USRE45476E1 - Coffee brewer - Google Patents

Coffee brewerDownload PDFInfo

- Publication number

- USRE45476E1 USRE45476E1US14/181,448US201414181448AUSRE45476EUS RE45476 E1USRE45476 E1US RE45476E1US 201414181448 AUS201414181448 AUS 201414181448AUS RE45476 EUSRE45476 EUS RE45476E

- Authority

- US

- United States

- Prior art keywords

- coffee

- brew basket

- brewer

- hot water

- brew

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 235000013353coffee beverageNutrition0.000titleclaimsabstractdescription177

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsabstractdescription115

- 238000003756stirringMethods0.000claimsabstractdescription16

- 230000000007visual effectEffects0.000claimsabstractdescription3

- 238000010438heat treatmentMethods0.000claimsdescription22

- 239000000796flavoring agentSubstances0.000abstractdescription11

- 235000019634flavorsNutrition0.000abstractdescription11

- 238000000605extractionMethods0.000abstractdescription4

- 238000000034methodMethods0.000abstractdescription4

- 230000037361pathwayEffects0.000description8

- 230000009471actionEffects0.000description6

- 238000009987spinningMethods0.000description6

- 230000000717retained effectEffects0.000description4

- 230000008901benefitEffects0.000description3

- 238000009835boilingMethods0.000description3

- 238000013124brewing processMethods0.000description3

- 230000009977dual effectEffects0.000description2

- 238000010907mechanical stirringMethods0.000description2

- 239000008399tap waterSubstances0.000description2

- 235000020679tap waterNutrition0.000description2

- 239000012780transparent materialSubstances0.000description2

- 238000009736wettingMethods0.000description2

- 235000019658bitter tasteNutrition0.000description1

- 230000015556catabolic processEffects0.000description1

- 230000005465channelingEffects0.000description1

- 238000004140cleaningMethods0.000description1

- 238000010276constructionMethods0.000description1

- 230000000994depressogenic effectEffects0.000description1

- 239000006185dispersionSubstances0.000description1

- 230000001747exhibiting effectEffects0.000description1

- 230000037406food intakeEffects0.000description1

- 230000005484gravityEffects0.000description1

- 239000007788liquidSubstances0.000description1

- 230000004048modificationEffects0.000description1

- 238000012986modificationMethods0.000description1

- 239000002991molded plasticSubstances0.000description1

- 238000010137moulding (plastic)Methods0.000description1

- 230000000737periodic effectEffects0.000description1

- 238000005086pumpingMethods0.000description1

- 230000008439repair processEffects0.000description1

- 230000000630rising effectEffects0.000description1

- 239000007921spraySubstances0.000description1

- 238000005507sprayingMethods0.000description1

- 239000000725suspensionSubstances0.000description1

- 235000019640tasteNutrition0.000description1

- 230000007704transitionEffects0.000description1

- 238000011144upstream manufacturingMethods0.000description1

Images

Classifications

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J31/00—Apparatus for making beverages

- A47J31/04—Coffee-making apparatus with rising pipes

- A47J31/057—Coffee-making apparatus with rising pipes with water container separated from beverage container, the hot water passing the filter only once i.e. classical type of drip coffee makers

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J31/00—Apparatus for making beverages

- A47J31/44—Parts or details or accessories of beverage-making apparatus

- A47J31/4403—Constructional details

- A47J31/4475—Hot water outlets for drip coffee makers

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J31/00—Apparatus for making beverages

- A47J31/44—Parts or details or accessories of beverage-making apparatus

- A47J31/46—Dispensing spouts, pumps, drain valves or like liquid transporting devices

- A47J31/462—Dispensing spouts, pumps, drain valves or like liquid transporting devices with an intermediate liquid storage tank

- A47J31/465—Dispensing spouts, pumps, drain valves or like liquid transporting devices with an intermediate liquid storage tank for the heated water

Definitions

- This inventionrelates generally to improvements in devices and systems for brewing coffee or the like. More particularly, this invention relates to an improved coffee brewer utilizing streams of heated water for turbulently agitating and stirring coffee grounds to produce a substantially fluidized bed of water-borne coffee grounds, to yield brewed coffee having improved flavor and enhanced aroma and other characteristics.

- Drip-style coffee brewersare available in a wide range of different configurations and sizes for use in residential or commercial environments to produce brewed coffee.

- Such coffee brewerscommonly include a water reservoir from which a controlled volume of water is heated and then dispensed downwardly by dripping or spraying onto coffee grounds contained within an underlying, upwardly open brew basket.

- the hot waterintermixes with the coffee grounds to produce the desired brewed coffee beverage which is drained from the brew basket through a filter element into an underlying coffee pot such as a carafe or decanter.

- the brewerincludes a refillable water reservoir from which the water is delivered through a heating element for drip-flow dispensing into the brew basket.

- the brewermay be coupled directly to a tap water supply or the like.

- modified coffee brewers and related brewing processeshave been provided in an attempt to overcome these problems and disadvantages by providing improved intermixing between the heated water and the coffee grounds within a filtered brew basket.

- such conceptsutilize mechanical stirring devices for improving thorough contact between the heated water and the coffee grounds. While such concepts may provide brewed coffee with enhanced and/or more consistent flavor characteristics, they inherently incorporate moving parts that increase the overall complexity and cost of the coffee brewer, and are susceptible to occasional break-down to require periodic repair or replacement.

- an improved coffee brewer and brewing methodfor producing brewed coffee with improved flavor.

- the coffee brewerincludes a removably mounted brew basket having jet ports connected to a source of heated water and positioned to deliver hot water streams into the brew basket at a location for turbulently agitating and stirring coffee grounds contained therein to produce a substantially fluidized bed of water-borne coffee grounds for improved flavor extraction.

- This fluidized bedis directed against one or more mesh filter elements forming a wall portion of the brew basket for outward passage of the thus-produced coffee which is then directed into an underlying carafe or the like.

- the coffee brewerincludes a water reservoir coupled via a first check valve for flow in heat transfer relation with a heating unit.

- the heating unitelevates the temperature of the water substantially to the boiling point, whereupon the heated water flows through a second check valve to the brew basket.

- the heated waterflows to and through the jet ports into the interior of the brew basket, with at least some of the jet ports being disposed at a position beneath the level of coffee grounds contained therein.

- the heated wateris jetted or sprayed into and thoroughly wets the coffee grounds with an agitating and stirring action that is effective to lift, suspend, and turbulently stir the grounds in a manner to produce a substantially fluidized bed of water-borne grounds.

- the jet portsare oriented for rotationally stirring the coffee grounds with a substantial spinning or orbital path of motion.

- the fluidized bed of water-borne coffee groundsprovides improved and consistent intermixing of the heated water with the coffee grounds for enhanced flavor extraction with minimal bitter and/or other undesirable attributes.

- This spinning fluidized bedis directed by centrifugal action in a generally radially outward direction against an inboard side wall of the brew basket, a portion of which is defined by the mesh filter element or elements which permit outward flow-through passage of the brewed liquid coffee while substantially preventing outward passage of the coffee grounds.

- the brewed coffee passed through the filter element or elementsis directed further as by gravity flow into an underlying coffee pot such as a carafe or decanter.

- a frontal portion of the brew basket side wallcomprises a substantially transparent window visible from the exterior of the coffee brewer, when the brew basket mounted is thereon. During a brewing cycle, the spinning fluidized bed of water-borne coffee grounds within the brew basket is thus externally observable.

- FIG. 1is a side perspective view illustrating a coffee brewer in accordance with the present invention, with a carafe positioned beneath an overlying head of the coffee brewer for drip-flow reception of brewed coffee;

- FIG. 2is a front perspective view of the coffee brewer of FIG. 1 , with the carafe removed;

- FIG. 3is a top perspective view of the coffee brewer, with a hinged lid on the brewer head disposed in an open position to expose an underlying reservoir for pour-in reception of a volume of water for use in brewing coffee;

- FIG. 4is another top perspective view similar to FIG. 3 , but depicting additional removal of a brew basket and cap therefor, to expose an upwardly open cavity on the brewer head for removably supporting the brew basket;

- FIG. 5is another top perspective view similar to FIG. 4 , but showing further removal of an upper housing member of the brewer head, to exposed underlying water flow conduits;

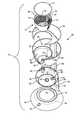

- FIG. 6is an exploded perspective view of the coffee brewer

- FIG. 7is a top perspective view of the brew basket

- FIG. 8is a bottom perspective view of the brew basket

- FIG. 9is a top plan view of the brew basket

- FIG. 10is a vertical sectional view taken generally on the line 10 - 10 of FIG. 9 ;

- FIG. 11is an enlarged fragmented sectional view showing a jet port in accordance with one preferred form of the invention, wherein heated water is jetted through the jet port into the brew basket.

- an improved coffee brewer referred to generally in FIGS. 1-6 by the reference numeral 10is provided for rapid and consistent high quality brewing of coffee.

- the coffee brewer 10includes a brew basket 12 ( FIGS. 4-10 ) for receiving a selected quantity of ground coffee (not shown).

- the brew basket 12is adapted for connection to a source of heated water, and includes at least one and preferably a plurality of jet ports 14 (FIGS. 7 and 9 - 11 ) positioned for agitating and turbulently stirring the coffee grounds to produce a substantially fluidized bed of suspended and water-borne coffee grounds within the brew basket 12 .

- This fluidized bedresults in substantially improved and intimately thorough wetting contact and intermixing between the hot water and the coffee grounds, for achieving enhanced flavor extraction to consistently produce a high quality, fuller-bodied and more robust coffee beverage.

- the improved coffee brewer 10 of the present inventionis shown generally in one preferred form in FIGS. 1-6 .

- the coffee brewer 10comprises a relatively compact base 16 having a platen 18 formed or carried thereon with a size and shape suitable for secure rested support of a coffee pot 20 such as a carafe or decanter or the like.

- An on-off button 22is exposed at a front side of the base 16 and may be depressed manually when brewing of a pot of coffee is desired, as will be described in more detail.

- a power cord 24( FIG. 1 ) protrudes rearwardly from the base 16 for connecting the brewer 10 to a suitable electrical power source.

- a support post 26extends upwardly from a rear side of the base 16 to support an upper brewer head 28 in a positioned generally cantilevered over the upwardly open coffee pot 20 supported on the base platen 18 .

- the brewer head 28comprises a relatively compact housing structure defining a water reservoir 30 ( FIGS. 3-4 ) for receiving a selected volume of water for use in brewing a pot of coffee, in combination with an upwardly open cavity 32 ( FIGS. 4-6 ) for removably supporting the brew basket 12 .

- a heating unit 34shown mounted within the base 16 as viewed in FIG.

- the illustrative brewer head 28includes an upper housing bowl 29 with an internal, generally vertically oriented divider wall 36 subdividing the brewer head 28 into the upwardly open water reservoir 30 occupying a rearward region of the head 28 , and the brewer basket cavity 32 at a forward region of the head 28 .

- a rear hinged lid 38is provided on the brewer head 28 for normally closing the water reservoir 30 , but this lid 38 is adapted for quick and easy pivoting movement to an open position (as viewed in FIGS. 3-4 ) to permit a selected volume of water to be poured into the reservoir 30 .

- the reservoir 30may be sized for receiving a standardized volume of water, such as a water volume sufficient to brew a standardized volume of coffee, such as 8, 10 or 12 cups.

- the brewer head 28may include volumetric gradation marks (not shown) indicating the volume of water contained therein, to facilitate brewing of different selected volumes of coffee.

- the coffee brewer 10may be connected directly to a tap water source or the like, in lieu of the reservoir 30 for pour-in reception of a selected water volume.

- the upper housing bowl 29 defining the water reservoir 30is mounted on a lower housing shell 39 (shown best in FIGS. 5-6 ) which is supported at an upper end of the support post 26 in cantilevered relation spaced above the base 16 .

- Water within the reservoir 30is coupled through a port 40 formed in a bottom wall of the upper bowl 29 ( FIG. 6 ) to an underlying receiver 44 which is mounted on the lower shell 39 within a compartment 46 defined cooperatively between the upper bowl 29 and lower shell 39 .

- This receiver 44may include a spring-loaded valve positioned for engagement by the upper bowl 29 for movement to an open position permitting downward water flow from the reservoir 30 , when the upper bowl 29 is mounted on the lower shell 39 .

- Such downward water flowproceeds through the receiver 44 and further through a short supply conduit 48 ( FIGS.

- a first check valve 45( FIG. 6 ) is mounted along this passage 50 within the support post 26 to permit water downflow, but to prevent upward backflow from the heating unit 34 toward the reservoir 30 .

- the heating unit 34although depicted generally in FIG. 6 by dotted lines, comprises a standard dual pathway device of the type known in the art for use in coffee brewers.

- the heating unit 34incorporates an electrical resistance heating element mounted within one annular pathway and disposed in heat transfer relation with water flow through an adjacent annular pathway.

- One exemplary dual pathway heating unit of this general typeis shown and described in U.S. Pat. No. 4,070,956, which is incorporated by reference herein. With this construction, the water downflow through the post passage 50 is circulated though the water pathway of the heating unit 34 which heats the water substantially to boiling. A downstream end of the water pathway through the heating unit 34 is coupled to a second flow passage 52 ( FIG. 6 ) for upward or return flow to the brewer head 28 .

- the upward return flow passage 52 through the support post 26delivers the heated water through a short transition conduit 54 to an inverted, generally U-shaped turn 56 positioned within the water reservoir 30 and disposed at least slightly above a maximum fill level of the reservoir.

- This inverted and elevated conduit turn 56prevents water within the reservoir 30 from draining past the turn 56 when the reservoir is filled with water.

- a downstream end of the inverted conduit turn 56is coupled by an additional supply conduit 58 to a second check valve 60 mounted at the underside of the upper bowl 29 to permit one-way flow-through passage of water from the supply conduit 58 to brew basket 12 , but prevents backflow of water to the conduit 58 .

- the second check valve 60is positioned in aligned relation with an inflow port 62 ( FIGS. 3 and 6 ) formed in the bottom wall of the upper housing bowl 29 , at a location generally centered within the brew basket cavity 32 .

- the brew basket 12includes a downwardly open feed port 64 having a size and shape for seated reception on the underlying inflow port 62 , when the brew basket 12 is positioned within the brew cavity 32 .

- This feed port 64communicates water inflow from the second check valve 60 to the jet ports 14 of the brew basket 12 .

- the brew basket 12may comprise a generally bowl-shaped component constructed primarily from lightweight molded plastic or the like, to provide a generally upwardly open geometry defined by a bottom wall 66 joined to an upstanding side wall 68 of generally cylindrical configuration.

- the bottom wall 68is formed to include the downwardly open feed port 64 for communicating hot water inflow upwardly into a false bottom or plenum chamber 70 ( FIG. 10 ) which distributes the hot water flow to at least one and preferably a plurality of hollow ribs 72 formed in the side wall 68 .

- each of said hollow ribs 72are formed in the side wall 68 at approximate 120° intervals, and each of these ribs 72 includes a closed upper end and has at least one and preferably multiple jet ports 14 formed along the height thereof for jetting hot water streams into the interior of the brew basket 12 .

- FIGS. 6-7 and 9 - 10illustrate each hollow rib 72 with a pair of vertically spaced jet ports 14 positioned and aimed for jetting water streams generally tangentially in a common swirling direction (clockwise, as viewed in FIG. 9 ) into the brew basket interior.

- At least the lower jet ports 14 on the hollow ribs 72are positioned at a level below a normal level or upper surface of a bed of dry coffee grounds placed into the brew basket 12 for brewing coffee, as indicated approximately by the dotted line 74 in FIG. 10 .

- the hot waterwhen the hot water is jetted through the jet ports 14 , at least a portion of the hot water stirs and agitates the body of coffee grounds to initiate a swirling or spinning action to create the fluidized bed of water-borne coffee grounds.

- a removable cap 77is normally provided to close the top of the brew basket 12 and thereby prevent undesired spilling of water or coffee grounds therefrom during the brewing procedure.

- each jet port 14can be shaped to define a tapered profile with a cross sectional size that reduces toward a downstream or discharge end thereof, in combination with a filter screen 15 which can be formed as by in-place plastic molding generally at an upstream or inlet end of the jet port 14 .

- a filter screen 15which can be formed as by in-place plastic molding generally at an upstream or inlet end of the jet port 14 .

- any particulate grounds which may flow or be drawn into the jet port 14are collected on the downstream side of the filter screen 15 , where they cannot clog internal flow passages of the coffee maker apparatus. Instead, such collected grounds are retained on the screen 15 where they are hydraulically delivered back into the brew basket 12 during a subsequent brew cycle.

- Alternative structures for capturing ingested coffee grounds and/or for preventing backflow of such coffee grounds into and/or through the jet ports 14will be apparent to persons skilled in the art.

- the thus-produced fluidized bedis swirled by centrifugal action against the inboard side of the brew basket side wall 68 , a portion of which is defined by one or more mesh or mesh-like filter elements 78 .

- Such filter elements 78are supported by the brew basket 12 in slightly spaced relation to the adjacent divider wall 36 to define a flow pathway for brewed coffee to pass therebetween to a drip outlet port 79 ( FIG. 6 ) formed in the upper bowl 29 and an underlying drip outlet port 80 ( FIGS. 5-6 ) formed in the lower shell 39 .

- This latter outlet port 80is positioned over the upwardly open coffee pot 20 , whereby the brewed coffee flows downwardly for collection within the pot 20 .

- the brew basket cavity 32 formed in the upper housing bowl 29may intersect and thereby interrupt a forward region of the bowl 29 , to form an arcuate recess 83 to expose a frontal portion or segment 82 of the brew basket 12 at a front side of the brewer head 28 .

- this exposed frontal segment 82 of the brew basket 12is desirably formed from a transparent or partially transparent material to permit visual observation of the swirling and spinning fluidized bed during the brewing procedure.

- a lower margin of the recess 83 in the upper bowl 29is disposed above the drip outlet port 79 .

- the removable cap 77may also be formed from a transparent or partially transparent material.

- a selected volume of wateris poured into the water reservoir 30 , and the brew basket 12 containing a selected quantity of ground coffee is placed into the associated brew basket cavity 32 in the brewer head 28 .

- a portion of the water within the reservoir 30will flow downwardly through the first check valve 45 to fill the associated pathway within the heating unit 34 .

- the heating unit 34is energized to raise the temperature of the water therein substantially to boiling, resulting in pressure-forced pumping the hot water upwardly through the inverted and elevated inverted conduit turn 56 and further through the second check valve 60 to the jet ports 14 within the brew basket 12 .

- This upwardly pumped wateris replaced by continued water downflow from the reservoir 30 , for heating by the heating unit 34 , until the reservoir 30 reaches a substantially empty condition.

- the hot wateris jetted into the interior of the brew basket 12 via the jet ports 14 , as described, to generate the swirling turbulent fluidized bed of water-borne coffee grounds.

- the thus-brewed coffeeis filtered through the mesh filter elements 78 for delivery into the underlying pot 20 , wherein the brewed coffee may be retained in a heated state by suitably controlling the heating unit 34 for heating the platen 18 .

- the heating unit 34may be designed to de-activate and the brewed coffee may be retained within an insulated decanter.

- the brew basket 12may be removed from the brewer head 28 for appropriate cleaning and discarding of the spent coffee grounds retained on the filter elements. Thereafter, the brew basket 12 may be refilled with coffee grounds for a subsequent brew cycle.

- the improved coffee brewer 10 of the present inventionthus produces brewed coffee by means of intimately thorough and consistent intermixing between the hot water and coffee grounds, to produce a coffee beverage of repeatable high quality taste and other characteristics.

- the resultant steam rising from the fluidized bedis believed to carry enhanced or intensified coffee aroma, thereby producing an enhanced of more enjoyable coffee brewing experience.

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Apparatus For Making Beverages (AREA)

Abstract

Description

Claims (19)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US14/181,448USRE45476E1 (en) | 2003-05-19 | 2014-02-14 | Coffee brewer |

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US47192603P | 2003-05-19 | 2003-05-19 | |

| US10/845,742US6968775B2 (en) | 2003-05-19 | 2004-05-14 | Coffee brewer |

| US11/247,564US7240611B2 (en) | 2003-05-19 | 2005-10-10 | Coffee brewer |

| US14/181,448USRE45476E1 (en) | 2003-05-19 | 2014-02-14 | Coffee brewer |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US11/247,564ReissueUS7240611B2 (en) | 2003-05-19 | 2005-10-10 | Coffee brewer |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| USRE45476E1true USRE45476E1 (en) | 2015-04-21 |

Family

ID=33476900

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US10/845,742Expired - LifetimeUS6968775B2 (en) | 2003-05-19 | 2004-05-14 | Coffee brewer |

| US11/247,564Expired - LifetimeUS7240611B2 (en) | 2003-05-19 | 2005-10-10 | Coffee brewer |

| US14/181,448Expired - Fee RelatedUSRE45476E1 (en) | 2003-05-19 | 2014-02-14 | Coffee brewer |

Family Applications Before (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US10/845,742Expired - LifetimeUS6968775B2 (en) | 2003-05-19 | 2004-05-14 | Coffee brewer |

| US11/247,564Expired - LifetimeUS7240611B2 (en) | 2003-05-19 | 2005-10-10 | Coffee brewer |

Country Status (7)

| Country | Link |

|---|---|

| US (3) | US6968775B2 (en) |

| EP (1) | EP1624780B1 (en) |

| JP (1) | JP4499105B2 (en) |

| CN (1) | CN1809303A (en) |

| CA (1) | CA2526280C (en) |

| DE (1) | DE602004018130D1 (en) |

| WO (1) | WO2004103129A2 (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20150099045A1 (en)* | 2012-04-25 | 2015-04-09 | Nestec S.A. | Method for the Preparation of a Beverage by Centrifugation Using a Container |

| US20150118367A1 (en)* | 2010-02-17 | 2015-04-30 | Koninklijke Douwe Egberts B.V. | Coffee bean packaging cartridge and coffee beverage system including the same |

| USD766655S1 (en)* | 2014-11-25 | 2016-09-20 | Bean Logik Llc | Body of a cold brew coffee system |

| US9962031B2 (en) | 2015-10-30 | 2018-05-08 | Adrian Rivera | Brewing chamber with dynamic water dispersion |

| US9980599B2 (en) | 2009-02-17 | 2018-05-29 | Koninklijke Douwe Egberts B.V. | Coffee bean packaging cartridge and coffee beverage system including same |

| KR20190044367A (en)* | 2017-10-20 | 2019-04-30 | 김인근 | A grinder of a coffee machine-an auxiliary holder which assists the coffee powder dispensed from the dispenser to be received at a uniform density on the holder cup |

| US12378061B2 (en) | 2010-07-12 | 2025-08-05 | Universal Coffee LLC | Apparatus and products for producing beverages, and methods for making and using same |

Families Citing this family (45)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7340991B2 (en)* | 2003-05-19 | 2008-03-11 | Aroma Fresh, Llc | Coffee brewer |

| GB2413479B (en)* | 2004-02-17 | 2006-06-28 | Kraft Foods R & D Inc | An insert and a system for the preparation of beverages |

| GB2413480B (en)* | 2004-02-17 | 2006-08-30 | Kraft Foods R & D Inc | An insert and a system for the preparation of beverages |

| ITMI20050880A1 (en)* | 2005-05-16 | 2006-11-17 | Saeco Internat Group S P A | STEAM UNIT WITH EXTERNAL ANCHORING INCLUDING A CARAFE FOR FOAMING MILK AND HEATING DRINKS FOR ESPRESSO DRINKING MACHINE |

| US9844292B2 (en) | 2009-10-30 | 2017-12-19 | Adrian Rivera | Coffee maker with multi and single cup modes |

| WO2007041954A1 (en)* | 2005-10-11 | 2007-04-19 | Zhiping Li | Coffee maker |

| CN101466809B (en) | 2006-06-15 | 2013-04-24 | 陶氏环球技术有限责任公司 | Functionalized olefin interpolymers, compositions and articles made therefrom, and methods of making them |

| US7661353B2 (en)* | 2006-10-17 | 2010-02-16 | Uni-Splendor Corp. | Hot beverage maker |

| US20080216663A1 (en)* | 2007-03-09 | 2008-09-11 | Steve Williamson | Brewed beverage maker with dispensing assembly |

| CN100462032C (en)* | 2007-04-20 | 2009-02-18 | 九阳股份有限公司 | Multifunctional soya-bean milk maker |

| US7980168B2 (en)* | 2007-06-26 | 2011-07-19 | Maurer Scott D | Hot beverage maker with filter deforming member |

| US20090178569A1 (en)* | 2007-07-11 | 2009-07-16 | Tucker George H | Tea brew basket |

| US11832755B2 (en) | 2007-07-13 | 2023-12-05 | Adrian Rivera | Brewing material container for a beverage brewer |

| US12342955B2 (en) | 2020-10-30 | 2025-07-01 | Adrian Rivera Maynez Enterprises, Inc. | Brewing material container for a beverage brewer |

| US11337543B2 (en) | 2007-07-13 | 2022-05-24 | Adrian Rivera | Brewing material holder |

| US9271597B2 (en)* | 2007-07-13 | 2016-03-01 | ARM Enterprises | Single serving reusable brewing material holder |

| US12396588B2 (en) | 2007-07-13 | 2025-08-26 | Adrian Rivera Maynez Enterprises, Inc. | Brewing material container for a beverage brewer |

| US10722066B2 (en) | 2010-12-04 | 2020-07-28 | Adrian Rivera | Windowed single serving brewing material holder |

| US8778414B2 (en)* | 2007-08-09 | 2014-07-15 | General Patent, Llc | Apparatus and method for cellular extract enhancement |

| IT1395827B1 (en)* | 2009-04-09 | 2012-10-26 | Saeco Strategic Services Ltd | "DRINKING MACHINE FOR BEVERAGE PRODUCTION" |

| US20110005398A1 (en)* | 2009-07-09 | 2011-01-13 | Wal-Mart Stores, Inc. | Method and System to Produce Gourmet Coffee |

| US8707855B2 (en) | 2011-05-09 | 2014-04-29 | Eko Brands, Llc | Beverage Brewing Device |

| FR2976778B1 (en)* | 2011-06-24 | 2013-07-12 | Philippe Lazareth | FORCED CIRCULATION INFUSION DEVICE |

| WO2013063717A1 (en)* | 2011-11-01 | 2013-05-10 | Jiang Wende | Apparatus for formulating powdery substances |

| JP6272772B2 (en) | 2011-11-23 | 2018-01-31 | スターバックス・コーポレイション | Beverage extraction apparatus, system and method |

| WO2013169678A2 (en) | 2012-05-06 | 2013-11-14 | Burrows Bruce D | Coffee brewer apparatuses and methods for brewing beverages |

| CN103284601B (en)* | 2013-06-21 | 2016-08-31 | 熊兴剑 | Frothing milk machine |

| WO2015077237A2 (en) | 2013-11-20 | 2015-05-28 | Starbucks Corporation D/B/A Starbucks Coffee Company | Cooking system power management |

| USD738667S1 (en) | 2013-11-20 | 2015-09-15 | Starbucks Corporation | Beverage brewing apparatus |

| US9307860B2 (en) | 2014-02-14 | 2016-04-12 | Remington Designs, Llc | Processor control of solute extraction system |

| US20170172338A1 (en)* | 2014-02-14 | 2017-06-22 | Remington Designs, Llc | Beverage brewer and related methods for brewing beverages |

| WO2017042247A1 (en)* | 2015-09-09 | 2017-03-16 | Vorwerk & Co. Interholding Gmbh | Tea machine, system and method for operating a tea machine |

| US20220225817A1 (en)* | 2016-09-29 | 2022-07-21 | LEVO Oil Infusion, Inc. | Apparatus and method for infusing and dispensing oils, and drying and heating infusing materials |

| FR3059220B1 (en)* | 2016-11-28 | 2018-11-16 | Seb S.A. | COFFEE FILTER MACHINE HAVING A BRIGHT MILLING DOSING DEVICE |

| USD852566S1 (en)* | 2017-03-17 | 2019-07-02 | Ene Holdings Ltd | Automatic pour over coffee maker |

| CN108720610B (en)* | 2018-09-07 | 2024-04-12 | 珠海横琴鑫润智能制造有限公司 | Brewing assembly and brewing equipment |

| US20200093315A1 (en)* | 2018-09-25 | 2020-03-26 | Bruce D. Burrows | Magnetically Driven Beverage Brewing System and Method |

| USD927250S1 (en) | 2020-03-23 | 2021-08-10 | Eko Brands, Llc | Reusable filter cartridge |

| US11805934B1 (en) | 2020-10-21 | 2023-11-07 | Adrian Rivera | Brewing material lid and container for a beverage brewer |

| USD1055632S1 (en) | 2021-02-26 | 2024-12-31 | Universal Coffee LLC | Reusable filter cartridge |

| US11457765B1 (en) | 2022-05-10 | 2022-10-04 | Havana Savannah, Llc | Magnetically driven beverage brewing and cleaning system |

| USD1023658S1 (en) | 2022-06-29 | 2024-04-23 | Havana Savannah, Llc | Coffee brewing system |

| USD1095143S1 (en) | 2022-06-29 | 2025-09-30 | Havana Savannah, Llc | Snorkel tube |

| CN120693088A (en)* | 2022-12-16 | 2025-09-23 | 菲利普斯基·詹姆斯知识产权有限责任公司 | Food grinding device |

| US20250204718A1 (en)* | 2023-12-20 | 2025-06-26 | Aereos Interior Solutions, LLC | Brew basket for an aircraft galley coffee maker |

Citations (36)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US670004A (en) | 1900-07-30 | 1901-03-19 | John F Normile | Automatic fountain coffee-pot. |

| US808730A (en) | 1905-03-27 | 1906-01-02 | Martin M De Grody | Coffee-pot. |

| US1602632A (en) | 1919-10-15 | 1926-10-12 | Manthey Zorn Lab Company | Apparatus for making coffee |

| US1706190A (en)* | 1924-04-29 | 1929-03-19 | Edison Electric Appliance Co I | Coffee-making apparatus |

| US2552169A (en)* | 1944-08-28 | 1951-05-08 | Maurice H Graham | Coffee maker |

| US2858762A (en) | 1957-04-29 | 1958-11-04 | Wade Maurice Ross | Coffee maker |

| US3368476A (en) | 1965-09-02 | 1968-02-13 | Mancioli Luciano | Apparatus for making a beverage, for example coffee |

| US3638555A (en) | 1968-12-30 | 1972-02-01 | Luciano Mancioli | Device for producing an infused liquid, particularly coffee |

| US3670641A (en) | 1969-12-31 | 1972-06-20 | Luciano Mancioli | Beverage infusion apparatus, for example coffee |

| US3967546A (en) | 1973-07-09 | 1976-07-06 | Serge Cailliot | Method and apparatus for making coffee |

| US4070956A (en) | 1976-07-12 | 1978-01-31 | General Electric Company | Coffeemaker with brewing water spreader |

| US4074621A (en) | 1975-06-13 | 1978-02-21 | Societe Normande De Services | Infusion-making machine |

| US4138936A (en) | 1977-05-20 | 1979-02-13 | Rival Manufacturing Company | Coffee brewing machine |

| US4401014A (en) | 1981-11-23 | 1983-08-30 | Mcgrail John F | Automatic coffee-brewing apparatus |

| US4473002A (en) | 1981-09-22 | 1984-09-25 | Bosch-Siemens Hausgeraete Gmbh | Electric coffee machine with a centrifugal filter |

| US4779520A (en) | 1986-12-22 | 1988-10-25 | Melitta-Werke Bentz & Sohn | Coffee maker or tea maker |

| US4962693A (en) | 1988-11-02 | 1990-10-16 | Kabushiki Kaisha Toshiba | Centrifugal brewing type coffee maker |

| US4983412A (en) | 1986-12-22 | 1991-01-08 | Melitta-Werke Bentz & Sohn | Method and device for producing aqueous extracts from coffee |

| US4995311A (en) | 1988-09-05 | 1991-02-26 | Kabushiki Kaisha Toshiba | Device for making liquid coffee |

| US5047252A (en) | 1989-02-22 | 1991-09-10 | Nestec S.A. | Beverage infusion device and method |

| US5265517A (en) | 1991-10-09 | 1993-11-30 | Industria Columbiana De Electronicos Y Electrodomesticos, Incelt S.A. Of Carrera | Method and apparatus for brewing coffee |

| US5305685A (en) | 1993-05-04 | 1994-04-26 | Bunn-O-Matic Corporation | Grounds removal centrifuge |

| US5358725A (en) | 1992-07-01 | 1994-10-25 | Mccoffee Co., Ltd. | Method and device for extracting effective ingredients from dried plant materials |

| DE4315213A1 (en) | 1993-05-07 | 1994-11-10 | Puehler Thomas Dipl Ing Fh | Water distributor for coffee machines |

| US5910205A (en) | 1997-07-24 | 1999-06-08 | Cafe 98 Industries Limited | Brew basket for coffee-making machine |

| US5957035A (en) | 1997-10-10 | 1999-09-28 | Richter; Walter M. | Swirling oscillation coffee maker |

| US5992299A (en) | 1998-05-21 | 1999-11-30 | Silver Plan Industrial Limited | Coffee makers |

| US6006655A (en) | 1996-03-12 | 1999-12-28 | Braun Aktiengesellschaft | Coffee machine and filter element therefor |

| US6079314A (en) | 1997-05-16 | 2000-06-27 | Office Perks Gourmet Coffee Service Inc. | Beverage brewer chamber assembly |

| US6244162B1 (en) | 2000-01-24 | 2001-06-12 | Grindmaster Corporation | Spray head for coffee brewer |

| US6279459B1 (en) | 1998-12-04 | 2001-08-28 | Amway Corporation | Coffee maker |

| US6324964B1 (en) | 1997-12-30 | 2001-12-04 | Anton Niederberger | Automatic tea-making machine |

| US20010052293A1 (en) | 2000-06-17 | 2001-12-20 | Christoph Lang | Device for making mocha coffee |

| US6564697B2 (en) | 2000-11-30 | 2003-05-20 | Lipton, Division Of Conopco, Inc. | Tea brewing method and apparatus |

| US20030157226A1 (en) | 2002-02-19 | 2003-08-21 | Leung Chi Wah | Method of making coffee and coffee maker |

| US20040060451A1 (en) | 2002-09-27 | 2004-04-01 | Leung Chi Wah | Method of making coffee and coffee maker |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2618218A (en)* | 1948-06-09 | 1952-11-18 | Cory Corp | Beverage maker |

| US2822746A (en)* | 1954-05-14 | 1958-02-11 | Wallin Ind Corp | Coffee brewing machine |

| US3638476A (en)* | 1969-12-08 | 1972-02-01 | Exxon Research Engineering Co | Oil and sampling system |

| JPS63125476A (en)* | 1986-11-15 | 1988-05-28 | Fuji Heavy Ind Ltd | Electric rear wheel steering device |

| JP2732626B2 (en)* | 1988-12-07 | 1998-03-30 | 松下電器産業株式会社 | Extractor for coffee etc. |

| JPH07289436A (en)* | 1993-09-01 | 1995-11-07 | Zuma Coffee Technol Inc | Method and device to extract coffee |

| US5584229A (en)* | 1995-08-14 | 1996-12-17 | Bunn-O-Matic Corporation | Reduced temperature coffee brewer |

| ES2178353T3 (en)* | 1998-12-24 | 2002-12-16 | Unilever Nv | MACHINE FOR THE PREPARATION OF TE. |

| US6425317B1 (en)* | 2000-09-12 | 2002-07-30 | Objective Design | Coffee maker filter basket with steeping feature |

| US6817280B2 (en)* | 2002-04-02 | 2004-11-16 | Brewbot, Inc. | System and method for brewing beverages |

- 2004

- 2004-05-14DEDE200460018130patent/DE602004018130D1/ennot_activeExpired - Lifetime

- 2004-05-14WOPCT/US2004/015228patent/WO2004103129A2/enactiveApplication Filing

- 2004-05-14JPJP2006533092Apatent/JP4499105B2/ennot_activeExpired - Fee Related

- 2004-05-14EPEP04752287Apatent/EP1624780B1/ennot_activeExpired - Lifetime

- 2004-05-14USUS10/845,742patent/US6968775B2/ennot_activeExpired - Lifetime

- 2004-05-14CACA2526280Apatent/CA2526280C/ennot_activeExpired - Fee Related

- 2004-05-14CNCNA2004800174436Apatent/CN1809303A/enactivePending

- 2005

- 2005-10-10USUS11/247,564patent/US7240611B2/ennot_activeExpired - Lifetime

- 2014

- 2014-02-14USUS14/181,448patent/USRE45476E1/ennot_activeExpired - Fee Related

Patent Citations (38)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US670004A (en) | 1900-07-30 | 1901-03-19 | John F Normile | Automatic fountain coffee-pot. |

| US808730A (en) | 1905-03-27 | 1906-01-02 | Martin M De Grody | Coffee-pot. |

| US1602632A (en) | 1919-10-15 | 1926-10-12 | Manthey Zorn Lab Company | Apparatus for making coffee |

| US1706190A (en)* | 1924-04-29 | 1929-03-19 | Edison Electric Appliance Co I | Coffee-making apparatus |

| US2552169A (en)* | 1944-08-28 | 1951-05-08 | Maurice H Graham | Coffee maker |

| US2858762A (en) | 1957-04-29 | 1958-11-04 | Wade Maurice Ross | Coffee maker |

| US3368476A (en) | 1965-09-02 | 1968-02-13 | Mancioli Luciano | Apparatus for making a beverage, for example coffee |

| US3638555A (en) | 1968-12-30 | 1972-02-01 | Luciano Mancioli | Device for producing an infused liquid, particularly coffee |

| US3670641A (en) | 1969-12-31 | 1972-06-20 | Luciano Mancioli | Beverage infusion apparatus, for example coffee |

| US3967546A (en) | 1973-07-09 | 1976-07-06 | Serge Cailliot | Method and apparatus for making coffee |

| US4074621A (en) | 1975-06-13 | 1978-02-21 | Societe Normande De Services | Infusion-making machine |

| US4070956A (en) | 1976-07-12 | 1978-01-31 | General Electric Company | Coffeemaker with brewing water spreader |

| US4138936A (en) | 1977-05-20 | 1979-02-13 | Rival Manufacturing Company | Coffee brewing machine |

| US4473002A (en) | 1981-09-22 | 1984-09-25 | Bosch-Siemens Hausgeraete Gmbh | Electric coffee machine with a centrifugal filter |

| US4401014A (en) | 1981-11-23 | 1983-08-30 | Mcgrail John F | Automatic coffee-brewing apparatus |

| US4779520A (en) | 1986-12-22 | 1988-10-25 | Melitta-Werke Bentz & Sohn | Coffee maker or tea maker |

| US4983412A (en) | 1986-12-22 | 1991-01-08 | Melitta-Werke Bentz & Sohn | Method and device for producing aqueous extracts from coffee |

| US4995311A (en) | 1988-09-05 | 1991-02-26 | Kabushiki Kaisha Toshiba | Device for making liquid coffee |

| US4962693A (en) | 1988-11-02 | 1990-10-16 | Kabushiki Kaisha Toshiba | Centrifugal brewing type coffee maker |

| US5047252A (en) | 1989-02-22 | 1991-09-10 | Nestec S.A. | Beverage infusion device and method |

| US5265517A (en) | 1991-10-09 | 1993-11-30 | Industria Columbiana De Electronicos Y Electrodomesticos, Incelt S.A. Of Carrera | Method and apparatus for brewing coffee |

| US5358725A (en) | 1992-07-01 | 1994-10-25 | Mccoffee Co., Ltd. | Method and device for extracting effective ingredients from dried plant materials |

| US5305685A (en) | 1993-05-04 | 1994-04-26 | Bunn-O-Matic Corporation | Grounds removal centrifuge |

| DE4315213A1 (en) | 1993-05-07 | 1994-11-10 | Puehler Thomas Dipl Ing Fh | Water distributor for coffee machines |

| US6006655A (en) | 1996-03-12 | 1999-12-28 | Braun Aktiengesellschaft | Coffee machine and filter element therefor |

| US6079314A (en) | 1997-05-16 | 2000-06-27 | Office Perks Gourmet Coffee Service Inc. | Beverage brewer chamber assembly |

| US5910205A (en) | 1997-07-24 | 1999-06-08 | Cafe 98 Industries Limited | Brew basket for coffee-making machine |

| US5957035A (en) | 1997-10-10 | 1999-09-28 | Richter; Walter M. | Swirling oscillation coffee maker |

| US6324964B1 (en) | 1997-12-30 | 2001-12-04 | Anton Niederberger | Automatic tea-making machine |

| US5992299A (en) | 1998-05-21 | 1999-11-30 | Silver Plan Industrial Limited | Coffee makers |

| US6279459B1 (en) | 1998-12-04 | 2001-08-28 | Amway Corporation | Coffee maker |

| US6532862B2 (en) | 1998-12-04 | 2003-03-18 | Access Business Group International Llc | Coffee maker |

| US6244162B1 (en) | 2000-01-24 | 2001-06-12 | Grindmaster Corporation | Spray head for coffee brewer |

| US20010052293A1 (en) | 2000-06-17 | 2001-12-20 | Christoph Lang | Device for making mocha coffee |

| US6564697B2 (en) | 2000-11-30 | 2003-05-20 | Lipton, Division Of Conopco, Inc. | Tea brewing method and apparatus |

| US20030157226A1 (en) | 2002-02-19 | 2003-08-21 | Leung Chi Wah | Method of making coffee and coffee maker |

| US20040060451A1 (en) | 2002-09-27 | 2004-04-01 | Leung Chi Wah | Method of making coffee and coffee maker |

| US6817279B2 (en) | 2002-09-27 | 2004-11-16 | Simatelex Manufactory Co., Ltd. | Method of making coffee and coffee maker |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9980599B2 (en) | 2009-02-17 | 2018-05-29 | Koninklijke Douwe Egberts B.V. | Coffee bean packaging cartridge and coffee beverage system including same |

| US10499763B2 (en) | 2009-02-17 | 2019-12-10 | Koninklijke Douwe Egberts B.V. | Coffee bean packaging cartridge and coffee beverage system including same |

| US20150118367A1 (en)* | 2010-02-17 | 2015-04-30 | Koninklijke Douwe Egberts B.V. | Coffee bean packaging cartridge and coffee beverage system including the same |

| US12378061B2 (en) | 2010-07-12 | 2025-08-05 | Universal Coffee LLC | Apparatus and products for producing beverages, and methods for making and using same |

| US20150099045A1 (en)* | 2012-04-25 | 2015-04-09 | Nestec S.A. | Method for the Preparation of a Beverage by Centrifugation Using a Container |

| US9149147B2 (en)* | 2012-04-25 | 2015-10-06 | Nestec S.A. | Method for the preparation of a beverage by centrifugation using a container |

| USD766655S1 (en)* | 2014-11-25 | 2016-09-20 | Bean Logik Llc | Body of a cold brew coffee system |

| US9962031B2 (en) | 2015-10-30 | 2018-05-08 | Adrian Rivera | Brewing chamber with dynamic water dispersion |

| KR20190044367A (en)* | 2017-10-20 | 2019-04-30 | 김인근 | A grinder of a coffee machine-an auxiliary holder which assists the coffee powder dispensed from the dispenser to be received at a uniform density on the holder cup |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1624780A2 (en) | 2006-02-15 |

| US20040231522A1 (en) | 2004-11-25 |

| US20060027102A1 (en) | 2006-02-09 |

| JP2007502195A (en) | 2007-02-08 |

| CA2526280C (en) | 2013-12-03 |

| US6968775B2 (en) | 2005-11-29 |

| WO2004103129A3 (en) | 2005-06-23 |

| CN1809303A (en) | 2006-07-26 |

| JP4499105B2 (en) | 2010-07-07 |

| CA2526280A1 (en) | 2004-12-02 |

| EP1624780A4 (en) | 2007-06-06 |

| DE602004018130D1 (en) | 2009-01-15 |

| WO2004103129A2 (en) | 2004-12-02 |

| US7240611B2 (en) | 2007-07-10 |

| EP1624780B1 (en) | 2008-12-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| USRE45476E1 (en) | Coffee brewer | |

| EP1978854B1 (en) | Coffee brewer | |

| US5927179A (en) | Apparatus for quick brewing of tea | |

| US6564697B2 (en) | Tea brewing method and apparatus | |

| US20050076783A1 (en) | Beverage device for making a beverage with a foam layer on top | |

| US20140123859A1 (en) | Preparation of an arabic coffee beverage | |

| CN107708506B (en) | Foaming stick | |

| EP1020152A2 (en) | Tea brewing apparatus | |

| JP2004528143A (en) | Apparatus and method for making a foamed beverage suitable for eating and drinking | |

| US5907993A (en) | Satellite brewing system | |

| JP2014533999A (en) | Milk whipping device and coffee or espresso machine and automatic beverage vending machine with this type of milk whipping device | |

| US3998144A (en) | Coffee urn | |

| US3859902A (en) | Pour in coffee maker | |

| US8132499B2 (en) | Heated substance reservoir baffle | |

| WO2013137728A1 (en) | Preparation of a liquid food product for human consumption, for example an arabic coffee beverage. | |

| HK1095718A (en) | Coffee brewer |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AS | Assignment | Owner name:REMINGTON DESIGNS, LLC, CALIFORNIA Free format text:ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:BURROWS, BRUCE D.;REEL/FRAME:032434/0231 Effective date:20140305 | |

| AS | Assignment | Owner name:MALETIS, ED, OREGON Free format text:SECURITY INTEREST;ASSIGNOR:REMINGTON DESIGNS, LLC;REEL/FRAME:039724/0539 Effective date:20160721 Owner name:MALETIS, CHRIS, OREGON Free format text:SECURITY INTEREST;ASSIGNOR:REMINGTON DESIGNS, LLC;REEL/FRAME:039724/0539 Effective date:20160721 | |

| AS | Assignment | Owner name:MALETIS, CHRIS, OREGON Free format text:CORRECTIVE ASSIGNMENT TO CORRECT THE PROPERTY NUMBER D734972 PREVIOUSLY RECORDED ON REEL 039724 FRAME 0539. ASSIGNOR(S) HEREBY CONFIRMS THE SECURITY INTEREST;ASSIGNOR:REMINGTON DESIGNS, LLC;REEL/FRAME:043790/0178 Effective date:20160721 Owner name:MALETIS, ED, OREGON Free format text:CORRECTIVE ASSIGNMENT TO CORRECT THE PROPERTY NUMBER D734972 PREVIOUSLY RECORDED ON REEL 039724 FRAME 0539. ASSIGNOR(S) HEREBY CONFIRMS THE SECURITY INTEREST;ASSIGNOR:REMINGTON DESIGNS, LLC;REEL/FRAME:043790/0178 Effective date:20160721 | |

| AS | Assignment | Owner name:HAGEN, DAVID, CALIFORNIA Free format text:ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:REMINGTON DESIGNS, LLC;REEL/FRAME:044256/0059 Effective date:20170831 | |

| AS | Assignment | Owner name:COFFEE SOLUTIONS, LLC, OREGON Free format text:ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:HAGEN, DAVID;REEL/FRAME:044207/0600 Effective date:20170901 | |

| AS | Assignment | Owner name:MALETIS, CHRIS, OREGON Free format text:NOTICE OF AMENDED AND RESTATED IP SECURITY AGREEMENT;ASSIGNOR:COFFEE SOLUTIONS, LLC;REEL/FRAME:044996/0938 Effective date:20171018 Owner name:MALETIS, ED, OREGON Free format text:NOTICE OF AMENDED AND RESTATED IP SECURITY AGREEMENT;ASSIGNOR:COFFEE SOLUTIONS, LLC;REEL/FRAME:044996/0938 Effective date:20171018 | |

| FEPP | Fee payment procedure | Free format text:MAINTENANCE FEE REMINDER MAILED (ORIGINAL EVENT CODE: REM.); ENTITY STATUS OF PATENT OWNER: SMALL ENTITY | |

| LAPS | Lapse for failure to pay maintenance fees | Free format text:PATENT EXPIRED FOR FAILURE TO PAY MAINTENANCE FEES (ORIGINAL EVENT CODE: EXP.); ENTITY STATUS OF PATENT OWNER: SMALL ENTITY |