WO2023274312A1 - Engineering vehicle battery heat management system and method - Google Patents

Engineering vehicle battery heat management system and methodDownload PDFInfo

- Publication number

- WO2023274312A1 WO2023274312A1PCT/CN2022/102460CN2022102460WWO2023274312A1WO 2023274312 A1WO2023274312 A1WO 2023274312A1CN 2022102460 WCN2022102460 WCN 2022102460WWO 2023274312 A1WO2023274312 A1WO 2023274312A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- electronic

- way valve

- battery

- water inlet

- temperature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/42—Methods or arrangements for servicing or maintenance of secondary cells or secondary half-cells

- H01M10/48—Accumulators combined with arrangements for measuring, testing or indicating the condition of cells, e.g. the level or density of the electrolyte

- H01M10/486—Accumulators combined with arrangements for measuring, testing or indicating the condition of cells, e.g. the level or density of the electrolyte for measuring temperature

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/61—Types of temperature control

- H01M10/613—Cooling or keeping cold

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/61—Types of temperature control

- H01M10/615—Heating or keeping warm

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/62—Heating or cooling; Temperature control specially adapted for specific applications

- H01M10/625—Vehicles

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/65—Means for temperature control structurally associated with the cells

- H01M10/656—Means for temperature control structurally associated with the cells characterised by the type of heat-exchange fluid

- H01M10/6561—Gases

- H01M10/6563—Gases with forced flow, e.g. by blowers

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/65—Means for temperature control structurally associated with the cells

- H01M10/656—Means for temperature control structurally associated with the cells characterised by the type of heat-exchange fluid

- H01M10/6567—Liquids

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/65—Means for temperature control structurally associated with the cells

- H01M10/656—Means for temperature control structurally associated with the cells characterised by the type of heat-exchange fluid

- H01M10/6569—Fluids undergoing a liquid-gas phase change or transition, e.g. evaporation or condensation

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/65—Means for temperature control structurally associated with the cells

- H01M10/657—Means for temperature control structurally associated with the cells by electric or electromagnetic means

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Definitions

- the inventionbelongs to the technical field of new energy, and in particular relates to a heat management system and method for engineering vehicle batteries.

- the traditional battery thermal management systemneeds to use the compressor frequently when the battery is cooled, resulting in increased system power consumption and greatly reducing the reliability of high-voltage accessories; when the battery is heated, it only relies on the heating film, the heating rate is slow and there is no battery insulation function , reducing the transport efficiency.

- the traditional battery thermal management systemhas a single heat dissipation and cooling mode, no shutdown heat preservation and self-circulation functions, and narrow coverage methods. These factors limit the performance of the vehicle to a certain extent.

- the present inventionproposes a battery heat management system that can control different heat dissipation methods according to the ambient temperature and battery temperature, which not only reduces the energy consumption of the vehicle but also improves the reliability of the battery system.

- the present inventionprovides a battery heat management system and method for engineering vehicles, which can deal with battery heat management problems under various complex working conditions.

- a battery heat management system for engineering vehiclesincluding a battery pack, the battery pack is provided with a water inlet and a water outlet, the water inlet is connected to a water pump, and also includes an electronic three-way valve A, an electronic Three-way valve B, radiator, plate changer and heater; the first end of the electronic three-way valve A is connected to the water outlet, the second end is connected to the first end of the electronic three-way valve B through the radiator, and the third The end is connected to the first end of the electronic three-way valve B through the plate changer; the second end of the electronic three-way valve B is connected to the water inlet through the heater, and the third end is directly connected to the water inlet; the water inlet is connected to the inlet A temperature sensor and a water pump, the water outlet is connected with an outlet temperature sensor.

- the plate exchangeris connected to a compressor and a condenser, the radiator and condenser are equipped with cooling fans, and the condenser is connected to the plate exchanger through an expansion valve.

- the battery packis provided with a heating film.

- the water inletis connected to an expansion tank.

- the heateris a water heating PTC heater.

- a heat management method for an engineering vehicle batterycomprising the following methods:

- Refrigeration methoddetect the battery temperature and ambient temperature, when the battery temperature > 30°C and the ambient temperature > 10°C, turn on the water pump, cooling fan, compressor and condenser, the electronic three-way valve A is connected to the plate changer, and the electronic three-way valve B is directly connected to the water inlet, and the coolant enters the plate changer from the water outlet through the electronic three-way valve A, and returns to the battery pack through the electronic three-way valve B and the water inlet after being cooled by the compressor and condenser;

- Air cooling methoddetect the battery temperature and ambient temperature, when the battery temperature is >30°C and the ambient temperature is ⁇ 10°C, turn on the water pump and cooling fan, the electronic three-way valve A is connected to the radiator, and the electronic three-way valve B is directly connected to the water inlet.

- the coolantenters the radiator through the electronic three-way valve A from the water outlet, and returns to the battery pack through the electronic three-way valve B and the water inlet after cooling;

- Low-temperature heating methoddetect the battery temperature and ambient temperature, when the battery temperature is ⁇ 0°C, turn on the water pump, heater and heating film, the electronic three-way valve A is connected to the plate changer, the electronic three-way valve B is connected to the heater, and the coolant From the water outlet, it enters the heater through the electronic three-way valve A, the plate changer, and the electronic three-way valve B, and flows back to the battery pack through the water inlet after heating;

- Low-temperature refrigeration methoddetect the battery temperature and ambient temperature, when the battery temperature is >30°C and the ambient temperature is ⁇ -26°C, turn on the water pump, the electronic three-way valve A is connected to the radiator, the electronic three-way valve B is directly connected to the water inlet, and the cooling liquid Enter the radiator through the electronic three-way valve A from the water outlet, and return to the battery pack through the electronic three-way valve B and the water inlet after cooling;

- Self-circulation methoddetect the battery temperature, when the battery temperature is between 15°C and 30°C, turn on the water pump, the electronic three-way valve A is connected to the plate changer, the electronic three-way valve B is directly connected to the water inlet, and the coolant passes through the water outlet

- the electronic three-way valve Aenters the plate changer, and then returns to the battery pack through the electronic three-way valve B and the water inlet;

- Stop heat preservation methoddetect the ambient temperature, when the ambient temperature is ⁇ -35°C, heat preservation through the heating film, and when the ambient temperature is ⁇ -40°C, heat preservation through the heater.

- the heat dissipation mode of the batterycan be automatically switched according to the ambient temperature and the battery temperature; 2.

- the heat management of the batterycan be realized in the whole temperature range; 3.

- the heat dissipation systemhas high efficiency and low energy consumption; 4.

- the management systemis convenient and flexible to adjust, with strong applicability and high reliability; 5.

- the power of the water pumpcan be adjusted according to the temperature of the battery.

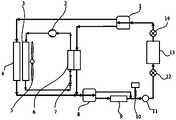

- Fig. 1is a schematic structural diagram of a battery heat management system of a pure electric mining dump truck of the present invention

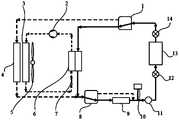

- Fig. 2is a schematic diagram of the refrigeration working condition of the heat management system of the present invention.

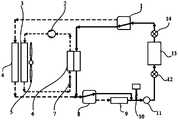

- FIG. 3is a schematic diagram of the heat management system of the present invention in the air-cooled working condition and the low-temperature refrigeration working condition;

- Fig. 4is a schematic diagram of the low-temperature heating working condition of the heat management system of the present invention.

- Fig. 5is a schematic diagram of the self-circulation working condition of the heat management system of the present invention.

- Fig. 6is a schematic diagram of the thermal management system of the present invention in a shutdown and heat preservation working condition

- this embodimentIn order to detect the ambient temperature, this embodiment is equipped with an ambient temperature sensor, and in order to realize the function of automatically switching working conditions, this embodiment is equipped with a controller, all of which are prior art.

- a heat management system for engineering vehicle batteriesincludes a battery pack 13, the battery pack 13 is provided with a water inlet and a water outlet, the water inlet is connected to a water pump 11, and it is characterized in that it also includes an electronic Three-way valve A1, electronic three-way valve B8, radiator 4, plate changer 6 and heater; the first end of the electronic three-way valve A is connected to the water outlet, and the second end is connected to the electronic three-way through the radiator 4

- the first end and the third end of the valve B8are connected to the first end of the electronic three-way valve B8 through the plate changer 6; the second end of the electronic three-way valve B8 is connected to the water inlet through the heater, and the third end is directly connected to the Water inlet; the water inlet is connected to the inlet temperature sensor 12 and the water pump 11 , and the water outlet is connected to the outlet temperature sensor 14 .

- the plate exchanger 6is connected to the compressor 2 and the condenser 3, the radiator 4 and the condenser 3 are equipped with a cooling fan 5, and the condenser 3 is connected to the plate exchanger through an expansion valve 7.

- the battery pack 13is provided with a heating film; the water inlet is connected to the expansion tank 10; the heater is a water heating PTC heater 9

- a heat management method for an engineering vehicle batterycomprising the following methods:

- Refrigeration methodAs shown in Figure 2, detect the battery temperature and ambient temperature, when the battery temperature > 30°C and the ambient temperature > 10°C, turn on the water pump 11, the cooling fan 5, the compressor 2 and the condenser 3, and the electronic three-way valve A1 is connected to the plate changer 6, and the electronic three-way valve B8 is directly connected to the water inlet.

- the coolantenters the plate changer 6 through the electronic three-way valve A1 from the water outlet, and passes through the electronic three-way valve B8 after being cooled by the compressor 2 and the condenser 3. and the water inlet back to the battery pack;

- Air-cooling methodAs shown in Figure 3, detect the battery temperature and ambient temperature. When the battery temperature is >30°C and the ambient temperature is ⁇ 10°C, turn on the water pump 11 and the cooling fan 5, and the electronic three-way valve A1 is connected to the radiator 4.

- the three-way valve B8is directly connected to the water inlet, and the coolant enters the radiator 4 from the water outlet through the electronic three-way valve A1, and returns to the battery pack through the electronic three-way valve B8 and the water inlet after cooling;

- Low-temperature heating methodAs shown in Figure 4, detect the battery temperature and ambient temperature, when the battery temperature is ⁇ 0°C, turn on the water pump 11, the heater and the heating film, the electronic three-way valve A1 is connected to the plate changer 6, and the electronic three-way The valve B8 is connected to the heater, and the coolant enters the heater from the water outlet through the electronic three-way valve A1, the plate changer 6, and the electronic three-way valve B8, and flows back to the battery pack 13 through the water inlet after heating;

- Low-temperature refrigeration methoddetect the battery temperature and ambient temperature, when the battery temperature is >30°C and the ambient temperature is ⁇ -26°C, turn on the water pump 11, the electronic three-way valve A1 is connected to the radiator 4, and the electronic three-way valve B8 is directly connected to the water inlet.

- the coolantenters the radiator 4 through the electronic three-way valve A1 from the water outlet, and returns to the battery pack through the electronic three-way valve B8 and the water inlet after cooling;

- Self-circulation methodAs shown in Figure 5, the battery temperature is detected. When the battery temperature is between 15°C and 30°C, the water pump 11 is turned on, the electronic three-way valve A1 is connected to the plate changer 6, and the electronic three-way valve B8 is directly connected to the The water outlet, the coolant enters the plate changer 6 through the electronic three-way valve A1 from the water outlet, and then returns to the battery pack through the electronic three-way valve B8 and the water inlet to balance the temperature difference between the cells in the battery pack;

- Stop heat preservation methodAs shown in Figure 6, check the ambient temperature. When the ambient temperature is ⁇ -35°C, use a heating film to keep warm. When the ambient temperature is ⁇ -40°C, use a heater to keep warm.

- the power of the water pump 11can be adjusted according to the temperature of the battery pack 13.

- the power of the water pump 11is reduced.

- the power of the water pump 11is increased. High, to speed up the circulation of the coolant, so that the battery pack can return to normal temperature as soon as possible.

- the present inventioncan control different heat dissipation modes according to ambient temperature and battery temperature. Energy consumption is saved, costs are reduced, and reliability of high-voltage components and the entire system is improved. For example, when the ambient temperature is low in spring, autumn and winter, there is no need to use a compressor to cool the battery, which reduces the quality risk and reduces the system power consumption by 70%. In extremely cold weather below -26°C, the battery can also be cooled when the battery temperature is high. Actively cool down to realize operation and management under all working conditions.

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Secondary Cells (AREA)

- Electric Propulsion And Braking For Vehicles (AREA)

Abstract

Description

Translated fromChinese本发明属于新能源技术领域,具体是一种工程车辆电池热量管理系统及方法。The invention belongs to the technical field of new energy, and in particular relates to a heat management system and method for engineering vehicle batteries.

随着电机、电池及控制技术的发展,越来越多的大型矿用设备采用电力驱动,包括电动挖掘机、电动装载机和矿用纯电动自卸车。尤其是纯电动自卸车,在大型矿山土石方运输方面占据了绝对优势。电池系统作为纯电动自卸车的重要部件之一,其性能好坏直接影响整车续驶里程。矿车工作环境恶劣,低温或高温环境下,纯电动矿车电池性能均受到不同程度的限制,因此,一款可靠的电池热量管理系统显得格外重要。With the development of motors, batteries and control technologies, more and more large-scale mining equipment is driven by electric power, including electric excavators, electric loaders and pure electric mine dump trucks. In particular, pure electric dump trucks have an absolute advantage in large-scale mine earthwork transportation. As one of the important components of a pure electric dump truck, the performance of the battery system directly affects the mileage of the vehicle. The working environment of the mine car is harsh, and the battery performance of the pure electric mine car is limited to varying degrees under low or high temperature environments. Therefore, a reliable battery heat management system is particularly important.

传统的电池热量管理系统在电池制冷时需要频繁使用压缩机,导致系统功耗增加且大大降低了高压附件的可靠性;在电池制热时仅依靠加热膜,加热速率较慢并且没有电池保温功能,降低了运输效率。另外传统的电池热管理系统散热制冷模式较为单一,没有停机保温和自循环功能,覆盖的方法窄,这些因素都在一定程度上限制了整车性能的发挥。为了解决这一问题,本发明提出了一种可根据环境温度和电池温度来控制不同散热方式的电池热量管理系统,既降低了整车能耗又提高了电池系统的可靠性。The traditional battery thermal management system needs to use the compressor frequently when the battery is cooled, resulting in increased system power consumption and greatly reducing the reliability of high-voltage accessories; when the battery is heated, it only relies on the heating film, the heating rate is slow and there is no battery insulation function , reducing the transport efficiency. In addition, the traditional battery thermal management system has a single heat dissipation and cooling mode, no shutdown heat preservation and self-circulation functions, and narrow coverage methods. These factors limit the performance of the vehicle to a certain extent. In order to solve this problem, the present invention proposes a battery heat management system that can control different heat dissipation methods according to the ambient temperature and battery temperature, which not only reduces the energy consumption of the vehicle but also improves the reliability of the battery system.

发明内容Contents of the invention

针对纯电动工程车运行环境温度差异大、工作过程温度变化复杂的问题,本发明提供了一种工程车辆电池热量管理系统及方法,可以应对多种复杂工况下的电池热量管理问题。Aiming at the problems of large temperature differences in the operating environment of pure electric engineering vehicles and complex temperature changes in the working process, the present invention provides a battery heat management system and method for engineering vehicles, which can deal with battery heat management problems under various complex working conditions.

本发明采用的技术方案:一种工程车辆电池热量管理系统,包括电池包,所述的电池包设有入水口和出水口,所述的入水口连接水泵,还包括电子三通阀A、电子三通阀B、散热器、板换器和加热器;所述的电子三通阀A的第一端连接出水口,第二端经散热器连接电子三通阀B的第一端,第三端经板换器连接电子三通阀B的第一端;所述的电子三通阀B的第二端经加热器连接入水口,第三端直接连接入水口;所述的入水口连接入口温度传感器和水泵,所述的出水口连接出口温度传感器。The technical solution adopted in the present invention: a battery heat management system for engineering vehicles, including a battery pack, the battery pack is provided with a water inlet and a water outlet, the water inlet is connected to a water pump, and also includes an electronic three-way valve A, an electronic Three-way valve B, radiator, plate changer and heater; the first end of the electronic three-way valve A is connected to the water outlet, the second end is connected to the first end of the electronic three-way valve B through the radiator, and the third The end is connected to the first end of the electronic three-way valve B through the plate changer; the second end of the electronic three-way valve B is connected to the water inlet through the heater, and the third end is directly connected to the water inlet; the water inlet is connected to the inlet A temperature sensor and a water pump, the water outlet is connected with an outlet temperature sensor.

优选的,所述的板换器连接压缩机和冷凝器,所述的散热器和冷凝器安装有冷却风扇,所述的冷凝器通过膨胀阀与板换器连接。Preferably, the plate exchanger is connected to a compressor and a condenser, the radiator and condenser are equipped with cooling fans, and the condenser is connected to the plate exchanger through an expansion valve.

优选的,所述的电池包内设有加热膜。Preferably, the battery pack is provided with a heating film.

优选的,所述的入水口连接膨胀水箱。Preferably, the water inlet is connected to an expansion tank.

优选的,所述的加热器采用的是水暖PTC加热器。Preferably, the heater is a water heating PTC heater.

一种工程车辆电池热量管理方法,包括以下方法:A heat management method for an engineering vehicle battery, comprising the following methods:

制冷方法:检测电池温度和环境温度,当电池温度>30℃且环境温度>10℃时,开启水泵、冷却风扇、压缩机和冷凝器,电子三通阀A连通板换器,电子三通阀B直接连通入水口,冷却液从出水口经过电子三通阀A进入板换器,经过压缩机和冷凝器冷却后经电子三通阀B和入水口回到电池包;Refrigeration method: detect the battery temperature and ambient temperature, when the battery temperature > 30°C and the ambient temperature > 10°C, turn on the water pump, cooling fan, compressor and condenser, the electronic three-way valve A is connected to the plate changer, and the electronic three-way valve B is directly connected to the water inlet, and the coolant enters the plate changer from the water outlet through the electronic three-way valve A, and returns to the battery pack through the electronic three-way valve B and the water inlet after being cooled by the compressor and condenser;

风冷方法:检测电池温度和环境温度,当电池温度>30℃且环境温度<10℃时,开启水泵和冷却风扇,电子三通阀A连通散热器,电子三通阀B直接连通入水口,冷却液从出水口经过电子三通阀A进入散热器,冷却后经电子三通阀B和入水口回到电池包;Air cooling method: detect the battery temperature and ambient temperature, when the battery temperature is >30°C and the ambient temperature is <10°C, turn on the water pump and cooling fan, the electronic three-way valve A is connected to the radiator, and the electronic three-way valve B is directly connected to the water inlet. The coolant enters the radiator through the electronic three-way valve A from the water outlet, and returns to the battery pack through the electronic three-way valve B and the water inlet after cooling;

低温制热方法:检测电池温度和环境温度,当电池温度<0℃时,开启水泵、加热器和加热膜,电子三通阀A连通板换器,电子三通阀B连通加热器,冷却液从出水口经过电子三通阀A、板换器、电子三通阀B进入加热器,加热后经入水口流回电池包;Low-temperature heating method: detect the battery temperature and ambient temperature, when the battery temperature is <0°C, turn on the water pump, heater and heating film, the electronic three-way valve A is connected to the plate changer, the electronic three-way valve B is connected to the heater, and the coolant From the water outlet, it enters the heater through the electronic three-way valve A, the plate changer, and the electronic three-way valve B, and flows back to the battery pack through the water inlet after heating;

低温制冷方法:检测电池温度和环境温度,当电池温度>30℃且环境温度<-26℃时,开启水泵,电子三通阀A连通散热器,电子三通阀B直接连通入水口,冷却液从出水口经过电子三通阀A进入散热器,冷却后经电子三通阀B和入水口回到电池包;Low-temperature refrigeration method: detect the battery temperature and ambient temperature, when the battery temperature is >30°C and the ambient temperature is <-26°C, turn on the water pump, the electronic three-way valve A is connected to the radiator, the electronic three-way valve B is directly connected to the water inlet, and the cooling liquid Enter the radiator through the electronic three-way valve A from the water outlet, and return to the battery pack through the electronic three-way valve B and the water inlet after cooling;

自循环方法:检测电池温度,当电池温度处于15℃-30℃之间时,开启水泵,电子三通阀A连通板换器,电子三通阀B直接连通入水口,冷却液从出水口经过电子三通阀A进入板换器,后经电子三通阀B和入水口回到电池包;Self-circulation method: detect the battery temperature, when the battery temperature is between 15°C and 30°C, turn on the water pump, the electronic three-way valve A is connected to the plate changer, the electronic three-way valve B is directly connected to the water inlet, and the coolant passes through the water outlet The electronic three-way valve A enters the plate changer, and then returns to the battery pack through the electronic three-way valve B and the water inlet;

停机保温方法:检测环境温度,当环境温度<-35℃,通过加热膜保温,当环境温度<-40℃,通过加热器保温。Stop heat preservation method: detect the ambient temperature, when the ambient temperature is <-35°C, heat preservation through the heating film, and when the ambient temperature is <-40°C, heat preservation through the heater.

本发明的有益效果:1、电池散热模式根据环境温度和电池温度可以自动切换;2、可以实现在全温度范围内对电池的热管理;3、散热系统效率高且能耗低;4、热管理系统调节方便灵活,适用性强,可靠性高;5、水泵可以根据电池温度调节功率。Beneficial effects of the present invention: 1. The heat dissipation mode of the battery can be automatically switched according to the ambient temperature and the battery temperature; 2. The heat management of the battery can be realized in the whole temperature range; 3. The heat dissipation system has high efficiency and low energy consumption; 4. The management system is convenient and flexible to adjust, with strong applicability and high reliability; 5. The power of the water pump can be adjusted according to the temperature of the battery.

图1为本发明的一种纯电动矿用自卸车电池热量管理系统结构示意图;Fig. 1 is a schematic structural diagram of a battery heat management system of a pure electric mining dump truck of the present invention;

图2为本发明的热量管理系统制冷工况的示意图;Fig. 2 is a schematic diagram of the refrigeration working condition of the heat management system of the present invention;

图3为本发明的热量管理系统风冷工况和低温制冷工况的示意图;3 is a schematic diagram of the heat management system of the present invention in the air-cooled working condition and the low-temperature refrigeration working condition;

图4为本发明的热量管理系统低温制热工况的示意图;Fig. 4 is a schematic diagram of the low-temperature heating working condition of the heat management system of the present invention;

图5为本发明的热量管理系统自循环工况的示意图;Fig. 5 is a schematic diagram of the self-circulation working condition of the heat management system of the present invention;

图6为本发明的热量管理系统停机保温工况的示意图;Fig. 6 is a schematic diagram of the thermal management system of the present invention in a shutdown and heat preservation working condition;

图中,1、电子三通水阀A;2、压缩机;3、冷凝器;4、散热器;5、冷却风扇;6、板换器;7、膨胀阀;8、电子三通水阀B;9、水暖PTC加热器;10、膨胀水箱;11、水泵;12、入口温度传感器;13、电池包;14、出口温度传感器。In the figure, 1. Electronic three-way water valve A; 2. Compressor; 3. Condenser; 4. Radiator; 5. Cooling fan; 6. Plate changer; 7. Expansion valve; 8. Electronic three-way water valve B; 9. Water heating PTC heater; 10. Expansion tank; 11. Water pump; 12. Inlet temperature sensor; 13. Battery pack; 14. Outlet temperature sensor.

为了进一步说明本发明技术细节及其优点,现结合附图进行说明。In order to further illustrate the technical details and advantages of the present invention, it will now be described in conjunction with the accompanying drawings.

为了检测环境温度,本实施例中配备了环境温度传感器,为了实现自动切换工况功能,本实施例中配备了控制器,以上均为现有技术。In order to detect the ambient temperature, this embodiment is equipped with an ambient temperature sensor, and in order to realize the function of automatically switching working conditions, this embodiment is equipped with a controller, all of which are prior art.

如图1所示,一种工程车辆电池热量管理系统,包括电池包13,所述的电池包13设有入水口和出水口,所述的入水口连接水泵11,其特征在于:还包括电子三通阀A1、电子三通阀B8、散热器4、板换器6和加热器;所述的电子三通阀A的第一端连接出水口,第二端经散热器4连接电子三通阀B8的第一端,第三端经板换器6连接电子三通阀B8的第一端;所述的电子三通阀B8的第二端经加热器连接入水口,第三端直接连接入水口;所述的入水口连接入口温度传感器12和水泵11,所述的出水口连接出口温度传感器14。As shown in Figure 1, a heat management system for engineering vehicle batteries includes a

本实施例中,所述的板换器6连接压缩机2和冷凝器3,所述的散热器4和冷凝器3安装有冷却风扇5,所述的冷凝器3通过膨胀阀7与板换器连接;所述的电池包13内设有加热膜;所述的入水口连接膨胀水箱10;所述的加热器采用的是水暖PTC加热器9In this embodiment, the

一种工程车辆电池热量管理方法,包括以下方法:A heat management method for an engineering vehicle battery, comprising the following methods:

制冷方法:如图2所示,检测电池温度和环境温度,当电池温度>30℃且环境温度>10℃时,开启水泵11、冷却风扇5、压缩机2和冷凝器3,电子三通阀A1连通板换器6,电子三通阀B8直接连通入水口,冷却液从出水口经过电子三通阀A1进入板换器6,经过压缩机2和冷凝器3冷却后经电子三通阀B8和入水口回到电池包;Refrigeration method: As shown in Figure 2, detect the battery temperature and ambient temperature, when the battery temperature > 30°C and the ambient temperature > 10°C, turn on the

风冷方法:如图3所示,检测电池温度和环境温度,当电池温度>30℃且环境温度<10℃时,开启水泵11和冷却风扇5,电子三通阀A1连通散热器4,电子三通阀B8直接连通入水口,冷却液从出水口经过电子三通阀A1进入散热器4,冷却后经电子三通阀B8和入水口回到电池包;Air-cooling method: As shown in Figure 3, detect the battery temperature and ambient temperature. When the battery temperature is >30°C and the ambient temperature is <10°C, turn on the

低温制热方法:如图4所示,检测电池温度和环境温度,当电池温度<0℃时,开启水泵11、加热器和加热膜,电子三通阀A1连通板换器6,电子三通阀B8连通加热器,冷却液从出水口经过电子三通阀A1、板换器6、电子三通阀B8进入加热器,加热后经入水口流回电池包13;Low-temperature heating method: As shown in Figure 4, detect the battery temperature and ambient temperature, when the battery temperature is <0°C, turn on the

低温制冷方法:检测电池温度和环境温度,当电池温度>30℃且环境温度<-26℃时,开启水 泵11,电子三通阀A1连通散热器4,电子三通阀B8直接连通入水口,冷却液从出水口经过电子三通阀A1进入散热器4,冷却后经电子三通阀B8和入水口回到电池包;Low-temperature refrigeration method: detect the battery temperature and ambient temperature, when the battery temperature is >30°C and the ambient temperature is <-26°C, turn on the

自循环方法:如图5所示,检测电池温度,当电池温度处于15℃-30℃之间时,开启水泵11,电子三通阀A1连通板换器6,电子三通阀B8直接连通入水口,冷却液从出水口经过电子三通阀A1进入板换器6,后经电子三通阀B8和入水口回到电池包,平衡电池包内各电芯间的温差;Self-circulation method: As shown in Figure 5, the battery temperature is detected. When the battery temperature is between 15°C and 30°C, the

停机保温方法:如图6所示,检测环境温度,当环境温度<-35℃,通过加热膜保温,当环境温度<-40℃,通过加热器保温。Stop heat preservation method: As shown in Figure 6, check the ambient temperature. When the ambient temperature is <-35°C, use a heating film to keep warm. When the ambient temperature is <-40°C, use a heater to keep warm.

在以上方法中,水泵11的功率可以随着电池包13的温度进行调节,当电池包处于正常温度范围时,水泵11的功率降低,当电池包处于非正常温度范围时,水泵11的功率升高,加快冷却液循环,使电池包尽快回归正常温度。In the above method, the power of the

经过实践,本发明可根据环境温度和电池温度来控制不同散热方式。节约了能耗,降低了成本,提高了高压部件及整个系统可靠性。例如在春季、秋冬季节环境温度低时,电池降温无需采用压缩机制冷,降低了质量风险,系统功耗下降70%;在极寒天气-26℃以下,电池温度高时,也能对电池进行主动降温,实现全工况运行管理。Through practice, the present invention can control different heat dissipation modes according to ambient temperature and battery temperature. Energy consumption is saved, costs are reduced, and reliability of high-voltage components and the entire system is improved. For example, when the ambient temperature is low in spring, autumn and winter, there is no need to use a compressor to cool the battery, which reduces the quality risk and reduces the system power consumption by 70%. In extremely cold weather below -26°C, the battery can also be cooled when the battery temperature is high. Actively cool down to realize operation and management under all working conditions.

Claims (6)

Translated fromChineseApplications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110726225.5ACN113451674B (en) | 2021-06-29 | 2021-06-29 | Engineering vehicle battery heat management system and method |

| CN202110726225.5 | 2021-06-29 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2023274312A1true WO2023274312A1 (en) | 2023-01-05 |

Family

ID=77813924

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/CN2022/102460CeasedWO2023274312A1 (en) | 2021-06-29 | 2022-06-29 | Engineering vehicle battery heat management system and method |

Country Status (2)

| Country | Link |

|---|---|

| CN (1) | CN113451674B (en) |

| WO (1) | WO2023274312A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115863838A (en)* | 2023-01-12 | 2023-03-28 | 北京集度科技有限公司 | Thermal management system, battery device, vehicle, charging device, and thermal management system for charging |

| CN117525673A (en)* | 2023-11-15 | 2024-02-06 | 深圳市国威科创新能源科技有限公司 | Efficient thermal management method for battery pack of electric motorcycle |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113451674B (en)* | 2021-06-29 | 2023-03-24 | 徐州徐工矿业机械有限公司 | Engineering vehicle battery heat management system and method |

| CN114335807B (en)* | 2021-12-30 | 2024-05-28 | 中联重科股份有限公司 | Battery cooling system and control method for electric mining dump truck |

| CN115548526B (en)* | 2022-11-08 | 2024-01-30 | 楚能新能源股份有限公司 | Battery thermal management system and control method thereof |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101577353A (en)* | 2009-05-07 | 2009-11-11 | 联合汽车电子有限公司 | Automobile battery thermal management system and working method thereof |

| US9680190B1 (en)* | 2017-02-27 | 2017-06-13 | Bordrin Motor Corporation, Inc. | Intelligent multiple-loop electric vehicle cooling system |

| CN106898841A (en)* | 2017-03-07 | 2017-06-27 | 重庆长安汽车股份有限公司 | Hybrid power automobile battery bag heat management system |

| CN107394314A (en)* | 2017-09-04 | 2017-11-24 | 昆山天元昌电子有限公司 | A kind of electric automobile battery box based on liquid cooling loop and active heating |

| CN109398032A (en)* | 2018-12-01 | 2019-03-01 | 重庆精信汽车热能科技有限公司 | New-energy automobile High Efficiency Thermal management system |

| CN109532563A (en)* | 2018-09-21 | 2019-03-29 | 江苏敏安电动汽车有限公司 | A kind of electric car low-power consumption heat management system |

| CN109818104A (en)* | 2018-12-27 | 2019-05-28 | 苏州新同创汽车空调有限公司 | A kind of BTS battery constant temperature system |

| CN209766604U (en)* | 2019-06-14 | 2019-12-10 | 厦门金龙汽车空调有限公司 | Energy-saving type water-way reversible battery thermal management system |

| CN110712565A (en)* | 2019-10-23 | 2020-01-21 | 西安电子科技大学芜湖研究院 | Novel battery thermal management system and control method |

| CN113451674A (en)* | 2021-06-29 | 2021-09-28 | 徐州徐工矿业机械有限公司 | Engineering vehicle battery heat management system and method |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3012133B1 (en)* | 2014-10-21 | 2017-10-25 | Atieva, Inc. | Ev multi-mode thermal management system |

| CN205194808U (en)* | 2015-11-12 | 2016-04-27 | 东软集团股份有限公司 | Electric automobile power battery's thermal management system and electric automobile |

| CN205790275U (en)* | 2016-04-21 | 2016-12-07 | 东软集团股份有限公司 | A kind of battery heat removal system |

| CN106921003B (en)* | 2016-10-25 | 2019-09-06 | 蔚来汽车有限公司 | Intelligent control system and method for electric vehicle battery pack temperature |

| CN206574821U (en)* | 2017-03-14 | 2017-10-20 | 浙江经济职业技术学院 | A kind of accumulator of electric car heat management device |

| CN109103548A (en)* | 2018-08-27 | 2018-12-28 | 苏州索贝斯新能源科技有限公司 | A kind of temperature control system and control method of power battery |

| CN209487668U (en)* | 2019-02-22 | 2019-10-11 | 奇瑞汽车股份有限公司 | The battery cooling system of electric car |

| JP7094908B2 (en)* | 2019-02-25 | 2022-07-04 | 本田技研工業株式会社 | Battery heating device for hybrid vehicles |

| CN211062833U (en)* | 2019-11-13 | 2020-07-21 | 海马新能源汽车有限公司 | Cooling plate, cooling structure and battery pack device |

| CN110838608B (en)* | 2019-11-14 | 2023-03-31 | 中车大连机车研究所有限公司 | Liquid-cooled heat management device for power battery of hybrid power locomotive |

| CN111361391B (en)* | 2020-05-07 | 2024-03-22 | 南京清研海易新能源动力有限责任公司 | Heat management control method based on automobile integrated heat management unit |

| CN112310512B (en)* | 2020-11-04 | 2021-08-17 | 烟台创为新能源科技股份有限公司 | Method and system for intelligently adjusting temperature of battery |

| CN112484376B (en)* | 2020-11-27 | 2023-01-17 | 扬州兆邦能源科技有限公司 | Heat exchange unit of energy storage battery cabinet |

- 2021

- 2021-06-29CNCN202110726225.5Apatent/CN113451674B/enactiveActive

- 2022

- 2022-06-29WOPCT/CN2022/102460patent/WO2023274312A1/ennot_activeCeased

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101577353A (en)* | 2009-05-07 | 2009-11-11 | 联合汽车电子有限公司 | Automobile battery thermal management system and working method thereof |

| US9680190B1 (en)* | 2017-02-27 | 2017-06-13 | Bordrin Motor Corporation, Inc. | Intelligent multiple-loop electric vehicle cooling system |

| CN106898841A (en)* | 2017-03-07 | 2017-06-27 | 重庆长安汽车股份有限公司 | Hybrid power automobile battery bag heat management system |

| CN107394314A (en)* | 2017-09-04 | 2017-11-24 | 昆山天元昌电子有限公司 | A kind of electric automobile battery box based on liquid cooling loop and active heating |

| CN109532563A (en)* | 2018-09-21 | 2019-03-29 | 江苏敏安电动汽车有限公司 | A kind of electric car low-power consumption heat management system |

| CN109398032A (en)* | 2018-12-01 | 2019-03-01 | 重庆精信汽车热能科技有限公司 | New-energy automobile High Efficiency Thermal management system |

| CN109818104A (en)* | 2018-12-27 | 2019-05-28 | 苏州新同创汽车空调有限公司 | A kind of BTS battery constant temperature system |

| CN209766604U (en)* | 2019-06-14 | 2019-12-10 | 厦门金龙汽车空调有限公司 | Energy-saving type water-way reversible battery thermal management system |

| CN110712565A (en)* | 2019-10-23 | 2020-01-21 | 西安电子科技大学芜湖研究院 | Novel battery thermal management system and control method |

| CN113451674A (en)* | 2021-06-29 | 2021-09-28 | 徐州徐工矿业机械有限公司 | Engineering vehicle battery heat management system and method |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115863838A (en)* | 2023-01-12 | 2023-03-28 | 北京集度科技有限公司 | Thermal management system, battery device, vehicle, charging device, and thermal management system for charging |

| CN117525673A (en)* | 2023-11-15 | 2024-02-06 | 深圳市国威科创新能源科技有限公司 | Efficient thermal management method for battery pack of electric motorcycle |

Also Published As

| Publication number | Publication date |

|---|---|

| CN113451674A (en) | 2021-09-28 |

| CN113451674B (en) | 2023-03-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2023274312A1 (en) | Engineering vehicle battery heat management system and method | |

| CN202076386U (en) | Battery temperature management system and automobile | |

| CN115465089B (en) | Thermal management system control method for hybrid vehicle and hybrid vehicle | |

| CN107791783B (en) | A new energy electric vehicle thermal management system and thermal management method | |

| CN103625242A (en) | Thermal management system of electric automobile | |

| CN108172865B (en) | Thermal management system and method for vehicle fuel cell | |

| CN106099256A (en) | A kind of electric motor car energy storage type heat management system | |

| CN107719136A (en) | Pure electric vehicles cooling system and car | |

| CN115139737B (en) | Whole-vehicle thermal management system of electric vehicle and control method | |

| CN216659503U (en) | Vehicle thermal management system | |

| CN203386864U (en) | Built-in thermal management system of lithium battery pack | |

| CN219667920U (en) | Hybrid power heavy truck thermal management system | |

| CN115139858A (en) | Vehicle thermal management system and vehicle | |

| CN113665318A (en) | Control system and method for power battery of plug-in hybrid vehicle | |

| CN116572707A (en) | Mixed motor vehicle type thermal management system integrating multiple operation modes | |

| CN108183283B (en) | Cooling device for electric automobile battery and charging pile | |

| CN208889808U (en) | A kind of BMS heat management system | |

| CN110828937A (en) | Temperature control system and method for power storage battery device | |

| CN111391616B (en) | Air conditioning system | |

| CN116936996B (en) | Integrated heat management system based on motor electric control lithium battery and control method thereof | |

| CN220510102U (en) | Integrated heat management system based on electric control lithium battery of motor | |

| CN219406077U (en) | New energy automobile thermal management system and new energy heavy truck automobile | |

| CN110385963A (en) | A kind of electric automobile air-conditioning system and its control method | |

| CN115848227A (en) | Battery heat management system and method for engineering vehicle | |

| KR20200072599A (en) | Thermal management system for vehicle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application | Ref document number:22832124 Country of ref document:EP Kind code of ref document:A1 | |

| NENP | Non-entry into the national phase | Ref country code:DE | |

| 122 | Ep: pct application non-entry in european phase | Ref document number:22832124 Country of ref document:EP Kind code of ref document:A1 |