USRE40145E1 - Ultra-thin flexible durable radio frequency identification devices and hot or cold lamination process for the manufacture of ultra-thin flexible durable radio frequency identification devices - Google Patents

Ultra-thin flexible durable radio frequency identification devices and hot or cold lamination process for the manufacture of ultra-thin flexible durable radio frequency identification devicesDownload PDFInfo

- Publication number

- USRE40145E1 USRE40145E1US10/773,810US77381004AUSRE40145EUS RE40145 E1USRE40145 E1US RE40145E1US 77381004 AUS77381004 AUS 77381004AUS RE40145 EUSRE40145 EUS RE40145E

- Authority

- US

- United States

- Prior art keywords

- core

- electronic element

- pressure

- plastic

- sheets

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime, expires

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/14—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers

- B32B37/16—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers with all layers existing as coherent layers before laminating

- B32B37/18—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers with all layers existing as coherent layers before laminating involving the assembly of discrete sheets or panels only

- B32B37/182—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers with all layers existing as coherent layers before laminating involving the assembly of discrete sheets or panels only one or more of the layers being plastic

- B32B37/185—Laminating sheets, panels or inserts between two discrete plastic layers

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06K—GRAPHICAL DATA READING; PRESENTATION OF DATA; RECORD CARRIERS; HANDLING RECORD CARRIERS

- G06K19/00—Record carriers for use with machines and with at least a part designed to carry digital markings

- G06K19/06—Record carriers for use with machines and with at least a part designed to carry digital markings characterised by the kind of the digital marking, e.g. shape, nature, code

- G06K19/067—Record carriers with conductive marks, printed circuits or semiconductor circuit elements, e.g. credit or identity cards also with resonating or responding marks without active components

- G06K19/07—Record carriers with conductive marks, printed circuits or semiconductor circuit elements, e.g. credit or identity cards also with resonating or responding marks without active components with integrated circuit chips

- G06K19/077—Constructional details, e.g. mounting of circuits in the carrier

- G06K19/07718—Constructional details, e.g. mounting of circuits in the carrier the record carrier being manufactured in a continuous process, e.g. using endless rolls

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06K—GRAPHICAL DATA READING; PRESENTATION OF DATA; RECORD CARRIERS; HANDLING RECORD CARRIERS

- G06K19/00—Record carriers for use with machines and with at least a part designed to carry digital markings

- G06K19/06—Record carriers for use with machines and with at least a part designed to carry digital markings characterised by the kind of the digital marking, e.g. shape, nature, code

- G06K19/067—Record carriers with conductive marks, printed circuits or semiconductor circuit elements, e.g. credit or identity cards also with resonating or responding marks without active components

- G06K19/07—Record carriers with conductive marks, printed circuits or semiconductor circuit elements, e.g. credit or identity cards also with resonating or responding marks without active components with integrated circuit chips

- G06K19/077—Constructional details, e.g. mounting of circuits in the carrier

- G06K19/07745—Mounting details of integrated circuit chips

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06K—GRAPHICAL DATA READING; PRESENTATION OF DATA; RECORD CARRIERS; HANDLING RECORD CARRIERS

- G06K19/00—Record carriers for use with machines and with at least a part designed to carry digital markings

- G06K19/06—Record carriers for use with machines and with at least a part designed to carry digital markings characterised by the kind of the digital marking, e.g. shape, nature, code

- G06K19/067—Record carriers with conductive marks, printed circuits or semiconductor circuit elements, e.g. credit or identity cards also with resonating or responding marks without active components

- G06K19/07—Record carriers with conductive marks, printed circuits or semiconductor circuit elements, e.g. credit or identity cards also with resonating or responding marks without active components with integrated circuit chips

- G06K19/077—Constructional details, e.g. mounting of circuits in the carrier

- G06K19/07749—Constructional details, e.g. mounting of circuits in the carrier the record carrier being capable of non-contact communication, e.g. constructional details of the antenna of a non-contact smart card

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06K—GRAPHICAL DATA READING; PRESENTATION OF DATA; RECORD CARRIERS; HANDLING RECORD CARRIERS

- G06K19/00—Record carriers for use with machines and with at least a part designed to carry digital markings

- G06K19/06—Record carriers for use with machines and with at least a part designed to carry digital markings characterised by the kind of the digital marking, e.g. shape, nature, code

- G06K19/067—Record carriers with conductive marks, printed circuits or semiconductor circuit elements, e.g. credit or identity cards also with resonating or responding marks without active components

- G06K19/07—Record carriers with conductive marks, printed circuits or semiconductor circuit elements, e.g. credit or identity cards also with resonating or responding marks without active components with integrated circuit chips

- G06K19/077—Constructional details, e.g. mounting of circuits in the carrier

- G06K19/07749—Constructional details, e.g. mounting of circuits in the carrier the record carrier being capable of non-contact communication, e.g. constructional details of the antenna of a non-contact smart card

- G06K19/07766—Constructional details, e.g. mounting of circuits in the carrier the record carrier being capable of non-contact communication, e.g. constructional details of the antenna of a non-contact smart card comprising at least a second communication arrangement in addition to a first non-contact communication arrangement

- G06K19/07769—Constructional details, e.g. mounting of circuits in the carrier the record carrier being capable of non-contact communication, e.g. constructional details of the antenna of a non-contact smart card comprising at least a second communication arrangement in addition to a first non-contact communication arrangement the further communication means being a galvanic interface, e.g. hybrid or mixed smart cards having a contact and a non-contact interface

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/22—Secondary treatment of printed circuits

- H05K3/28—Applying non-metallic protective coatings

- H05K3/281—Applying non-metallic protective coatings by means of a preformed insulating foil

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2305/00—Condition, form or state of the layers or laminate

- B32B2305/34—Inserts

- B32B2305/342—Chips

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2309/00—Parameters for the laminating or treatment process; Apparatus details

- B32B2309/02—Temperature

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2309/00—Parameters for the laminating or treatment process; Apparatus details

- B32B2309/04—Time

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2309/00—Parameters for the laminating or treatment process; Apparatus details

- B32B2309/12—Pressure

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2327/00—Polyvinylhalogenides

- B32B2327/06—PVC, i.e. polyvinylchloride

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2425/00—Cards, e.g. identity cards, credit cards

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2429/00—Carriers for sound or information

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2519/00—Labels, badges

- B32B2519/02—RFID tags

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/08—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the cooling method

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B38/06—Embossing

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B38/14—Printing or colouring

- B32B38/145—Printing

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/0001—Technical content checked by a classifier

- H01L2924/0002—Not covered by any one of groups H01L24/00, H01L24/00 and H01L2224/00

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2203/00—Indexing scheme relating to apparatus or processes for manufacturing printed circuits covered by H05K3/00

- H05K2203/02—Details related to mechanical or acoustic processing, e.g. drilling, punching, cutting, using ultrasound

- H05K2203/0228—Cutting, sawing, milling or shearing

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2203/00—Indexing scheme relating to apparatus or processes for manufacturing printed circuits covered by H05K3/00

- H05K2203/06—Lamination

- H05K2203/068—Features of the lamination press or of the lamination process, e.g. using special separator sheets

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K2203/00—Indexing scheme relating to apparatus or processes for manufacturing printed circuits covered by H05K3/00

- H05K2203/11—Treatments characterised by their effect, e.g. heating, cooling, roughening

- H05K2203/1105—Heating or thermal processing not related to soldering, firing, curing or laminating, e.g. for shaping the substrate or during finish plating

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/0011—Working of insulating substrates or insulating layers

- H05K3/0044—Mechanical working of the substrate, e.g. drilling or punching

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/22—Secondary treatment of printed circuits

- H05K3/28—Applying non-metallic protective coatings

- H05K3/284—Applying non-metallic protective coatings for encapsulating mounted components

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T156/00—Adhesive bonding and miscellaneous chemical manufacture

- Y10T156/10—Methods of surface bonding and/or assembly therefor

- Y10T156/1089—Methods of surface bonding and/or assembly therefor of discrete laminae to single face of additional lamina

- Y10T156/109—Embedding of laminae within face of additional laminae

Definitions

- the present inventionrelates generally to an ultra-thin flexible durable identification device and the manufacture thereof, and more particularly to radio frequency identification (RFID) devices and the manufacture of RFID devices that can be made in many shapes and sizes and that have superior outer surface matte or glossy such that device may receive dye sublimation printing or the like.

- RFIDradio frequency identification

- Identification devicessuch as cards, badges, tags labels and bracelets have been used for years for all kinds of identification, such as passports, luggage, all kinds of tickets, hospital/pharmacy medical records and access passes, all of which have not been totally free from theft and counterfeit resulting in the loss of thousands of dollars.

- identification devicesWith the rapid progress in new technology the problems associated with the use of such identification devices are being replaced with a more secure identification device having a RFID smart chip that gives more information such as biometrics and read write technology. Thus this more secure plastic device is very difficult or impossible to fraudulently manipulate.

- the present inventionis therefore directed to a ultra-thin flexible durable plastic device made in all shapes and sizes having at least one electronic element embedded therein and to a hot or cold lamination method for the manufacture of plastic devices including at least one electronic element therein.

- the devicecan be used as cards, tags, badges, bracelets and labels.

- the deviceis durable and flexible and it can be used as a sticker when adhesive is applied because it is ultra-thin.

- the devicehas an overall thickness in the range of 0.005 inches to 0.033 inches and comprises a plastic or other substrate core having at least one electronic element embedded therein with at least one of the upper and lower surfaces of the core comprising a coating printed or otherwise applied thereon.

- the hot or cold lamination method of the present inventioncomprises the steps of providing first and second plastic or other substrate core sheets, positioning at least one electronic element between the first and second core sheets to thus form a core and placing the core in a laminator and closing the lamination without applying laminator ram pressure to the core.

- a heat cycleis applied to the core sheets in the laminator thus liquefying or partially liquefying the sheets.

- the laminator ram pressureis then increased in combination with the heat.

- a cooling cycleis then applied to the core in the laminator preferably with an associated increase in ram pressure, and the core is removed from the laminator.

- the sheetsare then cut separating the individual device from the core sheet and this results in a plastic device having a thickness in the range of approximately 0.005 inches-0.033 inches with a surface glossy or matte dependent on customer's request.

- the inventionis also directed to a device manufactured in accordance with the above process which results in a plastic device having a thickness in the range of approximately 0.005 inches-0.033 inches with a surface smoothness of at least approximately 0.0005 inches.

- the present inventionprovides numerous advantages over known plastic devices and known plastic device with electronic elements such as a computer chip embedded therein with a pleasing aesthetic appearance and able to withstand various harsh chemicals and pressures.

- FIG. 1is a top plan view of a radio frequency device in accordance with the present invention.

- FIG. 2is a side elevational view of the device shown in FIG. 1 .

- FIGS. 3A-3Dare top plan views of various electronic elements that may be embedded in a device in accordance with the present invention.

- FIG. 4is an exploded schematic view of an electronic element positioned between two plastic core sheets to form a core.

- FIG. 5is a top plan view of a plurality of electronic elements positioned on a sheet of plastic or other substrate core stock such that they may be covered by a similar sheet or core stock.

- FIG. 6is a side plan view illustrating top and bottom sheets that may be pre-printed or blank sheets and also a schematic cross sectional view of one or more electronic elements positioned between sheets of plastic or other substrate core stock.

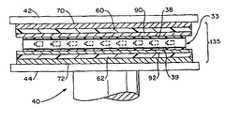

- FIG. 7schematically illustrates a book comprising the core as it is positioned in a laminator apparatus.

- FIG. 8schematically illustrates the core as it is being printed on after removal from the laminator using a printing press or similar printing apparatus.

- FIG. 9is a cross-sectional view schematically illustrating the application of a overlaminate film to at least one side of the core beginning a second lamination step as illustrated in FIG. 10 when necessary to protect the printing.

- FIG. 10schematically illustrates the core with overlaminate film as it is placed in a laminator for final processing to form a sheet core stock containing electronic devices.

- the present inventionrelates to a ultra-thin flexible durable plastic device including at least one electronic element embedded therein.

- the present inventionalso relates to a hot lamination process for the manufacture of plastic devices and more particularly to a hot or cold lamination process for the manufacture of plastic devices that include an electronic element such as a computer chip or other electronic element embedded therein.

- the electronic elementmay preform a wide variety of functions and take a wide variety of forms.

- RFIDradio frequency identification

- the present inventionalso relates to a ultra-thin durable plastic or other composition device in all shapes and sizes that can withstand harsh chemicals and various pressures that could be used in the are-o-space industry.

- FIG. 1there can be seen a plastic RFID device 10 manufactured in accordance with the present invention and including an electronic element 20 embedded therein.

- Device 10includes an upper surface 12 and a lower surface 14 .

- Electronic element 20may take a wide variety of forms and perform a wide variety of functions.

- electronic element 20 , 20 ′, 20 ′′, 20 ′′′may be provided by a micro-chip 22 including a wire antenna 24 , connected thereto, a micro-chip 22 ′ and a circuit board antenna 24 ′, a read/write micro-chip 22 ′′ and a wire coil antenna 24 ′′, a printed screen or litho conductive metallic or carbon ink antenna 24 ′′′ or any other suitable electronic element.

- a device in accordance with the present inventionhas a thickness of approximately in the range of 0.005 inches to 0.033 inches with a surface smoothness of 0.0005 inches. This surface may also have a matte finish on one or more sides.

- one or more devices 10 in accordance with the present inventionmay be manufactured by positioning an electronic element 20 between first and second sheets of core 30 , 32 to form a core 33 .

- a plurality of devicesare manufactured simultaneously, in thus, a plurality of electronic elements 20 are positioned between the first and second sheets of plastic core stock 30 , 32 (only the second sheet 32 being shown in FIG. 5 for clarity).

- electronic elements 20are properly positioned relative to one another such that a plurality devices may be out from the resulting core stock.

- Plastic core sheets 30 - 32may be provided by a wide variety of plastics or other substrates, the preferred being polyvinyl chloride (PVC) having a thickness in the range of 0.005 inches to 0.0225 inches. Those skilled in the art will recognize that the thickness of the plastic core sheets will depend upon the thickness of the one or more electronic elements that are to be embedded therebetween.

- PVCpolyvinyl chloride

- suitable plasticinclude polyester, acrylonitrile-butadiene-styrene (ABS), PET or composition of many.

- laminator 40includes upper and lower platens 42 , 44 for applying ram pressure to an article positioned therebetween.

- laminator 40is preferably of the type having controlled platens 42 , 44 that provide both heat and chill cycles and preferably includes cycle timer to regulate cycle time.

- Core 33is positioned between first and second laminating plates 50 , 52 , one of which is preferably matte finished to provide laminated core 33 with at least one textured outer surface.

- First and second laminating pads 60 , 62are positioned outside of the laminating plates 50 , 52 and first and second steel plates 70 , 72 are likewise positioned outside of pads of 60 , 62 and the entire assembly forms a book 37 for being positioned in laminator 40 between plates 42 , 44 .

- the first lamination cycleis initiated by closing laminator platens 42 , 44 , preferably applying little or no ram pressure to book 37 .

- a laminator heat cycleis initiated bringing the temperature of platens 42 , 44 up to range of 275° F. to 400° F. and most preferably up to a range of 300° F. to 370° F. for a period of greater than 5 minutes and preferably in the range of 7 to 10 minutes.

- the ram pressure of laminator 40is increased to facilitate the flow of the plastic core sheets 30 , 32 so that the one or more electronic elements 20 are encapsulated thereby, and so that sheets 30 , 32 form a uniform core 33 (seen most clearly in FIGS. 8-10 with upper and lower surfaces 34 , 35 .

- the use of matte finished laminator plates 50 , 52provides surfaces 34 , 35 with a slightly roughened or textured quality which will facilitate the application of a coating thereto as is discussed below.

- the ram pressure applied during the heat cycle and the length of the heat cyclemay vary, depending especially upon the size of sheets 30 , 32 .

- the cycle timemay be in the range of 10-15 minutes.

- a ram pressure of 940.135 pounds per square inch (p.s.i.)was applied for 10-15 minutes to form a uniform core 33 , using sheets 30 , 32 , of a size in the range of 12 inches by 24 inches to 24 inches by 36 inches.

- laminator 40applies a chill cycle to book 37 during which time and ram pressure of the laminator 40 is increased, preferably by approximately 25%, until the platens 42 , 44 have been cooled in approximately 40° F. to 65° F. for approximately 10-15 minutes. Core 33 may then be removed from laminator 40 for additional processing. If a single lamination step is used, a glossy plate might be used at this point of lamination to provide a mirror finish on the device. At this point the sheets will be ready for cutting out the devices separating the plurality of devices from the sheets.

- core 33is coated on at least one of its upper and lower surfaces 34 , 35 with a layer of printing ink 36 .

- Thismay be accomplished using a wide variety of printing techniques such as offset printing, letter-press printing, screen printing, roller coating, spray printing, litho-printing and other suitable printing techniques.

- core 33is fed in the direction indicated with arrow A through a printing press, a lithographic printer or a similar apparatus 80 . This printing step is performed to coat at least one surface 34 , 35 of core 33 with a layer of aesthetically pleasing ink 36 .

- This layer of ink 36cosmetically hides the one or more electronic elements 20 that are embedded within core 33 and prevents these one or more electronic elements 20 from showing through the relatively thin core 33 . In this manner, the one or more electronic elements 20 encapsulated in core 33 are completely hidden from view without requiring the plastic used in the manufacture core 33 to be excessively thick.

- core 33which now comprises a layer of ink 36 or the like on at least one surface 34 , 35 thereof, is schematically illustrated.

- a layer of overlaminate filmsuch as clear overlaminate film 38 , 39 is positioned on at least one ink coated surface 34 , 35 of core 33 , and preferably core 33 is positioned between two similar sheets of overlaminate film 38 , 39 as shown.

- Overlaminate filmis very thin, for example in the range of 0.0015 inches thick.

- a book 135is then constructed for insertion into laminator 40 as is schematically illustrated FIG. 10 .

- Book 135comprising core 33 , including at least one layer of ink 36 and at least one layer of overlamination film 38 , 39 is positioned between laminating plates which are preferably highly polished plates such as mirror finished stainless steel plates 90 , 92 .

- Book 135also comprises first and second laminating pads 60 , 62 and first and second steel plates 70 , 72 as is discussed above in relation to FIG. 7 .

- the laminatorWhen book 135 is positioned between upper and lower platens 42 , 44 of laminator 40 as shown in FIG. 10 , the laminator is closed and a heat cycle in the range of 175° F. to 300° F. and most preferably in the range of 180° F. to 275° F. is applied to book 135 for a period of 10 to 25 minutes with a ram pressure that varies depending upon sheet size or the ram size of the laminator 40 , but which is typically approximately 1000 p.s.i. with an 18 inch diameter ram.

- the laminator 40is then caused to execute a chill cycle, preferably with a corresponding increase in ram pressure.

- the chill temperaturemay be in the range of 40° F. to 65° F. and last for a period of 10 to 25 minutes.

- a ram pressure increase of approximately 25% over the pressure used for the heat cyclehas been found to be most preferable.

- a sheet of plastic or other substrate core stockwhich comprises at least core 33 with at least one surface 34 , 35 thereof covered by a layer of ink 36 and with at least one surface 34 , 35 thereof covered by a layer of overlaminate film 36 , 39 .

- plastic device stock manufactured in accordance with the present inventioncomprises core 33 covered on both surfaces 34 , 35 with a layer of ink 36 which is positioned between layers of overlaminate film 38 , 39 all of which has been laminated together as described.

- One or more devices 10then may be cut from the resulting plastic core stock and device 10 will have a thickness of in the range of 0.005 inches to 0.033 inches with variation in overall thickness across the surfaces 12 , 14 thereof being no greater than approximately 0.0005 inches.

- the one or more devices 10can thus be said to have a surface smoothness of approximately 0.0005 inches or better.

- a device 10 manufactured in accordance with the present inventionincludes at least one surface 12 , 14 at preferably both surfaces 12 , 14 that are sufficiently smooth and regular to receive dye sublimation printing.

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Computer Hardware Design (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Theoretical Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Credit Cards Or The Like (AREA)

Abstract

Description

Claims (44)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/773,810USRE40145E1 (en) | 1995-10-17 | 2004-02-06 | Ultra-thin flexible durable radio frequency identification devices and hot or cold lamination process for the manufacture of ultra-thin flexible durable radio frequency identification devices |

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US568595P | 1995-10-17 | 1995-10-17 | |

| US08/727,789US5817207A (en) | 1995-10-17 | 1996-10-07 | Radio frequency identification card and hot lamination process for the manufacture of radio frequency identification cards |

| US09/158,290US6214155B1 (en) | 1995-10-17 | 1998-09-22 | Radio frequency identification card and hot lamination process for the manufacture of radio frequency identification cards |

| US09/606,945US6441736B1 (en) | 1999-07-01 | 2000-06-29 | Ultra-thin flexible durable radio frequency identification devices and hot or cold lamination process for the manufacture of ultra-thin flexible durable radio frequency identification devices |

| US10/773,810USRE40145E1 (en) | 1995-10-17 | 2004-02-06 | Ultra-thin flexible durable radio frequency identification devices and hot or cold lamination process for the manufacture of ultra-thin flexible durable radio frequency identification devices |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US09/606,945ReissueUS6441736B1 (en) | 1995-10-17 | 2000-06-29 | Ultra-thin flexible durable radio frequency identification devices and hot or cold lamination process for the manufacture of ultra-thin flexible durable radio frequency identification devices |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| USRE40145E1true USRE40145E1 (en) | 2008-03-11 |

Family

ID=26674644

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US08/727,789Expired - LifetimeUS5817207A (en) | 1995-10-17 | 1996-10-07 | Radio frequency identification card and hot lamination process for the manufacture of radio frequency identification cards |

| US09/158,290Expired - LifetimeUS6214155B1 (en) | 1995-10-17 | 1998-09-22 | Radio frequency identification card and hot lamination process for the manufacture of radio frequency identification cards |

| US10/773,810Expired - LifetimeUSRE40145E1 (en) | 1995-10-17 | 2004-02-06 | Ultra-thin flexible durable radio frequency identification devices and hot or cold lamination process for the manufacture of ultra-thin flexible durable radio frequency identification devices |

Family Applications Before (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US08/727,789Expired - LifetimeUS5817207A (en) | 1995-10-17 | 1996-10-07 | Radio frequency identification card and hot lamination process for the manufacture of radio frequency identification cards |

| US09/158,290Expired - LifetimeUS6214155B1 (en) | 1995-10-17 | 1998-09-22 | Radio frequency identification card and hot lamination process for the manufacture of radio frequency identification cards |

Country Status (3)

| Country | Link |

|---|---|

| US (3) | US5817207A (en) |

| AU (1) | AU8498698A (en) |

| WO (1) | WO2000005071A1 (en) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20080149731A1 (en)* | 2004-01-23 | 2008-06-26 | Semiconductor Energy Laboratory Co., Ltd. | Id Label, Id Card, and Id Tag |

| US20100134291A1 (en)* | 2008-12-01 | 2010-06-03 | Lavedas Thomas G | Radio frequency identification inlay with improved readability |

| US9129200B2 (en) | 2012-10-30 | 2015-09-08 | Raytheon Corporation | Protection system for radio frequency communications |

| USD791772S1 (en)* | 2015-05-20 | 2017-07-11 | Chaya Coleena Hendrick | Smart card with a fingerprint sensor |

| US9812790B2 (en) | 2014-06-23 | 2017-11-07 | Raytheon Company | Near-field gradient probe for the suppression of radio interference |

| US10243088B1 (en)* | 2017-12-21 | 2019-03-26 | Capital One Services, Llc | Transaction card for transferring solar power |

| US10546227B2 (en) | 2017-05-11 | 2020-01-28 | Building Materials Investment Corporation | TPO and PVC membrane incorporating RFID tags |

| US11984922B2 (en) | 2021-11-30 | 2024-05-14 | Raytheon Company | Differential probe with single transceiver antenna |

Families Citing this family (87)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USRE42773E1 (en) | 1992-06-17 | 2011-10-04 | Round Rock Research, Llc | Method of manufacturing an enclosed transceiver |

| US7158031B2 (en)* | 1992-08-12 | 2007-01-02 | Micron Technology, Inc. | Thin, flexible, RFID label and system for use |

| US5817207A (en) | 1995-10-17 | 1998-10-06 | Leighton; Keith R. | Radio frequency identification card and hot lamination process for the manufacture of radio frequency identification cards |

| US6441736B1 (en) | 1999-07-01 | 2002-08-27 | Keith R. Leighton | Ultra-thin flexible durable radio frequency identification devices and hot or cold lamination process for the manufacture of ultra-thin flexible durable radio frequency identification devices |

| US6036099A (en)* | 1995-10-17 | 2000-03-14 | Leighton; Keith | Hot lamination process for the manufacture of a combination contact/contactless smart card and product resulting therefrom |

| DE19602821C1 (en)* | 1996-01-26 | 1997-06-26 | Siemens Ag | Method for producing a data card |

| EP0938412B1 (en)* | 1996-11-12 | 2004-02-11 | NagraID S.A. | Method for making cards |

| FR2760113B1 (en)* | 1997-02-24 | 1999-06-04 | Gemplus Card Int | METHOD FOR MANUFACTURING A CONTACTLESS CARD WITH A COILED ANTENNA |

| US6329213B1 (en)* | 1997-05-01 | 2001-12-11 | Micron Technology, Inc. | Methods for forming integrated circuits within substrates |

| US6980085B1 (en)* | 1997-08-18 | 2005-12-27 | Micron Technology, Inc. | Wireless communication devices and methods of forming and operating the same |

| US6339385B1 (en) | 1997-08-20 | 2002-01-15 | Micron Technology, Inc. | Electronic communication devices, methods of forming electrical communication devices, and communication methods |

| US20050040226A1 (en)* | 1997-10-01 | 2005-02-24 | Zaher Al-Sheikh | User authorization system containing a user image |

| US6030423A (en)* | 1998-02-12 | 2000-02-29 | Micron Technology, Inc. | Thin profile battery bonding method and method of conductively interconnecting electronic components |

| IL127569A0 (en) | 1998-09-16 | 1999-10-28 | Comsense Technologies Ltd | Interactive toys |

| US20100030838A1 (en)* | 1998-08-27 | 2010-02-04 | Beepcard Ltd. | Method to use acoustic signals for computer communications |

| US20020167500A1 (en)* | 1998-09-11 | 2002-11-14 | Visible Techknowledgy, Llc | Smart electronic label employing electronic ink |

| US6924781B1 (en) | 1998-09-11 | 2005-08-02 | Visible Tech-Knowledgy, Inc. | Smart electronic label employing electronic ink |

| US6753830B2 (en) | 1998-09-11 | 2004-06-22 | Visible Tech-Knowledgy, Inc. | Smart electronic label employing electronic ink |

| US6607136B1 (en) | 1998-09-16 | 2003-08-19 | Beepcard Inc. | Physical presence digital authentication system |

| US7334735B1 (en)* | 1998-10-02 | 2008-02-26 | Beepcard Ltd. | Card for interaction with a computer |

| US20060287030A1 (en)* | 1999-02-26 | 2006-12-21 | Briggs Rick A | Systems and methods for interactive game play |

| US7749089B1 (en) | 1999-02-26 | 2010-07-06 | Creative Kingdoms, Llc | Multi-media interactive play system |

| US6248199B1 (en) | 1999-04-26 | 2001-06-19 | Soundcraft, Inc. | Method for the continuous fabrication of access control and identification cards with embedded electronics or other elements |

| FR2796183B1 (en)* | 1999-07-07 | 2001-09-28 | A S K | CONTACTLESS ACCESS TICKET AND MANUFACTURING METHOD THEREOF |

| US6147662A (en)* | 1999-09-10 | 2000-11-14 | Moore North America, Inc. | Radio frequency identification tags and labels |

| US8019609B2 (en) | 1999-10-04 | 2011-09-13 | Dialware Inc. | Sonic/ultrasonic authentication method |

| US6943678B2 (en)* | 2000-01-24 | 2005-09-13 | Nextreme, L.L.C. | Thermoformed apparatus having a communications device |

| US6761637B2 (en) | 2000-02-22 | 2004-07-13 | Creative Kingdoms, Llc | Method of game play using RFID tracking device |

| US7445550B2 (en) | 2000-02-22 | 2008-11-04 | Creative Kingdoms, Llc | Magical wand and interactive play experience |

| US7878905B2 (en) | 2000-02-22 | 2011-02-01 | Creative Kingdoms, Llc | Multi-layered interactive play experience |

| WO2002011019A1 (en)* | 2000-08-01 | 2002-02-07 | First Usa Bank, N.A. | System and method for transponder-enabled account transactions |

| JP2002092575A (en)* | 2000-09-19 | 2002-03-29 | Mitsubishi Electric Corp | Small card and its manufacturing method |

| US7066781B2 (en) | 2000-10-20 | 2006-06-27 | Denise Chapman Weston | Children's toy with wireless tag/transponder |

| US6648232B1 (en) | 2000-10-24 | 2003-11-18 | Moore North America, Inc. | High temperature tag having enclosed transceiver |

| DE20100158U1 (en) | 2001-01-05 | 2002-05-08 | Bundesdruckerei GmbH, 10969 Berlin | Identification and security card made of laminated and / or molded plastics |

| AU2002249532A1 (en)* | 2001-03-22 | 2002-10-08 | Beepcard Inc. | Manufacture of self-powered identification devices |

| US9219708B2 (en) | 2001-03-22 | 2015-12-22 | DialwareInc. | Method and system for remotely authenticating identification devices |

| US7526449B1 (en) | 2001-04-17 | 2009-04-28 | Jpmorgan Chase Bank N.A. | Optically encoded card and system and method for using |

| US7614958B2 (en)* | 2001-11-16 | 2009-11-10 | Creative Kingdoms, Llc | Interactive quest game |

| FR2833801B1 (en)* | 2001-12-19 | 2005-07-01 | Oberthur Card Syst Sa | METHOD FOR PRODUCING A MICROCIRCUIT CARD |

| US8392301B1 (en) | 2002-03-08 | 2013-03-05 | Jpmorgan Chase Bank, N.A. | Financial system for isolated economic environment |

| US7593875B2 (en) | 2002-03-08 | 2009-09-22 | Jp Morgan Chase Bank | Financial system for isolated economic environment |

| US6967566B2 (en) | 2002-04-05 | 2005-11-22 | Creative Kingdoms, Llc | Live-action interactive adventure game |

| US20070066396A1 (en) | 2002-04-05 | 2007-03-22 | Denise Chapman Weston | Retail methods for providing an interactive product to a consumer |

| US7674184B2 (en) | 2002-08-01 | 2010-03-09 | Creative Kingdoms, Llc | Interactive water attraction and quest game |

| DE10248020B4 (en)* | 2002-10-15 | 2008-09-11 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Method and device for joining at least two components |

| US9446319B2 (en) | 2003-03-25 | 2016-09-20 | Mq Gaming, Llc | Interactive gaming toy |

| DE10335230A1 (en)* | 2003-08-01 | 2005-02-17 | Man Roland Druckmaschinen Ag | Process for the production of RFID labels |

| US20050134461A1 (en) | 2003-09-03 | 2005-06-23 | Alexander Gelbman | Electronically updateable label and display |

| WO2005044561A1 (en)* | 2003-10-27 | 2005-05-19 | Veritec, Inc. | Laminated cards and methods of manufacture for secure applications |

| US7225537B2 (en)* | 2005-01-27 | 2007-06-05 | Cardxx, Inc. | Method for making memory cards and similar devices using isotropic thermoset materials with high quality exterior surfaces |

| KR101017543B1 (en) | 2005-03-23 | 2011-02-28 | 카덱스, 인코포레이티드 | Method of manufacturing an improved smart card with integrated electronics using isotropic thermosetting adhesive with high quality outer surface |

| US7347148B2 (en)* | 2005-05-11 | 2008-03-25 | Hunter Paine Enterprises, Llc | Shipping pallet equipped with a non-structural member carrying a readable device |

| US7757957B2 (en)* | 2005-05-11 | 2010-07-20 | American Express Travel Related Services Company, Inc. | Textured transaction cards and methods of making the same |

| JP4545079B2 (en)* | 2005-10-19 | 2010-09-15 | トヨタ自動車株式会社 | Laser welding method and laser welding apparatus for thermoplastic resin member |

| US8067253B2 (en)* | 2005-12-21 | 2011-11-29 | Avery Dennison Corporation | Electrical device and method of manufacturing electrical devices using film embossing techniques to embed integrated circuits into film |

| US20070176007A1 (en)* | 2006-01-31 | 2007-08-02 | Priya Suresh C | Variably sized mini card |

| AU2007263131B2 (en) | 2006-06-19 | 2012-02-16 | Nagravision S.A. | Method of fabricating cards each comprising an electronic module and intermediate products |

| US8287991B2 (en)* | 2006-10-04 | 2012-10-16 | Eastman Chemical Company | Using branched polymers to control the dimensional stability of articles in the lamination process |

| US20080085390A1 (en) | 2006-10-04 | 2008-04-10 | Ryan Thomas Neill | Encapsulation of electrically energized articles |

| MX2009007905A (en)* | 2007-02-09 | 2009-07-31 | Nagraid Sa | Method for producing electronic cards including at least one printed pattern. |

| US20080308518A1 (en)* | 2007-06-14 | 2008-12-18 | Drug Plastics & Glass Company, Inc. | Container having an automatic identification device for identifying the contents therein |

| US20080314900A1 (en)* | 2007-06-14 | 2008-12-25 | Drug Plastics & Glass Company, Inc. | Enclosure having an automatic identification device |

| USD582476S1 (en) | 2008-02-21 | 2008-12-09 | Jpmorgan Chase Bank, N.A. | Pivoting transaction device |

| USD576671S1 (en) | 2008-02-21 | 2008-09-09 | Jpmorganchase Bank, N.A. | Overlapping transaction device |

| USD582977S1 (en) | 2008-02-21 | 2008-12-16 | Jpmorgan Chase Bank, N.A. | Transaction device |

| US20090266736A1 (en)* | 2008-04-25 | 2009-10-29 | Drug Plastics & Glass Company, Inc. | Container having an identification device molded therein and method of making same |

| USD635186S1 (en) | 2008-06-30 | 2011-03-29 | Jpmorgan Chase Bank, N.A. | Metal transaction device |

| US9305292B1 (en) | 2008-07-03 | 2016-04-05 | Jpmorgan Chase Bank, N.A. | Systems and methods for providing an adaptable transponder device |

| USD636021S1 (en) | 2008-07-17 | 2011-04-12 | Jpmorgan Chase Bank, N.A. | Eco-friendly transaction device |

| US8234507B2 (en) | 2009-01-13 | 2012-07-31 | Metrologic Instruments, Inc. | Electronic-ink display device employing a power switching mechanism automatically responsive to predefined states of device configuration |

| US8457013B2 (en) | 2009-01-13 | 2013-06-04 | Metrologic Instruments, Inc. | Wireless dual-function network device dynamically switching and reconfiguring from a wireless network router state of operation into a wireless network coordinator state of operation in a wireless communication network |

| USD602986S1 (en) | 2009-03-06 | 2009-10-27 | Jpmorgan Chase Bank, N.A. | Metal transaction device |

| US8690064B2 (en)* | 2009-04-30 | 2014-04-08 | Abnote Usa, Inc. | Transaction card assembly and methods of manufacture |

| FR2961318B1 (en)* | 2010-06-11 | 2013-07-19 | Oberthur Technologies | METHOD FOR MAKING AN IMPRINT ON AN ARTICLE |

| US9150006B2 (en) | 2011-06-23 | 2015-10-06 | Eastman Chemical Company | Lamination process optimization utilizing neopentyl glycol-modified polyesters |

| US9710745B1 (en)* | 2012-02-09 | 2017-07-18 | Dynamics Inc. | Systems and methods for automated assembly of dynamic magnetic stripe communications devices |

| GB201208680D0 (en) | 2012-05-17 | 2012-06-27 | Origold As | Method of manufacturing an electronic card |

| US9147149B2 (en)* | 2013-06-13 | 2015-09-29 | L'oreal | RFID tag for a personal care appliance |

| NZ726408A (en) | 2014-05-22 | 2018-09-28 | Composecure Llc | Transaction and id cards having selected texture and coloring |

| US10783422B2 (en) | 2014-11-03 | 2020-09-22 | Composecure, Llc | Ceramic-containing and ceramic composite transaction cards |

| CN104441874A (en)* | 2014-12-22 | 2015-03-25 | 永新电子常熟有限公司 | High-property electronic chip |

| US11300598B2 (en) | 2018-11-26 | 2022-04-12 | Tom Lavedas | Alternative near-field gradient probe for the suppression of radio frequency interference |

| US20210081743A1 (en) | 2019-08-12 | 2021-03-18 | Federal Card Services, LLC | Dual interface metal cards and methods of manufacturing |

| US12277462B2 (en) | 2019-08-14 | 2025-04-15 | Federal Card Services, LLC | Metal-containing dual interface smartcards |

| US11113593B2 (en) | 2019-08-15 | 2021-09-07 | Federal Card Services; LLC | Contactless metal cards with fingerprint sensor and display |

| US11341385B2 (en) | 2019-11-16 | 2022-05-24 | Federal Card Services, LLC | RFID enabled metal transaction card with shaped opening and shaped slit |

Citations (129)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2532501A (en) | 1944-01-27 | 1950-12-05 | Combined Optical Ind Ltd | Molding of plastics |

| US2874751A (en) | 1956-03-13 | 1959-02-24 | Thermel Inc | Temperature controlled press |

| DE1810986A1 (en) | 1968-11-26 | 1970-06-11 | Doboy Verpackungsmasch Gmbh | Method and device for cooling weld seams in plastic foils |

| US3681167A (en) | 1970-07-13 | 1972-08-01 | Richard E Moore | Method of making acrylic-polycarbonate laminate |

| US3769132A (en) | 1969-11-06 | 1973-10-30 | High Voltage Engineering Corp | Method of intimately bonding thermoplastics |

| US3820090A (en) | 1970-01-26 | 1974-06-25 | Vlinsky M | Bistable magnetic device |

| US3879251A (en) | 1971-12-07 | 1975-04-22 | R E Ingham & Co Limited | Apparatus for producing laminates requiring the application of heat |

| US3994225A (en) | 1974-02-27 | 1976-11-30 | Adcraft Mfg. Co. | Method of producing personalized badges and the like |

| US4108713A (en) | 1977-02-14 | 1978-08-22 | General Binding Corporation | Low mass electric heater |

| US4180608A (en)* | 1977-01-07 | 1979-12-25 | Del Joseph A | Process for making multi-layer printed circuit boards, and the article resulting therefrom |

| GB1567784A (en) | 1975-12-31 | 1980-05-21 | Inf Cit Honeywe Comp Int | Portable card for systems for processing electrical signals and a method of manufacturing such a card |

| US4204822A (en) | 1977-08-24 | 1980-05-27 | British Industrial Plastics Ltd. | Moulding machine |

| US4216577A (en) | 1975-12-31 | 1980-08-12 | Compagnie Internationale Pour L'informatique Cii-Honeywell Bull (Societe Anonyme) | Portable standardized card adapted to provide access to a system for processing electrical signals and a method of manufacturing such a card |

| US4242789A (en) | 1979-03-16 | 1981-01-06 | The United States Of America As Represented By The United States Department Of Energy | Method for making an improved magnetic encoding device |

| US4263523A (en) | 1978-04-18 | 1981-04-21 | The Echlin Manufacturing Company | Pulse generator using read head with Wiegand wire |

| US4290838A (en) | 1978-12-04 | 1981-09-22 | General Dynamics, Pomona Division | Method for vacuum lamination of flex circuits |

| JPS57135137A (en) | 1981-02-17 | 1982-08-20 | Asahi Chem Ind Co Ltd | Forming method for synthetic resin and apparatus therefor |

| JPS5752088Y2 (en) | 1979-08-20 | 1982-11-12 | ||

| EP0071255A2 (en) | 1981-07-30 | 1983-02-09 | Siemens Aktiengesellschaft | Portable card for information processing |

| EP0013557B1 (en) | 1979-01-12 | 1983-04-27 | Hoechst Aktiengesellschaft | Method of laminating sheets and a press comprising two plates for the application of this method |

| US4392909A (en)* | 1980-09-02 | 1983-07-12 | Robert Burkle Gmbh & Co. | Method and device for producing multilayer printed circuit boards |

| US4417413A (en) | 1979-05-17 | 1983-11-29 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Identification card with IC chip and a method for manufacturing the same |

| US4450024A (en) | 1980-08-07 | 1984-05-22 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Identification card with an IC-module and method for producing it |

| US4457798A (en) | 1981-06-10 | 1984-07-03 | Gao Gesellschaft Fur Automation And Organisation Mbh | Method of incorporating IC modules into identification cards |

| US4460825A (en) | 1980-12-08 | 1984-07-17 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Carrier element for an IC module |

| US4474292A (en) | 1980-05-20 | 1984-10-02 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Carrier element for an IC-chip |

| JPS5948985B2 (en) | 1980-10-08 | 1984-11-30 | 国産精工株式会社 | Mandarin orange continuous juice extraction device |

| DE3340600C1 (en) | 1983-11-10 | 1985-01-10 | Doduco KG Dr. Eugen Dürrwächter, 7530 Pforzheim | Read head for magnetic scanning of Wiegand wires |

| US4499371A (en) | 1979-11-27 | 1985-02-12 | Flonic S.A. | Electrical connection system |

| JPS60109817A (en) | 1983-07-01 | 1985-06-15 | ローランド・メルツア | Manufacture of plastic-card |

| US4550057A (en) | 1982-04-01 | 1985-10-29 | Asahi Kasei Kogyo Kabushiki Kaisha | Acrylic sheets |

| US4563575A (en) | 1981-05-08 | 1986-01-07 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Identification card having an embedded IC module |

| US4587413A (en) | 1981-03-24 | 1986-05-06 | Gao Gesellschaft Fur Automation Und Organisation Mbh | IC-module identification card |

| JPS61123596U (en) | 1985-01-23 | 1986-08-04 | ||

| WO1987001651A1 (en) | 1985-09-19 | 1987-03-26 | Darragon S.A. | Press-autoclave, for example for laminating printed circuits |

| US4668314A (en) | 1983-10-25 | 1987-05-26 | Casio Computer Co., Ltd. | Method of manufacturing a small electronic device |

| JPS62152798U (en) | 1986-03-20 | 1987-09-28 | ||

| US4697073A (en) | 1985-03-04 | 1987-09-29 | Casio Computer Co., Ltd. | IC card |

| US4701236A (en) | 1985-04-12 | 1987-10-20 | U.S. Philips Corporation | Method of manufacturing an electronic identification card |

| US4714980A (en) | 1985-09-24 | 1987-12-22 | Casio Computer Co., Ltd. | Memory card |

| US4746392A (en) | 1982-12-28 | 1988-05-24 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Method for producing an identification card with an integrated circuit |

| JPS63137897U (en) | 1987-02-28 | 1988-09-12 | ||

| WO1988008592A1 (en) | 1987-04-27 | 1988-11-03 | Soundcraft, Inc. | Method for the manufacture of and structure of a laminated proximity card |

| DE3721822C1 (en) | 1987-07-02 | 1988-11-10 | Philips Patentverwaltung | Chip card |

| US4788102A (en) | 1986-05-30 | 1988-11-29 | Papier-Plastic-Coating Groningen B.V. | Data-carrying card, method for producing such a card, and device for carrying out said method |

| US4792843A (en) | 1983-10-24 | 1988-12-20 | Haghiri Tehrani Yahya | Data carrier having an integrated circuit and method for producing same |

| US4795898A (en) | 1986-04-28 | 1989-01-03 | American Telephone And Telegraph Company | Personal memory card having a contactless interface using differential data transfer |

| US4803542A (en) | 1980-08-05 | 1989-02-07 | Gao Gessellschaft Fur Automation Und Organisation Mbh | Carrier element for an IC-module |

| US4824511A (en)* | 1987-10-19 | 1989-04-25 | E. I. Du Pont De Nemours And Company | Multilayer circuit board with fluoropolymer interlayers |

| US4837184A (en) | 1988-01-04 | 1989-06-06 | Motorola Inc. | Process of making an electronic device package with peripheral carrier structure of low-cost plastic |

| US4841134A (en) | 1985-07-27 | 1989-06-20 | Dai Nippon Insatsu Kabushika Kaisha | IC card |

| US4897533A (en) | 1987-07-07 | 1990-01-30 | National Business Systems, Inc. | Credit card and method of making the same |

| US4897602A (en) | 1988-01-04 | 1990-01-30 | Motorola, Inc. | Electronic device package with peripheral carrier structure of low-cost plastic |

| US4897534A (en) | 1986-11-20 | 1990-01-30 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Data carrier having an integrated circuit and a method for producing the same |

| EP0154970B1 (en) | 1984-03-16 | 1990-01-31 | DATACARD-MIDS GmbH | Laminating device for manufacturing identification cards |

| GB2225283A (en) | 1988-10-07 | 1990-05-30 | De La Rue Co Plc | Laminated IC card |

| US4931853A (en) | 1986-05-20 | 1990-06-05 | Kabushiki Kaisha Toshiba | IC card and method of manufacturing the same |

| DE3910021A1 (en) | 1989-03-28 | 1990-10-04 | Basf Ag | Process for the production of sandwich panels using semi-finished products made of high-performance composites with polymeric matrices |

| US4965689A (en) | 1986-11-03 | 1990-10-23 | Doduco Kg. Dr. Eugen Durrwachter | Thin, Planar shaped carrier with wiegand wires |

| US4980802A (en) | 1988-05-09 | 1990-12-25 | Bull Cp8 | Flexible printed circuit |

| US5067008A (en) | 1989-08-11 | 1991-11-19 | Hitachi Maxell, Ltd. | Ic package and ic card incorporating the same thereinto |

| JPH0355297Y2 (en) | 1986-05-09 | 1991-12-09 | ||

| US5097117A (en) | 1987-07-02 | 1992-03-17 | Bull Cp8 | Electronic microcircuit card and method for its manufacture |

| DE9111708U1 (en) | 1991-09-19 | 1992-04-16 | Anger Electronic Ges.m.b.H. Emco InnovationsCenter, Hallein | Device for laminating printed and unprinted films |

| JPH04115996A (en) | 1990-09-06 | 1992-04-16 | Kyodo Printing Co Ltd | Manufacture of ic card |

| JPH0459397B2 (en) | 1989-04-21 | 1992-09-22 | Ebara Udylite Kk | |

| US5173840A (en) | 1990-05-07 | 1992-12-22 | Mitsubishi Denki Kabushiki Kaisha | Molded ic card |

| US5200601A (en) | 1989-01-19 | 1993-04-06 | W. & T. Avery Limited | Flexible identification card or token |

| EP0209791B1 (en) | 1985-07-10 | 1993-04-14 | Casio Computer Company Limited | Electronic memory card |

| US5208450A (en) | 1988-04-20 | 1993-05-04 | Matsushita Electric Industrial Co., Ltd. | IC card and a method for the manufacture of the same |

| JPH05208577A (en) | 1992-01-31 | 1993-08-20 | Mitsubishi Denki Eng Kk | Memory card assembling device |

| US5244840A (en) | 1989-05-23 | 1993-09-14 | Mitsubishi Denki Kabushiki Kaisha | Method for manufacturing an encapsulated IC card having a molded frame and a circuit board |

| US5250341A (en) | 1990-03-26 | 1993-10-05 | Mitsubishi Denki Kabushiki Kaisha | IC card |

| WO1993020537A1 (en) | 1992-04-01 | 1993-10-14 | Picopak Oy | Method for connecting a microcircuit to the inductive coupling coil of a smart card and assembly for an inductively coupled smart card |

| EP0570062A1 (en) | 1992-05-11 | 1993-11-18 | N.V. Nederlandsche Apparatenfabriek NEDAP | Contactlessly operating electronic responder card |

| US5268699A (en) | 1992-09-24 | 1993-12-07 | Motorola, Inc. | Data communication receiver utilizing a loop antenna having a hinged connection |

| US5268043A (en) | 1991-08-02 | 1993-12-07 | Olin Corporation | Magnetic sensor wire |

| GB2267683A (en) | 1992-06-02 | 1993-12-15 | Gec Avery Ltd | Integrated circuit card or token |

| US5272596A (en) | 1991-06-24 | 1993-12-21 | At&T Bell Laboratories | Personal data card fabricated from a polymer thick-film circuit |

| US5283423A (en) | 1991-03-15 | 1994-02-01 | U.S. Philips Corporation | Contactless microcircuit card |

| JPH06176214A (en) | 1992-12-10 | 1994-06-24 | Mitsubishi Plastics Ind Ltd | Thin type non-contact ic card |

| US5341421A (en) | 1990-11-06 | 1994-08-23 | Bull Cp8 | Security device, including a memory and/or a microcomputer for data processing machines |

| EP0616906A2 (en) | 1989-02-20 | 1994-09-28 | Dai Nippon Insatsu Kabushiki Kaisha | Process for the preparation of decorative sheet |

| WO1994022111A1 (en) | 1993-03-17 | 1994-09-29 | Droz Francois | Method for producing a card with at least one electronic component |

| JPH06286377A (en) | 1993-04-05 | 1994-10-11 | Dainippon Printing Co Ltd | Non-contact ic card and manufacture thereof |

| US5357091A (en) | 1991-04-30 | 1994-10-18 | Fujitsu Limited | Card type input/output interface device and electronic device system using the same |

| EP0499513B1 (en) | 1991-02-11 | 1994-12-28 | AEROSPATIALE Société Nationale Industrielle | Device with variable thermal conductivity for placing between a heating and a cooling platen of a machine such as a press |

| GB2279610A (en) | 1993-07-02 | 1995-01-11 | Gec Avery Ltd | A method of manufacturing a laminated integrated circuit or smart card. |

| DE4141972C2 (en) | 1991-12-19 | 1995-02-02 | Interlock Ag | Method and device for laminating layers of identification cards and. the like |

| US5387306A (en) | 1988-06-21 | 1995-02-07 | Gec Avery Limited | Manufacturing integrated circuit cards |

| EP0640940A2 (en) | 1993-08-23 | 1995-03-01 | N.V. Nederlandsche Apparatenfabriek NEDAP | Contactless chip card |

| US5396650A (en) | 1991-07-22 | 1995-03-07 | Mitsubishi Denki Kabushiki Kaisha | Wireless communication device with multi-function integrated circuit processing card |

| US5399223A (en) | 1991-12-19 | 1995-03-21 | Interlock Ag | Method and device for laminating layers of identification cards, or the like |

| US5399907A (en) | 1992-02-28 | 1995-03-21 | Johnson Matthey Inc. | Low temperature flexible die attach adhesive and articles using same |

| US5399847A (en) | 1992-05-19 | 1995-03-21 | Droz; Francois | Card comprising at least one electronic element |

| WO1995009084A1 (en) | 1993-09-28 | 1995-04-06 | Minnesota Mining And Manufacturing Company | Security card and method for making same |

| US5412192A (en) | 1993-07-20 | 1995-05-02 | American Express Company | Radio frequency activated charge card |

| US5438219A (en) | 1993-11-30 | 1995-08-01 | Motorola, Inc. | Double-sided oscillator package and method of coupling components thereto |

| US5438750A (en) | 1991-06-17 | 1995-08-08 | U.S. Philips Corporation | Method of manufacturing a chip card |

| US5448110A (en) | 1992-06-17 | 1995-09-05 | Micron Communications, Inc. | Enclosed transceiver |

| US5479416A (en) | 1993-09-30 | 1995-12-26 | Micron Technology, Inc. | Apparatus and method for error detection and correction in radio frequency identification device |

| DE4431606A1 (en) | 1994-09-05 | 1996-03-07 | Siemens Ag | Chip card module with copper coil on a carrier |

| FR2716281B1 (en) | 1994-02-14 | 1996-05-03 | Gemplus Card Int | Method of manufacturing a contactless card. |

| US5519201A (en) | 1994-04-29 | 1996-05-21 | Us3, Inc. | Electrical interconnection for structure including electronic and/or electromagnetic devices |

| US5567362A (en) | 1991-12-20 | 1996-10-22 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Identity card and a method and apparatus for producing it |

| US5585618A (en) | 1993-03-18 | 1996-12-17 | Droz; Fran+525 Ois | Method of manufacture of a card comprising at least one electronic element and card obtained by such method |

| WO1997005571A1 (en) | 1995-08-01 | 1997-02-13 | Austria Card Plastikkarten Und Ausweissysteme Gesellschaft Mbh | Data carrier with a component-containing module and with a coil, method of producing such a data carrier and module therefor |

| WO1997005569A1 (en) | 1995-08-01 | 1997-02-13 | Austria Card Plastikkarten Und Ausweissysteme Gesellschaft Mbh | Data carrier with a component-bearing module and a coil, and a process for fabricating such a data carrier |

| US5612532A (en) | 1993-09-01 | 1997-03-18 | Kabushiki Kaisha Toshiba | Thin IC card and method for producing the same |

| DE19609636C1 (en) | 1996-03-12 | 1997-08-14 | Siemens Ag | Chip card and method for producing a chip card |

| US5719746A (en) | 1995-08-18 | 1998-02-17 | Mitsubishi Denki Kabushiki Kaisha | IC card |

| US5762741A (en)* | 1993-12-21 | 1998-06-09 | E.I. Du Pont De Nemours And Company | Method for bonding polymeric articles |

| US5774339A (en) | 1996-05-30 | 1998-06-30 | Mitsubishi Denki Kabushiki Kaisha | IC card and method of making the same |

| US5809633A (en) | 1994-09-05 | 1998-09-22 | Siemens Aktiengesellschaft | Method for producing a smart card module for contactless smart cards |

| US5817207A (en) | 1995-10-17 | 1998-10-06 | Leighton; Keith R. | Radio frequency identification card and hot lamination process for the manufacture of radio frequency identification cards |

| US5852289A (en) | 1994-09-22 | 1998-12-22 | Rohm Co., Ltd. | Non-contact type IC card and method of producing the same |

| EP0778542A3 (en) | 1995-12-06 | 1998-12-30 | Watada Printing Co., Ltd. | Plastic card |

| US5951927A (en) | 1996-05-16 | 1999-09-14 | Marley Mouldings Inc. | Method of making a polymer and wood flour composite extrusion |

| US6036099A (en) | 1995-10-17 | 2000-03-14 | Leighton; Keith | Hot lamination process for the manufacture of a combination contact/contactless smart card and product resulting therefrom |

| US6036797A (en) | 1992-08-28 | 2000-03-14 | Citizen Watch Co., Ltd. | Process of producing IC cards |

| DE4105869C2 (en) | 1991-02-25 | 2000-05-18 | Edgar Schneider | IC card and method of making it |

| US6081025A (en) | 1995-08-01 | 2000-06-27 | Austria Card Plastikkarten | Data carrier with a component-containing module and with a coil, method of producing such a data carrier and module therefor |

| US6095424A (en) | 1995-08-01 | 2000-08-01 | Austria Card Plasikkarten Und Ausweissysteme Gesellschaft M.B.H. | Card-shaped data carrier for contactless uses, having a component and having a transmission device for the contactless uses, and method of manufacturing such card-shaped data carriers, as well as a module therefor |

| US6248199B1 (en) | 1999-04-26 | 2001-06-19 | Soundcraft, Inc. | Method for the continuous fabrication of access control and identification cards with embedded electronics or other elements |

| EP0846895B1 (en) | 1996-12-05 | 2001-08-01 | Ford Global Technologies, Inc. | Stationary pulley and shaft assembly for a continuously variable transmission |

| US6305609B1 (en) | 1996-01-26 | 2001-10-23 | Infineon Technologies Ag | Data card, process for manufacturing a data card and apparatus for manufacturing a data card |

| US6441736B1 (en) | 1999-07-01 | 2002-08-27 | Keith R. Leighton | Ultra-thin flexible durable radio frequency identification devices and hot or cold lamination process for the manufacture of ultra-thin flexible durable radio frequency identification devices |

| US6521985B1 (en) | 1999-05-25 | 2003-02-18 | Gemplus | Method for the production of a portable integrated circuit electronic device comprising a low-cost dielectric |

| US6557766B1 (en) | 1999-10-01 | 2003-05-06 | Keith R. Leighton | Hot lamination method for a hybrid radio frequency optical memory card converting sheets into a web process |

- 1996

- 1996-10-07USUS08/727,789patent/US5817207A/ennot_activeExpired - Lifetime

- 1998

- 1998-07-20WOPCT/US1998/014941patent/WO2000005071A1/enactiveApplication Filing

- 1998-07-20AUAU84986/98Apatent/AU8498698A/ennot_activeAbandoned

- 1998-09-22USUS09/158,290patent/US6214155B1/ennot_activeExpired - Lifetime

- 2004

- 2004-02-06USUS10/773,810patent/USRE40145E1/ennot_activeExpired - Lifetime

Patent Citations (145)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2532501A (en) | 1944-01-27 | 1950-12-05 | Combined Optical Ind Ltd | Molding of plastics |

| US2874751A (en) | 1956-03-13 | 1959-02-24 | Thermel Inc | Temperature controlled press |

| DE1810986A1 (en) | 1968-11-26 | 1970-06-11 | Doboy Verpackungsmasch Gmbh | Method and device for cooling weld seams in plastic foils |

| US3769132A (en) | 1969-11-06 | 1973-10-30 | High Voltage Engineering Corp | Method of intimately bonding thermoplastics |

| US3820090A (en) | 1970-01-26 | 1974-06-25 | Vlinsky M | Bistable magnetic device |

| US3681167A (en) | 1970-07-13 | 1972-08-01 | Richard E Moore | Method of making acrylic-polycarbonate laminate |

| US3879251A (en) | 1971-12-07 | 1975-04-22 | R E Ingham & Co Limited | Apparatus for producing laminates requiring the application of heat |

| US3994225A (en) | 1974-02-27 | 1976-11-30 | Adcraft Mfg. Co. | Method of producing personalized badges and the like |

| US4216577A (en) | 1975-12-31 | 1980-08-12 | Compagnie Internationale Pour L'informatique Cii-Honeywell Bull (Societe Anonyme) | Portable standardized card adapted to provide access to a system for processing electrical signals and a method of manufacturing such a card |

| GB1567784A (en) | 1975-12-31 | 1980-05-21 | Inf Cit Honeywe Comp Int | Portable card for systems for processing electrical signals and a method of manufacturing such a card |

| US4180608A (en)* | 1977-01-07 | 1979-12-25 | Del Joseph A | Process for making multi-layer printed circuit boards, and the article resulting therefrom |

| US4108713A (en) | 1977-02-14 | 1978-08-22 | General Binding Corporation | Low mass electric heater |

| US4204822A (en) | 1977-08-24 | 1980-05-27 | British Industrial Plastics Ltd. | Moulding machine |

| US4263523A (en) | 1978-04-18 | 1981-04-21 | The Echlin Manufacturing Company | Pulse generator using read head with Wiegand wire |

| US4290838A (en) | 1978-12-04 | 1981-09-22 | General Dynamics, Pomona Division | Method for vacuum lamination of flex circuits |

| EP0013557B1 (en) | 1979-01-12 | 1983-04-27 | Hoechst Aktiengesellschaft | Method of laminating sheets and a press comprising two plates for the application of this method |

| US4242789A (en) | 1979-03-16 | 1981-01-06 | The United States Of America As Represented By The United States Department Of Energy | Method for making an improved magnetic encoding device |

| US4417413A (en) | 1979-05-17 | 1983-11-29 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Identification card with IC chip and a method for manufacturing the same |

| JPS5752088Y2 (en) | 1979-08-20 | 1982-11-12 | ||

| US4499371A (en) | 1979-11-27 | 1985-02-12 | Flonic S.A. | Electrical connection system |

| US4474292A (en) | 1980-05-20 | 1984-10-02 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Carrier element for an IC-chip |

| US4803542A (en) | 1980-08-05 | 1989-02-07 | Gao Gessellschaft Fur Automation Und Organisation Mbh | Carrier element for an IC-module |

| US4617216A (en) | 1980-08-07 | 1986-10-14 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Multi-layer identification card |

| US4450024A (en) | 1980-08-07 | 1984-05-22 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Identification card with an IC-module and method for producing it |

| US4392909A (en)* | 1980-09-02 | 1983-07-12 | Robert Burkle Gmbh & Co. | Method and device for producing multilayer printed circuit boards |

| JPS5948985B2 (en) | 1980-10-08 | 1984-11-30 | 国産精工株式会社 | Mandarin orange continuous juice extraction device |

| US4460825A (en) | 1980-12-08 | 1984-07-17 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Carrier element for an IC module |

| JPS57135137A (en) | 1981-02-17 | 1982-08-20 | Asahi Chem Ind Co Ltd | Forming method for synthetic resin and apparatus therefor |

| US4587413A (en) | 1981-03-24 | 1986-05-06 | Gao Gesellschaft Fur Automation Und Organisation Mbh | IC-module identification card |

| US4563575A (en) | 1981-05-08 | 1986-01-07 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Identification card having an embedded IC module |

| US4457798A (en) | 1981-06-10 | 1984-07-03 | Gao Gesellschaft Fur Automation And Organisation Mbh | Method of incorporating IC modules into identification cards |

| EP0071255A2 (en) | 1981-07-30 | 1983-02-09 | Siemens Aktiengesellschaft | Portable card for information processing |

| US4550057A (en) | 1982-04-01 | 1985-10-29 | Asahi Kasei Kogyo Kabushiki Kaisha | Acrylic sheets |

| US4752204A (en) | 1982-04-01 | 1988-06-21 | Asahi Kasei Kogyo Kabushiki Kaisha | Apparatus for compression forming thermoplastic resin sheets |

| US5013900A (en) | 1982-12-28 | 1991-05-07 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Identification card with integrated circuit |

| US4746392A (en) | 1982-12-28 | 1988-05-24 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Method for producing an identification card with an integrated circuit |

| JPS60109817A (en) | 1983-07-01 | 1985-06-15 | ローランド・メルツア | Manufacture of plastic-card |

| US4863546A (en) | 1983-07-01 | 1989-09-05 | Roland Melzer | Apparatus and method for manufacturing plastic cards |

| US4792843A (en) | 1983-10-24 | 1988-12-20 | Haghiri Tehrani Yahya | Data carrier having an integrated circuit and method for producing same |

| EP0140230B1 (en) | 1983-10-24 | 1990-01-10 | GAO Gesellschaft für Automation und Organisation mbH | Integrated circuit record carrier and process for making the same |

| US4668314A (en) | 1983-10-25 | 1987-05-26 | Casio Computer Co., Ltd. | Method of manufacturing a small electronic device |

| DE3340600C1 (en) | 1983-11-10 | 1985-01-10 | Doduco KG Dr. Eugen Dürrwächter, 7530 Pforzheim | Read head for magnetic scanning of Wiegand wires |

| EP0154970B1 (en) | 1984-03-16 | 1990-01-31 | DATACARD-MIDS GmbH | Laminating device for manufacturing identification cards |

| JPS61123596U (en) | 1985-01-23 | 1986-08-04 | ||

| EP0193856B1 (en) | 1985-03-04 | 1993-09-08 | Casio Computer Company Limited | Ic card |

| US4697073A (en) | 1985-03-04 | 1987-09-29 | Casio Computer Co., Ltd. | IC card |

| US4701236A (en) | 1985-04-12 | 1987-10-20 | U.S. Philips Corporation | Method of manufacturing an electronic identification card |

| EP0209791B1 (en) | 1985-07-10 | 1993-04-14 | Casio Computer Company Limited | Electronic memory card |

| US4841134A (en) | 1985-07-27 | 1989-06-20 | Dai Nippon Insatsu Kabushika Kaisha | IC card |

| WO1987001651A1 (en) | 1985-09-19 | 1987-03-26 | Darragon S.A. | Press-autoclave, for example for laminating printed circuits |

| US4714980A (en) | 1985-09-24 | 1987-12-22 | Casio Computer Co., Ltd. | Memory card |

| JPS62152798U (en) | 1986-03-20 | 1987-09-28 | ||

| US4795898A (en) | 1986-04-28 | 1989-01-03 | American Telephone And Telegraph Company | Personal memory card having a contactless interface using differential data transfer |

| JPH0355297Y2 (en) | 1986-05-09 | 1991-12-09 | ||

| US4931853A (en) | 1986-05-20 | 1990-06-05 | Kabushiki Kaisha Toshiba | IC card and method of manufacturing the same |

| US4788102A (en) | 1986-05-30 | 1988-11-29 | Papier-Plastic-Coating Groningen B.V. | Data-carrying card, method for producing such a card, and device for carrying out said method |

| US4965689A (en) | 1986-11-03 | 1990-10-23 | Doduco Kg. Dr. Eugen Durrwachter | Thin, Planar shaped carrier with wiegand wires |

| US4897534A (en) | 1986-11-20 | 1990-01-30 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Data carrier having an integrated circuit and a method for producing the same |

| JPS63137897U (en) | 1987-02-28 | 1988-09-12 | ||

| WO1988008592A1 (en) | 1987-04-27 | 1988-11-03 | Soundcraft, Inc. | Method for the manufacture of and structure of a laminated proximity card |

| US5097117A (en) | 1987-07-02 | 1992-03-17 | Bull Cp8 | Electronic microcircuit card and method for its manufacture |

| DE3721822C1 (en) | 1987-07-02 | 1988-11-10 | Philips Patentverwaltung | Chip card |

| US4897533A (en) | 1987-07-07 | 1990-01-30 | National Business Systems, Inc. | Credit card and method of making the same |

| US4824511A (en)* | 1987-10-19 | 1989-04-25 | E. I. Du Pont De Nemours And Company | Multilayer circuit board with fluoropolymer interlayers |

| US4897602A (en) | 1988-01-04 | 1990-01-30 | Motorola, Inc. | Electronic device package with peripheral carrier structure of low-cost plastic |

| US4837184A (en) | 1988-01-04 | 1989-06-06 | Motorola Inc. | Process of making an electronic device package with peripheral carrier structure of low-cost plastic |

| US5208450A (en) | 1988-04-20 | 1993-05-04 | Matsushita Electric Industrial Co., Ltd. | IC card and a method for the manufacture of the same |

| US4980802A (en) | 1988-05-09 | 1990-12-25 | Bull Cp8 | Flexible printed circuit |

| US5387306A (en) | 1988-06-21 | 1995-02-07 | Gec Avery Limited | Manufacturing integrated circuit cards |

| GB2225283A (en) | 1988-10-07 | 1990-05-30 | De La Rue Co Plc | Laminated IC card |

| US5200601A (en) | 1989-01-19 | 1993-04-06 | W. & T. Avery Limited | Flexible identification card or token |

| EP0616906A3 (en) | 1989-02-20 | 1994-12-14 | Dainippon Printing Co Ltd | Process for the preparation of decorative sheet. |

| EP0616906A2 (en) | 1989-02-20 | 1994-09-28 | Dai Nippon Insatsu Kabushiki Kaisha | Process for the preparation of decorative sheet |

| DE3910021A1 (en) | 1989-03-28 | 1990-10-04 | Basf Ag | Process for the production of sandwich panels using semi-finished products made of high-performance composites with polymeric matrices |

| JPH0459397B2 (en) | 1989-04-21 | 1992-09-22 | Ebara Udylite Kk | |

| US5244840A (en) | 1989-05-23 | 1993-09-14 | Mitsubishi Denki Kabushiki Kaisha | Method for manufacturing an encapsulated IC card having a molded frame and a circuit board |

| US5067008A (en) | 1989-08-11 | 1991-11-19 | Hitachi Maxell, Ltd. | Ic package and ic card incorporating the same thereinto |

| US5250341A (en) | 1990-03-26 | 1993-10-05 | Mitsubishi Denki Kabushiki Kaisha | IC card |

| US5173840A (en) | 1990-05-07 | 1992-12-22 | Mitsubishi Denki Kabushiki Kaisha | Molded ic card |

| JPH04115996A (en) | 1990-09-06 | 1992-04-16 | Kyodo Printing Co Ltd | Manufacture of ic card |

| US5341421A (en) | 1990-11-06 | 1994-08-23 | Bull Cp8 | Security device, including a memory and/or a microcomputer for data processing machines |

| EP0499513B1 (en) | 1991-02-11 | 1994-12-28 | AEROSPATIALE Société Nationale Industrielle | Device with variable thermal conductivity for placing between a heating and a cooling platen of a machine such as a press |

| DE4105869C2 (en) | 1991-02-25 | 2000-05-18 | Edgar Schneider | IC card and method of making it |

| US5283423A (en) | 1991-03-15 | 1994-02-01 | U.S. Philips Corporation | Contactless microcircuit card |

| US5357091A (en) | 1991-04-30 | 1994-10-18 | Fujitsu Limited | Card type input/output interface device and electronic device system using the same |

| US5438750A (en) | 1991-06-17 | 1995-08-08 | U.S. Philips Corporation | Method of manufacturing a chip card |

| US5272596A (en) | 1991-06-24 | 1993-12-21 | At&T Bell Laboratories | Personal data card fabricated from a polymer thick-film circuit |

| US5396650A (en) | 1991-07-22 | 1995-03-07 | Mitsubishi Denki Kabushiki Kaisha | Wireless communication device with multi-function integrated circuit processing card |

| US5268043A (en) | 1991-08-02 | 1993-12-07 | Olin Corporation | Magnetic sensor wire |

| DE9111708U1 (en) | 1991-09-19 | 1992-04-16 | Anger Electronic Ges.m.b.H. Emco InnovationsCenter, Hallein | Device for laminating printed and unprinted films |

| DE4141972C2 (en) | 1991-12-19 | 1995-02-02 | Interlock Ag | Method and device for laminating layers of identification cards and. the like |

| US5399223A (en) | 1991-12-19 | 1995-03-21 | Interlock Ag | Method and device for laminating layers of identification cards, or the like |

| EP0547524B1 (en) | 1991-12-19 | 1997-08-06 | Interlock Ag | Method and apparatus for laminating identity cards and the like |

| US5567362A (en) | 1991-12-20 | 1996-10-22 | Gao Gesellschaft Fur Automation Und Organisation Mbh | Identity card and a method and apparatus for producing it |

| JPH05208577A (en) | 1992-01-31 | 1993-08-20 | Mitsubishi Denki Eng Kk | Memory card assembling device |

| US5399907A (en) | 1992-02-28 | 1995-03-21 | Johnson Matthey Inc. | Low temperature flexible die attach adhesive and articles using same |