e.g. the surfactant is essentially not incorporated into the LNPs or LiNPs.

- the methodis a method of mitigating aggregation of lipid or lipidoid nanoparticles in a pharmaceutical formulation in the form of a lipid nanoparticle (LNP) suspension formulation or lipidoid nanoparticle (LiNP) suspension formulation comprising a plurality of LNPs or LiNPs, each comprising a lipid mix or lipidoid mix and a therapeutic agent, wherein the lipid mix or lipidoid mix comprises, as a component thereof, at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid.

- LNPlipid nanoparticle

- LiNPlipidoid nanoparticle

- the lipid nanoparticles or lipidoid nanoparticlesmay comprise a nucleic acid, e.g. RNA, and preferably mRNA, as a therapeutic agent, and the method in accordance with this aspect may comprise, e.g., the following steps: i) first, combining the nucleic acid and at least one selected from an ionizable lipid, ionizable lipidoid, and permanently cationic lipid to form LNPs or LiNPs, ii) second, purifying the LNPs or LiNPs iii) third, adding the stabilizing surfactant before TFF purification and/or during TFF purification in an exchange buffer, maintaining the surfactant in a steady concentration, iv) optionally wherein the stabilizing surfactant is added to the LNP or LiNP formulation after step (i).

- the method in accordance with this aspectmay alternatively comprise, e.g., the following steps: i) generating an LNP or LiNP preparation by mixing of at least one selected from a permanently cationic lipid, an ionizable lipid and an ionizable lipidoid dissolved in an organic phase with a therapeutic agent dissolved in an aqueous solution, ii) diluting the LNP or LiNP preparation by dilution with a first solution, iii) concentrating the LNP or LiNP preparation by buffer exchange using ultra/diafiltration via TFF wherein a second solution is used for the ultra/diafiltration, iv) obtaining a LNP or LiNP suspension in an aqueous vehicle solution, wherein the first solution comprises between about 0.01% w/v and 10% of the stabilizing surfactant, preferably between about 0.01% w/v surfactant and 5% w/v surfactant, more preferably between about 0.01 % w/v sur

- the inventionprovides a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation obtained by the method in accordance with the fourth to seventh aspect.

- this aspectprovides a pharmaceutical composition in the form of a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation, said composition comprising a surfactant which has been classified as being suitable for use as a stabilizing agent for a pharmaceutical composition in accordance with the method of the fourth aspect.

- the eighth aspectprovides pharmaceutical composition in the form of a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation, said composition comprising a surfactant which has been classified as being suitable for use as a stabilizing agent for a pharmaceutical composition comprising a lipid or lipidoid composition in accordance with the method of the fifth aspect.

- the eighth aspectprovides a pharmaceutical composition in the form of lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation obtained by the method in accordance with the sixth aspect.

- the eighth aspectprovides a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation, preferably a pharmaceutical composition in the form of a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation, obtained by the method in accordance with the sixth aspect.

- LNPlipid nanoparticle

- LiNPlipidoid nanoparticle

- the formulationis a lipid nanoparticle (LNP) suspension formulation or lipidoid nanoparticle (LiNP) suspension formulation.

- LNPlipid nanoparticle

- LiNPlipidoid nanoparticle

- the inventionprovides a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation in accordance with the first aspect, the second aspect, or the eighths aspect discussed above for use as a medicament.

- the LNPs or LiNPs of the lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation for use in accordance with this aspectcomprise a therapeutic agent, e.g. a nucleic acid such as RNA, preferably mRNA. They are preferably suspension formulations as discussed in the context of the concerned aspects.

- the inventionprovides a lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation in accordance with the first aspect, the second aspect, or the eighths aspect discussed above for use in the treatment or prevention of a disease.

- the LNPs or LiNPs of the lipid nanoparticle (LNP) formulation or lipidoid nanoparticle (LiNP) formulation for use in accordance with this aspectcomprise a therapeutic agent, e.g. a nucleic acid such as RNA, preferably mRNA. They are preferably suspension formulations as discussed in the context of the concerned aspects.

- the diseasemay be, e.g., a disease selected from Table A as disclosed herein below.