WO2017088303A1 - Kinetic-energy power generation apparatus, wireless transmitter, and manufacturing method and application thereof - Google Patents

Kinetic-energy power generation apparatus, wireless transmitter, and manufacturing method and application thereofDownload PDFInfo

- Publication number

- WO2017088303A1 WO2017088303A1PCT/CN2016/072177CN2016072177WWO2017088303A1WO 2017088303 A1WO2017088303 A1WO 2017088303A1CN 2016072177 WCN2016072177 WCN 2016072177WWO 2017088303 A1WO2017088303 A1WO 2017088303A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- coil

- magnetic

- kinetic energy

- magnetic gap

- circuit board

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02K—DYNAMO-ELECTRIC MACHINES

- H02K35/00—Generators with reciprocating, oscillating or vibrating coil system, magnet, armature or other part of the magnetic circuit

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02K—DYNAMO-ELECTRIC MACHINES

- H02K35/00—Generators with reciprocating, oscillating or vibrating coil system, magnet, armature or other part of the magnetic circuit

- H02K35/02—Generators with reciprocating, oscillating or vibrating coil system, magnet, armature or other part of the magnetic circuit with moving magnets and stationary coil systems

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02K—DYNAMO-ELECTRIC MACHINES

- H02K35/00—Generators with reciprocating, oscillating or vibrating coil system, magnet, armature or other part of the magnetic circuit

- H02K35/04—Generators with reciprocating, oscillating or vibrating coil system, magnet, armature or other part of the magnetic circuit with moving coil systems and stationary magnets

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04B—TRANSMISSION

- H04B1/00—Details of transmission systems, not covered by a single one of groups H04B3/00 - H04B13/00; Details of transmission systems not characterised by the medium used for transmission

- H04B1/02—Transmitters

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02K—DYNAMO-ELECTRIC MACHINES

- H02K2213/00—Specific aspects, not otherwise provided for and not covered by codes H02K2201/00 - H02K2211/00

- H02K2213/03—Machines characterised by numerical values, ranges, mathematical expressions or similar information

Definitions

- the present inventionrelates to the field of electronic devices, and more particularly to a kinetic energy generating device, a kinetic energy generating method, and a wireless transmitter using the kinetic energy generating device.

- Wireless controllershave been very commonly used in different electronic control devices.

- a commonly used home or office applianceis often equipped with a wireless controller, and a conventional wireless controller must use a battery as a power source. Therefore, after the end of the battery life cycle, the user must frequently replace the old battery with a new one.

- Another object of the present inventionis to provide a kinetic energy generating device and a wireless transmitter, and a method and a manufacturing method thereof, wherein the kinetic energy generating device realizes self-powering by converting mechanical energy into electric energy.

- Another object of the present inventionis to provide a kinetic energy generating device and a wireless transmitter, and a manufacturing method and application thereof, wherein the kinetic energy generating device includes a coil and has a magnetic gap by causing the coil to be in the magnetic gap The reciprocating motion is performed to cause the kinetic energy generating device to generate electricity.

- Another object of the present inventionis to provide a kinetic energy generating device and a wireless transmitter, and a manufacturing method and application thereof, wherein the kinetic energy generating device further includes a driving device capable of driving a coil or driving a magnetic circuit system

- the coilis capable of generating relative motion with the magnetic gap.

- the coilreciprocates in the magnetic gap under the driving of the driving device to generate electricity.

- Another object of the present inventionis to provide a kinetic energy generating device and a wireless transmitter, and a method and a method for manufacturing the same, wherein the driving device drives the coil to reciprocate in the magnetic force by up-and-down motion to generate electricity.

- Another object of the present inventionis to provide a kinetic energy generating device and a wireless transmitter, and a method and apparatus for manufacturing the same, wherein the driving device drives the coil to reciprocate in the magnetic gap by circular motion to generate electricity.

- Another object of the present inventionis to provide a kinetic energy generating device and a wireless transmitter, and a method and apparatus for manufacturing the same, wherein the driving device is capable of driving one or alternately driving a plurality of the coils to generate an induced current for power generation.

- Another object of the present inventionis to provide a kinetic energy generating device and a wireless transmitter, and a manufacturing method and application thereof, wherein the wireless transmitter drives a circuit board to generate a corresponding emission by inducing an induced current generated by the kinetic energy generating device jobs.

- Another object of the present inventionis to provide a kinetic energy generating device and a wireless transmitter, and a manufacturing method and application thereof, wherein the wireless transmitter includes a high frequency wireless transmitting circuit board to thereby generate the kinetic energy generating device The induced current drives the high frequency wireless transmitting circuit board to perform a corresponding transmitting operation.

- Another object of the present inventionis to provide a kinetic energy generating device and a wireless transmitter, and a manufacturing method and application thereof, wherein the wireless power generating method has a simple operation step and is efficient and quick.

- the present inventionmainly provides a kinetic energy generating device, which comprises:

- At least one coilAt least one coil

- At least one magnetic circuit systemhaving an annular magnetic gap

- At least one driving devicewherein the coil is capable of generating a relative displacement with the magnetic gap under the action of the driving device to cause the coil to be cut by a magnetic line of the magnetic circuit system to generate an induced current.

- the driving deviceis configured to drive the magnetic circuit system such that the magnetic gap of the magnetic circuit system and the coil generate a reciprocating relative displacement to cause the coil to generate the induced current .

- the driving deviceincludes a driver for driving a coil to cause a reciprocating relative displacement of the coil and the magnetic gap of the magnetic circuit system to cause the coil to be generated Said induced current.

- the magnetic circuit systemincludes a bottom magnetic conductive plate having a U-shaped longitudinal section, a permanent magnet, and a top magnetic conductive plate, wherein the permanent magnet and the top magnetic conductive plate are disposed on the The bottom magnetically conductive plate is formed to form the annular magnetic gap.

- the driverincludes a magnetizer, wherein the coil is fixed to the magnetizer, and the magnetizer is automatically reset by magnetic attraction of the magnetic circuit system to drive the coil to automatically reset.

- the actuatorincludes a resilient disc, wherein the coil is secured to the shrapnel, and the shrapnel is automatically reset by its own elastic recovery performance to drive the coil to automatically reset.

- the methodfurther includes a base and one or more elastic plate fixing seats, wherein the bottom magnetic conductive plate and the elastic piece fixing base are fixed to the base, and one end of the elastic piece is connected to the coil. The other end is fixed to the spring mount.

- the actuatorincludes an upper cam and a lower cam that are engageable and disengageable by male teeth, wherein the lower cam is fixed to the magnetic circuit system, and the upper cam is rotatable relative to the lower cam A circumferential rotational motion is performed to drive the coil to reciprocate in the magnetic gap.

- the driverfurther includes a magnetizer, wherein the magnetizer is capable of causing the upper cam and the lower cam to pass from magnetic attraction with the magnetic circuit system The separation state is automatically reset to the engaged state.

- the kinetic energy generating deviceincludes two of the coils and two of the magnetic circuit systems to form two kinetic energy generating units, wherein the driving device includes a seesaw and a point portion, wherein The fulcrum portion supports the slab, and the two ends of the sill plate are respectively fixed with two coils, and the two coils are respectively located at two sides of the fulcrum portion, wherein one of the coils is inserted into a corresponding one of the coils The magnetic gap of the magnetic circuit system, another The coil exits the magnetic gap of the corresponding other of the magnetic circuit systems such that the two coils are respectively cut by magnetic lines of the corresponding two of the magnetic circuit systems to generate the induced current, respectively.

- the two coils described aboveare connected in series or in parallel. Both ends of the raft are further configured to be capable of being attracted to the corresponding two of the magnetic circuit systems by magnetic force.

- itfurther includes a circuit board, wherein the coil is electrically connected to the circuit board, and the induced current generated in the coil is supplied to the circuit board.

- the methodfurther includes a circuit board, wherein the coil is electrically connected to the circuit board, and the coil is generated The induced current is supplied to the circuit board, wherein the circuit board is fixed to a top side of the magnetizer, and the coil is fixed to a bottom side of the magnetizer.

- the methodfurther includes a circuit board, wherein the coil is electrically connected to the circuit board, and the induction generated in the coil An electric current is supplied to the circuit board, wherein the circuit board is fixed to a top side of the elastic piece, and the coil is fixed to a bottom side of the elastic piece.

- the methodfurther includes a circuit board, wherein the coil is electrically connected to the circuit board, and the induced current generated in the coil is supplied

- the circuit boardwherein the coil is fixed to a bottom side of the circuit board, and the circuit board is connected to the upper cam, so that when the upper cam moves, the circuit board is driven to further drive the The coil moves.

- the magnetizeris disposed on the top side, the bottom side of the circuit board or integrally formed with the circuit board.

- the methodfurther includes a circuit board, wherein the coil is electrically connected to the circuit board, and the induced current generated in the coil is supplied to the supply The circuit board, wherein the circuit board is fixed to a top side of the raft.

- the methodfurther includes a circuit board, wherein the width of the magnetic gap is between 0.5 mm and 10 mm, and the number of turns of the coil is 50-800 circles. Between the coils, the wire diameter is between 0.06 mm and 0.5 mm. It is to be understood that the above specific values are by way of example only and not limiting of the invention.

- the present inventionfurther provides a wireless transmitter comprising the above kinetic energy generating device and a high frequency wireless transmitting circuit board, wherein the high frequency wireless transmitting circuit board includes a radio frequency module, the high The frequency wireless transmitting circuit board is electrically connected to the coil in the kinetic energy generating device.

- the present inventionprovides a kinetic energy generation method, wherein the kinetic energy generation method comprises the following steps:

- a relative displacement of a coil and a ring-shaped magnetic gap of a magnetic circuit systemcauses the coil to be cut by the magnetic line of the magnetic circuit system to generate an induced current.

- the kinetic energy generation methodfurther includes the following steps:

- the driving devicedrives the coil to reciprocate relative to the magnetic gap to cause the coil to be cut by a magnetic line of the magnetic circuit system to generate the induced current.

- the stepsare included:

- the magnetic attraction of the magnetizer and the magnetic circuit systemautomatically resets the magnetizer to drive the coil into the magnetic gap.

- the stepsare included:

- the elastic elastic recovery performancecauses the shrapnel to automatically reset to drive the coil into the magnetic gap.

- the stepsare included:

- the elastic elastic recovery performancecauses the shrapnel to automatically reset to drive the coil away from the magnetic gap.

- the stepsare included:

- the upper cam and the lower camre-engage and cause the coil to enter the magnetic gap.

- the stepsare included:

- the upper cam and the lower camre-engage and cause the coil to enter the magnetic gap under the magnetic attraction of a magnetizer and the magnetic circuit system.

- the lower camis secured to a bottom magnetically permeable plate of the magnetic circuit system, and the magnetizer is disposed on the circuit board.

- the stepsare included:

- a first coilResponding to the first end of a driving plate supported by a point of a slab is pressed, a first coil enters a corresponding first magnetic gap, and a second coil leaves a corresponding second magnetic gap; as well as

- the second coilIn response to the opposite second end of the seesaw being pressed, the second coil enters the corresponding second magnetic gap while the first coil exits the corresponding first magnetic gap.

- the methodfurther includes the steps of:

- the corresponding end of the seesawis further configured to be attracted to the corresponding magnetic circuit system by magnetic attraction.

- the magnetic gapis formed by the following steps:

- the permanent magnet and the top magnetic conductive plateare sequentially disposed in the bottom magnetic conductive plate to form the magnetic gap

- the kinetic energy generating device of the present inventionhas the advantages of simple structure, low cost, safety and reliability in the power generation process, no pollution to the environment, and maximum realization of power generation requirements and environmental requirements.

- the kinetic energy power generation method of the present inventionis simple and convenient to operate, and is very advantageous for realizing the current demand of common electronic equipment.

- the wireless transmitter of the inventionhas the advantages of simple structure, reliable performance and low cost.

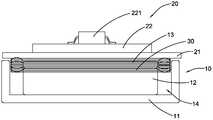

- Fig. 1is a front view showing the structure of a first embodiment of a kinetic energy generating device and a wireless transmitter according to the present invention.

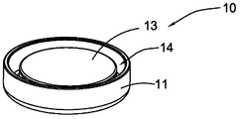

- FIG. 2is a perspective view showing the structure of the magnetic circuit system in the first embodiment of the kinetic energy generating device according to the present invention.

- FIG. 3is a schematic exploded view of the magnetic circuit system illustrated in FIG. 2.

- 4 to 6are schematic views showing the movement process of the kinetic energy generating device according to the present invention.

- Fig. 7is a schematic view showing the exploded structure of a second embodiment of the kinetic energy generating device and the wireless transmitter according to the present invention.

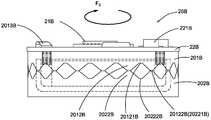

- FIGS. 8 to 10are schematic diagrams showing the working principle of the second first embodiment of the kinetic energy generating device and the wireless transmitter according to the present invention.

- Figure 11is a front elevational view showing the third embodiment of the kinetic energy generating device and the wireless transmitter of the present invention.

- Figure 12is a perspective view showing the third embodiment of the kinetic energy generating device and the wireless transmitter according to the present invention.

- Figure 13is a schematic view showing the exploded structure of a third embodiment of the kinetic energy generating device and the wireless transmitter according to the present invention.

- FIG. 14 to FIG. 16are schematic diagrams showing the working principle of a third embodiment of the kinetic energy generating device and the wireless transmitter according to the present invention.

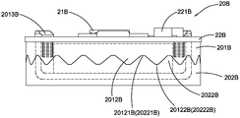

- Figure 17is a perspective view showing the structure of a fourth embodiment of the kinetic energy generating device and the wireless transmitter of the present invention.

- Figure 18is a schematic view showing the exploded structure of a fourth embodiment of the kinetic energy generating device and the wireless transmitter according to the present invention.

- Figure 19is a schematic illustration of the direction of motion of the drive unit in the wireless transmitter of Figure 17.

- 20 to 21are schematic diagrams showing the working principle of the fourth embodiment of the kinetic energy generating device and the wireless transmitter according to the present invention.

- the present inventionmainly provides a kinetic energy generating device, wherein the kinetic energy generating device provides a magnetic gap and a coil, and an exciting current is generated by the coil reciprocating in the magnetic gap, thereby causing the kinetic energy of the present invention.

- the power generation deviceachieves the effect of generating electricity.

- the kinetic energy generating deviceincludes a magnetic circuit system 10, a driving device 20, and a coil 30.

- the gap 14is formed in the magnetic circuit system 10, and the coil 30 is fixedly disposed on the driving device 20, and can reciprocate in the magnetic gap 14 under the driving of the driving device 20 to generate an induced current. Therefore, the kinetic energy generating device of the present invention achieves the effect of generating electricity.

- the magnetic circuit system 10forms an annular magnetic gap 14, and the coil 30 and the magnetic gap 14 are capable of generating a relative displacement, thereby causing the coil to generate an induced current, thereby performing a power generating operation.

- the magnetic gap 14may be fixed in position, and the coil 30 may move, or the coil 30 may be fixed in position, and the position of the magnetic gap 14 may be changed, thereby causing the coil 30 and A relative displacement occurs between the magnetic gaps 14.

- the magnetic circuit system 10may be stationary, and the driving device 20 is used to drive the coil 30 to move, or the coil 30 is fixed, and the driving device 20 is used for driving the driving station.

- the magnetic circuit system 10is moved such that the coil 30 and the magnetic circuit system 10 are relatively displaced, and the coil 30 reciprocates rapidly in the magnetic gap 14, causing the coil 30 to be magnetized.

- the magnetic line of the road system 10is fast

- the cuttingis performed to generate an induced current in the coil 30 based on the principle of electromagnetic induction.

- the drive unit 20is used to drive the coil 30 to generate an induced current.

- the magnetic circuit system 10includes a top magnetic conductive plate 13, a permanent magnet 12, and a bottom magnetic conductive plate 11.

- the bottom magnetic conductive plate 11has a recess 111

- the permanent magnet 12is disposed in the recess 111 of the bottom magnetic conductive plate 11 and has a space between the side walls of the bottom magnetic conductive plate 11 a top magnetic field 13 is attached to the top surface of the permanent magnet 12, so that the top magnetic conductive plate 13 and the permanent magnet 12 form a magnetic line in the bottom magnetic conductive plate 11

- the magnetic gap 14 of the ringis

- the bottom magnetic conductive plate 11is a cylindrical magnetic conductive plate whose longitudinal section is U-shaped, so that the groove 111 is also cylindrical, and the The magnet 12 is cylindrical and located in the groove 111 of the cylindrical bottom magnetic conductive plate 11 and the outer diameter of the permanent magnet 12 is smaller than the diameter of the groove 111, and the top magnetic conductive plate 13 is also The cylindrical shape and the outer diameter thereof are the same as the outer diameter of the permanent magnet 12, and therefore, the magnetic gap 14 in which the magnetic line is densely formed can be formed between the top magnetic conductive plate 13 and the bottom magnetic conductive plate 11.

- the top magnetic conductive plate 13 and the bottom magnetic conductive plate 11may also adopt other shapes or structures, for example, the bottom magnetic conductive plate 11 has a longitudinal cutting surface.

- a U-shaped hollow rectangular parallelepiped or the likemay be formed as long as the top magnetic conductive plate 13 and the permanent magnet 12 can form the magnetic flux line 14 in the bottom magnetic conductive plate 11.

- those skilled in the artcan also determine the manner of forming the magnetic gap 14 according to actual conditions, as long as the magnetic gap 14 can be generated, which belongs to the protection range of the kinetic energy generating device according to the present invention, and the present invention

- the specific implementation manneris not limited thereto.

- the driving device 20includes a driver, which in this embodiment is implemented as a magnetizer 21, which It is made of a magnetically permeable magnetic material. It can be understood that The driver may also be formed by coating a surface of a non-magnetically permeable material with a magnetically permeable material, and the invention is not limited in this respect.

- the driveris embodied as an iron plate.

- the coil 30has an O-shaped cross section and is fixed to a bottom surface of the magnetizer 21, and when the magnetizer 21 is placed on a top surface of the top magnetic conductive plate 13, the coil 30 can be inserted into the Magnetic gap 14.

- the magnetizer 21Due to the magnetic permeability of the magnetizer 21, when the magnetizer 21 is placed on the surface of the top magnetic conductive plate 13, it is tightly adsorbed due to the suction force of the permanent magnet 12 under the top magnetic conductive plate 13. On the top surface of the top magnetically permeable plate 13, and the coil 30 is correspondingly located in the magnetic gap 14, and the coil 30 is still in the magnetic gap 14 while still located in the magnetic circuit system 10. When the magnetic adsorption field is within the range, the coil 30 can be quickly moved back to the top magnetic conducting plate 13 under the magnetic attraction of the magnetic circuit system 10.

- FIG. 4 to FIG. 6are schematic diagrams showing the working process of the first embodiment of the kinetic energy generating device according to the present invention.

- the coil 30is located in the magnetic gap 14.

- the kinetic energy generating deviceis in a stationary state.

- the magnetizer 21is rapidly moved downward and reset under the magnetic attraction force of the permanent magnet 12 until it is reattached to the surface of the top magnetic conductive plate 13. Attached.

- the coil 30 fixedly disposed with the magnetizer 21is also rapidly moved downward by the magnetizer 21 to be inserted into the magnetic gap 14.

- the rapid movement of the coil 30 in the magnetic gap 14causes the coil 30 to be rapidly cut by the magnetic line of interest in the magnetic gap, thereby generating the induced current in the coil 30.

- the induced currentcan be used to drive a corresponding device to operate.

- the magnetizer 21is an iron plate.

- those skilled in the artmay make changes to the type of the magnetizer 21 according to actual conditions, such as cobalt, nickel, and alloys thereof.

- a person skilled in the artmay modify a specific technical solution according to the disclosure of the present invention, such as setting the coil 30 to move, and moving the magnetic circuit system 10, and then passing the magnetic circuit system.

- the magnetic induction line in 10cuts the coil to generate a current, in other words, as long as the coil 30 is cut by the magnetic line in the magnetic circuit system 10, a current can be generated, so that the present invention is employed.

- the same or similar technical solutions and the same or similar technical effects as the present inventionare all within the scope of the present invention, and the specific embodiments of the present invention are not limited thereto.

- the width of the magnetic gap 14is between 0.5 mm and 10 mm, and the number of turns of the coil 30 is between 50 and 800, the coil The wire diameter of 30 may be between 0.06 mm and 0.5 mm, and those skilled in the art may determine the width of the magnetic gap 14 and the number of turns of the coil 30 and the wire diameter of the coil 30 according to the demand for the electric power size, as long as

- the technical solutions that are the same as or similar to the present inventionare adopted, and the technical effects that are the same as or similar to the present invention are all within the scope of the present invention, and the specific embodiments of the present invention are not limited thereto.

- the return movement of the coil 30 in the magnetic gap 14may be achieved by suction, or may be elastic.

- the reciprocating motion of the coil 30 in the magnetic gap 14is realized, or the reciprocating motion of the coil 30 in the magnetic gap 14 is realized by inertial force, external force, or the like, and can be determined by a person skilled in the art according to specific conditions.

- the specific embodiment of the kinetic energy generating device of the present inventionis not limited thereto.

- the coil 30is electrically connected to the circuit board 22, and the circuit board 22 can be integrated with a series of circuit components 221, and the circuit board 22 can be fixed to the magnetizer 21 implemented as an iron plate.

- the top sidei.e., on the top side of the magnetic circuit system 10, forms a compact structure, as shown in Figure 4, although it will be understood by those skilled in the art that it may also be the circumference of the magnetic circuit system 10.

- the sidemay be electrically connected to the coil 30.

- the induced current generated by the coil 30will be converted to use power by a voltage converter in the circuit board 22 to provide power to the main control module of the board.

- the main control modulecan also generate a control command, and the control command is sent to various electronic devices through the high frequency radio frequency circuit, thereby Manipulating the electronic device.

- the control commandis sent to an electronic control system, and the electronic control system can function as a smart home control system, it can be operatively connected to different electronic devices through a central control unit, such as a illuminator, a curtain control unit air conditioner. Control unit, intelligent indicator unit, etc.

- the kinetic energy generating device of the present inventioncan be applied to a self-generating wireless switch, wherein the self-generating wireless switch is adapted to connect any electronic device.

- the self-generating wireless switch in which the kinetic energy generating device of the present invention is disposedis a self-generating device that controls the electronic device in a switching manner.

- the self-generating wireless switch according to the preferred embodimentis used to control one illuminator in a switching manner. It should be appreciated that the self-generating wireless switch can activate and deactivate other electronic devices, such as home or office appliances such as televisions, refrigerators, and electric fans.

- a kinetic energy generation methodfor providing power to a small electronic device, such as typically applied to a wireless switch, thereby forming a wireless self-generating switch, the method comprising the steps of: The magnet 21 is moved by an external force to drive the coil 30 connected thereto away from the annular magnetic gap 14 of the magnetic circuit system 10 by a predetermined distance;

- the magnetizer 21is magnetic in the magnetic circuit system 10 when the external force action disappears Re-absorption with the magnetic circuit system 10 under the action of the absorption force, while the coil 30 returns to the magnetic gap 14, causing the coil 30 to be cut by the magnetic line of the magnetic circuit system 10 and generating an induced current. Used for power generation.

- the iron platewhen the external force is used to lift the magnetizer 21, which is implemented as an iron plate, as shown in the figure, when the coil 30 is separated from the magnetic gap 14 by a predetermined interval, the iron plate is subjected to a downward pulling force of the magnet. Therefore, the coil 30 has potential energy. Since the iron plate is normally adsorbed by the magnet, when the external force attempts to separate it from the magnet, it will be subjected to the strong attraction of the magnet to maintain the potential energy. When the external force suddenly disappears, the iron plate will move down quickly under the attraction of the magnet until it re-engages with the magnet.

- the coil associated with the iron plateis also rapidly inserted downward into the magnetic gap 14, and the rapid movement of the coil causes the coil 30 to be quickly cut by the magnetic induction line.

- the coil 30will be An induced current is generated in it.

- the magnetizer 21when applied to a wireless switch or other small electronic device, it may be an external force of a user pressing, pushing, pushing, pulling, etc., causing the magnetizer 21 as the driver to move and leave the device.

- the magnetizer 21When the magnetic gap 14 is described and the external force applied by the user suddenly disappears, the magnetizer 21 will automatically return to the initial phase suction position under the magnetic attraction of the magnetic circuit system 10, so that the coil 30 is re-established. Entering the magnetic gap 14, such rapid reciprocation as to exit and enter the magnetic gap 14 causes it to be rapidly cut by the magnetic line of the magnetic circuit system 10 to cause an induced current.

- the magnetizer 21is automatically reset due to the magnetic action of the magnetic circuit system 10, so that the structure is simpler.

- the magnetizer 21may be further automatically reset by other means, such as by elastic deformation recovery performance to drive the magnetizer 21 to reset, ie, for example, the magnetizer 21 is coupled to a spring.

- the magnetizer 21is coupled to a spring.

- the coil 30in the initial state, the coil 30 is located in the magnetic gap 14, and in a primary power generating operation, the coil 30 is located in the magnetic gap 14 to leave the magnetic gap 14, The magnetic gap 14 is then returned. In other embodiments, it is also possible that in the initial state, the coil 30 is located outside the magnetic gap 14 in a power generation operation. The coil 30 is located outside the magnetic gap 14 to enter the magnetic gap 14 and then exit the magnetic gap 14. In summary, the coil 30 is caused to quickly enter and exit the magnetic gap 14, thereby causing induced currents in the coil 30.

- the wireless transmitterincludes a magnetic circuit system 10A.

- a driving device 20A and a coil 30Athe magnetic circuit system 10A includes a top magnetic conductive plate 13A, a permanent magnet 12A and a bottom magnetic conductive plate 11A.

- the permanent magnet 12Ais disposed on the bottom magnetic conductive plate 11A.

- the wireless transmitteruses a spring 21A to drive the coil 30A to reciprocate in the magnetic gap 14A to generate the induced current, and drives the circuit board 22A through the induced current. Launched.

- FIG. 7is a schematic view of an exploded structure of a first embodiment of the present invention.

- the circuit board 22Ais electrically connected to the coil 30 of the kinetic energy generating device, wherein the driving device 20A in the kinetic energy generating device includes a driver, which is Specifically, the elastic piece 21A is fixedly disposed on the bottom surface of the elastic piece 21A. The top surface of the elastic piece 21A is fixedly disposed with the circuit board 22A, and the circuit board 22A and the coil 30A are electrically connected.

- the coil 30Ais reciprocated in the magnetic gap 14A by the elastic force of the elastic piece 21A, thereby realizing the power generation effect of the kinetic energy power generation device.

- the circuit board 22Aneed not be fixed on the top surface of the elastic piece 21A, but is fixed at other positions of the entire power generation system.

- the elastic piece 21Ahas a first end 211A and a second end 212A.

- the first end 211Ahas a first fixing hole 2111A and a second fixing hole 2112A.

- the kinetic energy generating device of the embodiment of the present inventionfurther includes a base 40.

- the base 40is fixedly provided with a first fixing base 41 and a second fixing base 42, the first fixing base 41 and the The height of the second fixing base 42 is the same, and the elastic piece 21A passes through the first fixing hole 2111A and the second fixing hole 2112A respectively.

- the first fixing base 41 and the second fixing base 42are fixed to fix the base 40.

- the elastic piece 21Acan not only achieve relative fixation with the base 40, but also can be operated without external force.

- the horizontal positionis maintained, and the second end 212A of the elastic piece 21A is movable relative to the first end 211A of the elastic piece 21A when an external force is applied.

- the proximal end of the elastic piece 21Ais fixed in position by one or more fixing seats 41 and 42, and the bottom surface of the distal end fixes the coil 30A.

- the distal end of the elastic piecethat is, the second end 212A, can be rotated with its proximal end, that is, the first end 211A as a fulcrum, so as to be automatically reset. That is, unlike the above embodiment, the coil 30 is reset by magnetic attraction, and in this embodiment of the invention, the coil 30A is automatically reset by the elastic recovery property of the elastic piece 21A.

- the magnetic circuit system 10Ais located below the second end 212A of the elastic piece 21A, and the heights of the first fixing seat 41 and the second fixing seat 42 can ensure that the elastic piece 21A is just right when it is stationary.

- the coil 30Ais located in the magnetic gap 14A formed by the magnetic circuit system 10A. In other words, when the elastic piece 21A is stationary without an external force, its height is approximately the same as the height of the magnetic circuit system 10A, thereby ensuring that the coil 30A can be released when the external force on the elastic piece 21A disappears.

- the kinetic energy generating device of the present inventionLocated in the magnetic gap 14A formed by the magnetic circuit system 10A, the kinetic energy generating device of the present invention has a power generating function.

- the shape of the second end 212A of the elastic piece 21Acan ensure that the O-shaped coil 30A is fixed to the bottom surface thereof.

- the second end 212A of the elastic piece 21Ais a circular shape, and the circular second end 212A is an enlarged portion whose outer diameter is larger than the outer diameter of the coil 30A, so that the coil 30A can be stably fixed to the bottom surface of the second end 212A of the elastic piece 21A.

- the second end 212A of the elastic piece 21Afurther has a protrusion 2121A located at a side of the second end 212A of the elastic piece 21A for convenient operation by a user.

- FIG. 8 to FIG. 10are schematic diagrams showing a power generation process of the wireless transmitter according to this embodiment of the present invention.

- the second end 212A of the elastic piece 21A and the coil 30Aare located above the magnetic circuit system 10A, and at the same time, the coil 30A is located in the magnetic gap 14A formed by the magnetic circuit system 10A. At this time, the entire kinetic energy generating device is at a standstill.

- the circuit board 22Ais a high frequency wireless transmission circuit board, and the high frequency wireless transmission circuit board is integrated with a series of circuit board components 221A and a radio frequency module (RF radio frequency module).

- RF radio frequency moduleradio frequency module

- the coil 30A in the kinetic energy generating deviceis electrically connected to the high frequency wireless transmitting circuit board.

- the coil 30A in the kinetic energy generating deviceis densely covered by the magnetic gap 14A

- the induced currentdrives the high frequency wireless transmitting circuit board with the circuit board component 221A and the RF radio frequency module to emit high frequency radio waves, thereby controlling the electronic device working.

- the elastic piece 21A as a driver in this embodiment of the inventionpulsates the coil 30A in a lever-like manner to generate a rapid reciprocating displacement, thereby causing the coil 30 to generate an induced current.

- the coil 30Ain the initial state, the coil 30A is located in the magnetic gap 14A, and when the protrusion 2121A is lifted upward, so that the second end 212A of the elastic piece 21A is When the first end 211A is rotated upward by the fulcrum, the coil 30A leaves the magnetic gap 14A and the elastic piece 21A accumulates potential energy. When the external force disappears, the elastic piece 21A is automatically reset, thereby driving the coil 30A to enter again.

- the magnetic gap 14Ais described so as to be rapidly cut by the magnetic line of the magnetic circuit system 10A to generate an induced current. It can be understood that, in another embodiment, the height of the fixing bases 41 and 42 may be greater than the magnetic circuit system 10A, so that in the initial state, the coil 30A is located in the magnetic gap 14A.

- the coil 30Aenters the magnetic gap 14A and The elastic piece 21A accumulates potential energy, and when the external force disappears, the elastic piece 21A is automatically rotated upward and reset, thereby driving the coil 30A away from the magnetic gap 14A, so that the coil 30A quickly enters and leaves the magnetic gap 14A, The coil 30A is caused to be rapidly cut by the magnetic line of the magnetic circuit system 10A to generate an induced current.

- this embodiment of the inventionprovides a kinetic energy generation method for providing power to a small electronic device, such as typically applied to a wireless switch, thereby forming a wireless self-generating switch, the method comprising the following step:

- the elastic piece 21Ais leveraged by the second end 212A with the first end 211A as a fulcrum and elastically deformed by the external force, and drives the coil 30 connected thereto to leave the annular magnetic gap 14A of the magnetic circuit system 10A by a predetermined distance;

- the elastic piece 21Aautomatically resets and drives the coil 30A to automatically reset, wherein the coil 30A is cut by the magnetic induction line of the magnetic circuit system 10A to generate an induced current for power generation.

- the elastic piece 21Ais leveraged by the second end 212A with the first end 211A as a fulcrum and elastically deformed by the external force, and drives the coil 30A connected thereto to enter the annular magnetic gap 14A of the magnetic circuit system 10A;

- the elastic piece 21Aautomatically resets and drives the coil 30A away from the magnetic gap 14A, wherein the coil 30A is cut by the magnetic line of the magnetic circuit system 10A to generate an induced current for use in Power generation.

- the external force applied by the elastic piece 21Amay be a direct action from the user, or may be other indirect effects, as long as it can cause displacement of the distal end of the elastic piece 21A, thereby accumulating elasticity. Potential energy can be.

- the distal end of the elastic piece 21Acan be fixed to the magnetic circuit system 10A. Therefore, when the elastic piece 21A is subjected to an external force and its distal end is rotated relative to its proximal end, like a lever, the position of the coil 30A is unchanged and the magnetic circuit system 10A can be driven to move, and the external force suddenly disappears.

- the elastic piece 21Ais automatically reset due to the elastic recovery performance, the magnetic circuit system 10A is automatically reset, so that the magnetic gap 14A of the magnetic circuit system 10A and the coil 30A are relatively reciprocated. The displacement causes the coil 30A to generate an induced current.

- the coil 30Amay be located in the magnetic gap 14A, or may be located outside the magnetic gap 14A in a repeated cycle. In the middle, the movement of the magnetic circuit system 10A may cause the magnetic gap 14A to leave the coil 30A to return quickly, or the movement of the magnetic circuit system 10A may cause the magnetic gap 14A to be first placed in the The coil 30A is quickly separated from the coil 30A.

- the wireless transmitterincludes a magnetic circuit system 10B, a driving device 20B, and a coil 30B.

- the magnetic circuit system 10Bincludes a top magnetic conductive plate 13B, a permanent magnet 12B, and a bottom magnetic conductive plate 11B.

- the permanent magnet 12Bis disposed in the groove of the bottom magnetic conductive plate 11B and is magnetically coupled to the bottom.

- a magnetically sensitive wireis formed in the magnetic conductive plate 11B

- the magnetic gap 14Bis shaped.

- the third embodiment of the wireless transmitterdiffers from the first embodiment in that, in the third embodiment, the coil 30B is driven by the relative circumferential rotational motion of a cam in the magnetic gap 14B. The upper and lower reciprocating motions are performed to generate the induced current, and the circuit board 22B is driven by the induced current to perform a corresponding transmitting operation.

- the driving device 20Bincludes a driver including a cam having a cylindrical shape including an upper cam 201B and a lower portion.

- the cam 202Bhas a first space 2011B and the lower cam 202B has a second space 2021B.

- a plurality of consecutive first protruding teeth 2012Bare disposed on a circumference of the upper cam 201B, and each of the first protruding teeth 2012B includes a first upper end 20121B and a first lower end 20122B.

- the lower cam 202Bis provided with a plurality of second protruding teeth 2022B respectively engaged with the first protruding teeth 2012B, and each of the second protruding teeth 2022B includes a second upper end 20221B and a The second lower end 20222B.

- the first upper end 20121B of the first protruding tooth 2012Bis located at the second upper end 20221B of the second protruding tooth 2022B, and The first lower end 20122B of the first protruding tooth 2012B is located at the second lower end 20222B of the second protruding tooth 2022B;

- the upper cam 201Bperforms a circumferential rotational movement with respect to the lower cam 202B, the upper cam 201B

- the first upper end 20121B and the first lower end 20122B of the first protruding tooth 2012Bare respectively along the second upper end 20221B and the second lower end of the second protruding tooth 2022B on the lower cam 202B

- the 20222Bslides to reciprocate the upper cam 201B relative to the lower cam 202B.

- the wireless transmitterfurther includes a circuit board 22B, and the circuit board 22B is fixedly disposed on the upper cam 201B.

- the upper cam 201Bis provided with at least one buckle 2013B on the periphery thereof, and the peripheral edge of the circuit board 22B is provided with the same number of the card holes 222B as the buckles, so as to pass the buckle 2013B.

- the circuit board 22Bis fixed to the upper cam 201B in combination with the card hole 222B.

- three of the buckles 2013Bare disposed on the periphery of the upper cam 201B, and three corresponding card holes 222B are also disposed at corresponding positions of the circuit board 22B.

- the buckle 2013Bcan also be disposed on the circuit board 22B, and the card hole 222B can also be disposed on the upper cam 201B.

- the circuit board 22B and the upper cam 201Bmay be connected and fixed by other connection means, and the present invention is not limited in this respect.

- the coil 30Bis fixed to the bottom surface of the circuit board 22B and located in the first space 2011B of the upper cam 201B, and the top surface of the circuit board 22B further includes a magnetizer 21B, the guide The magnet 21B is fixed to the top surface of the circuit board 22B, and may be formed of a magnetically permeable material such as an iron plate or a magnetically permeable material coated with a non-magnetic material.

- the magnetic circuit system 10Bhas the same structure as that in the magnetic circuit system 10 of the first embodiment of the kinetic energy generating device, the magnetic circuit The system 10B is located in the second space 2021B of the lower cam, and when the upper cam 201B and the lower cam 202B are engaged, the coil 30B is located in the magnetic gap 14B formed by the magnetic circuit system 10B. in.

- the magnetizer 21Bmay also be located on the bottom surface of the circuit board 22B or integrated integrally with the circuit board 22B as long as it can generate magnetic attraction with the magnetic circuit system 10 and The cam is automatically reset to the engaged state.

- the magnetizer 21Bis fixed to the upper cam 201, and the circuit board 22B is fixedly coupled to the magnetizer 21B.

- FIG. 14 to FIG. 16are schematic diagrams showing the working process of the third embodiment of the wireless transmitter of the present invention.

- the magnetizer 21Bis affected by the magnetic force of the magnetic circuit system 10B, and when the upper cam 201B is continuously rotated rapidly, the first portion on the upper cam 201B is caused.

- a convex tooth 2012B and the second convex tooth 2022B on the lower cam 202Bare re-engaged, and at this time, the coil 30B falls back into the magnetic gap 14B as the upper cam 201B moves downward downward. And is quickly cut by the magnetic line of interest in the magnetic gap 14B.

- the rotation directions of the upper cam 201B and the lower cam 202Bmay be adjusted according to actual conditions, as long as the upper cam can be enabled.

- the 201B and the lower cam 202Bperform a circular motion along the first convex teeth 2012B and the second convex teeth 2022B, thereby driving the coil 30B to reciprocate in the magnetic gap 14B to generate an induced current.

- the magnetizer 21Bis embodied as an iron plate, and a person skilled in the art can also determine the specific material of the magnetizer 21B according to actual conditions.

- itmay be a magnetic material opposite to the magnetic pole of the magnetic circuit system 10B, and the specific embodiment of the present invention is not limited thereto as long as the magnetic permeability is within the scope of the present invention.

- a person skilled in the artcan also adjust the motion relationship between the upper cam 201B and the lower cam 202B according to customer needs or actual conditions.

- those skilled in the artcan set the upper cam 201B to be fixed, and the lower cam 202B carries the second protruding teeth 2022B along the first protruding teeth 2012B with respect to the upper cam 201B.

- Circular motionThat is, those skilled in the art can set the coil 30B to be stationary, and the magnetic circuit system 10B reciprocates relative to the coil 30B to generate the induced current.

- the specific implementation of the wireless transmitter of the present inventionis not To this end, as long as the same or similar technical solutions as the present invention are adopted, and the same or similar technical effects as the present invention are achieved, they are all within the protection scope of the wireless transmitter of the present invention.

- the circuit board 22Bis a high frequency wireless transmitting circuit board, and the high frequency wireless transmitting circuit board is electrically connected to a circuit board component 221B and a

- the RF moduleRF radio frequency module

- the coil 30B in the kinetic energy generating deviceis electrically connected to the high frequency wireless transmitting circuit board.

- the coil 30B in the kinetic energy generating devicegenerates an induced current due to a magnetic line cut in the magnetic gap 14B

- the induced currentdrives the board member 221B and the The high frequency wireless transmitting circuit board of the RF module emits high frequency radio waves to control the operation of the electronic device.

- this embodiment of the inventionprovides a kinetic energy generation method for providing power to a small electronic device, such as typically applied to a wireless switch, thereby forming a wireless self-generating switch, the method comprising the following step:

- the upper cam 201Bstarts to separate from the lower cam 202B by an external force, and drives the circuit board 22B connected thereto to move, so that the coil 30 assembled to the circuit board 22B leaves the ring of the magnetic circuit system 10B.

- the magnetic gap 14Bis a predetermined distance;

- the magnetic attraction between the magnetizer 21B and the magnetic circuit system 10Bautomatically resets the upper cam 201B and the circuit board 22B and drives the coil 30B to automatically reset.

- the coil 30Bis cut by the magnetic line of the magnetic circuit system 10B to generate an induced current for power generation.

- the lower cam 202Bstarts to separate from the upper cam 201B by an external force, and drives the magnetic circuit system 10B connected thereto to move, so that the coil 30B assembled to the circuit board 22B is separated. Opening the annular magnetic gap 14B of the magnetic circuit system 10B by a predetermined distance;

- the lower cam 202Bis automatically reset to mesh with the upper cam 201B, and the magnetic circuit system 10B is driven to automatically reset, so that the coil 30 enters the magnetic circuit system 10B.

- the magnetic gap 14Bis described in which the coil 30A is cut by the magnetic line of the magnetic circuit system 10B to generate an induced current for power generation.

- the wireless transmitteris The coil 30C is reciprocated in the magnetic gap 14C formed by the magnetic circuit system 10C by using the up and down movement of a slab, thereby generating an induced current, and driving the circuit board 22C by the induced current.

- the corresponding launch workis that, in this embodiment, the wireless transmitter is The coil 30C is reciprocated in the magnetic gap 14C formed by the magnetic circuit system 10C by using the up and down movement of a slab, thereby generating an induced current, and driving the circuit board 22C by the induced current.

- the wireless transmitterincludes a bottom plate 50, a kinetic energy generating device, and a circuit board 22C.

- the kinetic energy generating deviceis fixed on the floor and can generate an induced current.

- the circuit board 22Cis electrically connected to the kinetic energy generating device and is capable of performing a corresponding transmitting operation under the driving of the induced current.

- the driving deviceincludes a driver, which in this embodiment is embodied as a seesaw, the seesaw includes a The first end 21C and the second end 21C' are fixedly disposed with a point 503 on the bottom plate 50.

- the two sides of the fulcrum 503are respectively provided with two mounting seats to respectively form a first recess 501 and a first

- the two grooves 502are understood to be recessed to the bottom plate 50, and the invention is not limited in this respect.

- the kinetic energy generating device of the wireless transmitterincludes a first kinetic energy generating unit and a second kinetic energy generating unit, and the first kinetic energy generating unit and the second kinetic energy generating unit are respectively fixed

- the first groove 501 and the second groove 502are disposed on both sides of the fulcrum 503.

- the first kinetic energy generating unitincludes a first magnetic circuit system 10C, a first coil 30C and a first driving device 20C.

- the first magnetic circuit system 10Chas a first magnetic gap 14C

- the power generating unitincludes a second magnetic circuit system 10C', a second coil 30C', and a second driving device 20C'.

- the second magnetic circuit system 10C'has a second magnetic gap 14C', wherein the first The driving device 20C can drive the first coil 30C to reciprocate in the first magnetic gap 14C formed by the first magnetic circuit system 10C.

- the second driving device 20C'can drive the second coil 30C' to reciprocate in the second magnetic gap 14C' formed by the second magnetic circuit system 10C'.

- the circuit board 22Cis electrically connected to the first coil 30C and the second coil 30C', and performs a corresponding control command transmitting operation by driving the first induced current and the second induced current.

- the two driving devices 20Cform an integral driver structure, more specifically a slab that moves with the fulcrum portion 503 as a fulcrum.

- the two kinetic energy generating unitsmay be symmetrically located on both sides of the fulcrum portion 503, or may be reasonably allocated according to actual conditions to achieve a phase equilibrium state. For example, when the circuit board 22C is fixed to the left side of the seesaw, the fulcrum portion 503 may be located adjacent to the first kinetic energy generating unit on the left side.

- the number of coils and the wire diameter of the two coils 30C and 30C'may be the same or different.

- the first magnetic circuit system 10Cincludes a cylindrical first bottom magnetic conductive plate 11C having a U-shaped longitudinal section, a first permanent magnet 12C and a first top magnetic conductive plate 13C.

- the first bottom magnetic conductive plate 11Cis fixedly disposed in the first recess 501, and the first permanent magnet 12C and the first top magnetic conductive plate 13C are both cylindrical and the first permanent magnet 12C

- the first top magnetic conductive 13C plateis attached to the top surface of the first permanent magnet 12C so that the first magnetic circuit system 10C can be formed.

- the magnetic fluxis densely covered by the first magnetic gap 14C.

- the second magnetic circuit system 10C'includes a cylindrical second bottom magnetic conductive plate 11C' having a U-shaped longitudinal section, a second permanent magnet 12C' and a second top magnetic conductive plate 13C'.

- the second bottom magnetic conductive plate 11C'is fixedly disposed in the second recess 502, and the second permanent magnet 12C' and the second top magnetic conductive plate 13C' are both cylindrical and the first

- the second permanent magnet 12C'is disposed inside the second bottom magnetic conductive plate 11C', and the second top magnetic conductive plate 13C' is attached to the top surface of the second permanent magnet 12C' to make the first

- the second magnetic gap 14C' in which the magnetic line is densely formedcan be formed in the two magnetic circuit system 10C'. It is to be understood that the above-described magnetic gaps 14C and 14C' are annular, and the shape of the above-mentioned magnetic conductive plate is not limited to the above cylindrical shape.

- the first coil 30Cis O-shaped and fixedly disposed on a bottom surface of the first driving device 20C, and the first driving device 20C can drive the first coil 30C to enter the first magnetic circuit system 10C. In the first magnetic gap 14C.

- the second coil 30C'is O-shaped and fixedly disposed on a bottom surface of the second driving device 20C', and the second driving device 20C' can drive the second coil 30C' into the second magnetic circuit system 10C. 'In the second magnetic gap 14C' formed.

- the first driving device 20Cdrives the first coil 30C through the first end 21C of the seesaw.

- the second driving device 20C'is driving the second coil through the second end 21C' of the raft 30C' reciprocates in the second magnetic gap 14C' formed by the second magnetic circuit system 10C'.

- the circuit board 22Cis fixedly disposed on the top surface of the first driving device 20C. It is to be understood that the circuit board 22C may also be located on the top surface of the second driving device 20C', or in the middle of the seesaw, or may be fixed to the bottom plate 50.

- the first driving device 20C and the second driving device 20C'are connected to each other to form the seesaw, the fulcrum portion 503 is located in the middle of the bottom surface of the seesaw, and the two ends of the seesaw are symmetrically arranged

- the right side of 20C'is such that the other end of the raft can be tilted with the same force. It can be understood that the above-mentioned protrusions 211C and 211C' are arranged for convenient operation, and the user may directly press or lift both ends of the seesaw, and the aspect of the invention is not limited.

- the first driving device 20Cwhen an external force is applied to press the first protrusion 211C in the seesaw, the first driving device 20C is moved downward by the external force F3, and the second The driving device 20C' is tilted under the reaction of the fulcrum portion 503 and the external force F3.

- the first driving device 20C and the second driving device 20C'can swing up and down in the direction of the arrow shown by the external force F3 centering on the fulcrum portion 503.

- the outputs of the two coils 30C and 30C'are both connected to the circuit board 22C, and the two coils 30C and 30C' may be connected in series or in parallel.

- the fourth implementation of the wireless transmitter of the present inventionThe working process schematic of the example.

- the arrow in the figureindicates that the coil 30C on the left side moves downward, the coil 30C' on the right side moves upward; and when the coil 30C' on the right side moves downward, the coil 30C on the left side is upward. motion.

- the side of the seesawis lower on one side, that is, either one of the first driving device 20C or the second driving device 20C' and the first magnetic circuit system 10C or the second magnetic circuit system 10C' contacts, and drives the first coil 30C into the first magnetic gap 14C formed by the first magnetic circuit system 10C or drives the second coil 30C' into the The second magnetic gap 14C' formed by the second magnetic circuit system 10C'.

- the initial positionis that the first driving device 20C drives the first coil 30C into the first magnetic gap 14C formed by the first magnetic circuit system 10C.

- the second driving device 20C' in the second kinetic energy generating unitis rapidly moved downward by the external force F3'.

- the second driving device 20C'drives the second coil 30C' to move downward rapidly, thereby quickly entering the second magnetic gap 14C' formed by the second magnetic circuit system 10C', and being The closed magnetic line of interest in the second magnetic gap 14C' is rapidly cut to generate a second induced current.

- the first driving device 20Cperforms a motion opposite to the direction of the second driving device 20C' under the action of the external force F3' and the fulcrum portion 503, that is, When the first driving device 20C moves upward, the first coil 30C leaves the first magnetic gap 14C formed by the first magnetic circuit 10C under the driving of the first driving device 20C, so that the first When the coil 30C leaves the first magnetic gap 14C in the first magnetic circuit system 10C, it is bound to be cut by the magnetic line of interest in the first magnetic gap 14C, thus generating a first induced current.

- the first coil 30Cleaves the magnetic gap 14C, that is, in the left-handed state in the figure, a downward external force F3 is applied to the first protrusion 211C, then the first The driving device 20C rapidly moves downward under the driving of the external force F3, while driving the first coil 30C to quickly enter the first magnetic gap 14C in the first magnetic circuit system 10C, thereby causing the The first coil 30C is quickly cut by the magnetic flux line densely covered in the first magnetic gap 14C, thereby generating the first induced current again.

- the second driving device 20C'moves rapidly upwards under the joint action of the external force F3 and the fulcrum portion 503, and simultaneously drives the second coil 30C' to quickly leave the second magnetic circuit system 10C'.

- the second magnetic gap 14C' in the middleis rapidly cut by the dense magnetic line in the second magnetic gap 14C', so that the second induced current is generated again.

- the wireless transmitter of the present inventioncan generate primary electric energy, and the first driving device 20C and the second driving device 20C' continuously move in such a reciprocating manner, thereby continuously generating the first An induced current and the second induced current. Since the circuit board 22C is electrically connected to the first coil 30C and the second coil 30C', the first induced current and the second induced current can drive the circuit board 22C to perform corresponding wireless transmission. jobs. Accordingly, those skilled in the art can design the circuit module of the circuit board 22C to supply the induced current generated by the first and second coils 30C and 30C' in series or in parallel.

- the circuit board 22Cis disposed on a top surface of the first driving device 20C, and the first coil 30C and the second coil 30C' Both are electrically connected to the circuit board 22C to provide current drive for the circuit board 22C.

- a person skilled in the artmay also connect the first coil 30C and the second coil 30C' to different circuit boards 22C according to actual conditions, thereby inducing the induced current generated by the first kinetic energy generating device and the second The induced current shunt output generated by the kinetic energy generating device drives different boards for corresponding wireless transmitting work.

- the circuit board 22Cis a high frequency wireless transmitting circuit board, and the high frequency wireless transmitting circuit board is electrically connected to a circuit board component 221C and a a radio frequency module (RF radio frequency module) (not shown in the drawings, the same below), that is, the first coil 30C and the second coil 30C' in the kinetic energy generating device and the high frequency wireless transmitting circuit board, respectively Electrical connection.

- RF radio frequency moduleradio frequency module

- the induced currentis generated when the first coil 30C and the second coil 30C' are induced by a magnetic line cut in the first magnetic gap 14C and the second magnetic gap 14C' to generate an induced current.

- the high frequency wireless transmission circuit board with the circuit board component 221C and the RF radio frequency moduleis driven to emit high frequency radio waves, thereby controlling the operation of the electronic device.

- the two coils 30C and 30C'are fixed, and the two magnetic circuit systems 10C and 10C' are moved by the seesaw, thereby making the two An induced current is generated in the coils 30C and 30C'.

- both ends of the seesawmay also be made of a magnetic conductive material or an additional magnetizer such as an iron plate, so that during the movement of the coils 30C and 30C', The magnetic circuit systems 10C and 10C' respectively have magnetic attraction to both ends of the jaws for maintaining balance, and the ends of the jaws are respectively accelerated to move downward.

- this embodiment of the inventionprovides a kinetic energy generation method for providing power to a small electronic device, such as typically applied to a wireless switch, thereby forming a wireless self-generating switch, the method comprising the following step:

- the first coil 30C on one side of the seesawis inserted into the first magnetic gap 14C of the first magnetic circuit system 10C, and the second is located on the opposite side of the seesaw.

- the coil 30C'is located outside the second magnetic gap 14C' of the second magnetic circuit system 10C';

- the second coil 30C'When the other side of the seesaw is pressed, the second coil 30C' is inserted into the second magnetic gap 14C' of the second magnetic circuit system 10C', the first side of the seesaw side The coil 30C leaves the first magnetic gap 14C of the first magnetic circuit system 10C, so that the first and second coils 30C and 30C' respectively generate an induced current;

- the second coil on the other side of the seesaw 30C'leaves the second magnetic gap 14C' of the second magnetic circuit system 10C' such that the first and second coils 30C and 30C' respectively generate another induced current.

- the induced electromotive force and the number of turns of the first coil 30C and the second coil 30C', the first magnetic gap 14C and the The magnetic field strength of the second magnetic gap 14C' and the left and right sides of the seesaw The pressing speedis related to the formula:

- nthe number of turns of the coil

- a person skilled in the artcan modify the specific embodiment of the wireless transmitter according to the present invention as needed, as long as it has a mechanism for driving the movement of the coil, and can reciprocate the coil in the magnetic gap.

- the mechanism for generating a current by cutting the coil through the magnetic line in the magnetic gapis within the protection scope of the present invention, and the specific embodiment of the present invention is not limited thereto.

- the kinetic energy generating device of the present inventioncan be used for a push type wireless self-generating device.

- the switch boardwhen the switch board is pressed, the movement of the switch board drives the kinetic energy generating device to convert mechanical energy into electrical energy to drive a controller to operate, so that the controller further performs wireless control Control electronics.

- a person skilled in the artcan also develop an application of the kinetic energy generating device according to actual needs, such as combining the kinetic energy generating device with a remote controller, etc., when the button on the remote controller is pressed, the pressing action The kinetic energy generating device is driven to convert mechanical energy into electrical energy to drive the remote controller to operate.

- the kinetic energy generating device of the present inventionAs long as the same or similar technical solutions as the kinetic energy generating device of the present invention are adopted, and the same or similar technical effects as the present invention are achieved, it is within the protection scope of the present invention, and the specific application manner of the present invention is not This is limited.

- the present inventionfurther includes a kinetic energy generation method, the kinetic energy generation method comprising the following steps:

- the drive coilreciprocates in an annular magnetic gap to cause the coil to generate an induced current for power generation because the magnetic line is cut.

- the coilmay be reciprocated in the magnetic gap by a cooperation of magnetic force and external force.

- the coilis reciprocated in the magnetic gap by a cooperation of an elastic force and an external force.

- the speed of the movement of the coil in the magnetic gapcan be determined according to the amount of the user's demand for the electric energy.

- the specific embodiment of the kinetic energy generation method of the present inventionis not limited thereto, as long as it is the same as the present invention.

- a similar technical meanssolves the technical problems of the same or similar to the present invention, and achieves the same or similar technical effects as the present invention, and is within the scope of the present invention.

- the coilis reciprocated in the magnetic gap by a driving device.

- the driving devicecan drive the coil to reciprocate in the magnetic gap to generate an electric current, such as a manual driving, a mechanical external force driving manner, etc., and can be performed by a person skilled in the art according to customer requirements or actual conditions.

- the method for driving the coilis determined by the driving device.

- the specific embodiment of the kinetic energy generating method of the present inventionis not limited thereto, as long as the same or similar technical solutions are adopted as the present invention, and the same as the present invention is achieved. Or similar technical effects are within the scope of the present invention.

- the driving devicecan drive the coil to reciprocate in the magnetic gap by means of up-and-down motion or circular motion.

- the coilis driven to reciprocate in the magnetic gap by, for example, a shrapnel drive, a jaw drive or a cam drive.

- the coilis fixed to the elastic piece, and then the elastic force of the elastic piece is used to cause the coil to be in the Reciprocating motion in the magnetic gap to achieve power generation.

- the raftis double-sided under the action of the fulcrum Moving, and fixing the coil to the raft, then when the raft is moving up and down under an external force, the coil is also driven by the raft Reciprocating motion in the magnetic gap to achieve power generation.

- the seesawdrives the coil to move in the magnetic gap

- the coil and the magnetic gapmay be disposed on both sides of the raft, and then the reciprocating motion of the raft can cause the coils on both sides to generate current.

- the seesawin the power generation method of driving the coil to reciprocate in the magnetic gap by using the seesaw to generate an induced current, the seesaw can generate double induced current, thereby improving the Power generation efficiency of kinetic energy generation methods.

- the camis disposed as a pair of upper and lower cams that are engaged with each other, the upper cam and the lower cam Provided with continuous convex teeth respectively, the upper cam and the lower cam are engaged by the convex teeth, and the upper cam and the lower cam can be relatively rotated along the convex teeth .

- the coil and the magnetic gapare respectively fixed to the upper cam and the lower cam, so that with the relative circular motion between the upper cam and the lower cam, the coil is driven along with The circumferential rotation of the convex teeth is performed to move up and down, thereby achieving reciprocation of the coil in the magnetic gap to achieve power generation.

- the magnetic gapis obtained by a method of providing a magnetic circuit system, and the magnetic gap is annular.

- a person skilled in the artcan also set a magnetic gap by other means, and the shape and parameters of the magnetic gap can also be determined according to actual requirements, as long as the The same or similar technical solutions of the present invention, and achieving the same technical effects as the present invention, are all within the scope of the present invention.

- the reciprocating motion of the coil in the magnetic gapincludes not only a method of setting a coil motion or a magnetic gap motion, but also a coil motion and a magnetic gap motion.

- the methodas long as the coil can be relatively reciprocated in the magnetic gap and generate an induced current, the person skilled in the art can according to the actual situation, the relative motion of the coil and the magnetic gap, as long as Adopted the same as the present invention

- the embodiments of the present inventionare not limited thereto, and the technical solutions that are the same as or similar to the present invention are all within the scope of the present invention.

- the present inventionfurther includes a method of manufacturing a kinetic energy generating device, the method of manufacturing the kinetic energy generating device comprising the steps of:

- a coilis provided, the coil being capable of being driven to reciprocate in the magnetic gap.

- the method of manufacturing the kinetic energy generating device of the present inventionfurther includes the following steps:

- a driving deviceis provided, the driving device driving the coil to reciprocate in the magnetic gap.

- the driving deviceis arranged to drive the coil to reciprocate in the magnetic gap by moving up and down.

- a spring pieceis disposed in the driving device, and the coil is driven to reciprocate in the magnetic gap by the elastic piece.

- the coilis fixedly coupled to the elastic piece, so that the coil can move up and down along with the elastic force of the elastic piece, thereby further The reciprocating motion is performed in the gap to generate an induced current.

- the driving deviceis provided with a raft in which the coil is driven to reciprocate in the magnetic gap.

- a middle portion of the seesawis provided with a point portion through which both ends of the seesaw can be moved up and down by an external force, and the coil is fixed with the seesaw, so The coil is reciprocable in the magnetic gap as the both ends of the raft are moved up and down, thereby generating an induced current.

- both ends of the raftare simultaneously bidirectionally moved by the fulcrum portion, only the two ends of the raft are moved in opposite directions.

- the two ends of the seesawcan be simultaneously moved in opposite directions, and those skilled in the art can separately set the coil and the magnetic gap at both ends of the seesaw, and then The two coils are respectively fixed to both ends of the raft, so that an external force is in the raft

- the coils at both ends of the raftcan be driven to move in the magnetic gap.

- the coils at both ends of the raftare respectively reciprocated in the magnetic gap, thereby respectively generating an induced current.

- the raftis provided as a driving device to drive the coil to reciprocate in the magnetic gap, the same force is the same under other conditions.

- double the induced currentcan be generated, so that the power generation efficiency of the kinetic energy generating device can be improved.

- the drive meanscan also drive the coil to reciprocate in the magnetic gap by a rotary motion.

- a camis provided in the driving device, and the coil is driven to reciprocate in the magnetic gap by a circular motion of the cam.

- the camis disposed to be divided into a pair of upper and lower cams that are engaged with each other, and the upper cam and the lower cam are respectively provided with continuous convex teeth, and the upper cam is engaged by the engagement of the convex teeth Engagement is achieved with the lower cam, and the upper cam and the lower cam are capable of relative circumferential movement along the male teeth. Since the convex teeth are tooth-shaped, when the upper cam and the lower cam perform a relative circular motion along the convex teeth, the upper cam and the lower cam are also due to the convex teeth The shape is relatively up and down.

- the coilis disposed to be fixedly coupled to the upper cam, and the magnetic gap is disposed to be fixedly coupled to the lower cam, thereby

- the coilalso moves up and down along the shape of the convex tooth along the upper cam, thereby realizing the magnetic gap

- the reciprocating motion in the middlegenerates an induced current.

- the prior artA person may set a relative motion relationship between the coil and the magnetic gap according to a customer request or the actual situation, such as setting the magnetic gap to be non-moving, and the coil may reciprocate in the magnetic gap, or may be set.

- the coilis not moved, and the magnetic gap is reciprocated relative to the coil, as long as the same or similar technical solutions are adopted as in the present invention, and the same or similar technical effects as the present invention are achieved,

- the specific embodiments of the present inventionare not limited thereto.

- the magnetic gapis formed by the following steps:

- a circular magnet and a circular top magnetic plateare disposed, wherein an inner diameter of the magnet and the top magnetic plate is smaller than an outer diameter of the bottom magnetic plate;

- the magnet and the top magnetically permeable plateare disposed in the bottom magnetic conductive plate to form the magnetic gap of a dense magnetic line.