WO2021119981A1 - System used for providing mobile power - Google Patents

System used for providing mobile powerDownload PDFInfo

- Publication number

- WO2021119981A1 WO2021119981A1PCT/CN2019/125860CN2019125860WWO2021119981A1WO 2021119981 A1WO2021119981 A1WO 2021119981A1CN 2019125860 WCN2019125860 WCN 2019125860WWO 2021119981 A1WO2021119981 A1WO 2021119981A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- exhaust

- gas turbine

- vehicle

- providing mobile

- power generation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C6/00—Plural gas-turbine plants; Combinations of gas-turbine plants with other apparatus; Adaptations of gas-turbine plants for special use

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C7/00—Features, components parts, details or accessories, not provided for in, or of interest apart form groups F02C1/00 - F02C6/00; Air intakes for jet-propulsion plants

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C7/00—Features, components parts, details or accessories, not provided for in, or of interest apart form groups F02C1/00 - F02C6/00; Air intakes for jet-propulsion plants

- F02C7/32—Arrangement, mounting, or driving, of auxiliaries

Definitions

- the present inventionrelates to the field of fracturing technology, in particular to a system for providing mobile power.

- the electric drive fracturing complete set of equipmentwill effectively reduce the emission of environmental pollutants, greatly reduce the floor space, reduce noise and reduce operating and maintenance costs.

- the use of complete sets of electric drive fracturing equipment and the increasing power of electric drive fracturing equipmenthave put forward higher and higher requirements for the power supply at the job site.

- the wellsitecannot realize the power supply of fracturing equipment through the power grid.

- the fracturing operationhas the characteristics of short operation period, and the fracturing equipment needs to be moved between different wellsites.

- the components of the power supply systemhave different assembly methods, different vehicle configurations, and different installation methods.

- the installation time requiredis as long as one month and as short as half a month.

- a power supply system with a high level of integrationwill lead to overruns of transportation vehicles. Limited by road regulations and road carrying capacity, it is difficult or impossible to get on the road at all.

- the purpose of the present inventionovercomes the shortcomings of the prior art and provides a system for providing mobile power.

- the systemis divided into 3 transportation carriers, integrated with the equipment required for mobile power, and integrated on the gas turbine power generation transportation tool.

- Auxiliary systemssuch as lubricating oil system, fire-fighting system, fuel system, and power control system reduce the number of transport carriers of the system itself, save equipment costs, and reduce connection time, especially the connection time of electrical wiring.

- the exhaust system, the lifting mechanism, the up and down adjustment device and the parallelogram mechanismare integrated on the exhaust transportation tool, which can realize the side connection of the exhaust system and the gas turbine power generation transportation tool, and also realize the top connection, when it is the top connection When the lock mechanism is opened and closed, the exhaust system is separated from the exhaust vehicle.

- the exhaust systemcan be used as a part of the gas turbine power vehicle and move simultaneously with the gas turbine power vehicle.

- this integrated movementsaves the disassembly and reconnection of the exhaust system and the gas turbine engine, and also saves the moving cost and movement of the transportation carrier where the exhaust system is located. time.

- the air intake ventilation vehicleis connected to the direction of travel of the gas turbine power generation vehicle, so that the air intake ventilation vehicle can be transported separately as a whole or can be transported by the gas turbine power generation vehicle.

- the twoare flexible in use. It saves the connection time, especially when it is in the well site, it can realize the quick movement in place.

- the air intake system, the gas turbine engine and the generatorare arranged in the same axial direction to avoid unnecessary elbows, the intake pressure loss is small, and the flow direction is stable.

- the air intake ventilation transportation means and the gas turbine power generation transportation meansare integrated transportation, or the exhaust system and the gas turbine power generation transportation means are integrated transportation mode, when road transportation conditions permit, it is not limited to the wellsite.

- a system for providing mobile powerincluding gas turbine power generation vehicles, air intake ventilation vehicles and exhaust vehicles, the air intake ventilation vehicles in the gas turbine

- the power generation vehicleis docked in the traveling direction, and the exhaust vehicle is provided on one side of the gas turbine power generation vehicle.

- the exhaust vehicleincludes an exhaust system, and the exhaust system is connected to the side or top of the gas turbine power generation vehicle.

- the exhaust systemwhen the exhaust system is connected to the side of the gas turbine power generation vehicle, the exhaust system realizes the side docking through a lifting mechanism provided on the exhaust vehicle.

- the exhaust systemwhen the exhaust system is connected to the top of the gas turbine power generation vehicle, the exhaust system realizes the top docking through the lifting mechanism, the up and down adjustment device and the parallelogram mechanism provided on the exhaust vehicle.

- the exhaust systemis placed horizontally in the transportation state, and in the working state, the horizontal and vertical lifting is realized by the lifting mechanism.

- the exhaust systemincludes an exhaust muffler, an exhaust elbow, an exhaust reducing joint and an exhaust expansion joint, the exhaust muffler is connected to the exhaust elbow, and the exhaust elbow is connected to The exhaust reducing joint is hinged, and the exhaust reducing joint is connected with the exhaust expansion joint.

- the exhaust reducing joint and the exhaust expansion jointcan be rotated through the articulation to realize the exhaust changing

- the diameter jointis butted with the exhaust elbow.

- the exhaust systemwhen the exhaust system is connected to the top of the gas turbine power generation vehicle, the exhaust system and the exhaust vehicle are detachably connected.

- the exhaust systemwhen the exhaust system is connected to the top of the gas turbine power generation vehicle, the exhaust system can be detachably connected to the exhaust vehicle by being separated from the parallelogram mechanism.

- a locking mechanismis provided between the exhaust system and the parallelogram mechanism, and the separation of the exhaust system and the parallelogram mechanism is realized by opening and closing the locking mechanism.

- the up and down adjustment deviceincludes a first connecting plate, a first hydraulic cylinder and a second hydraulic cylinder, the first hydraulic cylinder is arranged between the first connecting plate and the lifting mechanism, and the first hydraulic cylinder is used for For the up and down adjustment of the first connecting plate, one end of the second hydraulic cylinder is connected with the first connecting plate, and the other end of the second hydraulic cylinder is connected with the parallelogram mechanism.

- the horizontal displacement of the exhaust systemis realized by the expansion and contraction of the second hydraulic cylinder.

- the parallelogram mechanismincludes supporting sides, the supporting sides are four, and the four supporting sides are hinged end to end to form a parallelogram.

- the gas turbine power generation vehicleprovides power to realize the transportation.

- the gas turbine power generation vehicleprovides power to realize the transportation.

- the gas turbine power generation vehicleincludes a gas turbine engine, a generator, an electric power control system, and a first transportation carrier.

- the gas turbine engine, the electric generator, and the electric power control systemare integrated on the first transportation carrier, and the gas turbine engine Connect with generator.

- the power control systemincludes a power unit and a control system, the power unit is used to output electricity from the generator, and the control system includes a gas turbine control unit and a generator control unit.

- the air intake ventilation transportation toolincludes an air intake system, a cabin ventilation cooling system and a second transportation carrier, the air intake system and the cabin ventilation cooling system are arranged on the second transportation carrier, and the air intake system It is connected with the air inlet of the gas turbine engine, and the air inlet system, the gas turbine engine and the generator are arranged in the same axial direction.

- the cabin ventilation cooling systemprovides clean air for cooling the gas turbine engine.

- the gas turbine power generation vehicleincludes an auxiliary system that provides services for the gas turbine engine and/or generator.

- the auxiliary systemincludes a lubricating oil system, a fire-fighting system, and a fuel system.

- the lubricating oil systemprovides lubrication for gas turbine engines and generators.

- the fire-fighting systemis used for fire protection of gas turbine power generation vehicles.

- the fuel systemis provided for gas turbine engines. fuel.

- the beneficial effect of the present inventionis to provide a system for providing mobile power.

- the systemis divided into 3 transportation carriers and integrates the equipment required for mobile power. It integrates auxiliary systems such as lubricating oil system, fire-fighting system and fuel system, as well as power control system, which reduces the number of transport carriers of the system itself, saves equipment costs, and reduces connection time, especially the connection time of electrical wiring.

- the exhaust system, the lifting mechanism, the up and down adjustment device and the parallelogram mechanismare integrated on the exhaust transportation tool, which can realize the side connection of the exhaust system and the gas turbine power generation transportation tool, and also realize the top connection, when it is the top connection When the lock mechanism is opened and closed, the exhaust system is separated from the exhaust vehicle.

- the exhaust systemcan be used as a part of the gas turbine power vehicle and move simultaneously with the gas turbine power vehicle.

- this integrated movementsaves the disassembly and reconnection of the exhaust system and the gas turbine engine, and also saves the moving cost and movement of the transportation carrier where the exhaust system is located. time.

- the air intake ventilation vehicleis connected to the direction of travel of the gas turbine power generation vehicle, so that the air intake ventilation vehicle can be transported separately as a whole, or can be transported by the gas turbine power generation vehicle to provide power.

- the twoare flexible in use. It saves connection time, especially in the well site, and can realize quick movement into place.

- the air intake system, the gas turbine engine and the generatorare arranged in the same axial direction to avoid unnecessary elbows, the intake pressure loss is small, and the flow direction is stable.

- the air intake ventilation transportation means and the gas turbine power generation transportation meansare transported together, or the exhaust system and the gas turbine power generation transportation means are transported together, when road transportation conditions permit, it is not limited to the wellsite.

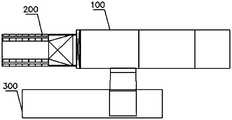

- Fig. 1is a schematic structural diagram of the exhaust side connection of the technical solution.

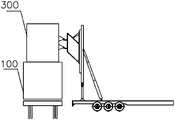

- Fig. 2is a schematic diagram of the structure of the exhaust top connection of the technical solution.

- Fig. 3is a schematic diagram of the structure of a gas turbine power generation vehicle.

- Figure 4is a schematic diagram of the structure of the air intake and ventilation vehicle.

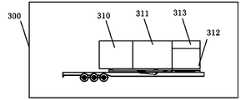

- Fig. 5is a schematic diagram of the structure of the side-connected exhaust vehicle in the transportation state.

- Fig. 6is a schematic structural diagram of a side-connected exhaust vehicle in working state.

- Fig. 7is a schematic diagram of the structure of the exhaust vehicle connected at the top in the transportation state.

- Fig. 8is a schematic diagram of the structure of the exhaust vehicle connected to the top in the working state.

- 100 gas turbine power generation vehicles200 air intake ventilation vehicles, 300 exhaust vehicles, 101 air inlets, 102 gas turbine engines, 103 generators, 104 power control systems, 201 air intake filter devices, and 202 air intakes Silencer, 203 ventilation filter device, 204 ventilation silencer, 205 ventilation fan, 301 exhaust system, 302 third hydraulic cylinder, 303 second connecting plate, 304 first connecting plate, 305 first hydraulic cylinder, 306 second hydraulic Cylinder, 307 parallelogram mechanism, 308 lock hook, 309 lock groove, 310 exhaust silencer, 311 exhaust elbow, 312 exhaust reducer, 313 exhaust expansion joint.

- a system for providing mobile powerincludes a gas turbine power generation vehicle 100, an intake ventilation vehicle 200, and an exhaust vehicle 300.

- the intake ventilation vehicle 200is installed in a gas turbine.

- the power generation vehicle 100is docked in the traveling direction, and the exhaust vehicle 300 is provided on one side of the gas turbine power generation vehicle 100.

- the exhaust vehicle 300includes an exhaust system 301, and the exhaust system 301 is connected to the side or top of the gas turbine power generation vehicle 100.

- the exhaust system 301When the exhaust system 301 is connected to the side of the gas turbine power generation vehicle 100, the exhaust system 301 realizes the side docking through a lifting mechanism provided on the exhaust vehicle 300. When the exhaust system 301 is connected to the top of the gas turbine power generation vehicle 100, the exhaust system 301 realizes the top docking through the lifting mechanism provided on the exhaust vehicle 300, the up-and-down adjustment device and the parallelogram mechanism 307. . Avoid hoisting, reduce the difficulty of operation, and improve the convenience of operation.

- the exhaust transportation tool 300also includes a third transportation carrier, an exhaust system 301, a lifting mechanism, an up and down adjustment device, and a parallelogram mechanism 307 are integrated on the third transportation carrier.

- the lifting mechanismincludes a third hydraulic cylinder 302 and a second connecting plate 303. One end of the third hydraulic cylinder 302 is connected to the second connecting plate 303, and the other end of the third hydraulic cylinder 302 is connected to a third transport carrier. The expansion and contraction of the third hydraulic cylinder 302 realizes the rotation of the second connecting plate 303 from horizontal to vertical.

- the exhaust system 301is placed horizontally in the transportation state, and in the working state, the horizontal and vertical lifting is realized by the lifting mechanism.

- the exhaust system 301includes an exhaust muffler 310, an exhaust elbow 311, an exhaust reducing joint 312 and an exhaust expansion joint 313.

- the exhaust muffler 310is connected to the exhaust elbow 311, and the exhaust muffler 310 is connected to the exhaust elbow 311.

- the air elbow 311is hinged to the exhaust reducing joint 312, and the exhaust reducing joint 312 is connected to the exhaust expansion joint 313. In the working state, the exhaust reducing joint 312 and the exhaust expansion joint 313 can be Through hinged rotation, the exhaust reducing joint 312 and the exhaust elbow 311 are connected to each other.

- the exhaust system 301When the exhaust system 301 is connected to the top of the gas turbine power generation vehicle 100, the exhaust system 301 and the exhaust vehicle 300 are detachably connected.

- the exhaust system 301When the exhaust system 301 is connected to the top of the gas turbine power generation vehicle 100, the exhaust system 301 is detachably connected to the exhaust vehicle 300 by being separated from the parallelogram mechanism 307.

- the separated exhaust system 301can be used as a part of the gas turbine power generation vehicle 100 and can be moved by the movement of the gas turbine power generation vehicle 100. Especially during short-distance movement in the well site, this integrated movement saves the disassembly and reconnection of the exhaust system 301 and the gas turbine engine 102, and also saves the moving cost and movement of the transportation carrier where the exhaust system 301 is located. time.

- a locking mechanismis provided between the exhaust system 301 and the parallelogram mechanism 307, and the separation of the exhaust system 301 and the parallelogram mechanism 307 is realized by opening and closing the locking mechanism.

- the locking mechanismis a lock groove 309 connected to the exhaust system 301 and a lock hook 308 connected to the parallelogram mechanism 307.

- the first connecting plate 304is adjusted to move downward through the expansion and contraction of the first hydraulic cylinder 305, The first connecting plate 304 drives the parallelogram mechanism 307 and the locking hook 308 to move downwards, thereby disengaging the locking hook 308 from the locking groove 309.

- the up and down adjustment deviceincludes a first connecting plate 304, a first hydraulic cylinder 305 and a second hydraulic cylinder 306, the first hydraulic cylinder 305 is arranged between the first connecting plate 304 and the second connecting plate 303 of the lifting mechanism ,

- the first hydraulic cylinder 305is used for up and down adjustment of the first connecting plate 304, one end of the second hydraulic cylinder 306 is connected to the first connecting plate 304, and the other end of the second hydraulic cylinder 306 is connected to the parallelogram mechanism 307 through

- the expansion and contraction of the second hydraulic cylinder 306realizes the horizontal displacement of the exhaust system 301.

- the parallelogram mechanism 307includes supporting sides, the supporting sides are four, and the four supporting sides are hinged end to end to form a parallelogram.

- One end of the second hydraulic cylinder 306is connected to one of the supporting edges, and the extension of the second hydraulic cylinder 306 pushes the parallelogram to deform in the positive or longitudinal direction, that is, the exhaust system 301 is pushed out in the horizontal direction.

- the air intake ventilation vehicle 200is transported separately as a whole or after being docked with the gas turbine power generation transportation tool 100, and then the gas turbine power generation transportation tool 100 provides power for transportation. It is suitable for different road conditions, the combination is more flexible and the application is wider.

- the gas turbine power generation vehicle 100After the air intake ventilation vehicle 200 is transported as a whole or is docked with the gas turbine power generation vehicle 100, the gas turbine power generation vehicle 100 provides power for transportation.

- the gas turbine power generation vehicle 100includes a gas turbine engine 102, a generator 103, a power control system 104, and a first transportation carrier.

- the gas turbine engine 102, the generator 103, and the power control system 104are integrated on the first transportation carrier.

- the gas turbine engine 102is connected to the generator 103. Avoid on-site PTO shaft alignment, which greatly reduces the accuracy and difficulty of on-site assembly and shortens the assembly time.

- the power control system 104includes a power unit and a control system.

- the power unitis used to output electricity from the generator 103 to the outside.

- the control systemincludes a gas turbine control unit and a generator 103 control unit.

- the integrated power control system 104reduces the workload of on-site cable connection and prolongs the service life of electrical components.

- the air intake ventilation transportation tool 200includes an air intake system, a cabin ventilation cooling system, and a second transportation carrier.

- the air intake system and the cabin ventilation cooling systemare arranged on the second transportation carrier.

- the intake port 101 of the turbine engine 102is connected.

- the gas turbine engine 102 and the generator 103are arranged in the same axial direction to avoid unnecessary elbows, the intake pressure loss is small, and the flow direction is stable.

- the intake systemincludes an intake filter 201 and an intake silencer 202 to provide the gas turbine engine 102 with clean air required for combustion.

- the air intake filter device 201cleans the air according to the accuracy required by the gas turbine engine 102; the air intake silencer device 202 reduces the noise generated during the intake process to a level that meets the requirements of the local environment.

- the cabin ventilation and cooling systemis connected to the cabin outside the gas turbine power generation transportation tool 100 through a flexible ventilation pipe, and provides clean air for cooling the gas turbine engine 102.

- the cabin ventilation cooling systemincludes a ventilation filter device 203, a ventilation silencer device 204 and a ventilation fan 205.

- the gas turbine power generation vehicle 100includes an auxiliary system, and the auxiliary system provides services for the gas turbine engine 102 and/or the generator 103.

- the auxiliary systemincludes a lubricating oil system, a fire fighting system and a fuel system.

- the lubricating oil systemprovides lubrication for the gas turbine engine 102 and the generator 103.

- the fire fighting systemis used for the fire fighting of the gas turbine power generation vehicle 100, and the fuel system is the gas turbine engine 102.

- Provide fuelThe lubricating oil system, the fire fighting system and the fuel system are integrated on the gas turbine power generation vehicle 100 to reduce the number of vehicles.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Engine Equipment That Uses Special Cycles (AREA)

Abstract

Description

Translated fromChinese本发明涉及压裂技术领域,具体涉及一种用于提供移动电力的系统。The present invention relates to the field of fracturing technology, in particular to a system for providing mobile power.

油气工业通常使用水力压裂来促进烃类井(比如油井或气井)的生产。传统压裂设备通常具有占地面积大、环境污染严重等问题,难以满足当前严峻的环境要求及井场作业占地面积要求。The oil and gas industry often uses hydraulic fracturing to promote the production of hydrocarbon wells (such as oil or gas wells). Traditional fracturing equipment usually has problems such as large floor area and serious environmental pollution, and it is difficult to meet the current severe environmental requirements and floor area requirements for wellsite operations.

电驱压裂成套设备将有效减少环境污染物的排放,大幅减少占地面积,降低噪声并降低作业和维护成本。成套电驱压裂设备的使用以及电驱压裂设备功率的不断增大,对作业现场的电力供应提出越来越高的要求。通常井场无法通过电网实现压裂设备的供电。而且压裂作业具有作业周期较短的特点,压裂设备需要在不同井场间进行移动。通常情况下,供电系统各部件之间因为组装方式不同,车载构成不同,安装方式不同,所需的安装时间长则1个月,短则半个月。而集成度太高的供电系统,又会导致运输工具的超限,受道路法规和道路承载力的限制,很难上路或根本无法上路。The electric drive fracturing complete set of equipment will effectively reduce the emission of environmental pollutants, greatly reduce the floor space, reduce noise and reduce operating and maintenance costs. The use of complete sets of electric drive fracturing equipment and the increasing power of electric drive fracturing equipment have put forward higher and higher requirements for the power supply at the job site. Usually, the wellsite cannot realize the power supply of fracturing equipment through the power grid. Moreover, the fracturing operation has the characteristics of short operation period, and the fracturing equipment needs to be moved between different wellsites. Under normal circumstances, the components of the power supply system have different assembly methods, different vehicle configurations, and different installation methods. The installation time required is as long as one month and as short as half a month. A power supply system with a high level of integration will lead to overruns of transportation vehicles. Limited by road regulations and road carrying capacity, it is difficult or impossible to get on the road at all.

如何为电驱压裂作业现场提供安装时间短,安装便捷、组合灵活、可移动式的电力供应成为当今电驱压裂作业面临的一大挑战。How to provide a short installation time, convenient installation, flexible combination, and portable power supply for the electric drive fracturing operation site has become a major challenge for today's electric drive fracturing operation.

发明内容Summary of the invention

本发明的目的克服现有技术的不足,提供一种用于提供移动电力的系统,所述系统分为3个运输载体,集成了移动电力所需的设备,在燃气涡轮发电运输工具上集成了润滑油系统,消防系统和燃料系统等辅助系统以及电 力控制系统,减少了系统本身的运输载体数量,也节约了设备成本,缩减了连接时间,尤其是电气接线的连接时间。在排气运输工具上集成了排气系统,举升机构,上下调节装置和平行四边形机构,即可实现排气系统与燃气涡轮发电运输工具的侧面连接,也可实现顶部连接,当为顶部连接时,通过锁止机构的开合,实现排气系统与排气运输工具的分离,即此种状态下,排气系统可作为燃气涡轮发电运输工具上的一部分,与燃气涡轮发电运输工具同时移动,尤其是井场内短距离的移动等情况时,这种一体式的移动节约了排气系统与燃气涡轮发动机的拆卸与重新连接,还节约了排气系统所在的运输载体的移动成本和移动时间。通过进气通风运输工具连接在燃气涡轮发电运输工具的行进方向上,使得进气通风运输工具既可以作为一个整体单独运输,也可以通过燃气涡轮发电运输工具提供动力实现运输,两者使用灵活,省去连接时间,尤其是在井场时,能实现快速移动到位。同时进气系统,燃气涡轮发动机和发电机同一轴向设置,避免不必要的弯头,进气压力损失小,流向稳定。当然进气通风运输工具与燃气涡轮发电运输工具一体运输,或/和排气系统与燃气涡轮发电运输工具一体运输的方式,在道路运输条件允许的情况下也是可以的,不局限于井场。The purpose of the present invention overcomes the shortcomings of the prior art and provides a system for providing mobile power. The system is divided into 3 transportation carriers, integrated with the equipment required for mobile power, and integrated on the gas turbine power generation transportation tool. Auxiliary systems such as lubricating oil system, fire-fighting system, fuel system, and power control system reduce the number of transport carriers of the system itself, save equipment costs, and reduce connection time, especially the connection time of electrical wiring. The exhaust system, the lifting mechanism, the up and down adjustment device and the parallelogram mechanism are integrated on the exhaust transportation tool, which can realize the side connection of the exhaust system and the gas turbine power generation transportation tool, and also realize the top connection, when it is the top connection When the lock mechanism is opened and closed, the exhaust system is separated from the exhaust vehicle. That is, in this state, the exhaust system can be used as a part of the gas turbine power vehicle and move simultaneously with the gas turbine power vehicle. Especially in the case of short-distance movement in the well site, this integrated movement saves the disassembly and reconnection of the exhaust system and the gas turbine engine, and also saves the moving cost and movement of the transportation carrier where the exhaust system is located. time. The air intake ventilation vehicle is connected to the direction of travel of the gas turbine power generation vehicle, so that the air intake ventilation vehicle can be transported separately as a whole or can be transported by the gas turbine power generation vehicle. The two are flexible in use. It saves the connection time, especially when it is in the well site, it can realize the quick movement in place. At the same time, the air intake system, the gas turbine engine and the generator are arranged in the same axial direction to avoid unnecessary elbows, the intake pressure loss is small, and the flow direction is stable. Of course, the air intake ventilation transportation means and the gas turbine power generation transportation means are integrated transportation, or the exhaust system and the gas turbine power generation transportation means are integrated transportation mode, when road transportation conditions permit, it is not limited to the wellsite.

本发明的目的是通过以下技术措施达到的:一种用于提供移动电力的系统,包括燃气涡轮发电运输工具,进气通风运输工具和排气运输工具,所述进气通风运输工具在燃气涡轮发电运输工具的行进方向上对接,所述排气运输工具设在燃气涡轮发电运输工具的一侧。The purpose of the present invention is achieved through the following technical measures: a system for providing mobile power, including gas turbine power generation vehicles, air intake ventilation vehicles and exhaust vehicles, the air intake ventilation vehicles in the gas turbine The power generation vehicle is docked in the traveling direction, and the exhaust vehicle is provided on one side of the gas turbine power generation vehicle.

进一步地,所述排气运输工具包括排气系统,所述排气系统与燃气涡轮发电运输工具侧面连接或顶部连接。Further, the exhaust vehicle includes an exhaust system, and the exhaust system is connected to the side or top of the gas turbine power generation vehicle.

进一步地,当所述排气系统与燃气涡轮发电运输工具侧面连接时,所述排气系统通过设在排气运输工具上的举升机构实现侧面的对接。Further, when the exhaust system is connected to the side of the gas turbine power generation vehicle, the exhaust system realizes the side docking through a lifting mechanism provided on the exhaust vehicle.

进一步地,所述排气系统与燃气涡轮发电运输工具顶部连接时,所述排气系统通过设在排气运输工具上的举升机构,上下调节装置和平行四边形机构共同作用实现顶部对接。Further, when the exhaust system is connected to the top of the gas turbine power generation vehicle, the exhaust system realizes the top docking through the lifting mechanism, the up and down adjustment device and the parallelogram mechanism provided on the exhaust vehicle.

进一步地,所述排气系统在运输状态为水平放置,在工作状态,通过举升机构实现水平向竖直的举升。Further, the exhaust system is placed horizontally in the transportation state, and in the working state, the horizontal and vertical lifting is realized by the lifting mechanism.

进一步地,所述排气系统包括排气消音器,排气弯头,排气变径接头和排气膨胀节,所述排气消音器和排气弯头连接,所述排气弯头与所述排气变径接头铰接,所述排气变径接头和排气膨胀节连接,工作状态时,所述排气变径接头和排气膨胀节可通过铰接旋转,实现所述排气变径接头与所述排气弯头对接。Further, the exhaust system includes an exhaust muffler, an exhaust elbow, an exhaust reducing joint and an exhaust expansion joint, the exhaust muffler is connected to the exhaust elbow, and the exhaust elbow is connected to The exhaust reducing joint is hinged, and the exhaust reducing joint is connected with the exhaust expansion joint. In the working state, the exhaust reducing joint and the exhaust expansion joint can be rotated through the articulation to realize the exhaust changing The diameter joint is butted with the exhaust elbow.

进一步地,所述排气系统与燃气涡轮发电运输工具顶部连接时,所述排气系统与所述排气运输工具可分离式连接。Further, when the exhaust system is connected to the top of the gas turbine power generation vehicle, the exhaust system and the exhaust vehicle are detachably connected.

进一步地,所述排气系统与燃气涡轮发电运输工具顶部连接时,所述排气系统通过与平行四边形机构的分离,实现与所述排气运输工具可分离式连接。Further, when the exhaust system is connected to the top of the gas turbine power generation vehicle, the exhaust system can be detachably connected to the exhaust vehicle by being separated from the parallelogram mechanism.

进一步地,所述排气系统与平行四边形机构之间设锁止机构,通过锁止机构的开合实现所述排气系统与平行四边形机构的分离。Further, a locking mechanism is provided between the exhaust system and the parallelogram mechanism, and the separation of the exhaust system and the parallelogram mechanism is realized by opening and closing the locking mechanism.

进一步地,所述上下调节装置包括第一连接板,第一液压缸和第二液压缸,所述第一液压缸设在第一连接板与举升机构之间,所述第一液压缸用于第一连接板的上下调节,第二液压缸的一端与第一连接板连接,第二液压缸 的另一端与平行四边形机构连接,通过第二液压缸的伸缩实现排气系统的水平位移。Further, the up and down adjustment device includes a first connecting plate, a first hydraulic cylinder and a second hydraulic cylinder, the first hydraulic cylinder is arranged between the first connecting plate and the lifting mechanism, and the first hydraulic cylinder is used for For the up and down adjustment of the first connecting plate, one end of the second hydraulic cylinder is connected with the first connecting plate, and the other end of the second hydraulic cylinder is connected with the parallelogram mechanism. The horizontal displacement of the exhaust system is realized by the expansion and contraction of the second hydraulic cylinder.

进一步地,所述平行四边形机构包括支撑边,所述支撑边为四条,四条支撑边通过首尾铰接形成平行四边形。Further, the parallelogram mechanism includes supporting sides, the supporting sides are four, and the four supporting sides are hinged end to end to form a parallelogram.

进一步地,所述进气通风运输工具作为一个整体单独运输或与燃气涡轮发电运输工具对接后,通过燃气涡轮发电运输工具提供动力实现运输。Further, after the air intake ventilation vehicle is transported separately as a whole or is docked with the gas turbine power generation vehicle, the gas turbine power generation vehicle provides power to realize the transportation.

进一步地,所述进气通风运输工具作为一个整体单独运输或与燃气涡轮发电运输工具对接后,通过燃气涡轮发电运输工具提供动力实现运输。Further, after the air intake ventilation vehicle is transported separately as a whole or is docked with the gas turbine power generation vehicle, the gas turbine power generation vehicle provides power to realize the transportation.

进一步地,所述燃气涡轮发电运输工具包括燃气涡轮发动机,发电机,电力控制系统和第一运输载体,所述燃气涡轮发动机,发电机和电力控制系统集成在第一运输载体上,燃气涡轮发动机与发电机连接。Further, the gas turbine power generation vehicle includes a gas turbine engine, a generator, an electric power control system, and a first transportation carrier. The gas turbine engine, the electric generator, and the electric power control system are integrated on the first transportation carrier, and the gas turbine engine Connect with generator.

进一步地,所述电力控制系统包括电力单元和控制系统,所述电力单元用于将发电机的电对外输出,所述控制系统包括燃气涡轮控制单元和发电机控制单元。Further, the power control system includes a power unit and a control system, the power unit is used to output electricity from the generator, and the control system includes a gas turbine control unit and a generator control unit.

进一步地,所述进气通风运输工具包括进气系统,舱体通风冷却系统和第二运输载体,所述进气系统和舱体通风冷却系统设在第二运输载体上,所述进气系统与燃气涡轮发动机的进气口连接,所述进气系统,燃气涡轮发动机和发电机为同一轴向设置。Further, the air intake ventilation transportation tool includes an air intake system, a cabin ventilation cooling system and a second transportation carrier, the air intake system and the cabin ventilation cooling system are arranged on the second transportation carrier, and the air intake system It is connected with the air inlet of the gas turbine engine, and the air inlet system, the gas turbine engine and the generator are arranged in the same axial direction.

进一步地,所述舱体通风冷却系统为燃气涡轮发动机提供冷却用清洁空气。Further, the cabin ventilation cooling system provides clean air for cooling the gas turbine engine.

进一步地,所述燃气涡轮发电运输工具包括辅助系统,所述辅助系统为燃气涡轮发动机和/或发电机提供服务。Further, the gas turbine power generation vehicle includes an auxiliary system that provides services for the gas turbine engine and/or generator.

进一步地,所述辅助系统包括润滑油系统,消防系统和燃料系统,润滑油系统为燃气涡轮发动机和发电机提供润滑,消防系统用于燃气涡轮发电运输工具的消防,燃料系统为燃气涡轮发动机提供燃料。Further, the auxiliary system includes a lubricating oil system, a fire-fighting system, and a fuel system. The lubricating oil system provides lubrication for gas turbine engines and generators. The fire-fighting system is used for fire protection of gas turbine power generation vehicles. The fuel system is provided for gas turbine engines. fuel.

与现有技术相比,本发明的有益效果是:提供一种用于提供移动电力的系统,所述系统分为3个运输载体,集成了移动电力所需的设备,在燃气涡轮发电运输工具上集成了润滑油系统,消防系统和燃料系统等辅助系统以及电力控制系统,减少了系统本身的运输载体数量,也节约了设备成本,缩减了连接时间,尤其是电气接线的连接时间。在排气运输工具上集成了排气系统,举升机构,上下调节装置和平行四边形机构,即可实现排气系统与燃气涡轮发电运输工具的侧面连接,也可实现顶部连接,当为顶部连接时,通过锁止机构的开合,实现排气系统与排气运输工具的分离,即此种状态下,排气系统可作为燃气涡轮发电运输工具上的一部分,与燃气涡轮发电运输工具同时移动,尤其是井场内短距离的移动等情况时,这种一体式的移动节约了排气系统与燃气涡轮发动机的拆卸与重新连接,还节约了排气系统所在的运输载体的移动成本和移动时间。通过进气通风运输工具连接在燃气涡轮发电运输工具的行进方向上,使得进气通风运输工具既可以作为一个整体单独运输,也可以通过燃气涡轮发电运输工具提供动力实现运输,两者使用灵活,省去连接时间,尤其是在井场时,能实现快速移动到位。同时进气系统,燃气涡轮发动机和发电机同一轴向设置,避免不必要的弯头,进气压力损失小,流向稳定。当然进气通风运输工具与燃气涡轮发电运输工具一体运输,或/和排气系统与燃气涡轮发电运输工具一体运输的方式,在道路运输条件允许的情况下也是可以的,不局限于井场。Compared with the prior art, the beneficial effect of the present invention is to provide a system for providing mobile power. The system is divided into 3 transportation carriers and integrates the equipment required for mobile power. It integrates auxiliary systems such as lubricating oil system, fire-fighting system and fuel system, as well as power control system, which reduces the number of transport carriers of the system itself, saves equipment costs, and reduces connection time, especially the connection time of electrical wiring. The exhaust system, the lifting mechanism, the up and down adjustment device and the parallelogram mechanism are integrated on the exhaust transportation tool, which can realize the side connection of the exhaust system and the gas turbine power generation transportation tool, and also realize the top connection, when it is the top connection When the lock mechanism is opened and closed, the exhaust system is separated from the exhaust vehicle. That is, in this state, the exhaust system can be used as a part of the gas turbine power vehicle and move simultaneously with the gas turbine power vehicle. Especially in the case of short-distance movement in the well site, this integrated movement saves the disassembly and reconnection of the exhaust system and the gas turbine engine, and also saves the moving cost and movement of the transportation carrier where the exhaust system is located. time. The air intake ventilation vehicle is connected to the direction of travel of the gas turbine power generation vehicle, so that the air intake ventilation vehicle can be transported separately as a whole, or can be transported by the gas turbine power generation vehicle to provide power. The two are flexible in use. It saves connection time, especially in the well site, and can realize quick movement into place. At the same time, the air intake system, the gas turbine engine and the generator are arranged in the same axial direction to avoid unnecessary elbows, the intake pressure loss is small, and the flow direction is stable. Of course, the air intake ventilation transportation means and the gas turbine power generation transportation means are transported together, or the exhaust system and the gas turbine power generation transportation means are transported together, when road transportation conditions permit, it is not limited to the wellsite.

下面结合附图和具体实施方式对本发明作详细说明。The present invention will be described in detail below with reference to the drawings and specific embodiments.

图1是本技术方案排气侧面连接的结构示意图。Fig. 1 is a schematic structural diagram of the exhaust side connection of the technical solution.

图2是本技术方案排气顶部连接的结构示意图。Fig. 2 is a schematic diagram of the structure of the exhaust top connection of the technical solution.

图3是燃气涡轮发电运输工具的结构示意图。Fig. 3 is a schematic diagram of the structure of a gas turbine power generation vehicle.

图4是进气通风运输工具的结构示意图。Figure 4 is a schematic diagram of the structure of the air intake and ventilation vehicle.

图5是运输状态时侧面连接的排气运输工具的结构示意图。Fig. 5 is a schematic diagram of the structure of the side-connected exhaust vehicle in the transportation state.

图6是工作状态时侧面连接的排气运输工具的结构示意图。Fig. 6 is a schematic structural diagram of a side-connected exhaust vehicle in working state.

图7是运输状态时顶部连接的排气运输工具的结构示意图。Fig. 7 is a schematic diagram of the structure of the exhaust vehicle connected at the top in the transportation state.

图8是工作状态时顶部连接的排气运输工具的结构示意图。Fig. 8 is a schematic diagram of the structure of the exhaust vehicle connected to the top in the working state.

其中,100燃气涡轮发电运输工具,200进气通风运输工具,300排气运输工具,101进气口,102燃气涡轮发动机,103发电机,104电力控制系统,201进气过滤装置,202进气消音装置,203通风过滤装置,204通风消音装置,205通风风机,301排气系统,302第三液压缸,303第二连接板,304第一连接板,305第一液压缸,306第二液压缸,307平行四边形机构,308锁钩,309锁槽,310排气消音器,311排气弯头,312排气变径接头,313排气膨胀节。Among them, 100 gas turbine power generation vehicles, 200 air intake ventilation vehicles, 300 exhaust vehicles, 101 air inlets, 102 gas turbine engines, 103 generators, 104 power control systems, 201 air intake filter devices, and 202 air intakes Silencer, 203 ventilation filter device, 204 ventilation silencer, 205 ventilation fan, 301 exhaust system, 302 third hydraulic cylinder, 303 second connecting plate, 304 first connecting plate, 305 first hydraulic cylinder, 306 second hydraulic Cylinder, 307 parallelogram mechanism, 308 lock hook, 309 lock groove, 310 exhaust silencer, 311 exhaust elbow, 312 exhaust reducer, 313 exhaust expansion joint.

如图1至8所示,一种用于提供移动电力的系统,包括燃气涡轮发电运输工具100,进气通风运输工具200和排气运输工具300,所述进气通风运输工具200在燃气涡轮发电运输工具100的行进方向上对接,所述排气运输工具300设在燃气涡轮发电运输工具100的一侧。As shown in Figures 1 to 8, a system for providing mobile power includes a gas turbine

所述排气运输工具300包括排气系统301,所述排气系统301与燃气涡轮发电运输工具100侧面连接或顶部连接。The

当所述排气系统301与燃气涡轮发电运输工具100侧面连接时,所述排气系统301通过设在排气运输工具300上的举升机构实现侧面的对接。所述排气系统301与燃气涡轮发电运输工具100顶部连接时,所述排气系统301通过设在排气运输工具300上的举升机构,上下调节装置和平行四边形机构307共同作用实现顶部对接。避免吊装,降低作业难度,提高操作便利性。When the

所述排气运输工具300还包括第三运输载体,排气系统301,举升机构,上下调节装置和平行四边形机构307集成在第三运输载体上。举升机构,包括第三液压缸302和第二连接板303,第三液压缸302的一端与第二连接板303连接,第三液压缸302的另一端与第三运输载体连接。通过第三液压缸302的伸缩实现第二连接板303由水平向竖直的转动。The

所述排气系统301在运输状态为水平放置,在工作状态,通过举升机构实现水平向竖直的举升。The

所述排气系统301包括排气消音器310,排气弯头311,排气变径接头312和排气膨胀节313,所述排气消音器310和排气弯头311连接,所述排气弯头311与所述排气变径接头312铰接,所述排气变径接头312和排气膨胀节313连接,工作状态时,所述排气变径接头312和排气膨胀节313可通过铰接旋转,实现所述排气变径接头312与所述排气弯头311对接。The

所述排气系统301与燃气涡轮发电运输工具100顶部连接时,所述排气系统301与所述排气运输工具300可分离式连接。When the

所述排气系统301与燃气涡轮发电运输工具100顶部连接时,所述排气 系统301通过与平行四边形机构307的分离,实现与所述排气运输工具300可分离式连接。分离之后的排气系统301可作为燃气涡轮发电运输工具100的一部分,通过燃气涡轮发电运输工具100的移动而移动。尤其是井场内短距离的移动时,这种一体式的移动节约了排气系统301与燃气涡轮发动机102的拆卸与重新连接,还节约了排气系统301所在的运输载体的移动成本和移动时间。When the

所述排气系统301与平行四边形机构307之间设锁止机构,通过锁止机构的开合实现所述排气系统301与平行四边形机构307的分离。锁止机构为与排气系统301连接的锁槽309和与平行四边形机构307连接的锁钩308,当需要分离时,通过第一液压缸305的伸缩,调节第一连接板304向下运动,第一连接板304带动平行四边形机构307和锁钩308向下运动,从而将锁钩308从锁槽309中脱离。A locking mechanism is provided between the

所述上下调节装置包括第一连接板304,第一液压缸305和第二液压缸306,所述第一液压缸305设在第一连接板304与举升机构的第二连接板303之间,所述第一液压缸305用于第一连接板304的上下调节,第二液压缸306的一端与第一连接板304连接,第二液压缸306的另一端与平行四边形机构307连接,通过第二液压缸306的伸缩实现排气系统301的水平位移。The up and down adjustment device includes a first connecting

所述平行四边形机构307包括支撑边,所述支撑边为四条,四条支撑边通过首尾铰接形成平行四边形。第二液压缸306的一端与其中一条支撑边连接,通过第二液压缸306的伸出,推动平行四边形向正方向或长方向变形,即排气系统301在水平方向上被推出。The

所述进气通风运输工具200作为一个整体单独运输或与燃气涡轮发电运 输工具100对接后,通过燃气涡轮发电运输工具100提供动力实现运输。适用于不同的道路情况,组合更灵活,应用更广泛。The air

所述进气通风运输工具200作为一个整体单独运输或与燃气涡轮发电运输工具100对接后,通过燃气涡轮发电运输工具100提供动力实现运输。After the air

所述燃气涡轮发电运输工具100包括燃气涡轮发动机102,发电机103,电力控制系统104和第一运输载体,所述燃气涡轮发动机102,发电机103和电力控制系统104集成在第一运输载体上,燃气涡轮发动机102与发电机103连接。避免现场进行动力输出轴系校中,极大降低现场装配的精度与难度,缩短装配时间。所述电力控制系统104包括电力单元和控制系统,所述电力单元用于将发电机103的电对外输出,所述控制系统包括燃气涡轮控制单元和发电机103控制单元。集成电力控制系统104,减少现场电缆连接工作量,同时延长电气元件的使用寿命。The gas turbine

所述进气通风运输工具200包括进气系统,舱体通风冷却系统和第二运输载体,所述进气系统和舱体通风冷却系统设在第二运输载体上,所述进气系统与燃气涡轮发动机102的进气口101连接,所述进气系统,燃气涡轮发动机102和发电机103为同一轴向设置,避免不必要的弯头,进气压力损失小,流向稳定。The air intake

进气系统包括进气过滤装置201和进气消音装置202,为燃气涡轮发动机102提供燃烧所需的洁净空气。进气过滤装置201按照燃气涡轮发动机102需要的精度对空气进行洁净;进气消音装置202把进气过程中产生的噪音降低到满足当地环境要求的水平。The intake system includes an

所述舱体通风冷却系统通过柔性通风管道连接到燃气涡轮发电运输工 具100外设的舱体上,为燃气涡轮发动机102提供冷却用清洁空气。舱体通风冷却系统包括通风过滤装置203,通风消音装置204和通风风机205。The cabin ventilation and cooling system is connected to the cabin outside the gas turbine power

所述燃气涡轮发电运输工具100包括辅助系统,所述辅助系统为燃气涡轮发动机102和/或发电机103提供服务。所述辅助系统包括润滑油系统,消防系统和燃料系统,润滑油系统为燃气涡轮发动机102和发电机103提供润滑,消防系统用于燃气涡轮发电运输工具100的消防,燃料系统为燃气涡轮发动机102提供燃料。将润滑油系统,消防系统和燃料系统集成在燃气涡轮发电运输工具100上,减少运输工具数量。The gas turbine

本行业的技术人员应该了解,本发明不受上述实施例的限制,上述实施例和说明书中描述的只是说明本发明的原理,在不脱离本发明精神和范围的前提下,本发明还会有各种变化和改进,这些变化和改进都落入要求保护的本发明范围内。本发明要求保护范围由所附的权利要求书及其等效物界定。Those skilled in the industry should understand that the present invention is not limited by the above-mentioned embodiments. The above-mentioned embodiments and descriptions only illustrate the principles of the present invention. Without departing from the spirit and scope of the present invention, the present invention may have Various changes and improvements, these changes and improvements all fall within the scope of the claimed invention. The scope of protection claimed by the present invention is defined by the appended claims and their equivalents.

Claims (18)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/CN2019/125860WO2021119981A1 (en) | 2019-12-17 | 2019-12-17 | System used for providing mobile power |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/CN2019/125860WO2021119981A1 (en) | 2019-12-17 | 2019-12-17 | System used for providing mobile power |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2021119981A1true WO2021119981A1 (en) | 2021-06-24 |

Family

ID=76478368

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/CN2019/125860CeasedWO2021119981A1 (en) | 2019-12-17 | 2019-12-17 | System used for providing mobile power |

Country Status (1)

| Country | Link |

|---|---|

| WO (1) | WO2021119981A1 (en) |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN201608528U (en)* | 2010-02-05 | 2010-10-13 | 河北天择重型机械有限公司 | Container type diesel power mobile supply station system |

| US20190203572A1 (en)* | 2014-12-19 | 2019-07-04 | Typhon Technology Solutions, Llc | Mobile fracturing pump transport for hydraulic fracturing of subsurface geological formations |

| CN110159433A (en)* | 2019-06-25 | 2019-08-23 | 烟台杰瑞石油装备技术有限公司 | A kind of dislocation generation system |

| CN110159432A (en)* | 2019-06-25 | 2019-08-23 | 烟台杰瑞石油装备技术有限公司 | It is a kind of for providing the system of moving electric power |

| CN110284972A (en)* | 2019-06-25 | 2019-09-27 | 烟台杰瑞石油装备技术有限公司 | A kind of method of dislocation generation system |

| CN110374745A (en)* | 2019-08-20 | 2019-10-25 | 烟台杰瑞石油装备技术有限公司 | A kind of mobile power system |

| CN110513155A (en)* | 2014-12-19 | 2019-11-29 | 进化井服务有限责任公司 | Mobile power generation equipment for hydraulic fracturing of underground geological formations |

| CN110848028A (en)* | 2019-12-17 | 2020-02-28 | 烟台杰瑞石油装备技术有限公司 | A system for providing mobile power |

- 2019

- 2019-12-17WOPCT/CN2019/125860patent/WO2021119981A1/ennot_activeCeased

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN201608528U (en)* | 2010-02-05 | 2010-10-13 | 河北天择重型机械有限公司 | Container type diesel power mobile supply station system |

| US20190203572A1 (en)* | 2014-12-19 | 2019-07-04 | Typhon Technology Solutions, Llc | Mobile fracturing pump transport for hydraulic fracturing of subsurface geological formations |

| CN110513155A (en)* | 2014-12-19 | 2019-11-29 | 进化井服务有限责任公司 | Mobile power generation equipment for hydraulic fracturing of underground geological formations |

| CN110159433A (en)* | 2019-06-25 | 2019-08-23 | 烟台杰瑞石油装备技术有限公司 | A kind of dislocation generation system |

| CN110159432A (en)* | 2019-06-25 | 2019-08-23 | 烟台杰瑞石油装备技术有限公司 | It is a kind of for providing the system of moving electric power |

| CN110284972A (en)* | 2019-06-25 | 2019-09-27 | 烟台杰瑞石油装备技术有限公司 | A kind of method of dislocation generation system |

| CN110374745A (en)* | 2019-08-20 | 2019-10-25 | 烟台杰瑞石油装备技术有限公司 | A kind of mobile power system |

| CN110848028A (en)* | 2019-12-17 | 2020-02-28 | 烟台杰瑞石油装备技术有限公司 | A system for providing mobile power |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US11105266B2 (en) | System for providing mobile power | |

| US11702980B2 (en) | Mobile power system | |

| US12140072B2 (en) | System for providing mobile power | |

| US11927129B2 (en) | System for providing mobile power | |

| US11053853B2 (en) | Method of mobile power generation system | |

| US11143000B2 (en) | Mobile power generation system | |

| CN210289932U (en) | Mobile power generation system | |

| CN210289931U (en) | System for providing mobile power | |

| US11702919B2 (en) | Adaptive mobile power generation system | |

| CN210660319U (en) | Double-vehicle-mounted gas turbine generator set | |

| CN210289933U (en) | Mobile power generation system | |

| US12180819B2 (en) | Fracturing apparatus and control method thereof, fracturing system | |

| CN110469405A (en) | A kind of double vehicle-mounted gas turbine generator groups | |

| CN110145399A (en) | A mobile power generation system | |

| CN105059168A (en) | Electricity-oil guarantee vehicle | |

| CN105604357A (en) | Main power house layout structure of single-shaft gas-steam combined cycle units | |

| WO2021119981A1 (en) | System used for providing mobile power | |

| CN211819657U (en) | System for providing mobile power | |

| US20240301777A1 (en) | Adaptive Mobile Power Generation System | |

| US12163514B2 (en) | Connecting structure, plunger pump device and generator device | |

| CN204279200U (en) | A kind of dead front type piggyback pod for high-altitude operation platform | |

| WO2020258005A1 (en) | System for providing mobile power | |

| WO2020258002A1 (en) | Method for moving power generation system | |

| WO2020258004A1 (en) | Portable power generation system | |

| WO2020258003A1 (en) | Mobile power generation system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application | Ref document number:19957011 Country of ref document:EP Kind code of ref document:A1 | |

| NENP | Non-entry into the national phase | Ref country code:DE | |

| 122 | Ep: pct application non-entry in european phase | Ref document number:19957011 Country of ref document:EP Kind code of ref document:A1 |