WO2024254281A2 - Compositions of conjugated and unconjugated proteins - Google Patents

Compositions of conjugated and unconjugated proteinsDownload PDFInfo

- Publication number

- WO2024254281A2 WO2024254281A2PCT/US2024/032770US2024032770WWO2024254281A2WO 2024254281 A2WO2024254281 A2WO 2024254281A2US 2024032770 WUS2024032770 WUS 2024032770WWO 2024254281 A2WO2024254281 A2WO 2024254281A2

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- protein

- molar amount

- conjugated

- unconjugated

- formulation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Classifications

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K47/00—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient

- A61K47/50—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates

- A61K47/51—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the non-active ingredient being a modifying agent

- A61K47/68—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the non-active ingredient being a modifying agent the modifying agent being an antibody, an immunoglobulin or a fragment thereof, e.g. an Fc-fragment

- A61K47/6801—Drug-antibody or immunoglobulin conjugates defined by the pharmacologically or therapeutically active agent

- A61K47/6803—Drugs conjugated to an antibody or immunoglobulin, e.g. cisplatin-antibody conjugates

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K47/00—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient

- A61K47/50—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates

- A61K47/51—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the non-active ingredient being a modifying agent

- A61K47/68—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the non-active ingredient being a modifying agent the modifying agent being an antibody, an immunoglobulin or a fragment thereof, e.g. an Fc-fragment

- A61K47/6835—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the non-active ingredient being a modifying agent the modifying agent being an antibody, an immunoglobulin or a fragment thereof, e.g. an Fc-fragment the modifying agent being an antibody or an immunoglobulin bearing at least one antigen-binding site

- A61K47/6849—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the non-active ingredient being a modifying agent the modifying agent being an antibody, an immunoglobulin or a fragment thereof, e.g. an Fc-fragment the modifying agent being an antibody or an immunoglobulin bearing at least one antigen-binding site the antibody targeting a receptor, a cell surface antigen or a cell surface determinant

Definitions

- the present inventionrelates to a composition comprising a mixture of unconjugated and conjugated proteins (e.g., antibodies and conjugates thereof) and methods of using and manufacturing said composition.

- BACKGROUND[0004] Diabetic retinopathy is a leading cause of blindness in people between the ages of about 20 to 64 years of age. Engelgau M, Geiss L, Saaddine J, Boyle J, et al. 2004. The Evolving Diabetes Burden in the United States. Ann of Int Med. 140 (11): 945-951. In the United States, diabetic retinopathy accounts for some 12% of new cases of blindness.

- diabetic retinopathytypically, in cases of diabetic retinopathy, retinal blood vessels will swell and leak fluid into the rear of the eye. Hyperglycemia induces intramural and thickening of the basement membrane, resulting in leaky or permeable blood vessels.

- changes in blood glucose levelcause changes to retinal blood vessels. All people with diabetes mellitus are at risk. The longer a person has diabetes, the higher their risk of developing some ocular problem. Between 40 to 45 percent of Americans diagnosed with diabetes have some stage of diabetic retinopathy. Causes and Risk Factors. Diabetic Retinopathy.

- Diabetic retinopathyis first exhibited in the development of microaneurysms in the retina. Microaneurysms occur when there is a swelling of capillaries (very small blood vessels) that feed the retina. The presence of relatively small numbers of microaneurysms will not usually cause problems with vision. However, if the retinopathy develops to later stages, there are significant chances of vision loss. Such early-stage retinopathy are referred to as background diabetic retinopathy or non-proliferative diabetic retinopathy (NPDR). While NPDR patients are generally asymptomatic, early detection of retinopathy is crucial because if the disease proceeds to later stages, significant vision loss is very likely.

- NPDRnon-proliferative diabetic retinopathy

- neovascularizationoccurs in the back of the eye (proliferative diabetic retinopathy).

- the neovasculatureis leaky and the vessels can burst, followed by bleeding and resulting in blurred or obscured vision. Due to lack of oxygen in the eye, still further neovascularization occurs.

- Blood vesselsgrow along the retina and in the vitreous humor. As these vessels burst, there is further bleeding and the retina can be badly damaged or destroyed.

- the accumulation of fluid in the macula due to leaking blood vesselsis called diabetic macular edema. Many patients with diabetic retinopathy will develop diabetic macular edema.

- VEGF-directed therapiesare effective not just for diabetic retinopathy, but also for retinal vascular diseases such as Age-Related Macular Degeneration (AMD), neovascular (wet) AMD and Retinal Vein Occlusion (RVO).

- AMDAge-Related Macular Degeneration

- RVORetinal Vein Occlusion

- proteinsshould be formulated in clear solutions. Such formulations can have a defined buffer system and some excipients added for further enhancement of protein stability. Proteins can be conjugated to other moieties to bring an enhanced property or set of properties to the protein. For example, the conjugation of the protein to a potent toxin to create an antibody drug conjugate that targets the toxin to particular receptor-containing cell type for enhanced potency or enhanced safety.

- the present disclosureis not limited to diabetic retinopathy, and can be applied to various indications as will be appreciated by those in the art.

- a formulationcomprising: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; a second molar amount of a second protein that is not conjugated to a phosphorylcholine- containing polymer; and a pharmaceutically acceptable carrier, wherein the formulation comprises the second protein at about 1% or more of a total molar amount of the conjugate and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount, wherein the formulation has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein.

- pIisoelectric point

- compositionscomprising: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; a second molar amount of a second protein that is not conjugated to a phosphorylcholine-containing polymer; and a therapeutically acceptable carrier, wherein the composition comprises the second protein at about 1% or more of a total molar amount of the conjugate and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount, wherein the composition has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein.

- pIisoelectric point

- a therapeutically acceptable compositioncomprising: a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; a second protein that is not conjugated to a phosphorylcholine-containing polymer; and a pharmaceutically acceptable carrier, wherein the percent composition of the second protein relative to the total protein mass weight concentration of the first protein and the second protein in the composition is about 1% or more, wherein the composition has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein.

- pIisoelectric point

- a formulationcomprising: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine- containing polymer; a second molar amount of a second protein that is not conjugated to a phosphorylcholine-containing polymer; and a pharmaceutically acceptable carrier, wherein the formulation comprises the second protein at about 1% or more of a total molar amount of the conjugate and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount, wherein the formulation has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein, wherein the formulation has a reduced viscosity and/or an enhanced injectability compared to a reference formulation comprising the conjugate at the total molar amount.

- pIisoelectric point

- a therapeutically acceptable compositioncomprising: a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; a second protein that is not conjugated to a phosphorylcholine-containing polymer; and a pharmaceutically acceptable carrier, wherein the percent composition of the second protein is about 1% or more, with the remainder comprising the first protein, wherein the composition has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein, wherein the composition has a reduced viscosity and/or an enhanced injectability compared to a reference composition comprising the conjugate, wherein the first protein of the conjugate is present in the reference composition at the total mass weight concentration of the first and second proteins in the composition.

- pIisoelectric point

- a low-viscosity formulation of a protein conjugatecomprising: a first molar amount of a conjugate comprising a protein conjugated to a phosphorylcholine-containing polymer; a second molar amount of the protein that is not conjugated to the phosphorylcholine-containing polymer; and a pharmaceutically acceptable carrier, wherein the formulation has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the protein, wherein the formulation has reduced viscosity and/or an enhanced injectability compared to a reference formulation comprising the conjugate at a total molar amount that is the sum of the first and second molar amounts.

- pIisoelectric point

- a low-viscosity therapeutically acceptable composition of a protein conjugatecomprising a first molar amount of a conjugate comprising a protein conjugated to a phosphorylcholine- containing polymer; a second molar amount of the protein that is not conjugated to the phosphorylcholine-containing polymer; and a pharmaceutically acceptable carrier, wherein the composition has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the protein, wherein the composition has reduced viscosity and/or an enhanced injectability compared to a reference composition comprising the conjugate at a total molar amount that is the sum of the first and second molar amounts.

- pIisoelectric point

- a formulationcomprising: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; a second molar amount of a second protein that is not conjugated to a phosphorylcholine- containing polymer; and a pharmaceutically acceptable carrier, wherein the second protein is present in the formulation at about 1% or more of a total molar amount of the conjugate and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount, wherein the formulation has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein, wherein the formulation has a reduced turbidity compared to a reference formulation comprising the first molar amount (e.g., the same first molar amount) of the conjugate and the second molar amount (e.g., the same second molar amount) of the second protein at a pH within 0.5

- the formulationcomprises: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; a second molar amount of a second protein that is not conjugated to a phosphorylcholine- containing polymer; and a pharmaceutically acceptable carrier, wherein the second protein is present in the formulation at about 1% or more of a total molar amount of the conjugate and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount, wherein the formulation has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein, wherein the formulation has a reduced turbidity compared to a reference formulation comprising the same first molar amount of the conjugate and the same second molar amount of the second protein at a pH about the same as (e.g., within 0.05, 0.1, 0.15, 0.2, 0.2, 0.3, 0.4, or

- a therapeutically acceptable compositioncomprising: a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; a second protein that is not conjugated to a phosphorylcholine-containing polymer; and a pharmaceutically acceptable carrier, wherein the percent composition of the second protein is about 1% or more, with the remainder comprising the first protein, wherein the composition has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein, wherein the composition has a reduced turbidity compared to a reference composition comprising the second protein at the percent composition (e.g., the same percent composition), with the remainder comprising the first protein, at a pH within 0.5 pH units of the pI of the second protein.

- a pharmaceutically acceptable carrierwherein the percent composition of the second protein is about 1% or more, with the remainder comprising the first protein, wherein the composition has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein

- the therapeutically acceptable compositioncomprises: a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; a second protein that is not conjugated to a phosphorylcholine-containing polymer; and a pharmaceutically acceptable carrier, wherein the percent composition of the second protein is about 1% or more, with the remainder comprising the first protein, wherein the composition has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein, wherein the composition has a reduced turbidity compared to a reference composition comprising the second protein at the same percent composition, with the remainder comprising the first protein, at a pH about the same as (e.g., within 0.05, 0.1, 0.15, 0.2, 0.3, 0.4, or 0.5 pH units of) the pI of the second protein.

- a pharmaceutical formulationcomprising: a first molar amount of a conjugate comprising a protein conjugated to a phosphorylcholine-containing polymer; a second molar amount the protein that is not conjugated to the phosphorylcholine-containing polymer; and a pharmaceutically acceptable carrier, wherein the formulation comprises the protein that is not conjugated to the phosphorylcholine-containing polymer at about 1% or more of a total molar amount of the conjugate and unconjugated proteins, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount, wherein the formulation has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the protein, wherein the formulation is substantially free of turbidity.

- pIisoelectric point

- a formulationcomprising: a phosphorylcholine-containing polymer present in the formulation at 100 mg/mL or higher; and a protein that is not conjugated to a phosphorylcholine-containing polymer, wherein the protein is present in the formulation at a second molar amount, wherein the protein is present in the formulation at about 1% or more of a total molar amount of the polymer and the protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount, wherein the formulation has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the protein.

- pIisoelectric point

- a formulationcomprising: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; a second molar amount of a second protein that is not conjugated to a phosphorylcholine- containing polymer; and a pharmaceutically acceptable carrier, wherein the difference between the pI of the second protein and the pH of the formulation in the acidic or basic direction is selected to be greater than the minimum difference in the corresponding acidic or basic direction between the pI of the second protein and the pH for a reference formulation comprising: a third molar amount of the conjugate comprising the first protein conjugated to the phosphorylcholine-containing polymer; a fourth molar amount of the second protein that is not conjugated to the phosphorylcholine-containing polymer; and the pharmaceutically acceptable carrier, wherein a first total molar amount comprising a sum of the first molar amount and the second molar amount, and a second total molar amount

- a therapeutically acceptable compositioncomprising: a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; a second protein that is not conjugated to a phosphorylcholine-containing polymer; and a pharmaceutically acceptable carrier, wherein the difference between the pI of the second protein and the pH of the formulation is selected to be greater than the minimum difference between the pI of the second protein and the pH for a reference formulation comprising: the conjugate comprising the first protein conjugated to the phosphorylcholine-containing polymer; the second protein that is not conjugated to the phosphorylcholine-containing polymer; and the pharmaceutically acceptable carrier, wherein the percent composition of the second protein in the composition is higher than the percent composition of the second protein in the reference composition, wherein the reference composition is substantially free of turbidity.

- a formulationcomprising: a first molar amount of a conjugate comprising a first protein conjugated to a polymer; and a second molar amount of a second protein that is not conjugated to a polymer, wherein the formulation comprises the second protein at about 1% or more of a total molar amount of the first protein and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount.

- a therapeutically acceptable compositioncomprising: a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; a second protein that is not conjugated to a phosphorylcholine-containing polymer; and a pharmaceutically acceptable carrier, wherein the percent composition of the second protein is about 1% or more, with the remainder comprising the first protein.

- compositioncomprising: a first molar amount of a conjugate comprising a first protein conjugated to a polymer; and a second molar amount of a second protein that is not conjugated to a polymer, wherein the composition comprises the second protein at about 1% or more of a total molar amount of the first protein and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount.

- a formulationcomprising: a first molar amount of a first protein that is conjugated to a polymer; and a second molar amount of a second protein that is not conjugated to a polymer, the further improvement comprising: the formulation comprises the second protein at about 1% or more of a total molar amount of the conjugate and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount.

- a therapeutically acceptable compositioncomprising: a first protein that is conjugated to a polymer; and a second protein that is not conjugated to a polymer, the further improvement comprising: the percent composition of the second protein is about 1% or more, with the remainder comprising the first protein.

- a formulationcomprising: a conjugate comprising a first protein conjugated to a polymer; and a second protein that is not conjugated to a polymer, wherein a first molar amount of the conjugate and a second molar amount of the second protein has been combined in the formulation such that the second molar amount is about 1% or more of a total molar amount of the conjugate and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount.

- a therapeutically acceptable compositioncomprising: a conjugate comprising a first protein conjugated to a polymer; and a second protein that is not conjugated to a polymer, wherein a first molar amount of the conjugate and a second molar amount of the second protein has been combined in the composition such that the second molar amount is about 1% or more of a total molar amount of the conjugate and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount.

- a therapeutically acceptable compositioncomprising: a conjugate comprising a first protein conjugated to a polymer; and a second protein that is not conjugated to a polymer, wherein the second protein at a percent composition relative to the total protein mass weight concentration of the first protein and the second protein in the composition of about 1% or more (e.g., about 5-90%, 15-25%, 25-35%, etc.) has been combined with the conjugate, wherein the remainder of the total protein mass weight concentration comprises the first protein.

- a formulationcomprising: a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer, wherein the polymer has 9 arms and a molecular weight of between 600,000 and 1,000,000 Da, wherein the polymer is present in the formulation at about 100 mg/mL or more; and a second protein that is not conjugated to a polymer, wherein the second protein is present in the formulation at 5-15 mg/mL.

- an intraocular therapeutic compositioncomprising an anti-VEGF-A antibody at about 50 mg/mL of protein, the anti-VEGF-A antibody comprising: a heavy chain comprising a complementarity determining region 1 (CDR H 1): GYDFTHYGMN (SEQ ID NO: 9), CDR H 2: WINTYTGEPTYAADFKR (SEQ ID NO: 10), and CDR H 3: YPYYYGTSHWYFDV (SEQ ID NO: 11); and a light chain comprising CDRL1: SASQDISNYLN (SEQ ID NO: 12), CDRL2: FTSSLHS (SEQ ID NO: 13), and CDRL3: QQYSTVPWT (SEQ ID NO: 14), wherein the anti-VEGF-A antibody is present in the composition as either an antibody conjugate or unconjugated antibody, wherein the unconjugated antibody is present in the formulation at between about 10% to about 30% of a total molar amount of the antibody conjugate and the unconjugate

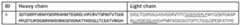

- an intraocular therapeutic compositioncomprising an anti- VEGF-A antibody at about 50 mg/mL of protein, the anti-VEGF-A antibody comprising: a heavy chain comprising an amino acid sequence of SEQ ID NO: 1 (with or without the C- terminal lysine); and a light chain comprising an amino acid sequence of SEQ ID NO: 2, wherein the anti-VEGF-A antibody is present in the composition as either an antibody conjugate or unconjugated antibody, wherein the unconjugated antibody is present in the formulation at between about 10% to about 30% of a total molar amount of the antibody conjugate and the unconjugated antibody, wherein the total molar amount is the sum of the molar amount of the antibody conjugate and the molar amount of the unconjugated antibody, wherein the antibody conjugate comprises the following structure: wherein: each heavy chain of the conjugate is denoted by the letter H, and each light chain of the conjugate is denoted by the letter L; the polymer is bonded

- an intraocular therapeutic compositioncomprising a fusion construct at about 53 mg/mL of protein, the fusion construct comprising a VEGF trap fused to an anti-IL-6 antibody, wherein the fusion construct comprises: a heavy chain comprising an amino acid sequence of SEQ ID NO:105 (with or without the C-terminal lysine); and a light chain comprising an amino acid sequence of SEQ ID NO:106, wherein the fusion construct is present in the composition as either a conjugate or an unconjugated fusion construct, wherein the unconjugated fusion construct is present in the formulation at between about 20% to about 40% of a total molar amount of the conjugate and the unconjugated fusion construct, wherein the total molar amount is the sum of the molar amount of the conjugate and the molar amount of the unconjugated fusion construct, wherein the conjugate comprises the fusion construct conjugated to a phosphorylcholine-containing polymer, wherein the phosphorylcholine

- an intraocular therapeutic compositioncomprising a fusion construct at about 50 mg/mL of protein, the fusion construct comprising a VEGF trap fused to an anti-IL-6 antibody, wherein the fusion construct comprises: a heavy chain comprising a complementarity determining region 1 (CDRH1): PFAMH (SEQ ID NO: 134), CDRH2: KISPGGSWTYYSDTVTD (SEQ ID NO: 135), and CDRH3: QAWGYYALDI (SEQ ID NO: 136); and a light chain comprising CDRL1: SASISVSYLY (SEQ ID NO: 137), CDRL2: DDSSLAS (SEQ ID NO: 138), and CDR L 3: QQWSGYPYT (SEQ ID NO: 139), wherein the fusion construct is present in the composition as either a conjugate or an unconjugated fusion construct, wherein the unconjugated fusion construct is present in the formulation at between about 20% to

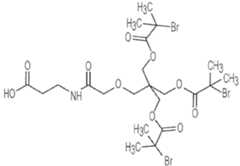

- the sum of n1, n2, n3, n4, n5, n6, n7, n8 and n9is about 1500 to about 3500 plus or minus about 10% to about 20%.

- an intraocular therapeutic compositioncomprising a fusion construct at about 50 mg/mL of protein, the fusion construct comprising a VEGF trap fused to an anti-IL-6 antibody, wherein the fusion construct comprises: a heavy chain comprising a complementarity determining region 1 (CDRH1): PFAMH (SEQ ID NO: 134), CDRH2: KISPGGSWTYYSDTVTD (SEQ ID NO: 135), and CDRH3: QAWGYYALDI (SEQ ID NO: 136); and a light chain comprising CDRL1: SASISVSYLY (SEQ ID NO: 137), CDRL2: DDSSLAS (SEQ ID NO: 138), and CDRL3: QQWSGYPYT (SEQ ID NO: 139), wherein

- each heavy chain of the conjugateis denoted by the letter H, and each light chain of the conjugate is denoted by the letter L; the polymer is bonded to the heavy chain of the conjugate through the sulfhydryl of C443 (EU numbering), which bond is depicted on one of the heavy chains;

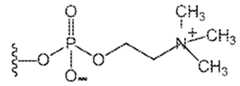

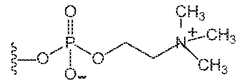

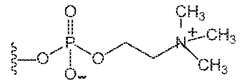

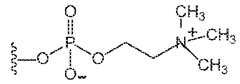

- PCis , where the curvy line indicates the point of attachment to the rest of the polymer, where X is a) –OR where R is –H, methyl, ethyl, propyl, isopropyl, b) –H, c) any halogen, including –Br, –Cl, or –I, d) –SCN, or e) –NCS; and n1, n2, n3, n4, n5, n6, n7, n8 and n9 are the same or different such that the sum of n1, n2, n3, n4, n5, n6, n7, n8 and

- a method of preparing a formulationcomprising combining in a formulation: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; and a second molar amount of a second protein that is not conjugated to a phosphorylcholine-containing polymer, wherein the formulation comprises the second protein at about 1% or more of a total molar amount of the conjugate and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount, wherein the formulation has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein.

- pIisoelectric point

- Also provided is a method of preparing a therapeutically acceptable compositioncomprising combining in a therapeutically acceptable composition: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; and a second molar amount of a second protein that is not conjugated to a phosphorylcholine-containing polymer, wherein the composition comprises the second protein at about 1% or more of a total molar amount of the conjugate and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount, wherein the composition has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein.

- a first molar amount of a conjugatecomprising a first protein conjugated to a phosphorylcholine-containing polymer

- a second molar amount of a second proteinthat is not conjugated to a phosphorylcholine-containing polymer

- a method of preparing a therapeutically acceptable compositioncomprising combining in a therapeutically acceptable composition: a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; and a second protein that is not conjugated to a phosphorylcholine-containing polymer, wherein the percent composition of the second protein is about 1% or more, with the remainder comprising the first protein, wherein the composition has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein.

- pIisoelectric point

- Also provided is a method of preparing a formulationcomprising adjusting the pH of a formulation to be about 0.5 pH units away or more from the isoelectric point (pI) of an unconjugated protein comprised in the formulation, wherein the formulation comprises: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; and a second molar amount of the unconjugated protein, wherein the unconjugated protein is not conjugated to a phosphorylcholine-containing polymer, wherein the formulation comprises the unconjugated protein at about 1% or more of a total molar amount of the conjugate and the unconjugated protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount.

- the formulationcomprises: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; and a second molar amount of the un

- a method of preparing a therapeutically acceptable compositioncomprising adjusting the pH of a composition to be about 0.5 pH units away or more from the isoelectric point (pI) of an unconjugated protein comprised in the composition, wherein the composition comprises: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; and a second molar amount of the unconjugated protein, wherein the unconjugated protein is not conjugated to a phosphorylcholine-containing polymer, wherein the composition comprises the unconjugated protein at about 0.1% or more of a total molar amount of the conjugate and the unconjugated protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount.

- Also provided is a method of preparing a therapeutically acceptable compositioncomprising adjusting the pH of a therapeutically acceptable composition to be about 0.5 pH units away or more from the isoelectric point (pI) of an unconjugated protein comprised in the composition, wherein the composition comprises: a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; and a second protein that is not conjugated to a phosphorylcholine-containing polymer, wherein the percent composition of the second protein is about 1% or more, with the remainder comprising the first protein.

- pIisoelectric point

- a method of preparing a low-viscosity formulation of a protein conjugated to a phosphorylcholine-containing polymercomprising combining in a formulation: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; and a second molar amount of the protein that is not conjugated to a phosphorylcholine-containing polymer, wherein the formulation comprises the protein that is not conjugated to the phosphorylcholine-containing polymer at about 1% or more of a total molar amount of the conjugate unconjugated proteins, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount, wherein the formulation has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein, wherein the formulation has reduced viscosity and/or an enhanced injectability compared to a reference formulation comprising the conjugate at the total

- Also provided is a method of preparing a formulationcomprising combining in a formulation: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; and a second molar amount of a second protein that is not conjugated to a phosphorylcholine-containing polymer, wherein the formulation comprises the second protein at about 1% or more of a total molar amount of the conjugate and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount.

- a method of preparing a therapeutically acceptable compositioncomprising combining in a therapeutically acceptable composition: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; and a second molar amount of a second protein that is not conjugated to a phosphorylcholine-containing polymer, wherein the composition comprises the second protein at about 1% or more of a total molar amount of the conjugate and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount.

- a method of preparing a therapeutically acceptable compositioncomprising combining in a therapeutically acceptable composition: a conjugate comprising a first protein conjugated to a phosphorylcholine- containing polymer; and a second protein that is not conjugated to a phosphorylcholine- containing polymer, wherein the percent composition of the second protein is about 1% or more, with the remainder comprising the first protein.

- a formulation or compositionmade by any one of the methods described herein.

- a method of treating a subjectcomprising: intraocularly administering a therapeutically effective amount of any one of the formulation or composition described herein to a subject in need thereof.

- a method of treating a subjectcomprising: intraocularly administering a therapeutically effective amount of a low-viscosity formulation to a subject in need thereof, wherein the formulation comprises: a first concentration of a conjugate comprising a first anti-VEGF antibody conjugated to a phosphorylcholine-containing polymer; a second concentration of an anti-VEGF agent that is not conjugated to a phosphorylcholine-containing polymer; and a pharmaceutically acceptable carrier, wherein the formulation has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the anti-VEGF agent.

- pIisoelectric point

- kitscomprising: a pre-filled syringe comprising a low- viscosity formulation comprising: a conjugate comprising a first protein conjugated to a phosphorylcholine-containing polymer; and a second protein that is not conjugated to a phosphorylcholine-containing polymer; and a syringe needle for injection of the low-viscosity formulation, wherein the gauge of the needle is 27 or higher.

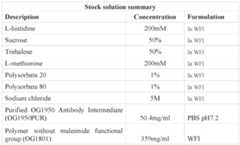

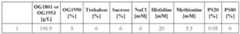

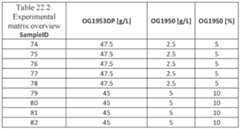

- a formulationcomprising about 40 to about 60 mM sodium acetate, about 0.01% to about 0.04% polysorbate 20, about 40 to about 60 mg/mL (total protein concentration) of a mixture of OG1950 and OG1953, the mixture containing about 15% to about 25% OG1950 and about 75% to about 85% OG1953 by molar amount, at pH about 4.5 to about 5.5.

- a formulationcomprising, consisting of, or consisting essentially of, about 50 mM sodium acetate, about 0.025% polysorbate 20, about 50 mg/mL (total protein concentration) of a mixture of OG1950 and OG1953, the mixture containing about 20% OG1950 and about 80% OG1953 by molar amount, at about pH 5.

- a method of storing a proteincomprising maintaining a protein in a formulation for at least 2 months and up to 2 years, the formulation comprising: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine- containing polymer; a second molar amount of a second protein that is not conjugated to a phosphorylcholine-containing polymer; and a pharmaceutically acceptable carrier, wherein the formulation comprises the second protein at about 1% or more of a total molar amount of the conjugate and the second protein, wherein the total molar amount comprises a sum of the first molar amount and the second molar amount, wherein the formulation has a pH that is about 0.5 pH units away or more from the isoelectric point (pI) of the second protein, wherein the protein comprises an antibody or a fusion construct.

- the formulationcomprising: a first molar amount of a conjugate comprising a first protein conjugated to a phosphorylcholine- containing polymer;

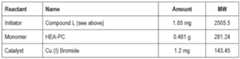

- FIG. 1shows Compound L.

- FIG. 2shows Compound K.

- FIG. 3shows the synthesis of OG1802 from R3707.

- FIG. 4shows OG1786.

- FIG. 5shows the synthesis of OG1546 from OG1550.

- FIG. 6shows the synthesis of OG1784 from OG1546 and OG1563.

- FIG. 7shows the synthesis of OG1405 from OG1784.

- FIG. 8shows the synthesis of OG 1785 from OG1405.

- FIG. 9shows the synthesis of OG1786 from OG1785. [0039] FIG.

- FIG. 10shows OG1802.

- FIG. 11shows Compound E.

- FIG. 12depicts some embodiments of anti-VEGF-A heavy chain with certain effector function mutations and L443C (EU numbering, which is position 449 in SEQ ID NO.1).

- FIG. 13depicts some embodiments of an anti-VEGF-A light chain (SEQ ID NO.2).

- FIG.14depicts some embodiments of a bevacizumab heavy chain (SEQ ID NO.3).

- FIG. 15depicts some embodiments of a bevacizumab light chain (SEQ ID NO.4).

- FIG.16depicts some embodiments of a ranibizumab heavy chain (SEQ ID NO.5).

- FIG. 17depicts some embodiments of a ranibizumab light chain (SEQ ID NO.6).

- FIG. 18depicts some embodiments of a method for preparing an antibody conjugate.

- FIG. 19depicts Ion Exchanger analysis (A280 absorbance) of reactions A through G.

- FIG. 20depicts the effect of various anti-VEGF molecules on binding of biotin-VEGF to plate bound VEGFR ECD-Fc protein, and their IC50 values.

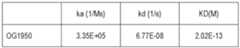

- FIG. 21depicts the OG1950 binding affinity to VEGF measured by BIAcore single cycle kinetics.

- FIG.22depicts binding of the OG1950 to Fc gamma receptor I.

- FIG. 23depicts binding of the OG1950 to Fc gamma receptor IIIa.

- FIG.24depicts binding of QG 1950 to human complement protein C1q.

- FIG.25depicts the results of a proliferation assay (including IC50 values).

- FIG.26depicts the results of single cycle kinetics of VEGF binding to anti- VEGF agents.

- FIG. 27depicts some embodiments of nucleic acid sequences encoding heavy and light chain variable regions.

- FIG.28is a collection of images and a table depicting results of mixing the free antibody with either polymer or OG1953 composition.

- FIG.29is a collection of images showing visual appearance of 30 different formulation conditions in two design of experiment (DOE) screenings.

- FIG. 30is a graph depicting turbidity measurements of formulations antibody with OG1801 polymer (samples #1-#30) in the presence of different excipients.

- FIG.31is a plot produced using JMP SAS software depicting the turbidity changes over time for one embodiment of a DOE experiment with the OG1950 antibody mixed with OG1801 polymer in the presence of different excipients.

- FIG. 32is an image and a table showing the effect of Histidine and pH on turbidity of the formulation.

- FIG. 30is a graph depicting turbidity measurements of formulations antibody with OG1801 polymer (samples #1-#30) in the presence of different excipients.

- FIG.31is a plot produced using JMP SAS software depicting the turbidity changes over time for one embodiment of a DOE experiment with the OG1950 antibody mixed with

- FIG. 33is an image showing some embodiments of formulations at differing pHs and corresponding turbidity results.

- FIG.34is a graph showing some embodiments of formulations at differing pHs and corresponding turbidity results.

- FIG.35Ais a collection of images showing the appearances of four different preparations at 50mg/ml of conjugated antibody supplemented with unconjugated antibody at different pH setpoints. From left to right: A, preparation at pH 6.5 results in a cloudy mixture; B-D, preparations at 5.0 - 5.2 result in a clear solution irrespective of the formulation buffer and percent unconjugated antibody. The mixtures are first prepared by concentrating the purified conjugated antibody to approx.

- FIG. 35B and 35Care a collection of chromatograms and tables showing cation exchanger chromatography (CEX) analysis and analytical size exclusion chromatography (SEC) analysis of several embodiments of formulations of OG1950/OG1953.

- FIG.36is a table showing the turbidity result for an embodiment of mixing the OG2072 fusion protein with its conjugated form OG2074.

- FIGS.37A and 37Bare a collection of a table, images, and a graph showing the screening result of mixing various proteins other than OG1950 antibody with a fixed concentration of OG1801 polymer. This is a control in order to evaluate if the turbidity is a more general phenomenon related to the presence of polymer.

- FIGs.38A and 38Bare a collection of images and a plot showing the effect of pH adjustment on the turbidity of formulations. The result demonstrated that the turbidity is reversible or reproducible dependent on the pI of the protein.

- FIG.39is a table showing the sample setup for formulations with different percentages of free protein relative to conjugated protein.

- FIG.40Ais a collection of images showing the appearance of formulations having different percentages of free protein relative to conjugated protein.

- FIG. 40Bis a collection of traces showing analysis of different partitions during the tandem method analysis of a formulation.

- FIG. 40Cis a collection of plots showing analysis of different partitions during the tandem method analysis of a formulation.

- FIG.40Dis a table showing peak area comparison of CEX bound (free protein) to unbound fraction (conjugate).

- FIG.40Eis a collection of traces showing analysis of different partitions during the tandem method analysis of a formulation.

- FIG. 40Fis a collection of plots showing analysis of different partitions during the tandem method analysis of a formulation.

- FIG. 40Gis a table showing peak area comparison of CEX bound (free protein) to unbound fraction (conjugate).

- FIG. 41is a table showing the sample setup for a long-term stability plan for various formulations of OG1953 conjugate containing free proteins from 7.5-20% with a total combined protein concentrations of 50-65mg/ml.

- FIGs. 42 and 43are a collection of tables and plots showing the results of ELISA assays measuring the potency of various formulations of OG1953 conjugate containing free proteins from 7.5-20% with a total combined protein concentrations of 50-65mg/ml after storage.

- FIG.44is a collection of a table and a graph showing protein concentration of formulations measured by SoloVPE OD280nm method.

- FIG. 45is a data table showing a summary of the results of the stability testing of formulations.

- Figs. 46Ais a collection of SEC-HPLC traces of formulation #4 (20% OG1950, 80% OG1953, 50 mM Na-acetate, 0.025% Tween 20, pH 5.0) after 6 months at the temperatures highlighted.

- FIG. 46Bprovides a table and graphs showing size exclusion chromatography analysis of formulations for the aggregation and degradation level of the OG1953 conjugate.

- FIG. 47Ashows a schematic diagram showing an overview of the Tandem HPLC method, which combines the CEX-HPLC in tandem with a SEC-HPLC column.

- FIG. 47Bis a collection of traces, a table, and graphs showing tandem method analysis of the OG1950 free protein and its aggregated forms (P1 and P2).

- FIGs. 47C and 47Dare a collection of traces and a table showing tandem method analysis of formulations.

- Figs. 48A-48Care a collection of a table, image and graph showing the design matrix and visual result of the formulations.

- Figs.49A and 49Bare a collection of plots showing analysis of the turbidity results against the concentration of polymer, free protein and pH.

- Figs. 49C and 49Dare a collection of plots and schematic representations showing turbidity of formulations at various pH for the different levels of OG1801 polymer and free protein.

- Fig. 49Eis a plot showing turbidity measurements results against the concentration of polymer, free protein and pH.

- Figs.49F-49Iare a collection of plots showing an overlay of the pH boundary curve plot with other OG1801 polymer with free protein only experimental data.

- Figs.49J-49Mare a collection of plots showing an overlay of the pH boundary curve plot with other OG1953 conjugate solution and free protein only experimental data.

- Fig. 49Nis a plot showing analysis of turbidity measurements in OG1801 polymer solution with free protein against the concentration of polymer, free protein and pH.

- Fig. 49Ois a plot showing analysis of turbidity measurements in OG1953 conjugate solution with free protein against the concentration of polymer, free protein and pH.

- Fig. 50Ais a collection of graphs and schematic diagram showing formulation viscosity at 25oC.

- Figs.50B and 50Care a collection of graphs and a table showing impact of increasing free protein percent composition on viscosity of formulations at 25oC.

- Fig. 50Dis a collection of plots and tables showing the viscosity of formulations with various concentrations of OG1801 polymer.

- Fig. 51is a collection of images showing air movement in syringes filled with different formulations.

- Figs. 52A-52Care a collection of plots and tables showing potency comparison of various OG1953 formulations using ELISA or cell-based assay.

- Figs. 50B and 50Care a collection of graphs and a table showing impact of increasing free protein percent composition on viscosity of formulations at 25oC.

- Fig. 50Dis a collection of plots and tables showing the viscosity of formulations with various concentrations of OG1801 polymer.

- Fig. 51is a collection of images showing air movement in syringes filled with different

- FIG. 53A-53Dare a collection of graphs, charts, and tables showing improved vision in wet AMD patients administered with OG1953, aflibercept, or other anti- VEGF agents.

- FIG. 54is a collection of sequences showing some non-limiting embodiments of a light chain and heavy chain of a fusion construct.

- FIG.55A and 55Bare a collection of sequences showing some non-limiting embodiments of a heavy chain and light chain, respectively, of a fusion construct.

- FIGs. 56A-56Care a collection of plots showing the level of impurities (e.g., aggregation and/or degradation level) in OG1953 conjugate formulations over time. [0100] FIGs.

- FIGS. 59A-59Ddepict continuous 80min tandem method separation with PhotoDiol Array (PDA) detection set at 200-350nm.

- FIG. 59Adepicts the 2D contour view of elution time versus wavelength;

- FIG.59Bdepicts the extracted wavelength profile at 280nm and the peak identification of the various eluted fractions collected for further characterization using SDS-PAGE analysis followed by Silver Staining, and results were shown in FIG.

- PDAPhotoDiol Array

- FIGS.60A-60Cdepict KSI-301 stability data up to 9 months under different temperature conditions; -20 ⁇ 5°C (FIG.60A), 5 ⁇ 3°C (FIG.60B), and 25 ⁇ 2°C/ 60 ⁇ 5% RH (relative humidity) (FIG.60C).

- FIG.61depicts KSI-501DS Batches 1-3 Lot Release Data.

- FIG. 62depicts an injection force comparison of (Panel A) OG1953 (100%) conjugate versus the KSI-301 mix formulation using a 27G or 29G dosing needle; (Panel B) OG2074 (100%) conjugate versus the KSI-501_batch 2 mix formulation using a 27G or 29G dosing needle.

- FIG.63depicts a viscosity comparison at ambient temperature of (Panel A) OG1953 (100%) conjugate versus the KSI-301 mix formulation; (Panel B) OG2074 (100%) conjugate versus various batches of the KSI-501 mix formulation.

- formulations and compositionscomprising a mixture of an unconjugated protein (e.g., an unconjugated anti-VEGF-A antibody) and conjugates thereof.

- the conjugatescan include a protein (which may or may not be the same as the unconjugated protein) conjugated to a phosphorylcholine-containing polymer.

- the pH of the formulationcan be different from the isoelectric point (pI) of the unconjugated protein in the formulation such that the formulation is not or is less turbid.

- the formulationhas reduced viscosity compared to a reference formulation of the conjugated protein (without the unconjugated protein).

- the reduced viscositycan improve injectability of the formulation (e.g. by a syringe) and/or handling of the formulation during manufacture.

- the compositioncan be used for the treatment of certain conditions, such as eye disorders, including retinal vascular disorders.

- the formulations, compositions, and methods of the present disclosurecan be provided for treating any disease or disorder as described herein, and is not necessarily limited to diabetic retinopathy or diabetic macular edema.

- a drug composition(a formulation) which is a mixture of a protein and a conjugate of that protein and which is a stable solution.

- lowering the end concentration of biopolymer while keeping the amount of the antibody bioactive the samecan result in (i) a decrease in solution viscosity which has many advantages for pharmaceutical manufacturing of drug substance and drug product, and (ii) better handling of the drug for dose preparation and handling in the physician office, and (iii) easier injectability into the patient for example in retina, where a needle is inserted into the vitreous of the eye and the syringe plunger is pushed with a maximum force of the hand, including shorter injection time, reduced force required to drive the plunger down to express out the drug, and a narrower needle such as 30G or 29G, a higher dose level with smaller volume.

- a mixture of unconjugated and conjugated proteincan benefit from the direct activity of the protein and a modified activity of the protein as modified by conjugation to a polymer.

- an immediacy of effect of the unconjugated protein at a defined ratiofor example, 20% of the administered antibody

- a modified durability of effect of the conjugated protein at a defined ratiofor example, the remaining 80% of the antibody is in a conjugated form

- the formulationis a clear solution containing the free (unconjugated) antibody, the antibody conjugated to the phosphorylcholine polymer, the buffer system and at a particular pH, where the formulation is stable and suitable for drug development, manufacturing and/or storage.

- an anti-VEGF antibody (OG1950) conjugated to a phosphorylcholine containing biopolymer (OG1802) which conjugate is called OG1953can be formulated at 50 mg/mL by weight of antibody and formulated in sodium phosphate pH 6.5 that is clear and stable, and adding a desired amount of the free unconjugated anti-VEGF antibody (OG1950) to create a solution of 40 mg/mL of conjugate (OG1953) and 10 mg/mL of OG1950 without adjusting the formulation system as provided herein can result in turbidity.

- formulations and methods provided hereincan provide a clear solution of the unconjugated and conjugated antibody coformulation.

- a clear and stable ‘formulation system’ of a protein with a phosphorylcholine-biopolymer-conjugated version of that proteinin which the protein can be soluble and clear and stable and avoids turbidity formation.

- a method to reduce the turbidityin some embodiments, can be applied to OG1953 to create OG195380% + OG195020% at a pH 5.0, thereby preventing turbidity that forms at a pH of 7.5, which is at or close to the pI of the protein.

- the solubility switchinvolves the application of pH to control this switch.

- this solubility switchis applied to OG2074 to create OG207470% + OG207230% at pH 5.0, for ophthalmology (intravitreal) injection or for systemic diseases.

- the concentration of the dose formulation, for OG1953is for example 50 mg/mL (as measured by the antibody portion)

- the bioconjugatehas durability due to the conjugated biopolymer, but to improve manufacturability the same amount of protein bioactive (5.0 mg in 100 microliter dose, i.e.50 mg/mL in the formulation by weight of antibody) is kept while increasing the relative amount of unconjugated protein.

- OG1953is 80% and OG1950 is 20%; or OG1953 is 75% and OG1950 is 25%; or OG1953 is 70% and OG1950 is 30%; or OG1953 is 65% and OG1950 is 35%; or OG1953 is 60% and OG1950 is 40%; or OG1953 is 50% and OG1950 is 50%.

- the pHis at 5.0 (without the addition of histidine or sucrose or trehalose) by shifting the pH to 5.0 and adjusting the formulation buffering constituents to acetate from phosphate.

- a high dose formulation with improved manufacturabilityis achieved because of decreased viscosity for drug substance and drug product (vials, prefilled syringes); improved usability and dose administration (because of decreased viscosity); improved clinical immediacy (so improved balance of clinical immediacy of the for example 20% mAb while retaining clinical durability of the for example 80% mAb-conjugate).

- the compositioncan be tuned to achieve an optimal viscosity to enable large scale manufacturing (of drug substance, of drug product, of pre-filled syringes) and to enable safer dose handling and preparation (for example by physicians and patients) and to enable safer dose administration for example injectability requiring lower injection force by the doctor.

- the injection forceis less than 10 Newtons, or less than 5 Newtons

- injection timeis 10 seconds or less, or 5 seconds or less

- the injection needlehas a bore size of between 30 gauge and 27 gauge, including 28 gauge or 29 gauge.

- the compositioncan be tuned to achieve an optimal balance of durability of clinical effect (a basal activity) and immediacy of clinical effect (a bolus activity).

- the therapeuticsare formulated into a clear solution with long-term stability.

- a “neovascular disorder”is a disorder or disease state characterized by altered, dysregulated or unregulated angiogenesis.

- neovascular disordersinclude neoplastic transformation (e.g., cancer) and ocular neovascular disorders including diabetic retinopathy and age-related macular degeneration.

- An “ocular neovascular” disorderis a disorder characterized by altered, dysregulated or unregulated angiogenesis in the eye of a patient.

- Such disordersinclude optic disc neovascularization, iris neovascularization, retinal neovascularization, choroidal neovascularization, corneal neovascularization, vitreal neovascularization, glaucoma, pannus, pterygium, macular edema, diabetic retinopathy, diabetic macular edema, vascular retinopathy, retinal degeneration, uveitis, inflammatory diseases of the retina, and proliferative vitreoretinopathy.

- the term “percent composition”refers to the percent amount (in mass or concentration units) of a component present in a composition.

- Percent compositionis calculated by determining the amount of a component in mass units (e.g., ⁇ g) or in concentration units (e.g., mg/mL), dividing that amount by the total amount of all components in the composition in the corresponding unit, and multiplying by 100.

- the amount of the unconjugated proteincan be divided by the total amount of the protein component in the solution (excluding the contribution from the polymer component of the conjugate to the mass of the conjugate) to obtain a percent composition.

- % total molar amountdenotes the proportion (in percent) of the amount (in moles or a molar concentration) of one component of a composition relative to the amount(s) (in moles or a molar concentration) of one or more other component of the composition, that together make up the whole (100%). It is understood that percent composition and % total molar amount can be converted between each other where the molecular weight of all of the relevant components is known.

- the term antibodyincludes intact antibodies and binding fragments thereof. A binding fragment refers to a molecule other than an intact antibody that comprises a portion of an intact antibody that binds the antigen to which the intact antibody binds.

- binding fragmentsinclude Fv, Fab', Fab'-SH, F(ab')2; diabodies; linear antibodies; single-chain antibody molecules (e.g., scFv); and multispecific antibodies formed from antibody fragments.

- scFv antibodiesare described in Houston JS. 1991. Methods in Enzymol. 203:46-96.

- antibody fragmentscomprise single chain polypeptides having the characteristics of a VH domain, namely being able to assemble together with a VL domain, or of a VL domain, namely being able to assemble together with a VH domain to a functional antigen binding site and thereby providing the antigen binding property of full-length antibodies.

- Specific binding of an antibody to its target antigen(s)means an affinity of at least 10 6 , 10 7 , 10 8 , 10 9 , or 10 10 M -1 . Specific binding is detectably higher in magnitude and distinguishable from non-specific binding occurring to at least one unrelated target. Specific binding can be the result of formation of bonds between particular functional groups or particular spatial fit (e.g., lock and key type) whereas nonspecific binding is usually the result of van der Waals forces. Specific binding does not however necessarily imply that an antibody or fusion protein binds one and only one target.

- a basic antibody structural unitis a tetramer of subunits.

- Each tetramerincludes two identical pairs of polypeptide chains, each pair having one "light” (about 25 kDa) and one "heavy” chain (about 50-70 kDa).

- the amino-terminal portion of each chainincludes a variable region of about 100 to 110 or more amino acids primarily responsible for antigen recognition. This variable region is initially expressed linked to a cleavable signal peptide.

- the variable region without the signal peptideis sometimes referred to as a mature variable region.

- a light chain mature variable regionmeans a light chain variable region without the light chain signal peptide.

- variable regiondoes not mean that a signal sequence is necessarily present; and in fact signal sequences are cleaved once the antibodies or fusion proteins have been expressed and secreted.

- a pair of heavy and light chain variable regionsdefines a binding region of an antibody. The carboxy-terminal portion of the light and heavy chains respectively defines light and heavy chain constant regions. The heavy chain constant region is primarily responsible for effector function. In IgG antibodies, the heavy chain constant region is divided into CH1, hinge, CH2, and CH3 regions. The CH1 region binds to the light chain constant region by disulfide and noncovalent bonding.

- the hinge regionprovides flexibility between the binding and effector regions of an antibody and also provides sites for intermolecular disulfide bonding between the two heavy chain constant regions in a tetramer subunit.

- the CH2 and CH3 regionsare the primary site of effector functions and FcR binding.

- Light chainsare classified as either kappa or lambda.

- Heavy chainsare classified as gamma, mu, alpha, delta, or epsilon, and define the antibody's isotype as IgG, IgM, IgA, IgD and IgE, respectively.

- variable and constant regionsare joined by a "J" segment of about 12 or more amino acids, with the heavy chain also including a "D” segment of about 10 or more amino acids.

- JThe mature variable regions of each light/heavy chain pair form the antibody binding site.

- an intact antibodyhas two binding sites, i.e., is divalent. In natural antibodies, the binding sites are the same. However, bispecific antibodies can be made in which the two binding sites are different (see, e.g., Songsivilai S, Lachmann PC. 1990.

- variable regionsall exhibit the same general structure of relatively conserved framework regions (FR) joined by three hypervariable regions, also called complementarity determining regions or CDRs.

- FRrelatively conserved framework regions

- CDRscomplementarity determining regions

- variable heavy CDRscan be referred to as CDRH1, CDRH2 and CDRH3; the variable light chain CDRs can be referred to as CDR L 1, CDR L 2 and CDR L 3.

- the assignment of amino acids to each domainis in accordance with the definitions of Kabat EA, et al. 1987 and 1991. Sequences of Proteins of Immunological Interest (National Institutes of Health, Bethesda, MD) or Chothia C, Lesk AM. 1987. Canonical Structures for the Hypervariable Regions of Immunoglobulins. J Mol Biol 196:901-917; Chothia C, et al. 1989. Conformations of Immunoglobulin Hypervariable Regions. Nature 342:877-883.

- Kabatalso provides a widely used numbering convention (Kabat numbering) in which corresponding residues between different heavy chain variable regions or between different light chain variable regions are assigned the same number. Although Kabat numbering can be used for antibody constant regions, EU numbering is more commonly used, as is the case in this application. Although specific sequences are provided for exemplary antibodies disclosed herein, it will be appreciated that after expression of protein chains one to several amino acids at the amino or carboxy terminus of the light and/or heavy chain, particularly a heavy chain C-terminal lysine residue, may be missing or derivatized in a proportion or all of the molecules. [0124] The term "epitope” refers to a site on an antigen to which an antibody or extracellular trap segment binds.

- An epitope on a proteincan be formed from contiguous amino acids or noncontiguous amino acids juxtaposed by tertiary folding of one or more proteins.

- Epitopes formed from contiguous amino acidsalso known as linear epitopes

- epitopes formed by tertiary foldingalso known as conformational epitopes

- An epitopetypically includes at least 3, and more usually, at least 5 or 8-10 amino acids in a unique spatial conformation. Methods of determining spatial conformation of epitopes include, for example, x-ray crystallography and 2-dimensional nuclear magnetic resonance.

- Antibodies that recognize the same or overlapping epitopescan be identified in a simple immunoassay showing the ability of one antibody to compete with the binding of another antibody to a target antigen.

- the epitope of an antibodycan also be defined by X-ray crystallography of the antibody (or Fab fragment) bound to its antigen to identify contact residues.

- two antibodieshave the same epitope if all amino acid mutations in the antigen that reduce or eliminate binding of one antibody reduce or eliminate binding of the other.

- Two antibodieshave overlapping epitopes if some amino acid mutations that reduce or eliminate binding of one antibody reduce or eliminate binding of the other.

- Competition between antibodiesis determined by an assay in which an antibody under test inhibits specific binding of a reference antibody to a common antigen (see, e.g., Junghans et al., Cancer Res. 50: 1495, 1990).

- a test antibodycompetes with a reference antibody if an excess of a test antibody (e.g., at least 2x, 5x, 10x, 20x or l00x) inhibits binding of the reference antibody by at least 50%.

- the test antibodyinhibits binding of the reference antibody by 75%, 90%, or 99% as measured in a competitive binding assay.

- Antibodies identified by competition assayinclude antibodies binding to the same epitope as the reference antibody and antibodies binding to an adjacent epitope sufficiently proximal to the epitope bound by the reference antibody for steric hindrance to occur.

- the term “conjugate”refers to a protein covalently linked to a polymer. In some embodiments, the protein is an antibody.

- conjugated and freewith reference to a protein or antibody are used interchangeably to denote the protein or antibody that is not conjugated to a polymer (e.g., not conjugated to a phosphorylcholine-containing polymer).

- VEGF Trapor similar term denotes the VEGF binding domains (e.g., VEGFR1 domain 2, VEGFR2 domain 3). This fragment allows for the protein to work as a VEGF trap, preventing VEGF from binding to cellularly expressed VEGF receptors. An example of this sequence can be found in Table 0.5. In some embodiments, the VEGF Trap only includes VEGFR1 domain 2, VEGFR2 domain 3.

- VEGF Trap proteinsare known in the art and can be found, for example in U.S. Pub. No. 20150376271, the entirety of which, with respect to various VEGF Trap embodiments (which are VEGFR proteins or fragments thereof) and fusions thereof, is incorporated herein by reference.

- the term “VEGF Trap” or similar termrefers to a full length extracellular region or any portion thereof, or combination of portions from different VEGF receptors that can antagonize signaling between at least one VEGF and VEGFR.

- the term "patient”includes human and other mammalian subjects that receive either prophylactic or therapeutic treatment. In some embodiments, the patient is a human patient.

- amino acidsare grouped as follows: Group I (hydrophobic side chains): met, ala, val, leu, ile; Group II (neutral hydrophilic side chains): cys, ser, thr; Group III (acidic side chains): asp, glu; Group IV (basic side chains): asn, gin, his, lys, arg; Group V (residues influencing chain orientation): gly, pro; and Group VI (aromatic side chains): trp, tyr, phe. Conservative substitutions involve substitutions between amino acids in the same class.

- Percentage sequence identitiesare determined with antibody sequences maximally aligned by the Kabat numbering convention for a variable region or EU numbering for a constant region. After alignment, if a subject antibody region (e.g., the entire mature variable region of a heavy or light chain) is being compared with the same region of a reference antibody, the percentage sequence identity between the subject and reference antibody regions is the number of positions occupied by the same amino acid in both the subject and reference antibody region divided by the total number of aligned positions of the two regions, with gaps not counted, multiplied by 100 to convert to percentage.

- Sequence identities of other sequencescan be determined by aligning sequences using algorithms, such as BESTFIT, FASTA, and TFASTA in the Wisconsin Genetics Software Package Release 7.0, Genetics Computer Group, 575 Science Dr., Madison, WI, using default gap parameters, or by inspection, and the best alignment (i.e., resulting in the highest percentage of sequence similarity over a comparison window). Percentage of sequence identity is calculated by comparing two optimally aligned sequences over a window of comparison, determining the number of positions at which the identical residues occurs in both sequences to yield the number of matched positions, dividing the number of matched positions by the total number of positions in the window of comparison (i.e., the window size), and multiplying the result by 100 to yield the percentage of sequence identity.

- algorithmssuch as BESTFIT, FASTA, and TFASTA in the Wisconsin Genetics Software Package Release 7.0, Genetics Computer Group, 575 Science Dr., Madison, WI, using default gap parameters, or by inspection, and the best alignment (i.e., resulting in

- compositions or methods "comprising" one or more recited elementsmay include other elements not specifically recited.

- a composition that comprises an antibodymay contain the antibody alone or in combination with other ingredients, such as an antibody conjugate.

- Compositionscan comprise a conjugated antibody and an unconjugated antibody.

- the term "antibody-dependent cellular cytotoxicity", or ADCCis a mechanism for inducing cell death that depends upon the interaction of antibody-coated target cells (i.e., cells with bound antibody) with immune cells possessing lytic activity (also referred to as effector cells). Such effector cells include natural killer cells, monocytes/macrophages and neutrophils.

- ADCCis triggered by interactions between the Fc region of an antibody bound to a cell and Fcy receptors, particularly Fc ⁇ RI and Fc ⁇ RIII, on immune effector cells such as neutrophils, macrophages and natural killer cells.

- Fcy receptorsparticularly Fc ⁇ RI and Fc ⁇ RIII

- the target cellis eliminated by phagocytosis or lysis, depending on the type of mediating effector cell. Death of the antibody-coated target cell occurs as a result of effector cell activity.

- opsonizationalso known as "antibody-dependent cellular phagocytosis", or ADCP, refers to the process by which antibody-coated cells are internalized, either in whole or in part, by phagocytic immune cells (e.g., macrophages, neutrophils and dendritic cells) that bind to an immunoglobulin Fc region.

- phagocytic immune cellse.g., macrophages, neutrophils and dendritic cells

- CDCcomplement-dependent cytotoxicity refers to a mechanism for inducing cell death in which an Fc effector domain(s) of a target-bound antibody activates a series of enzymatic reactions culminating in the formation of holes in the target cell membrane.

- antigen-antibody complexessuch as those on antibody- coated target cells bind and activate complement component Clq which in turn activates the complement cascade leading to target cell death.

- Activation of complementmay also result in deposition of complement components on the target cell surface that facilitate ADCC by binding complement receptors (e.g., CR3) on leukocytes.

- complement receptorse.g., CR3

- a humanized antibodyis a genetically engineered antibody in which the CDRs from a non-human "donor” antibody are grafted into human "acceptor” antibody sequences (see, e.g., Queen, US 5,530,101 and 5,585,089; Winter, US 5,225,539, Carter, US 6,407,213, Adair, US 5,859,205 6,881,557, Foote, US 6,881,557).

- the acceptor antibody sequencescan be, for example, a mature human antibody sequence, a composite of such sequences, a consensus sequence of human antibody sequences, or a germline region sequence.

- a humanized antibodyis an antibody having some or all CDRs entirely or substantially from a donor antibody and variable region framework sequences and constant regions, if present, entirely or substantially from human antibody sequences.

- a humanized heavy chainhas at least one, two and usually all three CDRs entirely or substantially from a donor antibody heavy chain, and a heavy chain variable region framework sequence and heavy chain constant region, if present, substantially from human heavy chain variable region framework and constant region sequences.

- a humanized light chainhas at least one, two and usually all three CDRs entirely or substantially from a donor antibody light chain, and a light chain variable region framework sequence and light chain constant region, if present, substantially from human light chain variable region framework and constant region sequences.

- a humanized antibodycomprises a humanized heavy chain and a humanized light chain.

- a CDR in a humanized antibodyis substantially from a corresponding CDR in a non-human antibody when at least 85%, 90%, 95% or 100% of corresponding residues (as defined by Kabat) are identical between the respective CDRs.

- the variable region framework sequences of an antibody chain or the constant region of an antibody chainare substantially from a human variable region framework sequence or human constant region respectively when at least 85, 90, 95 or 100% of corresponding residues defined by Kabat are identical.

- humanized antibodiesoften incorporate all six CDRs (which can be as defined by Kabat) from a mouse antibody, they can also be made with less than all CDRs (e.g., at least 3, 4, or 5 CDRs from a mouse antibody) (e.g., De Pascalis R, Iwahashi M, Tamura M, et al. 2002. Grafting “Abbreviated” Complementary-Determining Regions Containing Specificity-Determining Residues Essential for Ligand Contact to Engineer a Less Immunogenic Humanized Monoclonal Antibody. J Immunol. 169:3076-3084; Vajdos FF, Adams CW, Breece TN, Presta LG, de Vos AM, Sidhu, SS.

- CDRswhich can be as defined by Kabat

- a chimeric antibodyis an antibody in which the mature variable regions of light and heavy chains of a non-human antibody (e.g., a mouse) are combined with human light and heavy chain constant regions. Such antibodies substantially or entirely retain the binding specificity of the mouse antibody and are about two-thirds human sequence.

- a veneered antibodyis a type of humanized antibody that retains some and usually all of the CDRs and some of the non-human variable region framework residues of a non-human antibody but replaces other variable region framework residues that may contribute to B- or T-cell epitopes, for example exposed residues (Padlan EA.1991. A possible procedure for reducing the immunogenicity of antibody variable domains while preserving their ligand- binding properties. Mol Immunol.

- a human antibodycan be isolated from a human, or otherwise result from expression of human immunoglobulin genes (e.g., in a transgenic mouse, in vitro or by phage display).

- Methods for producing human antibodiesinclude the trioma method of ⁇ stberg L, Pursch E.1983. Human x (mouse x human) hybridomas stably producing human antibodies. Hybridoma 2:361-367; ⁇ stberg, U.S. Patent No.

- Polymerrefers to a series of monomer groups linked together. A polymer is composed of multiple units of a single monomer (a homopolymer) or different monomers (a heteropolymer).

- High MW polymersare prepared from monomers that include, but are not limited to, acrylates, methacrylates, acrylamides, methacrylamides, styrenes, vinylpyridine, vinylpyrrolidone and vinyl esters such as vinyl acetate. Additional monomers are useful in high MW polymers . When two different monomers are used, the two monomers are called “comonomers,” meaning that the different monomers are copolymerized to form a single polymer.

- one monomeris a phosphorylcholine-containing monomer

- a second comonomeris a different comonomer with a different pendant group chemistry (for example a click chemistry to be a reactive group / recipient of a chemical reaction to be conjugated, for example, to a small molecule bioactive or to a chemical linker).

- the polymercan be linear or branched. When the polymer is branched, each polymer chain is referred to as a “polymer arm.” The end of the polymer arm linked to the initiator moiety is the proximal end, and the growing-chain end of the polymer arm is the distal end.

- the polymer arm end groupcan be the radical scavenger, or another group.

- “Initiator”refers to a compound capable of initiating a polymerization using monomers or comonomers.

- the polymerizationcan be a conventional free radical polymerization or a controlled/”living” radical polymerization, such as Atom Transfer Radical Polymerization (ATRP), Reversible Addition-Fragmentation-Termination (RAFT) polymerization or nitroxide mediated polymerization (NMP).

- ATRPAtom Transfer Radical Polymerization

- RAFTReversible Addition-Fragmentation-Termination