US8514367B2 - Apparatus and method for maintaining immersion fluid in the gap under the projection lens during wafer exchange in an immersion lithography machine - Google Patents

Apparatus and method for maintaining immersion fluid in the gap under the projection lens during wafer exchange in an immersion lithography machineDownload PDFInfo

- Publication number

- US8514367B2 US8514367B2US11/822,804US82280407AUS8514367B2US 8514367 B2US8514367 B2US 8514367B2US 82280407 AUS82280407 AUS 82280407AUS 8514367 B2US8514367 B2US 8514367B2

- Authority

- US

- United States

- Prior art keywords

- projection system

- wafer

- flat pad

- substrate

- immersion liquid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related, expires

Links

Images

Classifications

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/027—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34

- H01L21/0271—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34 comprising organic layers

- H01L21/0273—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34 comprising organic layers characterised by the treatment of photoresist layers

- H01L21/0274—Photolithographic processes

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/027—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34

- H01L21/0271—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34 comprising organic layers

- H01L21/0273—Making masks on semiconductor bodies for further photolithographic processing not provided for in group H01L21/18 or H01L21/34 comprising organic layers characterised by the treatment of photoresist layers

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/70—Microphotolithographic exposure; Apparatus therefor

- G03F7/70216—Mask projection systems

- G03F7/70341—Details of immersion lithography aspects, e.g. exposure media or control of immersion liquid supply

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03B—APPARATUS OR ARRANGEMENTS FOR TAKING PHOTOGRAPHS OR FOR PROJECTING OR VIEWING THEM; APPARATUS OR ARRANGEMENTS EMPLOYING ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ACCESSORIES THEREFOR

- G03B27/00—Photographic printing apparatus

- G03B27/32—Projection printing apparatus, e.g. enlarger, copying camera

- G03B27/52—Details

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/20—Exposure; Apparatus therefor

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/20—Exposure; Apparatus therefor

- G03F7/2002—Exposure; Apparatus therefor with visible light or UV light, through an original having an opaque pattern on a transparent support, e.g. film printing, projection printing; by reflection of visible or UV light from an original such as a printed image

- G03F7/2012—Exposure; Apparatus therefor with visible light or UV light, through an original having an opaque pattern on a transparent support, e.g. film printing, projection printing; by reflection of visible or UV light from an original such as a printed image using liquid photohardening compositions, e.g. for the production of reliefs such as flexographic plates or stamps

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/20—Exposure; Apparatus therefor

- G03F7/2041—Exposure; Apparatus therefor in the presence of a fluid, e.g. immersion; using fluid cooling means

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/20—Exposure; Apparatus therefor

- G03F7/2051—Exposure without an original mask, e.g. using a programmed deflection of a point source, by scanning, by drawing with a light beam, using an addressed light or corpuscular source

- G03F7/2053—Exposure without an original mask, e.g. using a programmed deflection of a point source, by scanning, by drawing with a light beam, using an addressed light or corpuscular source using a laser

- G03F7/2055—Exposure without an original mask, e.g. using a programmed deflection of a point source, by scanning, by drawing with a light beam, using an addressed light or corpuscular source using a laser for the production of printing plates; Exposure of liquid photohardening compositions

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/20—Exposure; Apparatus therefor

- G03F7/2051—Exposure without an original mask, e.g. using a programmed deflection of a point source, by scanning, by drawing with a light beam, using an addressed light or corpuscular source

- G03F7/2059—Exposure without an original mask, e.g. using a programmed deflection of a point source, by scanning, by drawing with a light beam, using an addressed light or corpuscular source using a scanning corpuscular radiation beam, e.g. an electron beam

- G03F7/2063—Exposure without an original mask, e.g. using a programmed deflection of a point source, by scanning, by drawing with a light beam, using an addressed light or corpuscular source using a scanning corpuscular radiation beam, e.g. an electron beam for the production of exposure masks or reticles

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/26—Processing photosensitive materials; Apparatus therefor

- G03F7/30—Imagewise removal using liquid means

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/70—Microphotolithographic exposure; Apparatus therefor

- G03F7/70691—Handling of masks or workpieces

- G03F7/70716—Stages

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/70—Microphotolithographic exposure; Apparatus therefor

- G03F7/70691—Handling of masks or workpieces

- G03F7/70716—Stages

- G03F7/70725—Stages control

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/70—Microphotolithographic exposure; Apparatus therefor

- G03F7/70691—Handling of masks or workpieces

- G03F7/70733—Handling masks and workpieces, e.g. exchange of workpiece or mask, transport of workpiece or mask

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/70—Microphotolithographic exposure; Apparatus therefor

- G03F7/708—Construction of apparatus, e.g. environment aspects, hygiene aspects or materials

- G03F7/70808—Construction details, e.g. housing, load-lock, seals or windows for passing light in or out of apparatus

- G03F7/70833—Mounting of optical systems, e.g. mounting of illumination system, projection system or stage systems on base-plate or ground

Definitions

- a typical lithography systemincludes an optical assembly, a reticle stage for holding a reticle defining a pattern, a wafer stage assembly that positions a semiconductor wafer, and a measurement system that precisely monitors the position of the reticle and the wafer.

- an image defined by the reticleis projected by the optical assembly onto the wafer.

- the projected imageis typically the size of one or more die on the wafer.

- the wafer stage assemblymoves the wafer and then another exposure takes place. This process is repeated until all the die on the wafer are exposed. The wafer is then removed and a new wafer is exchanged in its place.

- Immersion lithography systemsutilize a layer of immersion fluid that completely fills a gap between the optical assembly and the wafer during the exposure of the wafer.

- the optic properties of the immersion fluid, along with the optical assembly,allow the projection of smaller feature sizes than is currently possible using standard optical lithography.

- immersion lithographyis currently being considered for next generation semiconductor technologies including 65 nanometers, 45 nanometers, and beyond. Immersion lithography therefore represents a significant technological breakthrough that will likely enable the continued use of optical lithography for the foreseeable future.

- the immersion fluidwould be removed from the gap and then replenished after the wafer is exchanged. More specifically, when a wafer is to be exchanged, the fluid supply to the gap is turned off, the fluid is removed from the gap (i.e., by vacuum), the old wafer is removed, a new wafer is aligned and placed under the optical assembly, and then the gap is re-filled with fresh immersion fluid. Once all of the above steps are complete, exposure of the new wafer can begin.

- Wafer exchange with immersion lithography as described aboveis problematic for a number of reasons.

- the repeated filling and draining of the gapmay cause variations in the immersion fluid and may cause bubbles to form within the immersion fluid. Bubbles and the unsteady fluid may interfere with the projection of the image on the reticle onto the wafer, thereby reducing yields.

- the overall processalso involves many steps and is time consuming, which reduces the overall throughput of the machine.

- An apparatus and method for maintaining immersion fluid in the gap adjacent to the projection lens when the wafer stage moves away from the projection lens, for example during wafer exchange,is therefore needed.

- An apparatus and methodmaintain immersion fluid in the gap adjacent to the projection lens in a lithography machine.

- the apparatus and methodinclude an optical assembly that projects an image onto a work piece and a stage assembly including a work piece table that supports the work piece adjacent to the optical assembly.

- An environmental systemis provided to supply and remove an immersion fluid from the gap. After exposure of the work piece is complete, an exchange system removes the work piece and replaces it with a second work piece.

- An immersion fluid containment systemis provided to maintain the immersion fluid in the gap when the work piece table moves away from the projection lens. The gap therefore does not have to be refilled with immersion fluid when the first work piece is replaced with a second work piece.

- FIG. 1is an illustration of an immersion lithography machine having features of the invention

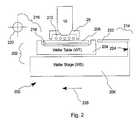

- FIG. 2is a cross section of an immersion lithography machine according to one embodiment of the invention.

- FIGS. 3A and 3Bare a cross section and a top down view of an immersion lithography machine according to another embodiment of the invention.

- FIGS. 4A and 4Bare cross section views of an immersion lithography machine according to another embodiment of the invention.

- FIGS. 5A and 5Bare top down views of two different twin wafer stages according to other embodiments of the invention.

- FIG. 6Ais a top down view of a twin stage lithography machine according to another embodiment of the invention.

- FIGS. 6B-6Eare a series of diagrams illustrating a wafer exchange according to the invention.

- FIG. 7Ais a flow chart that outlines a process for manufacturing a work piece in accordance with the invention.

- FIG. 7Bis a flow chart that outlines work piece processing in more detail.

- FIG. 1is a schematic illustration of a lithography machine 10 having features of the invention.

- the lithography machine 10includes a frame 12 , an illumination system 14 (irradiation apparatus), an optical assembly 16 , a reticle stage assembly 18 , a work piece stage assembly 20 , a measurement system 22 , a control system 24 , and a fluid environmental system 26 .

- the design of the components of the lithography machine 10can be varied to suit the design requirements of the lithography machine 10 .

- the lithography machine 10is used to transfer a pattern (not shown) of an integrated circuit from a reticle 28 onto a semiconductor wafer 30 (illustrated in phantom).

- the lithography machine 10mounts to a mounting base 32 , e.g., the ground, a base, or floor or some other supporting structure.

- the lithography machine 10can be used as a scanning type photolithography system that exposes the pattern from the reticle 28 onto the wafer 30 with the reticle 28 and the wafer 30 moving synchronously.

- a scanning type lithographic machinethe reticle 28 is moved perpendicularly to an optical axis of the optical assembly 16 by the reticle stage assembly 18

- the wafer 30is moved perpendicularly to the optical axis of the optical assembly 16 by the wafer stage assembly 20 . Scanning of the reticle 28 and the wafer 30 occurs while the reticle 28 and the wafer 30 are moving synchronously.

- the lithography machine 10can be a step-and-repeat type photolithography system that exposes the reticle 28 while the reticle 28 and the wafer 30 are stationary.

- the wafer 30is in a constant position relative to the reticle 28 and the optical assembly 16 during the exposure of an individual field.

- the wafer 30is consecutively moved with the wafer stage assembly 20 perpendicularly to the optical axis of the optical assembly 16 so that the next field of the wafer 30 is brought into position relative to the optical assembly 16 and the reticle 28 for exposure.

- the images on the reticle 28are sequentially exposed onto the fields of the wafer 30 , and then the next field of the wafer 30 is brought into position relative to the optical assembly 16 and the reticle 28 .

- the use of the lithography machine 10 provided hereinis not necessarily limited to a photolithography for semiconductor manufacturing.

- the lithography machine 10can be used as an LCD photolithography system that exposes a liquid crystal display work piece pattern onto a rectangular glass plate or a photolithography system for manufacturing a thin film magnetic head.

- the term “work piece”is generically used herein to refer to any device that may be patterned using lithography, such as but not limited to wafers or LCD substrates.

- the apparatus frame 12supports the components of the lithography machine 10 .

- the apparatus frame 12 illustrated in FIG. 1supports the reticle stage assembly 18 , the wafer stage assembly 20 , the optical assembly 16 and the illumination system 14 above the mounting base 32 .

- the illumination system 14includes an illumination source 34 and an illumination optical assembly 36 .

- the illumination source 34emits a beam (irradiation) of light energy.

- the illumination optical assembly 36guides the beam of light energy from the illumination source 34 to the optical assembly 16 .

- the beamilluminates selectively different portions of the reticle 28 and exposes the wafer 30 .

- the illumination source 34is illustrated as being supported above the reticle stage assembly 18 .

- the illumination source 34is secured to one of the sides of the apparatus frame 12 and the energy beam from the illumination source 34 is directed to above the reticle stage assembly 18 with the illumination optical assembly 36 .

- the illumination source 34can be a g-line source (436 nm), an i-line source (365 nm), a KrF excimer laser (248 nm), an ArF excimer laser (193 nm) or a F 2 laser (157 nm).

- the illumination source 34can generate an x-ray.

- the optical assembly 16projects and/or focuses the light passing through the reticle 28 to the wafer 30 .

- the optical assembly 16can magnify or reduce the image illuminated on the reticle 28 .

- the optical assembly 16need not be limited to a reduction system. It could also be a 1 ⁇ or greater magnification system.

- VUVvacuum ultra-violet radiation

- use of a catadioptric type optical systemcan be considered.

- a catadioptric type of optical systemare disclosed in Japanese Laid-Open Patent Application Publication No. 8-171054 and its counterpart U.S. Pat. No. 5,668,672, as well as Japanese Laid-Open Patent Publication No. 10-20195 and its counterpart U.S. Pat. No. 5,835,275.

- the reflecting optical systemcan be a catadioptric optical system incorporating a beam splitter and concave mirror.

- the reticle stage assembly 18holds and positions the reticle 28 relative to the optical assembly 16 and the wafer 30 .

- the reticle stage assembly 18includes a reticle stage 38 that retains the reticle 28 and a reticle stage mover assembly 40 that moves and positions the reticle stage 38 and reticle 28 .

- Each stage mover assembly 40 , 44can move the respective stage 38 , 42 with three degrees of freedom, less than three degrees of freedom, or more than three degrees of freedom.

- each stage mover assembly 40 , 44can move the respective stage 38 , 42 with one, two, three, four, five or six degrees of freedom.

- the reticle stage mover assembly 40 and the work piece stage mover assembly 44can each include one or more movers, such as rotary motors, voice coil motors, linear motors utilizing a Lorentz force to generate drive force, electromagnetic movers, planar motors, or some other force movers.

- linear motorssee U.S. Pat. Nos. 5,623,853 or 5,528,118 which are incorporated by reference herein in their entireties

- the linear motorscan be either an air levitation type employing air bearings or a magnetic levitation type using Lorentz force or reactance force.

- the stagecould move along a guide, or it could be a guideless type stage that uses no guide.

- one of the stagescould be driven by a planar motor, which drives the stage by an electromagnetic force generated by a magnet unit having two-dimensionally arranged magnets and an armature coil unit having two-dimensionally arranged coils in facing positions.

- a planar motorwhich drives the stage by an electromagnetic force generated by a magnet unit having two-dimensionally arranged magnets and an armature coil unit having two-dimensionally arranged coils in facing positions.

- either the magnet unit or the armature coil unitis connected to the stage base and the other unit is mounted on the moving plane side of the stage.

- reaction forces generated by the wafer (substrate) stage motioncan be mechanically transferred to the floor (ground) by use of a frame member as described in U.S. Pat. No. 5,528,100 and Japanese Laid-Open Patent Application Publication No. 8-136475.

- reaction forces generated by the reticle (mask) stage motioncan be mechanically transferred to the floor (ground) by use of a frame member as described in U.S. Pat. No. 5,874,820 and Japanese Laid-Open Patent Application Publication No. 8-330224.

- the disclosures of U.S. Pat. Nos. 5,528,100 and 5,874,820 and Japanese Paid-Open Patent Application Publication Nos. 8-136475 and 8-330224are incorporated herein by reference in their entireties.

- the measurement system 22monitors movement of the reticle 28 and the wafer 30 relative to the optical assembly 16 or some other reference. With this information, the control system 24 can control the reticle stage assembly 18 to precisely position the reticle 28 and the work piece stage assembly 20 to precisely position the wafer 30 .

- the design of the measurement system 22can vary. For example, the measurement system 22 can utilize multiple laser interferometers, encoders, mirrors, and/or other measuring devices.

- the control system 24receives information from the measurement system 22 and controls the stage assemblies 18 , 20 to precisely position the reticle 28 and the wafer 30 . Additionally, the control system 24 can control the operation of the components of the environmental system 26 .

- the control system 24can include one or more processors and circuits.

- the environmental system 26controls the environment in a gap (not shown) between the optical assembly 16 and the wafer 30 .

- the gapincludes an imaging field.

- the imaging fieldincludes the area adjacent to the region of the wafer 30 that is being exposed and the area in which the beam of light energy travels between the optical assembly 16 and the wafer 30 .

- the environmental system 26can control the environment in the imaging field.

- the desired environment created and/or controlled in the gap by the environmental system 26can vary accordingly to the wafer 30 and the design of the rest of the components of the lithography machine 10 , including the illumination system 14 .

- the desired controlled environmentcan be a fluid such as water.

- the desired controlled environmentcan be another type of fluid such as a gas.

- the gapmay range from 0.1 mm to 10 mm in height between top surface of the wafer 30 and the last optical element of the optical assembly 16 .

- the environmental system 26fills the imaging field and the rest of the gap with an immersion fluid.

- the design of the environmental system 26 and the components of the environmental system 26can be varied.

- the environmental system 26delivers and/or injects immersion fluid into the gap using spray nozzles, electro-kinetic sponges, porous materials, etc. and removes the fluid from the gap using vacuum pumps, sponges, and the like.

- the design of the environmental system 26can vary. For example, it can inject the immersion fluid at one or more locations at or near the gap.

- the immersion fluid systemcan assist in removing and/or scavenging the immersion fluid at one or more locations at or near the work piece 30 , the gap and/or the edge of the optical assembly 16 .

- the lithography machine 200includes a optical assembly 16 and a stage assembly 202 that includes a wafer table 204 and a wafer stage 206 .

- the wafer table 204is configured to support a wafer 208 (or any other type of work piece) under the optical assembly 16 .

- An environmental system 26surrounding the optical assembly 16 , is used to supply and remove immersion fluid 212 from the gap between the wafer 208 and the last optical element of the optical assembly 16 .

- a work piece exchange system 216including a wafer loader 218 (i.e., a robot) and an alignment tool 220 (i.e., a microscope and CCD camera), is configured to remove the wafer 208 on the wafer table 204 and replace it with a second wafer. This is typically accomplished using the wafer loader 218 to lift and remove the wafer 208 from the wafer table 204 . Subsequently, the second wafer (not shown) is placed onto the wafer chuck 218 , aligned using the alignment tool 220 , and then positioned under the optical assembly 16 on the wafer table 204 .

- a wafer loader 218i.e., a robot

- an alignment tool 220i.e., a microscope and CCD camera

- the wafer stage 206includes an immersion fluid containment system 214 that is configured to maintain the immersion fluid 212 in the gap adjacent to the last optical element of the optical assembly 16 during wafer exchange.

- the immersion fluid containment system 214includes a pad 222 that is adjacent to the wafer table 204 .

- a support member 224provided between the pad 222 and the wafer stage 206 , is used to support the pad 222 .

- the wafer table 204has a flat upper surface that is coplanar with a surface of the wafer 208 .

- the pad 222also has a flat upper surface that is coplanar with the upper surface of the wafer table 204 and the wafer surface.

- the pad 222is arranged adjacent to the wafer table 204 with a very small gap (e.g., 0.1-1.0 mm) so that the immersion fluid 212 is movable between the wafer table 204 and the pad 222 without leaking.

- the wafer stage 206is moved in the direction of arrow 226 so that the pad 222 is positioned under the optical assembly 16 in place of the wafer table 204 , maintaining the fluid in the gap or maintaining the size of the fluid gap.

- the wafer stageis moved back to its original position so that the pad 222 is removed from the gap as the second wafer is positioned under the optical assembly 16 .

- the pad 222is disposed continuously adjacent to the wafer table 204 with no gap. Vertical position and/or tilt of the wafer table 204 can be adjusted so that the wafer table surface is coplanar with the pad surface, before the wafer table 204 is moved out from under the optical assembly 16 . Maintaining the gap between the pad 222 and the optical assembly 16 is not limited to just a wafer exchange operation.

- the pad 222can be large enough to maintain the immersion fluid 212 in the space between the pad 222 and the optical assembly 16 during an alignment operation or a measurement operation. In those operations, a part of the area occupied by the immersion fluid 212 may be on the upper surface of the wafer table 204 .

- the lithography machine 300includes an optical assembly 16 and a stage assembly 302 that includes a wafer table 304 and a wafer stage 306 .

- the wafer table 304is configured to support a wafer 308 (or any other type of work piece) under the optical assembly 16 .

- An environmental system 26surrounding the optical assembly 16 , is used to supply and remove immersion fluid 312 from the gap between the wafer 308 and the lower most optical element of the optical assembly 16 .

- a work piece exchange system 316including a wafer loader 318 and an alignment tool 320 , is configured to remove the wafer 308 on the wafer table 304 and replace it with a second wafer. This is accomplished using the wafer loader 318 to remove the wafer 308 from the wafer table. Subsequently, the second wafer (not shown) is placed onto the wafer chuck 318 , aligned using the alignment tool 320 , and then positioned under the optical assembly 16 . As best illustrated in FIG. 3B , a set of motors 322 are used to move the wafer assembly 302 including the wafer table 304 and wafer stage 306 in two degrees of freedom (X and Y) during operation. As noted above, the motors 322 can be any type of motors, such as linear motors, rotary motors, voice coil motors, etc.

- the immersion lithography machine 300also includes an immersion fluid containment system 324 that is configured to maintain the immersion fluid 312 in the space below the optical assembly 16 while the wafer table 304 is away from under the optical assembly.

- the immersion fluid containment system 324includes a pad 326 , a motor 328 , and a control system 330 .

- the pad 326can be positioned adjacent to the optical assembly 16 and the wafer table 304 .

- the wafer table 304has a flat upper surface that is coplanar with a surface of the wafer 308 .

- the pad 326has a flat upper surface that is coplanar with the upper surface of the wafer table 304 and the wafer surface.

- the pad 326is movable in the X and Y directions using the motor 328 , which is controlled by the control system 330 .

- the motor 328can be any type of motor as well as the motors 322 .

- the pad 326is positioned under the optical assembly 16 when the wafer table 304 (the wafer stage 306 ) is away from under the optical assembly 16 .

- the wafer table 304moves away from the optical assembly 16 .

- the control system 330directs the motor 328 to move pad 326 under the optical assembly 16 , replacing the wafer table 304 .

- the pad 326thus retains the immersion fluid 312 within the gap under the optical assembly 16 .

- the wafer table 304is repositioned under the optical assembly 16 .

- the control system 330directs the motor 328 to retract the pad 326 from the gap, preventing the escape of the immersion fluid 312 .

- the control system 330moves the wafer table 304 and the pad 326 with a small gap between the wafer table 304 and the pad 326 , while the immersion fluid 312 below the optical assembly 16 moves between the wafer table 304 and the pad 326 .

- the immersion fluid containment system 324thus maintains the immersion fluid 312 from the gap during wafer exchange.

- the wafer table 304(the wafer stage 306 ) and the pad 326 are movable separately. Therefore, the wafer table 304 is movable freely while the immersion fluid 312 is maintained in the space between the pad 326 and the optical assembly 16 .

- the control system 330may be a separate control system or it can be integrated into the control system used to control the motors 322 for positioning the wafer stage 306 and wafer table 304 . Vertical position and/or tilt of at least one of the wafer table 304 and the pad 326 may be adjusted so that the wafer table surface is coplanar with the pad surface, before the wafer table is moved out from under the optical assembly 16 .

- the operation, in which the wafer table 304 is away from the optical assembly 16is not necessarily limited to a wafer exchange operation.

- an alignment operation, a measurement operation or other operationmay be executed while maintaining the immersion fluid 312 in the space between the pad 326 and the optical assembly 16 .

- the lithography machine 400includes an optical assembly 16 and a stage assembly 402 that includes a wafer table 404 and a wafer stage 406 .

- the wafer table 404is configured to support a wafer 408 (or any other type of work piece) under the optical assembly 16 .

- An environmental system 26( 410 ), surrounding the optical assembly 16 , is used to supply and remove immersion fluid 412 from the gap between the wafer 408 and the lower most optical element of the optical assembly 16 .

- a work piece exchange system 416including a wafer loader 418 and an alignment tool 420 , is configured to remove the wafer 408 on the wafer table 404 and replace it with a second wafer. This is accomplished using the wafer loader 418 to remove the wafer 408 from the wafer table 404 . Subsequently, the second wafer (not shown) is placed onto the wafer chuck 418 , aligned using the alignment tool 420 , and then positioned under the optical assembly 16 as illustrated in the FIG. 4A .

- the immersion lithography machine 400also includes an immersion fluid containment system 424 that is configured to maintain the immersion fluid 412 in the space below the optical assembly 16 while the wafer table 404 is away from under the optical assembly 16 .

- the immersion fluid containment system 424includes a pad 426 , a first clamp 428 provided on the optical assembly 16 and a second clamp 430 provided on the wafer table 404 .

- the pad 426is held by the second clamp 430 in place on the wafer table 404 .

- the pad 426is detached from the wafer table 404 and held by the first clamp 428 to maintain the immersion fluid 412 between the optical assembly 16 and the pad 426 .

- the wafer table 404has a flat upper surface that is coplanar with a surface of the wafer 408 .

- the pad 426 held on the wafer table 404also has a flat upper surface that is coplanar with the upper surface of the wafer table 404 and the wafer surface. Therefore, the immersion pad 426 and wafer 408 can be moved under the optical assembly without the immersion fluid leaking.

- the clamps 428 and 430can be vacuum clamps, magnetic, electro-static, or mechanical.

- the pad 426is positioned on the wafer table 404 during exposure of the wafer 408 .

- the second clamp 430is used to hold the pad 426 in place on the table 404 during the wafer exposure.

- the wafer table 404is moved in the direction of arrow 432 so that the pad 426 is positioned under the optical assembly 16 in place of the wafer 408 .

- the second clamp 430 holding the pad 426 to the wafer table 404is released while first clamp 428 clamps the pad 426 to the optical assembly 16 .

- the immersion fluid 412is maintained under the optical assembly while the wafer 408 is exchanged.

- the wafer table 404is moved in the direction opposite arrow 432 so that the new wafer is positioned under the optical assembly. Prior to this motion, the first clamp 428 is released while the second clamp 430 again clamps the pad 426 to the wafer table 404 . In this embodiment, the wafer table 404 is freely movable while the pad 426 is clamped by the first clamp 428 .

- the operation, in which the pad 426 is clamped by the first clamp 428is not limited to only a wafer exchange operation.

- An alignment operation, a measurement operation, or any other operationcan be executed while the immersion fluid 412 is maintained in the space between the optical assembly 16 and the pad 426 clamped by the first clamp 428 .

- the clamp 428can be provided on the frame 12 or other support member, and the clamp 430 can be provided on the wafer stage 406 .

- the pad 426can be held on a movable member other than the stage assembly 402 .

- FIGS. 5A and 5Bare top down views of two different twin stage immersion lithography systems according to other embodiments of the present invention.

- Motors 502are used to move or position the two stages WS 1 and WS 2 in the horizontal direction (in the drawings), whereas motors 504 are used to move or position the stages WS 1 and WS 2 in the vertical direction (in the drawings).

- the motors 502 and 504are used to alternatively position one stage under the optical assembly 16 while a wafer exchange and alignment is performed on the other stage. When the exposure of the wafer under the optical assembly 16 is complete, then the two stages are swapped and the above process is repeated.

- the various embodiments of the invention for maintaining immersion fluid in the gap under the optical assembly 16 as described and illustrated above with regard to FIGS. 2 through 4can be used with either twin stage arrangement. With regard the embodiment of FIG.

- each wafer stage SW 1 and SW 2 of either FIG. 5A or 5 Bcan be modified to include a pad 222 and a support member 224 .

- a single pad 326 , motor 328 , and control system 330could be used adjacent to the optical assembly 16 .

- the pad 326is movable separately from the stages SW 1 and SW 2 . During the time when stages SW 1 and SW 2 are to be swapped, the pad 326 is moved to under the optical assembly 16 to maintain the immersion fluid 312 below the optical assembly 16 .

- a detachable single padcan be used.

- the pad 426is used to maintain the immersion fluid in the gap as illustrated in FIG. 4B .

- the padis clamped onto the wafer table on the wafer stage that is being exposed. In this manner, only a single pad is needed for the two stages WS 1 and WS 2 .

- the second stagecan also be used as the pad.

- the immersion lithography system 600includes first stage 604 and second stage 606 .

- the two stagesare moved in the X and Y directions by motors 602 .

- the stages 604 and 606themselves are used to contain the immersion fluid in the gap.

- the first stage 604is positioned under the optical assembly 16 .

- the motors 602are used to position the second stage 606 with a second work piece adjacent to the first stage 604 . With the two stages positioned side-by-side, they substantially form a continuous surface.

- the motors 602are then used to move the two stages in unison so that the second stage 604 is position under the optical assembly 16 and the first stage is no longer under the optical assembly 16 .

- the immersion fluid in the gapis maintained by the second stage 606 , which forms the substantially continuous surface with the first stage.

- the second stage 606could also be a “pad” stage that contains a pad that is used to maintain the immersion liquid in the gap while a second work piece is being placed onto the first stage 604 .

- the motor arrangement shown in either FIG. 5A or 5 Bcould be used.

- FIGS. 6B-6Ea series of diagrams illustrating a work piece exchange according to one embodiment of the invention is illustrated.

- FIG. 6Bshows a wafer on stage 604 after exposure is completed.

- FIG. 6Cshows the second stage 606 in contact (or immediately adjacent) with the first stage 604 under the optical assembly 16 .

- FIG. 6Cshows a transfer taking place, i.e., the second stage 606 is positioned under the optical assembly 16 .

- the first stage 604is moved away from the optical assembly 16 .

- the two stages 604 and 606provide a continuous surface under the optical assembly 16 during a transfer, thus maintaining the immersion fluid in the gap.

- the second stage 606is a pad stage. This stage, however, could also be a work piece stage as noted above.

- the padcan be made of a number of different materials, such as ceramic, metal, plastic. These materials may also be coated with Teflon according to other embodiments.

- the size of the padalso should be sufficient to cover the area occupied by the immersion fluid.

- the surface of the last optical element of the optical assembly 16is constantly under immersion fluid environment, preventing the formation of a fluid mark (e.g. “a water mark”).

- step 701the work piece's function and performance characteristics are designed.

- step 702a mask (reticle) having a pattern is designed according to the previous designing step, and in a parallel step 703 a wafer is made from a silicon material.

- the mask pattern designed in step 702is exposed onto the wafer from step 703 in step 704 by a photolithography system described hereinabove in accordance with the invention.

- step 705the semiconductor work piece is assembled (including the dicing process, bonding process and packaging process); finally, the work piece is then inspected in step 706 .

- FIG. 7Billustrates a detailed flowchart example of the above-mentioned step 704 in the case of fabricating semiconductor work pieces.

- step 711oxidation step

- step 712CVD step

- step 713electrode formation step

- step 714ion implantation step

- steps 711 - 714form the preprocessing steps for wafers during wafer processing, and selection is made at each step according to processing requirements.

- step 715photoresist formation step

- step 716exposure step

- step 717developing step

- step 718etching step

- steps other than residual photoresistexposed material surface

- circuit patternsare formed by repetition of these preprocessing and post-processing steps.

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Health & Medical Sciences (AREA)

- Optics & Photonics (AREA)

- Environmental & Geological Engineering (AREA)

- Epidemiology (AREA)

- Public Health (AREA)

- Toxicology (AREA)

- Exposure And Positioning Against Photoresist Photosensitive Materials (AREA)

- Exposure Of Semiconductors, Excluding Electron Or Ion Beam Exposure (AREA)

- Container, Conveyance, Adherence, Positioning, Of Wafer (AREA)

Abstract

Description

This is a Divisional of U.S. patent application Ser. No. 11/237,721 filed Sep. 29, 2005, which in turn is a Continuation of International Application No. PCT/IB2004/001259 filed Mar. 17, 2004, which claims the benefit of U.S. Provisional Application No. 60/462,499 filed on Apr. 11, 2003. The entire disclosures of the prior applications are incorporated herein by reference in their entireties.

Lithography systems are commonly used to transfer images from a reticle onto a semiconductor wafer during semiconductor processing. A typical lithography system includes an optical assembly, a reticle stage for holding a reticle defining a pattern, a wafer stage assembly that positions a semiconductor wafer, and a measurement system that precisely monitors the position of the reticle and the wafer. During operation, an image defined by the reticle is projected by the optical assembly onto the wafer. The projected image is typically the size of one or more die on the wafer. After an exposure, the wafer stage assembly moves the wafer and then another exposure takes place. This process is repeated until all the die on the wafer are exposed. The wafer is then removed and a new wafer is exchanged in its place.

Immersion lithography systems utilize a layer of immersion fluid that completely fills a gap between the optical assembly and the wafer during the exposure of the wafer. The optic properties of the immersion fluid, along with the optical assembly, allow the projection of smaller feature sizes than is currently possible using standard optical lithography. For example, immersion lithography is currently being considered for next generation semiconductor technologies including 65 nanometers, 45 nanometers, and beyond. Immersion lithography therefore represents a significant technological breakthrough that will likely enable the continued use of optical lithography for the foreseeable future.

After a wafer is exposed, it is removed and exchanged with a new wafer. As currently contemplated in immersion systems, the immersion fluid would be removed from the gap and then replenished after the wafer is exchanged. More specifically, when a wafer is to be exchanged, the fluid supply to the gap is turned off, the fluid is removed from the gap (i.e., by vacuum), the old wafer is removed, a new wafer is aligned and placed under the optical assembly, and then the gap is re-filled with fresh immersion fluid. Once all of the above steps are complete, exposure of the new wafer can begin.

Wafer exchange with immersion lithography as described above is problematic for a number of reasons. The repeated filling and draining of the gap may cause variations in the immersion fluid and may cause bubbles to form within the immersion fluid. Bubbles and the unsteady fluid may interfere with the projection of the image on the reticle onto the wafer, thereby reducing yields. The overall process also involves many steps and is time consuming, which reduces the overall throughput of the machine.

An apparatus and method for maintaining immersion fluid in the gap adjacent to the projection lens when the wafer stage moves away from the projection lens, for example during wafer exchange, is therefore needed.

An apparatus and method maintain immersion fluid in the gap adjacent to the projection lens in a lithography machine. The apparatus and method include an optical assembly that projects an image onto a work piece and a stage assembly including a work piece table that supports the work piece adjacent to the optical assembly. An environmental system is provided to supply and remove an immersion fluid from the gap. After exposure of the work piece is complete, an exchange system removes the work piece and replaces it with a second work piece. An immersion fluid containment system is provided to maintain the immersion fluid in the gap when the work piece table moves away from the projection lens. The gap therefore does not have to be refilled with immersion fluid when the first work piece is replaced with a second work piece.

The invention will be described in conjunction with the following drawings of exemplary embodiments in which like reference numerals designate like elements, and in which:

In one embodiment, thelithography machine 10 is used to transfer a pattern (not shown) of an integrated circuit from areticle 28 onto a semiconductor wafer30 (illustrated in phantom). Thelithography machine 10 mounts to amounting base 32, e.g., the ground, a base, or floor or some other supporting structure.

In various embodiments of the invention, thelithography machine 10 can be used as a scanning type photolithography system that exposes the pattern from thereticle 28 onto thewafer 30 with thereticle 28 and thewafer 30 moving synchronously. In a scanning type lithographic machine, thereticle 28 is moved perpendicularly to an optical axis of theoptical assembly 16 by thereticle stage assembly 18, and thewafer 30 is moved perpendicularly to the optical axis of theoptical assembly 16 by thewafer stage assembly 20. Scanning of thereticle 28 and thewafer 30 occurs while thereticle 28 and thewafer 30 are moving synchronously.

Alternatively, thelithography machine 10 can be a step-and-repeat type photolithography system that exposes thereticle 28 while thereticle 28 and thewafer 30 are stationary. In the step and repeat process, thewafer 30 is in a constant position relative to thereticle 28 and theoptical assembly 16 during the exposure of an individual field. Subsequently, between consecutive exposure steps, thewafer 30 is consecutively moved with thewafer stage assembly 20 perpendicularly to the optical axis of theoptical assembly 16 so that the next field of thewafer 30 is brought into position relative to theoptical assembly 16 and thereticle 28 for exposure. Following this process, the images on thereticle 28 are sequentially exposed onto the fields of thewafer 30, and then the next field of thewafer 30 is brought into position relative to theoptical assembly 16 and thereticle 28.

However, the use of thelithography machine 10 provided herein is not necessarily limited to a photolithography for semiconductor manufacturing. Thelithography machine 10, for example, can be used as an LCD photolithography system that exposes a liquid crystal display work piece pattern onto a rectangular glass plate or a photolithography system for manufacturing a thin film magnetic head. Accordingly, the term “work piece” is generically used herein to refer to any device that may be patterned using lithography, such as but not limited to wafers or LCD substrates.

Theapparatus frame 12 supports the components of thelithography machine 10. Theapparatus frame 12 illustrated inFIG. 1 supports thereticle stage assembly 18, thewafer stage assembly 20, theoptical assembly 16 and theillumination system 14 above the mountingbase 32.

Theillumination system 14 includes anillumination source 34 and an illuminationoptical assembly 36. Theillumination source 34 emits a beam (irradiation) of light energy. The illuminationoptical assembly 36 guides the beam of light energy from theillumination source 34 to theoptical assembly 16. The beam illuminates selectively different portions of thereticle 28 and exposes thewafer 30. InFIG. 1 , theillumination source 34 is illustrated as being supported above thereticle stage assembly 18. Typically, however, theillumination source 34 is secured to one of the sides of theapparatus frame 12 and the energy beam from theillumination source 34 is directed to above thereticle stage assembly 18 with the illuminationoptical assembly 36.

Theillumination source 34 can be a g-line source (436 nm), an i-line source (365 nm), a KrF excimer laser (248 nm), an ArF excimer laser (193 nm) or a F2laser (157 nm). Alternatively, theillumination source 34 can generate an x-ray.

Theoptical assembly 16 projects and/or focuses the light passing through thereticle 28 to thewafer 30. Depending upon the design of thelithography machine 10, theoptical assembly 16 can magnify or reduce the image illuminated on thereticle 28. Theoptical assembly 16 need not be limited to a reduction system. It could also be a 1× or greater magnification system.

Also, with an exposure work piece that employs vacuum ultra-violet radiation (VUV) ofwavelength 200 nm or lower, use of a catadioptric type optical system can be considered. Examples of a catadioptric type of optical system are disclosed in Japanese Laid-Open Patent Application Publication No. 8-171054 and its counterpart U.S. Pat. No. 5,668,672, as well as Japanese Laid-Open Patent Publication No. 10-20195 and its counterpart U.S. Pat. No. 5,835,275. In these cases, the reflecting optical system can be a catadioptric optical system incorporating a beam splitter and concave mirror. Japanese Laid-Open Patent Application Publication No. 8-334695 and its counterpart U.S. Pat. No. 5,689,377 as well as Japanese Laid-Open Patent Application Publication No. 10-3039 and its counterpart U.S. Pat. No. 873,605 (Application Date: Jun. 12, 1997) also use a reflecting-refracting type of optical system incorporating a concave mirror, etc., but without a beam splitter, and also can be employed with this invention. The disclosures of the above-mentioned U.S. patents and applications, as well as the Japanese Laid-Open patent application publications are incorporated herein by reference in their entireties.

Thereticle stage assembly 18 holds and positions thereticle 28 relative to theoptical assembly 16 and thewafer 30. In one embodiment, thereticle stage assembly 18 includes areticle stage 38 that retains thereticle 28 and a reticlestage mover assembly 40 that moves and positions thereticle stage 38 andreticle 28.

Eachstage mover assembly respective stage stage mover assembly respective stage stage mover assembly 40 and the work piecestage mover assembly 44 can each include one or more movers, such as rotary motors, voice coil motors, linear motors utilizing a Lorentz force to generate drive force, electromagnetic movers, planar motors, or some other force movers.

In photolithography systems, when linear motors (see U.S. Pat. Nos. 5,623,853 or 5,528,118 which are incorporated by reference herein in their entireties) are used in the wafer stage assembly or the reticle stage assembly, the linear motors can be either an air levitation type employing air bearings or a magnetic levitation type using Lorentz force or reactance force. Additionally, the stage could move along a guide, or it could be a guideless type stage that uses no guide.

Alternatively, one of the stages could be driven by a planar motor, which drives the stage by an electromagnetic force generated by a magnet unit having two-dimensionally arranged magnets and an armature coil unit having two-dimensionally arranged coils in facing positions. With this type of driving system, either the magnet unit or the armature coil unit is connected to the stage base and the other unit is mounted on the moving plane side of the stage.

Movement of the stages as described above generates reaction forces that can affect performance of the photolithography system. Reaction forces generated by the wafer (substrate) stage motion can be mechanically transferred to the floor (ground) by use of a frame member as described in U.S. Pat. No. 5,528,100 and Japanese Laid-Open Patent Application Publication No. 8-136475. Additionally, reaction forces generated by the reticle (mask) stage motion can be mechanically transferred to the floor (ground) by use of a frame member as described in U.S. Pat. No. 5,874,820 and Japanese Laid-Open Patent Application Publication No. 8-330224. The disclosures of U.S. Pat. Nos. 5,528,100 and 5,874,820 and Japanese Paid-Open Patent Application Publication Nos. 8-136475 and 8-330224 are incorporated herein by reference in their entireties.

Themeasurement system 22 monitors movement of thereticle 28 and thewafer 30 relative to theoptical assembly 16 or some other reference. With this information, thecontrol system 24 can control thereticle stage assembly 18 to precisely position thereticle 28 and the workpiece stage assembly 20 to precisely position thewafer 30. The design of themeasurement system 22 can vary. For example, themeasurement system 22 can utilize multiple laser interferometers, encoders, mirrors, and/or other measuring devices.

Thecontrol system 24 receives information from themeasurement system 22 and controls thestage assemblies reticle 28 and thewafer 30. Additionally, thecontrol system 24 can control the operation of the components of theenvironmental system 26. Thecontrol system 24 can include one or more processors and circuits.

Theenvironmental system 26 controls the environment in a gap (not shown) between theoptical assembly 16 and thewafer 30. The gap includes an imaging field. The imaging field includes the area adjacent to the region of thewafer 30 that is being exposed and the area in which the beam of light energy travels between theoptical assembly 16 and thewafer 30. With this design, theenvironmental system 26 can control the environment in the imaging field. The desired environment created and/or controlled in the gap by theenvironmental system 26 can vary accordingly to thewafer 30 and the design of the rest of the components of thelithography machine 10, including theillumination system 14. For example, the desired controlled environment can be a fluid such as water. Alternatively, the desired controlled environment can be another type of fluid such as a gas. In various embodiments, the gap may range from 0.1 mm to 10 mm in height between top surface of thewafer 30 and the last optical element of theoptical assembly 16.

In one embodiment, theenvironmental system 26 fills the imaging field and the rest of the gap with an immersion fluid. The design of theenvironmental system 26 and the components of theenvironmental system 26 can be varied. In different embodiments, theenvironmental system 26 delivers and/or injects immersion fluid into the gap using spray nozzles, electro-kinetic sponges, porous materials, etc. and removes the fluid from the gap using vacuum pumps, sponges, and the like. The design of theenvironmental system 26 can vary. For example, it can inject the immersion fluid at one or more locations at or near the gap. Further, the immersion fluid system can assist in removing and/or scavenging the immersion fluid at one or more locations at or near thework piece 30, the gap and/or the edge of theoptical assembly 16. For additional details on various environmental systems, see U.S. provisional patent applications 60/462,142 entitled “Immersion Lithography Fluid Control System” filed on Apr. 9, 2003, 60/462,112 entitled “Vacuum Ring System and Wick Ring System for Immersion Lithography” filed on Apr. 10, 2003, 60/500,312 entitled “Noiseless Fluid Recovery With Porous Material” filed on Sep. 3, 2003, and 60/541,329 entitled “Nozzle Design for Immersion Lithography” filed on Feb. 2, 2004, all incorporated by reference herein in their entireties.

Referring toFIG. 2 , a cross section of a lithography machine illustrating one embodiment of the invention is shown. Thelithography machine 200 includes aoptical assembly 16 and astage assembly 202 that includes a wafer table204 and awafer stage 206. The wafer table204 is configured to support a wafer208 (or any other type of work piece) under theoptical assembly 16. Anenvironmental system 26, surrounding theoptical assembly 16, is used to supply and removeimmersion fluid 212 from the gap between thewafer 208 and the last optical element of theoptical assembly 16. A workpiece exchange system 216, including a wafer loader218 (i.e., a robot) and an alignment tool220 (i.e., a microscope and CCD camera), is configured to remove thewafer 208 on the wafer table204 and replace it with a second wafer. This is typically accomplished using thewafer loader 218 to lift and remove thewafer 208 from the wafer table204. Subsequently, the second wafer (not shown) is placed onto thewafer chuck 218, aligned using thealignment tool 220, and then positioned under theoptical assembly 16 on the wafer table204.

With this embodiment, thewafer stage 206 includes an immersionfluid containment system 214 that is configured to maintain theimmersion fluid 212 in the gap adjacent to the last optical element of theoptical assembly 16 during wafer exchange. The immersionfluid containment system 214 includes apad 222 that is adjacent to the wafer table204. Asupport member 224, provided between thepad 222 and thewafer stage 206, is used to support thepad 222. The wafer table204 has a flat upper surface that is coplanar with a surface of thewafer 208. Thepad 222 also has a flat upper surface that is coplanar with the upper surface of the wafer table204 and the wafer surface. Thepad 222 is arranged adjacent to the wafer table204 with a very small gap (e.g., 0.1-1.0 mm) so that theimmersion fluid 212 is movable between the wafer table204 and thepad 222 without leaking. During a wafer exchange, thewafer stage 206 is moved in the direction ofarrow 226 so that thepad 222 is positioned under theoptical assembly 16 in place of the wafer table204, maintaining the fluid in the gap or maintaining the size of the fluid gap. After the new wafer has been aligned, the wafer stage is moved back to its original position so that thepad 222 is removed from the gap as the second wafer is positioned under theoptical assembly 16. In various embodiments, thepad 222 is disposed continuously adjacent to the wafer table204 with no gap. Vertical position and/or tilt of the wafer table204 can be adjusted so that the wafer table surface is coplanar with the pad surface, before the wafer table204 is moved out from under theoptical assembly 16. Maintaining the gap between thepad 222 and theoptical assembly 16 is not limited to just a wafer exchange operation. Thepad 222 can be large enough to maintain theimmersion fluid 212 in the space between thepad 222 and theoptical assembly 16 during an alignment operation or a measurement operation. In those operations, a part of the area occupied by theimmersion fluid 212 may be on the upper surface of the wafer table204.

Referring toFIGS. 3A and 3B , a cross section and a top down view of another immersion lithography machine according to another embodiment of the present invention are shown. Thelithography machine 300 includes anoptical assembly 16 and astage assembly 302 that includes a wafer table304 and awafer stage 306. The wafer table304 is configured to support a wafer308 (or any other type of work piece) under theoptical assembly 16. Anenvironmental system 26, surrounding theoptical assembly 16, is used to supply and removeimmersion fluid 312 from the gap between thewafer 308 and the lower most optical element of theoptical assembly 16. A workpiece exchange system 316, including awafer loader 318 and analignment tool 320, is configured to remove thewafer 308 on the wafer table304 and replace it with a second wafer. This is accomplished using thewafer loader 318 to remove thewafer 308 from the wafer table. Subsequently, the second wafer (not shown) is placed onto thewafer chuck 318, aligned using thealignment tool 320, and then positioned under theoptical assembly 16. As best illustrated inFIG. 3B , a set ofmotors 322 are used to move thewafer assembly 302 including the wafer table304 andwafer stage 306 in two degrees of freedom (X and Y) during operation. As noted above, themotors 322 can be any type of motors, such as linear motors, rotary motors, voice coil motors, etc.

Theimmersion lithography machine 300 also includes an immersionfluid containment system 324 that is configured to maintain theimmersion fluid 312 in the space below theoptical assembly 16 while the wafer table304 is away from under the optical assembly. The immersionfluid containment system 324 includes apad 326, amotor 328, and acontrol system 330. Thepad 326 can be positioned adjacent to theoptical assembly 16 and the wafer table304. The wafer table304 has a flat upper surface that is coplanar with a surface of thewafer 308. Thepad 326 has a flat upper surface that is coplanar with the upper surface of the wafer table304 and the wafer surface. Thepad 326 is movable in the X and Y directions using themotor 328, which is controlled by thecontrol system 330. Themotor 328 can be any type of motor as well as themotors 322. Thepad 326 is positioned under theoptical assembly 16 when the wafer table304 (the wafer stage306) is away from under theoptical assembly 16. During a wafer exchange, the wafer table304 moves away from theoptical assembly 16. Simultaneously, thecontrol system 330 directs themotor 328 to movepad 326 under theoptical assembly 16, replacing the wafer table304. Thepad 326 thus retains theimmersion fluid 312 within the gap under theoptical assembly 16. After the new wafer has been aligned using thealignment tool 320, the wafer table304 is repositioned under theoptical assembly 16. At the same time, thecontrol system 330 directs themotor 328 to retract thepad 326 from the gap, preventing the escape of theimmersion fluid 312. In the wafer exchange operation, thecontrol system 330 moves the wafer table304 and thepad 326 with a small gap between the wafer table304 and thepad 326, while theimmersion fluid 312 below theoptical assembly 16 moves between the wafer table304 and thepad 326. The immersionfluid containment system 324 thus maintains theimmersion fluid 312 from the gap during wafer exchange. In this embodiment, the wafer table304 (the wafer stage306) and thepad 326 are movable separately. Therefore, the wafer table304 is movable freely while theimmersion fluid 312 is maintained in the space between thepad 326 and theoptical assembly 16. In various embodiments of the invention, thecontrol system 330 may be a separate control system or it can be integrated into the control system used to control themotors 322 for positioning thewafer stage 306 and wafer table304. Vertical position and/or tilt of at least one of the wafer table304 and thepad 326 may be adjusted so that the wafer table surface is coplanar with the pad surface, before the wafer table is moved out from under theoptical assembly 16. The operation, in which the wafer table304 is away from theoptical assembly 16, is not necessarily limited to a wafer exchange operation. For example, an alignment operation, a measurement operation or other operation may be executed while maintaining theimmersion fluid 312 in the space between thepad 326 and theoptical assembly 16.

Referring toFIGS. 4A and 4B , two cross sections of an immersion lithography machine are shown. Thelithography machine 400 includes anoptical assembly 16 and astage assembly 402 that includes a wafer table404 and awafer stage 406. The wafer table404 is configured to support a wafer408 (or any other type of work piece) under theoptical assembly 16. An environmental system26 (410), surrounding theoptical assembly 16, is used to supply and removeimmersion fluid 412 from the gap between thewafer 408 and the lower most optical element of theoptical assembly 16. A workpiece exchange system 416, including awafer loader 418 and analignment tool 420, is configured to remove thewafer 408 on the wafer table404 and replace it with a second wafer. This is accomplished using thewafer loader 418 to remove thewafer 408 from the wafer table404. Subsequently, the second wafer (not shown) is placed onto thewafer chuck 418, aligned using thealignment tool 420, and then positioned under theoptical assembly 16 as illustrated in theFIG. 4A .

Theimmersion lithography machine 400 also includes an immersionfluid containment system 424 that is configured to maintain theimmersion fluid 412 in the space below theoptical assembly 16 while the wafer table404 is away from under theoptical assembly 16. The immersionfluid containment system 424 includes apad 426, afirst clamp 428 provided on theoptical assembly 16 and asecond clamp 430 provided on the wafer table404. When theimmersion fluid 412 is between theoptical assembly 16 and the wafer table404 (or the wafer408), thepad 426 is held by thesecond clamp 430 in place on the wafer table404. When the wafer table404 is away from theoptical assembly 16, for example during a wafer exchange operation, thepad 426 is detached from the wafer table404 and held by thefirst clamp 428 to maintain theimmersion fluid 412 between theoptical assembly 16 and thepad 426. The wafer table404 has a flat upper surface that is coplanar with a surface of thewafer 408. Thepad 426 held on the wafer table404 also has a flat upper surface that is coplanar with the upper surface of the wafer table404 and the wafer surface. Therefore, theimmersion pad 426 andwafer 408 can be moved under the optical assembly without the immersion fluid leaking. In various embodiments, theclamps

As best illustrated inFIG. 4A , thepad 426 is positioned on the wafer table404 during exposure of thewafer 408. Thesecond clamp 430 is used to hold thepad 426 in place on the table404 during the wafer exposure. During a wafer exchange as illustrated inFIG. 4B , the wafer table404 is moved in the direction ofarrow 432 so that thepad 426 is positioned under theoptical assembly 16 in place of thewafer 408. When this occurs, thesecond clamp 430 holding thepad 426 to the wafer table404 is released whilefirst clamp 428 clamps thepad 426 to theoptical assembly 16. As a result, theimmersion fluid 412 is maintained under the optical assembly while thewafer 408 is exchanged. After the new wafer has been aligned, the wafer table404 is moved in the direction oppositearrow 432 so that the new wafer is positioned under the optical assembly. Prior to this motion, thefirst clamp 428 is released while thesecond clamp 430 again clamps thepad 426 to the wafer table404. In this embodiment, the wafer table404 is freely movable while thepad 426 is clamped by thefirst clamp 428.

In various embodiments, the operation, in which thepad 426 is clamped by thefirst clamp 428, is not limited to only a wafer exchange operation. An alignment operation, a measurement operation, or any other operation can be executed while theimmersion fluid 412 is maintained in the space between theoptical assembly 16 and thepad 426 clamped by thefirst clamp 428. Also, theclamp 428 can be provided on theframe 12 or other support member, and theclamp 430 can be provided on thewafer stage 406. Thepad 426 can be held on a movable member other than thestage assembly 402.

Referring toFIG. 6A , a top down view of a twin stage lithography machine illustrating one embodiment of practicing the invention is shown. In this embodiment, theimmersion lithography system 600 includesfirst stage 604 andsecond stage 606. The two stages are moved in the X and Y directions bymotors 602. In this embodiment, thestages first stage 604 is positioned under theoptical assembly 16. When it is time for the work piece to be exchanged, themotors 602 are used to position thesecond stage 606 with a second work piece adjacent to thefirst stage 604. With the two stages positioned side-by-side, they substantially form a continuous surface. Themotors 602 are then used to move the two stages in unison so that thesecond stage 604 is position under theoptical assembly 16 and the first stage is no longer under theoptical assembly 16. Thus when the first work piece is moved away from theoptical assembly 16, the immersion fluid in the gap is maintained by thesecond stage 606, which forms the substantially continuous surface with the first stage. In various alternative embodiments, thesecond stage 606 could also be a “pad” stage that contains a pad that is used to maintain the immersion liquid in the gap while a second work piece is being placed onto thefirst stage 604. Similarly, the motor arrangement shown in eitherFIG. 5A or5B could be used.

Referring toFIGS. 6B-6E , a series of diagrams illustrating a work piece exchange according to one embodiment of the invention is illustrated.FIG. 6B shows a wafer onstage 604 after exposure is completed.FIG. 6C shows thesecond stage 606 in contact (or immediately adjacent) with thefirst stage 604 under theoptical assembly 16.FIG. 6C shows a transfer taking place, i.e., thesecond stage 606 is positioned under theoptical assembly 16. Finally, inFIG. 6E , thefirst stage 604 is moved away from theoptical assembly 16. As best illustrated inFIGS. 6C and 6D , the twostages optical assembly 16 during a transfer, thus maintaining the immersion fluid in the gap. In the embodiment shown, thesecond stage 606 is a pad stage. This stage, however, could also be a work piece stage as noted above.

In the various embodiments described above, the pad can be made of a number of different materials, such as ceramic, metal, plastic. These materials may also be coated with Teflon according to other embodiments. The size of the pad also should be sufficient to cover the area occupied by the immersion fluid. In the various embodiments described above, the surface of the last optical element of theoptical assembly 16 is constantly under immersion fluid environment, preventing the formation of a fluid mark (e.g. “a water mark”).

Semiconductor wafers can be fabricated using the above described systems, by the process shown generally inFIG. 7A . Instep 701 the work piece's function and performance characteristics are designed. Next, instep 702, a mask (reticle) having a pattern is designed according to the previous designing step, and in a parallel step703 a wafer is made from a silicon material. The mask pattern designed instep 702 is exposed onto the wafer fromstep 703 instep 704 by a photolithography system described hereinabove in accordance with the invention. Instep 705 the semiconductor work piece is assembled (including the dicing process, bonding process and packaging process); finally, the work piece is then inspected instep 706.

At each stage of wafer processing, when the above-mentioned preprocessing steps have been completed, the following post-processing steps are implemented. During post-processing, first, in step715 (photoresist formation step), photoresist is applied to a wafer. Next, in step716 (exposure step), the above-mentioned exposure work piece is used to transfer the circuit pattern of a mask (reticle) to a wafer. Then in step717 (developing step), the exposed wafer is developed, and in step718 (etching step), parts other than residual photoresist (exposed material surface) are removed by etching. In step719 (photoresist removal step), unnecessary photoresist remaining after etching is removed.

Multiple circuit patterns are formed by repetition of these preprocessing and post-processing steps.

While the particular lithography machines as shown and disclosed herein are fully capable of obtaining the objects and providing the advantages herein before stated, it is to be understood that they are merely illustrative embodiments of the invention, and that the invention is not limited to these embodiments.

Claims (18)

1. A lithographic projection apparatus comprising:

a substrate table on which a substrate is held;

a projection system that projects a patterned beam onto a target portion of the substrate held by the substrate table, an immersion liquid, through which the beam is to be projected, being in a space between the projection system and the substrate; and

a flat pad that keeps the projection system in contact with the immersion liquid when the substrate, at least while held on the substrate table, comes out of contact with the immersion liquid, the flat pad being separate from the substrate table.

2. An apparatus according toclaim 1 , wherein the flat pad is positionable opposite the projection system such that the immersion liquid can be confined between the projection system and the flat pad.

3. An apparatus according toclaim 2 , further comprising an attachment device that releasably attaches the flat pad over a final optical element of the projection system.

4. An apparatus according toclaim 3 , wherein the attachment device comprises a vacuum outlet that attracts the flat pad toward the projection system.

5. An apparatus according toclaim 2 , wherein the substrate table comprises a holding device that releasably holds the flat pad to the substrate table.

6. An apparatus according toclaim 2 , wherein, in a stowed position, the flat pad has a primary surface substantially co-planar with a surface of the substrate facing the projection system.

7. An apparatus according toclaim 2 , wherein the lithographic apparatus comprises a controller that moves the substrate table relative to the projection system so that the flat pad confines the immersion liquid between the flat pad and the projection system.

8. An apparatus according toclaim 1 , wherein the flat pad has a primary surface substantially co-planar with a surface of the substrate facing the projection system and is closely adjacent to an edge of the substrate.

9. An apparatus according toclaim 1 , further comprising a structure extending along at least a part of a boundary of the space between the projection system and the substrate table and wherein the flat pad, when keeping the projection system in contact with the immersion liquid, is positioned to cover the structure.

10. An apparatus according toclaim 1 , wherein the flat pad keeps the projection system in contact with the immersion liquid when the substrate is moved away from under the projection system.