US5268093A - Portable water purification system - Google Patents

Portable water purification systemDownload PDFInfo

- Publication number

- US5268093A US5268093AUS07/879,093US87909392AUS5268093AUS 5268093 AUS5268093 AUS 5268093AUS 87909392 AUS87909392 AUS 87909392AUS 5268093 AUS5268093 AUS 5268093A

- Authority

- US

- United States

- Prior art keywords

- chamber

- container

- plunger

- filter

- contaminated water

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/001—Processes for the treatment of water whereby the filtration technique is of importance

- C02F1/003—Processes for the treatment of water whereby the filtration technique is of importance using household-type filters for producing potable water, e.g. pitchers, bottles, faucet mounted devices

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F9/00—Multistage treatment of water, waste water or sewage

- C02F9/20—Portable or detachable small-scale multistage treatment devices, e.g. point of use or laboratory water purification systems

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/50—Treatment of water, waste water, or sewage by addition or application of a germicide or by oligodynamic treatment

Definitions

- the inventionrelates to water purification systems. Specifically, the invention relates to portable water purification systems which include both a filter for physically removing particulate contaminants and larger pathogens from the water and a porous body of biocidally effective material for chemically disinfecting the water.

- Sources of fresh waterare often contaminated with disagreeable suspended solids and/or harmful pathogens including parasites such as schistosoma, cysts such as Giardia, bacteria such as cholera and viruses such as hepatitis.

- pathogensincluding parasites such as schistosoma, cysts such as Giardia, bacteria such as cholera and viruses such as hepatitis.

- the most constraining situation in the design of a purification systemis the design of a readily transportable system capable of microbiologically purifying water contaminated with both larger pathogens such as cysts (about 6 microns in diameter) which are resistant to chemical disinfection and smaller pathogens such as viruses (about 0.05 microns in diameter) which are difficult to filter.

- One method employed to microbiologically purify contaminated waterattempts to chemically disinfect the water by dissolving a biocide into the water or percolating the water through a biocidally active porous resin.

- Exemplary of the chemical disinfection methodare U.S. Pat. Nos. 4,151,092 and 4,298,475.

- U.S. Pat. No. 4,151,092issued to Grimm et al., discloses a portable water purification system that includes (i) a supply of biocidally effective tablets, (ii) a first container for retaining a supply of contaminated water treated with the biocide disinfectant, (iii) a second container sealingly receivable within the first container for exerting pressure upon the treated water contained within the first container when forced downward into the first container, and (iv) a replaceable filter cartridge coupled to the base of the second container for filtering the treated water retained within the first container as the water is forced from the first container into the second container.

- the filter cartridgeincludes a polyethylene filter to remove suspended solids, a layer of activated carbon to remove the biocide and other distasteful contaminants, and a layer of felt to retain the activated carbon. While generally effective, chemical disinfection requires that the contaminated water be treated for upwards of thirty minutes with the biocide prior to removal of the biocide by passage through the activated carbon and/or consumption of the water.

- U.S. Pat. No. 4,298,475issued to Gartner, discloses a portable water purification system operable by mouth suction which comprises a straw sequentially containing filter media for removing suspended solids form the water, biocidally active anion exchange resin for chemically disinfecting the water, filter media for further removing suspended solids, activated carbon for removing distasteful contaminants including residual disinfecting chemical, and filter media for retaining the activated carbon.

- Gartnerdoes not discuss the pore sizes of the filter medias.

- a second method employed to microbiologically purify contaminated waterattempts to filter the pathogens from the contaminated water employing a microfilter. While this method can be effective for removing the larger pathogens such as cysts and bacteria, such systems are generally ineffective for removing the smaller pathogens such as viruses, require significant operating energy, produce modest quantities of filtered water, and require frequent filter replacement.

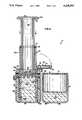

- FIG. 1is a perspective view of one embodiment of the invention in compacted storage form.

- FIG. 2is a cross-sectional front view of the invention embodiment depicted in FIG. 1 taken along line 2--2.

- FIG. 3is a cross-sectional view of the invention embodiment depicted in FIG. 2 in operational form.

- FIG. 4is a cross-sectional view of the first container portion of the invention embodiment depicted in FIG. 2.

- FIG. 5is a cross-sectional view of the plunger portion of the invention embodiment depicted in FIG. 2.

- FIG. 6is a logarithmic micron scale indicating the sizes of various particles.

- a manually operable apparatus for producing potable water from contaminated waterwhich includes (i) a first container having an open end and an outlet orifice, (ii) a filter operably positioned within the first container for filtering contaminated water placed within the first container as the contaminated water is forced out of the first container through the outlet orifice, (iii) a porous body of biocidally effective material operably positioned within the first container for disinfecting contaminated water placed within the first container as the contaminated water is forced out of the first container through the outlet orifice, and (iv) a plunger sealably receivable within the first container through the open end for forcing contaminated water retained within the first container through the filter and the porous body of biocidally effective material and out of the first container through the outlet orifice.

- the apparatusfurther includes (i) a means for abating the formation of a vacuum within the first chamber as the plunger is withdrawn from the first container, (ii) a nozzle in hinged communication with the outlet orifice in the first container for sealing the outlet orifice when placed in a first position and directing the flow of potable water flowing out of the first container through the outlet orifice when placed in a second position, and (iii) a second container having an open end which is operable as a drinking cup for the potable water generated by the system and as a cover for the first container.

- microbiologically purifiedand “microbiological purification”, when used in connection with microbiologically contaminated water, means sufficient removal and/or deactivation of potentially harmful cysts, bacteria and viruses so as to render the water microbiologically potable.

- the inventionis a compact, manually operable, portable water purification system capable of producing significant quantities of potable water.

- the system 10includes (i) a cylindrical first container 20 which accommodates a filter 80 and a porous body of biocidally effective material 90 and is operable for retaining a quantity of contaminated water 101 to be purified, (ii) a cylindrical second container 40 operable as a cover for the first container 20 and as a receptacle for retaining the potable water 103 generated by the system 10, and (iii) a cylindrical plunger 50 telescopingly and sealingly receivable within the first container 20 for forcing contaminated water 101 retained within the first container 20 through the filter 80 and the porous body of biocidally effective material 90 accommodated within the first container 20.

- the first container 20defines a cylindrical first chamber 30 which is subdivided into an upper portion 30a and a lower portion 30b by an upper horizontal annular flange 24 which changes the diameter of the cylindrical first chamber 30.

- the upper portion 30a of the first chamber 30has a smaller diameter than the lower portion 30b of the first chamber 30.

- the first container 20also includes a lower horizontal annular flange 25 immediately below the upper horizontal annular flange 24 which further increases the diameter of the lower portion 30b of the first chamber 30.

- the upper 24 and lower 25 horizontal annular flangesdivide the container sidewall 23 into an upper sidewall section 23a between the top 21 of the first container 20 and the upper horizontal annular flange 24, a middle sidewall section 23b between the upper 24 and a lower 25 horizontal annular flanges, and a lower sidewall section 23c between the lower horizontal annular flange 25 and the bottom 22 of the first container 20.

- a cylindrical baffle 26extends vertically within the first chamber 30 from the upper horizontal flange 24 to proximate the bottom 22 of the first container 20.

- the baffle 26terminates above the bottom 22 of the first container 20 so as to define an annular passage 34 around the baffle 26.

- the filter 80 accommodated within the firs container 20is cylindrical in shape and positioned inside the baffle 26.

- the top 81 and bottom 82 of the filter 80are sealingly coupled to the upper horizontal annular flange 24 and the bottom 22 of the first container 20 respectively.

- the filter 80 and baffle 26separate the lower portion 30b of the first chamber 30 into (i) a central cylindrical cavity 31 defined by the filter 80, (ii) an inner annular cavity 32 defined by the filter 80 and the baffle 26, and (iii) an outer annular cavity 33 defined by the baffle 26 and the lower section 23c of the sidewall 23.

- the inner surface 83 of the filter 80is substantially vertically aligned with the inner surface of the upper portion 30a of the first container 30 so as to provide a substantially continuous surface to reduce the space provided between the sidewall of the plunger 50 and the sidewall of the first container 20 and the interior surface of the filter 80.

- a first annular screen 27is positioned within the outer annular cavity 33 in abutment with the lower horizontal annular flange 25 and separates the outer annular cavity 33 into an upper portion 33a and a lower portion 33b.

- the upper portion 33a of the outer annular cavity 33is defined by the upper horizontal annular flange 24, the middle section 23b of the first container sidewall 23, the baffle 26, and the first annular screen 27.

- the lower portion 33b of the outer annular cavity 33is defined by the first annular screen 27, the lower section 23c of the first container sidewall 23, the baffle 26, and the bottom 22 of the first container 20.

- An outlet orifice 35 for the upper portion 33a of the outer annular cavity 33extends through the upper horizontal flange 24.

- the lower portion 33b of the outer annular cavity 33is packed with a layer of porous biocidally active material 90 and optionally with one or more layers of an active component 95 such as a layer of activated carbon for removing molecules which contribute undesired taste and odor, a layer of a chelating agent to remove hardness ions, and the like.

- the first screen 27prevents the biocidally effective material 90 and/or optional active component(s) 95 from flowing out of the first container 20 through the outlet orifice 35 along with the purified water ***.

- the filter 80, baffle 26, screen 27, and biocidally effective material 90may be retained within a replaceable cartridge (not shown) which is threadably engageable within the lower portion 30b of the first chamber 30 so as to sealingly contact the upper horizontal flange 24.

- the bottom of the cartridge (not shown)would form the bottom 22 of the first container 20 while the sides of the cartridge (not shown) would define a double sidewall with the lower section 23c of the first container sidewall 23.

- a nozzle 70is hingedly coupled to the first container 20 at the upper horizontal flange 24 and placed in fluid communication with the outlet orifice 35 in the first container 20.

- the proximal end 71 of the nozzle 70is rounded so as to permit hinged rotation of the nozzle 70 about the outlet orifice 35 in the first container 20 while permitting the proximal end 71 of the nozzle 70 to seal the outlet orifice 35 in the first container 20 when positioned parallel to the first container 20. Sealing of the outlet orifice 35 in the first container 20 prevents deactivation of the biocidally effective material 90 by preventing the material 90 from drying out.

- the nozzle 70has an inlet orifice 74 proximate the proximal end 71 of the nozzle 70 and an outlet orifice 75 proximate the distal end 72 of the nozzle 70.

- a passageway 73extends through the nozzle 70 and connects the inlet 74 and outlet 75 orifices.

- the inlet orifice 74is configured so that the orifice 74 aligns with the outlet orifice 35 in the first container 20 when the nozzle 70 is positioned to extend substantially transversely to the first container 20.

- the outlet orifice 75is configured so that purified water 103 exits the nozzle 70 in a downward fashion.

- the second container 40has an open top 41 and is configured for use as a cover for the first container 20 and as a receptacle for the potable water 103 generated by the system 10.

- An inwardly extending annular rib 46is provided on the sidewall 43 of the second container 40 proximate the top 41 of the second container 40.

- the rib 46is compatible with an annular notch 36 in the middle section 23b of the first container sidewall 23 for securing the second container 40 over the first container 20.

- the second container 40is sized to provide a gap between the upper sidewall section 23a of the first container 20 and the sidewall 43 of the second container 40 which is sufficient to accommodate the nozzle 70 when the nozzle 70 is positioned parallel to the first container 20.

- the plunger 50is configured to be telescopically received within the upper portion 30a of the first chamber 30 and the central cylindrical cavity 31 subdivision of the lower portion 30b of the first chamber 30.

- the body of the plunger 50is constructed as a right circular cylinder with a diameter slightly smaller than the smaller of the diameter of the upper portion 30a of the first chamber and the diameter of the central cavity 31.

- the proximal end 51 of the plunger 50is capped with a head 54 which provides a smooth, flat surface against which the palm of the hand may be comfortably placed for forcing the plunger 50 into the first container 20 and applying pressure to the supply of contaminated water 101 retained within the first container 20.

- the plunger 50defines an upper chamber 56 and a lower chamber 57.

- An upper orifice 58extends through the sidewall 53 of the plunger 50 proximate the proximal end 51 of the plunger 50 for providing access from the upper chamber 56 to the atmosphere.

- a middle orifice 59connects the upper chamber 56 and the lower chamber 57.

- a lower orifice 60extends through the distal end 52 of the plunger 50 for providing access from the first chamber 30 defined by the first container 20 into the lower chamber 57 defined by the plunger 50.

- the combination of upper 56 and lower 57 chambers along with the interconnecting upper 58, middle 59, and lower 60 orificesprovide a continuous passage from the first chamber 30 to the atmosphere.

- a check valve 55comprising a free-floating disc with several holes extending through the periphery of the disc, is configured within the lower chamber 57 so as to prevent flow through the smaller middle orifice 59 while the plunger 50 is being inserted into the first container 20 but permit flow through the larger lower orifice 60 while the plunger 50 is being withdrawn from the first container 20.

- the check valve 55functions to permit the plunger 50 to build pressure within the first chamber 30 during insertion while abating the formation of a vacuum within the first chamber 30 during withdrawal.

- the relative heights of the plunger 50 and the first chamber 30are such that the upper orifice 58 in the sidewall 53 of the plunger 50 will remain in constant communication with the atmosphere. Positioning of the upper orifice 58 within the first chamber 30 would prevent flow from the first chamber 30 to the atmosphere and result in the creation of a vacuum within the first chamber 30 when the plunger 50 is being withdrawn from the first chamber 30 until the upper orifice 58 is moved out of the first chamber 30.

- a seal 29is provided proximate the top 21 of the first container 20 to sealingly engage the sidewall 53 of the plunger 50.

- the first container 20, second container 40, and plunger 50may be constructed from any suitable structural material including wood, metal and plastic with molded plastic constituting the material of choice.

- the filter 80functions to remove both suspended solids and larger pathogens from the contaminated water 101. Removal of the suspended solids renders the water aesthetically agreeable and palatably acceptable. Generally, removal of those suspended solids which are visible to the naked eye (greater than about 40 microns) achieves the desired results. Removal of the larger pathogens is necessary because such pathogens are effectively resistant to chemical disinfection by the biocidally effective material 90.

- the larger pathogens generally resistant to chemical disinfectionare cysts such as Giardia lamblia and Giardia muris which are typically about 6 microns in size. Because of the significantly smaller size of the pathogens which must be removed (6 microns) as compared to the suspended solids (40 microns), pathogen removal controls selection of the filter media 80.

- the filter media 80 employed in the present inventionshould be capable of ensuring at least a three-log reduction in the concentration of cysts such as Giardia lamblia and Giardia muris.

- the filter 80may be constructed from any porous material capable of providing the necessary cyst reduction, structural integrity and chemical compatibility including carbon block, ceramic, woven and nonwoven fiber, natural and synthetic membranes, and the like.

- the biocidally effective material 90may be any sufficiently porous, biocidally effective material capable of disinfecting contaminated water with a single pass.

- biocidally effective materials suitable for use in the present inventionare disclosed in U.S. Pat. Nos. 4,238,477 and 3,817,860 issued to Lambert et al. Briefly, these references describe iodinated anion exchange resins, such a iodinated quaternary ammonium resins, which are effective for disinfecting contaminated water by percolation of the contaminated water through the resin.

- the amount of biocidally effective resin 90 which should be employed within the system 10depends upon a number of factors including the type and porosity of the biocidally effective resin, the configuration of the biocidally effective resin within the system 10, the rate of water flow through the system, and others. Generally, when an iodinated anion exchange resin is employed, the volumetric ratio of resin to water passing through the resin every second should be at least 2.5 and preferably at least 3.

- the first screen 27may be constructed from any suitably porous material capable of retaining the biocidally effective material 90 and the optional active component(s) 95 in the lower portion 33b of the outer annular cavity 33 while permitting substantially unrestricted flow of potable water through the screen 27.

- the second screen 28may be constructed from any suitably porous material capable of maintaining separation of the biocidally effective material 90 and the optional active component(s) 95 while permitting substantially unrestricted flow of potable water through the screen 28.

- Suitable materials for use as the screens 27,28include woven and nonwoven fibers of plastic, glass or other material which is chemically compatible with the biocidally effective material 90.

- a layer(s) of an active component(s) 95may optionally be placed within the lower portion 33b of the outer annular cavity 33 downstream from the biocidally effective material 90 for achieving a desired effect upon the purified water 103 such as a layer of activated carbon to remove undesirable tastes and odors, and/or a chelating agent to remove hardness ions from the purified water 103.

- a layer(s) of the optional active component(s) 95is employed, a second annular screen 28 should be placed between the layer of biocidally effective material 90 and the optional layer(s) of active component(s) 95 as well as between layers of active components 95 when multiple layers r of different active components are employed (not shown) to maintain separation of the materials 90,95.

- the system 10may be constructed to substantially any size but should generally provide a contaminated water 101 retention volume (displacement) defined by the first chamber upper portion 30A and the first chamber central cavity subdivision 31 of about 0.05 to about 0.2 liters.

- a system 10 providing a displacement of less than about 0.05 litersis laborious to operate because of the number of strokes required while a system 10 providing a displacement of greater than about 0.2 liters excessively cumbersome to transport and requires the use of significant energy to operate.

- a typical system 10 providing a displacement of about 100 mlrequires about 4 to about 10 seconds to fully depress the plunger 50 when the lower portion of the first chamber is filled with contaminated water 101.

- a system 10 providing a displacement of about 100 to 200 mlwill typically weight about 300 to about 500 grams.

- a typical system 10should cause a pressure drop between the central cavity 31 and the outlet orifice 35 in the first container 20 of about 5 to about 10 psig.

- operation of the system 10includes the steps of (i) separating the first 20 and second 40 containers, (ii) withdrawing the plunger 50 from the first container 20, (iii) pouring a supply of contaminated water 101 into the first container 20 through the open top 21, (iv) opening the outlet orifice 35 in the first container 20 by rotating the nozzle 70 from the parallel position to the transverse position, (v) positioning the second container 40 under the outlet o orifice 75 in the nozzle 70, (vi) reinserting the plunger 50 into the first container 20, and (vii) applying pressure to the contaminated water 101 retained within the first container 20 by pushing the plunger 50 against the contaminated water 101.

- steps (ii) and (iii)may be modified to (ii) depressing the plunger 50 completely into the first container 20, (iii)(a) pouring a supply of contaminated water 101 into the upper chamber 56 of the plunger 50 through the upper orifice 58 in the plunger 50 (preferably positioned through the head 54 of the plunger 50), and (iii)(b) pulling upward on the plunger 50 so as to open the check-valve 55 and suction the contaminated water 101 retained within the upper chamber 56 of the plunger 50 into the first chamber central cavity subdivision 31 and first chamber upper portion 30A.

- the application of pressure to the contaminated water 101 retained within the first container 20causes the contaminated water 101 to flow from the central cavity 31 through the filter 80 and into the inner annular cavity 32.

- the baffle 26then directs the filtered water 102 in the inner annular cavity 32 down towards the annular passage 34 between the baffle 26 and the bottom 22 of the first container 20.

- the filtered water 102passes through the annular passage 34 into the lower portion 33b of the outer annular cavity 33 where the filtered water 102 percolates up through the biocidally effective material 90 and the activated carbon 95 retained within the lower portion 33b of the outer annular cavity 33.

- the potable water 103then passes from the lower portion 33b of the outer annular cavity 33 through the screen 27, into the upper portion 33a of the outer annular cavity 33, out of the first container 20 through the outlet orifice 35 in the first container 20, into the nozzle 70 through the inlet orifice 74 in the nozzle 70, and out of the nozzle 70 through the outlet orifice 75 in the nozzle 70.

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Hydrology & Water Resources (AREA)

- Engineering & Computer Science (AREA)

- Environmental & Geological Engineering (AREA)

- Water Supply & Treatment (AREA)

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Clinical Laboratory Science (AREA)

- Water Treatment By Sorption (AREA)

Abstract

Description

Claims (11)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US07/879,093US5268093A (en) | 1990-04-05 | 1992-05-01 | Portable water purification system |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US50363590A | 1990-04-05 | 1990-04-05 | |

| US07/879,093US5268093A (en) | 1990-04-05 | 1992-05-01 | Portable water purification system |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US50363590AContinuation | 1990-04-05 | 1990-04-05 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US5268093Atrue US5268093A (en) | 1993-12-07 |

Family

ID=27054574

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US07/879,093Expired - LifetimeUS5268093A (en) | 1990-04-05 | 1992-05-01 | Portable water purification system |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US5268093A (en) |

Cited By (50)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5366642A (en)* | 1991-04-09 | 1994-11-22 | Kpa, Incorporated | Compact water filtration and purification pump |

| USD358632S (en) | 1993-11-16 | 1995-05-23 | Swick Dennis L | Osmosis treatment unit |

| US5431816A (en)* | 1991-04-09 | 1995-07-11 | Sweetwater, Inc. | Prefilter for a water purification pump |

| US5433848A (en)* | 1991-04-09 | 1995-07-18 | Kpa, Inc. | Water filtration pump with disposable filter cartridges |

| US5534145A (en)* | 1991-04-09 | 1996-07-09 | Sweetwater, Inc. | Compact water filtration pump |

| US5580447A (en)* | 1991-04-09 | 1996-12-03 | Sweetwater, Inc. | Biocide filter |

| US5709794A (en)* | 1995-05-19 | 1998-01-20 | Recovery Engineering, Inc. | Low-cost portable water filter |

| US5935426A (en) | 1997-08-08 | 1999-08-10 | Teledyne Industries, Inc., A California Corporation | Water treatment device with volumetric and time monitoring features |

| USD429312S (en)* | 1999-08-31 | 2000-08-08 | Kimberly-Clark Worldwide, Inc. | Travel filtration bottle |

| WO2000058222A1 (en)* | 1999-03-29 | 2000-10-05 | Pierre Jean Messier | Water filter cartridge |

| USD433729S (en)* | 1999-08-31 | 2000-11-14 | Kimberly-Clark Worldwide, Inc. | Filtration bottle with cap |

| US6149801A (en) | 1997-08-08 | 2000-11-21 | Water Pik, Inc,. | Water treatment device with volumetric monitoring features |

| US6290848B1 (en) | 1997-04-16 | 2001-09-18 | Pur Water Purification Products, Inc. | Filter cartridge for gravity-fed water treatment devices |

| US6454941B1 (en)* | 1998-12-17 | 2002-09-24 | Corning Incorporated | Gravity-flow water filtration device |

| US6565743B1 (en) | 1999-08-31 | 2003-05-20 | Kimberly-Clark Worldwide, Inc. | Portable purification container with cumulative use indicator |

| US6565749B1 (en) | 1999-07-21 | 2003-05-20 | The Procter & Gamble Company | Microorganism filter and method for removing microorganism from water |

| US6694739B2 (en) | 2001-10-12 | 2004-02-24 | Mesosystems Technology, Inc. | Modular water heater |

| US20050258082A1 (en)* | 2004-05-24 | 2005-11-24 | Lund Mark T | Additive dispensing system and water filtration system |

| US20060006107A1 (en)* | 2004-05-24 | 2006-01-12 | Olson Judd D | Additive dispensing system for a refrigerator |

| US20060191824A1 (en)* | 2004-05-24 | 2006-08-31 | Arett Richard A | Fluid container having an additive dispensing system |

| USD533622S1 (en) | 2003-10-01 | 2006-12-12 | Water Pik, Inc. | End-of-faucet filter |

| US20070138081A1 (en)* | 2005-10-28 | 2007-06-21 | Mike Rice | Portable Water Purification and Decontamination System |

| US7326334B2 (en) | 2003-10-01 | 2008-02-05 | Instapure Brands, Inc. | End-of-faucet filter |

| US20080087596A1 (en)* | 2006-10-13 | 2008-04-17 | Filtrex Holdings Pte Ltd. | Universal water purifier unit assembly device |

| US20080251434A1 (en)* | 2005-09-28 | 2008-10-16 | Koninklijke Philips Electronics N.V. | Manually Operable Water Purifying Device |

| US20090145839A1 (en)* | 2007-12-10 | 2009-06-11 | Miga Jr Charles W | Water Bottle with Filtration Feature |

| WO2009106084A1 (en)* | 2008-02-28 | 2009-09-03 | Vestergaard Sa | Centrifugal liquid filter |

| US20100032381A1 (en)* | 2008-08-08 | 2010-02-11 | O'brien Paul W | Double Chamber Water Purification Device |

| US20100065503A1 (en)* | 2008-09-18 | 2010-03-18 | 3M Innovative Properties Company | Portable water treatment apparatus and methods |

| US7712613B2 (en) | 2001-08-23 | 2010-05-11 | Pur Water Purification Products, Inc. | Water filter materials and water filters containing a mixture of microporous and mesoporous carbon particles |

| US7740765B2 (en) | 2001-08-23 | 2010-06-22 | The Procter & Gamble Company | Methods for treating water |

| US7740766B2 (en) | 2001-08-23 | 2010-06-22 | The Procter & Gamble Company | Methods for treating water |

| US7749394B2 (en) | 2001-08-23 | 2010-07-06 | The Procter & Gamble Company | Methods of treating water |

| US7850859B2 (en) | 2001-08-23 | 2010-12-14 | The Procter & Gamble Company | Water treating methods |

| US20110089103A1 (en)* | 2009-10-21 | 2011-04-21 | Filtrex Holdings Pte Ltd. | Vented filter cartridge for water treatment device |

| WO2011060527A1 (en)* | 2009-11-19 | 2011-05-26 | Patricia Kim Sturges | Drinking container with filter filling reservoir |

| WO2011067748A1 (en)* | 2009-12-01 | 2011-06-09 | Aqua-Nu Filtration Systems Limited | Apparatus and a method for filtering liquid |

| US20110233119A1 (en)* | 2010-03-29 | 2011-09-29 | Nelson Steven D | Sports bottle device with filter isolated from filtered fluid |

| US8216462B2 (en) | 2007-08-08 | 2012-07-10 | O'brien Paul W | Portable drinking water purification device |

| US8277666B2 (en) | 2009-11-19 | 2012-10-02 | Patricia Kim Sturgess | Drinking container with filter filling reservoir |

| US8313644B2 (en)* | 2010-01-13 | 2012-11-20 | OZOlab | Bottle with an integrated filtration assembly that is manually operated using a plunger |

| US8318011B2 (en) | 2008-10-15 | 2012-11-27 | Miracle Straw Corporation, Inc. | Portable drinking water purification device |

| US8425771B2 (en) | 2009-07-24 | 2013-04-23 | Miracle Straw Corporation, Inc. | Double chamber water purification device |

| US8808537B1 (en) | 2010-06-23 | 2014-08-19 | Eddie Carl Livingston | Self-contained transportable water treatment system |

| US8893927B2 (en) | 2004-05-24 | 2014-11-25 | Pur Water Purification Products, Inc. | Cartridge for an additive dispensing system |

| US8940163B2 (en) | 2008-07-21 | 2015-01-27 | 3M Innovative Properties Company | Apparatus for dispersing additive into a fluid stream |

| US20200070071A1 (en)* | 2018-09-05 | 2020-03-05 | Kin Mun Chin | Device for filtering |

| CN113531193A (en)* | 2021-07-30 | 2021-10-22 | 车金玲 | Instant heating water pipe joint |

| US20220355251A1 (en)* | 2017-12-28 | 2022-11-10 | Repligen Corporation | Plunger pumping arrangement for a hollow fiber filter |

| US12128334B2 (en)* | 2018-09-05 | 2024-10-29 | Kin Mun Chin | Filter press with threadably advanced filtrate receiving plunger |

Citations (55)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US492161A (en)* | 1893-02-21 | Filter | ||

| US1130725A (en)* | 1913-07-12 | 1915-03-09 | Frank E Getts | Liquid-strainer. |

| US1386340A (en)* | 1920-08-02 | 1921-08-02 | Wuster Robert | Filtering apparatus |

| GB148993A (en)* | 1918-03-16 | 1921-08-25 | Robert Wuester | Improvements in domestic and portable filters |

| US1510863A (en)* | 1920-12-23 | 1924-10-07 | William H Rose | Filter |

| US1689277A (en)* | 1927-09-24 | 1928-10-30 | Foist Kay | Cleaner for filtering elements |

| US1800757A (en)* | 1929-01-19 | 1931-04-14 | John J Schlosser | Cream and ice-cream mix filter |

| US1987142A (en)* | 1934-01-23 | 1935-01-08 | Jr Frank L Clements | Strainer for pipe lines |

| US1994656A (en)* | 1931-12-08 | 1935-03-19 | Motor Improvements Inc | Filter |

| GB467134A (en)* | 1935-07-15 | 1937-06-11 | Carlo Acquistapace | Portable apparatus for rapidly filtering and purifying liquids |

| US2338419A (en)* | 1940-07-25 | 1944-01-04 | Forrest William James | Filtering and like treatment of fluids |

| US2338417A (en)* | 1939-06-15 | 1944-01-04 | Forrest William James | Filtering and like treatment of fluids |

| US2338418A (en)* | 1939-06-09 | 1944-01-04 | Forrest William James | Filtering and like treatment of fluids |

| US2566371A (en)* | 1946-05-03 | 1951-09-04 | David H Quinn | Water filter |

| US2670081A (en)* | 1952-01-17 | 1954-02-23 | David H Quinn | Water purifier |

| US2869724A (en)* | 1955-06-29 | 1959-01-20 | Harry J Mcdevitt | Device for demineralizing water |

| US3316173A (en)* | 1963-05-27 | 1967-04-25 | Dow Chemical Co | Process for treating water with bromine |

| US3327859A (en)* | 1963-12-30 | 1967-06-27 | Pall Corp | Portable unit for potable water |

| US3379312A (en)* | 1965-03-16 | 1968-04-23 | North American Rockwell | Fluid strainers |

| US3425790A (en)* | 1967-01-31 | 1969-02-04 | Walter John Sloan | Process for obtaining equilibrium controlled amounts of halogen and/or interhalogen in a fluid medium |

| US3436345A (en)* | 1967-06-22 | 1969-04-01 | Dow Chemical Co | Water treatment with polybromide resin packets |

| US3462363A (en)* | 1967-07-14 | 1969-08-19 | Dow Chemical Co | Control of microorganisms with polyhalide resins |

| US3817860A (en)* | 1969-12-03 | 1974-06-18 | Univ Kansas State | Method of disinfecting water and demand bactericide for use therein |

| US3870639A (en)* | 1974-01-02 | 1975-03-11 | Moore Perk Corp | Filtering device |

| US3887468A (en)* | 1973-04-19 | 1975-06-03 | Desalination Systems | Feed water chlorinator for a reverse osmosis system |

| US3923665A (en)* | 1969-12-03 | 1975-12-02 | Univ Kansas State | Demand bactericide for disinfecting water and process of preparation |

| US3932277A (en)* | 1974-03-29 | 1976-01-13 | Bio-Logics Products, Inc. | Method and apparatus for separating blood fractions |

| IL40046A (en)* | 1972-08-03 | 1976-03-31 | Evron Kibbutz Hashomer Hatzair | Self cleaning filter |

| US4069153A (en)* | 1975-10-28 | 1978-01-17 | American Sterilizer Company | Method of destroying pyrogens |

| US4076622A (en)* | 1976-06-22 | 1978-02-28 | Rohm And Haas Company | Microbiocidal macroreticular ion exchange resins, their method of preparation and use |

| US4151092A (en)* | 1977-07-11 | 1979-04-24 | Teledyne Industries, Inc. | Portable water filter |

| US4187183A (en)* | 1975-03-28 | 1980-02-05 | Aqua-Chem, Inc. | Mixed-form polyhalide resins for disinfecting water |

| US4190529A (en)* | 1975-03-28 | 1980-02-26 | Aqua-Chem, Inc. | Mixed-form polyhalide resins for disinfecting water |

| US4238477A (en)* | 1979-04-20 | 1980-12-09 | Kansas State University Research Foundation | Process of preparing homogeneous resin-polyiodide disinfectants |

| US4298475A (en)* | 1980-07-18 | 1981-11-03 | Gartner William J | Water purification system |

| US4389311A (en)* | 1980-05-05 | 1983-06-21 | Freniere Henry | Portable water purifier |

| US4420590A (en)* | 1981-04-06 | 1983-12-13 | Halex, Inc. | Bacteriocidal resins and disinfection of water therewith |

| US4483771A (en)* | 1983-08-08 | 1984-11-20 | Elizabeth Koch | Multi-layer filter |

| US4594392A (en)* | 1984-02-13 | 1986-06-10 | Ametek, Inc. - Plymouth Products Division | Synergistically stabilized mixed form halogenated and/or interhalogenated resins for disinfecting water |

| US4632757A (en)* | 1984-10-04 | 1986-12-30 | Peretz Rosenberg | Filters cleanable by reverse flushing |

| US4681677A (en)* | 1978-02-17 | 1987-07-21 | Olin Corporation | Water processor having automatic shutoff and bypass means |

| US4694179A (en)* | 1986-05-27 | 1987-09-15 | Lew Hyok S | Symbiotic filter-sterilizer |

| USRE32537E (en)* | 1976-05-23 | 1987-11-03 | Self-cleanable filter | |

| US4769143A (en)* | 1987-02-17 | 1988-09-06 | Or-Tsurim | Device for purifying water |

| US4800018A (en)* | 1987-03-30 | 1989-01-24 | Moser Ronald T | Portable water purification system |

| US4816149A (en)* | 1988-03-01 | 1989-03-28 | Technique | Portable water filtration system |

| US4857204A (en)* | 1986-11-17 | 1989-08-15 | Joklik Otto F | Method of an apparatus for sterilizing aqueous media, more particularly drinking water |

| US4894154A (en)* | 1987-06-19 | 1990-01-16 | Societe De Recherche Techniques Et Industrielles (Srti) | Individual portable water-treatment device |

| US4913808A (en)* | 1988-10-03 | 1990-04-03 | Maqsood Haque | Subcompact interchangeable cartridge drinking water purification system |

| US4971687A (en)* | 1987-11-06 | 1990-11-20 | John B. Knight, Jr. | Apparatus for water treatment |

| US4995976A (en)* | 1990-05-31 | 1991-02-26 | Water Technologies Corporation | Water purification straw |

| US5032261A (en)* | 1988-05-24 | 1991-07-16 | Dufresne-Henry, Inc. | Compact biofilter for drinking water treatment |

| US5045195A (en)* | 1990-01-16 | 1991-09-03 | Accuventure, Inc. | Personal drinking water purification tube |

| US5061367A (en)* | 1989-10-13 | 1991-10-29 | Ametek, Inc. | Water purifying filter device |

| US5106500A (en)* | 1990-06-20 | 1992-04-21 | Recovery Engineering, Inc. | Portable water purification system including a filter cleaning mechanism |

- 1992

- 1992-05-01USUS07/879,093patent/US5268093A/ennot_activeExpired - Lifetime

Patent Citations (55)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US492161A (en)* | 1893-02-21 | Filter | ||

| US1130725A (en)* | 1913-07-12 | 1915-03-09 | Frank E Getts | Liquid-strainer. |

| GB148993A (en)* | 1918-03-16 | 1921-08-25 | Robert Wuester | Improvements in domestic and portable filters |

| US1386340A (en)* | 1920-08-02 | 1921-08-02 | Wuster Robert | Filtering apparatus |

| US1510863A (en)* | 1920-12-23 | 1924-10-07 | William H Rose | Filter |

| US1689277A (en)* | 1927-09-24 | 1928-10-30 | Foist Kay | Cleaner for filtering elements |

| US1800757A (en)* | 1929-01-19 | 1931-04-14 | John J Schlosser | Cream and ice-cream mix filter |

| US1994656A (en)* | 1931-12-08 | 1935-03-19 | Motor Improvements Inc | Filter |

| US1987142A (en)* | 1934-01-23 | 1935-01-08 | Jr Frank L Clements | Strainer for pipe lines |

| GB467134A (en)* | 1935-07-15 | 1937-06-11 | Carlo Acquistapace | Portable apparatus for rapidly filtering and purifying liquids |

| US2338418A (en)* | 1939-06-09 | 1944-01-04 | Forrest William James | Filtering and like treatment of fluids |

| US2338417A (en)* | 1939-06-15 | 1944-01-04 | Forrest William James | Filtering and like treatment of fluids |

| US2338419A (en)* | 1940-07-25 | 1944-01-04 | Forrest William James | Filtering and like treatment of fluids |

| US2566371A (en)* | 1946-05-03 | 1951-09-04 | David H Quinn | Water filter |

| US2670081A (en)* | 1952-01-17 | 1954-02-23 | David H Quinn | Water purifier |

| US2869724A (en)* | 1955-06-29 | 1959-01-20 | Harry J Mcdevitt | Device for demineralizing water |

| US3316173A (en)* | 1963-05-27 | 1967-04-25 | Dow Chemical Co | Process for treating water with bromine |

| US3327859A (en)* | 1963-12-30 | 1967-06-27 | Pall Corp | Portable unit for potable water |

| US3379312A (en)* | 1965-03-16 | 1968-04-23 | North American Rockwell | Fluid strainers |

| US3425790A (en)* | 1967-01-31 | 1969-02-04 | Walter John Sloan | Process for obtaining equilibrium controlled amounts of halogen and/or interhalogen in a fluid medium |

| US3436345A (en)* | 1967-06-22 | 1969-04-01 | Dow Chemical Co | Water treatment with polybromide resin packets |

| US3462363A (en)* | 1967-07-14 | 1969-08-19 | Dow Chemical Co | Control of microorganisms with polyhalide resins |

| US3817860A (en)* | 1969-12-03 | 1974-06-18 | Univ Kansas State | Method of disinfecting water and demand bactericide for use therein |

| US3923665A (en)* | 1969-12-03 | 1975-12-02 | Univ Kansas State | Demand bactericide for disinfecting water and process of preparation |

| IL40046A (en)* | 1972-08-03 | 1976-03-31 | Evron Kibbutz Hashomer Hatzair | Self cleaning filter |

| US3887468A (en)* | 1973-04-19 | 1975-06-03 | Desalination Systems | Feed water chlorinator for a reverse osmosis system |

| US3870639A (en)* | 1974-01-02 | 1975-03-11 | Moore Perk Corp | Filtering device |

| US3932277A (en)* | 1974-03-29 | 1976-01-13 | Bio-Logics Products, Inc. | Method and apparatus for separating blood fractions |

| US4187183A (en)* | 1975-03-28 | 1980-02-05 | Aqua-Chem, Inc. | Mixed-form polyhalide resins for disinfecting water |

| US4190529A (en)* | 1975-03-28 | 1980-02-26 | Aqua-Chem, Inc. | Mixed-form polyhalide resins for disinfecting water |

| US4069153A (en)* | 1975-10-28 | 1978-01-17 | American Sterilizer Company | Method of destroying pyrogens |

| USRE32537E (en)* | 1976-05-23 | 1987-11-03 | Self-cleanable filter | |

| US4076622A (en)* | 1976-06-22 | 1978-02-28 | Rohm And Haas Company | Microbiocidal macroreticular ion exchange resins, their method of preparation and use |

| US4151092A (en)* | 1977-07-11 | 1979-04-24 | Teledyne Industries, Inc. | Portable water filter |

| US4681677A (en)* | 1978-02-17 | 1987-07-21 | Olin Corporation | Water processor having automatic shutoff and bypass means |

| US4238477A (en)* | 1979-04-20 | 1980-12-09 | Kansas State University Research Foundation | Process of preparing homogeneous resin-polyiodide disinfectants |

| US4389311A (en)* | 1980-05-05 | 1983-06-21 | Freniere Henry | Portable water purifier |

| US4298475A (en)* | 1980-07-18 | 1981-11-03 | Gartner William J | Water purification system |

| US4420590A (en)* | 1981-04-06 | 1983-12-13 | Halex, Inc. | Bacteriocidal resins and disinfection of water therewith |

| US4483771A (en)* | 1983-08-08 | 1984-11-20 | Elizabeth Koch | Multi-layer filter |

| US4594392A (en)* | 1984-02-13 | 1986-06-10 | Ametek, Inc. - Plymouth Products Division | Synergistically stabilized mixed form halogenated and/or interhalogenated resins for disinfecting water |

| US4632757A (en)* | 1984-10-04 | 1986-12-30 | Peretz Rosenberg | Filters cleanable by reverse flushing |

| US4694179A (en)* | 1986-05-27 | 1987-09-15 | Lew Hyok S | Symbiotic filter-sterilizer |

| US4857204A (en)* | 1986-11-17 | 1989-08-15 | Joklik Otto F | Method of an apparatus for sterilizing aqueous media, more particularly drinking water |

| US4769143A (en)* | 1987-02-17 | 1988-09-06 | Or-Tsurim | Device for purifying water |

| US4800018A (en)* | 1987-03-30 | 1989-01-24 | Moser Ronald T | Portable water purification system |

| US4894154A (en)* | 1987-06-19 | 1990-01-16 | Societe De Recherche Techniques Et Industrielles (Srti) | Individual portable water-treatment device |

| US4971687A (en)* | 1987-11-06 | 1990-11-20 | John B. Knight, Jr. | Apparatus for water treatment |

| US4816149A (en)* | 1988-03-01 | 1989-03-28 | Technique | Portable water filtration system |

| US5032261A (en)* | 1988-05-24 | 1991-07-16 | Dufresne-Henry, Inc. | Compact biofilter for drinking water treatment |

| US4913808A (en)* | 1988-10-03 | 1990-04-03 | Maqsood Haque | Subcompact interchangeable cartridge drinking water purification system |

| US5061367A (en)* | 1989-10-13 | 1991-10-29 | Ametek, Inc. | Water purifying filter device |

| US5045195A (en)* | 1990-01-16 | 1991-09-03 | Accuventure, Inc. | Personal drinking water purification tube |

| US4995976A (en)* | 1990-05-31 | 1991-02-26 | Water Technologies Corporation | Water purification straw |

| US5106500A (en)* | 1990-06-20 | 1992-04-21 | Recovery Engineering, Inc. | Portable water purification system including a filter cleaning mechanism |

Non-Patent Citations (7)

| Title |

|---|

| First Need purifier product data.* |

| First Need® purifier product data. |

| Katadyn pocket filter product data.* |

| Marchin and Fina, "Contact and Demand-Release Disinfectants, Critical Reviews in Environmental Control", vol. 19, Issue 4, pp. 277-289 1989. |

| Marchin and Fina, Contact and Demand Release Disinfectants, Critical Reviews in Environmental Control , vol. 19, Issue 4, pp. 277 289 1989.* |

| The Fisher Scientific Catalog, 1988 p. 147.* |

| Water Tech water purifier product data.* |

Cited By (70)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5431816A (en)* | 1991-04-09 | 1995-07-11 | Sweetwater, Inc. | Prefilter for a water purification pump |

| US5433848A (en)* | 1991-04-09 | 1995-07-18 | Kpa, Inc. | Water filtration pump with disposable filter cartridges |

| US5534145A (en)* | 1991-04-09 | 1996-07-09 | Sweetwater, Inc. | Compact water filtration pump |

| US5580447A (en)* | 1991-04-09 | 1996-12-03 | Sweetwater, Inc. | Biocide filter |

| US5366642A (en)* | 1991-04-09 | 1994-11-22 | Kpa, Incorporated | Compact water filtration and purification pump |

| USD358632S (en) | 1993-11-16 | 1995-05-23 | Swick Dennis L | Osmosis treatment unit |

| US5709794A (en)* | 1995-05-19 | 1998-01-20 | Recovery Engineering, Inc. | Low-cost portable water filter |

| US6290848B1 (en) | 1997-04-16 | 2001-09-18 | Pur Water Purification Products, Inc. | Filter cartridge for gravity-fed water treatment devices |

| US5935426A (en) | 1997-08-08 | 1999-08-10 | Teledyne Industries, Inc., A California Corporation | Water treatment device with volumetric and time monitoring features |

| US6926821B2 (en) | 1997-08-08 | 2005-08-09 | Water Pik, Inc. | Water treatment device with volumetric and time monitoring features |

| US6149801A (en) | 1997-08-08 | 2000-11-21 | Water Pik, Inc,. | Water treatment device with volumetric monitoring features |

| US6284129B1 (en) | 1997-08-08 | 2001-09-04 | Water Pik, Inc. | Water treatment device with volumetric and time monitoring features |

| US6106705A (en) | 1997-08-08 | 2000-08-22 | Teledyne Industries, Inc. | Water treatment device with volumetric and time monitoring features |

| US6517707B2 (en) | 1997-08-08 | 2003-02-11 | Water Pik, Inc. | Water treatment device with volumetric and time monitoring features |

| US6454941B1 (en)* | 1998-12-17 | 2002-09-24 | Corning Incorporated | Gravity-flow water filtration device |

| WO2000058222A1 (en)* | 1999-03-29 | 2000-10-05 | Pierre Jean Messier | Water filter cartridge |

| US6565749B1 (en) | 1999-07-21 | 2003-05-20 | The Procter & Gamble Company | Microorganism filter and method for removing microorganism from water |

| US6565743B1 (en) | 1999-08-31 | 2003-05-20 | Kimberly-Clark Worldwide, Inc. | Portable purification container with cumulative use indicator |

| USD429312S (en)* | 1999-08-31 | 2000-08-08 | Kimberly-Clark Worldwide, Inc. | Travel filtration bottle |

| USD433729S (en)* | 1999-08-31 | 2000-11-14 | Kimberly-Clark Worldwide, Inc. | Filtration bottle with cap |

| US7740766B2 (en) | 2001-08-23 | 2010-06-22 | The Procter & Gamble Company | Methods for treating water |

| US8119012B2 (en) | 2001-08-23 | 2012-02-21 | The Procter & Gamble Company | Water filter materials and water filters containing a mixture of microporous and mesoporous carbon particles |

| US7922008B2 (en) | 2001-08-23 | 2011-04-12 | The Procter & Gamble Company | Water filter materials and water filters containing a mixture of microporous and mesoporous carbon particles |

| US7850859B2 (en) | 2001-08-23 | 2010-12-14 | The Procter & Gamble Company | Water treating methods |

| US7712613B2 (en) | 2001-08-23 | 2010-05-11 | Pur Water Purification Products, Inc. | Water filter materials and water filters containing a mixture of microporous and mesoporous carbon particles |

| US7749394B2 (en) | 2001-08-23 | 2010-07-06 | The Procter & Gamble Company | Methods of treating water |

| US7740765B2 (en) | 2001-08-23 | 2010-06-22 | The Procter & Gamble Company | Methods for treating water |

| US6694739B2 (en) | 2001-10-12 | 2004-02-24 | Mesosystems Technology, Inc. | Modular water heater |

| US7326334B2 (en) | 2003-10-01 | 2008-02-05 | Instapure Brands, Inc. | End-of-faucet filter |

| USD533622S1 (en) | 2003-10-01 | 2006-12-12 | Water Pik, Inc. | End-of-faucet filter |

| US7670479B2 (en) | 2004-05-24 | 2010-03-02 | PUR Water Purification, Inc. | Fluid container having an additive dispensing system |

| US8893927B2 (en) | 2004-05-24 | 2014-11-25 | Pur Water Purification Products, Inc. | Cartridge for an additive dispensing system |

| US10329134B2 (en) | 2004-05-24 | 2019-06-25 | Helen Of Troy Limited | Cartridge for an additive dispensing system |

| US9783405B2 (en) | 2004-05-24 | 2017-10-10 | Helen Of Troy Limited | Additive dispensing system for a refrigerator |

| US8556127B2 (en) | 2004-05-24 | 2013-10-15 | Pur Water Purification Products, Inc. | Additive dispensing system for a refrigerator |

| US8413844B2 (en) | 2004-05-24 | 2013-04-09 | Pur Water Purification Products, Inc. | Fluid container having an additive dispensing system |

| US20050258082A1 (en)* | 2004-05-24 | 2005-11-24 | Lund Mark T | Additive dispensing system and water filtration system |

| US20060006107A1 (en)* | 2004-05-24 | 2006-01-12 | Olson Judd D | Additive dispensing system for a refrigerator |

| US20060191824A1 (en)* | 2004-05-24 | 2006-08-31 | Arett Richard A | Fluid container having an additive dispensing system |

| US20080251434A1 (en)* | 2005-09-28 | 2008-10-16 | Koninklijke Philips Electronics N.V. | Manually Operable Water Purifying Device |

| US20070138081A1 (en)* | 2005-10-28 | 2007-06-21 | Mike Rice | Portable Water Purification and Decontamination System |

| US7507338B2 (en) | 2006-10-13 | 2009-03-24 | Filtrex Holdings Pte Ltd. | Universal water purifier unit assembly device |

| US20080087596A1 (en)* | 2006-10-13 | 2008-04-17 | Filtrex Holdings Pte Ltd. | Universal water purifier unit assembly device |

| US8216462B2 (en) | 2007-08-08 | 2012-07-10 | O'brien Paul W | Portable drinking water purification device |

| US20090145839A1 (en)* | 2007-12-10 | 2009-06-11 | Miga Jr Charles W | Water Bottle with Filtration Feature |

| US7810651B2 (en) | 2007-12-10 | 2010-10-12 | Medport, Llc | Water bottle with filtration feature |

| WO2009106084A1 (en)* | 2008-02-28 | 2009-09-03 | Vestergaard Sa | Centrifugal liquid filter |

| US8940163B2 (en) | 2008-07-21 | 2015-01-27 | 3M Innovative Properties Company | Apparatus for dispersing additive into a fluid stream |

| US20100032381A1 (en)* | 2008-08-08 | 2010-02-11 | O'brien Paul W | Double Chamber Water Purification Device |

| US8394268B2 (en) | 2008-08-08 | 2013-03-12 | Miracle Straw Corporation, Inc. | Double chamber water purification device |

| US20100065503A1 (en)* | 2008-09-18 | 2010-03-18 | 3M Innovative Properties Company | Portable water treatment apparatus and methods |

| US7854848B2 (en) | 2008-09-18 | 2010-12-21 | 3M Innovative Properties Company | Portable water treatment apparatus and methods |

| US8318011B2 (en) | 2008-10-15 | 2012-11-27 | Miracle Straw Corporation, Inc. | Portable drinking water purification device |

| US8425771B2 (en) | 2009-07-24 | 2013-04-23 | Miracle Straw Corporation, Inc. | Double chamber water purification device |

| US8986544B2 (en) | 2009-10-21 | 2015-03-24 | Marmon Water (Singapore) Pte. Ltd. | Vented filter cartridge for water treatment device |

| US9248391B2 (en) | 2009-10-21 | 2016-02-02 | Marmon Water (Singapore) Pte. Ltd. | Vented filter cartridge for water treatment device |

| US20110089103A1 (en)* | 2009-10-21 | 2011-04-21 | Filtrex Holdings Pte Ltd. | Vented filter cartridge for water treatment device |

| US8277666B2 (en) | 2009-11-19 | 2012-10-02 | Patricia Kim Sturgess | Drinking container with filter filling reservoir |

| WO2011060527A1 (en)* | 2009-11-19 | 2011-05-26 | Patricia Kim Sturges | Drinking container with filter filling reservoir |

| US8597512B2 (en) | 2009-11-19 | 2013-12-03 | Patricia Kim Sturgess | Drinking container with filter filling reservoir |

| WO2011067748A1 (en)* | 2009-12-01 | 2011-06-09 | Aqua-Nu Filtration Systems Limited | Apparatus and a method for filtering liquid |

| US8313644B2 (en)* | 2010-01-13 | 2012-11-20 | OZOlab | Bottle with an integrated filtration assembly that is manually operated using a plunger |

| US20110233119A1 (en)* | 2010-03-29 | 2011-09-29 | Nelson Steven D | Sports bottle device with filter isolated from filtered fluid |

| US8808537B1 (en) | 2010-06-23 | 2014-08-19 | Eddie Carl Livingston | Self-contained transportable water treatment system |

| US20220355251A1 (en)* | 2017-12-28 | 2022-11-10 | Repligen Corporation | Plunger pumping arrangement for a hollow fiber filter |

| US11813573B2 (en)* | 2017-12-28 | 2023-11-14 | Repligen Corporation | Plunger pumping arrangement for a hollow fiber filter |

| US20200070071A1 (en)* | 2018-09-05 | 2020-03-05 | Kin Mun Chin | Device for filtering |

| US12128334B2 (en)* | 2018-09-05 | 2024-10-29 | Kin Mun Chin | Filter press with threadably advanced filtrate receiving plunger |

| CN113531193A (en)* | 2021-07-30 | 2021-10-22 | 车金玲 | Instant heating water pipe joint |

| CN113531193B (en)* | 2021-07-30 | 2022-08-19 | 宁波昊盈卫浴科技有限公司 | Instant heating water pipe joint |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5268093A (en) | Portable water purification system | |

| US5106500A (en) | Portable water purification system including a filter cleaning mechanism | |

| US6733669B1 (en) | Water filter bottle | |

| US5562824A (en) | Gravity water purifier | |

| US7507338B2 (en) | Universal water purifier unit assembly device | |

| EP0056054B1 (en) | Water purification system | |

| US5653878A (en) | Single orifice bottle water filter | |

| US5122272A (en) | Drinking water supply container having a removably mounted filter device | |

| US20050035041A1 (en) | Hollow fiber membrane filters in various containers | |

| US6248244B1 (en) | Portable water treatment assembly | |

| US5545315A (en) | Water filtering and purifying apparatus | |

| CA2286223C (en) | Filter cartridge for gravity-fed water treatment devices | |

| EP0138060B1 (en) | Hollow-fiber filtering module and water purification device utilizing it | |

| US7585409B2 (en) | Multi-stage water purification device | |

| JPH034981A (en) | Container for cleaning water and cleaning water at water supply plug | |

| AU649189B2 (en) | Portable water purification system | |

| WO1993018837A1 (en) | Water purification system | |

| JPH04110186U (en) | drinking water purifier | |

| CA2500450A1 (en) | Water filter bottle | |

| JP2595427Y2 (en) | Sterilization and chlorine removal equipment using copper fiber filter | |

| WO2000063121A1 (en) | Fluid filtration system including a mechanism for increasing the flow through the filter | |

| JPH059687U (en) | Purification device for drinking water | |

| JPH09108662A (en) | Water purifier cartridge | |

| MXPA99009523A (en) | Filter cartridge for gravity-fed water treatment devices | |

| JPH04173571A (en) | Portable drinking water container |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STCF | Information on status: patent grant | Free format text:PATENTED CASE | |

| CC | Certificate of correction | ||

| RF | Reissue application filed | Effective date:19940929 | |

| FEPP | Fee payment procedure | Free format text:PAYOR NUMBER ASSIGNED (ORIGINAL EVENT CODE: ASPN); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY | |

| RF | Reissue application filed | Effective date:19960929 | |

| FPAY | Fee payment | Year of fee payment:4 | |

| FEPP | Fee payment procedure | Free format text:PAT HLDR NO LONGER CLAIMS SMALL ENT STAT AS INDIV INVENTOR (ORIGINAL EVENT CODE: LSM1); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY | |

| FPAY | Fee payment | Year of fee payment:8 | |

| FEPP | Fee payment procedure | Free format text:PAYOR NUMBER ASSIGNED (ORIGINAL EVENT CODE: ASPN); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY Free format text:PAYER NUMBER DE-ASSIGNED (ORIGINAL EVENT CODE: RMPN); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY | |

| AS | Assignment | Owner name:KATADYN HOLDING AG, SWITZERLAND Free format text:ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:PUR WATER PURIFICATION PRODUCTS, INC.;REEL/FRAME:013184/0283 Effective date:20020211 Owner name:PUR WATER PURIFICATION PRODUCTS, INC., OHIO Free format text:MERGER;ASSIGNOR:RECOVERY ENGINEERING, INC.;REEL/FRAME:013185/0807 Effective date:20010823 | |

| FEPP | Fee payment procedure | Free format text:PAYOR NUMBER ASSIGNED (ORIGINAL EVENT CODE: ASPN); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY Free format text:PAYER NUMBER DE-ASSIGNED (ORIGINAL EVENT CODE: RMPN); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY | |

| FEPP | Fee payment procedure | Free format text:PAYOR NUMBER ASSIGNED (ORIGINAL EVENT CODE: ASPN); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY Free format text:PAYER NUMBER DE-ASSIGNED (ORIGINAL EVENT CODE: RMPN); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY | |

| FPAY | Fee payment | Year of fee payment:12 |