WO2025023398A1 - Dispositif tampon et ensemble dispositif de diagnostic ultrasonore le comprenant - Google Patents

Dispositif tampon et ensemble dispositif de diagnostic ultrasonore le comprenantDownload PDFInfo

- Publication number

- WO2025023398A1 WO2025023398A1PCT/KR2023/020642KR2023020642WWO2025023398A1WO 2025023398 A1WO2025023398 A1WO 2025023398A1KR 2023020642 WKR2023020642 WKR 2023020642WWO 2025023398 A1WO2025023398 A1WO 2025023398A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- buffer

- main body

- imaging device

- shock

- ultrasonic imaging

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B8/00—Diagnosis using ultrasonic, sonic or infrasonic waves

Definitions

- the present disclosurerelates to a buffer device and an ultrasonic diagnostic device assembly including the same.

- various medical imaging deviceshave been widely used in the medical field to obtain information about the human body's biological tissues by visualizing them for the purpose of early diagnosis of various diseases or surgery.

- Representative examples of such medical imaging devicesinclude ultrasound diagnostic devices, CT (Computed Tomography) devices, and MRI (Magnetic Resonance Imaging) devices.

- An ultrasound diagnostic deviceis a device that noninvasively obtains at least one image of a part (e.g., soft tissue or blood flow) inside the target by irradiating an ultrasound signal generated from a transducer of a probe to the target and receiving information on a signal reflected from the target.

- An ultrasound diagnostic devicecan be used for medical purposes such as observing the inside of a target, detecting foreign substances, and measuring injuries.

- Such ultrasound diagnostic deviceshave the advantages of high stability compared to imaging devices using X-rays, real-time image display, and safety due to the absence of radiation exposure, and are therefore widely used together with other imaging devices.

- the ultrasonic diagnostic devicemay be implemented in a portable form that can be moved depending on the purpose of use. During the process of moving the ultrasonic diagnostic device, the risk of the ultrasonic diagnostic device being damaged by external impact may increase.

- a buffer device for protecting an ultrasonic diagnostic device from external impact and an ultrasonic diagnostic device assembly including the buffer deviceare provided.

- a buffer device with improved user convenience and an ultrasonic diagnostic device assembly including the buffer deviceare provided.

- a buffer device surrounding an ultrasonic imaging device having a main body and a handle portion coupled to the main bodymay include a first buffer portion surrounding an outer circumference of the main body and an outer circumference of the handle portion, and a second buffer portion disposed so as to be spaced apart from the first buffer portion by a predetermined distance and disposed between the main body and the handle portion.

- Itmay further include a connecting portion connecting the first buffer portion and the second buffer portion.

- At least one of the first buffer portion, the second buffer portion, and the connecting portionmay be formed integrally.

- the above second buffer membermay include a second-first buffer member and a second-second buffer member that are arranged to be spaced apart from each other along one direction.

- the above handle portionhas a handle portion thickness along the thickness direction of the ultrasonic imaging device, and a portion of the first buffer portion positioned to face the handle portion may have a thickness less than or equal to the handle portion thickness along the thickness direction of the ultrasonic imaging device.

- the above bodyhas a body thickness along the thickness direction of the ultrasonic imaging device, and at least one region of the first buffer portion may have a vertical buffer portion thickness exceeding the body thickness along the thickness direction of the ultrasonic imaging device.

- the second buffer portionmay include a first fixing portion that supports one side of the main body and fixes the position of the main body with respect to the second buffer portion

- the first buffer portionmay include a second fixing portion that supports the other side of the main body and fixes the position of the main body with respect to the first buffer portion

- a groovemay be arranged on one side of the main body, the first fixing part may include a stepped part having a shape corresponding to the groove, a plurality of protrusions may be arranged on the other side of the main body, and the second fixing part may include a plurality of recessed parts corresponding to the plurality of protrusions.

- the band fixing membermay further include a band fixing member arranged to cross one side of the main body and having both ends or one end detachably attached to the first buffering member or the second buffering member.

- the devicemay further include an intake passage part arranged to face an intake part disposed on one side of the main body with a predetermined gap therebetween, and an exhaust passage part arranged to face an exhaust part disposed on the other side of the main body with a predetermined gap therebetween.

- the above intake passage partmay have a plurality of intake passages extending in one direction, and the above exhaust passage part may have a plurality of exhaust holes.

- At least one of the first buffer portion and the second buffer portionmay include an elastic material.

- the above elastic materialmay include one or more of silicone rubber, ethylene vinyl acetate (EVA), ethylene propylene diene monomer rubber (EPDM rubber), fluoro elastomers, acrylonitrile butadiene rubber (NBR rubber), styrene butadiene rubber (SBR rubber), natural rubber (NR rubber), chloroprene rubber (CR rubber), expanded polyethylene (EPE), expanded polypropylene (EPP), expanded polystyrene (EPS), and plastic.

- silicone rubberethylene vinyl acetate (EVA), ethylene propylene diene monomer rubber (EPDM rubber), fluoro elastomers, acrylonitrile butadiene rubber (NBR rubber), styrene butadiene rubber (SBR rubber), natural rubber (NR rubber), chloroprene rubber (CR rubber), expanded polyethylene (EPE), expanded polypropylene (EPP), expanded polystyrene (EPS), and plastic.

- EVAethylene vinyl acetate

- EPDM rubber

- Itmay further include a reinforcing member positioned to be inserted into the center of the first buffer portion.

- the above reinforcing membermay include a different material from the first buffer portion.

- the devicemay further include a plurality of shock absorbing members arranged inside at least one of the first buffer member and the second buffer member and having at least one of a polygonal or circular cross-section.

- One or more connectorsare arranged on one side of the above body, and a connector hole arranged at a position corresponding to the one or more connectors and a connector hole opening/closing part for opening and closing the connector hole may be further included.

- a probe connected to the connector of the above main bodymay further include a groove portion arranged therein, and a shock-absorbing step portion formed in a shape corresponding to the groove portion and supporting the groove portion.

- the above bodymay further include a waterproof part having a predetermined groove portion arranged in a shape corresponding to the groove portion and inserted into the groove portion to block foreign substances entering from the outside.

- An ultrasonic diagnostic device assemblymay include an ultrasonic imaging device having the buffer device, a main body, a handle portion coupled to the main body, and a probe connected to the ultrasonic imaging device.

- a buffer device and an ultrasonic diagnostic device assembly including the buffer device according to an examplecan protect the ultrasonic diagnostic device from external impact.

- the buffer device and the ultrasonic diagnostic device assembly including the buffer devicecan improve the user convenience of the ultrasonic diagnostic device when the buffer device is arranged in the ultrasonic diagnostic device.

- FIG. 1is a block diagram illustrating the configuration of an ultrasound imaging system according to one embodiment of the present disclosure.

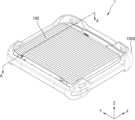

- FIG. 2is a perspective view of an ultrasonic diagnostic device assembly including a buffer device according to an example.

- Figure 3is a perspective view of a buffer device and an ultrasonic diagnostic device according to an example.

- Figure 4is a perspective view of a buffer device according to an example.

- Figure 5is a plan view of a buffer device according to an example.

- FIG. 6is a plan view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device arranged in a buffer device according to an example.

- Figure 7is an enlarged view of the P area shown in Figure 6.

- FIG. 8is a bottom view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device arranged in a buffer device according to an example.

- FIG. 9is a side view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device disposed in a buffer device according to an example.

- FIG. 10is a side view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device disposed in a buffer device according to an example.

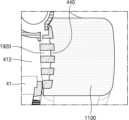

- FIG. 11is a cross-sectional view of the ultrasonic diagnostic device assembly taken along line A-A shown in FIG. 2.

- FIG. 12ais an enlarged cross-sectional view of a portion of the cross-sectional view of the ultrasonic diagnostic device assembly illustrated in FIG. 11.

- Fig. 12bis an enlarged cross-sectional view of a portion of the cross-sectional view of the ultrasonic diagnostic device assembly illustrated in Fig. 11.

- FIG. 13is a plan view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device arranged in a buffer device according to an example.

- FIG. 14is a bottom view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device arranged in a buffer device according to an example.

- FIG. 15is a cross-sectional view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device arranged in a buffer device according to an example.

- Fig. 16is an enlarged cross-sectional view of a portion of the cross-sectional view of the ultrasonic diagnostic device assembly illustrated in Fig. 15.

- Fig. 17is an enlarged cross-sectional view of a portion of the cross-sectional view of the ultrasonic diagnostic device assembly illustrated in Fig. 15.

- Fig. 18ais a cross-sectional view of the buffer device taken along the line B-B shown in Fig. 4.

- Figure 18bis a cross-sectional view of the buffer device taken along the line C-C shown in Figure 4.

- Fig. 19is a perspective projection view of a buffer device according to an example.

- FIG. 20is a side view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device disposed in a buffer device according to an example.

- FIG. 21is a side view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device disposed in a buffer device according to an example.

- FIG. 22is a partial cross-sectional view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device disposed in a buffer device according to an example.

- FIG. 23is a side view of an ultrasonic diagnostic device assembly with a probe coupled thereto according to an example.

- FIG. 24is a side view of an ultrasonic diagnostic device assembly with the probe separated according to an example.

- Fig. 25is a perspective view of a buffer device according to an example.

- Fig. 26is a partial cross-sectional view of an ultrasonic diagnostic device assembly according to an example.

- 'module' or 'unit'used in the specification may be implemented by one or a combination of two or more of software, hardware, or firmware, and according to the embodiments, a plurality of 'modules' or 'units' may be implemented as a single element, or a single 'module' or 'unit' may include a plurality of elements.

- each of the phrases “A or B”, “at least one of A and B”, “at least one of A or B”, “A, B, or C”, “at least one of A, B, and C”, and “at least one of A, B, or C”can include any one of the items listed together in the corresponding phrase, or all possible combinations thereof.

- the imagemay include a medical image acquired by a medical imaging device such as a magnetic resonance imaging (MRI) device, a computed tomography (CT) device, an ultrasound imaging device, or an X-ray imaging device.

- a medical imaging devicesuch as a magnetic resonance imaging (MRI) device, a computed tomography (CT) device, an ultrasound imaging device, or an X-ray imaging device.

- an 'object'is a subject of photography, and may include a person, an animal, or a part thereof.

- the objectmay include a part of a body (such as an organ or system) or a phantom.

- the term 'ultrasonic image'means an image of an object generated or processed based on an ultrasonic signal transmitted to the object and reflected from the object.

- FIG. 1is a block diagram illustrating the configuration of an ultrasound imaging system according to one embodiment of the present disclosure.

- an ultrasonic diagnostic device (100)may include a probe (20) and an ultrasonic imaging device (40).

- the probe (20)may include a display (112), a transmission module (113), a battery (114), a transducer (115), a charging module (116), a receiving module (117), an input interface (109), a processor (118), and a communication module (119).

- a display (112may include a display (112), a transmission module (113), a battery (114), a transducer (115), a charging module (116), a receiving module (117), an input interface (109), a processor (118), and a communication module (119).

- the probe (20)is illustrated as including both the transmission module (113) and the receiving module (117), but depending on the implementation form, the probe (20) may include only a part of the configurations of the transmission module (113) and the receiving module (117), and a part of the configurations of the transmission module (113) and the receiving module (117) may be included in the ultrasonic imaging device (40).

- the probe (20)may further include an image processor (130).

- the transducer (115)may include a plurality of transducers.

- the plurality of transducersmay be arranged in a predetermined arrangement and implemented as a transducer array.

- the transducer arraymay correspond to a one-dimensional (1D) array or a two-dimensional (2D) array.

- the plurality of transducersmay transmit ultrasonic signals to the target (10) according to a transmission signal applied from the transmission module (113).

- the plurality of transducersmay receive ultrasonic signals reflected from the target (10) and form or generate electrical reception signals.

- the charging module (116)can charge the battery (114).

- the charging module (116)can receive power from the outside. According to one embodiment of the present disclosure, the charging module (116) can receive power wirelessly. Also, according to one embodiment of the present disclosure, the charging module (116) can receive power wiredly. The charging module (116) can transfer the received power to the battery (114).

- the processor (118)controls the transmission module (113) to generate or form a transmission signal to be applied to each of the plurality of transducers, taking into account the positions and focus points of the plurality of transducers.

- the processor (118)controls the receiving module (117) to generate ultrasound data by converting an analog-to-digital reception signal received from the transducer (115) and adding the digitally converted reception signals by considering the positions and focal points of a plurality of transducers.

- an ultrasound imagecan be generated using the generated ultrasound data.

- the processor (118)can calculate a time delay value for digital beamforming for each sub-array of a plurality of sub-arrays included in the two-dimensional transducer array. In addition, the processor (118) can calculate a time delay value for analog beamforming for each transducer included in one of the plurality of sub-arrays. The processor (118) can control the analog beamformer and the digital beamformer to form a transmission signal to be applied to each of the plurality of transducers according to the time delay value for analog beamforming and the time delay value for digital beamforming.

- the processor (118)can control the analog beamformer to add up signals received from the plurality of transducers according to the time delay value for analog beamforming for each sub-array.

- the processor (118)can control the ultrasonic transmission/reception module (110) to convert the signal added for each sub-array into analog-to-digital.

- the processor (118)can control the digital beamformer to generate ultrasound data by adding digitally converted signals according to a time delay value for digital beamforming.

- the processor (118)controls the overall operation of the probe (20) and can control the operation of components of the probe (20).

- the processor (118)can perform or control various operations or functions of the probe (20) by executing programs or instructions stored in the memory (111).

- the processor (118)can receive a control signal from the input interface (109) of the probe (20) or an external device (e.g., an ultrasonic imaging device (40)) and control the operation of the probe (20).

- the processor (118)can receive a control signal from the input interface (109) or an external device and control the operation of the probe (20).

- the input interface (109)can receive a user's input for controlling the probe (20).

- user inputmay include, but is not limited to, inputs manipulating buttons, keypads, mouses, trackballs, jog switches, knobs, etc., inputs touching a touchpad or touchscreen, voice inputs, motion inputs, biometric inputs (e.g., iris recognition, fingerprint recognition, etc.), etc.

- inputs manipulating buttons, keypads, mouses, trackballs, jog switches, knobs, etc.inputs touching a touchpad or touchscreen

- voice inputse.g., voice inputs, motion inputs, biometric inputs (e.g., iris recognition, fingerprint recognition, etc.), etc.

- biometric inputse.g., iris recognition, fingerprint recognition, etc.

- the display (112)can display an ultrasonic image generated by the probe (20), an ultrasonic image generated by processing ultrasonic data generated by the probe (20), an ultrasonic image received from an ultrasonic imaging device (40), or various information processed by the ultrasonic diagnostic device (100).

- the display (112)can further display status information of the probe (20).

- the status information of the probe (20)can include at least one of device information of the probe (20), battery status information of the probe (20), frequency band information of the probe (20), output information of the probe (20), abnormality information of the probe (20), setting information of the probe (20), or temperature information of the probe (20).

- the probe (20)may include one or more displays (112) depending on the implementation form.

- the display (112)may include a touch panel or a touch screen.

- the display (112)may include a flexible display.

- the communication module (119)can wirelessly transmit generated ultrasonic data or ultrasonic images to an ultrasonic imaging device (40) via a wireless network.

- the communication module (119)can receive control signals and data from the ultrasonic imaging device (40).

- the ultrasonic imaging device (40)can receive ultrasonic data or ultrasonic images from the probe (20).

- the probe (20)when the probe (20) includes an image processor (130) capable of generating an ultrasound image using ultrasound data, the probe (20) can transmit the ultrasound data or the ultrasound image generated by the image processor (130) to the ultrasound imaging device (40).

- the probe (20)when the probe (20) does not include an image processor (130) capable of generating an ultrasound image using ultrasound data, the probe (20) may transmit the ultrasound data to an ultrasound imaging device (40).

- the ultrasound datamay include ultrasound raw data, and the ultrasound image may mean ultrasound image data.

- the ultrasonic imaging device (40)may include a processor (120), an image processor (130), a display (140), a memory (150), a communication module (160), and an input interface (170).

- the image processor (130)generates or processes an ultrasonic image using ultrasonic data received from the probe (20).

- the display (140)can display an ultrasonic image received from the probe (20), an ultrasonic image generated by processing ultrasonic data received from the probe (20), or various information processed in the ultrasonic diagnostic device (100).

- the ultrasonic imaging device (40)can include one or more displays (140) depending on the implementation type.

- the display (140)can include a touch panel or a touch screen.

- the display (140)can include a flexible display.

- the processor (120)controls the overall operation of the ultrasonic imaging device (40) and can control the operation of components of the ultrasonic imaging device (40).

- the processor (120)can execute a program or application stored in the memory (150) to perform or control various operations or functions of the ultrasonic imaging device (40).

- the processor (120)can receive a control signal from an input interface (170) or an external device and control the operation of the ultrasonic imaging device (40).

- the ultrasonic imaging device (40)includes a communication module (160) and can be connected to and communicate with an external device (e.g., a probe (20), a server, a medical device, a portable device (smartphone, tablet PC, wearable device, etc.)) through the communication module (160).

- an external devicee.g., a probe (20), a server, a medical device, a portable device (smartphone, tablet PC, wearable device, etc.

- the communication module (160)may include one or more components that enable communication with an external device.

- the communication module (160)may include, for example, at least one of a short-range communication module, a wired communication module, or a wireless communication module.

- the communication module (160) of the ultrasonic imaging device (40) and the communication module (119) of the probe (20)may communicate using a network or a short-range wireless communication method.

- the communication module (160) of the ultrasonic imaging device (40) and the communication module (119) of the probe (20)may communicate using any one of wireless data communication methods including Wireless LAN, Wi-Fi, Bluetooth, zigbee, WFD (Wi-Fi Direct), infrared Data Association (IrDA), Bluetooth LowEnergy (BLE), Near Field Communication (NFC), Wireless Broadband Internet (Wibro), World Interoperability for Microwave Access (WiMAX), Shared Wireless Access Protocol (SWAP), Wireless Gigabit Alliance (WiGig), RF communication, or 60GHz millimeter wave (mm Wave) short-range communication.

- wireless data communication methodsincluding Wireless LAN, Wi-Fi, Bluetooth, zigbee, WFD (Wi-Fi Direct), infrared Data Association (IrDA), Bluetooth LowEnergy (BLE), Near

- the communication module (160) of the ultrasound imaging device (40) and the communication module (119) of the probe (20)may include at least one of a wireless LAN communication module, a Wi-Fi communication module, a Bluetooth communication module, a zigbee communication module, a WFD (Wi-Fi Direct) communication module, an infrared communication (IrDA) module, a BLE (Bluetooth LowEnergy) communication module, an NFC (Near Field Communication) communication module, a Wibro (Wireless Broadband Internet) communication module, a WiMAX (World Interoperability for Microwave Access) communication module, a SWAP (Shared Wireless Access Protocol) communication module, a WiGig (Wireless Gigabit Alliance) communication module, an RF communication module, or a 60GHz millimeter wave (mm Wave) short-range communication module.

- a wireless LAN communication modulea Wi-Fi communication module

- a Bluetooth communication modulea zigbee communication module

- the probe (20)transmits device information (e.g., ID information) of the probe (20) to the ultrasonic imaging device (40) using a first communication method (e.g., BLE) and can be wirelessly paired with the ultrasonic imaging device (40).

- the probe (20)can transmit ultrasonic data and/or ultrasonic images to the paired ultrasonic imaging device (40).

- the device information of the probe (20)may include various information related to the serial number, model name, or battery status of the probe (20).

- the ultrasonic imaging device (40)may receive device information (e.g., ID information) of the probe (20) from the probe (20) using a first communication method (e.g., BLE), and may be wirelessly paired with the probe (20).

- the ultrasonic imaging device (40)may transmit an activation signal to the paired probe (20), and receive ultrasonic data and/or ultrasonic images from the probe (20).

- the activation signalmay include a signal for controlling the operation of the probe (20).

- the probe (20)may transmit device information (e.g., ID information) of the probe (20) to the ultrasonic imaging device (40) using a first communication method (e.g., BLE) and may be wirelessly paired with the ultrasonic imaging device (40).

- the probe (20)may transmit ultrasonic data and/or ultrasonic images to the ultrasonic imaging device (40) paired by the first communication method using a second communication method (e.g., 60 GHz millimeter wave, Wi-Fi).

- a first communication methode.g., BLE

- a second communication methode.g. 60 GHz millimeter wave, Wi-Fi

- the ultrasonic imaging device (40)may receive device information (e.g., ID information) of the probe (20) from the probe (20) using a first communication method (e.g., BLE) and may be wirelessly paired with the probe (20). In addition, the ultrasonic imaging device (40) may transmit an activation signal to the paired probe (20) and receive ultrasonic data and/or ultrasonic images from the probe (20) using a second communication method (e.g., 60 GHz millimeter wave, Wi-Fi).

- a first communication methode.g., BLE

- a second communication methode.g. 60 GHz millimeter wave, Wi-Fi

- a first communication method used to pair the probe (20) and the ultrasonic imaging device (40) with each othermay have a lower frequency band than a frequency band of a second communication method used to transmit ultrasonic data and/or ultrasonic images from the probe (20) to the ultrasonic imaging device (40).

- the display (140) of the ultrasonic imaging device (40)can display UIs (User Interfaces) indicating device information of the probe (20).

- the display (140)can display identification information of the wireless ultrasonic probe (20), a pairing method indicating a pairing method with the probe (20), a data communication status between the probe (20) and the ultrasonic imaging device (40), a method of performing data communication with the ultrasonic imaging device (40), or a UI indicating a battery status of the probe (20).

- the display (112) of the probe (20)may display a UI indicating device information of the probe (20).

- the display (112)may display identification information of the wireless ultrasonic probe (20), a pairing method indicating a pairing method with the probe (20), a data communication status between the probe (20) and the ultrasonic imaging device (40), a method of performing data communication with the ultrasonic imaging device (40), or a UI indicating a battery status of the probe (20).

- the communication module (160)can receive a control signal or data from an external device.

- the processor (120)can control the operation of the ultrasonic imaging device (40) according to the control signal received through the communication module (160).

- the processor (120)can transmit a control signal to an external device through a communication module (160) and control the external device according to the transmitted control signal.

- the external devicecan operate according to a control signal received from the ultrasonic imaging device (40) or process data received from the ultrasonic imaging device (40).

- An external devicemay receive or download a program or application related to an ultrasonic imaging device (40) from an ultrasonic imaging device (40), a probe (20), or a server, and install and execute the program or application on the external device.

- An ultrasonic imaging device (40), a probe (20), or a server that provides a program or applicationmay include a recording medium that stores instructions, commands, installation files, executable files, or related data of the program or application.

- the external devicemay also be sold with the program or application installed.

- the memory (150)can store various data or programs for driving and controlling the ultrasonic imaging device (40), input/output ultrasonic data, ultrasonic images, etc.

- FIG. 2is a perspective view of an ultrasonic diagnostic device assembly including a buffer device according to an example.

- FIG. 3is an exploded perspective view of the buffer device and the ultrasonic diagnostic device according to an example.

- an ultrasonic diagnostic device assembly (1)may include an ultrasonic diagnostic device (100) including a probe (20) and an ultrasonic imaging device (40), and a buffer device (1000) surrounding the ultrasonic imaging device (40).

- the ultrasound imaging device (40)may also be implemented in a portable form.

- portable ultrasound imaging devices (40)may include, but are not limited to, a smart phone, a laptop computer, a PDA, or a tablet PC including a probe and an application.

- a portable ultrasound imaging devicemay include a main body (41) and a handle portion (42) coupled to the main body (41).

- the handle portion (42)may include a grip portion (420) arranged to be spaced apart from the main body (41) by a predetermined distance, and a grip portion connecting portion (421) arranged at both ends of the grip portion (420) and connecting the grip portion (420) and the main body (41).

- a hollow area (422) in which a user's finger is placedmay be formed in the space arranged between the main body (41) and the grip portion (420). Since the handle portion (42) is arranged to be coupled to the main body (41) and the user can easily grip the main body (41), user convenience may be improved.

- the ultrasonic imaging device (40) and the probe (20)may be interconnected using connectors.

- the ultrasonic imaging device (40)may be provided with one or more connectors (470: see FIG. 20), and the probe (20) may be provided with a connector (210) coupled to one or more connectors (470) provided in the ultrasonic imaging device (40).

- the ultrasonic imaging device (40) and the probe (20)may establish communication or be paired using short-range wireless communication.

- the ultrasonic imaging device (40) and the probe (20)may perform communication using Bluetooth, BLE, Wi-Fi, or Wi-Fi Direct.

- the ultrasonic imaging device (40)can control the probe (20) and output information related to the probe (20) by executing a program or application related to the probe (20).

- the ultrasonic imaging device (40)can perform operations related to the probe (20) while communicating with a predetermined server.

- the probe (20)can be registered with the ultrasonic imaging device (40) or registered with a predetermined server.

- the ultrasonic imaging device (40)can communicate with the registered probe (20) and perform operations related to the probe (20).

- the ultrasonic imaging device (40)may include various types of input/output interfaces such as speakers, LEDs, and vibration devices.

- the ultrasonic imaging device (40)may output various information in the form of graphics, sounds, or vibrations through the input/output interface.

- the ultrasonic imaging device (40)may output various notifications or data through the input/output interface.

- the ultrasound imaging device (40)may process an ultrasound image or obtain additional information from an ultrasound image using an artificial intelligence (AI) model.

- AIartificial intelligence

- the ultrasound imaging device (40)may generate an ultrasound image or perform processing such as correction, image quality improvement, encoding, or decoding on an ultrasound image using an AI model.

- the ultrasound imaging device (40)may perform processing such as baseline definition, anatomical information acquisition, lesion information acquisition, surface extraction, boundary definition, length measurement, area measurement, volume measurement, or annotation generation from an ultrasound image using an AI model.

- the AI modelmay be provided on the ultrasound imaging device (40) or on the server.

- the AI modelmay be implemented using various artificial neural network models or deep neural network models.

- the AI modelmay be learned and generated using various machine learning algorithms or deep learning algorithms.

- the AI modelmay be implemented using, for example, models such as CNN (Convolutional Neural Network), RNN (Recurrent Neural Network), GAN (Generative Adversarial Network), and LSTM (Long Short-Term Memory).

- FIG. 4is a perspective view of a buffer device according to an example.

- FIG. 5is a plan view of a buffer device according to an example.

- FIG. 6is a plan view of an ultrasonic diagnostic device assembly in which an ultrasonic imaging device is arranged in a buffer device according to an example.

- FIG. 7is an enlarged view of a region P illustrated in FIG. 6.

- FIG. 8is a bottom view of an ultrasonic diagnostic device assembly in which an ultrasonic imaging device is arranged in a buffer device according to an example.

- the buffer device (1000)is arranged to surround the ultrasonic imaging device (40) to prevent the ultrasonic imaging device (40) from being damaged by external impact.

- the ultrasonic imaging device (40)is provided as a portable device, the user can move around while carrying the ultrasonic imaging device (40). At this time, the user may drop the ultrasonic imaging device (40) or collide it with an external structure, thereby damaging the ultrasonic imaging device (40).

- the buffer device (1000)can prevent the ultrasonic imaging device (40) from being damaged by external impact by absorbing impact that may be applied to the ultrasonic imaging device (40) in advance.

- a buffer device (1000)may include a first buffer part (1100) surrounding an outer circumference of a main body (41) and an outer circumference of a handle part (42), a second buffer part (1200) positioned so as to be spaced apart from the first buffer part (1100) by a predetermined distance and positioned between the main body (41) and the handle part (42), and a connecting part (1300) connecting the first buffer part (1100) and the second buffer part (1200).

- the main body (41)may include a main body case (410) forming the outer shape of the main body (41).

- the main body case (410)may be provided in a rectangular parallelepiped shape as illustrated in FIG. 3.

- the present disclosureis not limited thereto, and the main body case (410) may include different shapes depending on the intended use and the environment of use.

- the width direction of the main body case (410)is described as a first direction (X direction)

- the length direction of the main body case (410)is described as a second direction (Y direction)

- the thickness direction of the main body case (410)is described as a third direction (Z direction).

- the handle portion (42), as illustrated in FIG. 3,may include a grip portion (420) that is positioned to be spaced apart from the main body (41) by a predetermined interval along one direction, for example, the second direction (Y direction), and a grip portion connecting portion (421) that connects the grip portion (420) and the main body (41).

- the outer periphery of the handle portion (42)may be formed to extend from the main body case (410) along one plane (XY plane).

- the present disclosureis not limited thereto, and the shape of the handle portion (42) may include any shape that allows a predetermined hollow region (422) to be formed between the grip portion (420) and the main body (41) depending on the user's gripping method and the purpose of use.

- the outer periphery of the handle portion (42)is formed to extend from the main body case (410) along one plane (XY plane)

- the outer periphery of the main body case (410), the outer periphery of the grip portion (420), and the outer periphery of the grip portion connection portion (421)can have a shape substantially similar to a rectangular parallelepiped.

- the first buffer portion (1100)may be arranged to surround the outer circumference of the main body (41) and the outer circumference of the handle portion (42).

- the first buffer portion (1100)may include a side buffer portion (1110) for protecting the side of the main body case (410), a vertical buffer portion (1120) for protecting the upper and lower plates of the main body case (410) from vertical impact, and a handle buffer portion (1130) for protecting the side of the handle portion (42).

- the side buffer (1110)can protect at least one side of the outer periphery of the main body (41).

- the side buffer (1110)according to one example can have a shape corresponding to the side shape of the main body (41).

- the side buffer (1110)is arranged on the outer periphery of the side of the main body (41) and can protect the side of the main body (41) from an external impact applied along a direction of one plane (XY plane).

- the side buffer portion (1110)may include a first side buffer portion (1111) arranged to extend along the outer periphery of a first side (411) of the main body case (410), a second side buffer portion (1112) arranged to extend along the outer periphery of a second side (412) of the main body case (410), and a third side buffer portion (1113) arranged to extend along the outer periphery of a third side (413) of the main body case (410).

- the first side buffer (1111) and the third side buffer (1113)can be directly supported on the first side (411) of the main body case (410) and the third side (413) of the main body case (410) to protect the first side (411) and the third side (413) of the main body case (410) from external impact applied along a direction of one plane (XY plane).

- the second side buffer (1112)can be supported on the second side (412) of the main body case (410) to protect the second side of the main body case (410) from an external impact applied along a direction of one plane (XY plane).

- a stopper support (1150)can be arranged on the lower part of the second side (412) of the main body case (410) as illustrated in FIG. 8.

- the stopper support (1150)is provided in multiple pieces and can be arranged to be spaced apart from each other by a predetermined interval.

- the stopper support (1150)can be arranged to extend along the second direction (Y direction) and have one end supported on the second side (412) of the main body case (410) and the other end supported on the second side buffer (1112). Accordingly, the second side buffer (1112) and the stopper support (1150) are supported on the second side (412) of the main body case (410) and can protect the second side of the main body case (410) from an external impact applied along a plane (XY plane).

- the vertical buffer (1120)can protect the upper and lower plates of the main body case (410) from vertical impact.

- the vertical buffer (1120) according to an examplecan be arranged in one or more areas.

- the vertical buffer (1120)can be provided in multiple units and arranged between the first side buffer (1111) to the third side buffer (1113) and the handle buffer (1130) to be described later.

- the multiple vertical buffers (1120)can be arranged to be spaced apart from each other in four corner areas formed by the outer periphery of the main body case (410) and the outer periphery of the handle portion (42).

- the vertical buffer (1120) according to an examplecan have a thickness that exceeds the thickness of the main body (41) along the thickness direction of the ultrasonic imaging device (40), for example, the third direction (Z direction).

- the vertical buffer member (1120)when the vertical buffer member (1120) has a thickness exceeding the thickness of the main body (41) along the third direction (Z direction), the vertical buffer member (1120) can protect the upper or lower portion of the main body case (410) from an external impact applied along the vertical direction (Z direction). Matters related to the thickness of the vertical buffer member (1120) and the thickness of the main body (41) will be described in more detail later with reference to FIGS. 9 and 10.

- the handle buffer (1130)can protect at least one side surface of the outer periphery of the handle portion (42).

- the handle buffer (1130)can have a shape corresponding to the side surface shape of the handle portion (42).

- the handle buffer (1130)is arranged on the outer periphery of the side surface of the handle portion (42) to protect the side surface of the handle portion (42) from an external impact applied along a direction of one plane (XY plane).

- the handle buffer portion (1130)may include a shape extending along the outer periphery of the side surface of the grip portion (420).

- the handle buffer portion (1130)may protect the side surface of the grip portion (420) from an external impact applied along one plane (XY plane).

- the second buffer part (1200)is arranged between the main body (41) and the handle part (42) to prevent damage that may occur between the main body (41) and the handle part (42).

- the second buffer part (1200)may be arranged to be spaced apart from the first buffer part (1100) by a predetermined distance.

- the handle part (42)may be placed in the space formed between the first buffer part (1100) and the second buffer part (1200). Accordingly, the space (H) formed between the first buffer part (1100) and the second buffer part (1200) may be substantially equal to the width of the handle part (42).

- the present disclosureis not limited thereto, and when at least one of the first buffer portion (1100) or the second buffer portion (1200) includes an elastic material that can be deformed by external pressure, the gap (H) formed between the first buffer portion (1100) and the second buffer portion (1200) may be formed smaller than the width of the handle portion (42). In this case, the handle portion (42) may be fitted and seated between the first buffer portion (1100) and the second buffer portion (1200).

- the second buffer unit (1200)may be provided in multiple units. At this time, the multiple second buffer units (1200) may be arranged to be spaced apart from each other with a predetermined interval along one direction.

- the multiple second buffer units (1200)may include a 2-1 buffer unit (1210) and a 2-2 buffer unit (1220).

- the 2-1 buffer unit (1210) and the 2-2 buffer unit (1220)may be arranged to be spaced apart from each other along the first direction (X direction).

- the space spaced between the 2-1 buffer unit (1210) and the 2-2 buffer unit (1220)may be arranged to overlap with a hollow region (422) provided in the handle unit (42).

- the user's fingeris placed in the space between the 2-1 buffer part (1210) and the 2-2 buffer part (1220) and the hollow area (422) provided in the handle part (42), so that the user can more easily grasp the ultrasonic diagnostic device assembly (1) including the buffer device (1000).

- the connecting portion (1300)may be arranged between the first buffer portion (1100) and the second buffer portion (1200) to interconnect the first buffer portion (1100) and the second buffer portion (1200).

- the connecting portion (1300)may be arranged between the lower portions of the first buffer portion (1100) and the second buffer portion (1200).

- the connecting portion (1300)may be extended to a length equal to the spacing (H) formed between the first buffer portion (1100) and the second buffer portion (1200).

- a predetermined mounting portion (1350) having a groove shape, on which the handle portion (42) may be mounted,may be formed along the first buffer portion (1100), the connecting portion (1300), and the second buffer portion (1200).

- the connecting portion (1300)may also be provided in multiple units.

- the connecting portion (1300)may be provided in multiple units and include the first connecting portion (1310) and the second connecting portion (1320).

- the space spaced between the first connecting portion (1310) and the second connecting portion (1320)may be arranged to overlap with the hollow region (422) provided in the handle portion (42).

- At least one of the first buffer part (1100), the second buffer part (1200), and the connection part (1300)may be formed integrally.

- the first buffer part (1100), the second buffer part (1200), and the connection part (1300)may be formed integrally, thereby improving manufacturing convenience.

- the present disclosureis not limited thereto, and it goes without saying that the first buffer part (1100), the second buffer part (1200), and the connection part (1300) may be provided separately and then connected respectively.

- the elastic materialmay include at least one of silicone rubber, ethylene vinyl acetate (EVA), ethylene propylene diene monomer rubber (EPDM rubber), fluoro elastomers, acrylonitrile butadiene rubber (NBR rubber), styrene butadiene rubber (SBR rubber), natural rubber (NR rubber), chloroprene rubber (CR rubber), expandable polyethylene (EPE), expanded polypropylene (EPP), expanded polystyrene (EPS), and plastic.

- EVAethylene vinyl acetate

- EPDM rubberethylene propylene diene monomer rubber

- FBR rubberethylene propylene diene monomer rubber

- SBR rubberstyrene butadiene rubber

- NR rubbernatural rubber

- chloroprene rubberCR rubber

- EPEexpandable polyethylene

- EPPexpanded polypropylene

- EPSexpanded polystyrene

- At least one of the first buffer portion (1100) and the second buffer portion (1200)may include an elastic material. Accordingly, at least one of the first buffer part (1100) and the second buffer part (1200) can absorb shock applied from the outside and shock applied between the main body (41) and the handle part (42).

- FIG. 9is a side view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device disposed on a buffer device according to an example.

- FIG. 10is a side view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device disposed on a buffer device according to an example.

- a main body (41)may have a main body thickness (h 1 ) along a thickness direction of an ultrasonic imaging device, for example, a third direction (Z direction).

- a side buffer part (1110) for protecting a side surface of the main body (41), for example, a first side surface (411) of a main body case (410) to a third side surface (413) of a main body case (410), for example, the first side buffer part (1111) to the third side buffer part (1113)may have a side buffer part thickness (h 2 ) smaller than the main body thickness (h 1 ) along the third direction (Z direction).

- one or more regions of the first buffer portion (1100), for example, the vertical buffer portion (1120),may have a vertical buffer portion thickness (h 3 ) that exceeds the body thickness (h 1 ) along the thickness direction of the ultrasonic imaging device, for example, the third direction (Z direction).

- the vertical buffer portions (1120)may be provided in multiple pieces and arranged to be spaced apart from each other in four corner regions formed by the outer periphery of the body case (410) and the outer periphery of the handle portion (42).

- the vertical buffer portions (1120)may be provided in four pieces and may include the first vertical buffer portion (1121) to the fourth vertical buffer portions (1124).

- the first vertical buffer portion (1121) to the fourth vertical buffer portions (1124)may have a vertical buffer portion thickness (h 3 ) that exceeds the body thickness (h 1 ) along the third direction (Z direction). Accordingly, the first vertical buffer portion (1121) to the fourth vertical buffer portion (1124) can protect the upper surface (415) or the lower surface (416) of the main body case (410) from external impact applied along the vertical direction (Z direction).

- a handle portion (42)may have a handle portion thickness (h 4 ) along a thickness direction of an ultrasonic imaging device, for example, a third direction (Z direction).

- the handle portion thickness (h 4 )may be formed smaller than the main body thickness (h 1 ). Accordingly, a user may more easily grip the handle portion (42).

- a portion of a first buffer portion (1100) positioned to face the handle portion (42), for example, a handle buffer portion (1130),may have a handle buffer portion thickness (h 5 ) less than or equal to the handle portion thickness (h 4 ) along a thickness direction of an ultrasonic imaging device, for example, a third direction (Z direction ).

- the handle buffer thickness (h 5 ) of the handle buffer portion (1130)may be formed to be substantially the same as the handle portion thickness (h 4 ) of the handle portion (42). Accordingly, the handle buffer portion (1130) can protect the side of the handle portion (42) from external impact applied to the side of the handle portion (42) along a plane (XY plane) direction, and can also improve user convenience by minimizing the thickness of the grip portion so that the user can easily grip the handle portion (42).

- FIG. 11is a cross-sectional view of an ultrasonic diagnostic device assembly taken along the line A-A illustrated in FIG. 2.

- FIG. 12ais an enlarged cross-sectional view of a portion of the cross-sectional view of the ultrasonic diagnostic device assembly illustrated in FIG. 11.

- FIG. 12bis an enlarged cross-sectional view of a portion of the cross-sectional view of the ultrasonic diagnostic device assembly illustrated in FIG. 11.

- FIG. 13is a plan view of an ultrasonic diagnostic device assembly in which an ultrasonic imaging device is arranged in a buffer device according to an example.

- the ultrasonic imaging device (40)in order to protect the ultrasonic imaging device (40) from external impact, the ultrasonic imaging device (40) must be coupled to a buffer device (1000). In the case of a portable ultrasonic imaging device (40), since the ultrasonic imaging device (40) can be moved after being coupled to the buffer device (1000), the ultrasonic imaging device (40) must be coupled so as to be fixed to the buffer device (1000).

- the first fixing member (1910) and the second fixing member (1920)can fix the ultrasonic imaging device (40) to the buffer device (1000).

- four sides of the main body (41)can be supported by the first buffer member (1100) and the second buffer member (1200).

- the first side (411) to the third side (413) of the main body case (410)can be supported by the first buffer member (1100), and the fourth side (414) can be supported by the second buffer member (1200).

- the first fixing member (1910) and the second fixing member (1920) for fixing the ultrasonic imaging device (40) to the buffer device (1000)may be placed in at least one of the first buffer member (1100) or the second buffer member (1200).

- the first fixing member (1910)can be arranged on the second buffer member (1200) to support one side of the main body (41), thereby fixing the position of the main body (41) with respect to the second buffer member (1200).

- the first fixing member (1910) included in the second buffer member (1200)can fix the position of the fourth side (414) of the main body case (410) with respect to the second buffer member (1200).

- a groove (430)may be arranged on one side of the main body (41), for example, a fourth side (414) of the main body case (410).

- the first fixing part (1910)may include a stepped shape corresponding to the groove (430).

- the first fixing part (1910) of the stepped shape and the groove (430)may be mutually coupled to fix the position of the main body (41) with respect to the second buffer part (1200).

- the first fixing part (1910) included in the second buffer part (1200)may include an elastic material, the first fixing part (1910) may be mutually coupled with the groove (430) in a fitted form.

- the second fixing member (1920)can be arranged on the first buffer member (1100) to support another side of the main body (41), thereby fixing the position of the main body (41) with respect to the first buffer member (1100).

- the second fixing member (1920) included in the first buffer member (1100)can fix the position of the second side (412) of the main body case (410) with respect to the first buffer member (1100).

- a plurality of protrusions (440)may be arranged on another side of the main body (41), for example, a second side (412) of the main body case (410).

- the second fixing portion (1920)may include a plurality of recessed portions having shapes corresponding to the plurality of protrusions (440).

- the second fixing portion (1920) having a plurality of recessed portion shapes and the plurality of protrusions (440)may be mutually coupled to fix the position of the main body (41) with respect to the first buffer portion (1100).

- the second fixing portion (1920) included in the first buffer portion (1100)may include an elastic material, the second fixing portion (1920) may be mutually coupled with the plurality of protrusions (440) in a fitted form.

- a band fixing member (1500)can fix an ultrasonic imaging device (40) to a buffer device (1000).

- an upper surface or a lower surface of a main body (41)can be supported by a band fixing member (1500).

- an upper surface (415) or a lower surface (416) of a main body case (410)can be supported by a band fixing member (1500) arranged to cross the upper surface (415) or the lower surface (416) of the main body case (410).

- the band fixing member (1500) for fixing an ultrasonic imaging device (40) to a buffer device (1000)can be arranged on at least one of the upper surface (415) or the lower surface (416) of the main body case (410).

- the band fixing part (1500)may be provided in multiple pieces to support the upper surface (415) of the main body case (410).

- the band fixing part (1500)may include a first band fixing part (1510) and a second band fixing part (1520).

- the present disclosureis not limited thereto, and the band fixing part (1500) may be provided in a single piece.

- the first band fixing part (1510)may be arranged to cross the upper surface (415) of the main body case (410) along the first direction (X direction). At this time, both ends of the first band fixing part (1510) may be arranged to be detachably attached to the first buffer part (1100). For example, when the main body (41) is arranged in the buffer device (1000), both ends or one end of the first band fixing part (1510) may be separated from the first buffer part (1100). When the main body (41) is coupled to the buffer device (1000), both ends of the first band fixing part (1510) may be coupled to be fixed to the first buffer part (1100).

- the second band fixing part (1520)may be arranged to cross the upper surface (415) of the main body case (410) along the second direction (Y direction). At this time, one end of the second band fixing part (1520) may be arranged to be detachably attached to the first buffer part (1100). For example, when the main body (41) is arranged in the buffer device (1000), one end of the second band fixing part (1520) may be separated from the first buffer part (1100). When the main body (41) is coupled to the buffer device (1000), both ends of the second band fixing part (1520) may be coupled to be fixed to the first buffer part (1100).

- both ends or one end of the first band fixing member (1510) or the second band fixing member (1520)are described as being detachable from the first buffer member (1100), but the present disclosure is not limited thereto.

- both ends or one end of the band fixing member (1500)may be arranged to be detachable from the second buffer member (1200).

- FIG. 14is a bottom view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device disposed on a buffer device according to an example.

- FIG. 15is a cross-sectional view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device disposed on a buffer device according to an example.

- FIG. 16is an enlarged cross-sectional view of a portion of the cross-sectional view of the ultrasonic diagnostic device assembly illustrated in FIG. 15.

- FIG. 17is an enlarged cross-sectional view of a portion of the cross-sectional view of the ultrasonic diagnostic device assembly illustrated in FIG. 15.

- an ultrasonic imaging device (40)may include an intake part (450) through which outside air is introduced into the interior, and an exhaust part (460) through which the air introduced into the interior is discharged to the exterior.

- the intake part (450)may be disposed on one side of the main body (41), and the exhaust part (460) may be disposed on the other side of the main body (41).

- the intake part (450)may be disposed on the fourth side (414) of the main body case (410), and the exhaust part (460) may be disposed on the second side (412) of the main body case (410) opposite the fourth side (414) of the main body case (410).

- the present disclosureis not limited thereto, and the intake part (450) and the exhaust part (460) may be disposed on other than the mutually opposing sides of the main body (41).

- the intake path part (1610)may be arranged to be spaced apart from the intake part (450) by a predetermined distance.

- the intake path part (1610)may be arranged in the second buffer part (1200) facing the intake part (450) and may be arranged to be spaced apart from the intake part (450) by a predetermined distance along the second direction (Y direction).

- the space formed between the intake part (450) and the intake path part (1610)may form a path through which external air may be introduced.

- the intake path part (1610)may include a plurality of intake paths (1611) extending along one direction as a path guide through which external air may be introduced. At this time, each of the plurality of intake paths (1611) can be arranged to correspond to each of the plurality of intake holes (451) provided in the intake part (450).

- the exhaust path part (1620)may be arranged to be spaced apart from the exhaust part (460) by a predetermined distance.

- the exhaust path part (1620)may be arranged on the first buffer part (1100) facing the exhaust part (460) and may be arranged to be spaced apart from the exhaust part (460) by a predetermined distance along the second direction (Y direction).

- the space formed between the exhaust part (460) and the exhaust path part (1620)may form a path through which external air may be introduced.

- the exhaust path part (1620)may include a plurality of first exhaust holes (1621) as a path guide through which external air may be introduced. At this time, each of the plurality of first exhaust holes (1621) may be arranged to correspond to each of the plurality of second exhaust holes (461) provided in the exhaust part (460).

- Fig. 18ais a cross-sectional view of the buffer device taken along the line B-B shown in Fig. 4.

- Fig. 18bis a cross-sectional view of the buffer device taken along the line C-C shown in Fig. 4.

- a first buffer portion (1100)can protect an outer circumference of a side surface of a main body (41) and an outer circumference of a side surface of a handle portion (42).

- the side buffer portion (1110)can protect at least one side surface of the outer circumference of the main body (41).

- the side buffer portion (1110)is arranged on the outer circumference of the side surface of the main body (41) to protect the side surface of the main body (41) from an external impact applied along a direction of one plane (XY plane).

- the handle buffer portion (1130)can protect at least one side surface of the outer circumference of the handle portion (42).

- the handle buffer portion (1130)is arranged on the outer circumference of the side surface of the handle portion (42) to protect the side surface of the handle portion (42) from an external impact applied along a direction of one plane (XY plane).

- the first buffer part (1100)may include an elastic material. Accordingly, the first buffer part (1100) may absorb an impact applied from the outside and an impact applied to the main body (41) and the handle part (42). However, the amount of impact applied to the main body (41) and the handle part (42) may increase depending on the shape and weight of the main body (41) and the handle part (42). In order to protect the main body (41) and the handle part (42) from the increased amount of impact, a reinforcing member (1400) may be additionally placed on the first buffer part (1100).

- a reinforcing member (1400)may be positioned to be inserted into the center of the first buffer portion (1100). At this time, the reinforcing member (1400) may include a different material from the first buffer portion (1100). As an example, when the first buffer portion (1100) includes an elastic material, the reinforcing member (1400) may include a material having a different elastic coefficient from the elastic material. For example, the first buffer portion (1100) may include a rigid material such as a metal material or a plastic material.

- a reinforcing member (1400)may include a first reinforcing member (1410) and a third reinforcing member (1430) arranged at the center of the first side buffer portion (1111) and the third side buffer portion (1113), as illustrated in FIG. 18A.

- the reinforcing member (1400)may include the first reinforcing member (1410) and the third reinforcing member (1430) arranged to be surrounded by the first side buffer portion (1111) and the third side buffer portion (1113), respectively.

- first reinforcing member (1410) and the third reinforcing member (1430)may be arranged to extend in one direction, for example, in the second direction (Y direction), like the first side buffer portion (1111) and the third side buffer portion (1113).

- the reinforcing member (1400)may include a second reinforcing member (1420) and a fourth reinforcing member (1440) arranged at the center of the second side buffer portion (1112) and the handle buffer portion (1130), as illustrated in FIG. 18b.

- the reinforcing member (1400)may include the second reinforcing member (1420) and the fourth reinforcing member (1440) arranged to be surrounded by the second side buffer portion (1112) and the handle buffer portion (1130), respectively.

- the second reinforcing member (1420) and the fourth reinforcing member (1440)may be arranged to extend in one direction, for example, along the first direction (X direction), like the second side buffer portion (1112) and the handle buffer portion (1130).

- first reinforcing member (1410) and the second reinforcing member (1420) included in the reinforcing member (1400)may be provided in an integral shape in which they are interconnected, the second reinforcing member (1420) and the third reinforcing member (1430) are interconnected, the third reinforcing member (1430) and the fourth reinforcing member (1440) are interconnected, and the fourth reinforcing member (1440) and the first reinforcing member (1410) are interconnected.

- the present disclosureis not limited thereto, and the first reinforcing member (1410) to the second reinforcing member (1420) may be formed individually and arranged to be interconnected.

- Fig. 19is a perspective projection view of a buffer device according to an example.

- the first buffer part (1100) and the second buffer part (1200)can protect the main body (41) and the handle part (42) from external impact.

- the amount of impact applied to the main body (41) and the handle part (42)can increase.

- a plurality of impact-absorbing parts (1600)can be additionally arranged in the first buffer part (1100) and the second buffer part (1200).

- a plurality of shock absorbers (1600)may be arranged inside at least one of the first buffer unit (1100) and the second buffer unit (1200).

- the plurality of shock absorbers (1600)may have at least one of a polygonal or circular cross-section. Since the plurality of shock absorbers (1600) have at least one of a polygonal or circular cross-section, an impact applied from the outside may be prevented from being applied to the main body (41) or the handle unit (42) by the structural rigidity of the shape having the polygonal or circular cross-section.

- the plurality of shock absorbers (1600)may include the same or different material as the first buffer unit (1100) and the second buffer unit (1200).

- the plurality of shock absorbers (1600)may include a material having an elastic coefficient that is the same or different from that of the elastic material of the first buffer unit (1100) and the second buffer unit (1200).

- the plurality of shock absorbers (1600)may be formed integrally with the first buffer unit (1100) and the second buffer unit (1200).

- the present disclosureis not limited thereto, and a plurality of shock absorbing parts (1600) may be formed separately and combined inside the first buffer part (1100) and the second buffer part (1200).

- FIG. 20is a side view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device disposed on a buffer device according to an example.

- FIG. 21is a side view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device disposed on a buffer device according to an example.

- FIG. 22is a partial cross-sectional view of an ultrasonic diagnostic device assembly having an ultrasonic imaging device disposed on a buffer device according to an example.

- an ultrasonic imaging device (40)may include one or more connectors (470) to which a probe (20) may be connected.

- one or more connectors (470)may be arranged on one side of a main body (41).

- one or more connectors (470)may be arranged on one side of a main body case (410).

- the present disclosureis not limited thereto, and one or more connectors (470) may be arranged in any area of the main body case (410).

- a connector hole (1710)may be arranged at a position corresponding to one or more of the connectors (470) described above.

- the connector hole (1710)may be provided in an opening shape through which one or more of the connectors (470) may be exposed to the outside.

- the connector hole (1710)may be arranged on a first side buffer portion (1111) corresponding to the first side (411). Since one or more of the connectors (470) may be exposed to the outside, a foreign substance arranged on the outside may be inserted into one or more of the connectors (470).

- a connector hole opening/closing part (1720)can open/close a connector hole (1710) to prevent foreign substances placed externally from being inserted into one or more connectors (470).

- the connector hole opening/closing part (1720)can be a dustproof member and a waterproof member that prevent foreign substances placed externally from being inserted into one or more connectors (470).

- the connector hole opening/closing part (1720)may include a shape corresponding to the connector hole (1710).

- the connector hole opening/closing part (1720)may be coupled to the first buffer part (1100) so as to be able to open/close the connector hole (1710).

- the connector hole opening/closing part (1720)may be arranged to be rotatable about one axis on the first buffer part (1100). Accordingly, when the probe (20) is coupled to the connector (470), the connector hole opening/closing part (1720) may open the connector hole (1710) as illustrated in FIG. 21. In addition, when the probe (20) is not coupled to the connector (470), the connector hole opening/closing part (1720) may be rotated about one axis to shield the connector hole (1710).

- FIG. 23is a side view of an ultrasonic diagnostic device assembly with a probe coupled thereto according to an example.

- FIG. 24is a side view of an ultrasonic diagnostic device assembly with a probe separated therefrom according to an example.

- an ultrasonic imaging device (40)may include one or more connectors (470) to which a probe (20) may be connected.

- the probe (20)may include a recessed portion (220) arranged in a region other than the connector (210).

- the recessed portion (220) provided in the probe (20)may be arranged in a state spaced apart from the ultrasonic imaging device (40).

- an impact applied from the outsidemay be transmitted to the connector (210) provided in the probe (20).

- a shock-absorbing step (1730)may be provided in a shape corresponding to a groove (220) provided in a probe (20) to support the groove (220).

- the shock-absorbing step (1730)may be arranged at one end of a connector hole (1710).

- the shock-absorbing step (1730)may be provided integrally with the first buffer (1100) and may include an elastic material.

- the shock-absorbing step (1730)may be provided separately and arranged to be coupled to one end of the connector hole (1710).

- the shock-absorbing step (1730)can prevent shock from being applied from the outside to the connector (210) provided in the probe (20).

- Fig. 25is a perspective view of a buffer device according to an example.

- Fig. 26is a partial cross-sectional view of an ultrasonic diagnostic device assembly according to an example.

- the main body (41)may include a groove portion (480) having a predetermined groove shape.

- the groove portion (480) provided in the main body (41)may be a joint or a joining portion between different configurations.

- the present disclosureis not limited thereto, and the groove portion (480) may include any opening shape through which a foreign substance placed externally may be in fluid communication with a component placed internally of the main body case (410) provided in the ultrasonic imaging device (40).

- a waterproofing part (1800)may include a shape corresponding to a groove (480) provided in a main body (41).

- the waterproofing part (1800)may include a protrusion shape corresponding to the groove (480).

- a waterproofing part (1800)may be arranged in at least one of a first buffering part (1100) or a second buffering part (1200).

- the waterproofing part (1800)may be arranged on an inner surface of at least one of the first buffering part (1100) or the second buffering part (1200).

- the waterproofing part (1800)may be arranged to extend along a periphery of at least one of the first buffering part (1100) or the second buffering part (1200).

- the waterproofing part (1800)may be formed integrally with at least one of the first buffering part (1100) or the second buffering part (1200).

- the waterproofing part (1800)may include the same material as at least one of the first buffering part (1100) or the second buffering part (1200), for example, an elastic material.

- the present disclosureis not limited thereto, and the waterproofing part (1800) may be provided separately and coupled to at least one of the first buffering part (1100) or the second buffering part (1200).

- the waterproofing part (1800)may include a different material from at least one of the first buffering part (1100) or the second buffering part (1200).

- the waterproof part (1800)may be positioned to be inserted into the groove part (480) to block foreign substances from entering from the outside.

- the waterproof part (1800)includes an elastic material

- the waterproof part (1800) provided in the shape of a protrusionmay be positioned to be inserted into the groove part (480) in a fitting manner to block foreign substances from entering from the outside.

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Health & Medical Sciences (AREA)

- Biomedical Technology (AREA)

- Biophysics (AREA)

- Nuclear Medicine, Radiotherapy & Molecular Imaging (AREA)

- Pathology (AREA)

- Radiology & Medical Imaging (AREA)

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Heart & Thoracic Surgery (AREA)

- Medical Informatics (AREA)

- Molecular Biology (AREA)

- Surgery (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Ultra Sonic Daignosis Equipment (AREA)

Abstract

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR20230097063 | 2023-07-25 | ||

| KR10-2023-0097063 | 2023-07-25 | ||

| KR10-2023-0151948 | 2023-11-06 | ||

| KR1020230151948AKR20250015713A (ko) | 2023-07-25 | 2023-11-06 | 완충 장치 및 이를 포함하는 초음파 진단 장치 조립체 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2025023398A1true WO2025023398A1 (fr) | 2025-01-30 |

Family

ID=94375525

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/KR2023/020642PendingWO2025023398A1 (fr) | 2023-07-25 | 2023-12-14 | Dispositif tampon et ensemble dispositif de diagnostic ultrasonore le comprenant |

Country Status (1)

| Country | Link |

|---|---|

| WO (1) | WO2025023398A1 (fr) |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060274493A1 (en)* | 2001-11-19 | 2006-12-07 | Richardson Curtis R | Protective enclosure for electronic device |

| JP2015198804A (ja)* | 2014-04-09 | 2015-11-12 | コニカミノルタ株式会社 | 携帯型超音波画像診断装置の連結機構 |

| JP2015205005A (ja)* | 2014-04-21 | 2015-11-19 | 日立アロカメディカル株式会社 | 可搬型超音波撮像装置 |

| JP2016214723A (ja)* | 2015-05-25 | 2016-12-22 | 株式会社日立製作所 | 超音波診断装置 |

| US20190200958A1 (en)* | 2017-12-28 | 2019-07-04 | Konica Minolta, Inc. | Cradle apparatus |

- 2023

- 2023-12-14WOPCT/KR2023/020642patent/WO2025023398A1/fractivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060274493A1 (en)* | 2001-11-19 | 2006-12-07 | Richardson Curtis R | Protective enclosure for electronic device |

| JP2015198804A (ja)* | 2014-04-09 | 2015-11-12 | コニカミノルタ株式会社 | 携帯型超音波画像診断装置の連結機構 |

| JP2015205005A (ja)* | 2014-04-21 | 2015-11-19 | 日立アロカメディカル株式会社 | 可搬型超音波撮像装置 |

| JP2016214723A (ja)* | 2015-05-25 | 2016-12-22 | 株式会社日立製作所 | 超音波診断装置 |

| US20190200958A1 (en)* | 2017-12-28 | 2019-07-04 | Konica Minolta, Inc. | Cradle apparatus |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2018056572A1 (fr) | Sonde a ultrasons, appareil d'imagerie a ultrasons, système d'imagerie par ultrasons et son procédé de commande | |

| WO2018092993A1 (fr) | Dispositif de diagnostic ultrasonore et son procédé de fonctionnement | |

| WO2019039693A1 (fr) | Appareil de diagnostic à ultrasons et son procédé de fonctionnement | |

| WO2015141913A1 (fr) | Appareil de diagnostic par ultrasons et son procédé de fonctionnement | |

| EP3217871A1 (fr) | Appareil d'imagerie par résonance magnétique et procédé de traitement d'image par résonance magnétique | |

| WO2019039697A1 (fr) | Appareil de diagnostic à ultrasons et son procédé de fonctionnement | |

| WO2019066541A1 (fr) | Dispositif d'entrée, dispositif électronique, système comprenant ce dernier et procédé de commande correspondant | |

| WO2015072808A1 (fr) | Appareil d'imagerie par ultrasons et son procédé de commande | |

| WO2025023398A1 (fr) | Dispositif tampon et ensemble dispositif de diagnostic ultrasonore le comprenant | |

| WO2017095010A1 (fr) | Dispositif d'imagerie par ultrasons et procédé permettant de gérer la puissance du dispositif d'imagerie par ultrasons | |

| EP3179911A1 (fr) | Procédé et appareil de vérification de séquence d'impulsion d'appareil d'imagerie par résonance magnétique | |

| WO2016093453A1 (fr) | Appareil de diagnostic à ultrasons et son procédé de fonctionnement | |

| WO2017104998A1 (fr) | Appareil à ultrasons, procédé de commande de celui-ci et système de télémédecine | |

| WO2020184830A1 (fr) | Sonde ultrasonore et son procédé de fabrication | |

| WO2017082625A1 (fr) | Dispositif de sonde et son procédé de commande | |

| WO2021177562A1 (fr) | Appareil de diagnostic ultrasonore et son procédé de fonctionnement | |