US11981501B2 - Loading cassette for substrate including glass and substrate loading method to which same is applied - Google Patents

Loading cassette for substrate including glass and substrate loading method to which same is appliedDownload PDFInfo

- Publication number

- US11981501B2 US11981501B2US17/433,342US202017433342AUS11981501B2US 11981501 B2US11981501 B2US 11981501B2US 202017433342 AUS202017433342 AUS 202017433342AUS 11981501 B2US11981501 B2US 11981501B2

- Authority

- US

- United States

- Prior art keywords

- target substrate

- loading

- substrate

- supporting member

- condition

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active, expires

Links

- 239000000758substrateSubstances0.000titleclaimsabstractdescription349

- 238000011068loading methodMethods0.000titleclaimsabstractdescription166

- 239000011521glassSubstances0.000titleclaimsdescription77

- 238000000034methodMethods0.000claimsdescription19

- 238000004806packaging method and processMethods0.000claimsdescription18

- 239000004065semiconductorSubstances0.000claimsdescription9

- 238000009826distributionMethods0.000description15

- 125000006850spacer groupChemical group0.000description6

- 229910052782aluminiumInorganic materials0.000description5

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000description5

- 238000004519manufacturing processMethods0.000description5

- 239000000463materialSubstances0.000description5

- 229920006260polyaryletherketonePolymers0.000description4

- 230000008569processEffects0.000description4

- 238000012360testing methodMethods0.000description4

- 229910052751metalInorganic materials0.000description3

- 239000002184metalSubstances0.000description3

- 229920001774PerfluoroetherPolymers0.000description2

- 235000017276SalviaNutrition0.000description2

- 241001072909SalviaSpecies0.000description2

- 230000000052comparative effectEffects0.000description2

- 150000001875compoundsChemical class0.000description2

- 238000013461designMethods0.000description2

- 230000000694effectsEffects0.000description2

- 238000011156evaluationMethods0.000description2

- 239000000203mixtureSubstances0.000description2

- 238000007747platingMethods0.000description2

- 229920001343polytetrafluoroethylenePolymers0.000description2

- 229940058401polytetrafluoroethyleneDrugs0.000description2

- 239000004810polytetrafluoroethyleneSubstances0.000description2

- 238000003860storageMethods0.000description2

- 238000012546transferMethods0.000description2

- VGGSQFUCUMXWEO-UHFFFAOYSA-NEtheneChemical compoundC=CVGGSQFUCUMXWEO-UHFFFAOYSA-N0.000description1

- 239000005977EthyleneSubstances0.000description1

- 238000010521absorption reactionMethods0.000description1

- 239000002253acidSubstances0.000description1

- 230000004075alterationEffects0.000description1

- 238000005452bendingMethods0.000description1

- 230000008901benefitEffects0.000description1

- 230000015572biosynthetic processEffects0.000description1

- 230000000903blocking effectEffects0.000description1

- 230000015556catabolic processEffects0.000description1

- 238000005520cutting processMethods0.000description1

- 238000006731degradation reactionMethods0.000description1

- 230000000881depressing effectEffects0.000description1

- 239000006185dispersionSubstances0.000description1

- 239000012530fluidSubstances0.000description1

- 238000003780insertionMethods0.000description1

- 230000037431insertionEffects0.000description1

- 238000013508migrationMethods0.000description1

- 230000005012migrationEffects0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 230000000149penetrating effectEffects0.000description1

- 229920000515polycarbonatePolymers0.000description1

- 239000004417polycarbonateSubstances0.000description1

- 238000012545processingMethods0.000description1

- 238000007665saggingMethods0.000description1

- 239000000523sampleSubstances0.000description1

- 230000008685targetingEffects0.000description1

Images

Classifications

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/673—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere using specially adapted carriers or holders; Fixing the workpieces on such carriers or holders

- H01L21/6734—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere using specially adapted carriers or holders; Fixing the workpieces on such carriers or holders specially adapted for supporting large square shaped substrates

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/30—Containers, packaging elements or packages, specially adapted for particular articles or materials for articles particularly sensitive to damage by shock or pressure

- B65D85/48—Containers, packaging elements or packages, specially adapted for particular articles or materials for articles particularly sensitive to damage by shock or pressure for glass sheets

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/673—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere using specially adapted carriers or holders; Fixing the workpieces on such carriers or holders

- H01L21/67303—Vertical boat type carrier whereby the substrates are horizontally supported, e.g. comprising rod-shaped elements

- H01L21/67309—Vertical boat type carrier whereby the substrates are horizontally supported, e.g. comprising rod-shaped elements characterized by the substrate support

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/673—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere using specially adapted carriers or holders; Fixing the workpieces on such carriers or holders

- H01L21/6732—Vertical carrier comprising wall type elements whereby the substrates are horizontally supported, e.g. comprising sidewalls

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/677—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/677—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations

- H01L21/67763—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations the wafers being stored in a carrier, involving loading and unloading

- H01L21/67766—Mechanical parts of transfer devices

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/677—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations

- H01L21/67763—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations the wafers being stored in a carrier, involving loading and unloading

- H01L21/67778—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for conveying, e.g. between different workstations the wafers being stored in a carrier, involving loading and unloading involving loading and unloading of wafers

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K13/00—Apparatus or processes specially adapted for manufacturing or adjusting assemblages of electric components

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K13/00—Apparatus or processes specially adapted for manufacturing or adjusting assemblages of electric components

- H05K13/0061—Tools for holding the circuit boards during processing; handling transport of printed circuit boards

- H05K13/0069—Holders for printed circuit boards

Definitions

- An embodimentrelates to a loading cassette of a substrate including glass and a method of loading a substrate applied with the same.

- a cassetteis applied to transfer and store many substrates easily, accurately, and harmoniously.

- a cassetteallows many substrates to be loaded in up and down with space from each other in the inside of a frame whose one side surface is opened. And a method of withdrawing these loaded substrates for proceeding of work of the substrates and after that inserting the substrates processed by the work into a cassette again is carried out.

- a glass substrate for semiconductor packagingis utilized for a high-end packaging substrate, and forms multiple vias in a thin glass substrate for utilizing as a packaging substrate.

- a glass substrate with a comparatively thin thicknessmay be fragile to vibration or impact due to its properties, and in a case of a glass substrate with a large area, a sag may occur in a high possibility inside a cassette due to own weight and this may accelerate damage of the glass substrate.

- the background art described aboveis a technical information which has been kept by inventors for deriving example embodiments, or found in a process of deriving example embodiments, and is not necessarily a known art opened to general public before the present application.

- Objectives of an embodimentis to provide a loading cassette minimizing impact transmitted to a substrate including glass and particularly being suitable for loading and moving of a glass substrate with a large area, and a method of loading a substrate applied with the same.

- a loading cassetteaccording to one embodiment includes

- an edge supporting unitfor connecting the upper plate and the lower plate and supporting left and right edges of the target substrate

- a rear supporting unitfor connecting the upper plate and the lower plate and supporting a rear edge of the target substrate

- the rear supporting unitincludes

- a rear framebeing connecting the upper plate and the lower plate in a rear surface

- a middle supporting memberbeing protruding to the front direction from the rear frame

- the target substrateis a substrate including a glass substrate which includes or does not include a through hole

- the middle supporting membercontrols a maximum sag of the target substrate based on the edge supporting unit (as 0 mm) within 3 mm.

- D1when a thickness (mm) of the target substrate is expressed as GT, D1 is a distance (mm) between one side of the edge supporting member and the middle supporting unit and the D1 may satisfy below Condition (1) or Condition (2); When 0.1 ⁇ GT ⁇ 0.5,150 ⁇ D 1 ⁇ 275 Condition (1): When 0.5 ⁇ GT ⁇ 1.5,220 ⁇ D 1 ⁇ 330. Condition (2):

- the middle supporting membermay include a middle supporting bar, wherein the middle bearing member is disposed at one part of the middle supporting member and the rear frame is near to other part of the middle supporting member, the middle bearing member may be disposed to have gradient to be higher than the other part.

- the edge supporting unitmay include

- a side framebeing connecting the upper plate and the lower plate in both left and right sides respectively

- an edge supporting memberforming a side slot disposed in the rear frame to support the left and right edges of the target substrate and not allowing the target substrate to contact the side frame

- the side slotmay be formed in plurality along an up-and-down direction of the side frame with having intervals.

- the middle supporting membermay include

- a middle supporting barbeing protruding to the front from the connecting block, wherein the left-and-right width of the middle supporting bar is narrower as being distant from the connecting block,

- middle bearing membermay be disposed in the middle supporting bar in a number of one, two, or more.

- a length of the middle supporting barmay be 1 ⁇ 3 to 2 ⁇ 3 of the back-and-forth length of the loading space.

- the rear supporting unitmay include

- a rear framebeing connecting the upper plate and the lower plate at the rear surface and having rear inserting slots formed in a left-and-right direction

- a middle supporting memberbeing protruding to the front direction from the rear frame and being combined with the rear inserting slots and having a first area portion and a second area portion

- a middle bearing memberbeing protruding from the upper surface of the middle supporting member and directly connecting the target substrate to control sag of the target substrate

- first area portionmay be connected to the rear frame and the area of the second area portion may be narrower than the area of the first area portion.

- a method of loading a target substrateincludes

- the target substrateincludes a glass substrate with or without a through hole

- Condition (1)when the thickness (mm) of the target substrate is expressed as GT, D1 which is a distance (mm) between one side of the edge supporting member and the middle supporting member may satisfy below Condition (1) or Condition (2); When 0.1 ⁇ GT ⁇ 0.5,150 ⁇ D 1 ⁇ 275 Condition (1): When 0.5 ⁇ GT ⁇ 1.5,220 ⁇ D 1 ⁇ 330. Condition (2):

- a method of loading a target substrateincludes

- a carry-in stepfor allowing the entire target substrate to enter and be disposed inside a loading space, in which the target substrate is polygonal having L as the length (mm) and W as the width (mm) is carried in the loading space of a cassette, by applying a loading carrier having two or more hands with maintaining variation (D) indicated by below Formula (1) within ⁇ 15 to +10 mm;

- a support stepfor controlling a maximum sag of the target substrate to be within 3 mm based on the edge supporting unit (as 0 mm) by supporting the target substrate with a middle supporting member in at least one point or more of the middle;

- the target substrateis a glass substrate having many through holes or a substrate for semiconductor packaging in which an electrical conductive pattern and an insulating layer are laminated to the glass substrate, and

- Dh (mm)which is an interval between the edge supporting units neighboring to each other in up and down may satisfy below Formula (2);

- a cassettewhich can load a target substrate without occurring a sag of a target substrate and a problem of damage in a substrate due to the sag can be provided, as minimizing damage which can occur during loading, moving, and carrying out of glass even though the target substrate including a glass substrate of a large area with or without a through hole.

- a target substrate placed in a loading spacecan stably keep a loaded state through being supported by an edge supporting unit and a rear supporting unit, and can be protected from impact which can occur during loading, impact added from the external, and the like.

- FIG. 1is a perspective view for showing a loading cassette according to an embodiment of the present application

- FIG. 2is a schematic view for showing a state of a glass substrate loaded in a loading cassette of FIG. 1 ;

- FIG. 3is a cross sectional view cut along a III-III line from FIG. 2 ;

- FIG. 4is an enlarged view of A portion of FIG. 3 ;

- FIG. 5is an enlarged view of a center supporting unit of FIG. 3 ;

- FIG. 6is a perspective view for showing a loading cassette according to one embodiment of the present application.

- FIG. 7is a schematic view for showing a glass substrate loaded in a loading cassette of FIG. 6 ;

- FIG. 8is a cross sectional view cut along a VI-VI line from FIG. 7 ;

- FIG. 9is an enlarged view of A portion of FIG. 8 ;

- FIG. 10is an enlarged view of a center supporting unit of FIG. 8 ;

- FIG. 11is a side view for showing a center supporting unit of FIG. 10 ;

- FIG. 12is a schematic view for showing a state of a center supporting unit of FIG. 11 supporting a glass substrate.

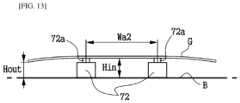

- FIG. 13is a conceptual view for illustrating a fork test conducted in the present application.

- FIGS. 14 A and 14 Bare conceptual views for illustrating a loading carrier and a target substrate of the present application, and a sag observed at a-a′, respectively;

- FIG. 15is a conceptual view for illustrating a process for a target substrate placed on a loading carrier to be inserted into a loading space

- X-basedmay mean that a compound includes a compound corresponding to X or a derivative of X.

- B being disposed on Ameans that B is disposed in direct contact with A or disposed over A with another layer interposed therebetween and thus should not be interpreted as being limited to B being disposed in direct contact with A.

- B being connected to Ameans that B is connected to A directly or through another element therebetween, and thus should not be interpreted as being limited to B being directly connected to A, unless otherwise noted.

- sagis evaluated for a position of a sagged portion from the reference position by mm unit, and expressed in a positive number.

- a loading cassette according to one embodimentwill be described with reference to FIGS. 1 to 5 .

- FIG. 1is a perspective view for showing a loading cassette according to an embodiment of the present application

- FIG. 2is a schematic view for showing a state of a glass substrate loaded in a loading cassette of FIG. 1

- FIG. 3is a cross sectional view cut along a III-III line from FIG. 2

- FIG. 4is an enlarged view of A portion of FIG. 3

- FIG. 5is an enlarged view of a center supporting unit of FIG. 3 .

- a loading cassette 1supports a loaded target substrate G and the like, and comprises an upper plate 10 , a lower plate 20 , an edge supporting unit 40 , and a rear supporting unit 50 .

- the loading cassette 1may further comprise a front stopper 60 .

- the upper plate 10 and the lower plate 20have a predetermined area and are apart from each other in an up-and-down direction.

- the lower plate 20may be formed by many frames connected in breadth and length directions.

- the upper plate 10 and the lower plate 20have an interval maintained by an edge supporting unit 40 and a rear supporting unit 50 . And, among them, a loading space 30 where a target substrate G is loaded is formed.

- a loading capacity of the loading space 30may be changed depending on the sizes of the upper plate 10 and the lower plate 20 ; and the up-and-down direction lengths of the edge supporting unit 40 and the rear supporting unit 50 .

- the loading capacity, in particularly the sizes of the upper plate 10 and the lower plate 20may be changed depending on the standard of the target substrate G.

- the target substrate Gmay be a substrate with a large area, and may be a glass substrate whose thickness is 1 mm or less, or a substrate in which an insulating layer and/or an electrical conductive layer are formed on the glass substrate (or glass substrate having through vias).

- the target substrate Gmay substantially have a quadrangle plate form whose one side is 400 mm or more, but its shape is not limited to a quadrangle plate form.

- a target substrate Gmay have a first surface and a second surface facing each other.

- a target substrate Gmay have a plurality a core via penetrating through the first surface and the second surface.

- the core viamay include a first opening part in contact with the first surface; a second opening part in contact with the second surface; and a minimum inner diameter part having the smallest inner diameter in the entire core via from the first opening part to the second opening part.

- An average diameter of the minimum inner diameter partmay be 50 ⁇ m to 95 ⁇ m.

- Equation 1The minimum inner diameter and satisfies the condition of Equation 1 below. 0.83 ⁇ D 90 ⁇ D 50 ⁇ 1.25 ⁇ D 10 [Equation 1]

- D 50is a value corresponding to 50% in the diameter distribution of the minimum inner diameter

- D 90is a value corresponding to 90% in the diameter distribution of the minimum inner diameter

- D 10is a value corresponding to 10% in the diameter distribution of the minimum inner diameter.

- An average diameter of the minimum inner diametermay be 55 ⁇ m to 85 ⁇ m, or 60 ⁇ m to 70 ⁇ m.

- the minimum inner partmay satisfy the condition of Equation 1-1 below. 0.83 ⁇ D 90 ⁇ D 50 ⁇ 1.25 ⁇ D 10 [Equation 1-1]

- D 50is a value corresponding to 50% in the diameter distribution of the minimum inner part

- D 90is a value corresponding to 90% in the diameter distribution of the minimum inner part

- D 10is a value corresponding to 10% in the diameter distribution of the minimum inner part.

- a target opening partwhich is a larger one between the first surface opening part diameter and the second surface opening part diameter, may have an average diameter of 70 ⁇ m to 120 ⁇ m.

- a target opening part which is a larger one between the first surface opening part diameter and the second surface opening part diametermay satisfy the condition of Equation 2 below. 0.9 ⁇ D 90 ⁇ D 50 ⁇ 1.1 ⁇ D 10 [Equation 2]

- D 50is a value corresponding to 50% in the diameter distribution of a target opening part

- D 90is a value corresponding to 90% in the diameter distribution of a target opening part

- D 10is a value corresponding to 10% in the diameter distribution of a target opening part.

- a target opening partwhich is a larger one between the first surface opening part diameter and the second surface opening part diameter, may have an average diameter of 80 ⁇ m to 105 ⁇ m.

- a target opening part which is a larger one between the first surface opening part diameter and the second surface opening part diametermay satisfy the condition of Equation 2-1 below. 0.92 ⁇ D 90 ⁇ D 50 ⁇ 1.08 ⁇ D 10 [Equation 2-1]

- D 50is a value corresponding to 50% in the diameter distribution of a target opening part

- D 90is a value corresponding to 90% in the diameter distribution of a target opening part

- D 10is a value corresponding to 10% in the diameter distribution of a target opening part.

- an average diameter of a target opening partwhich is a larger one between the first surface opening part diameter—which is a diameter at an opening part in contact with the first surface—and the second surface opening part diameter—which is a diameter at an opening part in contact with the second surface—may have a larger value than D 50 , which is a value corresponding to 50% in the diameter distribution of a target opening part.

- the diameter distribution described aboveis evaluated based on a diameter which is observed and measured by microscope in the cross-section, after dividing prepared samples into 9 compartments (3 ⁇ 3), and processing of cutting the samples of 5 areas (top left, bottom left, center, top right, bottom right).

- a loading cassette 1may load stably a target substrate which has a core via with the above-described diameter distribution and diameter.

- the point at which the minimum inner diameter part is locatedwhen the entire length of the core via is 100%, may be a point of 40% to 60% from the first opening part, and may be a point of 45% to 55%.

- the minimum inner diameter partis at the position described above, based on the entire length of core via, the design of electrically conductive layer of packaging substrate and the process of forming electrically conductive layer may be easier.

- a loading cassette according to an embodimentcan load this fragile target substrate stably.

- the core viamay be disposed in the number of 100 to 3000, or 100 to 2500, or 225 to 1024 based on a unit area (1 cm ⁇ 1 cm) of the target substrate.

- the core viamay be disposed at the target substrate in a pitch of 1.2 mm or less, may be disposed in a pitch of 0.12 to 1.2 mm, may be disposed in a pitch of 0.3 to 0.9 mm.

- a loading cassette according to an embodimentcan load this fragile target substrate stably.

- the target substrate Gmay be a stress-controlled glass substrate.

- the target substrate Gmay have a stress difference value (P) according to the below Formula (1) of 1.5 MPa or less; between a stress measured at a plain line which is a line linking places where the core via is not formed, and a stress measured at a via line which is a line linking places where the core via is formed.

- Pa stress difference value (P) according to the below Formula (1) of 1.5 MPa or less; between a stress measured at a plain line which is a line linking places where the core via is not formed, and a stress measured at a via line which is a line linking places where the core via is formed.

- PVp ⁇ Np Formula (1)

- the Pis a stress difference value measured at the same glass substrate

- the Vpis a difference between the maximum value and the minimum value of stress measured at a via line

- the Npis a difference between the maximum value and the minimum value of stress measured at a plain line.

- the P valuemay be 1.35 MPa or less, 1.2 MPa or less, or 1.1 MPa or less. Also, the P value may be 0.01 MPa or more, or 0.1 MPa or more.

- a glass substrate in which core vias having a stress difference value (P) in these ranges are formedis applied as a substrate for semiconductor packaging, it is possible to manufacture a packaging substrate having more stable mechanical properties, and a loading cassette according to an embodiment can load this fragile target substrate stably.

- the Vp valuemay be 2.5 MPa or less, or 2.3 MPa or less, and the Vp value may be 2.0 MPa or less, or 1.8 MPa or less. Also, the Vp value may be 0.2 MPa or more, or 0.4 MPa or more.

- Vpa difference between the maximum value and the minimum value of stress measured at a via line

- a glass substrate where core vias are formedis applied as a substrate for semiconductor packaging

- a loading cassette according to an embodimentcan load this fragile target substrate stably.

- the Np valuemay be 1.0 MPa or less, 0.9 MPa or less, or 0.8 MPa or less. Also, the Np value may be 0.1 MPa or more, or 0.2 MPa or more.

- a difference (Np) between the maximum value and the minimum value of stress measured at a plain lineis in these ranges, and a glass substrate where core vias are formed is applied as a substrate for semiconductor packaging, it is possible to manufacture a packaging substrate having more stable mechanical properties. And a loading cassette according to an embodiment can load this fragile target substrate stably.

- the glass substratemay satisfy a condition that a stress difference ratio (K) according to below Formula (2) is 6 or less.

- KLp/La Formula (2):

- the Kis stress difference ratio measured at the same plane of the same glass substrate

- the Lpis a difference of the maximum value and the minimum value of stress measured at a target line

- the Lais an average value of stress measured at the target line, wherein the target line is selected one from a plain line which is a line linking places where a core via is not formed and a via line which is a line linking places where a core via is formed.

- the K valuemay be 5 or less, 4.5 or less, or 4 or less.

- a target substrate where core vias are formedis applied as a substrate for semiconductor packaging, it is possible to manufacture a packaging substrate having more stable mechanical properties.

- a loading cassette according to an embodimentcan load this fragile target substrate stably.

- the stress difference ratio (K) which is measured at the plain linemay have a value of 2 or less.

- the stress difference ratio (Kn) of a plain linemay be 1.8 or less, more than 0.3, or more than 0.5.

- the stress difference ratio (K) which is measured at the via linemay have a value of 6 or less, or 5 or less.

- the stress difference ratio (Kv) of a via linemay be 4.5 or less, or 3 or less.

- the stress difference ratio of a via linemay be 0.5 or more, 1.0 or more, or 1.5 or more.

- the stressis analyzed by applying a birefringence 2D evaluation device.

- the birefringence 2D dispersion evaluation devicemay be WPA-200 device of NPM (NIPPON PULSE KOREA CO., LTD).

- measured valuessuch as a birefringence value are inputted by the device, and stress at a measuring route is presented by pressure unit (ex. MPa) through a predetermined calculation process.

- stresscan be measured by inputting a stress-optical coefficient and a thickness of a measuring target, and 2.4 is applied as the stress-optical coefficient in the present disclosure.

- the edge supporting units 40are arranged in a back-and-forth direction (Y) at both left and right sides of the upper plate 10 and the lower plate 20 , and connect the upper plate 10 and the lower plate 20 . And the edge supporting units 40 support the edges of both left and right sides of the target substrate G.

- the edge supporting unit 40may comprise a buffer covering layer placed in at least a part of its surface.

- the rear supporting unit 50connects the upper plate 10 and the lower plate 20 by being disposed at the rear of the upper plate 10 and the lower plate 20 .

- the rear supporting unit 50is disposed with having a certain distance with the center of the rear or the edge supporting unit 40 , and thereby controls the target substrate G loaded in the loading space 30 not to be sagged by its own weight.

- the rear supporting unit 50supports at least a part of the target substrate G and thereby prevents the target substrate G overall from sagging.

- the front stopper 60blocks the target substrate G loaded in the loading space 30 not to fall off to the external of the loading space 30 at the front of the loading space 30 .

- the front stopper 60may comprise a buffer covering layer placed in at least a part of its surface.

- the target substrate G of the loading space 30can maintain a stable loaded state by the edge supporting unit 40 and the rear supporting unit 50 . And the target substrate G of the loading space can be protected stably from impact which may occur during loading, impact added from external, and the like. Accordingly, damage of the target substrate G which may occur during loading and moving of the target substrate could be minimized.

- the edge supporting unit 40comprises a side frame 41 , and an edge supporting member 42 .

- the side frame 41has a predetermined length, its upper side is combined with a side surface of the upper plate 10 and its lower side is combined with a side surface of the lower plate 20 .

- the side frame 41is combined with a fastening means (not shown) like a bolt.

- the side frame 41may be formed with aluminum coated or not coated by a protecting layer or the like.

- a material of the side frame 41is not limited to aluminum.

- the edge supporting member 42is connected to the side frame 41 .

- the edge supporting members 42are arranged along an up-and-down direction (Z) of the side frame 41 with intervals. Accordingly, a side slot 421 is formed between the edge supporting members 42 neighboring to each other. A target substrate G inserted to the side slot 421 is placed in an upper surface of the edge supporting member 42 . On the other hand, neighboring edge supporting members 42 are connected from each other and their sides are not allowed to contact the side frame 41 when the target substrate G is loaded. And the edge supporting member 42 may comprise a buffer covering layer in at least a part of the surface thereof.

- the rear supporting unit 50may comprise a rear frame 51 , a middle supporting member 52 , a middle bearing member 53 and a rear stopper 54 .

- the rear frame 51has a predetermined length, its upper side is combined with the rear surface of the upper plate 10 and its lower side is combined with the rear surface of the lower plate 20 .

- the rear frame 51is also combined through a fastening means and may be formed with aluminum coated or not coated by a protecting layer or the like.

- the rear frame 51may comprise a rear main bar 511 in which holding slots where the connecting blocks are placed are formed along an up-and-down length direction, and a stopper combining bar 512 which is extended from both sides of the rear main bar to both left and right sides and combined with the rear stopper.

- the rear main bar 511may comprise a holding slot 511 a connected to a loading space 30 .

- the holding slot 511 amay be formed along an up-and-down length direction (Z) of the rear main bar 511 , and the area of the holding slot 511 a may become wider in a direction from the inner surface to the opened front.

- the stopper combining bar 512is extended in a left-and-right direction (X) from both sides of the rear main bar 511 and has a preset area.

- the stopper combining bar 512has a plane.

- the stopper combining bar 512is composed in one body with the rear main bar 511 and made with aluminum or the like which is coated or not coated.

- the middle supporting member 52may comprise a connecting block 521 and a middle supporting bar 522 .

- the connecting block 521is placed in a holding slot 511 a and fixed with a fastening means (not shown).

- the connecting block 521may be not dislocated from the holding slot 511 a . That is, the connecting block 512 may be placed inside the connecting block 521 .

- the middle supporting bar 522has a preset length, is connected to the rear main bar 511 by the connecting block 521 , and protrudes from the connecting block 521 to the front.

- the length of the middle supporting bar 522is equal to or shorter than the length of the loading space 30 in a back-and-forth direction Y, and in detail may be formed to be shorter.

- the length of the middle supporting barmay be 1 ⁇ 3 to 2 ⁇ 3, or 2 ⁇ 5 to 4 ⁇ 5 of the length from the front to the rear.

- the middle supporting bar 522supports a target substrate G from at least one or more points, and the supporting point is exemplified as a middle bearing member 53 described in below, but may support the target substrate by oneself.

- the position of the middle supporting bar 522may become gradually high as being far from a connecting block 522 , and thereby the height at one point where a middle supporting bar 522 and a target substrate G meet may be higher compared to a side slot 421 placed in a position neighboring to each other.

- a middle supporting baritself may sag slightly as some of the own weight of a target substrate is added to a middle supporting bar 522 at one point where the middle supporting bar 522 meets the target substrate. Additionally, when the middle supporting bar 522 itself is equipped to have a higher height than a side slot 421 placed in a position corresponding to this without such a gradient applied, it may increase a possibility of occurring damage or stain of a target substrate because a contact with a middle supporting bar 522 is caused even in a portion where sag is comparatively small in a target substrate.

- the variation of the height thereofcan be controlled within 3 mm compared to when the middle supporting bar 522 does not support a target substrate G.

- the thickness of the middle supporting bar 522can be modified, and the angle can be modified.

- the middle supporting bar 522may have a shape in which the area in one side which meets the target substrate is narrower and the area becomes wider as being close to a connecting block 521 .

- the middle supporting bar 522itself or the upper surface thereof may be gradient in a certain angle.

- the upper surface of the middle supporting member 52may have an angle at a point which a line from one end combined with the connecting block 521 to the other end contacting with the target substrate and a line parallel to the upper plate or the lower plate meet, and the angle may be 0.1 to 5 degree, or 0.1 to 3 degree.

- a sag of a middle supporting bar 522can be controlled and a sag of a target substrate G can be more efficiently controlled.

- the middle supporting members 52may be made with aluminum or the like which is coated or not coated, and are being arranged in an up-and-down direction (Z) in a loading space 30 .

- the arranging interval of middle supporting members 52may be substantially the same with the arranging interval of edge supporting members 42 .

- the middle bearing member 53is arranged in an upper surface of a middle supporting bar 522 to protrude to an upper portion and in contact with the center portion of a target substrate G.

- the middle bearing members 53may be arranged in 1, 2, or more with having intervals along a length direction (Y) of a middle supporting bar 522 .

- the middle bearing member 53may comprise a buffer covering layer placed on at least a part of the surface thereof.

- the middle supporting member 53may support some of a target substrate of a loading space 30 on a middle supporting member 52 along a length direction (Y) thereof, and the target substrate G may control sag of the target substrate which may occur in a loading space 30 .

- D1which is a distance (mm) between one side of the edge supporting member and the middle supporting member can satisfy a below Condition (1) or Condition (2).

- D1which is a distance (mm) between one side of the edge supporting member and the middle supporting member can satisfy a below Condition (1-1) or Condition (2-1).

- 0.2 ⁇ GT ⁇ 0.5,200 ⁇ D 1 ⁇ 275 Condition (1-1)When 0.5 ⁇ GT ⁇ 1.2,230 ⁇ D 1 ⁇ 300 Condition (2-1):

- the middle supporting member 52can control the maximum sag of the target substrate based on the edge supporting unit (0 mm) within 3 mm.

- a sag which occurs when the middle supporting member 52 supports the target substratecan be controlled within 3 mm based on when the middle supporting member 52 does not support the target substrate (0 mm).

- the target substrate Gmay be a glass substrate or a glass substrate in which a through hole is formed, and a thickness of it may be 0.25 to 0.45 mm D1 as a distance between one end within the edge supporting member 42 and the middle supporting member 52 may be applied to be 200 to 275 mm.

- a sag of a target substratemay be controlled within 2 mm, and the target substrate may be stored and moved more stably.

- the target substratemay be a glass substrate with through holes which has a metal plating layer and/or an insulting layer formed on at least one surface, and the total average thickness may of the target substrate be 0.3 to 1.2 mm, or 0.5 to 0.9 mm D1 as a distance between one end within the edge supporting member and the middle supporting member may be applied to be 230 to 300 mm.

- sag of the target substratemay be controlled within 1 mm, and the target substrate may be stored and moved more stably.

- the target substrate Gmay be a glass substrate having a cavity structure or a glass substrate having a cavity structure and through holes, and the thickness of a thick portion not having a cavity structure may be 0.4 to 1 mm, or 0.5 to 0.9 mm.

- D1 as a distance between one end of the edge supporting member and the middle supporting membermay be applied to be 200 to 275 mm. In such a case, a sag of a target substrate may be controlled within 2 mm, and the target substrate may be stored and moved more stably.

- the target substrate Gmay be a glass substrate having the cavity structure in which a metal plating layer and/or an insulting layer is formed on at least one surface, and the total average thickness of the target substrate may be 0.5 to 1.3 mm, or 0.7 to 1.2 mm D1 as a distance between one end within the edge supporting member 42 and the middle supporting member 52 may be applied to be 230 to 300 mm.

- a sag of a target substratemay be controlled within 1 mm, and the target substrate may be stored and moved more stably.

- a rear stopper 54is disposed in a loading space 30 and connected to a stopper combining bar 512 .

- the rear stoppers 54are arranged along to an up-and-down length direction (Z) of a stopper combining bar 512 . Between neighboring rear stoppers 54 , a rear slot 541 where a target substrate G is inserted is prepared, and the neighboring rear stoppers 54 are connected from each other. Here, an edge of a rear portion of a target substrate G may be disposed on an upper surface of a rear stopper 54 . In addition, the neighboring rear stoppers 54 are connected from each other. Accordingly, the rear part of a target substrate G disposed in a rear slot 541 is not in contact with a stopper combining bar 512 .

- the rear stopper 54may comprise a buffer covering layer in at least a part of the surface thereof.

- a front stopper 60may comprise a bar member 61 , a spacer 62 , a rod member 63 , and a stopper member 64 .

- the spacer 62is protruding to the front by being connected to an edge supporting unit 40 placed in the front.

- the spacers 62may be arranged along an up-and-down direction (Z) of the edge supporting unit 40 .

- the bar member 61has a predetermined length and is being connected to the spacer 62 .

- the bar member 61faces to the edge supporting unit 40 with having an interval by a spacer 62 .

- the rod member 63is being extended to the front from the bar member 61 to the edge supporting unit supporting a target substrate G.

- the stopper member 64faces the front (a thickness surface) of a target substrate G placed in the edge supporting member 42 with protruding to an up-and-down direction (Z) from an end portion of the rod member 63 .

- the front of the target substrate G placed in the edge supporting member 42is caught by the stopper member 64 and not to be fallen off to the front.

- the front stopper 60may be arranged along an up-and-down direction of the edge supporting unit 40 .

- the front stopper 60may comprise a buffer covering layer placed in at least a part of the surface thereof.

- the buffer covering layermay be overall placed in portions contacting with a target substrate G loaded in a loading space 30 , so that damage of the target substrate G, which can occur in loading or carrying our procedure, can be minimized. Also, when cassette is migrated with taking the target substrate G placed in a loading space 30 , a movement or damage of the target substrate G could not occur substantially. Accordingly, a loadability of the target substrate G can be increased and a reliability of the loading cassette can be increased.

- the buffer covering layermay comprise PTFE (Poly Tetra Fluoro Ethylene), FEP (Flourinated Ethylene Prophylene), PFA (Per Fluoro Alkoxy), or PEEK (polyaryletherketone), and specifically may comprise PEEK (polyaryletherketone).

- PTFEPoly Tetra Fluoro Ethylene

- FEPFlourinated Ethylene Prophylene

- PFAPer Fluoro Alkoxy

- PEEKpolyaryletherketone

- PEEKpolyaryletherketone

- the loading cassette 1may further comprise a loading carrier 70 for loading a target substrate G in a loading space 30 , or pulling the loaded target substrate G out.

- the loading cassette 1may be one cassette alone, or may be a cassette unit (not shown) formed by stacking the loading cassette 1 in a side direction and/or up-and-down direction.

- a fixing means(not shown) for fixing the loading cassettes neighboring to each other may be further applied, and the fixing means can be applied without limit if it does not disturb insertion and storage of the target substrate.

- the loading carrier 70is being connected to a robot arm (not shown) or the like, and can fix a target substrate G by an absorption method.

- the loading carrier 70allows the target substrate G to be inserted in a side slot 421 and places it on an edge bearing member 43 . On the contrary to this, a target substrate G placed on the edge bearing member 43 is lifted for the loaded target substrate G to be carried out from the loading space 30 .

- the loading carrier 70makes a target substrate G be placed on a depressurizing pad and after that the target substrate G be absorbed, fixed, and moved. For being detached subsequently, a method of releasing a pressure of the depressurizing pad can allow the target substrate G to be separated. In this time, when the depressing pad and the target substrate is not separated properly, compressed air may be added to the depressurizing pad to separate the depressurizing pad and the target substrate more easily.

- FIG. 6is a perspective view for showing a loading cassette according to one embodiment of the present application

- FIG. 7is a schematic view for showing a target substrate loaded in a loading cassette of FIG. 6

- FIG. 8is a cross sectional view cut along a VIII-VIII line from FIG. 7

- FIG. 9is an enlarged view of A portion of FIG. 8

- FIG. 10is an enlarged view of a rear supporting unit of FIG. 8

- FIG. 11is an side view for showing a rear supporting unit of FIG. 10

- FIG. 12is a schematic view for showing a state of a rear supporting unit of FIG. 11 supporting a target substrate.

- a loading cassette 2according to another example embodiment comprises an upper plate 10 , a lower plate 20 , an edge supporting unit 40 and a rear supporting unit 50 .

- the upper plate 10 and the lower plate 20is same as an upper plate and a lower plate of a loading cassette 1 described above according to FIGS. 1 to 7 , and thus the further description is omitted.

- An edge supporting unit 40comprises a side frame 41 , an edge supporting member 42 , and an edge bearing member 43 .

- a rear supporting unit 50comprises a rear frame 51 , a middle supporting member 52 , and a middle bearing member 53 .

- the side frame 41connects the upper plate 10 and the lower plate 20 . And a surface of the side frame 41 connected to a loading space 30 , side inserting slots 411 are formed in a back-and-forth direction (Y). The side inserting slots 411 are formed in plurality with having intervals along an up-and-down length direction (Z) of a side frame 41 .

- the edge supporting member 42is combined to the side inserting slots 411 and protruding to a loading space 30 .

- An upper surface and a side surface of the edge supporting member 42faces to a target substrate G.

- the edge bearing member 43protrudes from the upper surface of the edge supporting member 42 to an upper portion.

- the edge bearing members 43are arranged along a length direction (Y) of the edge supporting member 42 .

- the edge bearing member 43may comprise a buffer covering layer placed in at least a part of the surface thereof.

- the edge supporting member 42may also comprise a buffer covering layer placed in at least a part of the surface thereof.

- Such an edge supporting unit 40has a composition and an acting effect corresponding to the edge supporting unit according to embodiments of FIGS. 1 to 7 and thus the further description is omitted.

- a rear supporting unit 50may comprise a rear frame 51 , a middle supporting member 52 , and a middle bearing member 53 .

- the rear frame 51connects an upper plate 10 and a lower plate 20 .

- rear inserting slots 513may be formed in a left-and-right direction (X).

- Xleft-and-right direction

- a side inserting slot 411 and a rear inserting slot 513may be formed in the same position based on the lower plate 20 .

- the middle supporting member 52is combined with the rear inserting slot 513 and protrudes in a front direction from the rear frame 51 .

- the middle supporting member 52may face to a sagged portion of a target substrate G, and for example, may face to the center portion.

- the middle supporting member 52may have a first area portion 523 and a second area portion 524 whose area is narrower than the first area portion 523 .

- the length of the second area portion 524may be longer than the length of the first area portion 523 .

- the total length of the middle supporting member 52may be one-half or more of the front-and-rear length of a target space 30 .

- the gradient of the middle supporting member 52may be gradient in a lower direction from the second area portion 524 to the first area portion 523 . That is, the middle supporting member 52 may have a gradually gradient shape to a lower direction from the front to the rear. In this case, even though a sag of a target substrate occurs, a portion directly contacting with the middle supporting member 52 can be reduced, and the possibility of occurring damage of the target substrate can be reduced.

- the upper surface of the middle supporting member 52may have gradient in a certain angle.

- the upper surface of the middle supporting member 52may have an angle at a point where a line one end combined with the rear inserting slot 513 and the other end contacting with the target substrate and a line parallel to the upper plate or the lower plate meet, and the angle may be 0.1 to 10 degree, 0.1 to 5 degree, or 0.1 to 3 degree.

- the middle bearing member 53is protruding from an upper surface of the middle supporting member 52 .

- the middle bearing members 53are being arranged with having intervals along a length direction (Y) of the middle supporting member 52 .

- the middle bearing member 53may contact a target substrate G and thereby directly support the center portion of the target substrate G.

- the middle bearing member 53can support the center portion of a target substrate G through the middle supporting member 52 and thereby prevent the center portion of a target substrate G from sag by the own weight.

- FIGS. 1 to 5Various characteristics found in embodiments illustrated in FIGS. 1 to 5 also can be applied to the present embodiment.

- the loading cassettes ( 1 or 2 )may further comprise a protecting housing (not shown) for surrounding the edge supporting unit.

- the protecting housingmay have a shape of surrounding at least one between the upper plate and the lower plate, and the edge supporting unit.

- the protecting housingmay be an overall rectangular shape in which one surface is opened and may be covered on the loading cassette.

- the protecting housingmay further comprise a housing opening and shutting part (not shown) which allows a glass substrate to enter and can be opened and shut in a part or the whole within a surface surrounding the edge supporting unit.

- the protecting housingmay serve as preventing function from foreign material to be mixed when the loading cassette moves in a state of loading glass substrates and blocking the possibility of being damaged by flow of the fluid in a glass substrate.

- the protecting housingmay serve as a preventing role being damaged of the inside of another loading cassette or the loaded glass substrate even though some glass substrate of any one loading cassette is damaged when many loading cassettes have been loaded to be moved or stacked.

- a material of the protecting housinga material which is excellent in impact resistance, heat resistance, acid resistance, and so on and endures the weight of a glass substrate and a cassette, specifically a polycarbonate material which is clear or non-clear may be applied, and this case is advantageous in having a sufficient strength and excellent dimensional stability.

- a method of loading a target substratecomprises a carry-in step; a support step; and a completion step.

- a method of loading a target substrateis performed through the above described a loading cassette ( 1 or 2 ) and a loading carrier 70 below.

- the carry-in stepis a step that a target substrate G is moved by applying a loading carrier 70 having two or more hands 72 .

- the target substrate Gmay be a glass substrate having many through holes or a substrate for semiconductor packaging in which an electrically conductive pattern and an insulating layer are laminated to the glass substrate.

- the target substrate Ggenerally has a thin thickness (in general, 1500 ⁇ m or less) and thereby can be easily bended or curved. Also, because a glass substrate in which a through hole (core via) is formed in the predetermined size and position is applied as a target substrate, stress is concentrated in some section, imbalanced stress may occur in the glass substrate overall, and this may induce degradation of mechanical strength of the substrate. Accordingly, it is required to transfer and store a target substrate stably with minimizing sag or bending of the target substrate. And this is more important when applying a substrate with a larger area.

- the target substrate Gmay be a polygonal glass substrate having L as the length (mm) and W as the width (mm).

- the L and Wmay be respectively 400 mm or more, and the target substrate may, for example, comprise a glass substrate in a quadrangle shape.

- a target substrate Gis moved with controlling to occur variation predetermined or less.

- the variationis calculated by below Equation (1) (refer to FIG. 1 ).

- Variation ( D )Inside Height of Target Substrate ( H in,mm) ⁇ Outside Height of Target Substrate ( H out,mm) Equation (1):

- the inside height and the outside height of the target substrateis applied by measuring height at the same reference line (B).

- the variation (D)may be within ⁇ 15 to +10 mm, ⁇ 10 to 7 mm, or ⁇ 10 to 4 mm A variation in this range may be adjusted by changing the number of hands to be applied, and the position and the interval of the hand fork.

- the hands 72respectively have one or more hand forks 72 a and may have Wa2 (mm) as the shortest interval between hand forks 72 a placed in the hands 72 which respectively satisfies below Condition (1) or Condition (2).

- GTrefers to the thickness (mm) of the target substrate.

- the Wa2 (mm)may respectively satisfy below Condition (1-1) or Condition (2-1).

- Condition (1-1)When 0.1 ⁇ GT ⁇ 0.5,( W/ 2.5) ⁇ Wa 2 ⁇ ( W/ 1.9)

- Condition (1-1)When 0.5 ⁇ GT ⁇ 1.5,( W/ 2.2) ⁇ Wa 2 ⁇ ( W/ 1.8).

- Wa1 valuewhich is an interval between hand forks 72 a placed on the same hand 72 may satisfy below Condition (3) or Condition (4).

- Condition (3)When 0.1 ⁇ GT ⁇ 0.5,( L/ 3.4) ⁇ Wa 1 ⁇ ( L/ 1.8)

- Condition (3)When 0.5 ⁇ GT ⁇ 1.5,( W/ 2.3) ⁇ Wa 1 ⁇ ( W/ 1.6).

- the Wa1 valuemay satisfy below Condition (3-1) or Condition (4-1).

- Condition (3-1)When 0.1 ⁇ GT ⁇ 0.5,( L/ 2.5) ⁇ Wa 1 ⁇ ( L/ 1.9) Condition (3-1): When 0.5 ⁇ GT ⁇ 1.5,( L/ 2.2) ⁇ Wa 1 ⁇ ( L/ 1.8) Condition (4-1):

- the target substrate Gis carried in a loading space 30 of a loading cassette ( 1 or 2 ) with maintaining the variation (D) within a range described above, and the left and right edges of the target substrate is placed on the edge supporting unit 40 of the loading cassettes, thereby allowing the entire target substrate to enter and be placed inside the loading space 30 .

- This entrancemay be controlled by a loading carrier and hands moving along a predetermined moving route.

- the result of a fork test performed with a glass substrate in which has through viaswill be disclosed.

- the glass substratehad a size of 508 ⁇ 508 (length ⁇ width, mm) and a thickness of 0.3 to 0.7 mm was formed.

- a variationinside height-outside height

- a variationis 4.7 mm

- a variationis ⁇ 0.6 mm

- a variationis ⁇ 1 mm

- a fork intervalis 320 mm

- a variationis ⁇ 11 mm

- a fork intervalis 420 mm

- a variationis ⁇ 27.5 mm.

- the result of a test based on a glass substrate in which a through via is not formedwas; when a fork interval is 220 mm, a variation (inside height-outside height) is 4.9 mm; when a fork interval is 270 mm, a variation is ⁇ 0.4 mm; when a fork interval is 320 mm, a variation is ⁇ 5.1 mm; and when a fork interval is 420 mm, a variation is ⁇ 17.1 mm.

- the support stepis a step of controlling a maximum sag of a target substrate G within 3 mm by supporting the target substrate in at least one point or more of the middle thereof by a middle supporting member 52 .

- a sagis determined by an interval from an edge supporting unit 40 (basement, 0 mm)

- the maximum sagmay be negative, but it is expressed by converting to be positive.

- a maximum sag of the target substratemay be controlled by adjusting D1.

- the D1is a distance between one side of the edge supporting member 42 and a middle supporting member 52

- D1when a thickness of a target substrate is GT, D1 can satisfy below condition (5) or (6).

- condition (5)When 0.1 ⁇ GT ⁇ 0.5,150 ⁇ D 1 ⁇ 275 Condition (5): When 0.5 ⁇ GT ⁇ 1.5,220 ⁇ D 1 ⁇ 330 Condition (6):

- D1can satisfy below conditions (5-1) to (6-1).

- 5-1)0.2 ⁇ GT ⁇ 0.5,200 ⁇ D 1 ⁇ 275 Condition

- 6-1)0.5 ⁇ GT ⁇ 1.2,230 ⁇ D 1 ⁇ 300 Condition

- the middle supporting member 52may comprise a middle supporting bar 522 .

- the middle supporting bar 522has one portion which a middle bearing member 53 may be placed at and the other portion which is placed close to the rear frame 51 .

- the middle supporting bar 522have a gradient, which the one portion is placed to be higher than the other portion.

- the height of the middle bearing membermay be changed within 3 mm based on a height compared to not supporting the target substrate (0 mm) It may bring it to conduct a stabler supporting role.

- the completion stepis for releasing the fixation of the loading carrier 70 with the target substrate G and carrying out the loading carrier to external of the loading cassette ( 1 or 2 .)

- a hand 72 of the loading carrierhas a hand fork 72 a placed in a portion directly contacting with the target substrate, and the hand fork may have a pressure adjusting mean (not shown) selectively.

- the hand forkmay be adjusted to inhale or exhale air by being connected to a pressure controlling device (not shown) separately prepared through the hand.

- the target substratecan be fixed on a hand by depressurizing with letting the hand fork contact with the target substrate and inhale air.

- a force of fixing the target substrateis removed from the hand fork by relieving depressurizing state and the hand fork is allowed to exhale air temporarily to separate the hand fork and the target substrate easily.

- the loading cassette ( 1 or 2 )comprise multiple edge supporting units 40 .

- a distance between the edge supporting units neighboring up and down to each otheris Dh (unit: mm) Dh may satisfy below Equation (2). 25+( GT ⁇ 0.8)*8 ⁇ Dh Equation (2):

- the Dhmay be 40 mm or less, or 35 mm or less for efficiency of loading.

- a method of loading a target substratecomprises, an entering step for carrying in a target substrate comprising a glass substrate with or without a through hole to a loading space of a loading cassette;

- a supporting stepfor moving the entire target substrate to be placed inside the loading space and have left and right edges of the target substrate being placed on the edge supporting unit of the loading cassette by fixing the target substrate to a loading carrier, wherein at least one point or more of the middle of the target substrate supports at least a part of own weight of the target substrate though being placed on the middle supporting member; and a completing step for releasing the fixation of the loading carrier and the target substrate.

- the maximum sag of the target substrate based on the edge supporting unit (0 mm)is controlled within 3 mm.

- the method of loading the target substrateloads the target substrate by comprising an entering step for carrying in a target substrate fixed on a depressurizing pad (not shown) to a loading space to be placed in an edge supporting unit 40 ; and a supporting step for releasing pressure of the depressurizing pad and letting the left and right edges of the target substrate to be placed in the edge supporting unit 40 , wherein at least one point or more of the middle of the target substrate is supported by the middle supporting member supporting member 52 .

- the target substrateis the same as above description in that it is a substrate comprising a glass substrate with or without a through hole.

- the middle supporting member 52can control the maximum sag of a target substrate based on the edge supporting unit (0 mm) within 3 mm.

- the target substrate Gmay be supported by at least one surface contacting the gradient middle supporting member 52 from at least one point.

- sag occurring when the middle supporting member 52 supports the target substratecan be controlled within 3 mm based on when the middle supporting member 52 does not support the target substrate (0 mm).

- the middle supporting membermay comprise a middle supporting bar.

- the middle supporting barhas one portion which a middle bearing member may be placed at and the other portion which is placed close to the rear frame.

- the middle supporting bar 522has a gradient, which the one portion is placed to be higher than the other portion.

- the height of the middle bearing membermay be changed within 3 mm based on a height compared to not supporting the target substrate (0 mm.)

- a glass substrate GAs a target substrate, a glass substrate G was prepared, whose length and breadth were 500 mm respectively, thickness was about 0.4 mm, and the glass substrate was formed through vias as diameter of 100 ⁇ m and their pits of 1 mm.

- the prepared glass substratewas carried into the loading space through a loading carrier, and stayed for 24 hours.

- both left and right edges of the glass substratewere supported by edge supporting members, not applying middle supporting members, and a sag at the center of the glass substrate as a target substrate was occurred 30 mm or more.

- the prepared glass substratewas carried into the loading space through a loading carrier 70 , and stayed for 24 hours.

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Computer Hardware Design (AREA)

- Power Engineering (AREA)

- Mechanical Engineering (AREA)

- Robotics (AREA)

- Container, Conveyance, Adherence, Positioning, Of Wafer (AREA)

Abstract

Description

When 0.1<GT≤0.5,150≤D1≤275 Condition (1):

When 0.5<GT≤1.5,220≤D1≤330. Condition (2):

When 0.1<GT≤0.5,150≤D1≤275 Condition (1):

When 0.5<GT≤1.5,220≤D1≤330. Condition (2):

Variation (D)=Inside Height of Target Substrate (Hin,mm)−Outside Height of Target Substrate (Hout,mm) Equation (1):

When 0.1<GT≤0.5,(W/3.4)≤Wa2≤(W/1.8) Condition (1):

When 0.5<GT≤1.5,(W/2.3)≤Wa2≤(W/1.6). Condition (2):

0.83×D90≤D50≤1.25×D10 [Equation 1]

In the

0.83×D90≤D50≤1.25×D10 [Equation 1-1]

0.9×D90≤D50≤1.1×D10 [Equation 2]

0.92×D90≤D50≤1.08×D10 [Equation 2-1]

P=Vp−Np Formula (1)

K=Lp/La Formula (2):

When 0.1<GT≤0.5,150≤D1≤275 Condition (1):

When 0.5<GT≤1.5,220≤D1≤330 Condition (2):

When 0.2<GT≤0.5,200≤D1≤275 Condition (1-1):

When 0.5<GT≤1.2,230≤D1≤300 Condition (2-1):

Variation (D)=Inside Height of Target Substrate (Hin,mm)−Outside Height of Target Substrate (Hout,mm) Equation (1):

When 0.1<GT≤0.5,(W/3.4)≤Wa2≤(W/1.8) Condition (1):

When 0.5<GT≤1.5,(W/2.3)≤Wa2≤(W/1.6) Condition (2):

When 0.1<GT≤0.5,(W/2.5)≤Wa2≤(W/1.9) Condition (1-1):

When 0.5<GT≤1.5,(W/2.2)≤Wa2≤(W/1.8). Condition (2-1):

When 0.1<GT≤0.5,(L/3.4)≤Wa1≤(L/1.8) Condition (3):

When 0.5<GT≤1.5,(W/2.3)≤Wa1≤(W/1.6). Condition (4):

When 0.1<GT≤0.5,(L/2.5)≤Wa1≤(L/1.9) Condition (3-1):

When 0.5<GT≤1.5,(L/2.2)≤Wa1≤(L/1.8) Condition (4-1):

When 0.1<GT≤0.5,150≤D1≤275 Condition (5):

When 0.5<GT≤1.5,220≤D1≤330 Condition (6):

When 0.2<GT≤0.5,200≤D1≤275 Condition (5-1):

When 0.5<GT≤1.2,230≤D1≤300 Condition (6-1):

25+(GT−0.8)*8≤Dh Equation (2):

The Dh may be 40 mm or less, or 35 mm or less for efficiency of loading.

When 0.1<GT≤0.5,150≤D1≤275 Condition (1):

When 0.5<GT≤1.5,220≤D1≤330 Condition (2):

- an upper plate;

- a lower plate facing to the upper plate with an interval;

- a loading space between the upper plate and the lower plate and a target substrate being disposed in,

- an edge supporting unit for connecting the upper plate and the lower plate and supporting left and right edges of the target substrate, and

- a rear supporting unit for connecting the upper plate and the lower plate and supporting a rear edge of the target substrate,

- was prepared.

- an

upper plate 10; - a

lower plate 20 facing to the upper plate with an interval; - a

loading space 30 between the upper plate and the lower plate and a target substrate being disposed in, - an

edge supporting unit 40 for connecting the upper plate and the lower plate and supporting left and right edges of the target substrate, and - a

rear supporting unit 50 for connecting the upper plate and the lower plate and supporting a rear edge of the target substrate, - wherein the

rear supporting unit 50 comprises arear frame 51 being connecting theupper plate 10 and thelower plate 20 in a rear surface and amiddle supporting member 52 being protruding to the front direction from the rear frame, was prepared.

- an

| 1, 2: loading cassette | 10: upper plate | ||

| 20: lower plate | 30: loading space | ||

| 40: edge supporting unit | 41: side frame | ||

| 411: side inserting slot | 42: edge supporting member | ||

| 421: side slot | 43: edge bearing member | ||

| 50: rear supporting unit | 51: rear frame | ||

| 511: rear main bar | 511a: holding slot | ||

| 512: stopper combining bar | 513: rear inserting slot | ||

| 52: middle supporting member | 521: connecting block | ||

| 522: middle supporting bar | 523: first area portion | ||

| 524: second area portion | 53: middle bearing member | ||

| 54: rear stopper | 541: rear slot | ||

| 60: front stopper | 61: bar member | ||

| 62: spacer | 63: rod member | ||

| 64: stopper member | 70: loading carrier | ||

Claims (10)

When 0.1<GT≤0.5,150≤D1≤275 Condition (1):

When 0.5<GT≤1.5,220≤D1≤330. Condition (2):

When 0.1<GT≤0.5,150≤D1≤275 Condition (1):

When 0.5<GT≤1.5,220≤D1≤330. Condition (2):

Variation (D)=Inside Height of Target Substrate (Hin,mm)−Outside Height of Target Substrate (Hout,mm) Equation (1):

When 0.1<GT≤0.5,(W/3.4)≤Wa2≤(W/1.8) Condition (1):

When 0.5<GT≤1.5,(W/2.3)≤Wa2≤(W/1.6). Condition (2):

25+(GT−0.8)*8≤Dh. Equation (2):

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US17/433,342US11981501B2 (en) | 2019-03-12 | 2020-03-12 | Loading cassette for substrate including glass and substrate loading method to which same is applied |

Applications Claiming Priority (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201962816995P | 2019-03-12 | 2019-03-12 | |

| US201962816984P | 2019-03-12 | 2019-03-12 | |

| US201962826105P | 2019-03-29 | 2019-03-29 | |

| US201962826144P | 2019-03-29 | 2019-03-29 | |

| US201962826122P | 2019-03-29 | 2019-03-29 | |

| US17/433,342US11981501B2 (en) | 2019-03-12 | 2020-03-12 | Loading cassette for substrate including glass and substrate loading method to which same is applied |

| PCT/KR2020/003480WO2020185020A1 (en) | 2019-03-12 | 2020-03-12 | Loading cassette for substrate including glass and substrate loading method to which same is applied |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| US20220048699A1 US20220048699A1 (en) | 2022-02-17 |

| US11981501B2true US11981501B2 (en) | 2024-05-14 |

Family

ID=72426431

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US17/433,342Active2041-05-29US11981501B2 (en) | 2019-03-12 | 2020-03-12 | Loading cassette for substrate including glass and substrate loading method to which same is applied |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US11981501B2 (en) |

| KR (1) | KR102537005B1 (en) |

| CN (1) | CN113424304B (en) |

| WO (1) | WO2020185020A1 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6915037B2 (en)* | 2017-02-27 | 2021-08-04 | ミライアル株式会社 | Board storage container |

| KR20220121297A (en)* | 2021-02-24 | 2022-09-01 | 삼성디스플레이 주식회사 | Glass plate loading device and glass plate strengthening method using the same |

Citations (170)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4835598A (en) | 1985-06-13 | 1989-05-30 | Matsushita Electric Works, Ltd. | Wiring board |

| US5304743A (en) | 1992-05-12 | 1994-04-19 | Lsi Logic Corporation | Multilayer IC semiconductor package |

| KR970050005A (en) | 1995-12-13 | 1997-07-29 | 김광호 | Liquid Crystal Display Glass Loading Cassettes and Jigs |

| EP0526456B1 (en) | 1990-04-27 | 1997-08-27 | International Business Machines Corporation | A multi-layer package incorporating a recessed cavity for a semiconductor chip |

| KR0184043B1 (en) | 1995-08-01 | 1999-05-01 | 구자홍 | Multi-Interface System for VAudio |

| JP2000142876A (en) | 1999-01-01 | 2000-05-23 | Sharp Corp | Substrate storage cassette |

| JP2001007531A (en) | 1999-06-18 | 2001-01-12 | Ngk Spark Plug Co Ltd | Manufacture of wiring board |

| JP3173250B2 (en) | 1993-10-25 | 2001-06-04 | ソニー株式会社 | Method for manufacturing resin-encapsulated semiconductor device |

| CN1317163A (en) | 1998-09-10 | 2001-10-10 | 通道系统集团公司 | Non-circular micro-via |

| KR20010107033A (en) | 2000-05-24 | 2001-12-07 | 구본준, 론 위라하디락사 | Cassette for Loading Glass |

| KR20020008574A (en) | 2000-07-24 | 2002-01-31 | 김영민 | Multi-fork type end effector and the method to carry the glass substrate |

| KR200266536Y1 (en) | 2001-07-12 | 2002-02-28 | (주)상아프론테크 | Side frame for lcd glass cassette |

| US20020093120A1 (en) | 2000-12-28 | 2002-07-18 | Stmicroelectronics S.R.I. | Manufacturing method of an electronic device package |

| US20020180015A1 (en) | 2001-05-31 | 2002-12-05 | Yoshihide Yamaguchi | Semiconductor module |

| US20030179341A1 (en)* | 2002-03-25 | 2003-09-25 | Choo Hun Jun | Cassette for liquid crystal panel inspection and method of inspecting liquid crystal panel |

| WO2004053983A1 (en) | 2002-12-05 | 2004-06-24 | Intel Corporation | Metal core substrate packaging |

| KR100447323B1 (en) | 2002-03-22 | 2004-09-07 | 주식회사 하이닉스반도체 | Method of physical vapor deposition in a semiconductor device |

| JP2004311919A (en) | 2003-02-21 | 2004-11-04 | Shinko Electric Ind Co Ltd | Through-hole filling method |

| CN1614464A (en) | 2003-11-08 | 2005-05-11 | 纳伊系统株式会社 | Receiving box for glass substrate of liquid crystal panel |

| JP2005235497A (en) | 2004-02-18 | 2005-09-02 | Seiko Epson Corp | Organic electroluminescence device and electronic device |

| KR100538733B1 (en) | 2003-01-02 | 2005-12-26 | 이 아이 듀폰 디 네모아 앤드 캄파니 | Process for the constrained sintering of asymmetrically configured dielectric layers |

| WO2006050205A2 (en) | 2004-11-01 | 2006-05-11 | H.C. Starck Inc. | Refractory metal substrate with improved thermal conductivity |

| US20060179341A1 (en) | 2005-02-04 | 2006-08-10 | York International Corporation | Method of clearing an HVAC control fault code memory |