US8820656B2 - Dispenser for aerosol systems - Google Patents

Dispenser for aerosol systemsDownload PDFInfo

- Publication number

- US8820656B2 US8820656B2US13/742,232US201313742232AUS8820656B2US 8820656 B2US8820656 B2US 8820656B2US 201313742232 AUS201313742232 AUS 201313742232AUS 8820656 B2US8820656 B2US 8820656B2

- Authority

- US

- United States

- Prior art keywords

- actuator

- collar

- selector

- relative

- outlet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000000443aerosolSubstances0.000titleclaimsabstractdescription68

- 239000011344liquid materialSubstances0.000claimsabstractdescription13

- 238000000034methodMethods0.000claimsdescription11

- 238000006073displacement reactionMethods0.000claimsdescription3

- 239000012530fluidSubstances0.000claims1

- 239000000463materialSubstances0.000description16

- 239000012263liquid productSubstances0.000description10

- 239000000047productSubstances0.000description10

- 230000000881depressing effectEffects0.000description5

- 239000011261inert gasSubstances0.000description5

- 239000003380propellantSubstances0.000description4

- 238000003860storageMethods0.000description4

- 230000003993interactionEffects0.000description3

- IJGRMHOSHXDMSA-UHFFFAOYSA-NAtomic nitrogenChemical compoundN#NIJGRMHOSHXDMSA-UHFFFAOYSA-N0.000description2

- 238000010276constructionMethods0.000description2

- 239000000853adhesiveSubstances0.000description1

- 230000001070adhesive effectEffects0.000description1

- 230000004075alterationEffects0.000description1

- 230000000712assemblyEffects0.000description1

- 238000000429assemblyMethods0.000description1

- 230000002950deficientEffects0.000description1

- 230000000994depressogenic effectEffects0.000description1

- 238000001514detection methodMethods0.000description1

- 238000004519manufacturing processMethods0.000description1

- 229910052757nitrogenInorganic materials0.000description1

- 238000003825pressingMethods0.000description1

- 239000012858resilient materialSubstances0.000description1

- 239000007921spraySubstances0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers for dispensing liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant

- B65D83/16—Actuating means

- B65D83/22—Actuating means with means to disable actuation

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers for dispensing liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant

- B65D83/75—Aerosol containers not provided for in groups B65D83/16 - B65D83/74

- B65D83/753—Aerosol containers not provided for in groups B65D83/16 - B65D83/74 characterised by details or accessories associated with outlets

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B11/00—Single-unit hand-held apparatus in which flow of contents is produced by the muscular force of the operator at the moment of use

- B05B11/0005—Components or details

- B05B11/0089—Dispensing tubes

- B05B11/0091—Dispensing tubes movable, e.g. articulated on the sprayer

- B05B11/0094—Dispensing tubes movable, e.g. articulated on the sprayer movement of the dispensing tube controlling a valve

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers for dispensing liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant

- B65D83/145—Containers for dispensing liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant with tamper-indicating means, e.g. located in front of nozzle outlets

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers for dispensing liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant

- B65D83/16—Actuating means

- B65D83/20—Actuator caps

- B65D83/205—

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers for dispensing liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant

- B65D83/16—Actuating means

- B65D83/22—Actuating means with means to disable actuation

- B65D83/224—Tamper-indicating means obstructing initial actuation

- B65D83/226—Tamper-indicating means obstructing initial actuation preventing initial depression of the actuator

- B65D83/7538—

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B1/00—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means

- B05B1/30—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means designed to control volume of flow, e.g. with adjustable passages

- B05B1/32—Nozzles, spray heads or other outlets, with or without auxiliary devices such as valves, heating means designed to control volume of flow, e.g. with adjustable passages in which a valve member forms part of the outlet opening

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers for dispensing liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant

- B65D83/16—Actuating means

- B65D83/20—Actuator caps

- B65D83/206—Actuator caps comprising cantilevered actuating elements, e.g. levers pivoting about living hinges

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S239/00—Fluid sprinkling, spraying, and diffusing

- Y10S239/12—Flexible outlets

Definitions

- the present inventionrelates to aerosol systems having variable outlet openings.

- Aerosol systemscomprise an aerosol assembly and a liquid product to be dispensed.

- the aerosol assemblyconventionally comprises a container, a valve assembly, an actuator assembly, and a cap.

- the liquid productis disposed within the container along with a propellant material that pressurizes the product.

- the valve assemblyis normally in a closed configuration but may be placed in an open configuration to allow pressurized product to exit the container.

- the actuator assemblyengages the valve assembly such that pressing the actuator assembly places the valve assembly in the open configuration to allow the product to be dispensed through a nozzle formed by the actuator assembly.

- the capengages the container to protect the actuator assembly when the aerosol system is not in use.

- the actuator assemblydefines an outlet opening having an effective cross-sectional area that may be varied.

- actuators that define outlet openings the effective cross-sectional areas of which may be variedare described in the Applicant's U.S. Pat. No. 6,328,185, the specification of which is incorporated herein by reference.

- the outlet openingis changed to obtain different spray patterns and the like; this structure is of particular significance when the material to be dispensed is texture material. Texture material is deposited on a surface in a texture pattern for aesthetic purposes.

- the inventionwill be described herein in the context of an actuator assembly having a variable outlet opening, but certain aspects of the present invention may be applied to other types of actuators as will become apparent from the following discussion.

- the cap employed by many aerosol systemsprevents accidental discharge of product in many situations. However, it is possible that the cap may deformed by a load thereon sufficiently that product will be dispensed accidentally. In addition, the cap itself will not prevent malicious tampering with the product. A person wishing to tamper with the aerosol system can simply remove the cap and depress the actuator button.

- Tamperingis an even greater concern with a certain class of aerosol systems.

- certain aerosol systemsemploy a compressed inert gas such as air or nitrogen as the propellant material.

- the inert gasis typically lighter than the product being dispensed and will collect at the upper end of the container, so the aerosol assembly is designed with a dip tube that extends to the bottom of the container.

- the pressurized inert gasforces the product out of the container through the dip tube.

- the inert gasis free to flow out of the container through the dip tube in a very short time and without clear evidence that tampering has taken place.

- the aerosol systemcannot dispense any of the product within the container and is considered defective.

- the present inventionmay be embodied as an aerosol system for dispensing liquid material comprising a container assembly and an actuator assembly.

- the actuator assemblycomprises an outlet member defining an outlet opening, a collar member, an actuator member, and a selector member.

- the actuator memberis supported by the container assembly in first and second positions and supports the collar member and the outlet member such that movement of the collar member relative to the actuator member causes the collar member to deform the outlet member. Movement of the selector member relative to the collar member causes movement of the collar member relative to the actuator member. Deformation of the outlet member alters a cross-sectional area of the outlet opening.

- the present inventionmay also be embodied as a method of dispensing liquid material comprising the following steps.

- a container assembly, an outlet member defining an outlet opening, a collar member, an actuator member, and a selector memberare provided.

- the collar member and the outlet memberare supported on the actuator member.

- the selector memberis supported relative to the collar member such that movement of the selector member relative to the collar member causes movement of the collar member relative to the actuator member.

- the actuator memberis supported relative to the container assembly.

- the selector memberis moved relative to the collar member to move the collar member relative to the actuator member to cause the collar member to deform the outlet member and thereby alter a cross-sectional area of the outlet opening.

- the actuator memberis displaced to allow the liquid material to flow out of the container assembly through the outlet opening.

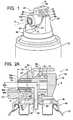

- FIG. 1is a perspective view of portion of a first embodiment of an aerosol assembly that is constructed in accordance with the principles of the present invention

- FIGS. 2A and 2Bare section views of the aerosol assembly of FIG. 1 ;

- FIG. 3is a section view similar to FIGS. 2A and 2B depicting the alteration of the aerosol assembly to allow discharge of material;

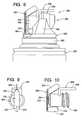

- FIG. 4is a perspective view of a second embodiment of an aerosol assembly of the present invention.

- FIG. 5is a front elevation view of the aerosol assembly of FIG. 4 ;

- FIG. 6is a side elevation view of a third embodiment of an aerosol assembly of the present invention.

- FIG. 7is a front elevation view of the aerosol assembly of FIG. 6 .

- FIG. 8is a side elevation view of a fourth embodiment of an aerosol assembly of the present invention.

- FIG. 9is a front elevation view of a nozzle member of the aerosol assembly of FIG. 8 ;

- FIG. 10is a side elevation view of the nozzle member of FIG. 9 ;

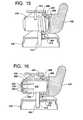

- FIG. 11is a side elevation view of a dispensing assembly that may be used as part of a fifth embodiment of an aerosol assembly of the present invention.

- FIGS. 12 and 13are side elevation, partial cutaway views of the dispensing assembly of FIG. 11 illustrating the removal of a security tab portion;

- FIG. 14is a rear elevation view of the dispensing assembly of FIGS. 11 and 12 ;

- FIG. 15is a side elevation, partial cutaway view of the dispensing assembly of FIGS. 11 and 12 illustrating the interaction of a base member with a selector member thereof;

- FIG. 16is a side elevation, partial cutaway view of the dispensing assembly of FIGS. 11 and 12 illustrating the interaction of the base member, collar member, selector member, and actuator member thereof;

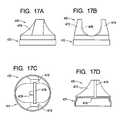

- FIGS. 17A-17Dare side elevation, front elevation, top plan, and side elevation cutaway views of a base member of the dispensing assembly of FIGS. 11 and 12 ;

- FIGS. 18A-Care side elevation, front elevation, and bottom plan views of the collar member (including security tab portion) of the dispensing assembly of FIGS. 11 and 12 ;

- FIG. 18Dis a side elevation cutaway view of the collar member of FIGS. 18A-C with the security tab portion removed;

- FIGS. 19A-19Eare side elevation, rear elevation, bottom plan, front elevation, and side elevation cutaway views of the selector member of the dispensing assembly of FIGS. 11 and 12 ;

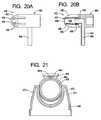

- FIG. 20Ais a side elevation view of the actuator member and outlet member of the dispensing assembly of FIGS. 11 and 12 ;

- FIG. 20Bis a side elevation cutaway view of the actuator member and outlet member depicted in FIG. 20A ;

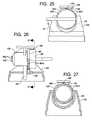

- FIG. 21is a front elevation view section view depicting the interaction of the base member with the selector member of the dispensing assembly of FIGS. 11 and 12 in a storage configuration;

- FIGS. 22 , 23 , and 24depict the orientation of the selector member and the collar member with respect to the base member of the dispensing assembly of FIGS. 11 and 12 in a first use configuration

- FIGS. 25 , 26 , and 27depict the orientation of the selector member and the collar member with respect to the base member of the dispensing assembly of FIGS. 11 and 12 in a second use configuration.

- the aerosol system 20comprises a container assembly 22 and an actuator assembly 24 .

- the aerosol system 20will also typically include a valve assembly, a liquid product to be dispensed, and a propellant material.

- the valve assembly, liquid product, and propellant materialare or may be conventional and are not shown in the drawings or described herein beyond what is necessary for a complete understanding of the present invention.

- the actuator assembly 24is mounted on the container assembly 22 for movement between first and second positions. In the first position, the valve assembly is closed and the liquid product cannot flow out of the container assembly 22 . In the second position, the valve assembly is opened and the liquid product is allowed to flow out of the container assembly 22 as will be described in further detail below.

- the actuator assembly 24comprises an actuator member 30 , a nozzle member 32 , a slide member 34 , and a collar member 36 .

- a base member 38is mounted on the container assembly 22 and engages the actuator assembly as will be described in further detail below.

- the actuator member 30comprises a nozzle portion 40 and a stem portion 42 and defines at least a portion of a discharge passageway 44 .

- the nozzle member 32is mounted on the nozzle portion 40 to define an outlet portion 50 of the discharge passageway 44 ; the portion of the discharge passageway 44 defined by the nozzle member 32 terminates in an outlet opening 52 .

- the exemplary nozzle member 32is a flexible, hollow cylindrical member and may be deformed to change an effective cross-sectional area of the outlet opening 52 of the discharge passageway 44 .

- the slide member 34comprises a finger portion 60 , a male threaded portion 62 , a locking tab portion 64 , and a button portion 66 .

- the collar member 36defines a rail portion 70 and a female threaded portion 72 .

- the finger portion 60 of the slide member 34extends around at least a portion of the nozzle member 32 that defines the outlet portion 50 of the discharge passageway 44 .

- the threaded portions 62 and 72 of the slide member 34 and collar member 36engage each other to allow displacement of the slide member 34 along an outlet axis A relative to the collar member 36 when the collar member 36 is rotated about the outlet axis A.

- the base member 38comprises a mounting portion 80 and defines groove portions 82 and through opening 84 .

- the exemplary base member 38further comprises ear portions 86 that extend the surface area in which the groove portions 82 are formed.

- the mounting portion 80engages the container 22 below the actuator assembly 24 .

- the stem portion 42 of the actuator member 30extends through the through opening 84 and into the container 22 to engage the valve assembly.

- the rail portion 70 on the collar member 36is annular, and the groove portions 82 in the base member 38 are arcuate.

- the rail portion 70engages the groove 82 to allow the collar member 36 to rotate about the outlet axis A but prevent movement of the collar member 36 along this axis A. Because the collar member 36 cannot move along the outlet axis A, when the collar member 36 is rotated about the axis A the threaded portions 62 and 72 engage each other to cause the slide member 34 to move along this axis A relative to the base member 38 , the actuator member 30 , and the nozzle member 32 .

- the stem portion 42 of the actuator member 30supports the actuator assembly 24 above the base member 38 such that the actuator assembly 24 moves within a defined range along a predetermined path relative to the base member 38 .

- identified by reference character Cis the distance along or range within which the actuator assembly 24 moves relative to the base member 38 and container assembly 22 .

- the locking tab portion 64 of the slide member 34is arranged between the nozzle portion 40 of the actuator member 30 and the base member 38 .

- the locking tab portion 64is sized and dimensioned to prevent downward movement of the actuator member 30 relative to the base member 38 .

- the locking tab portion 64thus prevents the movement of the actuator assembly 24 from the first position to the second position that would cause the valve assembly of the aerosol system 20 to open.

- an effective thickness D of the locking tab portion 64(between the actuator member 30 and base member 38 ) is approximately equal to the range or distance C along which the actuator assembly 24 travels. Accordingly, as long as the locking tab portion 64 is attached to the slide member 34 , the nozzle assembly 24 cannot move relative to the container assembly 22 and the aerosol system 20 cannot dispense texture material.

- the locking tab portion 64may be detached from the slide member 34 .

- the exemplary locking tab portion 64is scored along a parting line E such that, when the locking tap portion 64 is grasped and twisted about the parting line E, the locking tab portion 64 breaks off from the slide member 34 . With the locking tab portion 64 detached as just described, nothing prevents the actuator member 30 from moving towards the base member 38 .

- the actuator assembly 24thus operates in a locked state in which the locking tab portion 64 is arranged to prevent movement of the actuator member 30 towards the base member 38 and an unlocked state in which the locking tab portion 64 is detached from the slide member 34 .

- the exemplary locking tab portion 64is formed as part of the slide member 34 , and this structure is preferred; however, the locking tab portion 64 may be formed on any member of the actuator assembly 24 or even on the base member 38 or the container assembly 22 . In any configuration, the locking tab portion 64 is arranged to prevent movement of the actuator assembly 24 from its first position to its second position and then detached to allow such movement.

- the finger portion 60 of the slide member 34is sized and dimensioned to engage the nozzle member 32 as the slide member 34 moves along the outlet axis A.

- the outlet portion 50 of the nozzle member 32is not deformed; the effective area of the outlet opening 52 is thus determined by the diameter of the nozzle member 32 when not deformed.

- the finger portion 60engages and deforms the nozzle member 32 such that the effective area of the outlet opening 52 reduces.

- the resilient nozzle member 32returns to its original, non-deformed configuration.

- the collar member 36when rotated about the outlet axis, causes the effective area of the outlet opening 52 to vary continuously from a first value corresponding to the first end position of the slide member 36 down to a second value corresponding to the second end position of the slide member 36 .

- the ability to vary the effective cross-sectional area of the outlet opening 52is important with certain materials.

- texture materialmay be dispensed in different texture patterns to match an existing texture pattern.

- the structure employed to vary the cross-sectional area of the outlet openingmay be different from that disclosed above.

- the present invention in its broadest formdoes not require the use of an actuator assembly having a variable outlet opening.

- the actuator assembly 24 depicted herein, while desirable for dispensing texture material,is not the only actuator assembly that may be used to implement the principles of the present invention.

- the actuator assembly 24is assembled as follows.

- the base member 38is first attached to the container assembly 22 .

- the stem portion 42 of the actuator member 30is then inserted through the through opening 84 in the base member 38 until it engages the valve assembly within the container assembly 22 .

- the collar member 36is then arranged behind the actuator member 30 with the rail portion 70 thereof engaging the groove 82 in the base portion 38 .

- the slide member 34is then displaced along the outlet axis A towards the collar member 36 until the male threaded portion 62 of the slide member 34 engages the female threaded portion 72 of the collar member 36 .

- the collar member 36is then rotated relative to the slide member 34 such that the slide member 34 is drawn towards the collar member 36 .

- the slide member 34eventual reaches a locked location at which a notch 90 in the locking tab portion 64 engages a projection 92 on the base member 38 .

- the projection 92engages the notch 90 to prevent further movement of the slide member 34 towards the collar member 36 .

- the projection 92also engages the notch 90 to prevent the slide member 34 from rotating up relative to the base member 38 .

- the aerosol system 20will normally be shipped and stored with the actuator assembly 24 in its locked state.

- the locking tab portion 64will help prevent accidental discharge of the liquid product.

- the locking tab portion 64ensures that tampering without leaving evidence of such tampering takes significant effort (i.e., disassembly of the actuator assembly). Further, if the locking tab portion 64 is removed, this is evidence of tampering that allows manufacturers, distributors, and retailers to determine when and where the tampering is occurring.

- FIGS. 4 and 5depicted at 120 therein is an aerosol system constructed in accordance with a second embodiment of the present invention.

- the aerosol system 120is similar to the aerosol system 20 described above and will be described herein only to the extent that these systems 20 and 120 differ.

- the aerosol system 120comprises a container assembly 122 , an actuator assembly 124 , and a valve assembly (not shown).

- the actuator assembly 124comprises an actuator member 130 , a nozzle member 132 , a slide member 134 , and a collar member 136 .

- a base member 138is mounted on the container assembly 122 .

- the actuator member 130comprises a nozzle portion (not shown) and a stem portion (not shown) and defines at least a portion of a discharge passageway.

- the slide member 134comprises a finger portion 160 , a male threaded portion (not shown), a locking tab portion 164 , and a button portion 166 .

- the collar member 136defines a rail portion 170 and a female threaded portion (not shown).

- the base member 138comprises a mounting portion 180 and defines groove portions 182 , a through opening (not shown), and a pair of ear members 186 .

- the aerosol system 120differs from the system 20 in that the ear members 186 extend from the mounting portion 180 a distance F that is significantly larger than the distance that the ear members 86 extend from the mounting portion 80 . As perhaps best shown in FIG. 5 , this distance F is such that tips 190 of the ear members 186 are extend beyond and on either side of the button portion 166 . In particular, when the actuator assembly 124 is mounted on the container assembly 122 , an upper surface 192 of the button portion 166 is spaced a distance G from the mounting portion 180 . The distance G is slightly less than distance F associated with the ear members 186 .

- a load applied on the top of the aerosol system 20will thus engage the ear members 186 before engaging the button upper surface 192 .

- the ear members 186can be made in a geometric configuration that can bear loads that are significantly greater than the loads that can be carried by, for example, a conventional cap (not shown) commonly used to cover and protect the actuator assembly of an aerosol system.

- the ear members 186can also be made to bear loads larger than those that can be borne by the tab portion 164 of the slide member 132 .

- the ear members 186thus significantly increase the ability of the aerosol system 20 to bear top loads such as those that would be created by stacking heavy items on a container carrying a plurality of systems 120 .

- FIGS. 6 and 7depicted at 220 therein is an aerosol system constructed in accordance with a third embodiment of the present invention.

- the aerosol system 220is similar to the aerosol systems 20 and 120 described above and will be described herein only to the extent that it differs from the systems 20 and 120 .

- the aerosol system 220comprises a container assembly 222 , an actuator assembly 224 , and a valve assembly (not shown).

- the actuator assembly 224comprises an actuator member 230 , a nozzle member 232 , a slide member 234 , and a collar member 236 .

- a base member 238is mounted on the container assembly 222 .

- the actuator member 230comprises a nozzle portion (not shown) and a stem portion (not shown) and defines at least a portion of a discharge passageway.

- the slide member 234comprises a finger portion 260 , a male threaded portion (not shown) and a button portion 266 .

- the collar member 236defines a rail portion 270 and a female threaded portion (not shown).

- the base member 238comprises a mounting portion 280 and defines groove portions 282 , a through opening (not shown), and ear portions 286 .

- the aerosol system 120differs from the systems 20 and 120 in that the actuator assembly 224 further comprises a tab member 290 .

- the actuator assembly 224is placed in its locked configuration by arranging the tab member 290 to engage the button portion 266 and the ear members 286 .

- the button portion 266cannot move relative to the ear members 286 under normal conditions.

- the tab member 290thus functions as a tab portion that prevents movement of the actuator assembly 24 from its first position to its second position when attached to the button portion 266 .

- the tab member 290defines a locking channel 292 and a pair of elbow portions 294 .

- the button portion 266is sized and dimensioned to be received within the locking channel 292 .

- the tab member 290is moved into a locked position by displacing the member 290 such that the locking channel 292 receives at least a portion of the button portion 266 .

- the tab member 290can move only in a removal direction from the locked position, with friction maintaining the tab member on the button portion 266 .

- the elbow portions 294engage upper surfaces 296 formed on the ear members 286 .

- the elbow portions 294bridge over the top of the button portion 266 and suspend the button portion 266 below the locking channel 292 .

- the tab member 290thus protects the button portion 266 from top loads by forming a structural member that extends over the top of the button portion 266 and also prevents inadvertent depressing of the button portion 266 .

- a tamper sealmay be adhered to the tab member 290 and the button portion 266 such that the tamper seal must be destroyed before the tab member 290 is detached from the button portion 266 . Such a tamper seal will allow detection of tampering.

- the exemplary tab member 290engages the button portion 266 using a rail and channel, other attachment systems may be used.

- a peg that frictionally engages a peg, a snap fit, a temporary adhesive or the likemay be used as attachment systems.

- any such attachment systemshould require the tab member 290 to be displaced relative to the button portion in a direction perpendicular to the direction in which the button portion 266 is pressed. This avoids moving the actuator assembly 24 from its first to its second position while attaching the tab member 290 to the button portion 266 .

- FIGS. 8-10depicted at 320 therein is an aerosol system constructed in accordance with a third embodiment of the present invention.

- the aerosol system 320will be described herein primarily to the extent that it differs from the systems 20 , 120 , and 220 described above.

- the aerosol system 320comprises a container assembly 322 , an actuator assembly 324 , and a valve assembly (not shown) mounted on the container assembly 322 .

- the container assembly 322 and valve assemblyare or may be conventional and will not be described herein in detail.

- an optional base member 326may be mounted on the container assembly 322 .

- the actuator assembly 324comprises an actuator member 330 and a nozzle member 332 .

- the actuator member 330defines at least a portion of a discharge passageway and comprises a nozzle portion 340 and a stem portion (not shown in FIG. 8 ).

- a portion of the nozzle portion 340is configured to define an internal threaded portion (not shown in FIG. 8 ).

- the nozzle member 332comprises a locking tab portion 350 , nozzle portion 352 , a male threaded portion 354 , and a button portion 356 and at least a portion of the discharge passageway.

- the base member 326comprises a mounting portion 360 and a pair of ear portions 362 (only one shown in FIG. 8 ) and defines a stop surface 364 .

- the discharge passageway defined by the actuator member 330 and nozzle member 332may define a fixed outlet opening, or the outlet opening defined thereby may be adjustable as with the systems 20 , 120 , and 220 described above. If the discharge passageway is fixed, the functions of the actuator member 330 and nozzle member 332 may be implemented in a single part.

- Initial fabrication of the aerosol system 320is accomplished by engaging the male threaded portion 354 of the nozzle member 332 with the internal threaded portion of the actuator member 330 to form the actuator assembly 324 .

- the stem portion of the actuator member 330is then engaged with the valve assembly to form the aerosol system 320 .

- the locking tab portion 350comprises a lock portion 370 , a connecting portion 372 , and a handle portion 374 .

- the lock portion 370is connected to or integrally formed with the nozzle portion 340 of the actuator member 330 at a break line 376 .

- the connecting portion 372connects the lock portion 370 to the handle portion 374 .

- the lock portion 370When the system 320 is in the locked configuration, the lock portion 370 is arranged between the nozzle portion 352 of the actuator member 330 and the container assembly 322 . When an actuating force is applied to the button portion 356 , the lock portion 370 prevents the actuator member 330 from moving towards the container assembly 322 . The lock member 370 thus prevents movement of the actuator member 330 relative to the container assembly 322 that would place the valve assembly in its open configuration and cause product within the container assembly 322 to be dispensed.

- the handle portion 374is rotated or twisted to cause the locking tab portion 350 separate from the nozzle portion 340 at the break line 376 .

- the lock portion 370no longer arranged between the container assembly 322 and the nozzle portion 352 of the actuator member 330 , the aerosol assembly 320 is in an unlocked configuration.

- the actuator member 330is free to travel toward the container assembly 322 . Depressing the button portion 356 of the nozzle member 332 when the system 320 is in the unlocked position thus causes the valve assembly to open, thereby allowing material within the container assembly 322 to be dispensed along the discharge passageway.

- the base member 326is secured to the container assembly 322 such that the lock member 370 engages the stop surface 364 of the base member 326 when the system 320 is in the locked configuration.

- the lock member 370indirectly engages the container assembly 322 through the base member 326 .

- the ear portions 362 of the base member 326extend at least partly along opposing sides of the actuator assembly 324 .

- the ear portions 362thus protect the actuator assembly 324 from at least side impacts.

- FIGS. 11-27depicted at 420 therein is an dispensing assembly that may be used by a fifth embodiment of an aerosol system of the present invention.

- the dispensing assembly 420will be described herein primarily to the extent that it differs from the actuator assemblies 24 , 124 , 224 , and 324 described above.

- the aerosol system incorporating the example actuator system 420comprises a container assembly and a valve assembly mounted on the container assembly as generally described above.

- the container assembly and valve assemblyare or may be conventional and will not be described herein in detail.

- the dispensing assembly 420comprises a base member 430 , an actuator member 432 , an outlet member 434 , a collar member 436 , and a selector member 438 .

- the base member 430is adapted to engage the container assembly of the aerosol system.

- the actuator member 432extends through the base member 430 to engage the valve assembly of the aerosol system.

- the actuator member 432further supports the resilient outlet member 434 .

- the actuator member 432 and outlet member 434define an outlet passageway through which material is dispensed from the container assembly and through the valve assembly.

- the outlet passagewayterminates in an outlet opening defined by the outlet member 434 .

- the collar member 436extends around a portion of the actuator member 432 .

- the selector member 438engages the base member 430 and the collar member 436 such that rotation of the selector member 438 relative to the collar member 436 displaces the collar member 436 relative to the actuator member 432 .

- the collar member 436acts on the actuator member 432 such that the outlet member 434 is deformed. Deforming the outlet member 434 alters the cross-sectional area of the outlet opening defined by the outlet member 434 .

- the collar member 436comprises an engaging portion 440 , a security tab portion 442 , and a button portion 444 .

- a collar threaded portion 446is formed on the engaging portion 440

- a lock projection 448is formed on the button portion 444 .

- the collar member 436further defines a collar chamber 450 .

- a first collar opening surface 452 , second collar opening surface 454 , and collar slot 456allow access to the collar chamber 450 .

- FIGS. 18B and 18Dillustrate a reduced cross-section portion 458 that facilitates removal of the security tab portion 442 from the engaging portion 440 .

- the dispensing assembly 420cannot be operated until the security tab portion 442 is removed.

- the selector member 438comprises a receiving portion 460 , a handle portion 462 , a flange portion 464 , and selector threaded portion 466 .

- the selector threaded portion 466defines internal threads around a receiving recess 468 .

- a storage notch 464 a and ratchet notches 464 bare formed in the flange portion 464 .

- the internal selector threaded portion 466is sized and dimensioned to receive the collar threaded portion 446 .

- rotation of the selector member 438 relative to the collar member 436displaces the collar member 436 relative to the selector member 438 as will be described in further detail below.

- the lock projection 448 of the collar member 436is located to engage the flange portion 464 of the selector member 438 .

- the lock projection 448may extend into the storage notch 464 a or one of the ratchet notches 464 b in the flange portion 464 .

- the engagement of the lock projection 448 with the notch 464 a or one of the notches 464 b in the flange portion 464can fix an angular relationship between the collar member 436 and the selector member 438 against inadvertent movement.

- the deliberate application of manual forcecan rotate the selector member 438 relative to the collar member 436 when a change in the angular relationship therebetween is desired.

- the example base member 430comprises a container engaging portion 470 , first and second supports 472 and 474 , an alignment groove 476 , and a bottom opening 478 .

- the container engaging portion 470is sized and dimensioned to engage the container of the aerosol system, similar to the situation depicted in FIG. 2A of the drawing.

- the first and second supports 472 and 474extend from the container engaging portion 470 .

- the alignment groove 476extends along the inner surfaces of the supports 472 and 474 .

- the bottom opening 478allows access through the base member 430 as will be described in detail below.

- the example actuator member 432comprises a mounting portion 480 , a plurality of finger portions 482 , a valve stem 484 , and an outlet seat 486 .

- the term “plurality”is used in this application to denote two or more of an item.

- An actuator passageway 488extends through the valve stem 484 , the mounting portion 480 , and the outlet seat 486 .

- the example outlet member 434is a cylindrical tube 490 made of resilient material that defines an outlet passageway 492 .

- One end of the outlet member 434defines an outlet opening 494 .

- the other end of the outlet member 434defines a seat opening 496 that is sized and dimensioned to receive the outlet seat 486 .

- the outlet member 434is first placed within the finger portions 482 of the actuator member 432 such that the seat opening 496 snugly fits over the outlet seat 486 as shown in FIG. 20B .

- the engagement of the outlet member 434 with the outlet seat 486prevents inadvertent removal of the outlet member 434 from within the finger portions 482 .

- the actuator member 432with the outlet member 434 supported thereby, is then placed within the collar chamber 450 defined by the collar member 436 as perhaps best shown in FIG. 16 .

- the valve stem portion 484 of the actuator member 432passes through the collar slot 456 in the collar member 436 .

- the selector member 438is arranged such that the selector threaded portion 466 engages the collar threaded portion 446 of the collar member 436 .

- the selector member 438is then rotated until the lock projection 448 on the collar member 436 enters the storage notch 464 a in the flange 464 on the selector member 438 .

- the angular orientation of the selector member 438 relative to the collar memberis as shown, as examples, in FIGS. 11-16 and 21 .

- valve stem 484extends through the bottom opening 478 in the base member 430 ( FIG. 16 ).

- the flange 464 on the selector member 438is received by the alignment groove 476 .

- the valve stem 484engages the valve assembly in a conventional manner.

- the shape of the supports 472 and 474is such that the alignment groove 476 maintains the selector member 438 in a desired orientation relative to the base member 430 .

- the alignment groove 476is shaped to allow the actuator member 432 to be displaced towards the base member 430 as previously described.

- selector member 438is rotated as shown by arrow A in FIG. 22 to change an angular orientation of the selector member 438 relative to the collar member 436 .

- the lock projection 448engages a first end of the ratchet portion 464 b .

- the ratchetnotches engage the lock projection 448 to maintain the angular orientation as desired.

- the outlet opening 494is at its biggest cross-sectional area (outlet member 434 not deformed).

- the first opening surface 452 on the collar member 436engages the finger portions 482 on the actuator member 432 .

- These finger portions 482are flexible such that, when engaged by the opening surface 452 , the finger portions 482 deflect towards each other.

- the finger portions 482squeeze the outlet member 434 when the selector member 438 is rotated in the direction shown by arrows A and B in FIGS. 22 and 25 . Squeezing the outlet member 434 causes the cross-sectional area of the outlet opening 494 to be reduced. Rotating the selector member 438 in a direction opposite to the direction shown by arrows A and B in FIGS. 22 and 25 increases the cross-sectional area of the outlet opening 494 .

- the ratchet notchesengage the stop projection 448 to fix the angular orientation of the selector member 438 relative to the collar member 436 against inadvertent motion.

Landscapes

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Nozzles (AREA)

Abstract

Description

Claims (20)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/742,232US8820656B2 (en) | 2003-04-10 | 2013-01-15 | Dispenser for aerosol systems |

| US14/473,749US9132953B2 (en) | 2003-04-10 | 2014-08-29 | Dispenser for aerosol systems |

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US41177903A | 2003-04-10 | 2003-04-10 | |

| US11/502,250US7500621B2 (en) | 2003-04-10 | 2006-08-09 | Systems and methods for securing aerosol systems |

| US12/401,495US8033484B2 (en) | 2003-04-10 | 2009-03-10 | Dispensers for aerosol systems |

| US13/271,045US8353465B2 (en) | 2003-04-10 | 2011-10-11 | Dispensers for aerosol systems |

| US13/742,232US8820656B2 (en) | 2003-04-10 | 2013-01-15 | Dispenser for aerosol systems |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US13/271,045ContinuationUS8353465B2 (en) | 2003-04-10 | 2011-10-11 | Dispensers for aerosol systems |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US14/473,749ContinuationUS9132953B2 (en) | 2003-04-10 | 2014-08-29 | Dispenser for aerosol systems |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| US20130126632A1 US20130126632A1 (en) | 2013-05-23 |

| US8820656B2true US8820656B2 (en) | 2014-09-02 |

Family

ID=38667022

Family Applications (5)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US11/502,250Expired - LifetimeUS7500621B2 (en) | 2003-04-10 | 2006-08-09 | Systems and methods for securing aerosol systems |

| US12/401,495Expired - LifetimeUS8033484B2 (en) | 2003-04-10 | 2009-03-10 | Dispensers for aerosol systems |

| US13/271,045Expired - Fee RelatedUS8353465B2 (en) | 2003-04-10 | 2011-10-11 | Dispensers for aerosol systems |

| US13/742,232Expired - LifetimeUS8820656B2 (en) | 2003-04-10 | 2013-01-15 | Dispenser for aerosol systems |

| US14/473,749Expired - LifetimeUS9132953B2 (en) | 2003-04-10 | 2014-08-29 | Dispenser for aerosol systems |

Family Applications Before (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US11/502,250Expired - LifetimeUS7500621B2 (en) | 2003-04-10 | 2006-08-09 | Systems and methods for securing aerosol systems |

| US12/401,495Expired - LifetimeUS8033484B2 (en) | 2003-04-10 | 2009-03-10 | Dispensers for aerosol systems |

| US13/271,045Expired - Fee RelatedUS8353465B2 (en) | 2003-04-10 | 2011-10-11 | Dispensers for aerosol systems |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US14/473,749Expired - LifetimeUS9132953B2 (en) | 2003-04-10 | 2014-08-29 | Dispenser for aerosol systems |

Country Status (2)

| Country | Link |

|---|---|

| US (5) | US7500621B2 (en) |

| EP (1) | EP1886941B1 (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9079703B2 (en)* | 1992-02-24 | 2015-07-14 | Homax Products, Inc. | Actuator systems and methods for aerosol wall texturing |

| US9415927B2 (en) | 2007-04-04 | 2016-08-16 | Homax Products, Inc. | Spray texture material compositions, systems, and methods with anti-corrosion characteristics |

| USD787326S1 (en) | 2014-12-09 | 2017-05-23 | Ppg Architectural Finishes, Inc. | Cap with actuator |

| US9776785B2 (en) | 2013-08-19 | 2017-10-03 | Ppg Architectural Finishes, Inc. | Ceiling texture materials, systems, and methods |

Families Citing this family (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6883688B1 (en)* | 1992-02-24 | 2005-04-26 | Homax Products, Inc. | Aerosol spray texturing systems and methods |

| US5310095A (en)* | 1992-02-24 | 1994-05-10 | Djs&T Limited Partnership | Spray texturing apparatus and method having a plurality of dispersing tubes |

| US7500621B2 (en) | 2003-04-10 | 2009-03-10 | Homax Products, Inc. | Systems and methods for securing aerosol systems |

| US7677420B1 (en) | 2004-07-02 | 2010-03-16 | Homax Products, Inc. | Aerosol spray texture apparatus for a particulate containing material |

| US7487893B1 (en) | 2004-10-08 | 2009-02-10 | Homax Products, Inc. | Aerosol systems and methods for dispensing texture material |

| US7374068B2 (en) | 2004-10-08 | 2008-05-20 | Homax Products, Inc. | Particulate materials for acoustic texture material |

| US8726450B2 (en) | 2007-02-07 | 2014-05-20 | Homax Products, Inc. | Scraper system and methods |

| US9382060B1 (en) | 2007-04-05 | 2016-07-05 | Homax Products, Inc. | Spray texture material compositions, systems, and methods with accelerated dry times |

| US20100147869A1 (en)* | 2008-12-12 | 2010-06-17 | The Stanley Works | Blade dispenser |

| US9248457B2 (en) | 2011-07-29 | 2016-02-02 | Homax Products, Inc. | Systems and methods for dispensing texture material using dual flow adjustment |

| US9156042B2 (en) | 2011-07-29 | 2015-10-13 | Homax Products, Inc. | Systems and methods for dispensing texture material using dual flow adjustment |

| FR2985201B1 (en)* | 2012-01-03 | 2016-01-08 | Oreal | HOLLOW DISTRIBUTION HEAD |

| FR2985202A1 (en)* | 2012-01-03 | 2013-07-05 | Oreal | HEAD OF DISTRIBUTION |

| US9156602B1 (en) | 2012-05-17 | 2015-10-13 | Homax Products, Inc. | Actuators for dispensers for texture material |

| US9435120B2 (en) | 2013-03-13 | 2016-09-06 | Homax Products, Inc. | Acoustic ceiling popcorn texture materials, systems, and methods |

| JP6161958B2 (en)* | 2013-05-31 | 2017-07-12 | 東洋エアゾール工業株式会社 | Nozzle cap for aerosol containers |

| USD718624S1 (en) | 2013-06-14 | 2014-12-02 | Homax Products, Inc. | Actuator assembly |

| FR3007953B1 (en) | 2013-07-04 | 2015-07-24 | Oreal | AEROSOL ALCOHOLIC DEODORANT EQUIPPED WITH A HOLLOW DISTRIBUTION HEAD |

| FR3007952B1 (en)* | 2013-07-04 | 2015-07-24 | Oreal | AEROSOL CONTAINING AN EMULSION DEODORANT EQUIPPED WITH A HOLLOW DISTRIBUTION HEAD |

| AR101299A1 (en)* | 2015-07-24 | 2016-12-07 | Valvulas Prec De Argentina S A C I | PRECINTO WITH UNLOCKABLE SAFETY WORK, APPLICABLE TO LIQUID DISPENSING HEADS |

| US9856072B1 (en)* | 2016-08-03 | 2018-01-02 | Decon7 Systems, Llc | System for mixing and dispensing fluids |

| AU2017388358B2 (en)* | 2016-12-29 | 2019-12-05 | Decon7 Systems, Inc. | System for mixing and dispensing fluids |

| US10464736B1 (en) | 2017-09-21 | 2019-11-05 | The B'Laster Corporation | Spray can actuator |

| CN108910313A (en)* | 2018-08-08 | 2018-11-30 | 肇庆欧迪斯实业有限公司 | A kind of aerosol spray cap and aerosol spray container |

| US11370600B1 (en) | 2018-09-21 | 2022-06-28 | B'laster Llc. | Spray can actuator |

| USD929229S1 (en) | 2018-09-21 | 2021-08-31 | B'laster Llc | Spray can actuator |

| USD907491S1 (en) | 2018-09-21 | 2021-01-12 | B'laster Llc | Spray can actuator |

| USD987987S1 (en) | 2021-12-28 | 2023-06-06 | Garfield Campbell | Key fob arm band |

| US20250042644A1 (en)* | 2023-07-31 | 2025-02-06 | Precision Valve Corporation | Single piece actuator with slider lock |

Citations (409)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US208330A (en) | 1878-09-24 | Improvement in hose-nozzles | ||

| US351968A (en) | 1886-11-02 | Derrick | ||

| US568876A (en) | 1896-10-06 | Hose-nozzle | ||

| US579418A (en) | 1897-03-23 | bookwaltee | ||

| US582397A (en) | 1897-05-11 | John shone | ||

| US604151A (en) | 1898-05-17 | Spraying device | ||

| US625594A (en) | 1899-05-23 | Pneumatic sprayer | ||

| US658586A (en) | 1899-08-17 | 1900-09-25 | Meinhard Reiling | Fire-hose. |

| DE210449C (en) | 1907-02-22 | 1909-05-29 | ||

| US930095A (en) | 1909-02-10 | 1909-08-03 | Frederic S Seagrave | Nozzle. |

| US931757A (en) | 1907-01-02 | 1909-08-24 | Pneumatic Machinery Cleaner Company | Pneumatic machinery-cleaner. |

| US941671A (en) | 1908-02-17 | 1909-11-30 | James Winthrop Campbell | Sprinkler. |

| FR463476A (en) | 1913-09-18 | 1914-02-24 | Vital Habran | Oxy-acetylene autogenous welding torch |

| US1093907A (en) | 1913-03-10 | 1914-04-21 | Henry Birnbaum | Nozzle. |

| US1154974A (en) | 1915-03-22 | 1915-09-28 | Burr Custer | Welding-torch. |

| US1162170A (en) | 1914-06-01 | 1915-11-30 | Johnson Service Co | Automatic control device. |

| US1294190A (en) | 1916-05-13 | 1919-02-11 | Herman Edward Stuercke | Air-brush and similar apparatus. |

| US1332544A (en) | 1919-03-08 | 1920-03-02 | Spray Engineering Co | Means for applying coating |

| US1486156A (en) | 1919-08-13 | 1924-03-11 | Needham Joseph | Hydrocarbon burner |

| US1590430A (en) | 1922-12-22 | 1926-06-29 | Erby Philip | Spraying device |

| US1609465A (en) | 1922-04-01 | 1926-12-07 | Spray Painting & Finishing Equ | Tool for applying coating |

| US1643969A (en) | 1926-08-26 | 1927-10-04 | Hopkins Spray Equipment Compan | Means for controlling the distribution of liquids |

| US1650686A (en) | 1925-11-07 | 1927-11-29 | Binks Spray Equipment Co | Spray gun |

| US1656132A (en) | 1926-02-03 | 1928-01-10 | Claude C Arrasmith | Valve |

| US1755329A (en) | 1927-03-14 | 1930-04-22 | Lawrence E Mccormack | Pneumatic gun for applying mortar |

| US1770011A (en) | 1927-10-27 | 1930-07-08 | Emmett V Poston | Steam and clay mixing nozzle |

| US1809073A (en) | 1928-10-12 | 1931-06-09 | John F Schylander | Spray |

| US1863924A (en) | 1930-04-28 | 1932-06-21 | W E Dunn Mfg Company | Spraying device |

| US1988017A (en) | 1933-01-24 | 1935-01-15 | Anthony T Norwick | Spraying apparatus |

| DE634230C (en) | 1936-08-21 | Otto Helmer Lawaetz | Device for atomizing paints and oils | |

| GB470488A (en) | 1934-11-26 | 1937-08-13 | Bosch Robert | Improvements relating to the atomisation of paints or the like liquids |

| US2127188A (en) | 1937-09-11 | 1938-08-16 | Akron Brass Mfg Company Inc | Mist-producing nozzle |

| GB491396A (en) | 1936-07-14 | 1938-09-01 | Bosch Robert | Improvements in or relating to spraying apparatus |

| GB494134A (en) | 1937-01-25 | 1938-10-20 | Bosch Gmbh Robert | Improvements in or relating to a hand spraying implement |

| US2149930A (en) | 1934-08-23 | 1939-03-07 | Wil X M F G Corp | Nozzle for spraying devices |

| GB508734A (en) | 1938-03-30 | 1939-07-05 | Broughton Haggis | Improvements in spray producers |

| US2198271A (en) | 1938-06-30 | 1940-04-23 | Ingersoll W Mccallum | Plastering machine |

| GB534349A (en) | 1939-02-24 | 1941-03-05 | Bosch Gmbh Robert | A manually guided spraying device for paints and other liquids |

| US2305269A (en) | 1941-06-07 | 1942-12-15 | Moreland William | Spraying device |

| US2307014A (en) | 1939-11-02 | 1943-01-05 | Charles F Becker | Fire hose nozzle |

| US2320964A (en) | 1942-10-27 | 1943-06-01 | Harry A Yates | Safety air nozzle |

| US2353318A (en) | 1940-03-08 | 1944-07-11 | Linde Air Prod Co | Nozzle for desurfacing metal |

| US2388093A (en) | 1942-10-08 | 1945-10-30 | Smith Frank | Liquid delivery apparatus |

| US2530808A (en) | 1949-01-12 | 1950-11-21 | Vincent C Cerasi | Waterworks device |

| US2565954A (en) | 1946-02-23 | 1951-08-28 | Gaspray Corp | Valved closure for vessel with fluid under pressure, having manually operated valve actuator |

| GB675664A (en) | 1948-02-26 | 1952-07-16 | Burgess Vibrocrafters | Improvements in or relating to a sprayer or atomizer |

| US2612293A (en) | 1949-01-21 | 1952-09-30 | Michel Daniel | Container closure member having a dispensing valve therein |

| US2686652A (en) | 1951-01-29 | 1954-08-17 | Viking Valve Company | Valve apparatus |

| GB726455A (en) | 1953-04-17 | 1955-03-16 | Lister Welch | Improvements in or relating to electric spray-guns |

| US2704690A (en) | 1952-08-01 | 1955-03-22 | Eichenauer Rudolf | Spray gun |

| US2723200A (en) | 1950-11-08 | 1955-11-08 | Dev Res Inc | Method for packaging viscous food preparations |

| US2763406A (en) | 1952-06-05 | 1956-09-18 | James H Countryman | Valve construction for dispensing containers |

| US2764454A (en) | 1953-12-29 | 1956-09-25 | Albert L Edelstein | Aerosol apparatus for decorative coating and process for making said apparatus |

| US2785926A (en) | 1953-11-23 | 1957-03-19 | Lataste Bernard | Means for atomizing liquid |

| US2790680A (en) | 1955-01-27 | 1957-04-30 | Gordon T Rosholt | Combination hose nozzle, valve, and swivel coupler |

| US2801880A (en) | 1956-04-03 | 1957-08-06 | Rienecker Fred | Hopper spray gun |

| US2831618A (en) | 1956-04-12 | 1958-04-22 | Dev Res Inc | Dispensing valve dischargeable in upright position |

| US2839225A (en) | 1956-06-18 | 1958-06-17 | Dev Res Inc | Dispenser valve providing controlled flow and quick gassing |

| DE1047686B (en) | 1957-05-13 | 1958-12-24 | Eskil Axelson | Paint spray gun with device for operating the paint supply |

| US2887274A (en) | 1958-02-20 | 1959-05-19 | Swan V Swenson | Spray gun for applying plaster and the like |

| US2908446A (en) | 1956-05-18 | 1959-10-13 | Strouse Inc | Spray tube |

| US2923481A (en) | 1957-02-21 | 1960-02-02 | Hudson Mfg Co H D | Nozzle assembly for sprayers |

| US2932434A (en) | 1957-11-26 | 1960-04-12 | John J Baessler | Means for dispensing liquid concentrate drop by drop |

| US2965270A (en) | 1957-06-12 | 1960-12-20 | Dev Res Inc | Dispensing valve having spring of elastic material |

| US2968441A (en) | 1958-08-15 | 1961-01-17 | Doyle D Holcomb | Spray nozzle assembly for use with aerosol can |

| US2976897A (en) | 1959-02-10 | 1961-03-28 | Beckworth Dixie | Reusable pressurized canister |

| GB867713A (en) | 1959-02-27 | 1961-05-10 | Airtech Ltd | A new or improved nozzle for projecting liquid from a hose or the like |

| US2997243A (en) | 1958-08-27 | 1961-08-22 | George E Kolb | Aerosol container |

| US2999646A (en) | 1958-08-16 | 1961-09-12 | Charles S Tanner Company | Spray gun |

| US3027096A (en) | 1960-01-21 | 1962-03-27 | Sherwin Williams Co | Methods and apparatus for producing multi-component surface coatings |

| US3083872A (en) | 1959-01-02 | 1963-04-02 | Meshberg Philip | Selective dispensing nozzle |

| US3107059A (en) | 1961-08-15 | 1963-10-15 | Electrolux Ab | Spraying device |

| US3116879A (en) | 1962-01-30 | 1964-01-07 | Charles S Tanner Company | Spray head for spray gun |

| US3157360A (en) | 1963-02-25 | 1964-11-17 | William L Heard | Spray gun having valved flexible liner |

| GB977860A (en) | 1962-12-18 | 1964-12-16 | Nat Res Dev | Improvements in and relating to nozzles |

| US3167525A (en) | 1960-03-31 | 1965-01-26 | California Research Corp | Metal dispersions in polymers |

| FR84727E (en) | 1963-09-26 | 1965-04-02 | Interchangeable tip for tracer device with humection | |

| US3191809A (en) | 1961-12-29 | 1965-06-29 | Pillsbury Co | Pressurized container having a plurality of selectively attachable nozzles |

| US3196819A (en) | 1962-02-28 | 1965-07-27 | Rudolf Lechner Kommanditgeseil | Method of producing seamless metal bottles and an apparatus for carrying the method |

| US3198394A (en) | 1962-11-16 | 1965-08-03 | Lefer Samuel | Pressurized dispensers |

| US3207444A (en) | 1963-08-02 | 1965-09-21 | Dura Corp | Water spray attachment having air control and liquid additive passages connected to a mixing chamber |

| US3216628A (en) | 1965-01-12 | 1965-11-09 | Rust Oleum Corp | Paint spray can unit and extension attachment therefor |

| DE1926796U (en) | 1961-10-12 | 1965-11-11 | Heidolph Elektro K G | FAN. |

| US3236459A (en) | 1963-12-16 | 1966-02-22 | Thomas P Mcritchie | Apparatus for spraying materials |

| US3246850A (en) | 1964-05-20 | 1966-04-19 | Corn Products Co | Dual spray head |

| US3258208A (en) | 1964-05-07 | 1966-06-28 | Seaquist Valve Co | Aerosol valve |

| US3284007A (en) | 1964-11-03 | 1966-11-08 | Aerosol Tech Inc | Reversible aerosol spray tip |

| US3307788A (en) | 1963-12-03 | 1967-03-07 | Koppers Co Inc | Field application of foam coatings |

| US3314571A (en) | 1964-12-30 | 1967-04-18 | Seaquist Valve Co | Mother-daughter aerosols and valve button therefor |

| US3317140A (en) | 1964-11-12 | 1967-05-02 | John J Smith | Aerosol spray nozzle |

| US3342382A (en) | 1965-10-22 | 1967-09-19 | Clayton Corp Of Delaware | Pressured dispenser spout having plurality of decorator orifices |

| US3346195A (en) | 1964-10-22 | 1967-10-10 | Sprayon Products | Aerosol spray device |

| CA770467A (en) | 1967-10-31 | C. Hug Richard | Combination valve spout and spray head assembly | |

| US3373908A (en) | 1965-12-13 | 1968-03-19 | Johnson & Son Inc S C | Actuator cap with frangible guard |

| US3377028A (en) | 1966-04-05 | 1968-04-09 | L & A Products Inc | Self-sealing connector for multiaperture nozzle |

| US3390121A (en) | 1964-06-16 | 1968-06-25 | Argus Chem | Color indication in polyester resin curing |

| US3414171A (en) | 1966-10-05 | 1968-12-03 | Charles R. Grisham | Aerosol dispenser for dispensing measured amounts |

| US3415425A (en) | 1966-11-15 | 1968-12-10 | Johnson & Johnson | Aerosol dispenser |

| US3425600A (en) | 1966-08-11 | 1969-02-04 | Abplanalp Robert H | Pressurized powder dispensing device |

| US3428224A (en) | 1966-11-03 | 1969-02-18 | Roland C Eberhardt | Aerosol coatings applicator |

| GB1144385A (en) | 1966-12-19 | 1969-03-05 | Electrolube Ltd | Improvements in aerosol containers with extension tubes |

| US3433391A (en) | 1966-03-07 | 1969-03-18 | Continental Can Co | Dispensing container with collapsible compartment |

| US3445068A (en) | 1965-12-17 | 1969-05-20 | Josef Wagner | Liquid atomizer |

| US3450314A (en) | 1967-05-31 | 1969-06-17 | Clayton Corp | Dispensing valve having rubber-like dispensing head |

| US3467283A (en) | 1968-01-18 | 1969-09-16 | Continental Can Co | Dispensing container with collapsible compartment |

| US3472457A (en) | 1968-01-29 | 1969-10-14 | Valve Corp Of America | Aerosol tip and insert assembly |

| US3482738A (en) | 1966-03-15 | 1969-12-09 | Continental Can Co | Aerosol container and valve therefor |

| US3491951A (en) | 1967-09-18 | 1970-01-27 | Leroy H Knibb | Atomizing head and bottle combination for a liquid hair spray or the like |

| FR1586067A (en) | 1967-10-24 | 1970-02-06 | ||

| US3498541A (en) | 1968-03-25 | 1970-03-03 | Goodyear Tire & Rubber | Apparatus for altering the shape of an electrostatic spray pattern |

| US3513886A (en) | 1968-05-06 | 1970-05-26 | Pillsbury Co | Dispensing package with reactable propellant gas generating materials |

| US3514042A (en) | 1967-08-21 | 1970-05-26 | Marvin J Freed | Multiple purpose hose nozzle |

| US3544258A (en) | 1963-08-19 | 1970-12-01 | Aerosol Tech Inc | Self-propelled liquid dispenser containing an antiperspirant aluminum salt |

| US3548564A (en) | 1966-05-10 | 1970-12-22 | Sterigard Corp | Process for fabricating a pressurized container |

| US3550861A (en) | 1968-08-28 | 1970-12-29 | William R Teson | Hose nozzle |

| US3575319A (en) | 1968-07-11 | 1971-04-20 | Upjohn Co | Portable dispenser for polymer foams |

| US3592359A (en) | 1969-05-27 | 1971-07-13 | Leonard L Marraffino | Spring-valve member in pressurized two fluid dispenser |

| US3596835A (en) | 1968-12-26 | 1971-08-03 | Raymond D Smith | Adjustable turret spray nozzle |

| US3608822A (en) | 1968-07-12 | 1971-09-28 | Ciba Geigy Ag | Process and device for the mechanical spraying of liquids |

| US3613954A (en) | 1968-06-20 | 1971-10-19 | Schlitz Brewing Co J | Dispensing apparatus |

| US3647143A (en) | 1970-04-06 | 1972-03-07 | Champion Spark Plug Co | Atomizer |

| US3648932A (en) | 1969-10-27 | 1972-03-14 | Pittway Corp | Valve button with aspirator passageway |

| US3653558A (en) | 1970-10-15 | 1972-04-04 | Scovill Manufacturing Co | Aerosol valve having selectable spray rate |

| US3680789A (en) | 1970-04-18 | 1972-08-01 | Josef Wagner | Spray gun |

| US3698645A (en) | 1971-03-02 | 1972-10-17 | Harris Paint Co | Spray head |

| US3700136A (en) | 1966-03-25 | 1972-10-24 | Continental Can Co | End unit and liner for aerosol containers |

| US3703994A (en) | 1971-07-06 | 1972-11-28 | Gillette Co | Adjustable spray rate actuator |

| US3704831A (en) | 1971-02-22 | 1972-12-05 | B F Products Pty Ltd | Fire hose nozzle |

| US3704811A (en) | 1970-07-24 | 1972-12-05 | Creative Ideas Inc | Portable sandblaster |

| US3705669A (en) | 1970-06-08 | 1972-12-12 | Wham O Mfg Co | Foamable resinous composition |

| US3711030A (en) | 1970-06-22 | 1973-01-16 | Imp Oil Ltd | Multi-pattern spraying apparatus |

| US3764067A (en) | 1972-01-26 | 1973-10-09 | Harris Paint Co | Method for decorating surfaces |

| US3770166A (en) | 1971-10-18 | 1973-11-06 | Ciba Geigy Corp | Seal for aerosol dispenser |

| US3773706A (en) | 1971-11-26 | 1973-11-20 | Ubm Armonk | Method for indicating stage of cure of crosslinked resins and compositions resulting therefrom |

| US3776470A (en) | 1971-09-30 | 1973-12-04 | Gen Mills Inc | Variable nozzle |

| US3776702A (en) | 1970-02-11 | 1973-12-04 | Shell Oil Co | Apparatus for mineral-filled foam production |

| US3777981A (en) | 1971-11-18 | 1973-12-11 | Ransburg Electro Coating Corp | Spray apparatus and method |

| US3788521A (en) | 1972-07-10 | 1974-01-29 | Laauwe Robert H | Aerosol package |

| US3788526A (en) | 1973-02-12 | 1974-01-29 | Ciba Geigy Corp | Compressed air operated dispenser with mechanical force multiplying means |

| US3795366A (en) | 1971-08-12 | 1974-03-05 | Colgate Palmolive Co | Multiple spray pattern device |

| US3799398A (en) | 1968-08-01 | 1974-03-26 | Oreal | Method and apparatus for packaging products which are to be stored separately but dispensed simultaneously |

| US3806005A (en) | 1969-03-26 | 1974-04-23 | S Prussin | Aerosol container with plug-in cap and valve structure |

| US3811369A (en) | 1972-09-05 | 1974-05-21 | Hess & Cie Metallwarenfab | Air outlet for ventilation equipment |

| US3813011A (en) | 1971-05-11 | 1974-05-28 | S Harrison | Aerosol can for dispensing materials in fixed volumetric ratio |

| US3814326A (en) | 1971-04-13 | 1974-06-04 | L Bartlett | Spray nozzle |

| US3819119A (en) | 1972-01-26 | 1974-06-25 | Paint Co H | Sprayer for decorating surfaces |

| US3828977A (en) | 1972-06-14 | 1974-08-13 | Continental Can Co | Compartment bag assembly for dispensing containers |

| US3848778A (en) | 1972-08-14 | 1974-11-19 | P Meshberg | Childproof actuator assembly |

| US3848808A (en) | 1973-05-31 | 1974-11-19 | Wham O Mfg Co | Water squirt toy with protective sleeve |

| US3862705A (en) | 1973-09-07 | 1975-01-28 | Rca Corp | Hand-held dispenser with mixing valve and pressurizing valve |

| US3871553A (en) | 1973-03-15 | 1975-03-18 | Owatonna Tool Co | Dispensing gun for semi-liquid material |

| US3876154A (en) | 1973-05-16 | 1975-04-08 | Wagner Gmbh J | Spray nozzle |

| US3891128A (en) | 1971-02-24 | 1975-06-24 | Smrt Thomas John | Actuator for aerosol can valve |

| US3899134A (en) | 1973-07-20 | 1975-08-12 | Josef Wagner | Spray gun |

| CA976125A (en) | 1970-01-14 | 1975-10-14 | Lablabo | Valve |

| US3912132A (en) | 1973-09-27 | 1975-10-14 | Precision Valve Corp | Dispenser valve assembly for a pressurized aerosol dispenser |

| US3913803A (en) | 1974-12-20 | 1975-10-21 | Robert H Laauwe | Aerosol valve actuator with front end discharge governor |

| US3913804A (en) | 1974-07-19 | 1975-10-21 | Robert H Laauwe | Aerosol valve actuator |

| US3913842A (en) | 1973-12-14 | 1975-10-21 | Block Drug Co | Spray head for aerosol can |

| US3932973A (en) | 1974-11-18 | 1976-01-20 | Moore Alvin E | Insubars |

| US3936002A (en) | 1974-11-29 | 1976-02-03 | Geberth John Daniel Jun | Adjustable spray tip |

| US3938708A (en) | 1974-08-15 | 1976-02-17 | Norman D. Burger | Aerosol dispensing system |

| US3945571A (en) | 1975-01-23 | 1976-03-23 | Rash James E | Self-contained portable pressure apparatus and hand gun assembly |

| US3975554A (en) | 1974-10-15 | 1976-08-17 | Dow Corning Corporation | Process for priming |

| US3982698A (en) | 1976-01-29 | 1976-09-28 | Specialty Manufacturing Company | Nozzle selector valve |

| US3987811A (en) | 1975-07-09 | 1976-10-26 | Sioux Steam Cleaner Corporation | Control valve mechanism for cleaning apparatus using fluids |

| US3989165A (en) | 1973-02-23 | 1976-11-02 | Continental Can Company, Inc. | Compartment bag for aerosol container |

| US3992003A (en) | 1975-10-24 | 1976-11-16 | Visceglia Marco P | Aerosol container having sealed propellant means |

| US3991916A (en) | 1974-07-01 | 1976-11-16 | Bon F Del | Automatic closure device for the discharge of a foam product from a pressurized container |

| US4010134A (en) | 1974-05-15 | 1977-03-01 | Hoechst Aktiengesellschaft | Plaster mixture consisting of an aqueous polymer dispersion containing pigment and filler |

| US4032064A (en) | 1976-01-05 | 1977-06-28 | The Continental Group, Inc. | Barrier bag assembly for aerosol container |

| US4036673A (en) | 1973-12-28 | 1977-07-19 | Congoleum Corporation | Method for installing surface covering or the like |

| US4036438A (en) | 1975-07-21 | 1977-07-19 | Sperry Tech Corporation | Anti-injection paint spray nozzles |

| FR2336186A1 (en) | 1975-12-23 | 1977-07-22 | Jardin Ste Nle Ets | Applicator gun for plaster - using compressed air to draw material through trigger operated nozzle from container on gun |

| US4045860A (en) | 1975-05-07 | 1977-09-06 | Cebal | Method of assembling an aerosol dispenser |

| US4058287A (en) | 1975-09-19 | 1977-11-15 | Automatic Switch Company | Pilot-operated valve having constant closing rate |

| US4078578A (en) | 1975-03-07 | 1978-03-14 | The Cornelius Company | Beverage dispensing valve |

| US4089443A (en) | 1976-12-06 | 1978-05-16 | Zrinyi Nicolaus H | Aerosol, spray-dispensing apparatus |

| US4096974A (en) | 1977-03-11 | 1978-06-27 | Haber Terry M | Cover assembly for spray cans |

| US4117951A (en) | 1975-05-07 | 1978-10-03 | Cebal | Aerosol dispenser liner |

| US4123005A (en) | 1976-07-14 | 1978-10-31 | Blunk Glenn I | Acoustical texture applicator |

| US4129448A (en) | 1973-08-20 | 1978-12-12 | Rohm And Haas Company | Formaldehyde stabilized coating compositions |

| GB1536312A (en) | 1976-11-13 | 1978-12-20 | Shelter Islands Co Ltd | Spray gun |

| US4147284A (en) | 1977-05-25 | 1979-04-03 | Mizzi John V | Air propellant-aerosol dispenser and compressor |

| US4148416A (en) | 1976-08-20 | 1979-04-10 | Metal Box Limited | Aerosol containers |

| US4154378A (en) | 1976-11-04 | 1979-05-15 | L'oreal | Metering valve for pressurized container |

| US4159079A (en) | 1977-08-24 | 1979-06-26 | Sealed Air Corporation | Dispenser |

| US4164492A (en) | 1978-03-14 | 1979-08-14 | Alco Standard Corporation | Novel catalyst for curing polyester resins and method for determining the degree of cure in polyester and epoxy resin systems |

| USRE30093E (en) | 1975-01-27 | 1979-09-11 | Aerosol dispensing system | |

| US4171757A (en) | 1976-06-08 | 1979-10-23 | Diamond George B | Pressurized barrier pack |

| US4185758A (en) | 1978-08-01 | 1980-01-29 | The Continental Group, Inc. | Compartmentalized aerosol container |

| US4187959A (en) | 1978-08-17 | 1980-02-12 | The Continental Group, Inc. | Propellantless aerosol dispensing system |

| US4187985A (en) | 1978-12-08 | 1980-02-12 | The Continental Group, Inc. | Aerosol valve for barrier type packages |

| US4195780A (en) | 1977-12-01 | 1980-04-01 | Vortec Corporation | Flow amplifying nozzle |

| US4198365A (en) | 1979-01-08 | 1980-04-15 | The Continental Group, Inc. | Method of applying product bags in aerosol barrier packages |

| US4202470A (en) | 1977-03-07 | 1980-05-13 | Minoru Fujii | Pressurized dispensers for dispensing products utilizing a pressure transfer fluid |

| US4204645A (en) | 1978-05-17 | 1980-05-27 | Column Corporation | General purpose compression-type sprayer |

| US4232828A (en) | 1977-11-28 | 1980-11-11 | Shelly Jr Newton L | Hand held liquid spray head with removable liquid conduit |

| US4238264A (en) | 1979-01-15 | 1980-12-09 | The Continental Group, Inc. | Aerosol barrier package with a bag adhesively attached to the curl |

| US4258141A (en) | 1978-04-11 | 1981-03-24 | Basf Aktiengesellschaft | Process for manufacture of flexible polyurethane foams with cyanic acid derivatives |

| US4275172A (en) | 1980-01-28 | 1981-06-23 | Union Carbide Corporation | Frothable polyurethane composition and a cellular foam produced therefrom suitable for use in joints between wallboards |

| NL8000344A (en) | 1980-01-18 | 1981-08-17 | Dako Verf B V | Spray gun for dry paint - has trigger-operated control for pressurised propellant gas and paint feed also gas passage to paint feed chamber |

| US4293353A (en) | 1978-11-03 | 1981-10-06 | The Continental Group, Inc. | Sealing-attaching system for bag type aerosol containers |

| US4308973A (en) | 1978-06-30 | 1982-01-05 | The Continental Group, Inc. | Compartmented aerosol container |

| US4310108A (en) | 1978-06-08 | 1982-01-12 | Freund Industrial Co., Ltd. | Aerosol sprayer with pressure reservoir |

| US4322020A (en) | 1978-05-02 | 1982-03-30 | Raymond Stone | Invertible pump sprayer |

| US4346743A (en) | 1980-12-19 | 1982-08-31 | The Continental Group, Inc. | Product bag for aerosol container and method of utilizing the same to facilitate filling with propellant |

| US4354638A (en) | 1980-04-25 | 1982-10-19 | Bristol-Myers Company | Spiral actuator for aerosol powdered suspension product |

| US4358388A (en) | 1980-04-18 | 1982-11-09 | Rhone Poulenc Industries | Magnetic polymer latex and preparation process |

| US4364521A (en) | 1980-08-01 | 1982-12-21 | Stankowitz James L | Texture applicator |

| US4370930A (en) | 1980-12-29 | 1983-02-01 | Ford Motor Company | End cap for a propellant container |

| US4372475A (en) | 1981-04-29 | 1983-02-08 | Goforth Melvin L | Electronic assembly process and apparatus |

| US4401271A (en) | 1981-07-10 | 1983-08-30 | Minnesota Mining And Manufacturing Company | Aerosal fan spray head |

| US4401272A (en) | 1982-05-17 | 1983-08-30 | Minnesota Mining And Manufacturing Company | Aerosol fan sprayhead |

| US4411387A (en) | 1982-04-23 | 1983-10-25 | Stern Donald J | Manually-operated spray applicator |

| US4417674A (en) | 1978-04-13 | 1983-11-29 | Coster Tecnologie Speciali S.P.A. | Valve for the admixture of fluids and delivery of the resulting mixture |

| US4438221A (en) | 1981-06-18 | 1984-03-20 | Wm. T. Burnett & Co., Inc. | Polyurethane foam-filled foams and method of producing same |

| US4438884A (en) | 1981-11-02 | 1984-03-27 | Spraying Systems Company | Quick disconnect nozzle |

| US4442959A (en) | 1981-04-30 | 1984-04-17 | Luigi Del Bon | Self-closing valve-and-lid assembly |

| US4460719A (en) | 1980-10-17 | 1984-07-17 | Danville Carlos R | Pigmented peroxide and polyester compositions |

| US4482662A (en) | 1982-07-26 | 1984-11-13 | Plasti-Kote Company, Inc. | Water-soluble aerosol paint compositions |

| US4496081A (en) | 1983-07-08 | 1985-01-29 | Fomo Products, Inc. | Dispensing apparatus |

| US4546905A (en) | 1980-01-04 | 1985-10-15 | American Cyanamid Co. | Aerosol dispensing system |

| US4595127A (en) | 1984-05-21 | 1986-06-17 | Stoody William R | Self-contained fluid pump aerosol dispenser |

| US4609608A (en) | 1980-12-15 | 1986-09-02 | The Dow Chemical Company | Colloidal size hydrophobic polymer particulate having discrete particles of a metal dispersed therein |

| US4620669A (en) | 1985-08-22 | 1986-11-04 | Wagner Spray Tech Corporation | Blow-by circuit |

| US4641765A (en) | 1984-10-05 | 1987-02-10 | Diamond George B | Expandable pressurized barrier container |

| US4683246A (en) | 1986-03-14 | 1987-07-28 | Wm. T. Burnett & Co., Inc. | Polyurethane foam-fiber composites |

| US4685622A (en) | 1984-07-21 | 1987-08-11 | Meiji Kikai Seisakusyo Co., Ltd. | Piece gun for spraying |

| US4702400A (en) | 1983-11-18 | 1987-10-27 | Fisons Plc | Aerosol dispensing metering valve |

| US4706888A (en) | 1986-07-11 | 1987-11-17 | Calmar, Inc. | Multi-purpose nozzle assembly |

| US4728007A (en) | 1986-10-16 | 1988-03-01 | Minnesota Mining And Manufacturing Company | Dispensing assembly with nozzle storage |