WO2024115353A1 - Analytical composition for monitoring disinfection - Google Patents

Analytical composition for monitoring disinfectionDownload PDFInfo

- Publication number

- WO2024115353A1 WO2024115353A1PCT/EP2023/083109EP2023083109WWO2024115353A1WO 2024115353 A1WO2024115353 A1WO 2024115353A1EP 2023083109 WEP2023083109 WEP 2023083109WWO 2024115353 A1WO2024115353 A1WO 2024115353A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- lipid

- nucleic acid

- mol

- test sample

- lipid nanoparticles

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Classifications

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12Q—MEASURING OR TESTING PROCESSES INVOLVING ENZYMES, NUCLEIC ACIDS OR MICROORGANISMS; COMPOSITIONS OR TEST PAPERS THEREFOR; PROCESSES OF PREPARING SUCH COMPOSITIONS; CONDITION-RESPONSIVE CONTROL IN MICROBIOLOGICAL OR ENZYMOLOGICAL PROCESSES

- C12Q1/00—Measuring or testing processes involving enzymes, nucleic acids or microorganisms; Compositions therefor; Processes of preparing such compositions

- C12Q1/68—Measuring or testing processes involving enzymes, nucleic acids or microorganisms; Compositions therefor; Processes of preparing such compositions involving nucleic acids

- C12Q1/6844—Nucleic acid amplification reactions

Definitions

- Analytical composition for monitoring disinfectionTechnical Field

- the present inventionrelates to analytical compositions and kits, their use for monitoring disinfection procedures, and a method for monitoring a disinfection procedure.

- the analytical compositioncomprises lipid nanoparticles encapsulating a nucleic acid.

- microbial surrogate markersare used for monitoring the transmission of microorganisms.

- examples of traditional surrogate markersare live non-pathogenic viruses, bacteriophages, such as bacteriophage MS2, or cauliflower mosaic virus DNA.

- SPEDsilica nanoparticles with encapsulated DNA

- the term “monitoring a disinfection procedure”relates to an evaluation whether a successful disinfection of a surface was achieved. “Monitoring a disinfection procedure” thus includes validation of a disinfection procedure.

- the termfurther includes “monitoring transmission pathways of microorganisms between surfaces”, i.e. providing information whether microorganisms (the LNPs encapsulating a nucleic acid as described herein being a surrogate for microorganisms) have been transferred from a first surface to a second surface or a third surface, etc.

- Nucleic acidrefers to a deoxyribonucleotide or ribonucleotide polymer, in linear or circular conformation, and in either single- or double-stranded form (ss or ds, respectively).

- the termscan encompass known analogs of natural nucleotides, as well as nucleotides that are modified in the base, sugar and/or phosphate moieties (e.g. phosphorothioate or phosphorodithioate backbones).

- NucleotideThe term “nucleotide” refers to deoxyribonucleotides or ribonucleotides.

- the nucleotidesmay be standard nucleotides (i.e., adenosine, guanosine, cytidine, thymidine, and uridine) or nucleotide analogs.

- a nucleotide analogrefers to a nucleotide having a modified purine or pyrimidine base or a modified ribose moiety.

- a nucleotide analogmay be a naturally occurring nucleotide (e.g. inosine) or a non-naturally occurring nucleotide.

- Non-naturally occurring nucleotidesinclude nucleotides that are modified at the 2’-O position of the sugar such as 2’-OMe, 2’-MOE, 2’-F modified nucleotides, as well as locked nucleic acids (LNAs), peptide nucleic acids (PNA), and morpholinos.

- LNAslocked nucleic acids

- PNApeptide nucleic acids

- morpholinosmorpholinos.

- the skilled personunderstands that this list of modified nucleotides is not exhaustive and is able to select suitable modified nucleo- tides based on the present disclosure.

- LipidThe term “lipid” is known in the field and advantageously relates to biomolecules that are soluble in non-polar solvents such as benzene, chloroform, acetone, etc.

- lipidincludes for example fatty acids, waxes, sterols (e.g. cholesterol), fat-soluble vitamins (such as vitamins A, D, E, and K), monoglycerides, diglycerides, triglycerides, and phospholipids.

- amphiphilic lipidse.g. ionisable lipids and phospholipids

- LNPlipid nanoparticle

- LNPsare typically spherical with an average diameter between 20 nm and 1500 nm, e.g. between 50 nm to 1500 nm, such as between 50 nm to 300 nm.

- components of the LNPsare typically selected from four types of lipids: an ionisable lipid (positive charge supports binding to negatively charged nucleic acid), a phospholipid (improves / stabilizes the structure of the LNPs), cholesterol (improves / stabilizes the structure of the LNPs), and a lipid anchored PEG (improves the stability of the LNP, e.g. by preventing aggregation).

- LNPs suitable for the present inventionare non-toxic.

- Dispersionis known in the field. In general, the term “dispersion” relates to a system in which distributed particles of one material are dispersed in a continuous phase of another material. In an aqueous dispersion, the continuous phase thus contains or consists of water.

- the term “dispersion”includes the terms “suspension” such as a “colloidal suspension”, “emulsion” and “solution”.

- a dispersion containing lipid nanoparticlesrelates to a suspension, usually a colloidal suspension.

- lipid nanoparticle dispersionstypically are aqueous suspensions, usually aqueous colloidal suspensions.

- Dispersed phaseThe term “dispersed phase” is known in the field. In general, the term “dispersed phase” relates to colloids of a substance dispersed in another substance. For example, the dispersed phase of a lipid nanoparticle dispersion comprises of the lipid nanoparticles.

- Continuous phaseThe term “continuous phase” is known in the field. In general, the term “continuous phase” relates to the fluid phase in a dispersion within which solid or fluid particles are distributed. For example, the continuous phase of a lipid nanoparticle dispersion is the aqueous liquid the lipid nanoparticles are dispersed in.

- Nnitrogen

- Pnegatively-charged nucleic acid phosphate

- Ppositively-chargeable polymer amine groups

- Ptypically present in ionisable lipids.

- PolyethylenglycolThe term “polyethylenglycol” (PEG; also referred to as polyethylene oxide) is known in the field and relates to a polymer, specifically a polyether, composed of ethylene oxide monomeric units.

- the structure of PEGis commonly expressed as H ⁇ (O ⁇ CH 2 ⁇ CH 2 ) n ⁇ OH, wherein n is the number of ethylene oxide monomeric units.

- a PEG polymeris defined by its molecular weight, e.g. PEG1000 refers to PEG having an average molecular weight of 1000 Da.

- PEG1000refers to PEG having an average molecular weight of 1000 Da.

- the molecular weight of PEG, such as PEG1000is an average molecular weight based on the polydispersity of PEG.

- Ionisable lipidThe term “ionisable lipid” is known in the field and relates to lipid molecules containing a chargeable group, typically an amine group, such as 306Oi10 [e.g. Hou et al., 2021, Nat Rev Mater 6, 1078–1094 and references therein].

- PhospholipidThe term “phospholipid” is known in the field and relates to amphiphilic lipid molecules containing a hydrophilic "head” containing a phosphate group and two hydrophobic "tails" derived from fatty acids, joined by an alcohol residue, typically a glycerol.

- the phosphate groupmay be further modified with organic molecules, typically serine (e.g. phosphatidylserine), choline (e.g.

- Lipid anchored PEGThe term “lipid anchored PEG” is known in the field and relates to a PEG polymer covalently linked to a lipid (also referred to as PEG-derivatized lipids, PEG-lipids or PEGylated lipids).

- Lipid-anchored PEGsare generally described in, for example, U.S. 5,672,662 (also see e.g. Hou et al., 2021, Nat. Rev. Mater. 6, 1078–1094 and references therein).

- a lipid anchored PEGis referred to in the following way: C x PEG y , wherein x is the number of carbon atoms in the fatty acid component of the lipid and y is the average molecular weight of the PEG component.

- xis the number of carbon atoms in the fatty acid component of the lipid

- yis the average molecular weight of the PEG component.

- the molecular weight of a lipid anchored PEG such as C14PEG1000is an average molecular weight based on the polydispersity of PEG.

- Lipid anchored PEGsgenerally increase the stability of LNPs, e.g. by preventing aggregation.

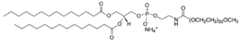

- C14PEG1000also referred to as 1,2-dimyristoyl-sn-glycero-3- phosphoethanolamine-N-[methoxy(polyethylene glycol)-1000] is shown below (ammonium salt):

- DisaccharideThe term “disaccharide” is known in the field and particularly describes carbohydrates composed of two monosaccharide units bound together by glycosidic linkages. It is understood that a disaccharide may comprise two identical monosaccharide units or may comprise two different monosaccharide units, which may also be chemically modified (e.g.

- polysaccharideis known in the field and particularly describes polymeric carbohydrates composed of monosaccharide units bound together by glycosidic linkages, either linear or branched. Such polysaccharides are characterized by their repeating units, each repeating unit described with their respective monosaccharide composition. Said repeating units include one or more monosaccharides which can also be chemically modified (e.g. amidated, sulphonated, acetylated, phos- phorylated, etc).

- Typical found monosaccharides in said repeating unitsare cyclic or linear monosaccharides containing three to seven carbon atoms.

- a number of abbreviationsare used, including: Delta Ct Difference between Ct values DLS Dynamic light scattering DNA Deoxyribonucleic acid DOPE 1,2-dioleoyl-sn-glycero-3-phosphoethanolamine ds double-stranded DSPC 1,2-distearoyl-sn-glycero-3-phosphocholin GC-MS gas chromatography mass spectrometry HPLC high performance liquid chromatography LNP lipid nanoparticle MALDI-TOF Matrix-assisted laser desorption ionisation- time-of- flight mass spectrometry MMLV Moloney Murine Leukemia Virus PEG polyethylenglycol RNA ribonucleic acid SEM Scanning electron microscopy SPED silica nanoparticles with encapsulated DNA ss single-stranded

- the analytical compositioncomprises lipid nanoparticles (LNPs) encapsulating a nucleic acid.

- the analytical compositionfurther complies with the following characteristics:

- the LNPsdisintegrate in 70% V/V ethanol.

- the term “disintegration of lipid nanoparticles”relates to an increase in concentration of any one of the lipid components of the LNP in the continuous phase of at least 100% compared the continuous phase of a reference dispersion of the same lipid nanoparticles in water. Disintegration can be measured by determining in the continuous phase the concentration of any one of the lipids that are present in the respective LNP in signification amounts, i.e.

- any one of the lipid components being present in the LNP in an amount of at least 1 mol%(also referred to as “constituent lipid”), e.g. in an amount of between 1 mol% to 100 mol%, such as 1 mol% to 50 mol%.

- the lipid component to be analysedmay be cholesterol or an ionisable lipid, such as oleylamine, dodecylamine, hexadecylamine or 306Oi10.

- the concentration of any one of the lipids in the continuous phasecan be measured by standard methods for lipid quantification, such as GC-MS, HPLC, MALDI-TOF.

- disintegrationis measured by GC-MS, e.g.

- the thereby determined concentration valueis compared to the concentration of the same lipid in the continuous phase of a reference dispersion of the same LNPs in water.

- the dispersed phaseis separated from the continuous phase by standard methods, usually employing centrifugation and filtration. Measuring the concentration of any one of the lipids in the continuous phase is within the ordinary skill.

- the term “disintegration”relates to an increase in concentration by 100% of a lipid component of the LNPs (i.e. any lipid being present in the LNP in an amount of at least 1 mol%, e.g.

- disintegrationmay be measured according to the following protocol: • Diluting a sample of the LNP (containing min.

- the LNPsprotect the nucleic acid encapsulated therein from nuclease degradation as measured by qPCR.

- the encapsulated nucleic acidhas a length of between 60 – 200 nucleotides, advantageously of between 60 – 120 nucleotides.

- the wt. ratio between the nucleic acid and the LNPs in the analytical compositionis in a range of between 0.01% to 15% nucleic acid, advantageously in a range of between 0.1% to 2% nucleic acid, such as 1% nucleic acid.

- the use of the analytical composition described abovehas the advantage that the encapsulated nucleic acid is protected from nuclease degradation as long as the LNPs are intact.

- the LNPsdisintegrate and the nucleic acid becomes susceptible to degradation, in particular nuclease degradation. It is considered beneficial that the nucleic acid can be quantified by well-established and sensitive detection methods, e.g. by quantitative polymerase chain reaction (qPCR).

- qPCRquantitative polymerase chain reaction

- the LNPs encapsulating the nucleic acid as described abovehave the advantage that they more closely mimic common pathogens than the tools provided in the prior art. Based on the present disclosure, the skilled person understands that the chemical composition of the LNPs can be adapted to particularly mimic certain pathogens, e.g.

- multi-drug resistant bacteriasuch as methicillin-resistant Staphylococcus aureus (MRSA) and vancomycin-resistant enterococci.

- MRSAmethicillin-resistant Staphylococcus aureus

- vancomycin-resistant enterococciSuch pathogens are of particular relevance in certain environments, e.g. in the intensive care unit of a hospital.

- the LNPs encapsulating the nucleic acidare thus improved surrogate markers for pathogens compared to the prior art.

- analytical compositions as described abovehave the advantage that the LNPs are susceptible to disinfection procedures.

- the use of the analytical compositionenables both monitoring the disinfection procedure of a single surface and monitoring the transmission of pathogens from a first surface to a further surface (e.g.

- the use of the analytical composition as described abovehas the advantage that the LNPs are non- infectious and thus well suited for use in a hospital, e.g. in an intensive care unit.

- the use of the analytical compositionhas the advantage that the nucleic acid can be detected with high sensitivity by established nucleic acid amplification techniques such as qPCR.

- the use of the analytical compositionhas the advantage that results can be obtained in a relatively short time period, typically results can be obtained within 2 hours.

- the encapsulated nucleic acidis deoxyribonucleic acid (DNA).

- the encapsulated DNAmay have the nucleotide sequence according to SEQ ID NO: 1 shown below: SEQ ID NO: 1: TTCTCTGCCCTTACGTTTATCTTAAGGGCCGGTCCACCAGTT GAACACGAACAAACCTCTTT

- the encapsulated nucleic acidis ribonucleic acid.

- the nucleic acidcomprises or consists of modified nucleotides. Based on the present disclosure, the skilled person understands that the nucleic acid may be either single- stranded (ss) or double-stranded (ds).

- the use of multiple analytical compositions, each containing LNPs encapsulating a nucleic acid, e.g. DNA, having a different sequenceenables monitoring of transmission pathways from multiple surfaces while providing information on the efficiency of the disinfection procedure.

- the lipid nanoparticles and the DNA encapsulated thereinhave a N/P ratio of between 1:1 and 10:1, e.g. between 5:1 and 10:1, such as 8:1 or 10:1.

- “protection from nuclease degradation”, such as protection from DNAse degradationrelates to a decrease of max. 75% of intact nucleic acid present in the analytical composition after treatment with a nuclease, e.g.

- benzonase(protection test sample E) compared to a reference analytical composition that was not treated with the nuclease (protection negative control F), as measured by quantitative polymerase chain reaction (qPCR).

- Decrease2 ⁇ (Delta Ct)

- a difference between Ct-values measured for (protection test sample E) – (protection negative control F) of 2corresponds to a 4-fold decrease in intact nucleic acid.

- a decrease of max. 75% intact nucleic acidcorresponds to a delta Ct between protection test sample E and protection negative control F of max. 2.

- nucleaseis adapted to the nucleic acid to be analysed.

- DNase degradationmay be measured by subjecting the analytical composition to digestion with benzonase.

- protection from nuclease degradationmay be measured according to the following protocol (cf.

- protection test sample E2.5 units Benzonase in 10 ⁇ l sample (1.25 ng/ml) diluted in 90 ⁇ l Tris buffer (10 mM, pH 7) with MgCl 2 (20 mM)

- Protection negative control F10 ⁇ l sample (1.25 ng/ml) diluted in 90 ⁇ l miliQ water • Incubating protection test sample E for 1 h at 37°C • Inactivating enzyme by incubation for 10 min at 75 °C • Measuring DNA concentration of protection test sample E and protection negative control F via qPCR (see Example 6, Step 5) • Calculating the concentration difference between protection test sample E and protection negative control F based on the difference between Ct values (delta Ct).

- RNAis to be analysed, i.e. the encapsulated nucleic acid being RNA

- a suitable RNasee.g. RNase A

- qPCR measurement of RNArequires a reverse transcription step, e.g. using a reverse transcriptase such as Moloney Murine Leukemia Virus (MMLV) Reverse Transcriptase, prior to the PCR step (referred to as RT-qPCR).

- MMLVMoloney Murine Leukemia Virus

- RT-qPCRPerforming qPCR or RT-qPCR is well known in the art and all required components are commercially available.

- the qPCR step, and optionally the RT stepneed to be adapted to these modified nucleotides, e.g. by varying the enzymes, buffer or temperature or by using an alternative qPCR / RT-qPCR technique such as e.g. chemical-ligation qPCR (e.g. Boos et al., 2013, Nucleic Acids Res 41(15):e145; Shivalingam et al., 2020, Angew. Chem. Int. Ed., 59:11416–11422).

- “stability upon drying on a surface”relates to a decrease of max.

- a difference between Ct-values measured for (stability test sample G) – (stability negative control H) of 2corresponds to a 4-fold decrease in intact nucleic acid. Accordingly, a decrease of max. 75% intact nucleic acid corresponds to a delta Ct between stability test sample G and stability negative control H of max. 2.

- “stability upon drying on a surface”may be measured according to the following protocol (cf.

- example 5Air drying 50 ⁇ l of the analytical composition containing 0.005 ng/ ⁇ l of the LNPs encapsulating the nucleic acid on a glass surface, • rehydrating the dried composition with 200 ⁇ l water, • Stability test sample G: 2.5 units Benzonase in 10 ⁇ l rehydrated sample (1.25 ng/ml) diluted in 90 ⁇ l Tris buffer (10 mM, pH 7) with MgCl 2 (20 mM) • Stability negative control H: 10 ⁇ l rehydrated sample (1.25 ng/ml) diluted in 90 ⁇ l miliQ water • Incubating stability test sample G for 1 h at 37°C • Inactivating benzonase by incubation for 10 min at 75 °C • Measuring DNA concentration of stability test sample G and stability negative control H via qPCR (see Example 6, Step 5) • Calculating the concentration difference between stability test sample G and stability negative control H based on the difference between Ct values (delta Ct).

- the lipid nanoparticleshave a particle diameter in the range of between 50 nm to 1500 nm, advantageously in the range of between 50 nm to 300 nm, as measured by dynamic light scattering.

- the LNPs encapsulating the nucleic acidare lyophilized prior to use.

- the lyophilized LNPsare dissolved in a liquid prior to application on a surface.

- the lyophilized LNPsare dissolved in water or buffer, optionally containing additives as described herein.

- additives as described hereinmay also be lyophilized together with the LNPs.

- lipid nanoparticlescontain at least one lipid component.

- the at least one lipid componentis selected from the group consisting of ionisable lipids, phospholipids, cholesterol, lipid anchored PEGs, and mixtures thereof.

- the lipid nanoparticlescontain an ionisable lipid, advantageously in an amount of between 35 mol% and 100 mol%, e.g. 35 mol%, e.g. 50 mol% to 60 mol% such as 55 mol%, 56 mol%, 57 mol%, and 58 mol%, e.g. 100 mol%.

- the lipid nanoparticlesconsist of, or essentially consist of, ionisable lipids.

- the lipid nanoparticlescontain a phospholipid, advantageously in an amount of between 10 mol% and 50 mol%, e.g. 16 mol%, e.g. in a range of between 20 mol% to 35 mol% such as 26 mol%, 27 mol%, 28 mol%, 29 mol% and 30 mol%.

- the lipid nanoparticlescontain cholesterol, advantageously in an amount of between 10 mol% and 50 mol%, e.g.

- the lipid nanoparticlescontain a lipid anchored PEG, preferably in an amount of between 1 mol% and 10 mol%, advantageously in an amount of between 2 mol% and 8 mol% such as 2 mol%, 2.5 mol%, 5 mol% and 7 mol%.

- the lipid nanoparticlescontain an ionisable lipid, advantageously in an amount as described above and further contain at least one of the following: • a phospholipid, advantageously in an amount of between 10 mol% and 50 mol%, e.g. 16 mol%, e.g. in a range of between 20 mol% to 35 mol% such as 26 mol%, 28 mol% and 29 mol%; • cholesterol, advantageously in an amount of between 10 mol% and 50 mol%, e.g. in a range of between 10 mol% to 15 mol% such as 11 mol% and 12 mol%, e.g.

- the lipid nanoparticlescontain or consist of an ionisable lipid, advantageously in an amount as described above, and a phospholipid, advantageously in an amount as described above.

- the lipid nanoparticlescontain or consist of an ionisable lipid, advantageously in an amount as described above, and cholesterol, advantageously in an amount as described above.

- the lipid nanoparticlescontain or consist of an ionisable lipid, advantageously in an amount as described above, and a lipid anchored PEG, advantageously in an amount as described above.

- the lipid nanoparticlescontain or consist of an ionisable lipid, advantageously in an amount as described above, a phospholipid, advantageously in an amount as described above, and cholesterol, advantageously in an amount as described above.

- the lipid nanoparticlescontain or consist of an ionisable lipid, advantageously in an amount as described above, cholesterol, advantageously in an amount as described above and a lipid anchored PEG, advantageously in an amount as described above.

- the lipid nanoparticlescontain or consist of an ionisable lipid, advantageously in an amount as described above, a phospholipid, advantageously in an amount as described above, cholesterol, advantageously in an amount as described above, and a lipid anchored PEG, advantageously in an amount as described above.

- the ionisable lipidis selected from the group consisting of oleylamine, dodecylamine, hexadecylamine, 306Oi10, and mixtures thereof, more advantageously selected from the group consisting of oleylamine and 306Oi10, most advantageously 306Oi10.

- 306Oi10is also referred to as tetrakis(8-methylnonyl) 3,3',3'',3'''-((methylazanediyl)bis(propane-3,1- diyl))bis(azanetriyl))-tetrapropionate (cf. e.g.

- the phospholipidis selected from the group consisting of 1,2-dioleoyl-sn-glycero-3- phosphoethanolamine (DOPE), 1,2-distearoyl-sn-glycero-3- phosphocholin (DSPC), and mixtures thereof.

- DOPE1,2-dioleoyl-sn-glycero-3- phosphoethanolamine

- DSPC1,2-distearoyl-sn-glycero-3- phosphocholin

- the lipid anchored PEGis C14PEG1000, also referred to as 1,2-dimyristoyl-sn-glycero-3- phosphoethanolamine-N-[methoxy(polyethylene glycol)- 1000].

- the lipid nanoparticlesconsist of, or essentially consist of, oleylamine.

- the lipid nanoparticlesconsist of, or essentially consist of, oleylamine, advantageously in an amount of between 55 mol% to 60 mol% such as 55 mol% or 58 mol%, DSPC, advantageously in an amount of between 25 mol% to 35 mol% such as 28 mol%, 29 mol% or 30 mol%, and cholesterol, advantageously in an amount of between 10 mol% to 15 mol% such as 12 mol% or 13 mol%.

- the lipid nanoparticlesconsist of, or essentially consist of, 58 mol% oleylamine, 29 mol% DSPC, and 13 mol% cholesterol.

- the lipid nanoparticlesconsist of, or essentially consist of, 58 mol% oleylamine, 30 mol% DSPC, and 12 mol% cholesterol.

- Non-lipid components of the lipid nanoparticlesin addition to the at least one lipid component, the lipid nanoparticles further contain an inert solid component, advantageously in an amount of 5 wt% to 80 wt%.

- inert solid componentrelates to an organic polymer, a metal oxide or semiconductor oxide that complies with the following characteristics: • Being solid at 22 °C; • having a primary particle size in the range of between 50 nm and 1500 nm; • being insoluble in water, ethanol and mixtures thereof, such as 70% V/V ethanol; i.e. max. 10 mg of the inert solid component can be dissolved in either of 100 ml of water, ethanol or a mixture thereof; • being unreactive with any of the lipid components described herein when being present in water at 22°C; i.e. the inert solid component does not chemically react with any of the lipid components described herein.

- the LNPsfurther contain an inert solid component

- the LNPshave a particle diameter in the range of between 50 nm to 1500 nm, advantageously in the range of between 50 nm to 300 nm, as measured by dynamic light scattering.

- the primary particle size of the inert solidis smaller than the particle diameter of the LNPs.

- the term “primary particle size”relates to the diameter of a single, non-aggregated particle.

- suitable organic polymersinclude polystyrene, polyethylene terephthalate (PET) and polyethene (PE).

- suitable metal oxidesinclude titania (TiO 2 ), alumina (Al 2 O 3 ), zirconia (ZrO 2 ) and ceria (CeO 2 ), advantageously titania (TiO2) and zirconia (ZrO 2 ).

- semiconductor oxiderelates to oxides of semiconductors, e.g. silica (SiO 2 ). The skilled person understands that silicon (Si) is a semiconductor whereas silica (SiO 2 ), i.e. a semiconductor oxide, is not a semiconductor.

- the term “semiconductor oxide”is not to be confused with the terms “semiconducting oxides” or “oxide semiconductors”, i.e. certain oxides that are semiconductors, e.g. zirconia (ZrO 2 ), zinc oxide (ZnO) and cadmium oxide (CdO).

- the inert solid componentis selected from the group consisting of titania (TiO2), zirconia (ZrO 2 ) and silica (SiO 2 ).

- the LNPscontain at least the following components: • an ionisable lipid, preferably in an amount of between 35 mol% and 100 mol% and preferably selected from the group consisting of oleylamine, dodecylamine, hexadecylamine, 306Oi10, and mixtures thereof, more preferably selected from the group consisting of oleylamine and 306Oi10, most preferably 306Oi10; and • an inert solid component selected from the group consisting of organic polymers (preferably selected from the group consisting of polystyrene, polyethylene terephthalate and polyethene), metal oxides (preferably selected from the group consisting of titania (TiO 2 ), alumina (Al 2 O 3 ), zirconia (ZrO 2 ) and ceria (CeO 2 )) and semiconductor oxides (preferably silica (SiO 2 )), preferably in an amount of between 5 wt% to 80 wt

- the analytical compositioncomprises additives.

- Ionic strength adjusting additivesIn certain advantageous embodiments, the analytical composition comprises ionic strength adjusting additives, including buffers and salts. Ionic strength adjusting additives may be added for example to adjust the zeta potential of a composition containing LNPs, thereby increasing the stability of the LNPs, e.g. by preventing or mitigating aggregation of the LNPs.

- ionic strength adjusting additivesA large variety of ionic strength adjusting additives is known in the field and suitable in the context of the present invention.

- suitable ionic strength adjusting additivesmay be selected from the group consisting of NaCl, such as an isotonic NaCl solution, PBS, citrate buffer, and isocitrate buffer.

- the analytical compositionhas a zeta potential in the range of between –30 mV to +30 mV as measured by electrophoretic light scattering, e.g. using a zetasizer.

- pH adjusting additivesThe skilled person understands that some additives, while having an effect on the ionic strength of the composition, may also be added to adjust the pH value. Adjusting the pH value may be performed e.g. to increase the stability of the LNPs, e.g. by preventing or mitigating aggregation of the LNPs.

- a large variety of pH adjusting additivesare known in the field and suitable in the context of the present invention, such as PBS, citrate buffer, and isocitrate buffer.

- the analytical compositionhas a pH value in the range of 6 to 8.

- Disaccharides and polysaccharidesIt has been surprisingly found that addition of disaccharides and polysaccharides increases the stability of the analytical composition upon drying.

- a large variety of disaccharides and polysaccharidesare known in the field and are suitable in the context of the present invention.

- the following disaccharides and polysaccharideshave been found particularly beneficial additives to increase the stability of the analytical composition upon drying:

- DisaccharidesTrehalose, sucrose, maltose, lactose, and mixtures thereof.

- PolysaccharidesAgarose, starch, dextran, and mixtures thereof.

- the wtthe wt.

- the analytical compositioncomprises PEG (also referred to as “free PEG”).

- PEGalso referred to as “free PEG”.

- free PEGis not a component of the LNPs but instead is added to the analytical composition and is present external to the LNPs.

- Addition of PEGhas been found to increase the stability of the LNPs, e.g. by preventing or mitigating aggregation of the LNPs.

- Addition of PEGhas also been found to increase the stability of the analytical composition upon drying.

- the analytical compositioncontains oleylamine, DSPC, cholesterol, and PEG1000, advantageously in a molar ratio of oleylamine:DSPC:cholesterol:PEG1000 of 55:28:12:5.

- the analytical compositioncontains oleylamine, DSPC, cholesterol and PEG2000, advantageously in a molar ratio of oleylamine:DSPC:cholesterol:PEG2000 of 57:29:12:2.

- the analytical compositioncontains hexadecylamine, DSPC, cholesterol and PEG600, advantageously in a molar ratio of hexadecylamine:DSPC:cholesterol:PEG600 of 56:26:11:7.

- the inventionrelates to a method for monitoring a disinfection procedure with an analytical composition as defined above for the first aspect.

- the methodcomprises the following steps: Step a: Applying the analytical composition onto a surface, advantageously air-drying the composition.

- at least 0.25 ng of the LNPs encapsulating the nucleic acidare applied on the surface, e.g.

- Step bAfter a pre-determined time period, taking a test sample from the surface or from a second surface to which at least part of the analytical composition has been transferred, thereby dissolving the test sample in an aqueous solution, e.g. water, to obtain an aqueous test sample, e.g. in one of the following manners: • adding water onto the (first) surface or the second surface, for example pipetting 200 ⁇ l water onto the surface, and recovering the water containing the aqueous test sample, e.g.

- the time period between step a and step bmay be varied depending on the cleaning strategy of the facility in which the analytical composition is used. For example, if the surface is scheduled to be disinfected every 24 h, the time period between step a and step b may also be 24 h.

- Step cSubjecting a portion A of the aqueous test sample to an enzymatic nuclease degradation step, in particular an enzymatic DNA degradation step, e.g. in the following manner: • Diluting a defined volume of the aqueous test sample, e.g. 10 ⁇ l, with a defined volume of Tris buffer (10 mM, pH 7) containing 20 mM MgCl2, e.g. 90 ⁇ l; • adding a suitable nuclease, e.g. 2.5 units of Benzonase; and • incubating the mixture, e.g. for 1 h at 37°C, • inactivating the nuclease, e.g.

- Step dExamining the portion A and a reference portion B of the aqueous test sample by a qPCR detection procedure using primers specific for the nucleic acid, in particular the DNA, encapsulated in the lipid nanoparticles, to differentiate with reference to portion B, whether • the detected nucleic acid originates from an intact lipid nanoparticle of portion A and was thus protected during the enzymatic DNA nuclease degradation step or, • the detected nucleic acid originates from a disintegrated lipid nanoparticle of portion A, wherein the lipid nanoparticle encapsulation was destroyed by the disinfection procedure and thus the nucleic acid was not protected during the enzymatic nuclease degradation step.

- the following qPCR conditionsmay be used: • Preactivation for 240s at 95°C; • Amplification (40 cycles) with each cycle comprising 2 s at 95°C, followed by 12 s at 58°C, followed by 4 s at 72°C.

- the reference portion B of the aqueous test sampleis prepared by diluting a defined volume of the aqueous test sample, e.g. 10 ⁇ l, in a defined volume of water, e.g. 90 ⁇ l. It is understood that the reference portion B is not subjected to an enzymatic nuclease degradation step.

- steps b – dfurther comprise the following steps: Step b) additionally comprises taking a third test sample from a third additional surface, thereby dissolving the third test sample in an aqueous solution, e.g. water, to obtain a third aqueous test sample. Step c) additionally comprises subjecting a portion A’ of the third aqueous test sample to an enzymatic nuclease degradation step.

- Step b)additionally comprises taking a third test sample from a third additional surface, thereby dissolving the third test sample in an aqueous solution, e.g. water, to obtain a third aqueous test sample.

- Step c)additionally comprises subjecting a portion A’ of the third aqueous test sample to an enzymatic nuclease degradation step.

- Step d)additionally comprises examining the portion A’ and a reference portion B’ of the third aqueous test sample by a qPCR detection procedure using primers specific for the nucleic acid encapsulated in the lipid nanoparticles to differentiate with reference to portion B’, whether • the detected nucleic acid originates from an intact lipid nanoparticle of portion A’ and was thus protected during the enzymatic nuclease degradation step or, • the detected nucleic acid originates from a disintegrated lipid nanoparticle of portion A’, wherein the lipid nanoparticle encapsulation was destroyed by the disinfection procedure and thus the nucleic acid was not protected during the enzymatic nuclease degradation step, or • the analytical composition is not present on the third surface.

- the reference portion B’ of the third aqueous test sampleis prepared by diluting a defined volume of the third aqueous test sample, e.g. 10 ⁇ l, in a defined volume of water, e.g. 90 ⁇ l. It is understood that the reference portion B’ is not subjected to an enzymatic nuclease degradation step.

- the detected DNA from the test sample, or optionally the second test sampleoriginates from disintegrated LNPs if the difference between Ct values (A-B) – (A0-B0) > 2 with • A0 being a control portion of A, and • B0 being a control portion of B.

- differences in the nucleic acid concentrations between different samples or portions of a samplecan be determined by comparing Ct values measured by a qPCR detection procedure, e.g. qPCR or RT-qPCR. Ct values so measured can be converted to an absolute concentration of nucleic acid by means of a calibration curve. However, in the context of the instant invention, it is not required to convert the Ct value to an absolute nucleic acid concentration. Instead it is sufficient to compare Ct values between different samples or portions of a sample, i.e. a relative comparison of the nucleic acid concentrations is sufficient. Determining the Ct value from a sample or portion of a sample by a qPCR detection procedure, e.g.

- the detected DNA from the third test sampleoriginates from disintegrated LNPs if the difference between Ct values (A’-B’) – (A0-B0) > 2 with • A0 being a control portion of A, respectively A’, and • B0 being a control portion of B, respectively B’.

- the control portion A0is a control portion for both portion A and portion A’.

- the control portion B0is a control portion for both portion B and portion B’.

- a control portion B0is prepared from the analytical composition (i.e.

- a portion of the analytical composition that was stored before application) in the same manner as the reference portion Bis prepared from the aqueous test sample, e.g. by diluting a defined volume of the analytical composition, e.g. 10 ⁇ l, in a defined volume of water, e.g. 90 ⁇ l.

- a control portion A0is obtained by subjecting a portion of the analytical composition (i.e. a portion of the analytical composition that was stored before application) to the same enzymatic nuclease degradation step as portion A.

- a conclusion whether the (first) surface, and optionally the second surface and / or the third surface was disinfected between step a and step bmay be reached in the following manner: • Calculating the difference between the nucleic acid concentration in portion A and in the reference portion B; • Calculating the difference between the nucleic acid concentration in the control portion A0 and in the control portion B0; • Comparing the difference between the nucleic acid concentration in portion A and in the reference portion B, i.e. comparing the Ct values measured by a qPCR detection procedure, with the difference between the nucleic acid concentration in the control portion A0 and in the control portion B0, and • if the difference between Ct values A-B ⁇ A0-B0, i.e.

- the difference between Ct values (A’- B’) – (A0-B0) ⁇ 2the detected nucleic acid originates from intact lipid nanoparticles, i.e. the surface was not disinfected, and • optionally if the difference between Ct values A’-B ’ ⁇ A0-B0, i.e. the difference between Ct values (A’- B’) – (A0-B0) > 2 the detected nucleic acid originates from disintegrated lipid nanoparticles, i.e. the surface was disinfected or the analytical composition was not present on the third surface.

- steps a, c and dcomprise the following substeps:

- at least 0.25 ng of the LNPs encapsulating the nucleic acidare applied on the surface, e.g. 50 ⁇ l of the analytical composition containing the LNPs encapsulating the nucleic acid in a concentration of 0.005 ng/ ⁇ l.

- a-2Storing a defined volume of the analytical composition, e.g. 50 ⁇ l, thereby obtaining a stored analytical composition.

- c-2Subjecting a portion of the stored analytical composition to the same enzymatic nuclease degradation step as portion A, to thereby obtain a control portion A0.

- c-3Preparing a reference portion B of the aqueous test sample, e.g. by diluting a defined volume of the aqueous test sample, e.g. 10 ⁇ l, in a defined volume of water, e.g. 90 ⁇ l. It is understood that the reference portion B is not subjected to an enzymatic nuclease degradation step.

- c-4Preparing a control portion B0 of the stored analytical composition in the same manner as the reference potion B is prepared from the aqueous test sample, e.g. by diluting a defined volume of the stored analytical composition, e.g. 10 ⁇ l, in a defined volume of water, e.g. 90 ⁇ l. It is understood that the reference portion B0 is not subjected to an enzymatic nuclease degradation step.

- c-5Subjecting a portion A’ of the third aqueous test sample to the same enzymatic nuclease degradation step as portion A.

- c-6Preparing a reference portion B’ of the third aqueous test sample, e.g.

- qPCR conditionsmay be used: • Preactivation for 240 s at 95°C; • Amplification (40 cycles) with each cycle comprising 2 s at 95°C, followed by 12s at 58°C, followed by 4s at 72°C.

- d-2Quantifying the nucleic acid present in the control portion A0 and in the control portion B0 in the same manner as portion A and reference portion B.

- d-3Comparing the Ct values measured for the portion A, for the reference portion B, for the control portion A0 and for the control portion B0 to differentiate whether • the detected nucleic acid originates from an intact lipid nanoparticle of portion A and was thus protected during the enzymatic nuclease degradation step or, • the detected nucleic acid originates from a disintegrated lipid nanoparticle of portion A, wherein the lipid nanoparticle encapsulation was destroyed by the disinfection procedure and thus the nucleic acid was not protected during the enzymatic nuclease degradation step.

- Optionally d-4Quantifying the nucleic acid, in particular the DNA, present in portion A’ and in the reference portion B’ of the third aqueous test sample by a qPCR detection procedure using primers that are specific for the encapsulated nucleic acid.

- Optionally d-5Comparing the Ct values measured for portion A’, for the reference portion B’, for the control portion A0 and for the control portion B0 to differentiate whether • the detected nucleic acid originates from an intact lipid nanoparticle of portion A’ and was thus protected during the enzymatic DNA nuclease degradation step or, • the detected nucleic acid originates from a disintegrated lipid nanoparticle of portion A’, wherein the lipid nanoparticle encapsulation was destroyed by the disinfection procedure and thus the nucleic acid was not protected during the enzymatic DNA nuclease degradation step.

- the inventionrelates to an analytical composition as described herein for the first aspect.

- the LNPs comprised within the analytical compositioncontain an ionisable lipid, preferably in an amount of between 35 mol% and 100 mol%, and/or contain at least one of the following: • a phospholipid, preferably in an amount of between 10 mol% and 50 mol%, • cholesterol, preferably in an amount of between 10 mol% and 50 mol%, and • a lipid anchored PEG, preferably in an amount of between 1 mol% and 10 mol%; • an inert solid component selected from the group consisting of organic polymers (preferably selected from the group consisting of polystyrene, polyethylene terephthalate and polyethene), metal oxides (preferably selected from the group consisting of titania (TiO 2 ), alumina (Al 2 O 3 ), zirconia (ZrO 2 ) and ceria (CeO 2 )) and semiconductor oxides (preferably silica (SiO 2 )), preferably in an amount of between 5 wt%

- the LNPscontain at least the following components: • an ionisable lipid, preferably in an amount of between 35 mol% and 100 mol% and preferably selected from the group consisting of oleylamine, dodecylamine, hexadecylamine, 306Oi10, and mixtures thereof, more preferably selected from the group consisting of oleylamine and 306Oi10, most preferably 306Oi10; and • an inert solid component selected from the group consisting of organic polymers (preferably selected from the group consisting of polystyrene, polyethylene terephthalate and polyethene), metal oxides (preferably selected from the group consisting of titania (TiO 2 ), alumina (Al 2 O 3 ), zirconia (ZrO 2 ) and ceria (CeO 2 )) and semiconductor oxides (preferably silica (SiO 2 )), preferably in an amount of 5 wt% to 80 wt%

- the inert solid componentis selected from the group consisting of titania (TiO 2 ), zirconia (ZrO 2 ) and silica (SiO 2 ).

- the inventionrelates to a kit of parts comprising an analytical composition as described herein for the first aspect, qPCR primers specific for the nucleic acid, and optionally one or more of the following: • a nuclease, • a DNA polymerase, • a qPCR buffer.

- ionisable lipid 306Oi10The ionisable lipid 306Oi10 was synthesised from 2-isodecyl acrylate (Sigma-Aldrich) and 3,3'-Diamino-N- methyldipropylamine (Aldrich-Fine Chemicals) in stochiometric amounts via stirring for 3 days at 90°C.

- Synthesis of TMAPS-functionalised silica particlesThe silica particles were functionalised by first sonicating a aqueous dispersion of silica nanoparticles (0.142 ⁇ m diameter, 5% w/v aq.

- LNP composition number 1LNP comprising DOPE, cholesterol, C14-PEG1000 and 306Oi10

- DOPEl,2-dioleoyl-sn-glycero-3- phosphoethanolamine, Avanti

- cholesterolSigma-Aldrich

- C14-PEG1000(1,2-dimyristoyl-sn-glycero-3- phosphoethanolamine-N-[methoxy(polyethylene glycol)- 1000], ammonium salt, Avanti

- the previously synthesised ionisable lipid 306Oi10were dissolved in 90% ethanol and 10% 10 nM citrate buffer at molar ratios of 16 : 46.5 : 2.5 : 35.

- LNP composition number 2LNP comprising oleylamine, DSPC, cholesterol and PEG 600 First, oleylamine, DSPC, cholesterol and PEG 600 were dissolved in methanol at molar ratios of 54:27:11.5:7.5.

- an aqueous phasewas DNA prepared consisting of DNA (ds DNA, 62 nt; SEQ ID NO: 1: TTCTCTGCCCTTACGTTTATCTTAAGGGCCGGTCCACCAGTTG AACACGAACAAACCTCTTT) in 0.1 M acetic acid with a final DNA concentration of 1 g/l. Both phases were preheated to 80°C and the methanol phase was added dropwise to the aqueous phase in 5:1 volumetric ratio (aqueous:methanol) and mixed by rapid pipette mixing. The mixture was allowed to cool down to room temperature.

- LNP composition number 3LNP comprising oleylamine First, oleylamine was dissolved in methanol.

- an aqueous phasewas DNA prepared consisting of DNA (ds DNA, 62 nt; SEQ ID NO: 1: TTCTCTGCCCTTACGTTTATCTTAAGGGCCGGTCCACCAGTTGAACACGAACAAACC TCTTT) in 0.1 M acetic acid with a final DNA concentration of 1 g/l. Both phases were preheated to 80°C and the methanol phase was added dropwise to the aqueous phase in 2.5:1 volumetric ratio (aqueous:methanol) and mixed by rapid pipette mixing. The mixture was allowed to cool down to room temperature.

- LNP composition number 4LNP comprising DOPE, cholesterol, C14-PEG1000 and 306Oi10 with silica nanoparticles

- DOPEl,2-dioleoyl-sn-glycero-3- phosphoethanolamine, Avanti

- cholesterolSigma-Aldrich

- C14-PEG1000(1,2-dimyristoyl-sn-glycero-3- phosphoethanolamine-N-[methoxy(polyethylene glycol)- 1000], ammonium salt, Avanti

- the previously synthesised ionisable lipid 306Oi10were dissolved in 90% ethanol and 10% 10 nM citrate buffer at molar ratios of 16 : 46.5 : 2.5 : 35.

- LNP composition number 5LNP comprising DOPE, cholesterol, C14-PEG1000 and 306Oi10 with silica nanoparticles via lipid rehydration

- DOPEl,2-dioleoyl-sn-glycero-3- phosphoethanolamine, Avanti

- cholesterolSigma-Aldrich

- C14-PEG10001,2-dimyristoyl-sn-glycero-3- phosphoethanolamine-N-[methoxy(polyethylene glycol)- 1000], ammonium salt, Avanti

- the previously synthesised ionisable lipid 306Oi10were dissolved in chloroform at molar ratios of 16 : 46.5 : 2.5 : 35.

- Example 2Preparation of analytical compositions To prepare an analytical composition, LNP dispersions were diluted in miliQ water to a final concentration of 0.005 ng/ ⁇ l. If additives were added, they were added in the respective amount to the LNP dispersion, which was subsequently diluted in miliQ water to a final concentration of 0.005 ng/ ⁇ l LNP.

- Example 3Disintegration of the LNPs in 70 vol.% ethanol The concentration of a LNP constituent lipid (i.e.

- any one of the lipid components being present in the LNP in an amount of at least 1 mol%)was measured in the continuous phase of an LNP dispersion comprising 150 ⁇ l LNP in miliQ water (0.2 ⁇ g/ ⁇ l constituent lipid; cf. example 2) in either 350 ⁇ l miliQ water (disintegration negative control D) or in 350 ⁇ l ethanol (resulting in 70% V/V ethanol; disintegration test sample C).

- the concentration of the lipid constituent in the continuous phasewas measured using a GC-MS-5977A series instrument (Agilent; column: DB-5MS 20 x 0.18 ⁇ m, oven temperature: 170°C ramped to 325°C at 8°C/min, with a final hold time of 20 min; detector temperature: 300°C). Results are shown in table 2 below.

- Step 1Application of the analytical composition on a surface. 50 ⁇ l of the analytical composition containing 0.005 ng/ ⁇ l LNPs encapsulating the DNA (SEQ ID NO: 1) were applied onto a clean glass surface (no residual DNA, LNPs on the surface). The analytical composition was air-dried on the surface. In addition, 200 ⁇ l of the same analytical composition containing 0.00125 ng/ ⁇ l LNPs encapsulating the DNA (sequence) were stored at 5°C for later use (referred to as the “stored analytical composition”). Step 2: Disinfection of the surface. The following disinfectants were tested, i.e.

- Step 3Taking a test sample from a surface.

- a test samplewas taken from the surface either • by pipetting 200 ⁇ l miliQ water onto the surface and recovering this liquid, or • by swabbing the surface with a premoistened swab and recovering the sample from the swab by dissolving it in 200 ⁇ l miliQ water.

- the results of the analysiswere comparable when either of the two methods of taking the test sample were used (step 3).

- the obtained test sampleis further referred to as the “aqueous test sample”.

- Step 4Enzymatic DNase digestion.

- a portion A of the aqueous test samplewas prepared by diluting 10 ⁇ l of the aqueous test sample with 90 ⁇ l of Tris buffer (10 mM, pH 7) containing 20 mM MgCl 2 .

- a reference portion B of the aqueous test samplewas prepared by diluting 10 ⁇ l of the aqueous test sample with 90 ⁇ l miliQ water. No nuclease digestion was performed on reference portion B (untreated sample).

- a control portion B0 of the stored analytical compositionwas prepared by diluting 10 ⁇ l of the stored analytical composition with 90 ⁇ l miliQ water. No nuclease digestion was performed on the control portion B0 (control for reference portion B).

- a control portion A0 of the stored analytical compositionwas prepared by diluting 10 ⁇ l of the stored analytical composition with 90 ⁇ l of Tris buffer (10mM, pH 7) containing 20 mM MgCl 2 . To this solution was added 2.5 units Benzonase and the mixture was incubated for 1 h at 37°C. After incubation, benzonase was inactivated by further incubation for 10 min at 75°C.

- Step 5qPCR analysis – assessment whether the surface was disinfected

- the following primerswere used: Forward primer (SEQ ID NO: 2): CTCTGCCCTTACGTTTATC Reverse primer (SEQ ID NO: 3): AGAGGTTTGTTCGTGTTC

- a qPCR master mixwas prepared for each sample by mixing 10 ⁇ l MasterMix (KAPA SYBR FAST for LightCycler 480, REF: KK4611 07959494001, kapa biosystems), 1 ⁇ l of each primer and 3 ⁇ l miliQ water.

- qPCRwas performed on a 96 well plate using a LightCycler 480 II, Roche Diagnostics by adding 15 ⁇ l of the respective qPCR master mix per well. Each sample (5 ⁇ l) was pipetted on the 96 well plate in duplicates and the plate was sealed. qPCR was performed according to the following protocol: Preactivation: 240 s at 95°C Amplification (40 cycles): 2 s at 95°C, 12 s at 58 °C, 4 s at 72 °C.

- a conclusion whether the surface was efficiently disinfected in step 2was reached in the following manner: • The difference between the Ct values measured for portion A and for the reference portion B was calculated; • The difference between the Ct values measured for the control portion A0 and for the control portion B0 was calculated; • The difference between the Ct values measured for portion A and for the reference portion B was compared to the difference between the Ct values measured for the control portion A0 and for the control portion B0; • if the difference between Ct values A-B ⁇ A0-B0, i.e. the difference between Ct values (A-B) – (A0-B0) ⁇ 2, the detected nucleic acid originates from intact LNPs, i.e.

- LNP composition number 1LNP comprising DOPE, cholesterol, C14-PEG1000 and 306Oi10; cf. example 1

Landscapes

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Organic Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Zoology (AREA)

- Wood Science & Technology (AREA)

- Proteomics, Peptides & Aminoacids (AREA)

- Health & Medical Sciences (AREA)

- Biophysics (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Immunology (AREA)

- Microbiology (AREA)

- Molecular Biology (AREA)

- Analytical Chemistry (AREA)

- Physics & Mathematics (AREA)

- Biotechnology (AREA)

- Biochemistry (AREA)

- Bioinformatics & Cheminformatics (AREA)

- General Engineering & Computer Science (AREA)

- General Health & Medical Sciences (AREA)

- Genetics & Genomics (AREA)

- Measuring Or Testing Involving Enzymes Or Micro-Organisms (AREA)

Abstract

Description