US20040007188A1 - Gas-purged vacuum valve - Google Patents

Gas-purged vacuum valveDownload PDFInfo

- Publication number

- US20040007188A1 US20040007188A1US10/447,446US44744603AUS2004007188A1US 20040007188 A1US20040007188 A1US 20040007188A1US 44744603 AUS44744603 AUS 44744603AUS 2004007188 A1US2004007188 A1US 2004007188A1

- Authority

- US

- United States

- Prior art keywords

- gate

- vacuum valve

- seat

- sealing face

- seal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

- 238000007789sealingMethods0.000claimsabstractdescription98

- 238000010926purgeMethods0.000claimsabstractdescription81

- 238000012545processingMethods0.000claimsabstractdescription40

- 239000007789gasSubstances0.000claimsdescription139

- 238000000034methodMethods0.000claimsdescription31

- 239000012159carrier gasSubstances0.000claimsdescription17

- 238000004377microelectronicMethods0.000claimsdescription15

- 230000008569processEffects0.000claimsdescription13

- 239000000203mixtureSubstances0.000claimsdescription12

- QVGXLLKOCUKJST-UHFFFAOYSA-Natomic oxygenChemical compound[O]QVGXLLKOCUKJST-UHFFFAOYSA-N0.000claimsdescription11

- 239000001301oxygenSubstances0.000claimsdescription11

- 229910052760oxygenInorganic materials0.000claimsdescription11

- 239000004065semiconductorSubstances0.000claimsdescription11

- 235000012431wafersNutrition0.000description10

- 238000012546transferMethods0.000description7

- 239000011261inert gasSubstances0.000description4

- 239000000463materialSubstances0.000description3

- 238000009826distributionMethods0.000description2

- 229920001971elastomerPolymers0.000description2

- 239000000806elastomerSubstances0.000description2

- 238000001125extrusionMethods0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- XUIMIQQOPSSXEZ-UHFFFAOYSA-NSiliconChemical compound[Si]XUIMIQQOPSSXEZ-UHFFFAOYSA-N0.000description1

- 238000013459approachMethods0.000description1

- 230000000712assemblyEffects0.000description1

- 238000000429assemblyMethods0.000description1

- 238000004140cleaningMethods0.000description1

- 238000011109contaminationMethods0.000description1

- 230000007812deficiencyEffects0.000description1

- 230000001419dependent effectEffects0.000description1

- 230000008021depositionEffects0.000description1

- 229920001973fluoroelastomerPolymers0.000description1

- 230000006872improvementEffects0.000description1

- 238000011065in-situ storageMethods0.000description1

- 230000002452interceptive effectEffects0.000description1

- 230000001788irregularEffects0.000description1

- 238000003754machiningMethods0.000description1

- 239000002184metalSubstances0.000description1

- 230000008520organizationEffects0.000description1

- 239000002245particleSubstances0.000description1

- 230000001681protective effectEffects0.000description1

- 229910052710siliconInorganic materials0.000description1

- 239000010703siliconSubstances0.000description1

- 229910001220stainless steelInorganic materials0.000description1

- 239000010935stainless steelSubstances0.000description1

- 239000000758substrateSubstances0.000description1

Images

Classifications

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67126—Apparatus for sealing, encapsulating, glassing, decapsulating or the like

Definitions

- This inventionrelates to processing of semiconductors used to make microelectronic devices and in particular to vacuum valves used in devices for processing such semiconductors.

- Processing chambersare utilized for a variety of processes performed on microelectronic devices such as microelectronic circuits formed on silicon semiconductor substrates. Since these processes may be operated and performed under vacuum, vacuum gate valves are typically employed. Such vacuum gate valves, when used as wafer pass-throughs between vacuum chambers, are often referred to as slit valves. When the slit valve gate is open, semiconductor wafers may be moved from a transfer chamber to a load lock or process chamber or vice-versa. When closed, these valves prevent gas leakage between the transfer chamber and the process chamber. While such slit valves provide generally reliable seals for most processes, certain new deposition and clean processes have been found to rapidly attack elastomeric seal materials utilized in the slit valves.

- a guillotine type valve assemblyemploys gas ducts either in the valve seat or in the valve plate. These gas ducts are used to carry a nonactive gas into the gap area between the valve plate and the valve seat. While such an approach has its advantages for shielding the 0 -rings used in the assembly with an inert gas during processing, the disclosed structure does not provide particularly effective control over the inert gas flow rate or distribution, and an overflow of such inert gas may interfere with the processing of the microelectronic device itself in the chamber.

- a vacuum valve assemblyfor use in a vacuum processing chamber comprising: a vacuum processing chamber vacuum valve; a seat defining an opening in the vacuum valve, the seat having a sealing face adjacent to the opening and normal to the direction of the opening; and a gate having a sealing face adapted to mate with the seat sealing face, the gate being movable toward and away from the seat sealing face to seal and open the vacuum valve opening.

- a continuous elastomeric sealextends around the vacuum valve opening between the gate sealing face and the seat sealing face of sufficient size such that when the gate is positioned to seal the vacuum valve opening, there exists a gap between the gate sealing face and the seat sealing face.

- a purge gas port systemhas an inlet for a purge gas, an essentially continuous outlet extending around the vacuum valve opening and adjacent the elastomeric seal and gap, and a manifold system connecting the inlet and the outlet. When a purge gas is introduced through the inlet, the manifold distributes the gas to the outlet which evenly distributes the gas to the vicinity of the continuous elastomeric seal around the vacuum valve opening in the gap between the gate sealing face and the seat sealing face.

- the purge gas port systemmay be disposed in the seat or in the gate.

- the purge gas port system outletis preferably defined by a first gate portion having the continuous elastomeric seal secured on the gate sealing face and a second gate portion secured within the first gate portion and facing the vacuum valve opening, so that the purge gas outlet is formed by a gap between the first and second gate portions extending essentially continuously around the first gate portion adjacent the elastomeric seal.

- the gap between the first and second gate portions forming the purge gas outletmay be smaller than the gap between the gate sealing face and the seat sealing face.

- the purge gas outletmay be formed by an opening narrower than the gap between the gate sealing face and the seat sealing face.

- the purge gas port system outletitself may be a slit, a series of holes or slots, a porous media adjacent the elastomeric seal, or a porous portion of the elastomeric seal.

- the present inventioncomprises a vacuum processing chamber comprising a vacuum processing chamber having a vacuum valve; a seat defining an opening in the vacuum valve, the seat having a sealing face adjacent the opening and normal to the direction of the opening; and a gate having a sealing face adapted to mate with the seat sealing face.

- the gateis movable toward and away from the seat sealing face to seal and open the vacuum valve opening, and includes a continuous elastomeric seal on the gate sealing face around the vacuum valve opening of sufficient size such that when the gate is positioned to seal the vacuum valve opening, there exists a gap between the gate sealing face and the seat sealing face.

- a purge gas port system in the gatehaving an inlet for a purge gas, an essentially continuous outlet in the gate sealing face extending around the vacuum valve opening and within and adjacent the elastomeric seal, and a manifold system connecting the inlet and the outlet.

- the manifolddistributes the gas to the outlet which evenly distributes the gas to the vicinity of the continuous elastomeric seal around the vacuum valve opening in the gap between the gate sealing face and the seat sealing face.

- the purge gas port system outletmay be defined by a first gate portion having the continuous elastomeric seal secured on the gate sealing face and a second gate portion secured within the first gate portion and facing the vacuum valve opening.

- the purge gas outletis formed by a gap between the first and second gate portions extending essentially continuously around the first gate portion adjacent the elastomeric seal. The gap between the first and second gate portions forming the purge gas outlet is smaller than the gap between the gate sealing face and the seat sealing face.

- the present inventionprovides a vacuum processing chamber having a vacuum valve; a seat defining an opening in the vacuum valve, the seat having a sealing face adjacent the opening and normal to the direction of the opening; and a gate having a sealing face adapted to mate with the seat sealing face.

- the gateis movable toward and away from the seat sealing face to seal and open the vacuum valve opening, and includes a continuous elastomeric seal on the gate sealing face around the vacuum valve opening of sufficient size such that when the gate is positioned to seal the vacuum valve opening, there exists a gap between the gate sealing face and the seat sealing face.

- a purge gas port system in the seathaving an inlet for a purge gas, an essentially continuous outlet in the seat sealing face extending around the vacuum valve opening and within and adjacent the elastomeric seal, and a manifold system connecting the inlet and the outlet.

- the manifolddistributes the gas to the outlet which evenly distributes the gas to the vicinity of the continuous elastomeric seal around the vacuum valve opening in the gap between the gate sealing face and the seat sealing face.

- the gap between the first and second gate portions forming the purge gas outletmay be smaller than the gap between the gate sealing face and the seat sealing face.

- a further aspect of the present inventionprovides a method of extending life to a seal in a vacuum valve used in a vacuum processing chamber.

- the methodcomprises providing a semiconductor wafer processing chamber having a vacuum valve seat, a gate closing the vacuum valve seat, and a seal between the gate and the vacuum valve seat, the seal being exposed to the chamber.

- the methodthen includes introducing a reactive gas mixture to the chamber to process a semiconductor wafer therein, the reactive gas mixture comprising a reactive gas, adapted to react with a portion of the semiconductor wafer, diluted by a carrier gas, the reactive gas also being reactive with the seal.

- the present inventionprovides a method of extending life to a seal in a vacuum valve used in a vacuum processing chamber comprising providing a microelectronic circuit processing chamber having a vacuum valve seat, a gate closing the vacuum valve seat, and a seal between the gate and the vacuum valve seat, the seal being exposed to the chamber.

- the methodthen includes introducing a reactive gas mixture to the chamber to process a microelectronic device therein, the reactive gas mixture comprising a reactive gas adapted to react with a portion of the microelectronic device, diluted by a carrier gas, wherein said reactive gas is also reactive with said seal.

- FIG. 3is a perspective view of the seat portion of the vacuum valve of FIG. 1.

- FIG. 6is a perspective view of the gate insert portion of the slit valve of FIG. 1.

- FIG. 8is a cross-sectional elevational view of a second embodiment of the vacuum valve of the present invention.

- the preferred embodiment of the present inventionprovides a method and system whereby purge gas employed to protect the elastomeric seal in a gate valve, e.g., a slit valve, assembly utilized in microelectronic device processing chambers is distributed via an outlet that follows the approximately rectangular geometry of the seal, or whatever geometry the seal utilizes.

- the purge gasis flowed directly at the seal via a precision slit or one or more other opening in the gate or seat, and is not dependent upon the often irregular gap between the gate and seat for distribution of the purge gas.

- Valve seat 30has essentially a planar face 31 which is spaced from and opposite planar gate face 43 .

- the generally rectangular slit valve opening in seat 30is formed by opening or walls 32 and conforms to and is aligned with opening 24 in the process module.

- a groove 42releaseably secures an elastomeric O-ring 44 and is configured so that the groove and O-ring received therein extend completely around gate face 43 and around seat opening 32 .

- the size and material of the O-ringis selected so that when gate 40 is closed and sealed against seat 30 , O-ring 44 provides a vacuum-tight seal between the seat and gate and further creates a gap 34 between seat face 31 and gate face 43 .

- the elastomeric O-ring sealmay be replaceable, or may be vulcanized to the groove, or may be attached to a thin frame so that the frame and seal may be removed or installed as a unit.

- a purge gas outlet 48comprises a slit in gate 40 which extends around the entirety of seat opening 32 in the vicinity of O-ring 44 .

- Slit 48meters the desired flow of purge gas to protect O-ring 44 .

- Preferably slit 48is narrower than gap 34 and is carefully controlled as desired to reduce excess purge gas flow. Such purge gas may interfere with the atmosphere required in processing chamber 20 and therefore excess quantities are undesirable.

- the present inventionmay use a series of holes or slots for the purge gas in the vicinity of O-ring 44 .

- the slit, holes or slotspreferably form an essentially continuous opening of purge gas outlet 48 .

- gate purge gas outlet 48is made by machining or otherwise forming an opening 45 in gate 40 which receives a gate insert 50 .

- Gate insert 50has approximately the same configuration as gate opening 45 but is formed so that when the insert is mated into the gate opening, a gap or slit is created which forms gas outlet opening between the two.

- the inserthas beveled edge 54 which corresponds to the angle of gate opening 45 .

- openingsare created 46 within the gate 40 which may efficiently deliver the desired amount of purge gas flow to outlet 48 .

- the gas inlet 41provides a passageway connection to manifold 46 .

- the purge gas outletis provided in the seat 30 A in the form of a continuous outlet 37 which again extends around the slit valve opening in the vicinity of the gate seal.

- the continuous seal outlet 37is formed by a seat insert 33 which fits within seat opening 32 and is spaced therefrom to create the controlled gap in outlet 39 .

- this gap 39 which forms the continuous seat outletis narrower than gap 34 between the gate face 43 and seat face 31 .

- outlet 37may comprise a plurality of holes, slots or other essentially continuous openings.

- Gasis provided to the seat outlet through an inlet 36 A which connects to a manifold 33 which distributes the gas evenly to the seat outlet 39 .

- Purge gas outlet 128extends into groove 42 to direct flow of purge gas through porous media 245 and into the vicinity of O-ring 244 .

- the purge gasis fed from the manifold through a porous co-extrusion (FIG. 10) or porous media (FIG. 11) so that it is distributed around the full extent of the slit valve in the vicinity of the O-ring seal to protect the O-ring during processing.

- the amount of oxygen utilized as the carrier gasis reduced by the amount which is used in the purge gas system, since the latter will eventually flow into the processing chamber and dilute the reactive gas as required.

- the amount of oxygen carrier gas to be used as a purge gasmay be determined without undue experimentation for any particular reactive gas system.

- the present inventionachieves the objects above.

- the use of the continuous outlets around the seat opening in the vicinity of the sealpermits more efficient usage of the purge gas.

- This openingmay be essentially continuous and interrupted to a small degree without effecting the essentially continuous flow around the seat opening.

- the use of non-inert carrier gases as purge gasesreduces the attack of the reactive gas in the system on the elastomeric seals, and not interfering with the conventional gas chemistry within the processing chamber.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Sliding Valves (AREA)

Abstract

Description

- 1. Field of the Invention[0001]

- This invention relates to processing of semiconductors used to make microelectronic devices and in particular to vacuum valves used in devices for processing such semiconductors.[0002]

- 2. Description of Related Art[0003]

- Processing chambers are utilized for a variety of processes performed on microelectronic devices such as microelectronic circuits formed on silicon semiconductor substrates. Since these processes may be operated and performed under vacuum, vacuum gate valves are typically employed. Such vacuum gate valves, when used as wafer pass-throughs between vacuum chambers, are often referred to as slit valves. When the slit valve gate is open, semiconductor wafers may be moved from a transfer chamber to a load lock or process chamber or vice-versa. When closed, these valves prevent gas leakage between the transfer chamber and the process chamber. While such slit valves provide generally reliable seals for most processes, certain new deposition and clean processes have been found to rapidly attack elastomeric seal materials utilized in the slit valves. The attack on such elastomeric seal materials typically causes particle contamination or “adders” on wafers and also may cause vacuum leakage across the valve itself. Although a wide variety of elastomers are available, none thus far tested have shown a significant improvement in life over the normally employed fluoroelastomers.[0004]

- The concept of purging the general area with an inert gas has been discussed in Japanese Patent Publication No. 6-185672. In this publication entitled Gate Valve Device For Use With A Vacuum, a guillotine type valve assembly employs gas ducts either in the valve seat or in the valve plate. These gas ducts are used to carry a nonactive gas into the gap area between the valve plate and the valve seat. While such an approach has its advantages for shielding the[0005]0-rings used in the assembly with an inert gas during processing, the disclosed structure does not provide particularly effective control over the inert gas flow rate or distribution, and an overflow of such inert gas may interfere with the processing of the microelectronic device itself in the chamber.

- Accordingly, there is a need for a valve system which may utilize a purge gas more efficiently and in a manner which would not tend to interfere with the processing of the microelectronic device.[0006]

- Bearing in mind the problems and deficiencies of the prior art, it is therefore an object of the present invention to provide an efficient purge gas system for elastomeric seals in gate or slit valve assemblies used in microelectronic device processing.[0007]

- It is another object of the present invention to provide a method and system whereby the purge gas is employed more efficiently.[0008]

- It is a further object of the present invention to provide a method and system in which the purge gas is less likely to interfere with the processing of the microelectronic device in the processing chamber.[0009]

- The above and other objects, which will be apparent to those skilled in the art, are achieved by the present invention which comprises, in a first aspect, a vacuum valve assembly for use in a vacuum processing chamber comprising: a vacuum processing chamber vacuum valve; a seat defining an opening in the vacuum valve, the seat having a sealing face adjacent to the opening and normal to the direction of the opening; and a gate having a sealing face adapted to mate with the seat sealing face, the gate being movable toward and away from the seat sealing face to seal and open the vacuum valve opening. A continuous elastomeric seal extends around the vacuum valve opening between the gate sealing face and the seat sealing face of sufficient size such that when the gate is positioned to seal the vacuum valve opening, there exists a gap between the gate sealing face and the seat sealing face. A purge gas port system has an inlet for a purge gas, an essentially continuous outlet extending around the vacuum valve opening and adjacent the elastomeric seal and gap, and a manifold system connecting the inlet and the outlet. When a purge gas is introduced through the inlet, the manifold distributes the gas to the outlet which evenly distributes the gas to the vicinity of the continuous elastomeric seal around the vacuum valve opening in the gap between the gate sealing face and the seat sealing face.[0010]

- The purge gas port system may be disposed in the seat or in the gate. When in the latter, the purge gas port system outlet is preferably defined by a first gate portion having the continuous elastomeric seal secured on the gate sealing face and a second gate portion secured within the first gate portion and facing the vacuum valve opening, so that the purge gas outlet is formed by a gap between the first and second gate portions extending essentially continuously around the first gate portion adjacent the elastomeric seal. The gap between the first and second gate portions forming the purge gas outlet may be smaller than the gap between the gate sealing face and the seat sealing face.[0011]

- In the vacuum valve assembly, the purge gas outlet may be formed by an opening narrower than the gap between the gate sealing face and the seat sealing face. The purge gas port system outlet itself may be a slit, a series of holes or slots, a porous media adjacent the elastomeric seal, or a porous portion of the elastomeric seal.[0012]

- In another aspect, the present invention comprises a vacuum processing chamber comprising a vacuum processing chamber having a vacuum valve; a seat defining an opening in the vacuum valve, the seat having a sealing face adjacent the opening and normal to the direction of the opening; and a gate having a sealing face adapted to mate with the seat sealing face. The gate is movable toward and away from the seat sealing face to seal and open the vacuum valve opening, and includes a continuous elastomeric seal on the gate sealing face around the vacuum valve opening of sufficient size such that when the gate is positioned to seal the vacuum valve opening, there exists a gap between the gate sealing face and the seat sealing face. There is also provided a purge gas port system in the gate having an inlet for a purge gas, an essentially continuous outlet in the gate sealing face extending around the vacuum valve opening and within and adjacent the elastomeric seal, and a manifold system connecting the inlet and the outlet. When a purge gas is introduced through the inlet, the manifold distributes the gas to the outlet which evenly distributes the gas to the vicinity of the continuous elastomeric seal around the vacuum valve opening in the gap between the gate sealing face and the seat sealing face.[0013]

- The purge gas port system outlet may be defined by a first gate portion having the continuous elastomeric seal secured on the gate sealing face and a second gate portion secured within the first gate portion and facing the vacuum valve opening. The purge gas outlet is formed by a gap between the first and second gate portions extending essentially continuously around the first gate portion adjacent the elastomeric seal. The gap between the first and second gate portions forming the purge gas outlet is smaller than the gap between the gate sealing face and the seat sealing face.[0014]

- In another aspect, the present invention provides a vacuum processing chamber having a vacuum valve; a seat defining an opening in the vacuum valve, the seat having a sealing face adjacent the opening and normal to the direction of the opening; and a gate having a sealing face adapted to mate with the seat sealing face. The gate is movable toward and away from the seat sealing face to seal and open the vacuum valve opening, and includes a continuous elastomeric seal on the gate sealing face around the vacuum valve opening of sufficient size such that when the gate is positioned to seal the vacuum valve opening, there exists a gap between the gate sealing face and the seat sealing face. There is also provided a purge gas port system in the seat having an inlet for a purge gas, an essentially continuous outlet in the seat sealing face extending around the vacuum valve opening and within and adjacent the elastomeric seal, and a manifold system connecting the inlet and the outlet. When a purge gas is introduced through the inlet, the manifold distributes the gas to the outlet which evenly distributes the gas to the vicinity of the continuous elastomeric seal around the vacuum valve opening in the gap between the gate sealing face and the seat sealing face. The gap between the first and second gate portions forming the purge gas outlet may be smaller than the gap between the gate sealing face and the seat sealing face.[0015]

- A further aspect of the present invention provides a method of extending life to a seal in a vacuum valve used in a vacuum processing chamber. The method comprises providing a semiconductor wafer processing chamber having a vacuum valve seat, a gate closing the vacuum valve seat, and a seal between the gate and the vacuum valve seat, the seal being exposed to the chamber. The method then includes introducing a reactive gas mixture to the chamber to process a semiconductor wafer therein, the reactive gas mixture comprising a reactive gas, adapted to react with a portion of the semiconductor wafer, diluted by a carrier gas, the reactive gas also being reactive with the seal. Thereafter, the method also includes introducing the carrier gas through an essentially continuous opening into the vicinity of the seal between the gate and the vacuum valve seat, with the carrier gas continuously flowing so as to initially shield the seal from the reactive gas and then subsequently pass into the chamber and mix with the reactive gas. The seal may form a gap between opposing sealing faces of the gate and seat, and the carrier gas may be introduced through an essentially continuous opening adjacent to narrower than the gap between the gate and seat sealing faces.[0016]

- In yet another aspect, the present invention provides a method of extending life to a seal in a vacuum valve used in a vacuum processing chamber comprising providing a microelectronic circuit processing chamber having a vacuum valve seat, a gate closing the vacuum valve seat, and a seal between the gate and the vacuum valve seat, the seal being exposed to the chamber. The method then includes introducing a reactive gas mixture to the chamber to process a microelectronic device therein, the reactive gas mixture comprising a reactive gas adapted to react with a portion of the microelectronic device, diluted by a carrier gas, wherein said reactive gas is also reactive with said seal. The method then includes introducing a portion of the reactive gas, such as oxygen into the vicinity of the seal between the gate and the vacuum valve seat, the reactive gas portion flowing so as to initially shield the seal and then subsequently pass into the chamber and mix with the remaining reactive gas. The carrier gas may also comprise oxygen. The reactive gas portion is preferably introduced through an essentially continuous opening into the vicinity of the seal between the gate and the vacuum valve seat. The seal may form a gap between opposing sealing faces of the gate and seat, so that the reactive gas portion is introduced through an essentially continuous opening in the gate or seat. The reactive gas may include NF[0017]3.

- The features of the invention believed to be novel and the elements characteristic of the invention are set forth with particularity in the appended claims. The figures are for illustration purposes only and are not drawn to scale, the invention itself, however, both as to organization and method of operation, may best be understood by reference to the detailed description which follows taken in conjunction with the accompanying drawings in which:[0018]

- FIG. 1 is a cross-sectional elevational view of a first embodiment of the vacuum valve of the present invention.[0019]

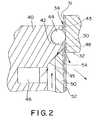

- FIG. 2 is a cross-sectional elevational view of a portion of the vacuum valve of FIG. 1 showing the purge gas outlet and seal.[0020]

- FIG. 3 is a perspective view of the seat portion of the vacuum valve of FIG. 1.[0021]

- FIG. 4 is a perspective view of the gate portion of the vacuum valve of FIG. 1.[0022]

- FIG. 5 is a cross-sectional elevational view of the gate of FIG. 4 along lines[0023]5-5.

- FIG. 6 is a perspective view of the gate insert portion of the slit valve of FIG. 1.[0024]

- FIG. 7 is a perspective view of the assembled gate and insert portions of the vacuum valve of FIG. 1.[0025]

- FIG. 8 is a cross-sectional elevational view of a second embodiment of the vacuum valve of the present invention.[0026]

- FIG. 9 is a perspective view of the seat portion of the vacuum valve of FIG. 8.[0027]

- FIG. 10 is a cross-sectional elevational view of another embodiment of the purge gas outlet and seal employed in the vacuum valve of FIG. 2.[0028]

- FIG. 11 is a cross-sectional elevational view of a further embodiment of the purge gas outlet and seal employed in the vacuum valve of FIG. 2.[0029]

- In describing the preferred embodiment of the present invention, reference will be made herein to FIGS.[0030]1-11 of the drawings in which like numerals refer to like features of the invention. Features of the invention are not necessarily shown to scale in the drawings.

- The preferred embodiment of the present invention provides a method and system whereby purge gas employed to protect the elastomeric seal in a gate valve, e.g., a slit valve, assembly utilized in microelectronic device processing chambers is distributed via an outlet that follows the approximately rectangular geometry of the seal, or whatever geometry the seal utilizes. The purge gas is flowed directly at the seal via a precision slit or one or more other opening in the gate or seat, and is not dependent upon the often irregular gap between the gate and seat for distribution of the purge gas.[0031]

- In a first embodiment as shown in FIGS.[0032]1-7, an otherwise

conventional processing module 20 having slit valve opening24 inwall 22 permits amicroelectronic device wafer 26 to be moved into and out of the processing chamber. Atransfer module 21 is attached to the process module in the vicinity of theopening 24 and facilitates the movement of thewafer 26 between stations into and out of the processing module. Between the transfer module and the processing module, there is a slit valve assembly which comprises avalve seat 30 and avalve gate 40.Gate 44 is moved into and out of position inseat 30 by anactuator 60. - [0033]

Valve seat 30 has essentially aplanar face 31 which is spaced from and oppositeplanar gate face 43. The generally rectangular slit valve opening inseat 30 is formed by opening orwalls 32 and conforms to and is aligned with opening24 in the process module. Agroove 42 releaseably secures an elastomeric O-ring 44 and is configured so that the groove and O-ring received therein extend completely aroundgate face 43 and aroundseat opening 32. The size and material of the O-ring is selected so that whengate 40 is closed and sealed againstseat 30, O-ring 44 provides a vacuum-tight seal between the seat and gate and further creates agap 34 betweenseat face 31 andgate face 43. The elastomeric O-ring seal may be replaceable, or may be vulcanized to the groove, or may be attached to a thin frame so that the frame and seal may be removed or installed as a unit. - To provide a protective blanket of a purge gas in the vicinity of elastomeric O-[0034]

ring 44 and protect the O-ring from any corrosive gases in theprocessing module 20 which flow into gate-seat gap 34, apurge gas outlet 48 comprises a slit ingate 40 which extends around the entirety ofseat opening 32 in the vicinity of O-ring 44.Slit 48 meters the desired flow of purge gas to protect O-ring 44. Preferably slit48 is narrower thangap 34 and is carefully controlled as desired to reduce excess purge gas flow. Such purge gas may interfere with the atmosphere required in processingchamber 20 and therefore excess quantities are undesirable. As an alternative to a slit, the present invention may use a series of holes or slots for the purge gas in the vicinity of O-ring 44. The slit, holes or slots preferably form an essentially continuous opening ofpurge gas outlet 48. - In the preferred embodiment depicted in FIGS.[0035]1-7, gate

purge gas outlet 48 is made by machining or otherwise forming anopening 45 ingate 40 which receives agate insert 50.Gate insert 50 has approximately the same configuration as gate opening45 but is formed so that when the insert is mated into the gate opening, a gap or slit is created which forms gas outlet opening between the two. Preferably, the insert has bevelededge 54 which corresponds to the angle ofgate opening 45. To provide a manifold for distributing the purge gas to the purge gas port outlet, openings are created46 within thegate 40 which may efficiently deliver the desired amount of purge gas flow tooutlet 48. Thegas inlet 41 provides a passageway connection tomanifold 46. - To supply purge gas to[0036]

gate inlet 41, the embodiment depicted utilizes aninput line 36 which travels throughseat 30 and out atransfer port 38 inseat face 31. Thistransfer port 38 aligns and mates by use of an O-ring orother seal 39 between thegate face 43 andseat face 31. - Thus, after a wafer is delivered into the[0037]

process module 20,gate 40 containinggate insert 50 is mated with and sealed againstseat 30 byactuator 60 to close slitvalve opening 32. A purge gas is then pumped throughinput line 36 intoseat 30 and out throughseat transfer port 38 intogate inlet 41 where it is thereupon distributed bymanifold 46 tooutlet 48.Outlet 48, in the form of a slit or plurality of holes or slots, evenly distributes the gas in measured quantities to the vicinity of the continuouselastomeric seal 44 around the slit valve opening utilizing thegap 34 between the gate sealing face and the seat sealing face. - In another embodiment of the invention depicted in FIGS. 8 and 9, the purge gas outlet is provided in the seat[0038]30A in the form of a

continuous outlet 37 which again extends around the slit valve opening in the vicinity of the gate seal. Thecontinuous seal outlet 37 is formed by aseat insert 33 which fits withinseat opening 32 and is spaced therefrom to create the controlled gap inoutlet 39. As with the previous embodiment, it is preferred that thisgap 39 which forms the continuous seat outlet is narrower thangap 34 between thegate face 43 andseat face 31. Also, as with the previous embodiment,outlet 37 may comprise a plurality of holes, slots or other essentially continuous openings. Gas is provided to the seat outlet through an inlet36A which connects to a manifold33 which distributes the gas evenly to theseat outlet 39. - Further embodiments of the purge gas outlet are depicted in FIGS. 10 and 11. In FIG. 10, purge[0039]

gas outlet 148 extends throughvalve gate 40 intoslit 42. The O-ring seated inslit 42 is partially an elastomeric seal144aand partially aporous elastomer co-extrusion 144b.Porous portion 144bpermits flow of the purge gas therethrough to protect elastomeric portion144a.In FIG. 11, O-ring 244 is seated ingroove 42 adjacent aporous media 245, such as a porous sintered metal such as stainless steel. Purge gas outlet128 extends intogroove 42 to direct flow of purge gas throughporous media 245 and into the vicinity of O-ring 244. In each case, the purge gas is fed from the manifold through a porous co-extrusion (FIG. 10) or porous media (FIG. 11) so that it is distributed around the full extent of the slit valve in the vicinity of the O-ring seal to protect the O-ring during processing. - The present invention also provides for the use of a portio of the reactive gas, such as oxygen, to purge the area around the[0040]

elastomeric seal 44. For example, where a reactive gas utilizes an oxygen carrier which dilutes the reactive gas, such oxygen carrier gas be utilized as the purge gas. By way of example, and not limitation, NF3gas is utilized to perform in-situ cleaning of semiconductor wafers in the processing chamber. The NF3utilizes oxygen as a carrier gas. Oxygen may be directed through the purge gas port system and utilized in the present invention to prevent the more reactive gas (e.g., NF3) from attacking the seal. The amount of oxygen utilized as the carrier gas is reduced by the amount which is used in the purge gas system, since the latter will eventually flow into the processing chamber and dilute the reactive gas as required. The amount of oxygen carrier gas to be used as a purge gas may be determined without undue experimentation for any particular reactive gas system. - Accordingly, the present invention achieves the objects above. The use of the continuous outlets around the seat opening in the vicinity of the seal permits more efficient usage of the purge gas. This opening may be essentially continuous and interrupted to a small degree without effecting the essentially continuous flow around the seat opening. Additionally, the use of non-inert carrier gases as purge gases reduces the attack of the reactive gas in the system on the elastomeric seals, and not interfering with the conventional gas chemistry within the processing chamber.[0041]

- While the present invention has been particularly described, in conjunction with a specific preferred embodiment, it is evident that many alternatives, modifications and variations will be apparent to those skilled in the art in light of the foregoing description. It is therefore contemplated that the appended claims will embrace any such alternatives, modifications and variations as falling within the true scope and spirit of the present invention.[0042]

Claims (20)

1. A vacuum valve assembly for use in a vacuum processing chamber comprising:

a vacuum processing chamber vacuum valve;

a seat defining an opening in said vacuum valve, said seat having a sealing face adjacent said opening and normal to the direction of said opening;

a gate having a sealing face adapted to mate with the seat sealing face, said gate being movable toward and away from the seat sealing face to seal and open the vacuum valve opening;

a continuous elastomeric seal around the vacuum valve opening between the gate sealing face and the seat sealing face of sufficient size such that when the gate is positioned to seal the vacuum valve opening, there exists a gap between the gate sealing face and the seat sealing face;

a purge gas port system having an inlet for a purge gas, an essentially continuous outlet extending around the vacuum valve opening and adjacent the elastomeric seal and gap, and a manifold system connecting the inlet and the outlet, such that when a purge gas is introduced through the inlet, the manifold distributes the gas to the outlet which evenly distributes the gas to the vicinity of the continuous elastomeric seal around the vacuum valve opening in the gap between the gate sealing face and the seat sealing face.

2. The vacuum valve ofclaim 1 wherein the purge gas port system is disposed in the seat.

3. The vacuum valve ofclaim 1 wherein the purge gas port system is disposed in the gate.

4. The vacuum valve ofclaim 3 wherein the purge gas port system outlet is defined by a first gate portion having the continuous elastomeric seal secured on the gate sealing face and a second gate portion secured within the first gate portion and facing the vacuum valve opening, the purge gas outlet being formed by a gap between the first and second gate portions extending essentially continuously around the first gate portion adjacent the elastomeric seal.

5. The vacuum valve assembly ofclaim 4 wherein the gap between the first and second gate portions forming the purge gas outlet is smaller than the gap between the gate sealing face and the seat sealing face.

6. The vacuum valve assembly ofclaim 1 wherein the purge gas outlet is formed by an opening narrower than the gap between the gate sealing face and the seat sealing face.

7. The vacuum valve ofclaim 1 wherein the purge gas port system outlet comprises a porous media adjacent the elastomeric seal.

8. The vacuum valve ofclaim 1 wherein the purge gas port system outlet comprises a porous portion of the elastomeric seal.

9. A vacuum processing chamber comprising:

a vacuum processing chamber having a vacuum valve;

a seat defining an opening in said vacuum valve, said seat having a sealing face adjacent said opening and normal to the direction of said opening;

a gate having a sealing face adapted to mate with the seat sealing face, said gate being movable toward and away from the seat sealing face to seal and open the vacuum valve opening, said gate including a continuous elastomeric seal on the gate sealing face around the vacuum valve opening of sufficient size such that when the gate is positioned to seal the vacuum valve opening, there exists a gap between the gate sealing face and the seat sealing face;

a purge gas port system in the gate having an inlet for a purge gas, an essentially continuous outlet in the gate sealing face extending around the vacuum valve opening and within and adjacent the elastomeric seal, and a manifold system connecting the inlet and the outlet, such that when a purge gas is introduced through the inlet, the manifold distributes the gas to the outlet which evenly distributes the gas to the vicinity of the continuous elastomeric seal around the vacuum valve opening in the gap between the gate sealing face and the seat sealing face.

10. The vacuum valve ofclaim 9 wherein the purge gas port system outlet is defined by a first gate portion having the continuous elastomeric seal secured on the gate sealing face and a second gate portion secured within the first gate portion and facing the vacuum valve opening, the purge gas outlet being formed by a gap between the first and second gate portions extending essentially continuously around the first gate portion adjacent the elastomeric seal.

11. The vacuum valve assembly ofclaim 10 wherein the gap between the first and second gate portions forming the purge gas outlet is smaller than the gap between the gate sealing face and the seat sealing face.

12. A vacuum processing chamber comprising:

a vacuum processing chamber having a vacuum valve;

a seat defining an opening in said vacuum valve, said seat having a sealing face adjacent said opening and normal to the direction of said opening;

a gate having a sealing face adapted to mate with the seat sealing face, said gate being movable toward and away from the seat sealing face to seal and open the vacuum valve opening, said gate including a continuous elastomeric seal on the gate sealing face around the vacuum valve opening of sufficient size such that when the gate is positioned to seal the vacuum valve opening, there exists a gap between the gate sealing face and the seat sealing face;

a purge gas port system in the seat having an inlet for a purge gas, an essentially continuous outlet in the seat sealing face extending around the vacuum valve opening and within and adjacent the elastomeric seal, and a manifold system connecting the inlet and the outlet, such that when a purge gas is introduced through the inlet, the manifold distributes the gas to the outlet which evenly distributes the gas to the vicinity of the continuous elastomeric seal around the vacuum valve opening in the gap between the gate sealing face and the seat sealing face.

13. The vacuum valve assembly ofclaim 12 wherein the gap between the first and second gate portions forming the purge gas outlet is smaller than the gap between the gate sealing face and the seat sealing face.

14. A method of extending life to a seal in a vacuum valve used in a vacuum processing chamber comprising:

providing a semiconductor wafer processing chamber having a vacuum valve seat, a gate closing the vacuum valve seat, and a seal between the gate and the vacuum valve seat, the seal being exposed to the chamber;

introducing a reactive gas mixture to the chamber to process a semiconductor wafer therein, the reactive gas mixture comprising a reactive gas, adapted to react with a portion of the semiconductor wafer, diluted by a carrier gas, said reactive gas also being reactive with said seal;

introducing said carrier gas through an essentially continuous opening into the vicinity of the seal between the gate and the vacuum valve seat, the carrier gas continuously flowing so as to initially shield the seal from the reactive gas and then subsequently pass into the chamber and mix with the reactive gas.

15. The method ofclaim 14 wherein the seal forms a gap between opposing sealing faces of the gate and seat, and wherein the carrier gas is introduced through an essentially continuous opening adjacent to narrower than the gap between the gate and seat sealing faces.

16. A method of extending life to a seal in a vacuum valve used in a vacuum processing chamber comprising:

providing a microelectronic circuit processing chamber having a vacuum valve seat, a gate closing the vacuum valve seat, and a seal between the gate and the vacuum valve seat, the seal being exposed to the chamber;

introducing a reactive gas mixture to the chamber to process a microelectronic device therein, the reactive gas mixture comprising a reactive gas adapted to react with a portion of the microelectronic device, diluted by a carrier gas, said reactive gas also being reactive with said seal;

introducing a portion of the reactive gas, such as oxygen into the vicinity of the seal between the gate and the vacuum valve seat, the reactive gas portion flowing so as to initially shield the seal and then subsequently pass into the chamber and mix with the remaining reactive gas.

17. The method ofclaim 16 wherein the carrier gas comprises oxygen.

18. The method ofclaim 16 wherein the reactive gas portion is introduced through an essentially continuous opening into the vicinity of the seal between the gate and the vacuum valve seat.

19. The method ofclaim 16 wherein the seal forms a gap between opposing sealing faces of the gate and seat, and wherein the reactive gas portion is introduced through an essentially continuous opening in the gate or seat.

20. The method ofclaim 19 wherein the reactive gas includes NF3.

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/447,446US20040007188A1 (en) | 2000-08-22 | 2003-05-27 | Gas-purged vacuum valve |

| US11/961,459US7585370B2 (en) | 2000-08-22 | 2007-12-20 | Gas-purged vacuum valve |

| US12/534,948US7754014B2 (en) | 2000-08-22 | 2009-08-04 | Gas-purged vacuum valve |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US09/643,523US6602346B1 (en) | 2000-08-22 | 2000-08-22 | Gas-purged vacuum valve |

| US10/447,446US20040007188A1 (en) | 2000-08-22 | 2003-05-27 | Gas-purged vacuum valve |

Related Parent Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US09/643,523ContinuationUS6602346B1 (en) | 2000-08-22 | 2000-08-22 | Gas-purged vacuum valve |

| US09/643,523DivisionUS6602346B1 (en) | 2000-08-22 | 2000-08-22 | Gas-purged vacuum valve |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US09/643,523ContinuationUS6602346B1 (en) | 2000-08-22 | 2000-08-22 | Gas-purged vacuum valve |

| US11/961,459ContinuationUS7585370B2 (en) | 2000-08-22 | 2007-12-20 | Gas-purged vacuum valve |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US20040007188A1true US20040007188A1 (en) | 2004-01-15 |

Family

ID=27623354

Family Applications (4)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US09/643,523Expired - LifetimeUS6602346B1 (en) | 2000-08-22 | 2000-08-22 | Gas-purged vacuum valve |

| US10/447,446AbandonedUS20040007188A1 (en) | 2000-08-22 | 2003-05-27 | Gas-purged vacuum valve |

| US11/961,459Expired - Fee RelatedUS7585370B2 (en) | 2000-08-22 | 2007-12-20 | Gas-purged vacuum valve |

| US12/534,948Expired - Fee RelatedUS7754014B2 (en) | 2000-08-22 | 2009-08-04 | Gas-purged vacuum valve |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US09/643,523Expired - LifetimeUS6602346B1 (en) | 2000-08-22 | 2000-08-22 | Gas-purged vacuum valve |

Family Applications After (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US11/961,459Expired - Fee RelatedUS7585370B2 (en) | 2000-08-22 | 2007-12-20 | Gas-purged vacuum valve |

| US12/534,948Expired - Fee RelatedUS7754014B2 (en) | 2000-08-22 | 2009-08-04 | Gas-purged vacuum valve |

Country Status (1)

| Country | Link |

|---|---|

| US (4) | US6602346B1 (en) |

Cited By (36)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20020190916A1 (en)* | 2000-12-06 | 2002-12-19 | Mitsuya Makino | Two-resonance antenna |

| US20040049908A1 (en)* | 2002-01-15 | 2004-03-18 | Quallion Llc | Electric storage battery construction and method of manufacture |

| US20040089240A1 (en)* | 2002-04-24 | 2004-05-13 | Dando Ross S. | Chemical vapor deposition apparatus |

| US20040154538A1 (en)* | 2003-02-11 | 2004-08-12 | Carpenter Craig M. | Reactors with isolated gas connectors and methods for depositing materials onto micro-device workpieces |

| US20040226507A1 (en)* | 2003-04-24 | 2004-11-18 | Carpenter Craig M. | Methods for controlling mass flow rates and pressures in passageways coupled to reaction chambers and systems for depositing material onto microfeature workpieces in reaction chambers |

| US20050016984A1 (en)* | 2002-08-15 | 2005-01-27 | Dando Ross S. | Reactors with isolated gas connectors and methods for depositing materials onto micro-device workpieces |

| US20050022739A1 (en)* | 2002-07-08 | 2005-02-03 | Carpenter Craig M. | Apparatus and method for depositing materials onto microelectronic workpieces |

| US6858264B2 (en) | 2002-04-24 | 2005-02-22 | Micron Technology, Inc. | Chemical vapor deposition methods |

| US20050039680A1 (en)* | 2003-08-21 | 2005-02-24 | Beaman Kevin L. | Methods and apparatus for processing microfeature workpieces; methods for conditioning ALD reaction chambers |

| US20050081786A1 (en)* | 2003-10-15 | 2005-04-21 | Kubista David J. | Systems for depositing material onto workpieces in reaction chambers and methods for removing byproducts from reaction chambers |

| US20050087130A1 (en)* | 2003-10-09 | 2005-04-28 | Derderian Garo J. | Apparatus and methods for plasma vapor deposition processes |

| US20050087302A1 (en)* | 2003-10-10 | 2005-04-28 | Mardian Allen P. | Apparatus and methods for manufacturing microfeatures on workpieces using plasma vapor processes |

| US20050126489A1 (en)* | 2003-12-10 | 2005-06-16 | Beaman Kevin L. | Methods and systems for controlling temperature during microfeature workpiece processing, e.g., CVD deposition |

| US20050164466A1 (en)* | 2004-01-28 | 2005-07-28 | Zheng Lingyi A. | Methods for forming small-scale capacitor structures |

| US20050249873A1 (en)* | 2004-05-05 | 2005-11-10 | Demetrius Sarigiannis | Apparatuses and methods for producing chemically reactive vapors used in manufacturing microelectronic devices |

| US20050249887A1 (en)* | 2004-05-06 | 2005-11-10 | Dando Ross S | Methods for depositing material onto microfeature workpieces in reaction chambers and systems for depositing materials onto microfeature workpieces |

| US20050268856A1 (en)* | 2004-06-02 | 2005-12-08 | Miller Matthew W | Reactors, systems and methods for depositing thin films onto microfeature workpieces |

| US20060027326A1 (en)* | 2002-02-22 | 2006-02-09 | Micron Technology, Inc. | Semiconductor substrate processing chamber and substrate transfer chamber interfacial structure |

| US20060115957A1 (en)* | 2003-09-17 | 2006-06-01 | Cem Basceri | Microfeature workpiece processing apparatus and methods for controlling deposition of materials on microfeature workpieces |

| US20060165873A1 (en)* | 2005-01-25 | 2006-07-27 | Micron Technology, Inc. | Plasma detection and associated systems and methods for controlling microfeature workpiece deposition processes |

| US20060198955A1 (en)* | 2003-08-21 | 2006-09-07 | Micron Technology, Inc. | Microfeature workpiece processing apparatus and methods for batch deposition of materials on microfeature workpieces |

| US20060205187A1 (en)* | 2003-08-28 | 2006-09-14 | Micron Technology, Inc. | Methods and apparatus for processing microfeature workpieces, e.g., for depositing materials on microfeature workpieces |

| US20060237138A1 (en)* | 2005-04-26 | 2006-10-26 | Micron Technology, Inc. | Apparatuses and methods for supporting microelectronic devices during plasma-based fabrication processes |

| US7282239B2 (en) | 2003-09-18 | 2007-10-16 | Micron Technology, Inc. | Systems and methods for depositing material onto microfeature workpieces in reaction chambers |

| US7481887B2 (en) | 2002-05-24 | 2009-01-27 | Micron Technology, Inc. | Apparatus for controlling gas pulsing in processes for depositing materials onto micro-device workpieces |

| US20090205563A1 (en)* | 2006-11-22 | 2009-08-20 | S.O.I.Tec Silicon On Insulator Technologies | Temperature-controlled purge gate valve for chemical vapor deposition chamber |

| US7584942B2 (en) | 2004-03-31 | 2009-09-08 | Micron Technology, Inc. | Ampoules for producing a reaction gas and systems for depositing materials onto microfeature workpieces in reaction chambers |

| US20090223453A1 (en)* | 2006-11-22 | 2009-09-10 | Chantal Arena | Equipment for high volume manufacture of group iii-v semiconductor materials |

| US20090223441A1 (en)* | 2006-11-22 | 2009-09-10 | Chantal Arena | High volume delivery system for gallium trichloride |

| KR100961678B1 (en)* | 2007-03-19 | 2010-06-09 | 도쿄엘렉트론가부시키가이샤 | Processing device provided with an on / off valve and its on / off valve |

| US20100242835A1 (en)* | 2006-06-09 | 2010-09-30 | S.O.I.T.E.C. Silicon On Insulator Technologies | High volume delivery system for gallium trichloride |

| US8197597B2 (en) | 2006-11-22 | 2012-06-12 | Soitec | Gallium trichloride injection scheme |

| US8382898B2 (en) | 2006-11-22 | 2013-02-26 | Soitec | Methods for high volume manufacture of group III-V semiconductor materials |

| DE102015105899A1 (en)* | 2014-04-30 | 2015-11-05 | Smc Corporation | spool valve |

| US9481943B2 (en) | 2006-11-22 | 2016-11-01 | Soitec | Gallium trichloride injection scheme |

| US9481944B2 (en) | 2006-11-22 | 2016-11-01 | Soitec | Gas injectors including a funnel- or wedge-shaped channel for chemical vapor deposition (CVD) systems and CVD systems with the same |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003009346A2 (en)* | 2001-07-15 | 2003-01-30 | Applied Materials,Inc. | Processing system |

| TW200508413A (en)* | 2003-08-06 | 2005-03-01 | Ulvac Inc | Device and method for manufacturing thin films |

| WO2006020424A2 (en)* | 2004-08-02 | 2006-02-23 | Veeco Instruments Inc. | Multi-gas distribution injector for chemical vapor deposition reactors |

| US20070272299A1 (en)* | 2004-12-03 | 2007-11-29 | Mks Instruments, Inc. | Methods and apparatus for downstream dissociation of gases |

| US9017481B1 (en)* | 2011-10-28 | 2015-04-28 | Asm America, Inc. | Process feed management for semiconductor substrate processing |

| KR102217790B1 (en)* | 2012-09-26 | 2021-02-18 | 어플라이드 머티어리얼스, 인코포레이티드 | An apparatus and method for purging gaseous compounds |

| WO2014200647A1 (en) | 2013-06-14 | 2014-12-18 | Applied Materials, Inc. | Particle reduction via throttle gate valve purge |

| US9587749B2 (en)* | 2013-08-12 | 2017-03-07 | Applied Materials Israel, Ltd. | Slit valve with a pressurized gas bearing |

| CN104930191A (en)* | 2014-03-19 | 2015-09-23 | 上海华虹宏力半导体制造有限公司 | Wafer box door improvement structure |

| US10090174B2 (en) | 2016-03-01 | 2018-10-02 | Lam Research Corporation | Apparatus for purging semiconductor process chamber slit valve opening |

| KR102437093B1 (en)* | 2017-07-31 | 2022-08-26 | 어플라이드 머티어리얼스, 인코포레이티드 | Gas supply member with baffle |

| KR102041308B1 (en) | 2017-09-27 | 2019-11-27 | 세메스 주식회사 | Apparatus and Method for treating substrate |

| JP7458267B2 (en)* | 2020-08-19 | 2024-03-29 | 東京エレクトロン株式会社 | SUBSTRATE PROCESSING APPARATUS AND SUBSTRATE TRANSFER METHOD |

| CN114464550A (en)* | 2020-11-09 | 2022-05-10 | 东京毅力科创株式会社 | Substrate processing system |

| US12158576B2 (en) | 2021-05-28 | 2024-12-03 | Kla Corporation | Counterflow gas nozzle for contamination mitigation in extreme ultraviolet inspection systems |

| US20250060041A1 (en)* | 2023-08-17 | 2025-02-20 | Applied Materials, Inc. | Multi-piece slit valve gate |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5997588A (en)* | 1995-10-13 | 1999-12-07 | Advanced Semiconductor Materials America, Inc. | Semiconductor processing system with gas curtain |

| US6056267A (en)* | 1998-05-19 | 2000-05-02 | Applied Materials, Inc. | Isolation valve with extended seal life |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2637027B2 (en) | 1992-12-21 | 1997-08-06 | 株式会社日本製鋼所 | Gate valve device for vacuum |

| JP3151076B2 (en)* | 1992-12-25 | 2001-04-03 | 日本碍子株式会社 | Valve with gas or liquid purge mechanism |

| JP3891682B2 (en)* | 1998-01-05 | 2007-03-14 | 株式会社荏原製作所 | Valve device and on-off valve cleaning method |

| US20020033183A1 (en)* | 1999-05-29 | 2002-03-21 | Sheng Sun | Method and apparatus for enhanced chamber cleaning |

| JP2000357678A (en)* | 1999-06-17 | 2000-12-26 | Nec Corp | Semiconductor manufacture apparatus |

| US6800172B2 (en)* | 2002-02-22 | 2004-10-05 | Micron Technology, Inc. | Interfacial structure for semiconductor substrate processing chambers and substrate transfer chambers and for semiconductor substrate processing chambers and accessory attachments, and semiconductor substrate processor |

- 2000

- 2000-08-22USUS09/643,523patent/US6602346B1/ennot_activeExpired - Lifetime

- 2003

- 2003-05-27USUS10/447,446patent/US20040007188A1/ennot_activeAbandoned

- 2007

- 2007-12-20USUS11/961,459patent/US7585370B2/ennot_activeExpired - Fee Related

- 2009

- 2009-08-04USUS12/534,948patent/US7754014B2/ennot_activeExpired - Fee Related

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5997588A (en)* | 1995-10-13 | 1999-12-07 | Advanced Semiconductor Materials America, Inc. | Semiconductor processing system with gas curtain |

| US6056267A (en)* | 1998-05-19 | 2000-05-02 | Applied Materials, Inc. | Isolation valve with extended seal life |

Cited By (68)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20020190916A1 (en)* | 2000-12-06 | 2002-12-19 | Mitsuya Makino | Two-resonance antenna |

| US20040049908A1 (en)* | 2002-01-15 | 2004-03-18 | Quallion Llc | Electric storage battery construction and method of manufacture |

| US7192487B2 (en) | 2002-02-22 | 2007-03-20 | Micron Technology, Inc. | Semiconductor substrate processing chamber and accessory attachment interfacial structure |

| US20060027326A1 (en)* | 2002-02-22 | 2006-02-09 | Micron Technology, Inc. | Semiconductor substrate processing chamber and substrate transfer chamber interfacial structure |

| US7270715B2 (en) | 2002-04-24 | 2007-09-18 | Micron Technology, Inc. | Chemical vapor deposition apparatus |

| US6858264B2 (en) | 2002-04-24 | 2005-02-22 | Micron Technology, Inc. | Chemical vapor deposition methods |

| US20050142291A1 (en)* | 2002-04-24 | 2005-06-30 | Dando Ross S. | Chemical vapor deposition methods |

| US20040089240A1 (en)* | 2002-04-24 | 2004-05-13 | Dando Ross S. | Chemical vapor deposition apparatus |

| US7481887B2 (en) | 2002-05-24 | 2009-01-27 | Micron Technology, Inc. | Apparatus for controlling gas pulsing in processes for depositing materials onto micro-device workpieces |

| US20050022739A1 (en)* | 2002-07-08 | 2005-02-03 | Carpenter Craig M. | Apparatus and method for depositing materials onto microelectronic workpieces |

| US7387685B2 (en) | 2002-07-08 | 2008-06-17 | Micron Technology, Inc. | Apparatus and method for depositing materials onto microelectronic workpieces |

| US20050016984A1 (en)* | 2002-08-15 | 2005-01-27 | Dando Ross S. | Reactors with isolated gas connectors and methods for depositing materials onto micro-device workpieces |

| US7588804B2 (en) | 2002-08-15 | 2009-09-15 | Micron Technology, Inc. | Reactors with isolated gas connectors and methods for depositing materials onto micro-device workpieces |

| US6926775B2 (en)* | 2003-02-11 | 2005-08-09 | Micron Technology, Inc. | Reactors with isolated gas connectors and methods for depositing materials onto micro-device workpieces |

| US20040154538A1 (en)* | 2003-02-11 | 2004-08-12 | Carpenter Craig M. | Reactors with isolated gas connectors and methods for depositing materials onto micro-device workpieces |

| US7427425B2 (en) | 2003-02-11 | 2008-09-23 | Micron Technology, Inc. | Reactors with isolated gas connectors and methods for depositing materials onto micro-device workpieces |

| US20050028734A1 (en)* | 2003-02-11 | 2005-02-10 | Carpenter Craig M. | Reactors with isolated gas connectors and methods for depositing materials onto micro-device workpieces |

| US20040226507A1 (en)* | 2003-04-24 | 2004-11-18 | Carpenter Craig M. | Methods for controlling mass flow rates and pressures in passageways coupled to reaction chambers and systems for depositing material onto microfeature workpieces in reaction chambers |

| US7335396B2 (en) | 2003-04-24 | 2008-02-26 | Micron Technology, Inc. | Methods for controlling mass flow rates and pressures in passageways coupled to reaction chambers and systems for depositing material onto microfeature workpieces in reaction chambers |

| US7235138B2 (en) | 2003-08-21 | 2007-06-26 | Micron Technology, Inc. | Microfeature workpiece processing apparatus and methods for batch deposition of materials on microfeature workpieces |

| US7344755B2 (en) | 2003-08-21 | 2008-03-18 | Micron Technology, Inc. | Methods and apparatus for processing microfeature workpieces; methods for conditioning ALD reaction chambers |

| US20050039680A1 (en)* | 2003-08-21 | 2005-02-24 | Beaman Kevin L. | Methods and apparatus for processing microfeature workpieces; methods for conditioning ALD reaction chambers |

| US20060198955A1 (en)* | 2003-08-21 | 2006-09-07 | Micron Technology, Inc. | Microfeature workpiece processing apparatus and methods for batch deposition of materials on microfeature workpieces |

| US20060205187A1 (en)* | 2003-08-28 | 2006-09-14 | Micron Technology, Inc. | Methods and apparatus for processing microfeature workpieces, e.g., for depositing materials on microfeature workpieces |

| US7422635B2 (en) | 2003-08-28 | 2008-09-09 | Micron Technology, Inc. | Methods and apparatus for processing microfeature workpieces, e.g., for depositing materials on microfeature workpieces |

| US7056806B2 (en) | 2003-09-17 | 2006-06-06 | Micron Technology, Inc. | Microfeature workpiece processing apparatus and methods for controlling deposition of materials on microfeature workpieces |

| US20060115957A1 (en)* | 2003-09-17 | 2006-06-01 | Cem Basceri | Microfeature workpiece processing apparatus and methods for controlling deposition of materials on microfeature workpieces |

| US7279398B2 (en) | 2003-09-17 | 2007-10-09 | Micron Technology, Inc. | Microfeature workpiece processing apparatus and methods for controlling deposition of materials on microfeature workpieces |

| US7282239B2 (en) | 2003-09-18 | 2007-10-16 | Micron Technology, Inc. | Systems and methods for depositing material onto microfeature workpieces in reaction chambers |

| US20050087130A1 (en)* | 2003-10-09 | 2005-04-28 | Derderian Garo J. | Apparatus and methods for plasma vapor deposition processes |

| US7323231B2 (en) | 2003-10-09 | 2008-01-29 | Micron Technology, Inc. | Apparatus and methods for plasma vapor deposition processes |

| US7581511B2 (en) | 2003-10-10 | 2009-09-01 | Micron Technology, Inc. | Apparatus and methods for manufacturing microfeatures on workpieces using plasma vapor processes |

| US20050087302A1 (en)* | 2003-10-10 | 2005-04-28 | Mardian Allen P. | Apparatus and methods for manufacturing microfeatures on workpieces using plasma vapor processes |

| US20050081786A1 (en)* | 2003-10-15 | 2005-04-21 | Kubista David J. | Systems for depositing material onto workpieces in reaction chambers and methods for removing byproducts from reaction chambers |

| US7647886B2 (en) | 2003-10-15 | 2010-01-19 | Micron Technology, Inc. | Systems for depositing material onto workpieces in reaction chambers and methods for removing byproducts from reaction chambers |

| US7258892B2 (en) | 2003-12-10 | 2007-08-21 | Micron Technology, Inc. | Methods and systems for controlling temperature during microfeature workpiece processing, e.g., CVD deposition |

| US20060204649A1 (en)* | 2003-12-10 | 2006-09-14 | Micron Technology, Inc. | Methods and systems for controlling temperature during microfeature workpiece processing, E.G. CVD deposition |

| US7771537B2 (en) | 2003-12-10 | 2010-08-10 | Micron Technology, Inc. | Methods and systems for controlling temperature during microfeature workpiece processing, E.G. CVD deposition |

| US8518184B2 (en) | 2003-12-10 | 2013-08-27 | Micron Technology, Inc. | Methods and systems for controlling temperature during microfeature workpiece processing, E.G., CVD deposition |

| US20050126489A1 (en)* | 2003-12-10 | 2005-06-16 | Beaman Kevin L. | Methods and systems for controlling temperature during microfeature workpiece processing, e.g., CVD deposition |

| US7906393B2 (en) | 2004-01-28 | 2011-03-15 | Micron Technology, Inc. | Methods for forming small-scale capacitor structures |

| US20050164466A1 (en)* | 2004-01-28 | 2005-07-28 | Zheng Lingyi A. | Methods for forming small-scale capacitor structures |

| US8384192B2 (en) | 2004-01-28 | 2013-02-26 | Micron Technology, Inc. | Methods for forming small-scale capacitor structures |

| US7584942B2 (en) | 2004-03-31 | 2009-09-08 | Micron Technology, Inc. | Ampoules for producing a reaction gas and systems for depositing materials onto microfeature workpieces in reaction chambers |

| US20050249873A1 (en)* | 2004-05-05 | 2005-11-10 | Demetrius Sarigiannis | Apparatuses and methods for producing chemically reactive vapors used in manufacturing microelectronic devices |

| US20050249887A1 (en)* | 2004-05-06 | 2005-11-10 | Dando Ross S | Methods for depositing material onto microfeature workpieces in reaction chambers and systems for depositing materials onto microfeature workpieces |

| US9023436B2 (en) | 2004-05-06 | 2015-05-05 | Micron Technology, Inc. | Methods for depositing material onto microfeature workpieces in reaction chambers and systems for depositing materials onto microfeature workpieces |

| US8133554B2 (en) | 2004-05-06 | 2012-03-13 | Micron Technology, Inc. | Methods for depositing material onto microfeature workpieces in reaction chambers and systems for depositing materials onto microfeature workpieces |

| US20050268856A1 (en)* | 2004-06-02 | 2005-12-08 | Miller Matthew W | Reactors, systems and methods for depositing thin films onto microfeature workpieces |

| US7699932B2 (en) | 2004-06-02 | 2010-04-20 | Micron Technology, Inc. | Reactors, systems and methods for depositing thin films onto microfeature workpieces |

| US20060165873A1 (en)* | 2005-01-25 | 2006-07-27 | Micron Technology, Inc. | Plasma detection and associated systems and methods for controlling microfeature workpiece deposition processes |

| US20060237138A1 (en)* | 2005-04-26 | 2006-10-26 | Micron Technology, Inc. | Apparatuses and methods for supporting microelectronic devices during plasma-based fabrication processes |

| US20100242835A1 (en)* | 2006-06-09 | 2010-09-30 | S.O.I.T.E.C. Silicon On Insulator Technologies | High volume delivery system for gallium trichloride |

| US8887650B2 (en) | 2006-11-22 | 2014-11-18 | Soitec | Temperature-controlled purge gate valve for chemical vapor deposition chamber |

| US9481943B2 (en) | 2006-11-22 | 2016-11-01 | Soitec | Gallium trichloride injection scheme |

| US8323407B2 (en) | 2006-11-22 | 2012-12-04 | Soitec | Gallium trichloride injection scheme |

| US8382898B2 (en) | 2006-11-22 | 2013-02-26 | Soitec | Methods for high volume manufacture of group III-V semiconductor materials |

| US20090223441A1 (en)* | 2006-11-22 | 2009-09-10 | Chantal Arena | High volume delivery system for gallium trichloride |

| US20090223453A1 (en)* | 2006-11-22 | 2009-09-10 | Chantal Arena | Equipment for high volume manufacture of group iii-v semiconductor materials |

| US8197597B2 (en) | 2006-11-22 | 2012-06-12 | Soitec | Gallium trichloride injection scheme |

| US9580836B2 (en)* | 2006-11-22 | 2017-02-28 | Soitec | Equipment for high volume manufacture of group III-V semiconductor materials |

| US8545628B2 (en) | 2006-11-22 | 2013-10-01 | Soitec | Temperature-controlled purge gate valve for chemical vapor deposition chamber |

| US9481944B2 (en) | 2006-11-22 | 2016-11-01 | Soitec | Gas injectors including a funnel- or wedge-shaped channel for chemical vapor deposition (CVD) systems and CVD systems with the same |

| US20090205563A1 (en)* | 2006-11-22 | 2009-08-20 | S.O.I.Tec Silicon On Insulator Technologies | Temperature-controlled purge gate valve for chemical vapor deposition chamber |

| KR100961678B1 (en)* | 2007-03-19 | 2010-06-09 | 도쿄엘렉트론가부시키가이샤 | Processing device provided with an on / off valve and its on / off valve |

| DE102015105899A1 (en)* | 2014-04-30 | 2015-11-05 | Smc Corporation | spool valve |

| US9599233B2 (en) | 2014-04-30 | 2017-03-21 | Smc Corporation | Gate valve |

| DE102015105899B4 (en) | 2014-04-30 | 2022-05-12 | Smc Corporation | slide valve |

Also Published As

| Publication number | Publication date |

|---|---|

| US7754014B2 (en) | 2010-07-13 |

| US20090291207A1 (en) | 2009-11-26 |

| US6602346B1 (en) | 2003-08-05 |

| US7585370B2 (en) | 2009-09-08 |

| US20080168947A1 (en) | 2008-07-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6602346B1 (en) | Gas-purged vacuum valve | |

| US6374859B1 (en) | Manifold system for enabling a distribution of fluids | |

| US6884317B2 (en) | Method and installation for etching a substrate | |

| JP3131005B2 (en) | Compound semiconductor vapor deposition equipment | |

| US6296712B1 (en) | Chemical vapor deposition hardware and process | |

| US6080241A (en) | Chemical vapor deposition chamber having an adjustable flow flange | |

| US6068703A (en) | Gas mixing apparatus and method | |

| US20100084398A1 (en) | Balanced purge slit valve | |

| JPH09283504A (en) | Feed of mixed gas, mixed gas feeding device and semiconductor manufacturing device provided with these | |

| CN101314867B (en) | Slit valve | |

| JPH1050791A (en) | Improved slit valve door | |

| US6056267A (en) | Isolation valve with extended seal life | |

| US10872787B2 (en) | Apparatus for purging semiconductor process chamber slit valve opening | |

| JP2000346238A (en) | Valve | |

| EP0764726B1 (en) | Method for tuning barrel reactor purge system | |

| KR20230104704A (en) | Devices and Systems for Delivering Gases to Process Chambers | |

| US6015463A (en) | Method and system for trapping contaminants formed during chemical vapor deposition processing of semiconductor wafers | |

| US4539062A (en) | Modular plasma reactor with local atmosphere | |

| US20060191636A1 (en) | Valve assembly, semiconductor device manufacturing apparatus comprising the same, and method of cleaning a trap of a semiconductor device manufactuing apparatus | |

| JPH01228123A (en) | Processor for semiconductor device | |

| JP3269883B2 (en) | Semiconductor manufacturing equipment | |

| KR20220062114A (en) | Cleaning isolation valve for reduced dead volume | |

| KR100752148B1 (en) | Substrate processing equipment | |

| US20240344198A1 (en) | Backing plate and diffuser plate assembly | |

| US20240363380A1 (en) | Method and device to distribute gas into a container |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STCB | Information on status: application discontinuation | Free format text:ABANDONED -- AFTER EXAMINER'S ANSWER OR BOARD OF APPEALS DECISION |