US3762879A - Loop conveyor for automatic chemical testing apparatus - Google Patents

Loop conveyor for automatic chemical testing apparatusDownload PDFInfo

- Publication number

- US3762879A US3762879AUS00155153AUS3762879DAUS3762879AUS 3762879 AUS3762879 AUS 3762879AUS 00155153 AUS00155153 AUS 00155153AUS 3762879D AUS3762879D AUS 3762879DAUS 3762879 AUS3762879 AUS 3762879A

- Authority

- US

- United States

- Prior art keywords

- conveyor

- tubes

- loop

- rotated

- heating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000013098chemical test methodMethods0.000titleclaimsabstractdescription9

- 238000010438heat treatmentMethods0.000claimsabstractdescription40

- 238000001035dryingMethods0.000claimsabstractdescription12

- 238000007705chemical testMethods0.000claimsabstractdescription10

- 238000004140cleaningMethods0.000claims5

- 238000012360testing methodMethods0.000claims5

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claims3

- 239000007788liquidSubstances0.000claims2

- 230000001012protectorEffects0.000claims2

- 238000005507sprayingMethods0.000claims2

- 102100035591POU domain, class 2, transcription factor 2Human genes0.000description1

- 101710084411POU domain, class 2, transcription factor 2Proteins0.000description1

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/02—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor using a plurality of sample containers moved by a conveyor system past one or more treatment or analysis stations

- G01N35/021—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor using a plurality of sample containers moved by a conveyor system past one or more treatment or analysis stations having a flexible chain, e.g. "cartridge belt", conveyor for reaction cells or cuvettes

Definitions

- ABSTRACTA loop conveyor for automatic chemical testing apparatus having a plurality of rigid slats for carrying a row of reaction tubes intermediate their ends with the open ends extending upwardly above the conveyor and the lower closed ends extending beneath the upper portion of the loop whereby chemical tests may be performed in the tube as the conveyor is indexed along the various positions.

- Heating meanspositioned inside the conveyor and movable upward for heating the bottom of some of the tubes and movable downwardly for allowing the conveyor to rotate.

- Power meansfor rotating the conveyor and lowering and raising the heating means and moving drying means into and out of the tubes and having a lost motion connection between the power means and the conveyor for allowing the heating means to be lowered and the drying means to be retracted away from the tubes before the conveyor is rotated.

- a second lost motion connectionfor allowing the conveyor to be rotated before the heating means is raised and the drying means is moved into the tubes.

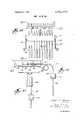

- PATENTEU 2I975 sum 11 or 33 cfaf/w J Mara/7 1N VENTOR.

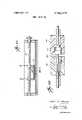

- PATENIEUHBI 21msum 12 0F 33 INVENTOR.

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Physical Or Chemical Processes And Apparatus (AREA)

Abstract

Description

United StatesPatent 1 1 Moran 1 Oct. 2, 1973 1 LOOP CONVEYOR FOR AUTOMATIC CHEMICAL TESTING APPARATUS [75] Inventor: John J. Moran, Houston, Tex.

[73] Assignee: Hycel, Inc., Houston, Tex.

[22] Filed: June 21,197]

[21] Appl. No.: 155,153

Related US. Application Data [62] Division of Scr. No. 737,065, June 14, 1968, Pat. No.

[52] U.S. Cl. 23/259, 23/253 R [51] Int. Cl.G0ln 1/14, G01nl/18 [58] Field ofSearch 23/253, 259, 292;

[56] References Cited UNITED STATES PATENTS 3,432,271 3/1969 Wasilewski 23/253 R 3,475,130 10/1969 Baruch 23/259 X 3,481,709 12/1969 Sloner 23/259 X 3,487,862 l/l970 Soderblom 23/259 X 3,533,744 10/1970 Ungcr 23/259 X 3,556,731 l/l97l Martin 23/259 X 3,578,412 5/1971 Martin 23/259 Primary Examiner-Morris O. Wolk Assistant ExaminerR. E. Serwin Attorney-James F. Weiler et al.

[57] ABSTRACT A loop conveyor for automatic chemical testing apparatus having a plurality of rigid slats for carrying a row of reaction tubes intermediate their ends with the open ends extending upwardly above the conveyor and the lower closed ends extending beneath the upper portion of the loop whereby chemical tests may be performed in the tube as the conveyor is indexed along the various positions. Heating means positioned inside the conveyor and movable upward for heating the bottom of some of the tubes and movable downwardly for allowing the conveyor to rotate. Power means for rotating the conveyor and lowering and raising the heating means and moving drying means into and out of the tubes and having a lost motion connection between the power means and the conveyor for allowing the heating means to be lowered and the drying means to be retracted away from the tubes before the conveyor is rotated. A second lost motion connection for allowing the conveyor to be rotated before the heating means is raised and the drying means is moved into the tubes. An indexing pawl engaging the conveyor for allowing the conveyor to index only a predetermined distance, and a locking means for holding the conveyor in a fixed position after each indexing movement.

18 Claims, 68 Drawing Figures lil PAIENTEB 081 21975 (fa/$0 cf Mora/7 I N VENTOR.

SHEET 02 0F 33 JU ULLIULLULUULILILILIUL In I 1H Hlll I III IHH HHIHH PATENTEDUCI 212m SHEU 03 0F 3 INVENTOR.

PATENTEDUBI 2mm summar 33 00 00 00 00 0O 00 O0 O0 0 0 O 0 0 O 0 db/Y/Y J Mara/7 INVENTOR.

PATENTEU 2 I975sum

PATENIEUHBI 21m sum 12 0F 33 INVENTOR.

BY M/ ATTOR/VE YJ PATENTEDUBT 21915 3.762.879

c7060 J Mara/7 I N VEN TOR.

ATTOR/VEVJ PATENTEI]OCT 2 I973SHEET 180F 33 WWW;

(5&0 J Mora/7 INVENTOR.

w BY 1

Claims (17)

- 2. The apparatus of claim 1 wherein the liquid heating bath includes water.

- 3. The apparatus of claim 2 wherein the conveyor including a plurality of sprocket wheels and further including means engaging one of the wheels for allowing the conveyor to index only a predetermined distance comprising, a shaft rotated by the power means, a supporting arm connected to and movable by said shaft, an indexing pawl rotatably carried by the arm, and positioned to engage the sprockets on one of said wheels when the shaft is rotated, and stop means for limiting the amount of travel of said pawl and thus the limit of travel of said conveyor when the pawl is in engagement with the sprocket.

- 4. The apparatus of claim 3 including sprocket locking means connected to and rotatable with said shaft, said locking means being moved into engagement with a sprocket when the shaft is rotated in one direction, and being moved out of engagement with the sprockets when the shaft is rotated in a second direction.

- 5. The apparatus of claim 2 including, a threaded pin for each opening positioned in the slats and extending to the openings for holding and aligning a tube in place in the slat opening, and a resilient protector positioned between each pin and a tube.

- 6. The apparatus of claim 2 wherein the power means include, a power means for rotating said conveyor and for lowering and raising the heating means, a lost motion connection between the power means and the conveyor for allowing the heating means to be lowered and retracted away from the tubes before the conveyor is rotated, and a lost motion connection between the power means and the heating means for allowing the conveyor to be rotated before the heating means is raised toward the tubes.

- 7. The apparatus of claim 1 wherein the power means periodically indexes the loop.

- 8. In a chemical testing apparatus in which a plurality of reaction tubes are indexed through various positions where test samples are dispensed into the reaction tubes and chemical tests are performed therein, the improvement in a loop conveyor means for carrying the reaction tubes comprising, a loop conveyor having a plurality of sprocket wheels supported on axles and including a plurality of rows of reaction tubes having an open end and secured to and supported intermediate their ends from the conveyor with the open ends extending upwardly above the top of the upper portions of the loop and the lower ends extending beneath the upper portion of the loop, heating means positioned inside said loop and movable toward the bottom of at least some of said tubes positioned on the upper portion of the loop and movable away from said tubes for allowing the conveyor to rotate, piston and power cylinder means for providing the power for rotating said conveyor and moving the heating means, a conveyor moving power lever connected to a sprocket wheel through a one-way clutch and connected to said power means, an actuating lever connected to said power means and said heating means for moving said heating means toward and away from the bottom of the reaction tubes, a lost motion connection between the power meanS and the conveyor for allowing the heating means to be moved away from the tubes before the conveyor is rotated, and a lost motion connection between the power means and the actuating lever for allowing the conveyor to be rotated before the heating means is moved toward the tubes.

- 9. The invention of claim 8 including an indexing means for allowing the conveyor to rotate only a predetermined amount including, shaft means adjacent one of the sprockets and actuated by the power means, a supporting arm connected to and movable by said shaft means, an indexing pawl rotatably carried by the arm, and positioned to engage the sprockets on one of said wheels when the shaft means is rotated, and stop means for limiting the amount of travel of said pawl and thus limiting the travel of said conveyor when the pawl is in engagement with the sprockets.

- 10. The apparatus of claim 9 including sprocket locking means connected to and rotatable with said shaft means, said locking means being moved into engagement with a sprocket when the shaft means is rotated in one direction, and being moved out of engagement with the sprockets when the shaft is rotated in a second direction.

- 11. In a chemical testing apparatus in which a plurality of reaction tubes are indexed to various positions, test samples are dispensed into the reaction tubes at one position, and chemical tests are performed at other positions, the improvement in a loop conveyor means for supporting and indexing the reaction tubes comprising, axle supported sprocket wheels, two chains, each chain engaging two of the wheels, a plurality of transversely positioned rigid slats, one end of which engages one of the chains, each slat including a plurality of openings, a reaction tube supported in each opening, said reaction tubes having open ends extending upwardly above the top the the upper portion of the loop and having lower closed ends extending beneath the upper portion of the loop whereby chemical tests may be performed in the tubes as they are moved along to various positions as the loop is rotated and where the tubes will be inverted and the contents thereafter emptied out, heating means positioned inside said loop and movable upwardly for heating the bottom of at least some of said tubes positioned on the upper portion of said loop and movable downwardly for allowing the conveyor to rotate, spraying means positioned outside said conveyor for spraying and cleaning the tubes which are disposed upside down in the lower portion of the loop, tube drying means positioned outside the conveyor for drying the tubes, piston and cylinder power means for providing the power for rotating said conveyor and for lowering and raising the heating means, shaft means, heating means support means supporting said heating means and connected to said shaft means, said support means being lowered when the shaft is rotated in a first direction and said support means being raised when the shaft is rotated in a second direction, a conveyor moving power lever connected to a sprocket wheel axle through a one-way clutch and connected to said power means, an actuating lever connected to said power means for actuating said shaft means, a lost motion connection between the power means and the conveyor for allowing the heating means to be lowered and retracted away from the tubes before the conveyor is rotated, a lost motion connection between the power means and the actuating lever for allowing the conveyor to be rotated before the heating means is raised, a supporting arm connected to and movable by said shaft means, an indexing pawl rotatably carried by the supporting arm, and positioned to engage the sprockets on one of said wheels and the shaft means is rotated, stop means for limiting the amount of travel of said pawl and thus limit the travel of said conveyor when the pawl is in engagement with the sprockets, and locking means connected to and rotataBle with said shaft means, said locking means being moved into engagement with the sprockets when the shaft means is rotated in said second direction, and being moved out of engagement with the sprockets when the shaft means is rotated in said one direction.

- 12. The apparatus of claim 11 including, a threaded pin for each opening positioned in the slots and extending to the opening for holding a tube in place in the slot opening, and a resilient protector positioned between each pin and tube.

- 13. The apparatus of claim 11 wherein the heating means includes a temperature controlled water bath.

- 14. In a chemical testing apparatus in which a plurality of reaction tubes are indexed through various positions where test samples are dispensed into the reaction tubes and chemical tests are performed therein, the improvement in a loop conveyor for supporting and indexing the reaction tubes comprising, a loop conveyor including a plurality of rows of reaction tubes having an open end and secured to and supported intermediate their ends from the conveyor with the open ends extending upwardly above the top of the upper portion of the loop and the lower ends extending beneath the upper portion of the loop, heating means positioned inside said loop and movable upwardly for heating the bottom of at least some of said tubes positioned on the upper portion of the loop and movable downwardly for allowing the conveyor to rotate, piston and cylinder power means for rotating said conveyor and lowering and raising the heating means, a lost motion connection between the power means and the conveyor for allowing the heating means to be lowered and retracted away from the tubes before the conveyor is rotated, and a lost motion connection between the power means and the heating means for allowing the conveyor to be rotated before the heating means is raised toward the tubes.

- 15. The invention of claim 14 including, cleaning means positioned outside said conveyor for cleaning tubes disposed in the lower portion of the loop, and tube drying means positioned outside the conveyor for drying the tubes.

- 16. In an automatic chemical testing apparatus in which a plurality of reaction tubes are indexed through various positions where test samples are dispersed into the tubes and chemical tests are performed therein, the improvement in a loop conveyor for carrying the reaction tubes comprising, two chains, a drive wheel engaging at least one of the chains, a plurality of substantially rigid sections secured to the chains to form a loop conveyor having upper and lower portions, each section including at least one opening for receiving a reaction tube, a reaction tube positioned in each of the openings having a top opening above the upper portion of the cnoveyor and having a lower closed end extending beneath the opening whereby chemical tests may be performed as the tubes are moved along various positions as the loop is rotated and where the tubes will be inverted, the contents emptied, and the tubes recycled, a temperature controlled water heating bath positioned inside said loop and movable upwardly for heating the bottom of at least some of the tubes on the upper portion and movable downwardly for allowing the conveyor to rotate, power means for lowering and raising said heating bath and indexing said loop a predetermined amount, and means engaging said conveyor for allowing the conveyor to index only a predetermined distance.

- 17. The apparatus of claim 16 including, cleaning means positioned outside said conveyor for cleaning tubes disposed in the lower portion of the loop, and tube drying means positioned outside the conveyor for drying the tubes.

- 18. In an automatic chemical testing apparatus in which a plurality of reaction containers are indexed through various positions while test samples are dispersed into the containers and chemical tests are performed therein, the improvement in a convEyor for carrying the reaction containers comprising, said conveyor being an endless loop including a plurality of substantially rigid sections connected together, each section including at least one opening for receiving an elongate reaction container, an elongate reaction container positioned in each of the openings having a top opening above the top of the conveyor and having a lower closed end extending beneath the opening whereby chemical tests may be performed as the loop is rotated and where the containers will be inverted, the contents emptied and the containers recycled, a temperature controlled liquid heating bath positioned inside said loop for heating the bottom of at least some of said containers positioned on the upper portion of the loop on relative movement of the bath and the upper portion of the loop towards each other, and power means for rotating said conveyor a predetermined amount.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US73706568A | 1968-06-14 | 1968-06-14 | |

| US15515371A | 1971-06-21 | 1971-06-21 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US3762879Atrue US3762879A (en) | 1973-10-02 |

Family

ID=26852049

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US00155153AExpired - LifetimeUS3762879A (en) | 1968-06-14 | 1971-06-21 | Loop conveyor for automatic chemical testing apparatus |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US3762879A (en) |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4067694A (en)* | 1976-12-17 | 1978-01-10 | Eastman Kodak Company | Loading and unloading mechanism for continuously rotating container |

| US4090848A (en)* | 1975-03-20 | 1978-05-23 | Nihon Denshi Kabushiki Kaisha | Automatic analyzing apparatus |

| US4155978A (en)* | 1977-04-27 | 1979-05-22 | Nihon Denshi Kabushiki Kaisha | Automatic chemical analyzer |

| US4200607A (en)* | 1977-11-21 | 1980-04-29 | Olympus Opitcal Co., Ltd. | Automatic chemical analyzer |

| US4224032A (en)* | 1976-12-17 | 1980-09-23 | Eastman Kodak Company | Method and apparatus for chemical analysis |

| US4259288A (en)* | 1978-02-15 | 1981-03-31 | Welch Henry H | Automatic multichannel apparatus for performing analyses on fluids, in particular for performing clinical-chemistry analyses on biological liquids |

| US4265855A (en)* | 1978-11-03 | 1981-05-05 | Electro-Nucleonics, Inc. | System for performing immunochemical and other analyses involving phase separation |

| US4313735A (en)* | 1979-08-22 | 1982-02-02 | Hitachi, Ltd. | Automatic chemical analyzing method and apparatus |

| US4387076A (en)* | 1981-10-14 | 1983-06-07 | Coulter Electronics, Inc. | Sample feeding arrangement |

| US4664885A (en)* | 1981-07-13 | 1987-05-12 | Tokyo Shibaura Denki Kabushiki Kaisha | Automatic chemical analyzer |

| US5350564A (en)* | 1993-06-28 | 1994-09-27 | Baxter Diagnostics Inc. | Automated chemical analyzer with apparatus and method for conveying and temporary storage of sample tubes |

| US20050233409A1 (en)* | 2002-08-29 | 2005-10-20 | George Posthuma | Device and method for carrying out immunological marking techniques for thin-sectioned tissue |

| US20060118492A1 (en)* | 2004-12-08 | 2006-06-08 | Chia-Hui Shieh | Integrated column, related system and method for liquid chromatography |

| US9513303B2 (en) | 2013-03-15 | 2016-12-06 | Abbott Laboratories | Light-blocking system for a diagnostic analyzer |

| US9632103B2 (en) | 2013-03-15 | 2017-04-25 | Abbott Laboraties | Linear track diagnostic analyzer |

| US9993820B2 (en) | 2013-03-15 | 2018-06-12 | Abbott Laboratories | Automated reagent manager of a diagnostic analyzer system |

- 1971

- 1971-06-21USUS00155153Apatent/US3762879A/ennot_activeExpired - Lifetime

Cited By (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4090848A (en)* | 1975-03-20 | 1978-05-23 | Nihon Denshi Kabushiki Kaisha | Automatic analyzing apparatus |

| US4224032A (en)* | 1976-12-17 | 1980-09-23 | Eastman Kodak Company | Method and apparatus for chemical analysis |

| US4067694A (en)* | 1976-12-17 | 1978-01-10 | Eastman Kodak Company | Loading and unloading mechanism for continuously rotating container |

| US4155978A (en)* | 1977-04-27 | 1979-05-22 | Nihon Denshi Kabushiki Kaisha | Automatic chemical analyzer |

| US4200607A (en)* | 1977-11-21 | 1980-04-29 | Olympus Opitcal Co., Ltd. | Automatic chemical analyzer |

| US4259288A (en)* | 1978-02-15 | 1981-03-31 | Welch Henry H | Automatic multichannel apparatus for performing analyses on fluids, in particular for performing clinical-chemistry analyses on biological liquids |

| US4265855A (en)* | 1978-11-03 | 1981-05-05 | Electro-Nucleonics, Inc. | System for performing immunochemical and other analyses involving phase separation |

| US4313735A (en)* | 1979-08-22 | 1982-02-02 | Hitachi, Ltd. | Automatic chemical analyzing method and apparatus |

| US4664885A (en)* | 1981-07-13 | 1987-05-12 | Tokyo Shibaura Denki Kabushiki Kaisha | Automatic chemical analyzer |

| US4387076A (en)* | 1981-10-14 | 1983-06-07 | Coulter Electronics, Inc. | Sample feeding arrangement |

| US5350564A (en)* | 1993-06-28 | 1994-09-27 | Baxter Diagnostics Inc. | Automated chemical analyzer with apparatus and method for conveying and temporary storage of sample tubes |

| US20050233409A1 (en)* | 2002-08-29 | 2005-10-20 | George Posthuma | Device and method for carrying out immunological marking techniques for thin-sectioned tissue |

| US7115386B2 (en)* | 2002-08-29 | 2006-10-03 | Leica Mikrosysteme Gmbh | Device and method for carrying out immunological marking techniques for thin-sectioned tissue |

| US20060118492A1 (en)* | 2004-12-08 | 2006-06-08 | Chia-Hui Shieh | Integrated column, related system and method for liquid chromatography |

| US9513303B2 (en) | 2013-03-15 | 2016-12-06 | Abbott Laboratories | Light-blocking system for a diagnostic analyzer |

| US9632103B2 (en) | 2013-03-15 | 2017-04-25 | Abbott Laboraties | Linear track diagnostic analyzer |

| US9993820B2 (en) | 2013-03-15 | 2018-06-12 | Abbott Laboratories | Automated reagent manager of a diagnostic analyzer system |

| US10330691B2 (en) | 2013-03-15 | 2019-06-25 | Abbott Laboratories | Light-blocking system for a diagnostic analyzer |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3762879A (en) | Loop conveyor for automatic chemical testing apparatus | |

| US3645690A (en) | Automated chemical analyzer | |

| DE2710020C2 (en) | ||

| US3219416A (en) | Apparatus for the automatic chemical sequential treatment and analysis of small quantities of material | |

| US3644095A (en) | Apparatus for performing chemical analyses | |

| CA1217790A (en) | Method and apparatus for storing and dispensing analysis slides | |

| US3578412A (en) | Automated transport system | |

| ES358684A1 (en) | Automatic chemical testing apparatus | |

| CN100545655C (en) | Device for automatically analyzing a liquid sample | |

| FI91451C (en) | Device for setting test strips one by one | |

| CA1053549A (en) | Incubation apparatus | |

| US4035642A (en) | Gamma counter apparatus | |

| US3552536A (en) | Test sample carrier transport apparatus | |

| US3511613A (en) | Transporter for sample tubes | |

| NO116482B (en) | ||

| US4252229A (en) | Walking beam treatment apparatus with rotatable workpiece containing barrels | |

| DE3162094D1 (en) | Machine for filling or emptying containers used for the transport of arranged articles | |

| US1842890A (en) | Apparatus for and method of handling films or other articles | |

| US3551112A (en) | Multiple pipetting apparatus | |

| CN217147637U (en) | A test tube rack transport device | |

| US2541809A (en) | Quantity bottle loader for automatic beverage bottle washing machines | |

| SU1014789A1 (en) | Arrangement for transporting liquid-filled vessels | |

| SU502591A3 (en) | Device for moving the container with the product | |

| CN222167050U (en) | A reagent strip pushing device for a chemiluminescent immunoassay analyzer | |

| US3789572A (en) | Apparatus for temporarily closing cylindrical containers |