US7116912B2 - Method and apparatus for pluggable fiber optic modules - Google Patents

Method and apparatus for pluggable fiber optic modulesDownload PDFInfo

- Publication number

- US7116912B2 US7116912B2US10/118,761US11876102AUS7116912B2US 7116912 B2US7116912 B2US 7116912B2US 11876102 AUS11876102 AUS 11876102AUS 7116912 B2US7116912 B2US 7116912B2

- Authority

- US

- United States

- Prior art keywords

- printed circuit

- circuit board

- fiber optic

- optical

- pcb

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased, expires

Links

- 239000000835fiberSubstances0.000titleclaimsabstractdescription259

- 238000000034methodMethods0.000titledescription13

- 230000005693optoelectronicsEffects0.000claimsabstractdescription64

- 230000003287optical effectEffects0.000claimsdescription217

- 239000013307optical fiberSubstances0.000claimsdescription59

- 229910000679solderInorganic materials0.000claimsdescription51

- 239000004033plasticSubstances0.000claimsdescription25

- 230000008878couplingEffects0.000claimsdescription22

- 238000010168coupling processMethods0.000claimsdescription22

- 238000005859coupling reactionMethods0.000claimsdescription22

- 239000002184metalSubstances0.000claimsdescription17

- 230000005672electromagnetic fieldEffects0.000claimsdescription6

- MPCDNZSLJWJDNW-UHFFFAOYSA-N1,2,3-trichloro-4-(3,5-dichlorophenyl)benzeneChemical compoundClC1=CC(Cl)=CC(C=2C(=C(Cl)C(Cl)=CC=2)Cl)=C1MPCDNZSLJWJDNW-UHFFFAOYSA-N0.000description86

- BQENMISTWGTJIJ-UHFFFAOYSA-N2,3,3',4,5-pentachlorobiphenylChemical compoundClC1=CC=CC(C=2C(=C(Cl)C(Cl)=C(Cl)C=2)Cl)=C1BQENMISTWGTJIJ-UHFFFAOYSA-N0.000description83

- 239000004593EpoxySubstances0.000description18

- 239000003292glueSubstances0.000description13

- 230000006854communicationEffects0.000description9

- 238000004891communicationMethods0.000description9

- 238000004519manufacturing processMethods0.000description7

- 239000004065semiconductorSubstances0.000description7

- 239000003990capacitorSubstances0.000description6

- 238000002955isolationMethods0.000description4

- 239000000463materialSubstances0.000description4

- 230000008901benefitEffects0.000description3

- 238000012986modificationMethods0.000description3

- 230000004048modificationEffects0.000description3

- 230000003068static effectEffects0.000description3

- 239000000758substrateSubstances0.000description3

- 230000005540biological transmissionEffects0.000description2

- 238000010586diagramMethods0.000description2

- 238000001746injection mouldingMethods0.000description2

- 230000007246mechanismEffects0.000description2

- 230000004044responseEffects0.000description2

- 238000005476solderingMethods0.000description2

- 239000000853adhesiveSubstances0.000description1

- 230000001070adhesive effectEffects0.000description1

- 230000003321amplificationEffects0.000description1

- 238000005452bendingMethods0.000description1

- 230000007175bidirectional communicationEffects0.000description1

- 238000000071blow mouldingMethods0.000description1

- 239000000919ceramicSubstances0.000description1

- 239000004020conductorSubstances0.000description1

- 238000010276constructionMethods0.000description1

- 238000001514detection methodMethods0.000description1

- 230000009977dual effectEffects0.000description1

- 230000005684electric fieldEffects0.000description1

- 238000005242forgingMethods0.000description1

- 230000004927fusionEffects0.000description1

- 239000007924injectionSubstances0.000description1

- 238000003780insertionMethods0.000description1

- 230000037431insertionEffects0.000description1

- 239000012212insulatorSubstances0.000description1

- 238000003754machiningMethods0.000description1

- 230000013011matingEffects0.000description1

- 238000002844meltingMethods0.000description1

- 230000008018meltingEffects0.000description1

- 230000007176multidirectional communicationEffects0.000description1

- 230000006855networkingEffects0.000description1

- 239000012811non-conductive materialSubstances0.000description1

- 238000003199nucleic acid amplification methodMethods0.000description1

- 239000004417polycarbonateSubstances0.000description1

- 229920000515polycarbonatePolymers0.000description1

- 230000008569processEffects0.000description1

- 230000005855radiationEffects0.000description1

- 238000011084recoveryMethods0.000description1

- 238000000926separation methodMethods0.000description1

- 239000011343solid materialSubstances0.000description1

- 229910001220stainless steelInorganic materials0.000description1

- 239000010935stainless steelSubstances0.000description1

- 229920001169thermoplasticPolymers0.000description1

- 239000004416thermosoftening plasticSubstances0.000description1

- 230000002463transducing effectEffects0.000description1

- 238000001721transfer mouldingMethods0.000description1

- 239000001993waxSubstances0.000description1

- 238000003466weldingMethods0.000description1

Images

Classifications

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B6/00—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings

- G02B6/24—Coupling light guides

- G02B6/42—Coupling light guides with opto-electronic elements

- G02B6/4201—Packages, e.g. shape, construction, internal or external details

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B6/00—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings

- G02B6/24—Coupling light guides

- G02B6/42—Coupling light guides with opto-electronic elements

- G02B6/4201—Packages, e.g. shape, construction, internal or external details

- G02B6/4204—Packages, e.g. shape, construction, internal or external details the coupling comprising intermediate optical elements, e.g. lenses, holograms

- G02B6/4214—Packages, e.g. shape, construction, internal or external details the coupling comprising intermediate optical elements, e.g. lenses, holograms the intermediate optical element having redirecting reflective means, e.g. mirrors, prisms for deflecting the radiation from horizontal to down- or upward direction toward a device

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B6/00—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings

- G02B6/24—Coupling light guides

- G02B6/42—Coupling light guides with opto-electronic elements

- G02B6/4201—Packages, e.g. shape, construction, internal or external details

- G02B6/4219—Mechanical fixtures for holding or positioning the elements relative to each other in the couplings; Alignment methods for the elements, e.g. measuring or observing methods especially used therefor

- G02B6/4236—Fixing or mounting methods of the aligned elements

- G02B6/424—Mounting of the optical light guide

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B6/00—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings

- G02B6/24—Coupling light guides

- G02B6/42—Coupling light guides with opto-electronic elements

- G02B6/4201—Packages, e.g. shape, construction, internal or external details

- G02B6/4246—Bidirectionally operating package structures

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B6/00—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings

- G02B6/24—Coupling light guides

- G02B6/42—Coupling light guides with opto-electronic elements

- G02B6/4201—Packages, e.g. shape, construction, internal or external details

- G02B6/4251—Sealed packages

- G02B6/4253—Sealed packages by embedding housing components in an adhesive or a polymer material

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B6/00—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings

- G02B6/24—Coupling light guides

- G02B6/42—Coupling light guides with opto-electronic elements

- G02B6/4201—Packages, e.g. shape, construction, internal or external details

- G02B6/4256—Details of housings

- G02B6/4257—Details of housings having a supporting carrier or a mounting substrate or a mounting plate

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B6/00—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings

- G02B6/24—Coupling light guides

- G02B6/42—Coupling light guides with opto-electronic elements

- G02B6/4201—Packages, e.g. shape, construction, internal or external details

- G02B6/4256—Details of housings

- G02B6/426—Details of housings mounting, engaging or coupling of the package to a board, a frame or a panel

- G02B6/4261—Packages with mounting structures to be pluggable or detachable, e.g. having latches or rails

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B6/00—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings

- G02B6/24—Coupling light guides

- G02B6/42—Coupling light guides with opto-electronic elements

- G02B6/4201—Packages, e.g. shape, construction, internal or external details

- G02B6/4256—Details of housings

- G02B6/4262—Details of housings characterised by the shape of the housing

- G02B6/4263—Details of housings characterised by the shape of the housing of the transisitor outline [TO] can type

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B6/00—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings

- G02B6/24—Coupling light guides

- G02B6/42—Coupling light guides with opto-electronic elements

- G02B6/4201—Packages, e.g. shape, construction, internal or external details

- G02B6/4274—Electrical aspects

- G02B6/4277—Protection against electromagnetic interference [EMI], e.g. shielding means

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B6/00—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings

- G02B6/24—Coupling light guides

- G02B6/42—Coupling light guides with opto-electronic elements

- G02B6/4201—Packages, e.g. shape, construction, internal or external details

- G02B6/4274—Electrical aspects

- G02B6/428—Electrical aspects containing printed circuit boards [PCB]

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B6/00—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings

- G02B6/24—Coupling light guides

- G02B6/42—Coupling light guides with opto-electronic elements

- G02B6/4201—Packages, e.g. shape, construction, internal or external details

- G02B6/4274—Electrical aspects

- G02B6/4284—Electrical aspects of optical modules with disconnectable electrical connectors

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B6/00—Light guides; Structural details of arrangements comprising light guides and other optical elements, e.g. couplings

- G02B6/24—Coupling light guides

- G02B6/42—Coupling light guides with opto-electronic elements

- G02B6/4292—Coupling light guides with opto-electronic elements the light guide being disconnectable from the opto-electronic element, e.g. mutually self aligning arrangements

Definitions

- This inventionrelates to fiber optic modules.

- Fiber optic modulesinterface optical fibers to electronic circuitry transducing communication by light or photons with communication by electrical signals.

- a fiber optic modulemay be a fiber optic receiver, transmitter or transceiver including both receive and transmit functions.

- the fiber optic receiver, transmitter and transceivereach have optical elements (OE) and electrical elements (EE).

- the fiber optic transmitter OEincludes an emitter (such as a semiconductor LED or Laser) mounted in a package and an optical coupling element for coupling light or photons from the OE into the optical fiber.

- the type of semiconductor laser(light amplification by stimulated emission of radiation) may be a vertical cavity surface emitting laser (VCSEL).

- the fiber optic receiver OEincludes a photodetector (such as a photodiode) mounted in a package and an optical coupling element for coupling light or photons from the optical fiber into the photodetector.

- the EE for eachincludes integrated circuits and passive elements mounted on a substrate such as a printed circuit board (PCB) or ceramic.

- PCBprinted circuit board

- the OE and EEare connected electrically at the emitter and photodetector.

- the fiber optic transceiverIn order to reduce EMI, shielding of the electrical components is required which is usually accomplished by attaching a metal shield to the substrate of the fiber optic module and connecting it to ground. In order to avoid electronic crosstalk and EMI, the fiber optic transceiver usually employs separate components and separate shielding of fiber optic receiver and fiber optic transmitter components. In order to avoid optical crosstalk where light or photons can interfere between communication channels, the fiber optic transceiver usually employs separate optical elements for coupling light or photons into and out of the optical fiber for fiber optic receiver and fiber optic transmitter. Using separate optical elements requires additional components and increases the costs of fiber optic transceivers. It is desirable to reduce the component count of fiber optic transceivers such that they are less expensive to manufacture.

- the form factor or size of the fiber optic moduleis of concern.

- the fiber optic transceiver, receiver, and transmitterutilized horizontal boards or substrates which mounted parallel with a system printed circuit board utilized significant footprint or board space.

- the horizontal boardsprovided nearly zero optical crosstalk and minimal electronic crosstalk when properly shielded.

- the horizontal boards, parallel to the system printed circuit boardrequired large spacing between optical fiber connectors to make the connection to the optical fibers. While this may have been satisfactory for early systems using minimal fiber optic communication, the trend is towards greater usage of fiber optic communication requiring improved connectivity and smaller optical fiber connectors to more densely pack them on a system printed circuit board.

- the OEis desirable to minimize the size of system printed circuit boards (PCBs) and accordingly it is desirable to reduce the footprint of the fiber optic module which will attach to such system PCBs.

- PCBssystem printed circuit boards

- the desire for tighter interconnect leads of fiber optic cablesrestricts the size of the OE's.

- the header dimension of the interconnect leadis normally 5.6 mm.

- the two optical fibersare separated by a distance of only 0.75 mm. This severely restricts the method of coupling light or photons from the OE into and out of fiber optic cables.

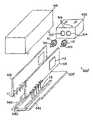

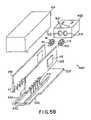

- FIG. 1is a simplified top cutaway view of a first embodiment of the invention.

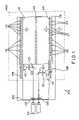

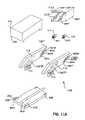

- FIG. 2is an exploded view of the first embodiment of the invention.

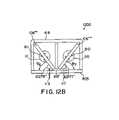

- FIG. 3Ais a cross-sectional view from the top of the optic block for the first embodiment of the invention.

- FIG. 3Bis a front side perspective view from the left of the optic block for the first embodiment of the invention.

- FIG. 3Cis a frontal view of the optic block for the first embodiment of the invention.

- FIG. 3Dis a back side perspective view from the right of the optic block for the first embodiment of the invention.

- FIG. 3Eis a back view of the optic block for the first embodiment of the invention.

- FIG. 3Fis a right side view of the optic block for the first embodiment of the invention.

- FIG. 3Gis a left side view of the optic block for the first embodiment of the invention.

- FIG. 3His a cross-sectional view of the optic block for the first embodiment of the invention.

- FIG. 3Iis a magnified cross-sectional view of the alignment post of the optic block.

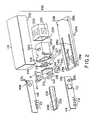

- FIG. 4is a simplified top cutaway view of another embodiment of the invention.

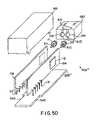

- FIG. 5Ais an exploded view of the embodiment of the invention of FIG. 4 .

- FIG. 5Bis an exploded view of an alternate embodiment of the invention of FIG. 4 .

- FIG. 5Cis an exploded view of another alternate embodiment of the invention of FIG. 4 .

- FIG. 5Dis an exploded view of another alternate embodiment of the invention of FIG. 4 .

- FIG. 6Ais a cross-sectional view from the top of the optic block for embodiments of the invention.

- FIG. 6Bis a front side view of the optic block for the embodiments of the invention.

- FIG. 6Cis a back side view of the optic block for the embodiments of the invention.

- FIG. 6Dis a top side view of the optic block for the embodiments of the invention.

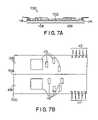

- FIG. 7Ais a top view of a manufacturing step of the invention.

- FIG. 7Bis a side view of a manufacturing step of the invention.

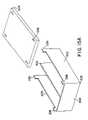

- FIG. 8Ais an exploded view of another embodiment of the invention.

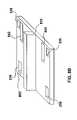

- FIG. 8Bis perspective view of an alternate baseplate for embodiments of the invention.

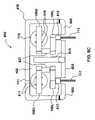

- FIG. 8Cis a rear cross sectional view of the assembled invention illustrated in FIG. 8A .

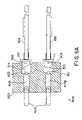

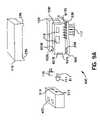

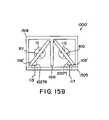

- FIG. 9Ais an exploded view of another embodiment of the invention.

- FIG. 9Bis a rear cross sectional view of the assembled invention illustrated in FIG. 9A .

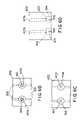

- FIG. 9Cillustrates an alternate embodiment of a single ground plane for a printed circuit board.

- FIG. 9Dillustrates an alternate embodiment of a single ground plane for a printed circuit board.

- FIG. 9Eillustrates an alternate embodiment of a ground plane sandwiched between layers in a multilayer printed circuit board.

- FIG. 10Ais an exploded view of another embodiment of the invention.

- FIG. 10Bis a rear cross sectional view of the assembled invention illustrated in FIG. 10A .

- FIG. 11Ais an exploded view of another embodiment of the invention.

- FIG. 11Bis a rear cross sectional view of the assembled invention illustrated in FIG. 11A .

- FIG. 12Ais an exploded view of another embodiment of the invention.

- FIG. 12Bis a rear cross sectional view of the assembled invention illustrated in FIG. 12A .

- FIG. 13illustrates a receive optical block and a transmit optical block as an alternative to a single optical block.

- FIG. 14Aillustrates how the pin configuration of the fiber optic modules can plug into a socket on a host printed circuit board.

- FIG. 14Billustrates how a socket configuration of the fiber optic modules can plug into a socket on a host printed circuit board.

- FIG. 14Cillustrates how a socket configuration of the fiber optic modules can horizontally plug into a socket on a host printed circuit board.

- FIG. 15Aillustrates a bottom perspective view of an alternate embodiment of the shielded housing or cover and base of the invention.

- FIG. 15Billustrates a rear cross sectional view of the assembled invention illustrated in FIG. 10A substituting the alternate embodiment of the shielded housing or cover of FIG. 15A .

- FIG. 15Cillustrates a rear cross sectional view of the alternate embodiment of the shielded housing or cover of FIG. 15A .

- FIG. 15Dillustrates a cross sectional view of another alternate embodiment of the shielded housing or cover.

- FIG. 15Eillustrates a cross sectional view of another alternate embodiment of the shielded housing or cover.

- FIG. 15Fillustrates a cross sectional view of another alternate embodiment of the shielded housing or cover.

- FIG. 15Gillustrates a cross sectional view of another alternate embodiment of the shielded housing or cover.

- FIG. 16Aillustrates a rear cross sectional view of an assembled alternate embodiment of the invention.

- FIG. 16Billustrates a rear cross sectional view of an assembled alternate embodiment of the invention.

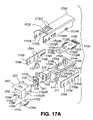

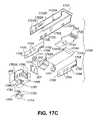

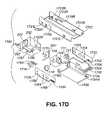

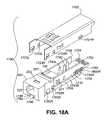

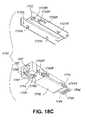

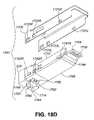

- FIGS. 17A–17Dillustrate exploded perspective views of an embodiment of the invention.

- FIGS. 18A–18Dillustrate a perspective views of the embodiment of the invention illustrated in FIGS. 17A–17D without the cover/housing assembled thereto.

- FIGS. 19A–19Eare views of an exemplary cage assembly or module receptacle for fiber optic modules.

- FIG. 20is a side view of an embodiment of a fiber optic module and an exemplary host connector without the exemplary cage assembly of FIGS. 19A–19E .

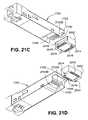

- FIGS. 21A–21Dare perspective views of an embodiment of a fiber optic module and an exemplary host connector without the exemplary cage assembly of FIGS. 19A–19E .

- FIGS. 22A–22Bare cross section views illustrating an embodiment of a fiber optic module coupling to the exemplary host connector of FIGS. 20 , 21 A– 21 D and the exemplary cage assembly of FIGS. 19A–19E .

- FIGS. 23A–23Cillustrate an example of how an electrical connection between the interface printed circuit board of an embodiment of the fiber optic module and the host connector of a host printed circuit board is formed.

- the embodiments of the inventioninclude a method, apparatus and system for vertical board construction of fiber optic transmitters, receivers and transceivers.

- fiber optic transmitter and receiver electrical elementsare implemented on at least two separate printed circuit boards (PCBs) in a fiber optic module.

- the separate boardsare arranged within the fiber optic module to reduce the footprint of the fiber optic module.

- bending light or photons through ninety degrees, the light transmitter (a packaged type of emitter) and a light receiver (a packaged type of photodetector)are each mounted substantially perpendicular to the transmit and receive boards respectively such that their active areas are nearly facing each other but offset.

- a single optical blockcan be used to implement lenses and reflecting surfaces to minimize manufacturing costs.

- the light receiver and light transmitterare mounted offset from each other in the optical block in order to avoid optical cross talk.

- the light transmitter (emitter) and the light receiver (photodetector)are each mounted substantially parallel with the transmit and receive boards respectively, the optical axis of transmitter and receiver and the connection to the optical fibers.

- the separate receive and transmit boardscan be provided with ground planes in order to minimize electrical cross talk.

- Preferably the ground planes on the back sides of the printed circuit boardsface each other.

- a module outer shielded housing or cover, manufactured out of metal or metal plated plastic,provides further shielding for EMI.

- the separate boardsmay be extended to support multiple channels or multiple parallel fibers such as in a ribbon optical fiber cable. Manufacturing steps of the boards for the fiber optic module are disclosed to provide reduced manufacturing costs.

- FIG. 1illustrates a fiber optic module 100 coupling to a pair of fiber optic cables 101 .

- Fiber optic module 100includes an optical block 102 and an electrical element 104 .

- the optical block 102may also be referred to as a nose, an optical port, an alignment block, an optical connector, an optical receptacle or receptacle.

- the optical block 102can interface to an optical connector such as an LC, MT-RJ or VF-45 optical connector.

- the electrical element 104includes a transmit printed circuit board (PCB) 106 , a receive PCB 108 , an optional internal shield 109 , a light transmitter 110 , a light receiver 111 , and a shielded housing or cover 119 .

- the light transmitter 110 and light receiver 111are optoelectronic devices for communicating with optical fibers using light of various wavelengths or photons.

- An optoelectronic deviceis a device which can convert or transduce light or photons into an electrical signal or an electrical signal into light or photons.

- the transmitter 110is a packaged emitter, that converts an electrical signal into emitting light or photons, such as a semiconductor laser or LED, preferably packaged in a TO can.

- the receiver 111is a packaged photodetector, that detects or receives light or photons and converts it into an electrical signal, such as a photo diode, preferably package in a TO can. However other packages, housings or covers, or optoelectronic devices for receiving and transmitting light or photon may be used for the receiver 111 or transmitter 110 .

- Each of the optoelectronic devices, receiver 111 and transmitter 110have terminals.

- terminals of one or more optoelectronic devicescouple to thruholes of the PCB 106 or PCB 108 or both.

- terminals of one or more optoelectronic devicescouple to an edge connector of the PCB 106 or PCB 108 or both.

- the transmit PCB 106includes electrical components 112 (transmitter integrated circuit (laser driver), resistors, capacitors and other passive or active electrical components), pins 113 , and a ground plane 114 .

- the electrical components 112control the transmitter 110 and buffer the data signal received from a system for transmission over an optical fiber.

- the receive PCB 108includes electrical components 116 (receiver integrated circuit (transimpedance amplifier and post amplifier), resistors, capacitors and other passive or active electrical components), pins 117 , and a ground plane 118 .

- the electrical components 116control the receiver 111 and buffer the data signal received from an optical fiber.

- the ground planes 114 and 118 and the shielded housing or cover 119are coupled to ground.

- a pin headerconsisting of a dielectric medium that is molded over a plurality of pins, is used to couple to through holes in the PCB 108 or PCB 106 .

- the electrical components 116 and pins 117are sandwiched between the ground plane 118 and the shielding 119 to shunt electromagnetic fields to ground and avoid crosstalk in the receive PCB 108 .

- Electrical components 112 and pins 113are sandwiched between the ground plane 114 and the shielded housing or cover 119 to shunt electromagnetic fields generated by these components to ground and avoid crosstalk in the transmit PCB 106 .

- Optional internal shielding 109further provides additional crosstalk protection between printed circuit boards. If ground planes 114 and 118 are not used, then internal shielding 109 is required to reduce the electromagnetic fields that may be generated.

- the optical block 102includes lenses 120 – 123 and reflectors 124 – 125 .

- Lenses 120 – 123may be any collimating lenses including aspheric lenses, ball lenses, and GRIN lenses.

- Lenses 121 – 123may be symmetric (circular symmetry) or asymmetric to provide optical steering.

- Lens 123is for collimating the light or photons diverging from the transmitter 110 and lens 122 is for focussing the collimated light or photons into an optical fiber.

- Lens 120is for collimating the light or photons diverging out from the end of an optical fiber and lens 121 is for focusing the collimated light or photons into the receiver 111 .

- Reflectors 124 – 125may be facets formed in the optical block having angles to provide total internal reflection between the optical block material and the atmosphere. Preferably they are forty five degree angle facets. Alternatively, they may be facets coated with a reflective surface or mirror surface to reflect light or photons off the reflective coated surface or facets having an optical grating surface to reflect photons.

- the optical block 102is preferably constructed of a thermoplastic or polycarbonate which is clear to the desired wavelengths of light or photons.

- the reflectors 124 – 125 , lenses 120 – 123 and other elements of the optical block 102 described beloware preferably formed through injection molding of the desired material.

- Transmitter 110is inserted into an opening 214 in the optical block 102 .

- Receiver 111is inserted into an opening 213 in optical block 102 .

- An epoxyis injected into top and bottom tacking holes 215 in order to hold the transmitter 110 and receiver 111 in openings 214 and 213 respectively.

- An MT alignment plate 201has optical block alignment holes 216 , an optical opening 217 and fiber optic connector alignment pins 218 for alignment purposes.

- the optical block holes 216couple to optical block alignment pins in the optical block 102 , not illustrated in FIG. 2 .

- the fiber optic connector alignment pins 218are for aligning optical fibers that couple to the fiber optic module 100 .

- the fiber optic module 100has a nose 202 and a nose shield 203 .

- the nose 202includes an optical fiber opening 222 and a latch opening 223 .

- the latch opening 223receives the optical fiber connector and holds the optical fiber substantially fixed in place and aligned with the optical opening 217 of the alignment plate 201 .

- the nose shield 203includes an opening 224 for insertion over the nose 202 and shield tabs 225 for coupling to the ground plane of the package.

- the nose shielding 203further reduces EMI.

- the transmitter 110 and receiver 111may be aligned to provide optimal light or photon output and reception. Alignment of the transmitter 110 and receiver 111 in optical block 102 is performed by active alignment where the receiver 111 and transmitter 110 are powered up to detect and emit photons. The receiver 111 and transmitter 110 are properly aligned in the optical block 102 to provide maximum photon detection from or coupling into fiber 101 .

- the tacking holes 215extend into the openings 213 and 214 such that epoxy may poured in to hold the optoelectronic devices to the optical block. After alignment is complete, the epoxy is UV cured and allowed to set such that the receiver 111 and transmitter 110 are substantially coupled to the optical block 102 .

- the receive PCB 108 and the transmit PCB 106may be attached to the receiver 111 and transmitter 110 respectively.

- Receiver thruholes 232 in the receive PCB 108are aligned and slid over terminals 211 of the receiver 111 .

- the terminals 211are then soldered to make an electrical connection on the component side (opposite the side of the ground plane 118 ) of the receive PCB 108 .

- Transmitter thruholes 233 in the transmit PCB 106are aligned and then slid over the terminals 210 of the transmitter 110 .

- the terminals 210are then soldered to make an electrical connection on the component side (opposite the side of the ground plane 114 ) of transmit PCB 106 .

- Ground planes 114 and 118have sufficient material removed around the transmitter thruholes 233 and the receiver thruholes 232 respectively to avoid shorting the terminals of the transmitter 110 and receiver 111 to ground.

- the assemblyis inserted into the shielded housing or cover 119 .

- the optional internal shield 109is next assembled into the shielded housing or cover 119 between the PCBs 106 and 108 .

- the optional internal shield 109has pin slots 230 to surround the pins 113 and 117 and avoid shorting thereto.

- the shielded housing or cover 119includes clips or tabs 236 at each corner for mating to a base 205 .

- the base 205includes PCB slots 240 , clip openings or slots 238 into which the clips or tabs 236 may be inserted, and base pin holes 242 into which the PCB pins 113 and 117 may be inserted.

- the base 205includes a guide post 244 for mounting the fiber optic module into a system printed circuit board. The bottom of the base mounts parallel to the printed circuit board of the system such that when horizontal, the receive PCB 108 and the transmit PCB 106 are vertical and substantially perpendicular in reference to the printed circuit board of the system and the base 205 .

- the base 205has its base pin holes 242 slid over the PCB pins 113 and 117 , the printed circuit boards 106 and 108 are guided to mate with the PCB slots 240 , and the clips or tabs 236 of the shielded housing or cover 119 are guided into the clip openings or slots 238 .

- the receive PCB pins 113 and the transmit PCB pins 117are vertical and substantially perpendicular in reference to the printed circuit board of the system and the base 205 .

- the clips or tabs 236are bent, twisted, or otherwise changed in order to hold the base 205 in place.

- the shielded housing or cover 119may use plastic clips, or a ridge, integrated into each side that couples to base 205 appropriately.

- the shielded housing or cover 119which is coupled to ground, encases the PCBs 106 and 108 to reduce the electromagnetic fields generated by the electrical components coupled thereto by shunting the electric fields to ground to reduce electromagnetic interference (EMI).

- EMIelectromagnetic interference

- the transmitter 110 , the receiver 111 , and the MT alignment plate 201are coupled to the optical block 102 .

- the light transmitter 110includes an emitter 302 for generation of light or photons in response to electrical signals from the transmit PCB 106 .

- the light receiver 111includes a detector 304 to receive light or photons and generate electrical signals in response to light or photons coupled thereto.

- Light or photons emitted by the emitter 302are coupled into lens 123 and collimated onto the reflector 125 at an incident angle I 1 (angle with the perpendicular to reflector 125 surface) preferably of substantially forty five degrees.

- Reflector 125reflects the incident light or photons on a refraction angle R 1 (angle with the perpendicular to reflector 125 surface) equivalent to incident angle I 1 preferably of substantially forty five degrees.

- the reflected light or photonspreferably travel perpendicular to the incident light or photons towards the lens 122 .

- Lens 122focuses the light or photons from the emitter 302 into an aligned optical fiber through the optical port 217 in the MT alignment plate 201 .

- light or photons coupled or launched into an optical fiber, defining a first optical axisare preferably substantially perpendicular to the light or photons emitted and incident upon lens 123 from the emitter 302 of the transmitter 110 .

- Lens 120collimates the incident light or photons from a fiber optic cable onto the reflector 124 at an incident angle I 2 of preferably substantially forty five degrees.

- Reflector 124reflects incident light or photons at a refractive angle R 2 equivalent to incident angle I 2 of preferably substantially forty five degrees towards lens 121 .

- Lens 121focuses the light or photons received from a fiber optical cable onto the detector 304 .

- Light or photons incident from a fiber optic cable, defining a second optical axis,are preferably substantially perpendicular to the light or photons incident upon the detector 304 .

- FIG. 3Billustrates a frontal perspective view from the left side of the optical block 102 .

- the front side of the optical block 102includes optical block alignment pins 316 and an optical output opening 317 .

- the optical block alignment pins 316couple to the alignment holes 216 of the alignment plate 201 such that the optical output opening 317 is aligned with the optical port 217 in the alignment plate 201 .

- FIG. 3Cillustrates the front side of the optical block 102 .

- the optical output opening 317is indicated.

- FIG. 3Dis a back side perspective view from the right of the optical block 102 .

- the back side of the optical block 102includes a cavity 322 that is used to form the shape of the reflective surfaces 124 – 125 during manufacturing of the optical block 102 .

- FIG. 3Eis a back view of the optic block illustrating the opening into the cavity 322 .

- FIG. 3Fillustrates the right side of the optical block 102 which has the opening 214 to mate with the type of housing of the transmitter 110 .

- the lens 123can be viewed near the center of the opening 214 .

- FIG. 3Gillustrates the left side of the optical block 102 . which has the opening 213 to mate with the type of housing of the receiver 111 .

- the lens 121can be viewed near the center of the opening 213 . Comparing FIGS. 3F and 3G , the offset between openings 213 and 214 to avoid optical crosstalk is visible.

- receiver 111is closer to the optical opening 317 in order to minimize the loss of incoming received optical power. However, the position of receiver 111 and transmitter 110 can be interchanged.

- FIG. 3Gillustrates the right side of the optical block 102 which has the opening 214 to mate with the type of housing of the transmitter 110 .

- the lens 123can be viewed near the center of the opening 214 .

- FIG. 3Gillustrates the left

- FIG. 3His a cross-sectional view of the optical block 102 illustrating the relative position of the optical block alignment posts 316 .

- the area 324 surrounding the alignment post 316is magnified in FIG. 3I .

- FIG. 3Iprovides a magnified cross-sectional view of the alignment post 316 .

- FIG. 4illustrates another embodiment of the invention.

- a fiber optic module 400includes an optical block 402 and electrical elements 404 .

- the optical block 402may also be referred to as a nose, an optical port, an alignment block, an optical connector, an optical receptacle or receptacle.

- the optical block 402can interface to an optical connector such as an LC, MT-RJ or VF-45 optical connector.

- Electrical elements 404include transmitter PCB 106 , receiver PCB 108 , light receiver 111 , light transmitter 110 , and a shielded housing or cover 419 .

- Shielded housing or cover 419may be narrower than shielded housing or cover 119 due to receiver 111 and transmitter 110 being parallel with the PCBs 108 and 106 .

- the optical or alignment block 402may include lens 423 and lens 421 for coupling light or photons into and out of the fiber optic cable 101 .

- the lens 423 and 421may be coupled to the receiver 111 and transmitter 110 .

- Lens 423 and 421may be spherical lenses or each may be a pair of aspheric lenses on the same optical axis.

- Light or photons emitted by the transmitter 110are collected and focused by lens 423 into a transmit fiber optic cable.

- Light or photons on a receive fiber optic cableare collected and focused by lens 421 into the receiver 111 .

- fiber optic module 400preferably keeps light or photons substantially in parallel and does not have to reflect the light or photons to couple it with receiver 111 or transmitter 110 .

- FIG. 5Aillustrates an exploded diagram of the fiber optic module 400 .

- Fiber optic module 400is assembled similar to fiber optic module 100 as previously described with reference to FIG. 2 .

- optical or alignment block 402differs from optical block 102 .

- Receiver 111 and transmitter 110are inserted into openings 513 and 514 respectively in the optical or alignment block 402 .

- the receiver and transmittermay be held in place by a press fit or glued in place.

- an epoxy or glueis injected in top and bottom tacking holes 515 of the optical or alignment block 402 while the receiver 111 and transmitter 110 are tested and aligned to substantially couple light or photons into and out of fiber optic cables.

- the transmit PCB 106 and the receive PCB 108are coupled respectively to the transmitter 110 and the receiver 111 .

- the terminals 511 and 510 of the receiver 111 and the transmitter 110respectively are soldered directly onto the PCB.

- the high frequency pins associated with the receiver 111 and transmitter 110are preferably soldered on the component side of the printed circuit boards in order to provide proper shielding.

- the alignment plate 201 , the nose 202 and the nose shielding 203are unnecessary in this embodiment of the invention. Fiber ferrules are utilized instead for alignment between the optical or alignment block 402 and the optical fibers 101 .

- Fiber optic module 400 ′is assembled similar to fiber optic module 400 as previously described with reference to FIG. 5A but a different base 205 ′ is utilized.

- the base 205 ′differs from base 205 in that it has a pair of guide rails 540 to hold the PCBs 106 and 108 in place and a pair of cutouts or open slots 542 for the pins 113 and 117 to extend through. In this manner, the PCBs 106 and 108 may slide into place onto the base 205 ′.

- Fiber optic module 400 ′′is assembled similar to fiber optic module 400 as previously described with reference to FIG. 5A but a different base 205 ′′ is utilized.

- the base 205 ′′differs from base 205 in that it has pairs of mounting brackets 540 ′ to hold the PCBs 106 and 108 in place and a pair of openings 542 ′ for the pins 113 and 117 to extend through.

- FIG. 5Dillustrates an exploded view of a fiber optic module 400 ′′′.

- Fiber optic module 400 ′′′is assembled similar to fiber optic module 400 as previously described with reference to FIG. 5A but a different base 205 ′′′ is utilized and a slightly different optical block 502 is utilized.

- the base 205 ′′′differs from base 205 in that there are no slots 240 and that there are a pair of cutouts or open slots 542 for the pins 113 and 117 to extend through.

- the optical block 502differs from the optical block 402 in that a pair of slots 525 are provided to align the PCBs 106 and 108 with the optical block.

- the transmitter 110 and the receiver 111are coupled to the optical or alignment block 402 .

- the transmitter 110includes an emitter 302 for generation of light or photons.

- the receiver 111includes a detector 304 to receive light or photons.

- Light or photons emitted by the emitter 302are coupled into lens 423 , collected and focused into the optical fiber through the optical port 417 A.

- Light or photons, incident from a fiber optic cable coupled to the fiber optic module 400is received through the optical port 417 B. Photons from the fiber optic cable are incident upon the lens 421 .

- Lens 421collects and focuses the incident light or photons from the fiber optic cable onto the detector 304 of the receiver 111 .

- a pair of fiber ferrules 421are provided. The fiber ferrules 421 are inserted into the optical ports 417 A and 417 B.

- FIG. 6Billustrates the front side of the optical or alignment block 402 .

- the front side of the optical or alignment block 402includes optical output ports 417 A and 417 B.

- the lens 421is visible through the optical output port 417 B and lens 423 is visible through the optical output port 417 A.

- FIG. 6Cis an illustration of the back side of the optical or alignment block 402 .

- the lens 421is visible through opening 513 and lens 423 is visible through opening 514 .

- FIG. 6Dillustrates the top side of the optical or alignment block 402 which has the tacking holes 515 coupling to the openings 513 and 514 . Epoxy may be inserted into the top and bottom tacking holes 515 to hold the transmitter 110 and receiver 111 in position in the optical or alignment block 402 .

- Transmit PCB 106 and receive PCB 108are assembled as one unit on one printed circuit board 700 with a center score 702 defining a boundary line between transmit and receive components. After all components have been attached and assembled onto the unitary PCB 700 , the PCB 700 is flexed along the score 702 such that the transmit PCB 106 and the receive PCB 108 may be separated. Transmit PCB 106 and the receive PCB 108 may thereafter be assembled as part of the fiber optic module 100 and the fiber optic module 400 .

- the transmit PCB 106 and the receive PCB 108may each be approximately 6.5 mm in height excluding pins 113 and 117 .

- FIG. 8Aillustrates an exploded view of a fiber optic module 800 .

- the fiber optic module 800includes an upper transmit PCB 106 U, a lower transmit PCB 106 L, an upper receive PCB 108 U, a lower receive PCB 108 L, the transmitter 110 , the receiver 111 , the optical block 402 , the shielded housing or cover 419 , a first and second PCB interconnect pin headers 827 , a first terminal pin header 813 for the transmitter, a second terminal pin header 817 for the receiver, and a baseplate 805 .

- the transmitter 110is a transmit optical subassembly (Tx OSA) that includes a VCSEL or other semiconductor device that transduces electrical signals into photons or a light output.

- the receiver 111is a receive optical subassembly (Rx OSA) including a PIN diode or other device that converts photons or light input into electrical signals.

- the Tx OSA and Rx OSAare attached to physically separated transmit and receive electrical subassemblies (ESA's).

- the transmit ESAincludes an upper and lower transmit PCBs 106 U and 106 L with components 116 mounted thereto.

- the receive ESAincludes an upper and lower receive PCBs 108 U and 108 L with components 112 mounted thereto.

- the lower transmit PCB 106 L and the upper transmit PCB 106 Uprovide similar functionality to that of the transmit PCB 106 and include components 112 .

- the lower receive PCB 108 L and the upper receive PCB 108 Uprovide similar functionality to that of the receive PCB 108 and include components 116 .

- the upper and lower transmit PCBs 106 U and 106 Lare parallel to each other in a horizontal plane and parallel with the optical axis of the transmitter 110 .

- the upper and lower receive PCBs 108 U and 108 Lare parallel to each other in a horizontal plane and parallel with the optical axis of the receiver 111 .

- This configuration of parallel horizontal boards for each of the transmit and receive capabilitycan be referred to as dual-stack horizontal modular PCBs.

- the first and second pin interconnect headers 827include the conductive signal pins 837 molded into a non-conductive medium.

- the first and second pin interconnect headers 827are used to interconnect lower and upper PCB's.

- the first pin header 827provides signal interconnection between the upper and lower transmit PCBs 106 U and 106 L.

- the first pin header 827provides signal interconnection between the upper and lower transmit PCBs 106 U and 106 L.

- the second pin header 827provides signal interconnection between the upper and lower receive PCBs 108 U and 108 L.

- the second pin header 827has pins 837 that couple into upper throughholes 847 U in the upper receive PCB 108 U and lower through holes 847 L in the lower receive PCB 108 L.

- the first pin header 827similarly has pins 837 that couple into upper and lower throughholes in the upper and lower transmit PCBs 106 U and 106 L respectively.

- the first and second terminal pin headers 817 and 813include conductive signal pins molded into a non-conductive medium.

- the first and second terminal pin headers 817 and 813are used to route electrical signals to and from the fiber optic module 800 to a host system.

- the first terminal pin header 813has pins 113 that couple to through holes 842 in the lower transmit PCB 106 L.

- the second terminal pin header 817has pins 117 that couple to through holes 842 in the lower receive PCB 108 L.

- the transmitter 110couples to the upper transmit PCB 106 U in one embodiment.

- the terminals 810 of the transmitter 110couple to the upper transmit PCB 106 U in one embodiment.

- one or more terminalscouple to upper edge traces 820 U on a top side of the upper transmit PCB 106 U and one or more terminals couple to lower edge traces 820 L on a back side of the upper transmit PCB 106 U.

- the optoelectronic devicei.e. the transmitter 110 or the receiver 111

- the terminals 810may couple to the lower transmit PCB 106 U.

- the terminals 810may couple between the upper and lower receive PCBs so that one or more couple to the upper PCB and one or more couple to the lower PCB.

- the terminals 810may couple into holes of the upper or lower transmit PCBs or both upper and lower transmit PCBs.

- the optoelectronic devicei.e. the transmitter 110 or the receiver 111

- the optoelectronic devicehas its optical axis nearly parallel with a plane of the printed circuit board.

- the receiver 111couples to the upper receive PCB 108 U in one embodiment.

- the terminals 811 of the receiver 111couple to the upper receive PCB 108 U in one embodiment.

- one or more terminalscouple to upper edge traces 821 U on a top side of the upper receive PCB 108 U and one or more terminals couple to lower edge traces 821 L on a back side of the upper receive PCB 108 U.

- the terminals 811may couple to the lower receive PCB 108 U.

- the terminals 811may couple between the upper and lower receive PCBs so that one or more couple to the upper PCB and one or more couple to the lower PCB.

- the terminals 811may couple into holes of the upper or lower receive PCBs or both upper and lower receive PCBs.

- the baseplate 805may include an inner septum 815 that divides the transceiver and receiver into two separate cavities, for EMI and electrical isolation of the transmitter from the receiver or between channels.

- the baseplate 805acts like a chassis or frame to provide support for the shielded housing or cover 419 and the receiver and transmit subassemblies.

- the baseplate 805may include an inner septum 815 , one or more openings 242 to receive the pins 113 and 117 , and one or more clip openings or slots 238 to receive the clips or tabs 236 .

- the baseplate 805in one embodiment is plastic in other embodiments that baseplate may be metal or a metalized plastic to provide shielding.

- the inner septum 815provides separation between the transmitter and the receiver or between channels.

- Baseplate 805 ′differs from baseplate 805 in that it includes slots 842 for pins 113 and 117 .

- Baseplate 805 ′may similarly include clip openings or slots 238 and the inner septum 815 .

- the baseplate 805 with the inner septum 815can divide the fiber optic module 800 into two separate cavities.

- the separate cavitiescan improve EMI and electrical isolation of the transmitter from the receiver.

- the receiver 111couples to the upper receive PCB 108 U with its terminals 811 using a straddle mount in one embodiment.

- the transmitter 111couples to the upper transmit PCB 106 U with its terminals 810 using a straddle mount in one embodiment.

- the upper and lower transmit PCBs 106 U and 106 Lare parallel to each other in a horizontal plane and parallel with the optical axis of the transmitter 110 .

- the upper and lower receive PCBs 108 U and 108 Lare parallel to each other in a horizontal plane and parallel with the optical axis of the receiver 111 .

- This configuration of parallel horizontal boards for each channelcan be referred to as dual-stack horizontal modular PCBs.

- the dual stacked horizontal PCB'sallow an increase in component surface mounting area for a given volume. Both sides of the upper and lower transmit and receive PCB's can be utilized to mount electronic components. This increased surface area can provide increased functionality in a fiber optic module by allowing additional components such as integrated circuits and passive components such as filters, capacitors, and inductors to be utilized.

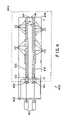

- FIG. 9Aillustrates an exploded view of a fiber optic module 900 .

- the fiber optic module 900utilizes a motherboard which is common to daughtercards PCBs which are substantially perpendicular to the motherboard. Assuming the motherboard is horizontal, the daughtercard PCBs are substantially vertical to the motherboard and can be also be referred to as vertical PCBs. The substantially vertical PCB's couple to the common motherboard.

- the fiber optic module 900includes a vertical transmit PCB 106 ′ and a vertical receive PCB 108 ′ in parallel coupled to a horizontal motherboard PCB 905 .

- the motherboard PCB 905can separate ground and power planes between receiver and transmitter channels in order to maximize isolation and minimize cross talk.

- the vertical transmit PCB and the vertical receive PCBmay have traces soldered to traces of the motherboard for electrical connectivity or otherwise include pins that plugged into holes or sockets of the motherboard to ease replacement or to expand the number of transmit or receive channels with additional transmit PCBs or receive PCBs.

- the electrical connection between the vertical transmit PCB and the vertical receive PCB and motherboard PCBmay be made with electrical connectors in lieu of solder joints.

- the mother board PCBincludes Input/Output Pins (I/O Pins) or an I/O socket connector to couple to holes or a socket of a host system PCB to interface with a host system.

- the vertical transmit PCB and the vertical receive PCBprovides mounting surfaces for components on both the left and right side surfaces (or front and back surfaces). Additionally, a top surface of the motherboard PCB 905 may also be used to mount components or circuits for increased electrical functionality such as a clock/data recovery (CDR) function and minimize the form factor of the fiber optic module.

- CDRclock/data recovery

- an inner shield similar to the shield 109may be used.

- one or both of the vertical transmit PCB and the vertical receive PCBmay have a ground plane on of its left or right side surfaces (sometimes referred to as a backside ground plane).

- the vertical PCBs 106 ′ and 108 ′are similar to PCBs 106 and 108 but for the coupling to the horizontal motherboard PCB 905 .

- the vertical PCBs 106 ′ and 108 ′have signal traces soldered to signal traces of the horizontal motherboard PCB 905 which can also mechanically support the vertical PCBs 106 ′ and 108 ′.

- Solder joints 917 Rcouple the receive PCB 108 ′ to the horizontal motherboard PCB 905 .

- Solder joints 917 Tcouple the transmit PCB 106 ′ to the horizontal motherboard PCB 905 (see FIG. 9B ).

- the fiber optic module 900can be referred to as having vertical PCB's with a horizontal motherboard PCB.

- the horizontal motherboard PCB 905includes input/output (I/O) pins 113 and 117 to couple to a host system and wire traces to route power, ground and signals between the pins 113 and 117 and the vertical PCBs 106 ′ and 108 ′.

- I/Oinput/output

- the fiber optic module 900further includes the transmitter 110 , the receiver 111 , the optical block 402 , and the shielded housing or cover 419 .

- the shielded housing or cover 419has clips or tabs 236 that couple into clip openings or slots 238 in the motherboard PCB 905 .

- the clips or tabs 236can be held in place in the slots by a friction fit or glued in place or they may extend through the motherboard PCB 905 and be turned and or bent to couple the shielded housing or cover 419 and the motherboard PCB 905 together.

- the clips or tabs 236 of the shielded housing or cover 419can wrap around the motherboard PCB 905 to couple them together.

- the transmitter 110couples into the opening 514 of the optical block 402 .

- the receiver 111couples into the opening 513 of the optical block. They are held in place by either a friction fit or a glue such as an epoxy.

- the transmitter 110couples to the transmit PCB 106 ′.

- the terminals 810 of the transmitter 110couple to the transmit PCB 106 ′.

- one or more terminals 810couple to left edge traces 920 L on a left side and one or more terminals 810 couple to right edge traces 920 R on a right side of the transmit PCB 106 ′.

- the terminals 810may couple to one side of the transmit PCB 106 ′.

- the terminals 810may couple into holes of the transmit PCB 106 ′.

- the receiver 111couples to the receive PCB 108 ′.

- the terminals 811 of the receiver 111couple to the receive PCB 108 ′.

- one or more terminals 811couple to left edge traces 921 L on a left side and one or more terminals 811 couple to right edge traces 921 R on a right side of the receive PCB 108 ′.

- the terminals 811may couple to one side of the receive PCB 108 ′.

- the terminals 811may couple into holes of the receive PCB 108 ′.

- FIG. 9Ba rear cross-sectional view of the assembled fiber optic module 900 is illustrated.

- Traces 920 on the motherboard PCBroute signals to components on the motherboard PCB, the I/O pins 113 and 117 , and the solder joints 917 R and 917 T.

- a ground plane 118can be coupled to a side the vertical receive PCB 108 ′ or a ground plane 114 can be coupled to a side of the vertical transmit PCB 106 ′ or both.

- the vertical transmit PCB 106 ′includes the ground plane 114 and the vertical receive PCB 108 ′ is without a ground plane to allow room for added components 116 on each side; Referring to FIG.

- the vertical receive PCB 108 ′includes the ground plane 118 and the vertical transmit PCB 106 ′ is without a ground plane to allow room for added components 112 on each side.

- An optional inner shield 109can also be used for further isolation between channels to reduce cross-talk and EMI as illustrated in FIG. 9B .

- the ground plane 114 and 118will have cutouts for traces to coupled to the terminals 810 and 811 and may have additional cutouts for components 112 or 116 as the case may be. Referring now to FIG.

- the ground plane 118 or the ground plane 114may be alternatively sandwiched between layers of either the vertical receive PCB 108 ′ or the vertical transmit PCB 106 ′ or both as a part of a multilayer PCB as illustrated by FIG. 9C . This can allow for further components 116 and 112 to be added to both sides of the vertical receive PCB 108 ′ and the vertical transmit PCB 106 ′.

- FIG. 10Aillustrates an exploded view of a fiber optic module 1000 .

- the fiber optic module 1000has angled PCBs with respect to a horizontal or vertical axis of the fiber optic module 1000 .

- the length of the PCBsremain parallel to the optical axis of the receiver 111 and transmitter 110 .

- the PCBsmay be made smaller to fit a smaller form factor or alternatively the surface area can be increased. That is the available PCB surface area for mounting components can be increased for a given volume by angling the PCBs.

- the increased surface areacan give the final assembled fiber optic module increased functionality by allowing components such as integrated circuits and passive components such as filters, capacitors, and inductors to be added. More room can also be provided in the fiber optic module 1000 for mounting larger components by angling the PCBs.

- the fiber optic module 1000includes an angled transmit PCB 106 ′′, an angled receive PCB 108 ′′, the transmitter 110 , the receiver 111 , an optical block 402 ′, the shielded housing or cover 419 , a first terminal pin header 1027 T for the transmitter, a second terminal pin header 1027 R for the receiver, and the baseplate 805 or 805 ′.

- the angled transmit PCB 106 ′′ and the angled receive PCB 108 ′′are arranged within the fiber optic module at an angle with respect to the horizontal axis thereof as defined by a line normal to both receiver and transmitter optical axes.

- the angled transmit PCB 106 ′′ and the angled receive PCB 108 ′′are held in place having a width that is on an angle with respect to a horizontal or vertical axis of the fiber optic module 1000 .

- the length of the angled transmit PCB 106 ′′ and the angled receive PCB 108 ′′are parallel to the optical axis of the receiver 111 and transmitter 110 .

- the angled transmit PCB 106 ′′includes components 116 and left and right edge traces 921 L and 921 R.

- the first terminal pin header 1027 Thas pins 117 that couple to holes of the angled transmit PCB 106 ′′ on one end.

- the angled receive PCB 108 ′′includes components 112 and left and right edge traces 920 L and 920 R.

- the second terminal pin header 1027 Rhas pins 113 that couple to holes of the angled receive PCB 108 ′′ on one end.

- the transmitter 110is a transmit optical subassembly (Tx OSA) that includes a VCSEL or other semiconductor device that transduces electrical signals into photons or a light output.

- the receiver 111is a receive optical subassembly (Rx OSA) including a PIN diode or other device that converts photons or light input into electrical signals.

- the Tx OSA and Rx OSAare attached to physically separated transmit and receive electrical subassemblies (ESA's).

- the transmit ESAincludes the angled transmit PCB 106 ′′ with components 116 and the first terminal pin header 1027 T mounted thereto.

- the receive ESAincludes the angled receive PCB 108 ′′ with components 112 and the second terminal pin header 1027 R mounted thereto.

- the optical block 402 ′is similar to the optical block 402 but has some modifications to accommodate the angled transmit PCB 106 ′′ and the angled receive PCB 108 ′′.

- the optical block 402 ′includes openings 513 ′ and 514 ′ to receive the receiver 111 and transmitter 110 respectively and angled slots 1015 to receive the angled transmit PCB 106 ′′ and the angled receive PCB 108 ′′.

- the angled slots 1015can provide a friction fit with the angled transmit PCB 106 ′′ and the angled receive PCB 108 ′′ or glue or epoxy can be used to couple them together.

- the angled slots 1015can also serve to tack the receiver 111 and transmitter 110 in place within the optical block 402 ′.

- the transmitter 110couples into the opening 514 ′ of the optical block 402 ′.

- the receiver 111couples into the opening 513 ′ of the optical block 402 ′. They can be held in place by either a friction fit or a glue such as an epoxy.

- the transmitter 110also couples to the transmit PCB 106 ′′.

- the terminals 810 of the transmitter 110couple to the transmit PCB 106 ′′ in one embodiment.

- one or more terminals 810couple to left edge traces 920 L on a left side and one or more terminals 810 couple to right edge traces 920 R on a right side of the transmit PCB 106 ′′.

- the terminals 810may couple to one side of the transmit PCB 106 ′′.

- the terminals 810may couple into holes of the transmit PCB 106 ′′.

- the receiver 111also couples to the receive PCB 108 ′′.

- the terminals 811 of the receiver 111couple to the receive PCB 108 ′′.

- one or more terminals 811couple to left edge traces 921 L on a left side and one or more terminals 811 couple to right edge traces 921 R on a right side of the receive PCB 108 ′′.

- the terminals 811may couple to one side of the receive PCB 108 ′′.

- the terminals 811may couple into holes of the receive PCB 108 ′′.

- the first terminal pin header 1027 Tis coupled to the angled transmit PCB 1027 T so that pins 117 are vertical with the reference axis.

- the second terminal pin header 1027 Ris coupled to the angled receive PCB 108 ′′ so that pins 113 are vertical with the reference axis.

- a ground plane 118can be coupled to a side the angled receive PCB 108 ′′ or a ground plane 114 can be coupled to a side of the angled transmit PCB 106 ′′ or both similar to previously described with reference to the vertical boards and FIGS. 9B–9E .

- the shield housing or cover 419couples to the base or baseplate 805 or 805 ′ around the printed circuit boards.

- the angles ⁇ 1 and ⁇ 2 which the printed boards make with the base or baseplate 805 or 805 ′can vary between zero and ninety degrees.

- FIG. 11Aillustrates an exploded view of a fiber optic module 1100 .

- the fiber optic module 1100has parallel angled or slanted PCBs with respect to a horizontal or vertical axis of the fiber optic module 1100 .

- the length of the PCBsremain parallel to the optical axis of the receiver 111 and transmitter 110 .

- the PCBsmay be made smaller to fit a smaller form factor or alternatively the surface area can be increased. That is the available PCB surface area for mounting components can be increased for a given volume by angling the PCBs.

- the increased surface areacan give the final assembled fiber optic module increased functionality by allowing components such as integrated circuits and passive components such as filters, capacitors, and inductors to be added. More room can also be provided in the fiber optic module 1100 for mounting larger components by angling the PCBs in parallel together.

- the fiber optic module 1100includes an angled transmit PCB 106 ′′′, an angled receive PCB 108 ′′′, the transmitter 110 , the receiver 111 , an optical block 402 ′′, the shielded housing or cover 419 , a first terminal pin header 1027 T′ for the transmitter, a second terminal pin header 1027 R′ for the receiver, and a baseplate 805 ′′.

- the angled transmit PCB 106 ′′′ and the angled receive PCB 108 ′′′are arranged in parallel and at an angle with respect to a horizontal datum plane that passes through and is normal to receiver and transmitter optical axes.

- the angled transmit PCB 106 ′′′ and the angled receive PCB 108 ′′′are slanted in parallel to the right but can be easily arranged so as to slant in parallel to the left.

- the angled transmit PCB 106 ′′′ and the angled receive PCB 108 ′′′are held in place having a width that is on an angle with respect to a horizontal or vertical axis of the fiber optic module 1100 .

- the length of the angled transmit PCB 106 ′′′ and the angled receive PCB 108 ′′′are parallel to the optical axis of the receiver 111 and transmitter 110 .

- the angled transmit PCB 106 ′′′includes components 116 and left and right edge traces 921 L and 921 R.

- the first terminal pin header 1027 T′has pins 117 that couple to holes of the angled transmit PCB 106 ′′′ on one end.

- the angled receive PCB 108 ′′′includes components 112 and left and right edge traces 920 L and 920 R.

- the second terminal pin header 1027 R′has pins 113 that couple to holes of the angled receive PCB 108 ′′′ on one end.

- the transmitter 110is a transmit optical subassembly (Tx OSA) that includes a VCSEL or other semiconductor device that transduces electrical signals into photons or a light output.

- the receiver 111is a receive optical subassembly (Rx OSA) including a PIN diode or other device that converts photons or light input into electrical signals.

- the Tx OSA and Rx OSAare attached to physically separated transmit and receive electrical subassemblies (ESA's).

- the transmit ESAincludes the angled transmit PCB 106 ′′′ with components 116 and the first terminal pin header 1027 T′ mounted thereto.

- the receive ESAincludes the angled receive PCB 108 ′′′ with components 112 and the second terminal pin header 1027 R′ mounted thereto.

- the baseplate 805 ′′is similar to the baseplate 805 and 805 ′ but has angled inner septum 815 ′ to be angled in parallel with the angled transmit PCB 106 ′′′ and the angled receive PCB 108 ′′′.

- the baseplates 805 , 805 ′, 805 ′′in one embodiment may be a dielectric to isolate components and insulate them from one another.

- baseplates 805 , 805 ′, 805 ′′may be an insulator.

- baseplates 805 , 805 ′, 805 ′′may have their septum 815 or 815 ′ metalized so as to provide EMI and crosstalk shielding.

- a metal shieldmy be placed on top of the septum 815 or 815 ′ such as shield 109 .

- the optical block 402 ′′is similar to the optical block 402 but has some modifications to accommodate the angled transmit PCB 106 ′′′ and the angled receive PCB 108 ′′′.

- the optical block 402 ′′includes openings 513 ′′ and 514 ′′ to receive the receiver 111 and transmitter 110 respectively and angled slots 1115 to receive the angled transmit PCB 106 ′′′ and the angled receive PCB 108 ′′′.

- the angled slots 1115can provide a friction fit with the angled transmit PCB 106 ′′′ and the angled receive PCB 108 ′′′ or glue or epoxy can be used to couple them together.

- the angled slots 1115can also serve to tack the receiver 111 and transmitter 110 in place within the optical block 402 ′′.

- the transmitter 110couples into the opening 514 ′′ of the optical block 402 ′′.

- the receiver 111couples into the opening 513 ′′ of the optical block 402 ′′. They can be held in place by either a friction fit or a glue such as an epoxy.

- the transmitter 110also couples to the transmit PCB 106 ′′′.

- the terminals 810 of the transmitter 110couple to the transmit PCB 106 ′′′ in one embodiment.

- one or more terminals 810couple to left edge traces 920 L on a left side and one or more terminals 810 couple to right edge traces 920 R on a right side of the transmit PCB 106 ′′′.

- the terminals 810may couple to one side of the transmit PCB 106 ′′′.

- the terminals 810may couple into holes of the transmit PCB 106 ′′′.

- the receiver 111also couples to the receive PCB 108 ′′′.

- the terminals 811 of the receiver 111couple to the receive PCB 108 ′′′.

- one or more terminals 811couple to left edge traces 921 L on a left side and one or more terminals 811 couple to right edge traces 921 R on a right side of the receive PCB 108 ′′′.

- the terminals 811may couple to one side of the receive PCB 108 ′′′.

- the terminals 811may couple into holes of the receive PCB 108 ′′′.

- FIG. 11Ba rear cross-sectional view of the assembled fiber optic module 1100 is illustrated.

- the angled receive PCB 108 ′′′ and the angled transmit PCB 106 ′′′ of the fiber optic module 1100are angled in parallel together with respect to a horizontal or vertical axis thereof.

- the first terminal pin header 1027 T′is coupled to the angled transmit PCB 1027 T′ so that pins 117 are vertical with the reference axis.

- the second terminal pin header 1027 R′is coupled to the angled receive PCB 108 ′′′ so that pins 113 are vertical with the reference axis.

- a ground plane 118can be coupled to a side the angled receive PCB 108 ′′′ or a ground plane 114 can be coupled to a side of the angled transmit PCB 106 ′′′ or both similar to previously described with reference to the vertical boards and FIGS. 9B–9E .

- the shield housing or cover 419couples to the baseplate 805 ′′ around the printed circuit boards.

- the angles ⁇ 3 and ⁇ 4 which the printed boards make with the base or baseplate 805 ′′ and the angle ⁇ 5 which the septum 815 ′ makes with the base or baseplate 805 ′′can vary between zero and ninety degrees.

- FIG. 12Aillustrates an exploded view of a fiber optic module 1200 .

- the fiber optic module 1200has angled or slanted PCBs with respect to a horizontal or vertical axis of the fiber optic module 1200 .

- the PCBsare angled or slanted away at top edges to form a V configuration of PCB orientation.

- the length of the PCBsremain parallel to the optical axis of the receiver 111 and transmitter 110 .

- the PCBsmay be made smaller to fit a smaller form factor or alternatively the surface area can be increased.

- the available PCB surface area for mounting componentscan be increased for a given volume by angling the PCBs.

- the increased surface areacan give the final assembled fiber optic module increased functionality by allowing components such as integrated circuits and passive components such as filters, capacitors, and inductors to be added. More room can also be provided in the fiber optic module 1200 for mounting larger components by angling the PCBs.

- the fiber optic module 1200includes an angled transmit PCB 106 ′′′′, an angled receive PCB 108 ′′′′, the transmitter 110 , the receiver 111 , an optical block 402 ′′′, the shielded housing or cover 419 , a first terminal pin header 1027 T′′ for the transmitter, a second terminal pin header 1027 R′′ for the receiver, and the baseplate 805 or 805 ′.

- the angled transmit PCB 106 ′′′′ and the angled receive PCB 108 ′′′′are arranged at an angle with respect to the horizontal axis of the fiber optic module as defined by a line normal to both receiver and transmitter optical axes.

- the angled transmit PCB 106 ′′′′ and the angled receive PCB 108 ′′′′slant away from each other to form the V configuration.

- the angled transmit PCB 106 ′′′′ and the angled receive PCB 108 ′′′′are held in place having a width that is on an angle with respect to a horizontal or vertical axis of the fiber optic module 1200 .

- the length of the angled transmit PCB 106 ′′′′ and the angled receive PCB 108 ′′′′are parallel to the optical axis of the receiver 111 and transmitter 110 .

- the angled transmit PCB 106 ′′′′includes components 116 and left and right edge traces 921 L and 921 R.

- the first terminal pin header 1027 T′′has pins 117 that couple to holes of the angled transmit PCB 106 ′′′′ on one end.

- the angled receive PCB 108 ′′′′includes components 112 and left and right edge traces 920 L and 920 R.

- the second terminal pin header 1027 R′′has pins 113 that couple to holes of the angled receive PCB 108 ′′′′ on one end.

- the transmitter 110is a transmit optical subassembly (Tx OSA) that includes a VCSEL or other semiconductor device that transduces electrical signals into photons or a light output.

- the receiver 111is a receive optical subassembly (Rx OSA) including a PIN diode or other device that converts photons or light input into electrical signals.

- the Tx OSA and Rx OSAare attached to physically separated transmit and receive electrical subassemblies (ESA's).

- the transmit ESAincludes the angled transmit PCB 106 ′′′′ with components 116 and the first terminal pin header 1027 T′′ mounted thereto.

- the receive ESAincludes the angled receive PCB 108 ′′′′ with components 112 and the second terminal pin header 1027 R′′ mounted thereto.

- the optical block 402 ′′′is similar to the optical block 402 but has some modifications to accommodate the angled transmit PCB 106 ′′′′ and the angled receive PCB 108 ′′′′.

- the optical block 402 ′′′includes openings 513 ′′′ and 514 ′′′ to receive the receiver 111 and transmitter 110 respectively and angled slots 1215 to receive the angled transmit PCB 106 ′′′′ and the angled receive PCB 108 ′′′′.

- the angled slots 1215can provide a friction fit with the angled transmit PCB 106 ′′′′ and the angled receive PCB 108 ′′′′ or glue or epoxy can be used to couple them together.

- the angled slots 1215can also serve to tack the receiver 111 and transmitter 110 in place within the optical block 402 ′′′.

- the transmitter 110couples into the opening 514 ′′′ of the optical block 402 ′′′.

- the receiver 111couples into the opening 513 ′′′ of the optical block 402 ′′′. They can be held in place by either a friction fit or a glue such as an epoxy.

- the transmitter 110also couples to the transmit PCB 106 ′′′′.

- the terminals 810 of the transmitter 110couple to the transmit PCB 106 ′′′′ in one embodiment.

- one or more terminals 810couple to left edge traces 920 L on a left side and one or more terminals 810 couple to right edge traces 920 R on a right side of the transmit PCB 106 ′′′′.

- the terminals 810may couple to one side of the transmit PCB 106 ′′′′.

- the terminals 810may couple into holes of the transmit PCB 106 ′′′′.

- the receiver 111also couples to the receive PCB 108 ′′′′.

- the terminals 811 of the receiver 111couple to the receive PCB 108 ′′′′.

- one or more terminals 811couple to left edge traces 921 L on a left side and one or more terminals 811 couple to right edge traces 921 R on a right side of the receive PCB 108 ′′′′.

- the terminals 811may couple to one side of the receive PCB 108 ′′′′.

- the terminals 811may couple into holes of the receive PCB 108 ′′′′.

- FIG. 12Ba rear cross-sectional view of the assembled fiber optic module 1200 is illustrated.

- the angled receive PCB 108 ′′′′ and the angled transmit PCB 106 ′′′′ of the fiber optic module 1200are angled away from each other with respect to a horizontal or vertical axis thereof.

- the first terminal pin header 1027 T′′is coupled to the angled transmit PCB 1027 T′′ so that pins 117 are vertical with the reference axis.

- the second terminal pin header 1027 R′′is coupled to the angled receive PCB 108 ′′′′ so that pins 113 are vertical with the reference axis.

- a ground plane 118can be coupled to a side the angled receive PCB 108 ′′′′ or a ground plane 114 can be coupled to a side of the angled transmit PCB 106 ′′′′ or both similar to previously described with reference to the vertical boards and FIGS. 9B–9E .

- the shield housing or cover 419couples to the baseplate 805 or 805 ′ around the printed circuit boards.

- the angles ⁇ 6 and ⁇ 7 which the printed boards make with the base or baseplate 805 or 805 ′can vary between zero and ninety degrees.

- FIG. 16Aillustrates a fiber optic module 1600 with such an arrangement for an alternate embodiment of the invention.

- a receiver optical block 402 R and a transmitter optical block 402 Tare illustrated as an alternative to the optical block 402 or 402 ′.

- the fiber optic moduleswere described and illustrate using a single optical block 402 or 402 ′.

- the optical blocks 402 R and 402 Tcan provide similar functionality to the single optical block 402 or 402 ′.