US9962155B2 - Apparatus and method for minimally invasive suturing - Google Patents

Apparatus and method for minimally invasive suturingDownload PDFInfo

- Publication number

- US9962155B2 US9962155B2US15/671,450US201715671450AUS9962155B2US 9962155 B2US9962155 B2US 9962155B2US 201715671450 AUS201715671450 AUS 201715671450AUS 9962155 B2US9962155 B2US 9962155B2

- Authority

- US

- United States

- Prior art keywords

- needle

- suturing

- head assembly

- pawl

- drive

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/04—Surgical instruments, devices or methods for suturing wounds; Holders or packages for needles or suture materials

- A61B17/0469—Suturing instruments for use in minimally invasive surgery, e.g. endoscopic surgery

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/04—Surgical instruments, devices or methods for suturing wounds; Holders or packages for needles or suture materials

- A61B17/0482—Needle or suture guides

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/04—Surgical instruments, devices or methods for suturing wounds; Holders or packages for needles or suture materials

- A61B17/0491—Sewing machines for surgery

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/04—Surgical instruments, devices or methods for suturing wounds; Holders or packages for needles or suture materials

- A61B17/06—Needles ; Sutures; Needle-suture combinations; Holders or packages for needles or suture materials

- A61B17/06066—Needles, e.g. needle tip configurations

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/04—Surgical instruments, devices or methods for suturing wounds; Holders or packages for needles or suture materials

- A61B17/06—Needles ; Sutures; Needle-suture combinations; Holders or packages for needles or suture materials

- A61B17/062—Needle manipulators

- A61B17/0625—Needle manipulators the needle being specially adapted to interact with the manipulator, e.g. being ridged to snap fit in a hole of the manipulator

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/28—Surgical forceps

- A61B17/29—Forceps for use in minimally invasive surgery

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/34—Trocars; Puncturing needles

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B34/00—Computer-aided surgery; Manipulators or robots specially adapted for use in surgery

- A61B34/30—Surgical robots

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B34/00—Computer-aided surgery; Manipulators or robots specially adapted for use in surgery

- A61B34/70—Manipulators specially adapted for use in surgery

- A61B34/71—Manipulators operated by drive cable mechanisms

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B2017/0023—Surgical instruments, devices or methods disposable

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B2017/00367—Details of actuation of instruments, e.g. relations between pushing buttons, or the like, and activation of the tool, working tip, or the like

- A61B2017/00398—Details of actuation of instruments, e.g. relations between pushing buttons, or the like, and activation of the tool, working tip, or the like using powered actuators, e.g. stepper motors, solenoids

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B2017/00367—Details of actuation of instruments, e.g. relations between pushing buttons, or the like, and activation of the tool, working tip, or the like

- A61B2017/00407—Ratchet means

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B2017/0046—Surgical instruments, devices or methods with a releasable handle; with handle and operating part separable

- A61B2017/00473—Distal part, e.g. tip or head

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/04—Surgical instruments, devices or methods for suturing wounds; Holders or packages for needles or suture materials

- A61B17/0469—Suturing instruments for use in minimally invasive surgery, e.g. endoscopic surgery

- A61B2017/047—Suturing instruments for use in minimally invasive surgery, e.g. endoscopic surgery having at least one proximally pointing needle located at the distal end of the instrument, e.g. for suturing trocar puncture wounds starting from inside the body

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/04—Surgical instruments, devices or methods for suturing wounds; Holders or packages for needles or suture materials

- A61B17/0469—Suturing instruments for use in minimally invasive surgery, e.g. endoscopic surgery

- A61B2017/0474—Knot pushers

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/04—Surgical instruments, devices or methods for suturing wounds; Holders or packages for needles or suture materials

- A61B17/06—Needles ; Sutures; Needle-suture combinations; Holders or packages for needles or suture materials

- A61B17/06004—Means for attaching suture to needle

- A61B2017/06028—Means for attaching suture to needle by means of a cylindrical longitudinal blind bore machined at the suture-receiving end of the needle, e.g. opposite to needle tip

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/04—Surgical instruments, devices or methods for suturing wounds; Holders or packages for needles or suture materials

- A61B17/06—Needles ; Sutures; Needle-suture combinations; Holders or packages for needles or suture materials

- A61B17/06066—Needles, e.g. needle tip configurations

- A61B2017/0608—J-shaped

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/04—Surgical instruments, devices or methods for suturing wounds; Holders or packages for needles or suture materials

- A61B17/06—Needles ; Sutures; Needle-suture combinations; Holders or packages for needles or suture materials

- A61B17/06066—Needles, e.g. needle tip configurations

- A61B2017/06085—Needles, e.g. needle tip configurations having a blunt tip

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/28—Surgical forceps

- A61B17/29—Forceps for use in minimally invasive surgery

- A61B17/2909—Handles

- A61B2017/2912—Handles transmission of forces to actuating rod or piston

- A61B2017/2923—Toothed members, e.g. rack and pinion

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/28—Surgical forceps

- A61B17/29—Forceps for use in minimally invasive surgery

- A61B2017/2926—Details of heads or jaws

- A61B2017/2927—Details of heads or jaws the angular position of the head being adjustable with respect to the shaft

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/28—Surgical forceps

- A61B17/29—Forceps for use in minimally invasive surgery

- A61B2017/2926—Details of heads or jaws

- A61B2017/2932—Transmission of forces to jaw members

- A61B2017/2943—Toothed members, e.g. rack and pinion

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B2217/00—General characteristics of surgical instruments

- A61B2217/002—Auxiliary appliance

- A61B2217/007—Auxiliary appliance with irrigation system

Definitions

- the embodiments disclosed hereinrelate to a medical device for suturing tissue, and more particularly to a device for the manipulation and control of a suturing needle during minimally invasive suturing, methods for making such a device and methods for using such a device for suturing tissue.

- MISMinimally invasive surgery

- keyhole surgeryor through natural orifices, including for example the vagina, the esophagus, or the anus.

- a small punctureis typically made in the body. Medical instruments are then inserted through a cannula.

- a cannulahas a small inside diameter, typically 5-10 millimeters (mm), and sometimes up to 20 millimeters (mm) or more. A number of such cannulas may be inserted into the body for any given operation. Minimally invasive surgical instruments are necessarily smaller, and are also generally longer and therefore are more difficult to manipulate with precision.

- Suturingrequires coordinated manipulation with both hands of small needles and sutures that are difficult to visualize (particularly when only indirect, two-dimensional video imaging is available) as well as the several instruments (including needle-drivers and pick-up forceps) ordinarily used to suture by hand.

- several instrumentsincluding needle-drivers and pick-up forceps ordinarily used to suture by hand.

- many surgeonsfind minimally invasive suturing by hand an extremely difficult, often virtually impossible, surgical task.

- a grasping forceps(“needle driver”) is held by the surgeon and is used to grip a curved needle near the needle's tail. Pronation of the surgeon's wrist drives the needle into the tissue. When the point of the curved needle emerges from the tissue, the surgeon releases the needle from the grip of the needle driver and grasps the point with another forceps (“pick-ups”). The surgeon then pulls the curved needle by the needle point, preferably in a circular path following the arc of the needle's curvature to follow the most atraumatic path through the tissue, until the entire length of the needle has exited the tissue. Each time a stitch is placed, the curved needle is thus driven around in a complete circular arc.

- the direct handling of the needlecan result in accidental needle pricks through a surgeon or nurse's gloves, posing a potential risk of infection for the surgeon, nurse, staff, and patient, or cause the needle to become contaminated with pathogenic bacteria that can cause onset of infection at the site of the sutures. There is also a risk of the needle penetrating internal organs or vessels and causing a serious, and often fatal infection.

- U.S. Pat. No. 5,437,681U.S. Pat. No. 5,540,705 and U.S. Pat. No. 6,923,819 disclose a suturing device with thread management comprising a protective cartridge, suturing needle and needle rotation drive, the disclosures of which are hereby incorporated by reference.

- the devices described in the above-mentioned patents and patent applicationcomprise a mechanism for driving a protected needle however, the needle is rotated about an axis that is parallel to the axis of the device.

- the orientation and size of the suturing devicemakes it difficult to visualize and cumbersome to use for MIS.

- a minimally invasive suturing devicethat is easily manipulated within the small diameter of the cannula; functions in an environment characterized by limited space, limited visualization, and limited mobility; mimics the preferred method of suturing used by surgeons; permits the surgeon to secure and tie knots quickly and with controlled tension; places continuous stitches; and protects user's from accidental needle sticks during needle handling, as well as internal organs and vessels, from inadvertent needle-pricks.

- a medical device for closing openings internal to a patient's bodywhich closely emulates or replicates the manual suturing actions carried out by a surgeon.

- the deviceoffers several advantages over conventional methods used by surgeons for suturing tissue during minimally invasive surgery in that the device provides a hand-held suturing instrument of relatively simple mechanical construction that requires no external motive source.

- the presently disclosed embodimentsprovide relative ease of operation for the surgeon with only one hand.

- a suture head assemblymay be removably attached to an actuator mechanism of the suturing device.

- the diameter of the deviceis small enough to fit into a typical cannula, thus making the device extremely easy to maneuver, as well as suture, during endoscopic or other MIS procedures.

- the suture head assembly of the devicecan be laterally articulated to the left of center, to the right of center, up, and down, once inside the cannula, which is ideal for use in the course of endoscopic surgery, including laparoscopy, thoracoscopy and arthroscopy, as well as other less-invasive surgical procedures.

- the device of the present disclosed embodimentsclosely emulates or replicates the manual suturing actions carried out by a surgeon.

- the needleis held in forceps and travels in a circular arc with no obstructions anywhere in the interior of the arc.

- the design of the suturing device of the present disclosed embodimentsallows for a lack of obstruction in the center of the arc of the needle during suturing. In other words, there is no hub at the center of the circular arc of the suturing needle. The entire area within the circular arc of the needle is unobstructed. This allows for the user to have better visualization during operation, unlike the present mechanical suturing methods, while maintaining control over needle movement.

- a “locomotive-type” drive mechanismfor advancing the needle about a path of travel.

- This embodiment of a driveenables the small diameter of the device and affords better visualization during operation because of the lack of a hub.

- the suturing device of the presently disclosed embodimentscan be used to ligate, that is, place a loop of suture around a blood vessel, duct, or other tubular structure; and the device can be inserted further into smaller incisions/openings (one side of the aperture can be inserted deeply, for example).

- a benefit provided by the suturing device of the presently disclosed embodimentsis that the device enables maneuvering a suturing material through a tissue incision in a manner substantially similar to the way a surgeon would do so by hand.

- the suturing devicefirst pushes a suturing needle from the tail of the needle and drives the point of the needle through the tissue.

- the devicepicks up the point of the needle that passed through the tissue, and pulls the remainder of the suturing needle and the suture attached to the suturing needle through the tissue.

- the suturing needlethus consistently follows the arc of the needle's own curve, which is the preferred method of suturing, in the most atraumatic way of passing a needle through tissue.

- a benefit provided by the suturing device of the presently disclosed embodimentsis the ability of the suturing needle to pull the suturing thread entirely through the tissue segments being closed, following each stitch.

- no ancillary instruments or toolssuch as needle holders, pick-up forceps or the like are needed to complete the stitch.

- a forcepscan be used to tighten the knots.

- a suturing devicethat includes a suturing needle that is protected by a housing, the suturing needle is not exposed to or handled directly by the user, thereby preventing inadvertent needle sticks.

- the configuration of the suturing device of the presently disclosed embodimentsalso protects against inadvertent penetration of internal organs or vessels by the needle, since the housing acts as a shield between the organs and the needle.

- the suturing device of the presently disclosed embodimentsis useful for suturing tissue internal to a body.

- An embodiment of the deviceincludes an elongated barrel having a proximal end, a distal end, and a longitudinal axis therebetween; a suture head assembly extending from the distal end of the elongated barrel; a suturing needle having a pointed end and a blunt end, the suturing needle capable of rotating about an axis approximately perpendicular to a longitudinal axis of the elongated barrel, wherein the pointed end of the suturing needle is positioned within the suture head assembly prior to and after rotation of the suturing needle; and an actuator extending from the proximal end of the elongated barrel to actuate a drive mechanism having a needle driver for engaging and rotating the suturing needle.

- a method for suturing tissue during minimally invasive surgeryincludes: (a) engaging a cartridge to a suture head assembly at a distal end of a suturing device, the cartridge having a protective housing and a suturing needle with a pointed end and a blunt end; (b) introducing the distal end of the suturing device into a body cavity; (c) positioning an opening in the cartridge to span a plurality of separated tissue segments or a single tissue segment; (d) activating an actuator coupled to a drive mechanism that engages the suturing needle to cause rotational movement of the suturing needle about an axis approximately perpendicular to a longitudinal axis of the suturing device and advance the suturing needle through the plurality of separated tissue segments or the single tissue segment; (e) pulling a suturing material attached to the suturing needle through the plurality of separated tissue segments or the single tissue segment forming a stitch; and repeating steps (c) through (e) to cause a pluralit

- a method for suturing tissue during minimally invasive surgerythat includes: (a) engaging a suturing needle with a pointed end and a blunt end to a suture head assembly at a distal end of a suturing device, the suture head assembly includes a curved track, whereby the suturing needle follows a curved path along the track during rotation of the suturing needle, and a latch that provides a protective housing for the suturing needle; (b) introducing the distal end of the suturing device into a body cavity; (c) positioning an opening in the needle holder assembly to span a plurality of separated tissue segments or a single tissue segment; (d) activating an actuator coupled to a drive mechanism that engages the suturing needle to cause rotational movement of the suturing needle about an axis approximately perpendicular to a longitudinal axis of the suturing device and advance the suturing needle through the plurality of separated tissue segments or the single tissue segment; (e) pulling a su

- a method for suturing tissue during minimally invasive surgeryincludes inserting a distal end of a suturing device having a suturing needle with a pointed end into a body; positioning the suturing needle to span a plurality of separated tissue segments; activating an actuator a first time causing the pointed end of the suturing needle to extend beyond a protective housing of a cartridge to engage the plurality of separated tissue segments; and activating the actuator a second time to cause the suturing needle to complete a revolution and pull a suture extending from the suturing needle through the plurality of separated tissue segments to form a stitch.

- the suturing device of the presently disclosed embodimentsis relatively simple and cost efficient to manufacture. Therefore, the suturing device should find widespread suturing applications that include single stitches or continuous stitches, e.g. spiral, mattress, purse string, etc., that are required to close tissue incisions, attach grafts, or the like.

- FIG. 1is a perspective view of a suturing device of the presently disclosed embodiments.

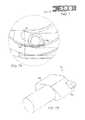

- FIGS. 2A and 2Bare views of the suture head assembly of the suturing device of FIG. 1 .

- FIG. 2Ais a perspective assembly view of the suture head.

- FIG. 2Bis a cutaway perspective view of the suture head.

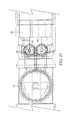

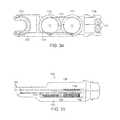

- FIGS. 3A and 3Bare segmented assembly views of the suture head assembly of FIG. 2 .

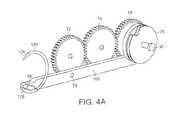

- FIGS. 4A and 4Bare cutaway segmental views of the suture head assembly showing interaction points of a suturing needle with a portion of the drive mechanism.

- FIG. 4Ashows the position of the suturing needle and drive mechanism in a “home” position prior to use or after a complete full cycle.

- FIG. 4Bshows the position of the suturing needle and drive mechanism after one full actuation of the handle, where the suturing needle is in a “rotation” position.

- FIG. 5including FIGS. 5A and 5B are expanded views of the working end of the suture head assembly with a suturing needle in the home position.

- FIG. 5Ashows the relationship between the pawl and anti-rotate spring when the suturing needle is in the home position.

- FIG. 5Bshows a close-up view of the anti-rotate spring.

- FIGS. 6A and 6Bare expanded views of the working end of the suture head assembly during use of the device.

- FIG. 6Ashows the position of the suturing needle and the pawl immediately after the user squeezes the handle. The user then releases the handle and the pawl returns to the start position ( FIG. 6B ) while the suturing needle remains in the rotation position.

- FIG. 7including FIGS. 7A and 7B are expanded views of the pawl in contact with the C-brace while driving the suturing needle.

- FIG. 7Ashows a close-up view of the pawl spring loaded with a spring.

- FIG. 7Bshows a close-up view of the pawl, showing the heel and tip.

- FIGS. 8 and 9are side elevational views of a much larger scale of the internal portions of the drive mechanism located within the handle and elongated barrel.

- FIG. 8shows the drive mechanism when the handle is in an open position

- FIG. 9shows the drive mechanism when the handle is in a closed position.

- FIGS. 10-13are top and bottom views of the suture head assembly, including cables that provide the connection between the drive mechanism located in the suture head assembly and the elongated barrel when the handle is in the open and closed positions.

- FIG. 10shows a top view when the handle is in the open position.

- FIG. 11shows a bottom view when the handle is in the open position.

- FIG. 12shows a top view when the handle is in the closed position.

- FIG. 13shows a bottom view when the handle is in the closed position.

- FIG. 14is a close-up view of the cartridge holder with a tab that locks into a mating groove on the cartridge holder assembly.

- FIG. 15is a view depicting the suturing needle positioned in the track of the cartridge.

- FIG. 16is a view showing the relation between the cartridge holder assembly, cartridge, latch and C-brace.

- FIGS. 17A, 17B and 17Cshow the suture head assembly.

- FIG. 17Ashows a side view of the suture head assembly.

- FIG. 17Bis a close-up side view showing the relationship between the lever and latch during attachment and ejection of the needle and cartridge from the cartridge holder assembly.

- FIG. 17Cshows a top view of the suture head assembly.

- FIG. 18is an expanded view of a curved suturing needle with notches depicted on the surface of the needle.

- FIGS. 19A and 19Bdepict two exemplary embodiments of the curved suturing needle.

- FIGS. 20-23show different views of the suture head assembly attached to the elongated barrel via a rotation rod.

- the primary fixation point of the suture head assembly to the elongated barrelis depicted as being at the axis of lateral rotation.

- FIG. 20shows a side view of the suture head assembly.

- FIG. 21shows a bottom view of the suture head assembly.

- FIG. 22shows a bottom view of the suture head assembly articulated to the left.

- FIG. 23shows a bottom view of the suture head assembly articulated to the right.

- FIGS. 24 and 25are perspective views of a suturing device.

- FIG. 24shows a perspective view of the suturing device with the handles in the open position.

- FIG. 25shows a perspective view of the suturing device with the handles in the closed position.

- FIG. 26is a segmented assembly view of the suture head assembly of FIGS. 24 and 25 .

- FIGS. 27A and 27Bare cutaway segmental views of the suture head assembly of FIGS. 24 and 25 showing interaction points of a suturing needle with a portion of the drive mechanism.

- FIG. 27Ashows the position of the suturing needle and drive mechanism in a “home” position prior to use or after a complete full cycle.

- FIG. 27Bshows another view of the suturing needle and drive mechanism.

- FIG. 28is a close-up view of the needle holder assembly for the suture head assembly of FIGS. 24 and 25 .

- FIG. 29is a close-up view of the distal end of the suture head assembly of FIGS. 24 and 25 .

- FIGS. 30 and 31show the suture head assembly of FIGS. 24 and 25 .

- FIG. 30shows the suture head assembly with the latch in the open position.

- FIG. 31shows the suture head assembly with the latch in the closed or locked position.

- FIG. 32is a view of a curved suturing needle with notches on the face of the suturing needle to be used with the suturing device of FIGS. 24 and 25 .

- FIG. 33shows a view of the pawl in contact with the suturing needle for the suturing device of FIGS. 24 and 25 .

- FIGS. 34 and 35show a close-up view of the suture head assembly of FIGS. 24 and 25 and the associated pulleys that move the drive mechanism.

- FIG. 34shows a top view of the suture head assembly.

- FIG. 35shows a side view of the suture head assembly.

- FIGS. 36 and 37are top views of the suture head assembly and cables that connect the drive mechanism located in the suture head assembly and the elongated barrel when the handle is in the open position for the suture device of FIGS. 24 and 25 .

- FIG. 36shows a top view of the front pulley and cable when the handle is in the open position.

- FIG. 37shows a top view of the return pulley and cable when the handle is in the open position.

- FIG. 38shows a side elevational view of the suturing device of FIGS. 24 and 25 showing parts of the drive mechanism.

- FIG. 39Ashows a top perspective view of a second embodiment of the suture head assembly made in accordance with the teachings of the invention, in which a resilient elongated member moves proximally and distally to actuate movement of the suturing needle about a circular path.

- FIG. 39Bdepicts the suturing head of FIG. 39A incorporated into a suturing device having a flexible steerable proximal segment.

- FIG. 40shows a sectional view of the drive track of the second embodiment of the suture head assembly, depicting the course of the drive tendon, the drive pawl, and the anti-rotate spring in relation to the suturing needle.

- FIG. 41is a close-up view of the distal end of the drive tendon with attached pawl.

- FIG. 42Ais an isolated view of the tendon and pawl engaging a notch in the suturing needle

- FIG. 42Bis an isolated view of an exemplary suturing needle that may be used with the second suturing head embodiment, showing a leading notch and a trailing notch on the side of the needle, and an anti-rotate notch on the outer circumference of the needle.

- FIG. 43is a sectional view of the inside structure of the drive track component of the second embodiment of the suture head assembly, without the tendon, pawl, anti-rotate spring and needle present to highlight the engagement and disengagement tracks, including a flat spring in the proximal chamber used to press the pawl against the drive notch of the needle.

- FIG. 44is a perspective view of a portion of the inside structure of the needle track component of the second embodiment of the suture head assembly, showing one of the pawl body guides, and the aperture through which the anti-rotation spring engages the outer circumference of the needle.

- FIG. 45is a top perspective view of the second embodiment of the suture head assembly, showing the placement of the thrust collar over the lateral side of the needle track, enclosing the needle within it.

- FIG. 46Ais a sectional view through the upper portion of the second embodiment of the suture head assembly, revealing the cross-section of the pawl as it engages the trailing notch of the needle, and showing the distal ends of both pawl body guides, separating the engagement track from the disengagement track. The relationship of the thrust collar to the needle and needle track is also apparent.

- FIG. 46Bis a view of the thrust collar in isolation.

- FIG. 47is a sectional view of the second embodiment of the suture head assembly showing the pawl body positioned against the flat spring, which urges the pawl tip against the side of the needle.

- the needleis partially spanning the aperture of the suture head assembly, and the anti-rotate spring is visible as it contacts the outer circumference of the needle.

- FIG. 48is an isolated view of the anti-rotate spring.

- FIG. 49is an isolated view of the flat spring, which presses against the pawl body to urge the pawl tip against the side of the needle.

- FIG. 50Ais a sectional view of the second embodiment of the suture head assembly in which the pawl is at the proximal end of the engagement drive track, immediately proximal to the trailing notch of the needle.

- FIG. 50Bis a view through section B-B of FIG. 50A showing the pawl tip pressed against the side of the needle above the notch by a compressed flat spring.

- FIG. 50Cis a top view through section C-C of FIG. 50A showing how the flat spring is deflected, pressing the pawl against the side of the needle.

- FIG. 51Ais a sectional view of the second embodiment of the suture head assembly in which the pawl is within the trailing notch of the needle at the proximal end of the engagement drive track.

- FIG. 51Bis a view through section B-B of FIG. 51A showing how the flat spring is relaxed against the pawl when the pawl tip is within the notch of the needle.

- FIG. 51Cis a top view through section C-C of FIG. 51A showing the flat spring in a non-deflected state with the pawl tip advanced within the notch of the needle, now in position to drive the needle forward.

- FIG. 52is a sectional side view of the second embodiment of the suture head assembly, showing the needle in the ‘home’ position, the anti-rotate spring engaging the needle, and the pawl within the trailing notch, in position to drive the needle through a suturing cycle.

- FIG. 53is a sectional side view of the second embodiment of the suture head assembly, showing the needle at the end of the push stroke of the first suturing cycle, the pawl having pushed the needle through the aperture, and ready to disengage from the trailing notch.

- FIG. 54is a sectional side view of the second embodiment of the suture head assembly, showing the pawl being released from the trailing notch into the distal end of the disengagement track.

- FIG. 55is a sectional side view of the second embodiment of the suture head assembly, showing the pawl being pulled by the tendon to the proximal end of the track in the pull stroke of the first suturing cycle.

- FIG. 56is a sectional side view of the second embodiment of the suture head assembly, showing the pawl approaching the proximal chamber where the proximal ends of the engagement and disengagement tracks merge. The distal end of the tendon has been deflected away from the leading notch of the needle.

- FIG. 57is a sectional side view of the second embodiment of the suture head assembly, showing the pawl being released into the leading notch of the needle by spring force from the distal tendon that had been deflected as shown in FIG. 56 .

- FIG. 58is a sectional side view of the second embodiment of the suture head assembly, showing the push stroke of the second suturing cycle, in which the pointed end of the needle is being advanced to the ‘home’ position by the pawl.

- FIG. 59is a sectional side view of the second embodiment of the suture head assembly, showing the push stroke of the second suturing cycle having been completed, the pawl being urged into the distal end of the disengagement track by the spring force of the distal tendon, and the trailing notch in proper alignment with the proximal chamber.

- FIG. 60is a sectional side view of the second embodiment of the suture head assembly, showing the pull stroke of the second suturing cycle, bringing the pawl back to the proximal end of the disengagement track to be positioned to re-initiate the suturing cycle. Backward rotation of the needle is prevented in this stroke by the anti-rotate spring engaging the anti-rotate notch of the needle.

- FIGS. 61-71Bdescribe a further embodiment of a device made in accordance with the invention.

- FIGS. 72-85describe still a further embodiment of a device made in accordance with the invention.

- the suturing device of the presently disclosed embodimentsis shown generally at 50 in FIG. 1 .

- the suturing device 50can be used to produce a continuous or interrupted stitch or suture so as to enable closure of openings internal to a patient's body.

- the suturing device 50can be utilized to suture any type of anatomical tissue in any type of anatomical cavity; and, accordingly, while the device 50 is described hereinafter for use with a cannula in endoscopic procedures, such as laparoscopy, the device 50 can be used in open surgery and with catheters and other small and large diameter tubular or hollow, cylindrical members providing access to small cavities, such as veins and arteries, as well as large cavities, such as the abdomen.

- suturing device 50includes an actuator mechanism shown generally at 52 which comprises an elongated barrel 54 and a handle 60 that extends from the undersides at a proximal end of the elongated barrel 54 .

- a suture head assembly 56is attached to the distal end of the elongated barrel 54 .

- the suture head assembly 56is removably attached to the distal end of the elongated barrel 54 .

- the length of the suture head assembly 56can range from about 20 mm to about 100 mm. In an embodiment, the length of the suture head assembly 56 is about 50 mm.

- the length of the elongated barrel 54can range from about 50 mm to about 400 mm.

- the elongated barrel 54can be made shorter or longer depending on the intended use of the device 50 .

- the elongated barrel 54is about 300 mm. In an embodiment, the elongated barrel 54 is about 350 mm.

- An articulation lever 66just distal to the top of the handle 60 is pushed or pulled to cause the suture head assembly 56 to rotate. Moving the articulation lever 66 clockwise, moves the suture head assembly 56 to the right and moving the articulation lever 66 counterclockwise, moves the suture head assembly 56 to the left. The articulation lever 66 can also be moved to articulate the suture head assembly 56 up and down.

- the suture head assembly 56is locked in place with a locking lever 64 located on an underside of the device 50 , below the articulation lever 66 .

- the suture head assembly 56may be articulated, and the elongated barrel 54 may be any length appropriate for the intended clinical application of the device 50 .

- the diameter of the device 50can range from about 3 mm to about 20 mm. In an embodiment, the diameter of the device 50 is about 12 mm. In an embodiment, the diameter of the device 50 is about 3 mm.

- a flush port 62is located on the side of the elongated barrel 54 in order to provide a port of entry for cleaning fluids or suction such that the device 50 can be cleaned prior to or after use.

- the handle 60is a grip that is squeezed in order to actuate the suturing device 50 .

- the suturing device 50is actuated by the actuator mechanism 52 coupled to a drive mechanism 70 .

- the actuator mechanism 52 of the suturing device 50may comprise a triggering mechanism that is known in the art, such as for example, the triggering mechanisms disclosed in U.S. Pat. Nos. 6,053,908 and 5,344,061, both of which are hereby incorporated by reference.

- the actuator mechanismcan be either a manually operable button or switch, or a mechanically operable by an automated electrical or a fuel driven device, such as for example, an electrical, electromagnetic or pneumatic motor powered by electrical, electromagnetic, compressed air, compressed gas, hydraulic, vacuum or hydrocarbon fuels.

- any actuator mechanism of any type known in the artcan be within the spirit and scope of the presently disclosed embodiments.

- the suturing needle(e.g., 120 , 220 ) used with the suturing device 50 has an engagement or gripping surface at one or more locations along its length.

- an engagement mechanism in the suture head assembly 56can grip the needle to advance it through the target tissue.

- This gripping surfacecan take on a number of different forms, including, for example, one or more serrations or teeth raised above or depressed below the generally toroidal surface of the suturing needle, and properly oriented to allow the suturing needle to advance smoothly through tissue.

- the engagement mechanism in the suture head assembly 56can include one or more number of interfitting teeth.

- the gripping or engagement surface of the suturing needlecan also take the form of hatch marks engraved on the surface of the suturing needle, which either may be raised above or depressed slightly below the surface of the suturing needle.

- the engagement mechanism in the suture head assembly 56can comprise a rubberized contact surface, or a collapsible mesh that can surround the body of the needle at the gripping surface to apply a trapping force against the needle.

- the gripping surfacemay include one or more notches that penetrate the surface of a suturing needle that is generally toroidal in shape, with the notches located on the outer circumference, inner circumference, or on one or both sides of the suturing needle.

- a corresponding engagement mechanism in the suture head assembly 56can comprise a pawl, which can take many forms, but which at a minimum must effectively contact the leading or forward wall of a notch on the suturing needle, either to drive the needle in a forward direction, or to prevent the needle from moving in a reverse direction.

- the following descriptionuses a particular embodiment of the gripping surface for illustrative purposes, and is not intended to limit the scope of the invention illustrated herein.

- FIG. 2Ais a perspective view of the suture head assembly 56 with a cartridge holder assembly 90 located at the distal end to which a cartridge 88 can be attached.

- the suture head assembly 56may be fabricated as a single piece.

- FIG. 2Bis a perspective assembly view of the suture head assembly of the presently disclosed embodiments showing part of the drive mechanism 70 , shown as a gear train/pulley system including pulleys 72 , 74 , 76 and 78 .

- Located within the elongated barrel 54are mechanical parts including drive shafts, belts, rods, cables, or hydraulic tubes which run from the elongated barrel 54 through the spherical portion 58 and then engages with the drive mechanism 70 in the suture head assembly 56 .

- a spherical portion 58that contains part of the drive mechanism 70 including two idler pulleys 80 and cables 84 and 86 .

- the spherical portion 58resides within the distal portion of the elongated barrel 54 and rotates in a substantially frictionless fashion.

- the drive mechanism 70includes a gear train/pulley system (“locomotive-type” drive mechanism) and cables and rods that extend from the distal end of the suture head assembly 56 to the proximal end of the elongated barrel 54 .

- the suture head assembly 56is that portion of the device 50 within which the mechanism for driving the curved needle 120 in a complete 360-degree circular arc, as well as the cartridge holder assembly 90 for attaching and releasing the cartridge 88 are situated.

- the suturing device 50is unique in the fact that the orientation of the suture head assembly 56 is such that when the cartridge 88 is attached to the suture head assembly 56 the needle 120 is driven in a curved path about an axis approximately perpendicular to the longitudinal axis of the device 50 . In this way, the needle 120 may be optimally visualized as the needle 120 is driven in a circular arc. Also, as shown in FIG. 2B , the needle 120 and cartridge 88 are in a plane parallel to the drive mechanism 70 and fit into the same space in the suture head assembly 56 .

- the improved visibility offered by the shape and configuration of the suture head assembly 56enables precise device placement over the incision or other target tissue of interest, and uniform advancement of the suturing device 50 after every stitch to provide a uniform and symmetric suture, thereby minimizing the risk of tearing tissue and bleeding due to a stitch being positioned too close to the edge of the incised tissue.

- the entire device 50 or parts of the device 50such as the suture head assembly 56 , the elongated barrel 54 , the handle 60 , and the needle 120 and cartridge 88 , may be composed of a sterilizable medical grade plastic material, in which case, the entire device 50 or parts of the device 50 may discarded and disposed after a single use.

- the device 50may be composed of a sterilizable medical grade metallic material such as stainless steel to enable reuse subsequent to sterilization following a prior use.

- the device 50is composed of a sterilizable medical grade metallic material such as titanium to enable reuse subsequent to sterilization following a prior use.

- the use of titaniumis ideal for certain procedures including Magnetic Resonance Imaging (MRI) and Computed Tomography (CT) because they are X-Ray radiolucent and do not interfere with MRI and CT scans.

- FIGS. 3A and 3Bprovide detailed segmental views of the suture head assembly 56 showing the cartridge holder assembly 90 , the disposable needle cartridge 88 , a curved suturing needle 120 , and parts of the drive mechanism 70 including a plurality of pulleys, 72 , 74 , 76 , 78 and 80 involved in driving the needle driver 98 through a semicircular path.

- the needle driveris a pawl 98 .

- a shoulder screw 108is used to keep a latch 110 locked in place over the disposable cartridge 88 and the suturing needle 120 .

- Pulleys 72 , 74 , 76 and 78are engaged with an actuator arm 102 , which is attached to the pawl 98 .

- the pawl 98interfits with two notches 132 (as depicted in FIG. 15 ) located on the needle 120 at 180 degrees apart from each other which drives the curved needle 120 in a completely circular arc.

- the suture head assembly 56is preferably configured so that the pawl 98 (or other needle driver), does not intrude into or obstruct the area within the curve of the needle 120 .

- the entire area within the circular arc of the needle 120is unobstructed; there is no hub at the center of the circular arc so that the device 50 can encompass the maximum volume of tissue within the circular arc of the curved needle 120 . In this way, the needle 120 may be rotated through a relatively large arc, allowing the needle 120 to obtain a sufficient “bite” into the tissue.

- the needle 120will have a radius of curvature of about 3 mm to about 40 mm.

- the device 50sutures within the limit of the diameter of the suture head assembly 56 , which is advantageous to suturing through small cannulas during minimally invasive surgery.

- the diameter of the curved needle 120does not exceed the diameter of the suture head assembly 56 .

- FIGS. 4A and 4Bshow detailed views of the drive mechanism 70 located in the suture head assembly 56 with respect to driving the needle 120 during use of the device 50 (the cartridge housing 88 has been removed to show the drive mechanism 70 in detail).

- the drive mechanism 70includes a plurality of pulleys, 72 , 74 , 76 and 78 , and the associated axle pins 82 , involved in driving the pawl 98 through a semicircular path.

- the actuator arm 102engages pulleys 72 and 76 and are pinned 75 to pulleys 72 and 76 .

- pulley 74acts as an idler pulley, transferring the motion to the most distal pulley 72 .

- Pulley 72 and pulley 76rotate through identical arcs.

- the actuator arm 102provides a connection to the pawl 98 .

- the pawl 98is located in the distal end of the actuator arm 102 .

- the pawl 98is attached to the actuator arm 102 by an integral shaft and collar 100 that fits loosely into the actuator arm 102 allowing smooth movement. As the handle 60 is closed and opened, the pawl 98 moves through the same arc as pulleys 72 and 76 .

- FIG. 4Ashows a detailed view of the drive mechanism 70 and the suturing needle 120 either prior to using the device 50 or after one complete full cycle of the device 50 .

- FIG. 4Bshows a detailed view of the drive mechanism 70 and the suturing needle 120 after one squeeze of the handle 60 .

- the drive mechanism 70has moved in a circular arc greater than about 180 degrees, (about 190 degrees), while the suturing needle 120 has moved in a circular arc of about 190 degrees to drive through the tissue or vessel to be sutured.

- the outer surface of the actuator arm 102is shaped to accommodate a C-brace (shown as 106 in FIG. 7 ) that causes the pawl 98 to engage the needle 120 and thereby remain in contact.

- the advancing movement of the needle 120 during operationcauses the notches 132 along the radially inner edge of the needle 120 to align with the pawl 98 in the actuator arm 102 , thereby causing the pawl 98 to engage the notches 132 due to a positive pressure exerted by the C-brace (not shown), and to “lock” into the notches 132 .

- the rotary advancing movement of the needle 120is therefore controlled to occur sequentially through about 190 degrees each time the needle is actuated.

- FIG. 5Ashows a close-up view of the distal end of the suture head assembly 56 with the cartridge 88 and the needle 120 in view as well as the relationship between the pawl 98 and the actuator arm 102 with respect to the needle 120 .

- the needle 120is enclosed within the cartridge 88 , so the sharp pointed end 124 is not exposed.

- This needle position, as loaded,is referred to as the “home” position ( FIG. 5A ).

- the needle 120In the home position, the needle 120 is fully contained within the cartridge housing 88 to eliminate needle-pricks during handling of the cartridge 88 or the loaded device. Squeezing the device handle 60 fully, two times, operates the device 50 through one full cycle. As shown in FIG.

- the first full actuation of the handle 60drives the needle 120 through an about 190 degree arc.

- the pointed end of the needle 124exits the protective enclosure of the cartridge 88 , drives through the tissue to be sutured, and re-enters the protection of the cartridge 88 of the device 50 .

- This positionafter the first squeeze of the handle 60 , is referred to as the “rotation” position.

- the handle 60is then released, and the needle 120 remains in the rotation position while the pawl 98 and the actuator arm 120 return to their start position.

- the handle 60is then squeezed again driving the needle 120 through an about 190 degree arc and returning the needle 120 to the home position.

- FIG. 5Ashows the needle 120 in the home position, the pawl 98 is engaged in the notch 132 near the suture end of needle 126 .

- An anti-rotate spring 136is engaged in the notch 134 on the outer surface of the needle 120 , not allowing the needle 120 to move backwards in the cartridge 88 of the device 50 .

- a close-up view of the anti-rotate spring 136is shown in FIG. 5B .

- the needle 120comprises at least one anti-rotate notch 134 and is engaged with at least one anti-rotate spring 136 .

- the anti-rotate spring 136slips out of the notch 134 and slides over the outer surface of the needle 120 .

- the anti-rotate spring 136snaps in behind the rear corner of the needle 120 , near the suturing material or thread 146 (see FIG. 6A ).

- the anti-rotate spring 136holds the needle 120 in place, preventing the needle 120 from moving with the pawl 98 back toward the start position.

- the pawl 98returns to the start position and engages the notch 132 in the needle 120 near the pointed end 124 (see FIG. 6B ).

- the width of the aperture 118 in the cartridge 88is comparable to and corresponds with the width of the gap in the needle 120 so that when the needle 120 is in the home position (as shown in FIG. 5A ) the needle 120 does not project materially into the aperture 118 .

- Such an alignmentcauses the needle 120 to reside entirely within the cartridge 88 , thereby preventing inadvertent contact of the sharp pointed end 124 with the user's fingers during handling of the disposable needle cartridge 88 for placement on the cartridge holder assembly 90 or disposal after use, and while operating the suturing device 50 .

- Such protection of the needle 120 in the suturing device 50prevents accidental “needle-pricks” from occurring, thereby substantially reducing the risk of infection caused by pathogenic bacteria or viruses that may contaminate the needle 120 during or after use prior to disposal.

- the needle 120may be rotated in a curved track 92 of the cartridge 88 about the longitudinal axis of the suturing device 50 to advance the pointed needle end 124 so that the needle 120 first spans the aperture 118 and then returns to the home position.

- the suturing material or thread 146is attached to the needle 120 , and therefore follows the path of the needle 120 .

- the suturing material or thread 146may then be cut and secured by an appropriate method, such as for example, by tying, or additional stitches may be placed along the entire wound or incision by repeating the aforementioned process. Every stitch, whether a single, interrupted stitch, or one of a series of continuous, running stitches may be placed in like manner.

- the suturing device 50may be used to insert either a single stitch, or to insert a suture comprising a plurality of continuous stitches as a replacement method for a more tedious and time-consuming manual suturing process.

- the terminal end of the suturing material or thread 146may contain a knot or button to prevent the suturing material or thread 146 from pulling through the sutured tissue during placement of the first stitch.

- the cartridge 88comprises the suturing needle 120 attached to the terminal end suturing material or thread 146 , and an appropriate length of suturing material or thread 146 are all packaged in a sterilizable medical packaging material.

- FIG. 7Ashows a close-up view of the pawl 98 which rides in a track formed by the C-brace 106 and the suture head assembly 56 .

- the pawl 98is spring loaded with a spring 104 .

- the spring 104is engaged to the tip of the pawl 98 b as shown in FIG. 7A .

- the spring 104engages the pawl tip 98 b into the notch 132 in the needle 120 during the driving stroke of the device 50 when the handle 60 is closed.

- the spring 104also allows the tip of the pawl 98 b to rotate out of notch 132 of the needle 120 during the return of the pawl 98 to the start position when the handle 60 is opened.

- FIG. 7Bshows a close-up view of the pawl 98 showing the pawl heel 98 a and the pawl tip 98 b.

- the userintroduces the distal end portion of suturing device 50 into a body cavity, via a cannula assembly (not shown), and then laterally articulates the suture head assembly 56 using the articulation lever 66 located just distal to the top of the handle 60 .

- the suture head assembly 56is then positioned relative to the tissue/vessel to be sutured, and the user locks the suture head assembly 56 in place using the locking lever 64 .

- the userthen, through manipulation of suturing device 50 , positions a plurality of separated tissue segments into the opening defined at the distal end portion of the suture head assembly 56 and within the aperture of the cartridge 118 .

- the usermay manipulate the device 50 while actuating the handle 60 to close an incision with a continuous suture whose stitches may be individually tensioned precisely and uniformly along the length of the suture similar to suturing done by hand in the conventional way.

- the usermay employ a single suture which would extend the entire length of the incision or multiple sutures.

- the device 50starts with the needle 120 in the home position and the handle 60 fully open (see FIG. 8 ).

- the handle 60is made up of a grip which rests in the user's palm and is squeezed in order to actuate the device 50 .

- the usersqueezes the handle 60 moving the needle 120 from the home position to the rotation position.

- the handle 60contains linkages 144 to both the upper drive rod 142 and the lower drive rod 140 . Squeezing the handle 60 (see FIG. 9 ) causes the two drive rods 140 and 142 to move in opposite directions.

- the upper drive rod 142moves forward while the lower drive rod 140 moves backward.

- the drive rodsare connected to the suture head assembly 56 with cables 84 and 86 and idler pulleys 80 .

- the upper rod 142is connected to pulley 78 with cable 84 .

- the lower rod 140is connected to pulley 76 with cable 86 .

- FIGS. 10 and 11 in conjunction with FIG. 8show the connections and positions of cables 84 and 86 and the drive pulleys 72 , 74 , 76 and 78 when the handle 60 is in the open position.

- FIGS. 12 and 13 in conjunction with FIG. 9show the connections and positions of cables 84 and 86 and the drive pulleys 72 , 74 , 76 and 78 when the handle 60 is in the closed position.

- the force to move needle 120 from the home position to the rotation positioncomes from the lower rod 140 pulling backward on the drive cable 86 .

- the lower rod 140extends nearly the full length of the elongated barrel 54 , connecting to drive cable 86 , at the proximal end of the elongated barrel 54 . As shown in FIG.

- cable 86exits the elongated barrel 54 and enters the suture head assembly 56 , passing over an idler pulley 80 located in the spherical portion 58 , then wrapping clockwise (as viewed from the bottom) around pulley 76 and is secured to pulley 76 located in the suture head assembly 56 .

- the pulling action of cable 86causes pulley 76 to rotate through an arc of approximately 190 degrees.

- the upper rod 142moves forward.

- the upper rod 142also extends nearly the full length of the elongated barrel 54 , connecting to drive cable 84 , at the proximal end of the elongated barrel 54 . As shown in FIG.

- cable 84also exits the elongated barrel 54 and enters suture head assembly 56 , passing over a second idler pulley 80 located in the spherical portion 58 , then wrapping (clockwise as viewed from the top) around pulley 78 and is secured to pulley 78 located in the suture head assembly 56 .

- Pulley 78is directly linked to pulley 76 through the actuator arm 102 , and cables 84 and 86 are wrapped in opposing directions, so that as cable 86 unwinds from pulley 76 , cable 84 winds onto pulley 78 .

- the needle 120is held in a path of rotation by a combination of three components.

- the cartridge 88 , the C-brace 106 and the cartridge holder assembly 90interact to constrain the needle 120 to the path of rotation (see FIG. 5 ).

- the cartridge 88is a semicircular shaped component that is held into the device 50 by a plurality of extensions 94 located on each end of the cartridge 88 (see FIGS. 14 and 15 ).

- the plurality of extensions 94takes the form of tabs.

- the cartridge 88is made from a sterilizable medical grade metallic material such as stainless steel.

- the cartridge 88provides some of the support structure for keeping the needle 120 in a rotational path and therefore should be constructed from a material with structural integrity.

- the plurality of extensionsare tabs extending from the cartridge housing 88 .

- the plurality of extensions 94lock into mating grooves 96 located along on the distal edge of the cartridge holder assembly 90 that are located diametrically opposite to one another, and are capable of engaging the plurality of extensions 94 correspondingly located in the needle cartridge housing 88 as shown in FIG. 16 .

- the proximal end of cartridge 88is held in place by a cartridge holder assembly 90 , as shown in FIG. 17A .

- the cartridge holder assembly 90also includes a latch 110 , a lever 112 , associated pins 114 and 116 , a shoulder screw 108 , an anti-rotate spring 136 and at least one groove 96 that can engage with the plurality of extensions 94 located on the cartridge 88 . It is the interaction of all of the elements of the cartridge holder assembly 90 that hold and lock the cartridge 88 in place.

- the latch 110slides back to release the cartridge 88 and forward to lock the cartridge 88 in place.

- the latch 110also has a built into ejector feature, as shown in FIG. 17B .

- a lever 112is located distal and below the needle 120 and the cartridge 88 .

- the lever 112pivots on a pin 114 .

- a second pin 116located above the pivot pin 114 , engages with a slot in the latch 110 .

- the latch 110is pulled back and the lever 112 is rotated up and back, causing pin 116 to move back with the latch 110 and to rotate about pin 114 thus pushing the needle 120 and the cartridge 88 from the cartridge holder assembly 90 .

- the needle 120 and the cartridge 88are then removed from the device 50 by a slight proximal motion to disengage the plurality of extensions 94 from their mating grooves 96 in the cartridge holder assembly 90 .

- 17Cshows the needle 120 as it is driven through a first semi circular arc (the handle 60 has partially completed a first full squeeze).

- the anti-rotate spring 136slips out of the notch 134 and slides over the outer surface of the needle 120 .

- Loading of the needle 120 and the cartridge 88is accomplished by engaging the plurality of extensions 94 into both grooves 96 on the cartridge holder assembly 90 and then pressing the proximal ends down against the sloped distal surface of the latch 110 .

- the latch 110is spring loaded at the proximal end, thus can slide back as the needle 120 and the cartridge 88 are pressed into place and then snap closed to the locked position, retaining the needle 120 and the cartridge 88 .

- the lever 112is down and out of the way of the operation of the needle 120 and the cartridge 88 .

- FIG. 18shows a close-up view of the needle 120 .

- the two notches 132are located about 180 degrees apart on the inner surface and assist in driving the needle 120 .

- the pawl 98engages the notches 132 when driving the needle 120 through the circular motion.

- a third notch 134is located on the outer surface of the needle 120 .

- the notch 134assists in preventing rotation of the needle 120 and provides an anti-rotation feature.

- the needle 120is formed as a circular split ring with a gap 122 , a sharp, pointed end 124 , and a blunt end 126 .

- the needle 120further comprises an opening 130 to accommodate the leading end of the suturing material or thread 146 .

- the opening 130is the form of an eye though which the leading end of the suturing material or thread 146 may be passed through for attachment to the needle 120 .

- the opening 130is located adjacent to the blunt end 126 .

- the opening 130can be positioned anywhere along the arc or the needle 120 between the apex 128 and the blunt end 126 .

- the needle 120comprises an opening 130 in the form of a cylindrical bore aligned axially with respect to the needle 120 , located at the blunt end 126 ( FIG. 19B ). The leading end of the suturing material or thread 146 is inserted into the opening 130 and restrained by mechanically crimping.

- the arc length of the needle 120is preferably about 240 degrees to about 300 degrees.

- the needle 120comprises two symmetric notches 132 along the radially inner edge (“inner notches”) that are positioned proximally to the sharp, pointed end 124 and the blunt end 126 of the needle 120 .

- the notches 132are located directly opposite to each other, each having a perpendicular (about 90 degree) segment and an angular segment that makes an angle of about 60 degrees with the perpendicular segment.

- the inner notches 132are engaged by the needle driver 98 of the drive mechanism 70 and enable the needle 120 to undergo a rotary movement upon actuation of the drive mechanism 70 , thereby causing the needle 120 to penetrate into and advance through tissue.

- a similar triangular notch 134is located on the radially outer edge (“outer notch”) of the needle 120 proximally to the inner notch 132 closer to the sharp, pointed end 124 .

- the outer notch 134engages with the anti-rotate spring 136 located on the cartridge holder assembly 90 , whereby rotation of the needle 120 in a direction opposite to the advancing direction or “needle backing-up” is prevented.

- the positive engagement of the needle outer notch 134 during operation of the suturing deviceprecludes needle 120 from straying out of sequence during the suturing process.

- the suture head assembly 56 of the device 50can be laterally articulated to the left of center and also to the right of center. In one embodiment, the suture head assembly 56 can be laterally articulated through an arc of about 22.5 degrees to the left of center and also to the right of center, for a total of about 45 degrees or more. In addition, the suture head assembly can be articulated up and down. In one embodiment, the suture head assembly 56 can be articulated up and down. The ability of the suture head assembly 56 to be articulated to the left and right of center, as well as up and down, permits the user to position the suture head assembly 56 for many different types of suturing applications.

- the articulation lever 66just distal of the top of the handle 60 , is pushed or pulled to cause the suture head assembly 56 to rotate. Viewed from above, moving the articulation lever 66 clockwise moves suture head assembly 56 to the right and moving the articulation lever 66 counterclockwise moves suture head assembly 56 to the left. The suture head assembly 56 is locked in place with the locking lever 64 located on the bottom of the device 50 , below the articulation lever 66 . Movement is accomplished using the solid articulation rod 68 to link the articulation lever 66 to the suture head assembly 56 .

- the articulation rod 68is pinned to the articulation lever 66 and to one side of the most proximal section of the suture head assembly 56 so that the articulation rod 68 pushes or pulls the suture head assembly 56 through a full range of motion (see FIGS. 20-23 ).

- FIGS. 20-23show the articulation rod 68 in the elongated barrel 54 and the connection to the suture head assembly 56 .

- the suture head assembly 56is shown moving from left articulation, to straight to right articulation (some components are not shown to allow clear viewing of the linkage).

- FIG. 20shows a side view of the suture head assembly 56 .

- FIG. 21shows a bottom view of the suture head assembly 56 with no articulation.

- FIG. 22shows a bottom view of the suture head assembly 56 articulated to the left.

- FIG. 23shows a bottom view of the suture head assembly 56 articulated to the right.

- FIGS. 20-23show a number of items.

- the articulation rod 68runs down the center of the elongated barrel 54 and is attached to one side of the spherical portion 58 .

- the function of the articulation rod 68is to push and pull the suture head assembly 56 through an articulation.

- the two idler pulleys 80which drive cables 84 and 86 are located in the spherical portion 58 . Looking at FIG. 20 , the two idler pulleys 80 seem to be one on top of the other. Instead however, they are located in plane with either pulley 76 and lower rod 140 or pulley 78 and upper rod 142 .

- the entire suturing device 50can be designed as a single unit which may be either reusable or disposed after a single use. If desired, the entire suturing device 50 can be designed from a number of units which, each unit may be either reusable or disposed after a single use.

- the suturing device 50is preferably configured to provide a “pistol like” grip for the user that includes an elongated barrel 54 and a handle 60 that extends from the proximal end of the elongated barrel 54 .

- the elongated barrel 54has either a linear or non-linear configuration, including but not limited to, straight, curved and angled configurations.

- a suture head assembly 56is removably attached to the distal end of the elongated barrel 54 .

- the suture head assembly 56contains a portion of the drive mechanism 70 of the device 50 .

- the working end of the suture head assembly 56has a cartridge holder assembly 90 to which a disposable cartridge 88 that is capable of accommodating a suturing needle 120 may reside.

- the disposable cartridge 88preferably has a generally cylindrical housing with an opening or aperture 118 in the sidewall of the housing at the distal or working end thereof.

- An arcuate suturing needle 120having a sharp, pointed end 124 is slidably mounted in a circular track 92 of the cartridge 88 .

- a blunt end of the needle 126is connected to a suturing material or thread 146 .

- the radius of the arc defining the arcuate suturing needle 120is approximately equal to the circumference to the cartridge housing 88 at the aperture 118 therein.

- the needle 120normally resides in a “home” position in the track 92 such that the gap in the arcuate suturing needle 122 is in alignment with the aperture 118 in the cartridge 88 .

- the sharp, pointed end of the needle 124is situated on one side and entirely within the confines of the housing aperture 118 ; the pointed end of the needle 124 is, therefore, shielded by the cartridge housing 88 .

- the blunt end of the suturing needle 126 that is attached to the suturing material or thread 146is located at the opposite side of the aperture 118 .

- the sharp, pointed end of the needle 124is, therefore, wholly contained within the cartridge 88 and does not protrude beyond the housing of the cartridge 88 . Thus, the sharp pointed end of the needle 124 is not exposed to the user.

- the needle 120may be releasably engaged by a needle driver 98 that is rotatably mounted within the suture head assembly 56 so that the needle 120 can be rotated from the home position by about 360 degrees about the central vertical axis of the cartridge 88 .

- a rotary action of the needle 120causes the sharp point 124 to advance across the cartridge housing 88 so as to span the aperture 118 .

- the needle 120penetrates the tissue segments and spans the incision between them.

- a continued rotary movement of the needle 120causes the needle 120 to return to the home position, and thereby causes the suturing material or thread 146 attached to the needle 120 to be pulled into and through the tissue in an inward direction on one side of the tissue incision, and upwards and out through the tissue on the opposite side of the incision.

- the suture material or thread 146follows the curved path of the needle 120 to bind the tissues together with a stitch of material or thread 146 across the incision in a manner similar to manual suturing, wherein the needle 120 is “pushed” from the blunt end 126 and then “pulled” from the pointed end 124 by the pawl 98 .

- an anchoring mechanismis provided at the trailing terminal end of the suturing material or thread 146 to prevent the material 146 from being pulled completely through and out of the tissue segments.

- the anchoring mechanismcan be a pre-tied or a welded loop, a knot wherein the suture material or thread 146 is simply tied, or a double-stranded, looped suture is that attached to the suturing needle 120 .

- the rotary movement of the needle 120 within the needle cartridge 88is accomplished by a pawl 98 that may be operated by the user by holding the suturing device 50 with one hand in a pistol-like grip around the handle 60 , and using at least one finger of that hand to activate.

- the suturing device 50 of the presently disclosed embodimentscan be used for a laparoscopic procedure, including but not limited to laparoscopic colostomy, colectomy, adrenalectomy, splenectomy, repair of paraesophageal hernia, inguinal hernia repair, ventral hernia repair, Nissen fundoplication, liver lobectomy, gastrectomy, small bowel resection, treatment of small bowel obstruction, distal pancreatectomy, nephrectomy and gastric bypass.

- laparoscopic procedureincluding but not limited to laparoscopic colostomy, colectomy, adrenalectomy, splenectomy, repair of paraesophageal hernia, inguinal hernia repair, ventral hernia repair, Nissen fundoplication, liver lobectomy, gastrectomy, small bowel resection, treatment of small bowel obstruction, distal pancreatectomy, nephrectomy and gastric bypass.

- laparoscopic colostomyincluding but not limited

- the abdomenis insufflated with gas to create a working space for the user.

- gasAny gas known to those skilled in the art including, but not limited to, nitrogen or carbon dioxide, can be used.

- Access portalsare established using trocars in locations to suit the particular surgical procedure. A variety of surgical instruments may then be inserted into the body through these access ports/cannulas. The user then introduces the distal end portion of suturing device 50 into a cannula, and then laterally articulates the suture head assembly 56 using the articulation lever 66 located just distal to the top of the handle 60 .

- the suture head assembly 56is then positioned relative to the tissue/vessel to be sutured together, and the user locks the suture head assembly 56 in place using the locking lever 64 .

- the userthen, through manipulation of suturing device 50 , positions a plurality of separated tissue segments into the opening defined at the distal end portion of the suture head assembly 56 and within the aperture 118 of the cartridge 88 .

- the userusing only one hand, may manipulate the device 50 while actuating the handle 60 to close an incision with a continuous suture whose stitches may be individually tensioned precisely and uniformly along the length of the suture similar to suturing done by hand in the conventional way.

- the usermay employ a single suture which would extend the entire length of the incision or multiple sutures.

- the suturing device 50enables the user to lay down a running stitch or interrupted stitch to close the tissue incision in a time efficient manner.

- any conventional procedure for conducting laparoscopic surgerycan be used with the device 50 .

- the needle cartridge 88is disposably mounted on a cartridge holder assembly 90 at the distal end of the suture head assembly 56 .

- the minimalized structural design of the suture head assembly 56enables the user to have a clear, unobstructed view of the suturing needle 120 during advancement through the tissue segments during the course of a suturing operation, thereby enabling precise placement of the suturing device 50 to provide uniform sutures and precluding the risk of tearing tissue by placement too close to the edge of the incision.

- the suturing device 50is then advanced a short distance along the incision and the aforementioned operation is repeated to produce another stitch comprising the suturing material or thread 146 .

- the usermay continue to manipulate the suturing device 50 , alternately advancing and actuating rotation of the needle 120 about an axis that is generally parallel to the direction of advancement to create a continuous suture which may extend through the entire length of the incision or a series of interrupted stitches.

- the stitchis tightened by exerting a pull on the suturing material or thread 146 so that the resultant suture is tensioned uniformly along the length of the incised tissue segments. Therefore, a tight closure of the segments is accomplished and bleeding and tearing of tissue are minimized.

- the usercan use a needle grasper to tighten and knot the formed stitches.

- the presently disclosed embodimentsprovide a method for suturing tissue during minimally invasive surgery including engaging a cartridge 88 to a suture head assembly 56 at a distal end of a suturing device 50 , the cartridge 88 having a protective housing and a suturing needle 120 with a pointed end 124 and a blunt end 126 ; introducing the distal end of the suturing device 50 into a body cavity; positioning an opening 118 in the cartridge 88 to span a plurality of separated tissue segments; activating an actuator 52 coupled to a drive mechanism 70 that engages the suturing needle 120 to cause rotational movement of the suturing needle 120 about an axis approximately perpendicular to a longitudinal axis of the suturing device 50 and advance the suturing needle 120 through the plurality of separated tissue segments; and pulling a suturing material 146 attached to the suturing needle 120 through the plurality of separated tissue segments forming a stitch.

- the presently disclosed embodimentsprovide a method for suturing tissue during minimally invasive surgery including (a) engaging a cartridge 88 to a suture head assembly 56 at a distal end of a suturing device 50 , the cartridge 88 having a protective housing and a suturing needle 120 with a pointed end 124 and a blunt end 126 ; (b) introducing the distal end of the suturing device 50 into a body cavity; (c) positioning an opening 118 in the cartridge 88 to span a plurality of separated tissue segments; (d) activating an actuator 52 coupled to a drive mechanism 70 that engages the suturing needle 120 to cause rotational movement of the suturing needle 120 about an axis approximately perpendicular to a longitudinal axis of the suturing device 50 and advance the suturing needle 120 through the plurality of separated tissue segments; (e) pulling a suturing material 146 attached to the suturing needle 120 through the plurality of separated tissue segments forming a stitch and repeating steps (c) through (e

- the presently disclosed embodimentsprovide a method for suturing tissue during minimally invasive surgery including inserting a distal end of a suturing device 50 having a suturing needle 120 with a pointed end 124 into a body; positioning the suturing needle 120 to span a plurality of separated tissue segments; activating an actuator 52 a first time causing the pointed end 124 of the suturing needle 120 to extend beyond a protective housing of a cartridge 88 to engage the plurality of separated tissue segments; activating the actuator 52 a second time to cause the suturing needle 120 to complete a revolution and pull a suture 146 extending from the suturing needle 120 through the plurality of separated tissue segments to form a stitch.

- the suturing device 50may be configured in different ways with respect to length and angle of the suture head assembly 56 .

- the size of the needle 120 , the needle cartridge 88 , the cartridge aperture 118 and the aperture positionmay also be varied for use in open surgery to perform procedures such as closing of the fascia, skin closure, soft tissue attachment, anastomosis, fixation of mesh, grafts and other artificial materials.

- FIGS. 24 and 25show an alternative embodiment of a suturing device shown generally at 150 .

- the suturing device 150can be used to produce a continuous or interrupted stitch or suture so as to enable closure of openings internal to a patient's body.