US20070147961A1 - Robot system and method for maintenance of base plates in electrometallurgical and industrial processes - Google Patents

Robot system and method for maintenance of base plates in electrometallurgical and industrial processesDownload PDFInfo

- Publication number

- US20070147961A1 US20070147961A1US11/598,137US59813706AUS2007147961A1US 20070147961 A1US20070147961 A1US 20070147961A1US 59813706 AUS59813706 AUS 59813706AUS 2007147961 A1US2007147961 A1US 2007147961A1

- Authority

- US

- United States

- Prior art keywords

- base plates

- electrometallurgical

- maintenance

- industrial processes

- robot system

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

- 238000012423maintenanceMethods0.000titleclaimsabstractdescription42

- 238000000034methodMethods0.000titleclaimsabstractdescription37

- 238000004519manufacturing processMethods0.000titleclaimsdescription37

- 238000005498polishingMethods0.000claimsabstractdescription17

- 230000008569processEffects0.000claimsabstractdescription17

- 230000007246mechanismEffects0.000claimsabstractdescription15

- 238000009413insulationMethods0.000claimsabstractdescription13

- 239000002184metalSubstances0.000claimsdescription4

- 229910052751metalInorganic materials0.000claimsdescription4

- 238000004891communicationMethods0.000claimsdescription3

- 150000002739metalsChemical class0.000claimsdescription3

- 230000007613environmental effectEffects0.000claims2

- 238000007517polishing processMethods0.000claims2

- 230000006698inductionEffects0.000claims1

- 230000007423decreaseEffects0.000abstract1

- 238000004070electrodepositionMethods0.000description2

- 238000005201scrubbingMethods0.000description2

- RYGMFSIKBFXOCR-UHFFFAOYSA-NCopperChemical compound[Cu]RYGMFSIKBFXOCR-UHFFFAOYSA-N0.000description1

- 238000005452bendingMethods0.000description1

- 230000008901benefitEffects0.000description1

- 229910052802copperInorganic materials0.000description1

- 239000010949copperSubstances0.000description1

- 238000005260corrosionMethods0.000description1

- 230000007797corrosionEffects0.000description1

- 238000005516engineering processMethods0.000description1

- 238000003306harvestingMethods0.000description1

- PWPJGUXAGUPAHP-UHFFFAOYSA-NlufenuronChemical compoundC1=C(Cl)C(OC(F)(F)C(C(F)(F)F)F)=CC(Cl)=C1NC(=O)NC(=O)C1=C(F)C=CC=C1FPWPJGUXAGUPAHP-UHFFFAOYSA-N0.000description1

- 238000005065miningMethods0.000description1

- 230000008439repair processEffects0.000description1

- 239000000126substanceSubstances0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B27/00—Other grinding machines or devices

- B24B27/033—Other grinding machines or devices for grinding a surface for cleaning purposes, e.g. for descaling or for grinding off flaws in the surface

- B24B27/04—Grinding machines or devices in which the grinding tool is supported on a swinging arm

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25J—MANIPULATORS; CHAMBERS PROVIDED WITH MANIPULATION DEVICES

- B25J11/00—Manipulators not otherwise provided for

- B25J11/005—Manipulators for mechanical processing tasks

- B25J11/0065—Polishing or grinding

Definitions

- This inventionrelates to the use of robotic technology in mining industry, specifically in electrometallurgical and industrial processes.

- the electrodeposition processis one of the current and simplest methods to recover, in a pure and selective way, the metals in a solution

- This processmainly uses the permanent cathodes or base plates, which are deposited in tanks for a determined period of time and through the electrometallurgical process, the metal in the solution starts to deposit in the walls of the plate until reaching a determined weight. Once the weight is reached, the cathodes are retrieved (harvest) through an operation carried out by the bridge crane, which takes the volume of cathodes of each cell and moves them to the scrubbing tunnel. From the scrubbing tunnel the cathodes pass to the stripping machine where the copper is finally separated from the base plates.

- the base platesdeteriorates on a continuous basis which is caused by the chemical (corrosion) or mechanical (bending, and hammering during stripping) effects. Due to this, the base plates should be constantly subjected to repair where the surface is polished and the insulation is replaced.

- the maintenance of the base platesis carried out manually, which presents high maintenance costs and low quality levels. This causes the electrodeposition process to have low quality base plates that affect the efficiency of the process.

- a robotic systemhas been developed for the maintenance of the base plates where one robotic arm polishes the base plate then a second robotic arm replaces their insulation in an automated way.

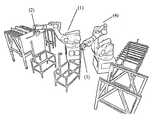

- FIG. 1View of a robotic manipulator system for the maintenance process of base plates in electrometallurgical and industrial processes.

- FIG. 2View of a robotic manipulator system for the maintenance process of base plates in electrometallurgical and industrial processes

- FIG. 3View of a robotic manipulator system for the maintenance process of base plates in electrometallurgical and industrial processes

- This inventionrefers to a new robot system for the maintenance of base plates in electrometallurgical and industrial processes, where the polishing and replacement of base plates is carried out automatically.

- the robot systemis composed mainly of one robotic manipulator ( 1 ) of at least 5 degrees of freedom, provided with a communication, acquisition and control system, and a gripping mechanism ( 2 ) which allows to take the polishing device ( 3 ) from a tool holder, so as a second robotic manipulator ( 4 ), provided with a communication, acquisition and control system, and a gripping mechanism ( 5 ) removes and replace the base plate insulation.

- the systemcould be integrated into a single manipulator which has the two functions.

- the configuration of one or two manipulatorswill depend on the flow of base plates to be subjected to maintenance.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Robotics (AREA)

- Manipulator (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

Abstract

Description

- This application claims the benefit of provisional patent application Ser. No. 60/734,982 filed 2005 Nov. 10 by the present inventor

- Not Applicable

- Not Applicable

- 1. Field of Invention

- This invention relates to the use of robotic technology in mining industry, specifically in electrometallurgical and industrial processes.

- 2. Prior Art

- The electrodeposition process is one of the current and simplest methods to recover, in a pure and selective way, the metals in a solution This process mainly uses the permanent cathodes or base plates, which are deposited in tanks for a determined period of time and through the electrometallurgical process, the metal in the solution starts to deposit in the walls of the plate until reaching a determined weight. Once the weight is reached, the cathodes are retrieved (harvest) through an operation carried out by the bridge crane, which takes the volume of cathodes of each cell and moves them to the scrubbing tunnel. From the scrubbing tunnel the cathodes pass to the stripping machine where the copper is finally separated from the base plates.

- As a result of this process the base plates deteriorates on a continuous basis which is caused by the chemical (corrosion) or mechanical (bending, and hammering during stripping) effects. Due to this, the base plates should be constantly subjected to repair where the surface is polished and the insulation is replaced.

- At present, the maintenance of the base plates is carried out manually, which presents high maintenance costs and low quality levels. This causes the electrodeposition process to have low quality base plates that affect the efficiency of the process.

- A robotic system has been developed for the maintenance of the base plates where one robotic arm polishes the base plate then a second robotic arm replaces their insulation in an automated way.

- In the drawings, closely related figures share the same numbers, with different alphabetic suffixes.

FIG. 1 . View of a robotic manipulator system for the maintenance process of base plates in electrometallurgical and industrial processes.FIG. 2 . View of a robotic manipulator system for the maintenance process of base plates in electrometallurgical and industrial processesFIG. 3 . View of a robotic manipulator system for the maintenance process of base plates in electrometallurgical and industrial processes- 1. Robotic manipulator

- 2. Gripping mechanism

- 3. Polishing device

- 4. Robotic manipulator

- 5. Gripping mechanism

- This invention refers to a new robot system for the maintenance of base plates in electrometallurgical and industrial processes, where the polishing and replacement of base plates is carried out automatically.

- With reference to

FIG. 1 ,FIG. 2 , andFIG. 3 , the robot system is composed mainly of one robotic manipulator (1) of at least 5 degrees of freedom, provided with a communication, acquisition and control system, and a gripping mechanism (2) which allows to take the polishing device (3) from a tool holder, so as a second robotic manipulator (4), provided with a communication, acquisition and control system, and a gripping mechanism (5) removes and replace the base plate insulation. - Additionally the system could be integrated into a single manipulator which has the two functions. The configuration of one or two manipulators will depend on the flow of base plates to be subjected to maintenance.

Claims (31)

1. A robot system for the maintenance of base plates in electrometallurgical and industrial processes, comprising two anthropomorphous robotic arms of at least 5 degrees of freedom, each of which is provided with one control, communication and programming unit, one gripper adapter, one pneumatic gripper, its fingers, one pneumatic gripper driving system, one electric supply system, one polishing device and a tool holder wherein the first anthropomorphous robotic arm of at least 5 degrees of freedom is provided with a multifunctional gripping mechanism which allows in a sequential and programmed way to take a polishing device from a tool holder located at one of its sides, and move it through a defined path to the polishing area where the polishing process of the base plates is carried out and once this task is ended a second anthropomorphous robotic arm of at least 5 degrees of freedom carries out the replacement of base plates insulation in an automated way.

2. A robot system for the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein the anthropomorphous robotic manipulator could communicate by itself or through a PLC interface with the control system.

3. A robot system for the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein the anthropomorphous robotic manipulator has the capacity to obtain and interpret the information from installed analogue and/or digital sensors.

4. A robot system for the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein the anthropomorphous robotic manipulator has the capacity to generate analogue and/or digital signals to control analogue and/or digital input devices.

5. A robot system for the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein a multifunctional gripping mechanism is used to manipulate and polish the base plates.

6. A robot system for the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein a multifunctional gripper is used to remove and replace the insulation and also to move the base plates.

7. A robot system for the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein it has the capacity to move, manipulate and release the polishing device for the base plates and/or cathodes in different paths within the work volume of the robotic system.

8. A robot system for the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein the anthropomorphous robotic arms of at least 5 degrees of freedom are mounted on a fixed and/or mobile support.

9. A robot system for the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein a multifunctional pneumatic gripper is used which allows in a sequential and programmed way to take, manipulate and release the polishing device of the base plates and/or cathodes.

10. A robot system for the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein a pneumatic gripper is used comprising of at least 4 fingers, which allows to grasp and/or release the polishing device of the base plates and/or cathodes.

11. A robot system for the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein a multifunctional pneumatic gripping mechanism is used to carry out the automated replacement of base plates insulation in a sequential and programmed way.

12. A robot system for el the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein the anthropomorphous robotic manipulator has an electrical system driven by three-stage induction motors, with vectorial and/or scalar control.

13. A robot system for the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein productivity and efficiency in the polishing procedures of the base plates and the replacement of base plates insulation in electrometallurgical processes of different metals increases.

14. A robot system for the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein the system may operate automatically, or semiautomatically, and also allows solutions scalability.

15. A robot system for el the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein the system could be integrated to the ISA process and the Kidd process.

16. A robot system for the maintenance of base plates in electrometallurgical and industrial processes according toclaim 1 , wherein it prevents the plant personnel from being subjected to a high physical demand and harsh environmental conditions.

17. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein the first anthropomorphous robotic arm of at least 5 degrees of freedom is provided with a multifunctional gripping mechanism which allows in a sequential and programmed way to take a polishing device from a tool holder located at one of its sides, and moves it through a defined path, to the polishing area where the polishing process of the base plates will take place, so as once this process is ended a second anthropomorphous robotic arm of at least 5 degrees of freedom replaces the insulation of base plates in an automated way.

18. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein the anthropomorphous robotic manipulator could communicate by itself or through a PLC interface with the control system.

19. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein the anthropomorphous robotic manipulator has the capacity to obtain and interpret the information from installed analogue and/or digital sensors.

20. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein the anthropomorphous robotic manipulator has the capacity to generate analogue and/or digital signals to control the analogue and/or digital inputs devices.

21. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein a multifunctional gripping mechanism is used to manipulate and polish the base plates.

22. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein a multifunctional gripping mechanism is used to remove and replace the insulation and also moves the base plates.

23. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein it has the capacity to move, manipulate and release the polishing device of the base plates and/or cathodes in different paths within the work volume of the robotic system.

24. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein the anthropomorphous robotic arms of at least 5 degrees of freedom are mounted on a fixed and/or mobile support.

25. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein a multifunctional gripping mechanism is used to take, manipulate and release in a sequential and programmed way the base plates and/or cathodes.

26. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein a pneumatic gripping mechanism is used comprising at least 4 fingers which allow to grasp and/or release the polishing device of base plates and/or cathodes.

27. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein a multifunctional gripping mechanism is used to replace in a sequential and programmed way the insulation of the base plates and/or cathodes in an automated way.

28. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein productivity and efficiency in the polishing procedures of the base plates and replacement of the insulation of base plates in electrometallurgical processes of different metals.

29. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein the system may operate automatically or semiautomatically, and also allows solution scalability.

30. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein the system could be integrated both to the ISA process and to the Kidd process.

31. Method for the maintenance of base plates in electrometallurgical and industrial processes using the robot System ofclaim 1 to16, wherein it prevents the plant personnel from being subjected to a high physical demand and hash environmental conditions.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/598,137US20070147961A1 (en) | 2005-11-10 | 2006-11-13 | Robot system and method for maintenance of base plates in electrometallurgical and industrial processes |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US73498205P | 2005-11-10 | 2005-11-10 | |

| US11/598,137US20070147961A1 (en) | 2005-11-10 | 2006-11-13 | Robot system and method for maintenance of base plates in electrometallurgical and industrial processes |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US11/598,138Continuation-In-PartUS20090121061A1 (en) | 2005-11-10 | 2006-11-13 | Robot system and method for unblocking the primary crusher |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US11/598,123Continuation-In-PartUS20070153260A1 (en) | 2005-11-10 | 2006-11-13 | Robot system and method for anode surface inspection and burr elimination in smelting and electrorefining processes |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US20070147961A1true US20070147961A1 (en) | 2007-06-28 |

Family

ID=38193956

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US11/598,137AbandonedUS20070147961A1 (en) | 2005-11-10 | 2006-11-13 | Robot system and method for maintenance of base plates in electrometallurgical and industrial processes |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US20070147961A1 (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20070149098A1 (en)* | 2005-11-10 | 2007-06-28 | Hugo Salamanca | Robot system and method for ball loading for loading into SAG and/or ball mills in ore concentration processes |

| US20070156287A1 (en)* | 2005-11-10 | 2007-07-05 | Hugo Salamanca | Robot system and method for inspecting and repairing casts in smelting processes |

| US8607837B2 (en) | 2009-02-06 | 2013-12-17 | Xstrata Technology Pty Ltd. | Apparatus for stripping metal from a cathode plate |

| US20150367464A1 (en)* | 2014-06-23 | 2015-12-24 | Taizhou Federal Robot Technology Co., Ltd | Processing System and Method for a Work Piece Surface |

| CN105643636A (en)* | 2016-04-13 | 2016-06-08 | 广州文冲船厂有限责任公司 | Robot polishing device |

| CN109581956A (en)* | 2018-11-16 | 2019-04-05 | 广东利迅达机器人系统股份有限公司 | A kind of intelligence of lorry axle housing polishing station takes knife-changing system and its control method |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4603511A (en)* | 1983-11-15 | 1986-08-05 | Aida Engineering Limited | Grinding robot |

| US4608651A (en)* | 1982-10-28 | 1986-08-26 | Kabushiki Kaisha Kobe Seiko Sho | Control system for direct teaching/playback type robots |

| US5789890A (en)* | 1996-03-22 | 1998-08-04 | Genmark Automation | Robot having multiple degrees of freedom |

| US20040022940A1 (en)* | 2001-02-23 | 2004-02-05 | Mizuki Nagai | Cooper-plating solution, plating method and plating apparatus |

| US6689257B2 (en)* | 2000-05-26 | 2004-02-10 | Ebara Corporation | Substrate processing apparatus and substrate plating apparatus |

| US20040254677A1 (en)* | 2003-06-11 | 2004-12-16 | Torgny Brogardh | Method for fine tuning of a robot program |

| US20040251866A1 (en)* | 2003-06-11 | 2004-12-16 | Zhongxue Gan | Method for calibrating and programming of a robot application |

| US6913650B2 (en)* | 2002-11-12 | 2005-07-05 | Godfrey & Wing, Inc. | Component impregnation |

| US20050155865A1 (en)* | 2003-05-16 | 2005-07-21 | Koji Mishima | Electrolytic processing apparatus and method |

| US7033464B2 (en)* | 2001-04-11 | 2006-04-25 | Speedfam-Ipec Corporation | Apparatus for electrochemically depositing a material onto a workpiece surface |

| US7260450B2 (en)* | 2003-09-22 | 2007-08-21 | Matsushita Electric Industrial Co., Ltd. | Apparatus and method for controlling elastic actuator |

- 2006

- 2006-11-13USUS11/598,137patent/US20070147961A1/ennot_activeAbandoned

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4608651A (en)* | 1982-10-28 | 1986-08-26 | Kabushiki Kaisha Kobe Seiko Sho | Control system for direct teaching/playback type robots |

| US4603511A (en)* | 1983-11-15 | 1986-08-05 | Aida Engineering Limited | Grinding robot |

| US5789890A (en)* | 1996-03-22 | 1998-08-04 | Genmark Automation | Robot having multiple degrees of freedom |

| US6037733A (en)* | 1996-03-22 | 2000-03-14 | Genmark Automation | Robot having multiple degrees of freedom |

| US6689257B2 (en)* | 2000-05-26 | 2004-02-10 | Ebara Corporation | Substrate processing apparatus and substrate plating apparatus |

| US20040022940A1 (en)* | 2001-02-23 | 2004-02-05 | Mizuki Nagai | Cooper-plating solution, plating method and plating apparatus |

| US7033464B2 (en)* | 2001-04-11 | 2006-04-25 | Speedfam-Ipec Corporation | Apparatus for electrochemically depositing a material onto a workpiece surface |

| US6913650B2 (en)* | 2002-11-12 | 2005-07-05 | Godfrey & Wing, Inc. | Component impregnation |

| US20050155865A1 (en)* | 2003-05-16 | 2005-07-21 | Koji Mishima | Electrolytic processing apparatus and method |

| US20040254677A1 (en)* | 2003-06-11 | 2004-12-16 | Torgny Brogardh | Method for fine tuning of a robot program |

| US20040251866A1 (en)* | 2003-06-11 | 2004-12-16 | Zhongxue Gan | Method for calibrating and programming of a robot application |

| US7260450B2 (en)* | 2003-09-22 | 2007-08-21 | Matsushita Electric Industrial Co., Ltd. | Apparatus and method for controlling elastic actuator |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20070149098A1 (en)* | 2005-11-10 | 2007-06-28 | Hugo Salamanca | Robot system and method for ball loading for loading into SAG and/or ball mills in ore concentration processes |

| US20070156287A1 (en)* | 2005-11-10 | 2007-07-05 | Hugo Salamanca | Robot system and method for inspecting and repairing casts in smelting processes |

| US7551981B2 (en)* | 2005-11-10 | 2009-06-23 | Hugo Salamanca | Robot system and method for inspecting and repairing casts in smelting processes |

| US7567855B2 (en)* | 2005-11-10 | 2009-07-28 | Hugo Salamanca | Robot system and method for ball loading for loading into SAG and/or ball mills in ore concentration processes |

| US8607837B2 (en) | 2009-02-06 | 2013-12-17 | Xstrata Technology Pty Ltd. | Apparatus for stripping metal from a cathode plate |

| US20150367464A1 (en)* | 2014-06-23 | 2015-12-24 | Taizhou Federal Robot Technology Co., Ltd | Processing System and Method for a Work Piece Surface |

| US9393653B2 (en)* | 2014-06-23 | 2016-07-19 | Taizhou Federal Robot Technology Co., Ltd | Processing system and method for a work piece surface |

| CN105643636A (en)* | 2016-04-13 | 2016-06-08 | 广州文冲船厂有限责任公司 | Robot polishing device |

| CN109581956A (en)* | 2018-11-16 | 2019-04-05 | 广东利迅达机器人系统股份有限公司 | A kind of intelligence of lorry axle housing polishing station takes knife-changing system and its control method |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20070144894A1 (en) | Robot system and method for cathode stripping in electrometallurgical and industrial processes | |

| US20070147961A1 (en) | Robot system and method for maintenance of base plates in electrometallurgical and industrial processes | |

| US20070152616A1 (en) | Robot system and method for cathode selection and handling procedures after the harvest | |

| US20070144005A1 (en) | Robot system and method for reposition and/or removal of base plates from cathode stripping machines in electrometallurgical processes | |

| US20070267043A1 (en) | Robot system and method for washing and unclogging procedures of machines under maintenance | |

| CN101294291B (en) | Shifting apparatus for electrolytic deposition metal | |

| CN204621750U (en) | A robot combined grinding system | |

| CN107803819B (en) | Robot system | |

| US20070144006A1 (en) | Robotic system and method for a transfer station for cathodes and/or base plates | |

| CN106743550B (en) | Flexible compensation robot automatic loading and unloading system | |

| US20070151580A1 (en) | Robot system and method for cathode washing in industrial and electrometallurgical processes | |

| CN106737795B (en) | A kind of the tool fast replacing device and method of dynamic power machine hand | |

| US20070149098A1 (en) | Robot system and method for ball loading for loading into SAG and/or ball mills in ore concentration processes | |

| NO336059B1 (en) | Method and apparatus for cleaning carbon anodes | |

| CN202107783U (en) | Manganese and zinc electrolysis and electrodeposition robot washing, stripping and polishing machine set | |

| US20070145649A1 (en) | Robot system and method for copper concentrate injector cleaning in the flash furnace | |

| CN105204479A (en) | Centralized control system and control method for zinc stripping production line | |

| WO2022071931A1 (en) | Gripper multi tool to perform multiple functions subsea | |

| CN212981567U (en) | Motor assembly material taking and overturning device | |

| US20070185610A1 (en) | Robot system and method for the application of dislodging material and pin positioning in casting wheels | |

| US7551981B2 (en) | Robot system and method for inspecting and repairing casts in smelting processes | |

| JP2008169409A (en) | Electrolytically cleaned metal plate cleaning equipment | |

| CN103849892A (en) | Novel equipment for cleaning residual anode electrolyte | |

| US20090121061A1 (en) | Robot system and method for unblocking the primary crusher | |

| US20070153260A1 (en) | Robot system and method for anode surface inspection and burr elimination in smelting and electrorefining processes |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AS | Assignment | Owner name:MI ROBOTIC SOLUTIONS (MIRS), CHILE Free format text:ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:SALAMANCA P., HUGO;REEL/FRAME:022990/0599 Effective date:20090717 Owner name:MI ROBOTIC SOLUTIONS (MIRS),CHILE Free format text:ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:SALAMANCA P., HUGO;REEL/FRAME:022990/0599 Effective date:20090717 | |

| STCB | Information on status: application discontinuation | Free format text:ABANDONED -- FAILURE TO RESPOND TO AN OFFICE ACTION |