WO2021082971A1 - System and method for constructing fully mechanized coal mining face digital mining model - Google Patents

System and method for constructing fully mechanized coal mining face digital mining modelDownload PDFInfo

- Publication number

- WO2021082971A1 WO2021082971A1PCT/CN2020/121924CN2020121924WWO2021082971A1WO 2021082971 A1WO2021082971 A1WO 2021082971A1CN 2020121924 WCN2020121924 WCN 2020121924WWO 2021082971 A1WO2021082971 A1WO 2021082971A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- dimensional

- preliminary

- model

- mechanized mining

- mobile device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T17/00—Three dimensional [3D] modelling, e.g. data description of 3D objects

- G06T17/05—Geographic models

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F16/00—Information retrieval; Database structures therefor; File system structures therefor

- G06F16/20—Information retrieval; Database structures therefor; File system structures therefor of structured data, e.g. relational data

- G06F16/29—Geographical information databases

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q50/00—Information and communication technology [ICT] specially adapted for implementation of business processes of specific business sectors, e.g. utilities or tourism

- G06Q50/02—Agriculture; Fishing; Forestry; Mining

Definitions

- the inventionrelates to the technical field of coal automatic mining, in particular to a system and method for building a digital mining model for a fully mechanized mining face.

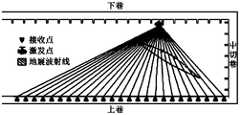

- FIG. 1is a schematic diagram of the seismic wave CT detection technology scheme.

- the receiving point and the excitation pointare respectively located in the upper and lower lanes of the working face. Multiple rays are formed between the receiving point and the excitation point. According to the distribution of rays, the geological occurrence of the working face can be obtained. data.

- the seismic wave CT technologycan realize the detection of the coal seam of the working face to form a geological model of the working face.

- the fully mechanized mining equipment roomThe spatial and physical association of the mine cannot be sensed, so it is only limited to the geological exploration stage of the stope, and cannot meet the guidance and support for the intelligent control of fully mechanized mining equipment.

- the process of mining, dropping, supporting and transporting coalis essentially the interaction between mining equipment and the coal seam to be stopped.

- the coupling effect and efficiency between the twodirectly affect the efficiency of coal production.

- the automatic and intelligent mining system of fully mechanized miningis still mainly concentrated on the equipment control level, and the coupling relationship between different mining equipment, mining equipment and stope is still in a weak correlation state, which greatly affects the mining efficiency.

- the technical problem to be solved by the present inventionis that in the prior art, the existence of advanced detection cannot be realized, and the automatic mining of coal still needs to rely on manual labor, thereby providing a system and method for constructing a digital mining model for a fully mechanized mining face.

- the construction of the three-dimensional geographic model of the coal seam to be mined and the absolute three-dimensional positioning of the fully mechanized mining equipmentform a digital mining model to realize the advance planning of the fully mechanized mining equipment control decision-making and meet the requirements of automatic and unmanned operation of the fully mechanized coal mining face.

- the inventionprovides a digital mining model construction system for a fully mechanized mining face, including:

- the summary 3D model building moduleis used to construct the preliminary 3D model of the coal seam geographic information of the working face

- the inspection componentis used to obtain the three-dimensional space information of the working surface and the three-dimensional space information of the top and bottom plates of the working surface;

- the mobile device positioning moduleis used to obtain the spatial position coordinates of the mobile device in the working surface in the preliminary three-dimensional model

- the positioning module of the fully mechanized mining deviceis used to obtain the spatial position coordinates of the fully mechanized mining device at a fixed position in the working face in the preliminary three-dimensional model;

- Sensor moduleused to detect the working state of the mobile device or the fully mechanized mining device

- the model building moduleis used to combine the three-dimensional spatial information of the top and bottom plates of the working face, the spatial position coordinates of the mobile device in the preliminary three-dimensional model, and the spatial position of the fully-mechanized mining device in the preliminary three-dimensional model

- the coordinates and the working state of the mobile device or the fully mechanized mining deviceare merged with the preliminary three-dimensional model to obtain the digital mining model of the fully mechanized mining face.

- the summary three-dimensional model establishment moduleis used to obtain the geological information of the working face, and construct the preliminary three-dimensional coal seam geographic information of the working face according to the three-dimensional coordinate information of the working face contained in the geological information and any position in the coal seam to be mined model;

- the inspection componentis arranged in the work surface to perform inspection on the work surface, and includes an inertial navigation module and a three-dimensional laser scanning module, and the inertial navigation module is used to obtain three-dimensional spatial information of the work surface,

- the three-dimensional laser scanning moduleis used to obtain three-dimensional spatial information of the top and bottom plates of the working surface;

- the mobile device positioning moduleis used to obtain the first spatial distance between the mobile device in the working surface and a positioning reference point, according to the spatial position coordinates of the positioning reference point in the preliminary three-dimensional model and the The first spatial distance determines the spatial position coordinates of the mobile device in the preliminary three-dimensional model;

- the fully mechanized mining device positioning moduleis used to obtain the second spatial distance between the fully mechanized mining device in the working face and the mobile device, according to the spatial position coordinates of the mobile device in the preliminary three-dimensional model and The second spatial distance determines the spatial position coordinates of the fully mechanized mining device in the preliminary three-dimensional model;

- the sensor moduleincludes multiple types of sensors, and each of the sensors is correspondingly arranged at a specific position of the mobile device or the fully-mechanized mining device to realize the working status of the mobile device or the fully-mechanized mining device. Carry out testing;

- the model construction moduledetermines the position coordinates of the mobile device in the preliminary three-dimensional model, the working state of the mobile device, the structural data of the mobile device, and the three-dimensional space information of the working surface.

- the absolute three-dimensional coordinate value of the mobile device in the preliminary three-dimensional modelaccording to the spatial position coordinates of the fully-mechanized mining device in the preliminary three-dimensional model, the working state of the fully-mechanized mining device, and the structural data of the fully-mechanized mining device

- the summary three-dimensional model establishment moduleincludes a geophysical prospecting device and a GIS unit, among which:

- the geophysical prospecting deviceis used for detecting geological information of a working face, the geological information including three-dimensional coordinate information of any position in the working face and the coal seam to be mined;

- the GIS unitreceives the geological information output by the geophysical prospecting device, and constructs a preliminary three-dimensional model of the coal seam geographic information of the working face according to the three-dimensional coordinate information of the working face and any position in the coal seam to be mined.

- the mobile device positioning moduleincludes a positioning tag and a wireless base station, wherein:

- the positioning tagis arranged on the mobile device and moves together with the mobile device;

- the wireless base stationis set at a positioning reference point in the working surface; the wireless base station establishes a communication connection with the positioning tag to obtain first spatial distance information between the positioning tag and the positioning reference point ; Determine the spatial position coordinates of the mobile device in the preliminary three-dimensional model according to the spatial position coordinates of the positioning reference point in the preliminary three-dimensional model and the first spatial distance.

- the inspection deviceincludes:

- a trackwhich is arranged in the working surface and its length is adapted to the length of the working surface

- the sliding partis slidably arranged in the track, and the inertial navigation module and the three-dimensional laser scanning module are arranged on the sliding part.

- the three-dimensional laser scanning moduleincludes two, which are respectively deployed at the head and tail of the bracket or scraper conveyor.

- the sensor moduleincludes:

- the support formed on the supportis moved to form a sensor, a support height sensor, a support attitude sensor, and a support position sensor; a shearer rocker arm swing angle sensor, a shearer position encoder, a drum height sensor and a machine body are provided on the shearer Inclination sensor; three-machine matching device of support, coal mining machine and scraper conveyor.

- the inspection componentis arranged on the mobile device in the working surface.

- the inventionalso provides a method for constructing a digital mining model for a fully mechanized mining face, which includes the following steps:

- the fully mechanized mining deviceis a fully mechanized mining device at a fixed position in the working face

- the three-dimensional spatial information of the top and bottom plates of the working face, the spatial position coordinates of the mobile device in the preliminary three-dimensional model, the spatial position coordinates of the fully-mechanized mining device in the preliminary three-dimensional model, and the mobile device Or the working state of the fully mechanized mining deviceis merged with the preliminary three-dimensional model to obtain the digital mining model of the fully mechanized mining face.

- the present inventionalso provides a computer-readable storage medium in which program information is stored, and the computer reads the program information and executes the above-mentioned method for constructing a digital mining model for a fully mechanized mining face.

- the present inventionalso provides an electronic device, including at least one processor and at least one memory, at least one of the memory stores program information, and at least one of the processors reads the program information and executes the above-mentioned comprehensive mining Construction method of digital mining model for working face.

- the system and method for building a digital mining model for a fully mechanized mining faceincludes: a summary three-dimensional model building module for building a preliminary three-dimensional model of coal seam geographic information; The three-dimensional space information of the working surface, and the three-dimensional space information of the top and bottom plates of the working surface; a mobile device positioning module for obtaining the spatial position coordinates of the mobile device in the working surface in the preliminary three-dimensional model;

- the mining device positioning moduleis used to obtain the spatial position coordinates of the fully mechanized mining device in the working face in the preliminary three-dimensional model;

- the sensor moduleis used to detect the working status of the mobile device or the fully mechanized mining device

- Model construction moduleused to combine the three-dimensional space information of the top and bottom plates of the working face, the spatial position coordinates of the mobile device in the preliminary three-dimensional model, and the space of the fully-mechanized mining device in the preliminary three-dimensional model

- the position coordinates and the working state of the mobile device or the fully mechanized mining deviceare merged with the preliminary

- the three-dimensional geographic model of the working facecan be modeled through the three-dimensional space positioning method and the three-dimensional space inspection component, and at the same time, the physics between the mobile device and the fixed position of the fully mechanized mining device and the working face can be completed.

- Figure 1is a schematic diagram of the principle of the seismic CT detection technology in the prior art

- FIG. 2is a schematic block diagram of a digital mining model construction system for a fully mechanized mining face according to an embodiment of the present invention

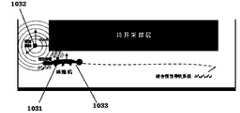

- FIG. 3is a schematic diagram of the principle of acquiring three-dimensional coordinate positioning of a mobile device in a working plane according to an embodiment of the present invention

- FIG. 4is a schematic diagram of the principle of obtaining three-dimensional coordinate positioning of a fully mechanized mining device in a working face according to an embodiment of the present invention

- Fig. 5is a flowchart of a method for constructing a digital mining model for a fully mechanized mining face according to an embodiment of the present invention

- Fig. 6is a schematic diagram of the hardware structure connection relationship of the electronic equipment for realizing the construction of the digital mining model of the fully mechanized mining face according to an embodiment of the present invention.

- This embodimentprovides a digital mining model construction system for a fully mechanized mining face, as shown in Fig. 2, including:

- the summary three-dimensional model building module 101is used to build a preliminary three-dimensional model of the coal seam geographic information of the working face.

- the preliminary three-dimensional modelrefers to a three-dimensional model with only the geological structure information of the working face itself, and does not yet contain the coal mining device information in the working face.

- the summary three-dimensional model building module 101can obtain the geological information of the working face, and construct the preliminary coal seam geographic information of the working face according to the three-dimensional coordinate information of the working face contained in the geological information and any position in the coal seam to be mined.

- Three-dimensional model; the geological information of the working facecan be detected by a geophysical device, and the geological information of the working face is detected by the geophysical device.

- the geological informationincludes the three-dimensional coordinate information of the working face and any position in the coal seam to be mined; preliminary three-dimensional The model can be constructed by a GIS unit.

- the GIS unitreceives the geological information output by the geophysical prospecting device, and constructs a preliminary three-dimensional model of the coal seam geographic information of the working face according to the three-dimensional coordinate information of the working face and any position in the coal seam to be mined.

- the geophysical devicesare various devices that measure geological information before mining, and can detect and obtain data such as drilling location, drilling depth, and geological information for measurement.

- the GIS unitis a unit loaded with the Geographic Information System system. , It is a specific and very important spatial information system. After obtaining the three-dimensional coordinate information of the working face and any position in the coal seam to be mined, it can calculate and analyze the relevant geographic distribution data in the entire working face space to construct Preliminary 3D model.

- the inspection component 102is used to obtain the three-dimensional space information of the working surface and the three-dimensional space information of the top and bottom plates of the working surface.

- the inspection component 102is arranged in the work surface to perform inspection on the work surface. It may include an inertial navigation module and a three-dimensional laser scanning module.

- the inertial navigation moduleis used to obtain the three-dimensional space of the work surface.

- Information, such as the level and verticality of the working surfacethe three-dimensional laser scanning module is used to obtain the three-dimensional spatial information of the top and bottom of the working surface; the inertial navigation module and the three-dimensional laser scanning module are installed along the track

- the inertial navigation moduleis used to realize the perception of straightness and levelness of the working surface.

- the electric laser three-dimensional scanning devicemoves along the working face to realize the full range inspection of the fully mechanized mining face.

- the three-dimensional point cloud data obtained by the laser three-dimensional scanning devicecombined with the recognition of the top and bottom of the coal seam to be mined, realizes the extraction of the three-dimensional coordinates of the top and bottom of the working face.

- the 3D laser scannerobtains the distance between the 3D laser scanner and the top and bottom plates by measuring the laser emission time, the laser reflection receiving time and the frequency of the laser, and the working surface can be determined on the premise that the current position of the 3D laser scanner can be determined. The location of the top and bottom plates.

- the mobile device positioning module 103is configured to obtain the spatial position coordinates of the mobile device in the working surface in the preliminary three-dimensional model. Specifically, reference positioning points can be selected in the working face, for example, the two ends of the fully mechanized mining face are used as positioning reference points, and the three-dimensional coordinates of the positioning reference points in the preliminary three-dimensional model are determined. The mobile device positioning module 103 obtains the first spatial distance between the mobile device in the working surface and the positioning reference point, and according to the spatial position coordinates of the positioning reference point in the preliminary three-dimensional model and the first spatial distance A spatial distance determines the spatial position coordinates of the mobile device in the preliminary three-dimensional model.

- the mobile device positioning module 103may include a positioning tag 1031 and a wireless base station 1032, wherein: the positioning tag 1031 is set on the mobile device (the shearer 1033 in the figure) And move together with the mobile device; the wireless base station 1032 is set at the positioning reference point in the working surface; the wireless base station 1032 establishes a communication connection with the positioning tag 1031 to obtain the positioning tag 1031 and The first spatial distance information between the positioning reference points; afterwards, it can be determined that the mobile device is in the preliminary position according to the spatial position coordinates of the positioning reference points in the preliminary three-dimensional model and the first spatial distance. The spatial position coordinates in the 3D model.

- the fully mechanized mining device positioning module 104is used to obtain the spatial position coordinates of the fully mechanized mining device at a fixed position in the working face in the preliminary three-dimensional model.

- the fixed-position fully mechanized mining devicerefers to a fully mechanized mining device that does not need to be moved in a mining cycle, such as the scraper conveyor 1041, the bracket 1042, etc. in FIG. 4.

- the fully mechanized mining device positioning module 104obtains the second spatial distance between the fully mechanized mining device in the working face and the mobile device, and according to the spatial position coordinates of the mobile device in the preliminary three-dimensional model and the The second spatial distance determines the spatial position coordinates of the fully mechanized mining device in the preliminary three-dimensional model.

- the absolute spatial coordinates of the wireless base station 1032 in the preliminary three-dimensional modelare determined, the absolute spatial coordinates of mobile devices such as the shearer 1033 can be determined according to the communication connection between the positioning tag 1031 and the wireless base station 1032, and the scraper conveyor 1041 and The relative position between the fully mechanized mining device such as the bracket 1042 and the mobile device can be obtained, so that the absolute spatial position coordinates of the fully mechanized mining device in the preliminary three-dimensional model can be obtained.

- the sensor module 105is used to detect the working state of the mobile device or the fully mechanized mining device. It includes multiple types of sensors, and each sensor is correspondingly arranged at a specific position of the mobile device or the fully mechanized mining device to detect the working state of the mobile device or the fully mechanized mining device.

- the support forming sensor, the support height sensor, the support attitude sensor, and the support position sensorare arranged on the support 1042; the shearer rocker arm swing angle sensor, the shearer position encoder, and the drum are provided on the shearer 1033. Height sensor and body inclination sensor; bracket 1042, shearer 1033 and scraper conveyor 1041 three-machine matching device, etc.

- the model construction module 106is used to combine the three-dimensional space information of the top and bottom plates of the working face, the spatial position coordinates of the mobile device in the preliminary three-dimensional model, and the space of the fully-mechanized mining device in the preliminary three-dimensional model.

- the position coordinates and the working state of the mobile device or the fully mechanized mining deviceare merged with the preliminary three-dimensional model to obtain the fully mechanized mining face digital mining model.

- it is determined that the mobile deviceis in position according to the spatial position coordinates of the mobile device in the preliminary three-dimensional model, the working state of the mobile device, the structural data of the mobile device, and the three-dimensional space information of the working surface.

- the absolute three-dimensional coordinate value in the preliminary three-dimensional modelaccording to the spatial position coordinates of the fully-mechanized mining device in the preliminary three-dimensional model, the working state of the fully-mechanized mining device, the structural data of the fully-mechanized mining device, and the The three-dimensional space information of the working face determines the absolute three-dimensional coordinate value of the fully-mechanized mining device in the preliminary three-dimensional model; the three-dimensional space information of the working face and the three-dimensional space information of the top and bottom plates of the working face are used to determine the The absolute three-dimensional coordinate values of the top and bottom of the working face in the preliminary three-dimensional model; the absolute three-dimensional coordinate values of the mobile device, the fully mechanized mining device, and the top and bottom of the working face in the preliminary three-dimensional model are merged

- the digital mining model of the fully mechanized mining faceis obtained from the preliminary three-dimensional model.

- the inertial navigation module and the three-dimensional laser scanning modulecan be installed on a mobile device (such as a coal shearer body) or a special inspection mechanism in the working surface, as long as the device It can be moved to achieve full coverage of the working surface. Therefore, this embodiment provides the following two implementation modes:

- the inspection deviceincludes a track and a sliding part; the track is arranged in the working surface and its length is adapted to the length of the working face; the sliding part is slidably arranged in the track, and the inertial

- the guiding module and the three-dimensional laser scanning moduleare arranged on the sliding part.

- the inertial navigation module and the three-dimensional laser scanning modulemay be arranged on a mobile device in a working surface.

- multiple three-dimensional laser scanning devicescan also be set up to achieve full coverage scanning in the working surface.

- the three-dimensional laser scanning moduleincludes two, which are respectively deployed on the head and the machine of the bracket or scraper conveyor. At the tail position.

- the laser point cloud data obtained by the two three-dimensional laser scanning devicescan synchronize the point cloud data coordinates by data conversion of the same observation point, thereby ensuring the accuracy of the detected data.

- this embodimentalso provides a method for constructing a digital mining model for a fully mechanized mining face, which can be applied to a monitoring system for a fully mechanized mining face, as shown in FIG. 5, including the following steps:

- S101Acquire geological information of the working face, and construct a preliminary three-dimensional model of the coal seam geographic information of the working face according to the three-dimensional coordinate information of the working face contained in the geological information and any position in the coal seam to be mined; in this step, collect

- the summary geological information of the fully mechanized mining face collected by geological explorationincludes the geological information of the coal seam to be mined, such as the thickness of the coal seam to be mined, the absolute three-dimensional coordinate information of the opening and the roadway, as well as the seam contour, The absolute coordinates of the height and position of the coal seam of the sampling point of the borehole are drilled, and a preliminary three-dimensional model describing the geographic information of the coal seam of the working face is constructed in the three-dimensional GIS system. All data points in this preliminary 3D model are based on the absolute coordinate system.

- S102Acquire the three-dimensional space information of the working surface and the three-dimensional space information of the top and bottom plates of the working surface; an inertial navigation device can be mounted on the mobile device, and the mobile device can realize the straightness and levelness of the working surface along a fixed walking track Perception.

- the mobile deviceis equipped with a laser three-dimensional scanning device, and the mobile device is used to patrol the full range of the fully mechanized mining face to realize the three-dimensional laser scanning of the coal seam currently to be mined on the working face.

- the fully mechanized mining deviceis a fully mechanized mining device at a fixed position in the working face; Set the positioning reference point in the lane, deploy the wireless base station on the positioning reference point, and configure the positioning tag on the mobile device to establish the absolute positioning system of the working face mobile device.

- the wireless reference of the positioning reference pointreceives the pulse signal of the positioning tag of the mobile device, and measures and calculates the relative spatial distance between the positioning tag on the mobile device and the wireless base station. Then, according to the absolute three-dimensional coordinate information of the wireless base station in the preliminary three-dimensional model, it is reversed. To calculate the absolute three-dimensional coordinates of the mobile device.

- S104Obtain the working status information of the mobile device and the fully mechanized mining device; based on the inertial navigation data, combined with the data of the sensing device of the working face equipment, such as support travel sensor, support height sensor, support attitude sensor, support position sensor , Shearer rocker arm swing angle sensor, shearer position encoder, etc., as well as the three-machine supporting structure of hydraulic support, shearer, and scraper conveyor, to realize the three-dimensional positioning of fully mechanized mining equipment in the working face.

- the absolute three-dimensional coordinate points of the mobile device acquired in step S103are combined with the data of the inertial navigation module to realize the calculation of the absolute coordinate points of the mobile device in the working plane.

- the absolute spatial coordinate data of all devices in the working face in fully mechanized miningcan be obtained.

- S105Combine the three-dimensional spatial information of the top and bottom plates of the working face, the spatial position coordinates of the mobile device in the preliminary three-dimensional model, the spatial position coordinates of the fully-mechanized mining device in the preliminary three-dimensional model, and the The working state of the mobile device or the fully mechanized mining device is merged with the preliminary three-dimensional model to obtain the digital mining model of the fully mechanized mining face.

- the detailed coal seam data in the working face and the three-dimensional absolute positioning coordinate values of the mobile and fixed coal mining devicescan be obtained. All the data is added and integrated into the preliminary three-dimensional model to achieve an increase in the amount of coordinate information of the preliminary three-dimensional model, and clear

- the spatial relative relationship between fully mechanized mining equipment and geographic modelsforms a digital mining model for fully mechanized mining face to guide the intelligent control of fully mechanized mining equipment.

- This embodimentalso provides a computer-readable storage medium in which program information is stored, and the computer reads the program information and executes the above-mentioned method for constructing a digital mining model for a fully mechanized mining face.

- This embodimentprovides an electronic device. As shown in FIG. 6, it includes at least one processor 1 and at least one memory 2. At least one of the memories 2 stores instruction information, and at least one of the processors 1 reads the After the program instructions, the digital mining model construction method of fully mechanized mining face described in any of the above schemes can be executed.

- the above-mentioned devicemay further include: an input device 3 and an output device 4.

- the processor 1, the memory 2, the input device 3, and the output device 4may be connected by a bus or in other ways.

- the above-mentioned productscan execute the methods provided in the embodiments of the present application, and have functional modules and beneficial effects corresponding to the execution methods. For technical details that are not described in detail in this embodiment, please refer to the method provided in the embodiment of this application.

- the mobile deviceis equipped with a laser scanning device to realize three-dimensional scanning of the coal seam to be mined on the working face, thereby establishing the three-dimensional spatial positioning of the top and bottom of the working face.

- the absolute position positioning of the mobile equipmentis realized.

- the sensor equipment of the fully mechanized mining equipmentsuch as stroke sensor, angle sensor, attitude sensor, and height sensor data, combined with the structure and size data of the equipment, the three-dimensional spatial positioning of the fully mechanized mining equipment in the working face is realized, and the equipment is two or two. The spatial position relationship.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Theoretical Computer Science (AREA)

- General Physics & Mathematics (AREA)

- Software Systems (AREA)

- Geometry (AREA)

- Remote Sensing (AREA)

- Databases & Information Systems (AREA)

- Business, Economics & Management (AREA)

- Tourism & Hospitality (AREA)

- Marine Sciences & Fisheries (AREA)

- Marketing (AREA)

- Primary Health Care (AREA)

- Strategic Management (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Health & Medical Sciences (AREA)

- General Business, Economics & Management (AREA)

- Economics (AREA)

- Health & Medical Sciences (AREA)

- Mining & Mineral Resources (AREA)

- Human Resources & Organizations (AREA)

- Data Mining & Analysis (AREA)

- General Engineering & Computer Science (AREA)

- Animal Husbandry (AREA)

- Agronomy & Crop Science (AREA)

- Computer Graphics (AREA)

- Length Measuring Devices With Unspecified Measuring Means (AREA)

- Testing Or Calibration Of Command Recording Devices (AREA)

- Geophysics And Detection Of Objects (AREA)

- Electrically Operated Instructional Devices (AREA)

- Disintegrating Or Milling (AREA)

Abstract

Description

Translated fromChinese本申请要求在2019年10月28日提交中国专利局、申请号为201911032511.0、发明名称为“一种综采工作面数字化开采模型构建系统及方法”的中国专利申请的优先权,其全部内容通过引用结合在本申请中。This application claims the priority of a Chinese patent application filed with the Chinese Patent Office on October 28, 2019, the application number is 201911032511.0, and the invention title is "a system and method for building a digital mining model for fully mechanized mining face". The entire content of the application is approved The reference is incorporated in this application.

本发明涉及煤炭自动化开采技术领域,具体涉及一种综采工作面数字化开采模型构建系统及方法。The invention relates to the technical field of coal automatic mining, in particular to a system and method for building a digital mining model for a fully mechanized mining face.

针对当前煤矿综采工作面智能化开采技术发展态势,越来越多的煤炭生产企业与煤机装备企业认识到目前智能化开采仅能提供装备层面的智能化控制解决方案,煤炭赋存的不确定性直接导致了煤炭开采系统缺乏判断的依据。赋存超前探测具有如下困难:煤层形成过程中受地壳运动的影响,造成了煤层赋存的复杂多变性。依据已经揭露出来的围岩特征是无法推理出尚待开采煤层的赋存条件及其演化趋势。同时在工作面开采过程中开采扰动对煤岩的动态影响及装备与围岩耦合关系也暂无方法剖析清晰。因此,如何实现综采工作面赋存超前探测,建立融合综采成套装备与待开采煤层的数字化开采模型,进而指导生产过程中装备与采场的耦合关联,实现综采装备智能控制,真正实现综采工作面生产模式迈入无人化开采,成为了煤矿综采智能化开采所面临的重要问题。In view of the current development trend of intelligent mining technology for fully mechanized coal mining faces, more and more coal production companies and coal machinery equipment companies realize that current intelligent mining can only provide intelligent control solutions at the equipment level, and coal does not exist. Certainty directly leads to the lack of a basis for judgment in the coal mining system. Advance detection of occurrence has the following difficulties: the formation of coal seams is affected by crustal movement, resulting in the complex and variability of occurrence of coal seams. Based on the features of the surrounding rock that have been revealed, it is impossible to infer the occurrence conditions and evolution trends of the coal seams yet to be mined. At the same time, there is no way to analyze the dynamic impact of mining disturbance on coal and rock and the coupling relationship between equipment and surrounding rock during the mining process. Therefore, how to realize the advanced detection of fully mechanized mining face, establish a digital mining model that integrates fully mechanized mining equipment and the coal seam to be mined, and then guide the coupling and association of equipment and stope in the production process, and realize the intelligent control of fully mechanized mining equipment. The production mode of fully mechanized mining face has entered unmanned mining, which has become an important problem faced by the intelligent mining of fully mechanized coal mining.

目前,现有方案采用震波CT(Computerized Tomography)探测技术对工作面煤层进行地质探测。图1是震波CT探测技术方案示意图,接收点和激发点分别位于工作面的上巷和下巷中,接收点与激发点之间形成多条射线,根据射线分布情况可以得到工作面地质赋存数据。将获得的工作面地质赋存数据与待开采煤层的实测地质数据相互结 合,进而建立工作面的地质三维模型,并在GIS软件平台下建立三维坐标系的工作面煤层顶底板数字模型,建立待开采煤层顶部的三维立体模型。现有技术的如下方案,存在如下技术问题:通过震波CT技术能实现对工作面煤层的探测,形成工作面地质模型,对于综采装备在工作面内所处的绝对空间位置,综采装备间的空间物理关联情况无法感知,因此仅局限于对于采场的地质探测阶段,并不能够满足对综采装备智能控制的指导和支撑。At present, the existing scheme uses seismic CT (Computerized Tomography) detection technology to conduct geological detection of coal seams in the working face. Figure 1 is a schematic diagram of the seismic wave CT detection technology scheme. The receiving point and the excitation point are respectively located in the upper and lower lanes of the working face. Multiple rays are formed between the receiving point and the excitation point. According to the distribution of rays, the geological occurrence of the working face can be obtained. data. Combine the obtained geological occurrence data of the working face with the measured geological data of the coal seam to be mined, and then establish a three-dimensional geological model of the working face, and establish a digital model of the coal roof and floor of the working face with a three-dimensional coordinate system under the GIS software platform to establish A three-dimensional model of the top of the mining coal seam. The following solutions in the prior art have the following technical problems: the seismic wave CT technology can realize the detection of the coal seam of the working face to form a geological model of the working face. For the absolute spatial position of the fully mechanized mining equipment in the working face, the fully mechanized mining equipment room The spatial and physical association of the mine cannot be sensed, so it is only limited to the geological exploration stage of the stope, and cannot meet the guidance and support for the intelligent control of fully mechanized mining equipment.

而煤炭开采的采、落、支、运的过程从本质上来讲是开采装备与待采场煤层的相互作用,两者间的耦合效果、效率直接影响着煤矿生产的效率。目前综采自动化、智能化开采系统仍主要集中在装备控制层面,对于不同开采装备相互之间、开采装备与采场间的耦合关系仍处于一个较弱的关联状态,极大地影响了开采效率。The process of mining, dropping, supporting and transporting coal is essentially the interaction between mining equipment and the coal seam to be stopped. The coupling effect and efficiency between the two directly affect the efficiency of coal production. At present, the automatic and intelligent mining system of fully mechanized mining is still mainly concentrated on the equipment control level, and the coupling relationship between different mining equipment, mining equipment and stope is still in a weak correlation state, which greatly affects the mining efficiency.

发明内容Summary of the invention

本发明要解决的技术问题是现有技术中无法实现赋存超前探测导致煤炭自动化开采依然需要依赖人工,进而提供一种综采工作面数字化开采模型构建系统及方法,可以实现对综采工作面待开采煤层的三维地理模型构建、综采装备绝对三维定位,形成数字化开采模型,以实现对综采装备控制决策的提前规划,满足煤矿综采工作面自动化、无人化运行要求。The technical problem to be solved by the present invention is that in the prior art, the existence of advanced detection cannot be realized, and the automatic mining of coal still needs to rely on manual labor, thereby providing a system and method for constructing a digital mining model for a fully mechanized mining face. The construction of the three-dimensional geographic model of the coal seam to be mined and the absolute three-dimensional positioning of the fully mechanized mining equipment form a digital mining model to realize the advance planning of the fully mechanized mining equipment control decision-making and meet the requirements of automatic and unmanned operation of the fully mechanized coal mining face.

本发明提供一种综采工作面数字化开采模型构建系统,包括:The invention provides a digital mining model construction system for a fully mechanized mining face, including:

概要三维模型建立模块,用于构建工作面煤层地理信息的初步三维模型;The summary 3D model building module is used to construct the preliminary 3D model of the coal seam geographic information of the working face;

巡检组件,用于获取所述工作面的三维空间信息,以及所述工作面顶板及底板的三维空间信息;The inspection component is used to obtain the three-dimensional space information of the working surface and the three-dimensional space information of the top and bottom plates of the working surface;

移动装置定位模块,用于获取所述工作面中的移动装置在所述初步三维模型中的空间位置坐标;The mobile device positioning module is used to obtain the spatial position coordinates of the mobile device in the working surface in the preliminary three-dimensional model;

综采装置定位模块,用于获取所述工作面中固定位置的综采装置在所述初步三维模型中的空间位置坐标;The positioning module of the fully mechanized mining device is used to obtain the spatial position coordinates of the fully mechanized mining device at a fixed position in the working face in the preliminary three-dimensional model;

传感器模块,用于对所述移动装置或所述综采装置的工作状态进 行检测;Sensor module, used to detect the working state of the mobile device or the fully mechanized mining device;

模型构建模块,用于将所述工作面顶板及底板的三维空间信息、所述移动装置在所述初步三维模型中的空间位置坐标、所述综采装置在所述初步三维模型中的空间位置坐标和所述移动装置或所述综采装置的工作状态与所述初步三维模型融合后得到所述综采工作面数字化开采模型。The model building module is used to combine the three-dimensional spatial information of the top and bottom plates of the working face, the spatial position coordinates of the mobile device in the preliminary three-dimensional model, and the spatial position of the fully-mechanized mining device in the preliminary three-dimensional model The coordinates and the working state of the mobile device or the fully mechanized mining device are merged with the preliminary three-dimensional model to obtain the digital mining model of the fully mechanized mining face.

可选地,上述的综采工作面数字化开采模型构建系统中:Optionally, in the above-mentioned comprehensive mining face digital mining model construction system:

所述概要三维模型建立模块,用于获取工作面的地质信息,并根据所述地质信息中包含的所述工作面以及待开采煤层中任意位置的三维坐标信息构建工作面煤层地理信息的初步三维模型;The summary three-dimensional model establishment module is used to obtain the geological information of the working face, and construct the preliminary three-dimensional coal seam geographic information of the working face according to the three-dimensional coordinate information of the working face contained in the geological information and any position in the coal seam to be mined model;

所述巡检组件,设置于所述工作面内,对所述工作面进行巡检,包括惯导模块和三维激光扫描模块,所述惯导模块用于获取所述工作面的三维空间信息,所述三维激光扫描模块用于获取所述工作面顶板及底板的三维空间信息;The inspection component is arranged in the work surface to perform inspection on the work surface, and includes an inertial navigation module and a three-dimensional laser scanning module, and the inertial navigation module is used to obtain three-dimensional spatial information of the work surface, The three-dimensional laser scanning module is used to obtain three-dimensional spatial information of the top and bottom plates of the working surface;

所述移动装置定位模块,用于获取所述工作面中的移动装置与定位基准点之间的第一空间距离,根据所述定位基准点在所述初步三维模型中的空间位置坐标和所述第一空间距离确定所述移动装置在所述初步三维模型中的空间位置坐标;The mobile device positioning module is used to obtain the first spatial distance between the mobile device in the working surface and a positioning reference point, according to the spatial position coordinates of the positioning reference point in the preliminary three-dimensional model and the The first spatial distance determines the spatial position coordinates of the mobile device in the preliminary three-dimensional model;

所述综采装置定位模块,用于获取所述工作面中的综采装置与所述移动装置之间的第二空间距离,根据所述移动装置在所述初步三维模型中的空间位置坐标和所述第二空间距离确定所述综采装置在所述初步三维模型中的空间位置坐标;The fully mechanized mining device positioning module is used to obtain the second spatial distance between the fully mechanized mining device in the working face and the mobile device, according to the spatial position coordinates of the mobile device in the preliminary three-dimensional model and The second spatial distance determines the spatial position coordinates of the fully mechanized mining device in the preliminary three-dimensional model;

所述传感器模块,包括多种类型的传感器,每一所述传感器对应地设置于所述移动装置或所述综采装置的特定位置处以实现对所述移动装置或所述综采装置的工作状态进行检测;The sensor module includes multiple types of sensors, and each of the sensors is correspondingly arranged at a specific position of the mobile device or the fully-mechanized mining device to realize the working status of the mobile device or the fully-mechanized mining device. Carry out testing;

所述模型构建模块,根据所述移动装置在所述初步三维模型中的空间位置坐标、所述移动装置的工作状态、所述移动装置的结构数据和所述工作面的三维空间信息确定所述移动装置在所述初步三维模型中的绝对三维坐标值;根据所述综采装置在所述初步三维模型中的空间位置坐标、所述综采装置的工作状态、所述综采装置的结构数据 和所述工作面的三维空间信息确定所述综采装置在所述初步三维模型中的绝对三维坐标值;根据所述工作面的三维空间信息,以及所述工作面顶板、底板的三维空间信息确定所述工作面顶板、底板在所述初步三维模型中的绝对三维坐标值;将所述移动装置、所述综采装置和所述工作面顶板、底板在所述初步三维模型中的绝对三维坐标值融合至所述初步三维模型中得到所述综采工作面数字化开采模型。The model construction module determines the position coordinates of the mobile device in the preliminary three-dimensional model, the working state of the mobile device, the structural data of the mobile device, and the three-dimensional space information of the working surface. The absolute three-dimensional coordinate value of the mobile device in the preliminary three-dimensional model; according to the spatial position coordinates of the fully-mechanized mining device in the preliminary three-dimensional model, the working state of the fully-mechanized mining device, and the structural data of the fully-mechanized mining device And the three-dimensional space information of the working face to determine the absolute three-dimensional coordinate value of the fully-mechanized mining device in the preliminary three-dimensional model; according to the three-dimensional information of the working face and the three-dimensional information of the roof and bottom of the working face Determine the absolute three-dimensional coordinate values of the top and bottom plates of the working face in the preliminary three-dimensional model; determine the absolute three-dimensional coordinates of the moving device, the fully mechanized mining device, and the top and bottom plates of the working face in the preliminary three-dimensional model The coordinate values are fused into the preliminary three-dimensional model to obtain the digital mining model of the fully mechanized mining face.

可选地,上述的综采工作面数字化开采模型构建系统中:Optionally, in the above-mentioned comprehensive mining face digital mining model construction system:

所述概要三维模型建立模块包括物探装置和GIS单元,其中:The summary three-dimensional model establishment module includes a geophysical prospecting device and a GIS unit, among which:

所述物探装置,用于对工作面的地质信息进行探测,所述地质信息包括所述工作面以及待开采煤层中任意位置的三维坐标信息;The geophysical prospecting device is used for detecting geological information of a working face, the geological information including three-dimensional coordinate information of any position in the working face and the coal seam to be mined;

所述GIS单元,接收所述物探装置输出的所述地质信息,根据所述工作面以及待开采煤层中任意位置的三维坐标信息构建工作面煤层地理信息的初步三维模型。The GIS unit receives the geological information output by the geophysical prospecting device, and constructs a preliminary three-dimensional model of the coal seam geographic information of the working face according to the three-dimensional coordinate information of the working face and any position in the coal seam to be mined.

可选地,上述的综采工作面数字化开采模型构建系统中:Optionally, in the above-mentioned comprehensive mining face digital mining model construction system:

所述移动装置定位模块包括定位标签和无线基站,其中:The mobile device positioning module includes a positioning tag and a wireless base station, wherein:

所述定位标签,设置于所述移动装置上并与所述移动装置一同移动;The positioning tag is arranged on the mobile device and moves together with the mobile device;

所述无线基站,设置于所述工作面中的定位基准点处;所述无线基站与所述定位标签建立通信连接以获取所述定位标签与所述定位基准点之间的第一空间距离信息;根据所述定位基准点在所述初步三维模型中的空间位置坐标和所述第一空间距离确定所述移动装置在所述初步三维模型中的空间位置坐标。The wireless base station is set at a positioning reference point in the working surface; the wireless base station establishes a communication connection with the positioning tag to obtain first spatial distance information between the positioning tag and the positioning reference point ; Determine the spatial position coordinates of the mobile device in the preliminary three-dimensional model according to the spatial position coordinates of the positioning reference point in the preliminary three-dimensional model and the first spatial distance.

可选地,上述的综采工作面数字化开采模型构建系统中:Optionally, in the above-mentioned comprehensive mining face digital mining model construction system:

所述巡检装置包括:The inspection device includes:

轨道,其设置于所述工作面内且其长度与所述工作面的长度相适配;A track, which is arranged in the working surface and its length is adapted to the length of the working surface;

滑动部,其可滑动地设置于所述轨道中,所述惯导模块和三维激光扫描模块设置于所述滑动部上。The sliding part is slidably arranged in the track, and the inertial navigation module and the three-dimensional laser scanning module are arranged on the sliding part.

可选地,上述的综采工作面数字化开采模型构建系统中:Optionally, in the above-mentioned comprehensive mining face digital mining model construction system:

所述三维激光扫描模块包括两个,分别部署于支架或刮板输送机 的机头与机尾位置处。The three-dimensional laser scanning module includes two, which are respectively deployed at the head and tail of the bracket or scraper conveyor.

可选地,上述的综采工作面数字化开采模型构建系统中:Optionally, in the above-mentioned comprehensive mining face digital mining model construction system:

所述传感器模块包括:The sensor module includes:

设置于支架上的支架推移形成传感器、支架高度传感器、支架姿态传感器、支架位置传感器;设置于采煤机上的采煤机摇臂摆角传感器、采煤机位置编码器、滚筒高度传感器和机身倾角传感器;支架、采煤机和刮板输送机的三机配套装置。The support formed on the support is moved to form a sensor, a support height sensor, a support attitude sensor, and a support position sensor; a shearer rocker arm swing angle sensor, a shearer position encoder, a drum height sensor and a machine body are provided on the shearer Inclination sensor; three-machine matching device of support, coal mining machine and scraper conveyor.

可选地,上述的综采工作面数字化开采模型构建系统中:Optionally, in the above-mentioned comprehensive mining face digital mining model construction system:

所述巡检组件设置于所述工作面中的所述移动装置上。The inspection component is arranged on the mobile device in the working surface.

本发明还提供一种综采工作面数字化开采模型构建方法,包括如下步骤:The invention also provides a method for constructing a digital mining model for a fully mechanized mining face, which includes the following steps:

获取工作面的地质信息,并根据所述地质信息中包含的所述工作面以及待开采煤层中任意位置的三维坐标信息构建工作面煤层地理信息的初步三维模型;Acquire geological information of the working face, and construct a preliminary three-dimensional model of the coal seam geographic information of the working face according to the three-dimensional coordinate information of the working face contained in the geological information and any position in the coal seam to be mined;

获取所述工作面的三维空间信息和所述工作面顶板及底板的三维空间信息;Acquiring the three-dimensional space information of the working surface and the three-dimensional space information of the top and bottom plates of the working surface;

获取所述工作面中的移动装置和综采装置在所述初步三维模型中的空间位置坐标,所述综采装置为工作面中固定位置的综采装置;Acquiring the spatial position coordinates of the mobile device and the fully mechanized mining device in the working face in the preliminary three-dimensional model, and the fully mechanized mining device is a fully mechanized mining device at a fixed position in the working face;

获取所述移动装置和所述综采装置的工作状态信息;Acquiring working status information of the mobile device and the fully mechanized mining device;

将所述工作面顶板及底板的三维空间信息、所述移动装置在所述初步三维模型中的空间位置坐标、所述综采装置在所述初步三维模型中的空间位置坐标和所述移动装置或所述综采装置的工作状态与所述初步三维模型融合后得到所述综采工作面数字化开采模型。The three-dimensional spatial information of the top and bottom plates of the working face, the spatial position coordinates of the mobile device in the preliminary three-dimensional model, the spatial position coordinates of the fully-mechanized mining device in the preliminary three-dimensional model, and the mobile device Or the working state of the fully mechanized mining device is merged with the preliminary three-dimensional model to obtain the digital mining model of the fully mechanized mining face.

本发明还提供一种计算机可读存储介质,所述存储介质中存储有程序信息,计算机读取所述程序信息后执行以上所述的综采工作面数字化开采模型构建方法。The present invention also provides a computer-readable storage medium in which program information is stored, and the computer reads the program information and executes the above-mentioned method for constructing a digital mining model for a fully mechanized mining face.

本发明还提供一种电子设备,包括至少一个处理器和至少一个存储器,至少一个所述存储器中存储有程序信息,至少一个所述处理器读取所述程序信息后执行以上所述的综采工作面数字化开采模型构建方法。The present invention also provides an electronic device, including at least one processor and at least one memory, at least one of the memory stores program information, and at least one of the processors reads the program information and executes the above-mentioned comprehensive mining Construction method of digital mining model for working face.

与现有技术相比,本发明实施例提供的上述技术方案至少具有以下有益效果:Compared with the prior art, the above technical solutions provided by the embodiments of the present invention have at least the following beneficial effects:

本发明实施例提供的综采工作面数字化开采模型构建系统及方法,其中的系统包括:概要三维模型建立模块,用于构建工作面煤层地理信息的初步三维模型;巡检组件,用于获取所述工作面的三维空间信息,以及所述工作面顶板及底板的三维空间信息;移动装置定位模块,用于获取所述工作面中的移动装置在所述初步三维模型中的空间位置坐标;综采装置定位模块,用于获取所述工作面中的综采装置在所述初步三维模型中的空间位置坐标;传感器模块,用于对所述移动装置或所述综采装置的工作状态进行检测;模型构建模块,用于将所述工作面顶板及底板的三维空间信息、所述移动装置在所述初步三维模型中的空间位置坐标、所述综采装置在所述初步三维模型中的空间位置坐标和所述移动装置或所述综采装置的工作状态与所述初步三维模型融合后得到所述综采工作面数字化开采模型。采用本发明的以上方案,通过三维空间定位方法、以及三维空间的巡检组件实现对工作面三维地理模型建模的同时,能完成移动装置和固定位置的综采装置与工作面之间的物理关联,建立综采工作面数字化开采模型,提供对综采装置、移动装置智能控制的基准与依据。The system and method for building a digital mining model for a fully mechanized mining face provided by an embodiment of the present invention includes: a summary three-dimensional model building module for building a preliminary three-dimensional model of coal seam geographic information; The three-dimensional space information of the working surface, and the three-dimensional space information of the top and bottom plates of the working surface; a mobile device positioning module for obtaining the spatial position coordinates of the mobile device in the working surface in the preliminary three-dimensional model; The mining device positioning module is used to obtain the spatial position coordinates of the fully mechanized mining device in the working face in the preliminary three-dimensional model; the sensor module is used to detect the working status of the mobile device or the fully mechanized mining device Model construction module, used to combine the three-dimensional space information of the top and bottom plates of the working face, the spatial position coordinates of the mobile device in the preliminary three-dimensional model, and the space of the fully-mechanized mining device in the preliminary three-dimensional model The position coordinates and the working state of the mobile device or the fully mechanized mining device are merged with the preliminary three-dimensional model to obtain the fully mechanized mining face digital mining model. By adopting the above scheme of the present invention, the three-dimensional geographic model of the working face can be modeled through the three-dimensional space positioning method and the three-dimensional space inspection component, and at the same time, the physics between the mobile device and the fixed position of the fully mechanized mining device and the working face can be completed. Associate, establish a digital mining model for fully mechanized mining face, and provide a basis and basis for intelligent control of fully mechanized mining devices and mobile devices.

图1为现有技术中震波CT探测技术的原理示意图;Figure 1 is a schematic diagram of the principle of the seismic CT detection technology in the prior art;

图2为本发明一个实施例所述的综采工作面数字化开采模型构建系统的原理框图;2 is a schematic block diagram of a digital mining model construction system for a fully mechanized mining face according to an embodiment of the present invention;

图3为本发明一个实施例所述获取移动装置在工作面内三维坐标定位的原理示意图;3 is a schematic diagram of the principle of acquiring three-dimensional coordinate positioning of a mobile device in a working plane according to an embodiment of the present invention;

图4为本发明一个实施例所述获取综采装置在工作面内三维坐标定位的原理示意图;4 is a schematic diagram of the principle of obtaining three-dimensional coordinate positioning of a fully mechanized mining device in a working face according to an embodiment of the present invention;

图5为本发明一个实施例所述综采工作面数字化开采模型构建方法的流程图;Fig. 5 is a flowchart of a method for constructing a digital mining model for a fully mechanized mining face according to an embodiment of the present invention;

图6为本发明一个实施例所述实现综采工作面数字化开采模型构 建的电子设备的硬件结构连接关系示意图。Fig. 6 is a schematic diagram of the hardware structure connection relationship of the electronic equipment for realizing the construction of the digital mining model of the fully mechanized mining face according to an embodiment of the present invention.

为了使本发明的上述目的、特征和优点能够更为明显易懂,下面结合附图对本发明的具体实施方式做详细的说明。在本发明的描述中,需要说明的是,术语“第一”、“第二”、“第三”仅用于描述目的,而不能理解为指示或暗示相对重要性。除非另有明确的规定和限定,术语“安装”、“相连”、“连接”应做广义理解,对于本领域的普通技术人员而言,可以具体情况理解上述术语在本发明中的具体含义。In order to make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. In the description of the present invention, it should be noted that the terms "first", "second", and "third" are only used for descriptive purposes, and cannot be understood as indicating or implying relative importance. Unless otherwise clearly defined and limited, the terms "installed", "connected", and "connected" should be interpreted broadly, and those of ordinary skill in the art can understand the specific meaning of the above terms in the present invention under specific circumstances.

在本发明的描述中,需要说明的是,除非另有明确的规定和限定,术语“安装”、“相连”、“连接”应做广义理解,例如,可以是固定连接,也可以是可拆卸连接,或一体地连接;可以是机械连接,也可以是电连接;可以是直接相连,也可以通过中间媒介间接相连,可以是两个组件内部的连通。对于本领域的普通技术人员而言,可以具体情况理解上述术语在本发明中的具体含义。In the description of the present invention, it should be noted that the terms "installed", "connected", and "connected" should be understood in a broad sense unless otherwise clearly specified and limited. For example, they can be fixed or detachable. Connected or integrally connected; it can be a mechanical connection or an electrical connection; it can be directly connected or indirectly connected through an intermediate medium, and it can be the internal communication between two components. For those of ordinary skill in the art, the specific meanings of the above-mentioned terms in the present invention can be understood in specific situations.

本实施例提供一种综采工作面数字化开采模型构建系统,如图2所示,包括:This embodiment provides a digital mining model construction system for a fully mechanized mining face, as shown in Fig. 2, including:

概要三维模型建立模块101,用于构建工作面煤层地理信息的初步三维模型。初步三维模型是指只有工作面本身地质结构信息的三维模型,还未包含工作面中的采煤装置信息。在实现时,概要三维模型建立模块101可获取工作面的地质信息,并根据所述地质信息中包含的所述工作面以及待开采煤层中任意位置的三维坐标信息构建工作面煤层地理信息的初步三维模型;工作面的地质信息可以通过物探装置探测得到,利用物探装置对工作面的地质信息进行探测,所述地质信息包括所述工作面以及待开采煤层中任意位置的三维坐标信息;初步三维模型可以通过GIS单元进行构建,所述GIS单元接收所述物探装置输出的所述地质信息,根据所述工作面以及待开采煤层中任意位置的三维坐标信息构建工作面煤层地理信息的初步三维模型。其中的物探装置为开采之前对于地质信息进行测量的各类装置,能够探测得到钻孔位置、钻孔深度、地测信息等数据进行测量。在实现这些数据 测量时,都是严格基于相同的坐标系来实现的,因此所测量得到的结果都是位于同一坐标系下具有绝对的坐标信息,而GIS单元是装载了Geographic Information System系统的单元,它是一种特定的十分重要的空间信息系统,在得到了工作面以及待开采煤层中任意位置的三维坐标信息后,能够对整个工作面空间中的有关地理分布数据进行运算分析,从而构建初步三维模型。The summary three-dimensional

巡检组件102,用于获取所述工作面的三维空间信息,以及所述工作面顶板及底板的三维空间信息。所述巡检组件102设置于所述工作面内,对所述工作面进行巡检,其可以包括惯导模块和三维激光扫描模块,所述惯导模块用于获取所述工作面的三维空间信息,例如工作面的水平度和垂直度,所述三维激光扫描模块用于获取所述工作面顶板及底板的三维空间信息;所述惯导模块和三维激光扫描模块装设在能够沿着轨道行走的装置上,惯导模块用于实现对工作面直线度、水平度感知。通过电动激光三维扫描装置沿着工作面移动以实现在综采工作面全范围巡检。通过激光三维扫描装置获取的三维点云数据,结合对待开采煤层顶、底板的识别,实现工作面顶、底板的三维坐标提取。三维激光扫描仪通过测量激光发射时间和激光反射接收时间以及激光的频率得到三维激光扫描仪与顶板和底板之间的距离,而三维激光扫描仪当前位置能够确定的前提下,就能够确定工作面顶板和底板的位置。The

移动装置定位模块103,用于获取所述工作面中的移动装置在所述初步三维模型中的空间位置坐标。具体地,在工作面中可以选择基准定位点,例如以综采工作面的两端处为定位基准点,定位基准点在初步三维模型中的三维坐标是确定的。所述移动装置定位模块103,获取所述工作面中的移动装置与定位基准点之间的第一空间距离,根据所述定位基准点在所述初步三维模型中的空间位置坐标和所述第一空间距离确定所述移动装置在所述初步三维模型中的空间位置坐标。例如,如图3所示,所述移动装置定位模块103可以包括定位标签1031和无线基站1032,其中:所述定位标签1031,设置于所述移动装置(如图中的采煤机1033)上并与所述移动装置一同移动;所述 无线基站1032,设置于所述工作面中的定位基准点处;所述无线基站1032与所述定位标签1031建立通信连接以获取所述定位标签1031与所述定位基准点之间的第一空间距离信息;之后便可以根据所述定位基准点在所述初步三维模型中的空间位置坐标和所述第一空间距离确定所述移动装置在所述初步三维模型中的空间位置坐标。The mobile

综采装置定位模块104,用于获取所述工作面中固定位置的综采装置在所述初步三维模型中的空间位置坐标。其中固定位置的综采装置是指一个开采循环中不必移动的综采装置,如图4中的刮板输送机1041,支架1042等。所述综采装置定位模块104,获取所述工作面中的综采装置与所述移动装置之间的第二空间距离,根据所述移动装置在所述初步三维模型中的空间位置坐标和所述第二空间距离确定所述综采装置在所述初步三维模型中的空间位置坐标。因此,无线基站1032在初步三维模型中的绝对空间坐标确定后,根据定位标签1031与无线基站1032的通信连接能够确定如采煤机1033等移动装置的绝对空间坐标,而刮板输送机1041和支架1042等综采装置与移动装置之间的相对位置可以获取,从而就能够获得综采装置在初步三维模型中的绝对空间位置坐标了。The fully mechanized mining

传感器模块105,用于对所述移动装置或所述综采装置的工作状态进行检测。其包括多种类型的传感器,每一所述传感器对应地设置于所述移动装置或所述综采装置的特定位置处以实现对所述移动装置或所述综采装置的工作状态进行检测。例如,设置于支架1042上的支架推移形成传感器、支架高度传感器、支架姿态传感器、支架位置传感器;设置于采煤机1033上的采煤机摇臂摆角传感器、采煤机位置编码器、滚筒高度传感器和机身倾角传感器;支架1042、采煤机1033和刮板输送机1041的三机配套装置等。The

模型构建模块106,用于将所述工作面顶板及底板的三维空间信息、所述移动装置在所述初步三维模型中的空间位置坐标、所述综采装置在所述初步三维模型中的空间位置坐标和所述移动装置或所述综采装置的工作状态与所述初步三维模型融合后得到所述综采工作面数字化开采模型。优选地,根据所述移动装置在所述初步三维模型 中的空间位置坐标、所述移动装置的工作状态、所述移动装置的结构数据和所述工作面的三维空间信息确定所述移动装置在所述初步三维模型中的绝对三维坐标值;根据所述综采装置在所述初步三维模型中的空间位置坐标、所述综采装置的工作状态、所述综采装置的结构数据和所述工作面的三维空间信息确定所述综采装置在所述初步三维模型中的绝对三维坐标值;根据所述工作面的三维空间信息,以及所述工作面顶板、底板的三维空间信息确定所述工作面顶板、底板在所述初步三维模型中的绝对三维坐标值;将所述移动装置、所述综采装置和所述工作面顶板、底板在所述初步三维模型中的绝对三维坐标值融合至所述初步三维模型中得到所述综采工作面数字化开采模型。The

也就是说,采用本实施例的上述方案首先获得的是工作面中每一设备在初步三维模型中的空间位置坐标,之后能够根据每一采煤设备的工作姿态、其本身的结构(例如形状、长度、宽度、高度等)就能够得到该采煤设备在工作面中的所占空间的轮廓信息,相应地就能够得到该采煤设备在工作面中的初步三维模型中的绝对空间位置坐标。之后将工作面顶板、底板、每一设备在初步三维模型中的绝对空间位置坐标填充至初步三维模型中,就得到了所述综采工作面数字化开采模型。That is to say, using the above-mentioned solution of this embodiment, firstly obtain the spatial position coordinates of each equipment in the working face in the preliminary three-dimensional model, and then it can be based on the working posture of each coal mining equipment and its own structure (such as shape). , Length, width, height, etc.) can obtain the contour information of the space occupied by the mining equipment in the working face, and correspondingly, the absolute spatial position coordinates of the preliminary three-dimensional model of the mining equipment in the working face can be obtained. . Then, the absolute space position coordinates of the top plate, bottom plate, and each device in the preliminary three-dimensional model of the working face are filled into the preliminary three-dimensional model, and the digital mining model of the fully-mechanized mining face is obtained.

进一步地,以上方案中,所述惯导模块和所述三维激光扫描模块可以设置于工作面中的移动装置上(例如采煤机机身)或者是专设的巡检机构上,只要该装置可通过移动实现对工作面的空间全覆盖即可。因此,本实施例提供如下两种实现方式:Further, in the above solution, the inertial navigation module and the three-dimensional laser scanning module can be installed on a mobile device (such as a coal shearer body) or a special inspection mechanism in the working surface, as long as the device It can be moved to achieve full coverage of the working surface. Therefore, this embodiment provides the following two implementation modes:

方式一:method one:

所述巡检装置包括轨道和滑动部;轨道设置于所述工作面内且其长度与所述工作面的长度相适配;滑动部,其可滑动地设置于所述轨道中,所述惯导模块和三维激光扫描模块设置于所述滑动部上。The inspection device includes a track and a sliding part; the track is arranged in the working surface and its length is adapted to the length of the working face; the sliding part is slidably arranged in the track, and the inertial The guiding module and the three-dimensional laser scanning module are arranged on the sliding part.

方式二:Way two:

所述惯导模块和所述三维激光扫描模块可以设置于工作面中的移动装置上。另外,还可以通过设置多个三维激光扫描装置的方式以实现对工作面中进行全面覆盖扫描,例如所述三维激光扫描模块包括 两个,分别部署于支架或刮板输送机的机头与机尾位置处。两个三维激光扫描装置获得的激光点云数据可通过对同一观测点的数据转换进行点云数据坐标同步,从而确保检测到的数据的准确性。The inertial navigation module and the three-dimensional laser scanning module may be arranged on a mobile device in a working surface. In addition, multiple three-dimensional laser scanning devices can also be set up to achieve full coverage scanning in the working surface. For example, the three-dimensional laser scanning module includes two, which are respectively deployed on the head and the machine of the bracket or scraper conveyor. At the tail position. The laser point cloud data obtained by the two three-dimensional laser scanning devices can synchronize the point cloud data coordinates by data conversion of the same observation point, thereby ensuring the accuracy of the detected data.

基于同一发明构思,本实施例还提供一种综采工作面数字化开采模型构建方法,可应用于综采工作面的监控系统中,如图5所示,包括如下步骤:Based on the same inventive concept, this embodiment also provides a method for constructing a digital mining model for a fully mechanized mining face, which can be applied to a monitoring system for a fully mechanized mining face, as shown in FIG. 5, including the following steps:

S101:获取工作面的地质信息,并根据所述地质信息中包含的所述工作面以及待开采煤层中任意位置的三维坐标信息构建工作面煤层地理信息的初步三维模型;本步骤中,通过收集由地质勘探采集的综采工作面概要地质信息,包括切眼、两巷等揭露的待开采煤层地质信息,如待开采煤层厚度、切眼及巷道等绝对三维坐标信息,以及煤层等厚线、钻孔采样点的煤层高度及位置绝对坐标,并在三维GIS系统中构建描绘工作面煤层地理信息的初步三维模型。此初步三维模型中所有数据点均以绝对坐标系为基准。S101: Acquire geological information of the working face, and construct a preliminary three-dimensional model of the coal seam geographic information of the working face according to the three-dimensional coordinate information of the working face contained in the geological information and any position in the coal seam to be mined; in this step, collect The summary geological information of the fully mechanized mining face collected by geological exploration includes the geological information of the coal seam to be mined, such as the thickness of the coal seam to be mined, the absolute three-dimensional coordinate information of the opening and the roadway, as well as the seam contour, The absolute coordinates of the height and position of the coal seam of the sampling point of the borehole are drilled, and a preliminary three-dimensional model describing the geographic information of the coal seam of the working face is constructed in the three-dimensional GIS system. All data points in this preliminary 3D model are based on the absolute coordinate system.

S102:获取所述工作面的三维空间信息和所述工作面顶板及底板的三维空间信息;移动装置上可以搭载惯性导航装置,移动装置沿固定的行走轨道实现对工作面的直线度、水平度感知。通过移动装置上搭载激光三维扫描装置,通过移动装备在综采工作面全范围巡检,实现对工作面当前待开采煤层的三维激光扫描。通过激光三维扫描装置获取的三维点云数据,结合对待开采煤层顶、底板的识别,实现工作面顶、底板的三维坐标提取。S102: Acquire the three-dimensional space information of the working surface and the three-dimensional space information of the top and bottom plates of the working surface; an inertial navigation device can be mounted on the mobile device, and the mobile device can realize the straightness and levelness of the working surface along a fixed walking track Perception. The mobile device is equipped with a laser three-dimensional scanning device, and the mobile device is used to patrol the full range of the fully mechanized mining face to realize the three-dimensional laser scanning of the coal seam currently to be mined on the working face. The three-dimensional point cloud data obtained by the laser three-dimensional scanning device, combined with the recognition of the top and bottom of the coal seam to be mined, realizes the extraction of the three-dimensional coordinates of the top and bottom of the working face.

S103:获取所述工作面中的移动装置和综采装置在所述初步三维模型中的空间位置坐标,所述综采装置为工作面中固定位置的综采装置;通过在综采工作面两巷设置定位基准点,定位基准点上部署无线基站,同时移动装置上配置定位标签,建立工作面移动装置的绝对定位系统。定位基准点的无线基准接收移动装置的定位标签的脉冲信号,测量计算出移动装置上的定位标签与无线基站的相对空间距离,然后在根据无线基站在初步三维模型中的绝对三维坐标信息,反向计算出移动装置的绝对三维坐标。S103: Obtain the spatial position coordinates of the mobile device and the fully mechanized mining device in the working face in the preliminary three-dimensional model. The fully mechanized mining device is a fully mechanized mining device at a fixed position in the working face; Set the positioning reference point in the lane, deploy the wireless base station on the positioning reference point, and configure the positioning tag on the mobile device to establish the absolute positioning system of the working face mobile device. The wireless reference of the positioning reference point receives the pulse signal of the positioning tag of the mobile device, and measures and calculates the relative spatial distance between the positioning tag on the mobile device and the wireless base station. Then, according to the absolute three-dimensional coordinate information of the wireless base station in the preliminary three-dimensional model, it is reversed. To calculate the absolute three-dimensional coordinates of the mobile device.

S104:获取所述移动装置和所述综采装置的工作状态信息;基于 惯性导航数据,结合工作面装备的传感装置数据,如支架推移行程传感器、支架高度传感器、支架姿态传感器、支架位置传感器、采煤机摇臂摆角传感器、采煤机位置编码器等以及液压支架、采煤机、刮板输送机的三机配套结构,实现综采装备在工作面内的空间三维定位。通过步骤S103中获取的移动装置的绝对三维坐标点,结合惯导模块的数据实现移动装置在工作面内绝对坐标点计算。同时再结合工作面中所有装置的相关距离、高度、位置传感数据并以装备配套尺寸数据为基础,就能够获得综采中所有装置在工作面内的绝对空间坐标数据。S104: Obtain the working status information of the mobile device and the fully mechanized mining device; based on the inertial navigation data, combined with the data of the sensing device of the working face equipment, such as support travel sensor, support height sensor, support attitude sensor, support position sensor , Shearer rocker arm swing angle sensor, shearer position encoder, etc., as well as the three-machine supporting structure of hydraulic support, shearer, and scraper conveyor, to realize the three-dimensional positioning of fully mechanized mining equipment in the working face. The absolute three-dimensional coordinate points of the mobile device acquired in step S103 are combined with the data of the inertial navigation module to realize the calculation of the absolute coordinate points of the mobile device in the working plane. At the same time, combined with the relevant distance, height, and position sensor data of all devices in the working face and based on the size data of the equipment, the absolute spatial coordinate data of all devices in the working face in fully mechanized mining can be obtained.

S105:将所述工作面顶板及底板的三维空间信息、所述移动装置在所述初步三维模型中的空间位置坐标、所述综采装置在所述初步三维模型中的空间位置坐标和所述移动装置或所述综采装置的工作状态与所述初步三维模型融合后得到所述综采工作面数字化开采模型。S105: Combine the three-dimensional spatial information of the top and bottom plates of the working face, the spatial position coordinates of the mobile device in the preliminary three-dimensional model, the spatial position coordinates of the fully-mechanized mining device in the preliminary three-dimensional model, and the The working state of the mobile device or the fully mechanized mining device is merged with the preliminary three-dimensional model to obtain the digital mining model of the fully mechanized mining face.

通过上述方法能够获得工作面中详细的煤层数据、移动以及固定采煤装置的三维绝对定位坐标值,所有数据添加、整合到初步三维模型内,实现初步三维模型的坐标信息量的增加,以及明确综采装备与地理模型之间的空间相对关系,从而形成综采工作面数字化开采模型,用以指导综采装备的智能化控制。Through the above method, the detailed coal seam data in the working face and the three-dimensional absolute positioning coordinate values of the mobile and fixed coal mining devices can be obtained. All the data is added and integrated into the preliminary three-dimensional model to achieve an increase in the amount of coordinate information of the preliminary three-dimensional model, and clear The spatial relative relationship between fully mechanized mining equipment and geographic models forms a digital mining model for fully mechanized mining face to guide the intelligent control of fully mechanized mining equipment.

本实施例还提供一种计算机可读存储介质,所述存储介质中存储有程序信息,计算机读取所述程序信息后执行以上所述的综采工作面数字化开采模型构建方法。This embodiment also provides a computer-readable storage medium in which program information is stored, and the computer reads the program information and executes the above-mentioned method for constructing a digital mining model for a fully mechanized mining face.

本实施例提供一种电子设备,如图6所示,包括至少一个处理器1和至少一个存储器2,至少一个所述存储器2中存储有指令信息,至少一个所述处理器1读取所述程序指令后可执行以上任一方案所述的综采工作面数字化开采模型构建方法。上述装置还可以包括:输入装置3和输出装置4。处理器1、存储器2、输入装置3和输出装置4可以通过总线或者其他方式连接。上述产品可执行本申请实施例所提供的方法,具备执行方法相应的功能模块和有益效果。未在本实施例中详尽描述的技术细节,可参见本申请实施例所提供的方法。This embodiment provides an electronic device. As shown in FIG. 6, it includes at least one

本实施例提供的以上技术方案,能够实现如下有益效果:The above technical solutions provided by this embodiment can achieve the following beneficial effects:

1、能够建立一种基于融合综采工作面基础物探地理信息和由绝对定位系统、传感装置所感知、识别的工作面待开采煤层和装备的地理信息的综采工作面数字化开采模型。1. It is possible to establish a digital mining model for a fully mechanized mining face based on fusion of basic geophysical geographic information of a fully mechanized mining face and geographic information of the coal seam to be mined and equipment sensed and identified by the absolute positioning system and sensor devices.

2、能够通过移动装置搭载激光扫描装置实现对工作面待开采煤层三维扫描,从而建立工作面顶、底板的三维空间定位。2. The mobile device is equipped with a laser scanning device to realize three-dimensional scanning of the coal seam to be mined on the working face, thereby establishing the three-dimensional spatial positioning of the top and bottom of the working face.

3、通过在两巷布置定位基站,移动装备上配置定位标签,实现对移动装备的绝对位置定位。同时依据综采装备的传感设备,如行程传感器、角度传感器、姿态传感器、高度传感器数据,结合装备配套的结构尺寸数据,实现综采装备在工作面内的三维空间定位,以及设备两两间的空间位置关系。3. By arranging positioning base stations in the two lanes and configuring positioning tags on the mobile equipment, the absolute position positioning of the mobile equipment is realized. At the same time, based on the sensor equipment of the fully mechanized mining equipment, such as stroke sensor, angle sensor, attitude sensor, and height sensor data, combined with the structure and size data of the equipment, the three-dimensional spatial positioning of the fully mechanized mining equipment in the working face is realized, and the equipment is two or two. The spatial position relationship.

最后应说明的是:以上实施例仅用以说明本发明的技术方案,而非对其限制;尽管参照前述实施例对本发明进行了详细的说明,本领域的普通技术人员应当理解:其依然可以对前述各实施例所记载的技术方案进行修改,或者对其中部分技术特征进行等同替换;而这些修改或者替换,并不使相应技术方案的本质脱离本发明各实施例技术方案的精神和范围。Finally, it should be noted that the above embodiments are only used to illustrate the technical solutions of the present invention, not to limit them; although the present invention has been described in detail with reference to the foregoing embodiments, those of ordinary skill in the art should understand that: The technical solutions recorded in the foregoing embodiments are modified, or some of the technical features thereof are equivalently replaced; these modifications or replacements do not cause the essence of the corresponding technical solutions to deviate from the spirit and scope of the technical solutions of the embodiments of the present invention.

Claims (11)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AU2020375860AAU2020375860B2 (en) | 2019-10-28 | 2020-10-19 | System and method for constructing fully mechanized coal mining face digital mining model |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201911032511.0 | 2019-10-28 | ||

| CN201911032511.0ACN111223182B (en) | 2019-10-28 | 2019-10-28 | Fully mechanized coal mining face digital mining model construction system and method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2021082971A1true WO2021082971A1 (en) | 2021-05-06 |

Family

ID=70830489

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/CN2020/121924CeasedWO2021082971A1 (en) | 2019-10-28 | 2020-10-19 | System and method for constructing fully mechanized coal mining face digital mining model |

Country Status (3)

| Country | Link |

|---|---|

| CN (1) | CN111223182B (en) |

| AU (1) | AU2020375860B2 (en) |

| WO (1) | WO2021082971A1 (en) |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113686251A (en)* | 2021-08-19 | 2021-11-23 | 山东科技大学 | A method and system for measuring the upward and downward displacement of fully mechanized mining face equipment |

| CN114329687A (en)* | 2021-11-19 | 2022-04-12 | 太原理工大学 | Method for constructing virtual coal seam of to-be-mined area based on small sample geological data |

| CN114352278A (en)* | 2022-01-07 | 2022-04-15 | 郑州煤机液压电控有限公司 | Evaluation method of fully mechanized coal mining face straightening system |

| CN114359477A (en)* | 2021-12-16 | 2022-04-15 | 北京天玛智控科技股份有限公司 | Coal mine underground intelligent positioning method and system |

| CN114397864A (en)* | 2021-12-08 | 2022-04-26 | 北京京能电力股份有限公司 | Intelligent fuel management and control system |

| CN115270497A (en)* | 2022-08-09 | 2022-11-01 | 安徽庐江龙桥矿业股份有限公司 | Underground two-step mining filling method |

| CN115330983A (en)* | 2022-08-11 | 2022-11-11 | 煤炭科学研究总院有限公司 | CPS generation method, device, electronic device and medium for coal mine |

| CN115454035A (en)* | 2022-10-09 | 2022-12-09 | 天地上海采掘装备科技有限公司 | System and method for testing working surface straightness control system device based on inertial navigation |

| CN115493531A (en)* | 2022-09-29 | 2022-12-20 | 南京北路智控科技股份有限公司 | Method for monitoring straightness of coal face equipment |

| CN115507912A (en)* | 2022-09-28 | 2022-12-23 | 天地(常州)自动化股份有限公司 | Calculation method and calculation system for measuring coal mine yield in real time |

| CN115597537A (en)* | 2022-09-29 | 2023-01-13 | 西安煤矿机械有限公司(Cn) | Mining height monitoring method for coal mining machine |

| CN115688514A (en)* | 2022-10-18 | 2023-02-03 | 中煤科工开采研究院有限公司 | Method, system and equipment for constructing digital twin body of fully mechanized mining face surrounding rock |