US11325336B2 - Method and system for forming packages - Google Patents

Method and system for forming packagesDownload PDFInfo

- Publication number

- US11325336B2 US11325336B2US16/720,126US201916720126AUS11325336B2US 11325336 B2US11325336 B2US 11325336B2US 201916720126 AUS201916720126 AUS 201916720126AUS 11325336 B2US11325336 B2US 11325336B2

- Authority

- US

- United States

- Prior art keywords

- web

- tube

- forming

- assembly

- blank

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active, expires

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B70/00—Making flexible containers, e.g. envelopes or bags

- B31B70/008—Stiffening or reinforcing

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D33/00—Details of, or accessories for, sacks or bags

- B65D33/02—Local reinforcements or stiffening inserts, e.g. wires, strings, strips or frames

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/02—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/10—Particular design of joint configurations particular design of the joint cross-sections

- B29C66/11—Joint cross-sections comprising a single joint-segment, i.e. one of the parts to be joined comprising a single joint-segment in the joint cross-section

- B29C66/112—Single lapped joints

- B29C66/1122—Single lap to lap joints, i.e. overlap joints

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/40—General aspects of joining substantially flat articles, e.g. plates, sheets or web-like materials; Making flat seams in tubular or hollow articles; Joining single elements to substantially flat surfaces

- B29C66/41—Joining substantially flat articles ; Making flat seams in tubular or hollow articles

- B29C66/43—Joining a relatively small portion of the surface of said articles

- B29C66/431—Joining the articles to themselves

- B29C66/4312—Joining the articles to themselves for making flat seams in tubular or hollow articles, e.g. transversal seams

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/80—General aspects of machine operations or constructions and parts thereof

- B29C66/81—General aspects of the pressing elements, i.e. the elements applying pressure on the parts to be joined in the area to be joined, e.g. the welding jaws or clamps

- B29C66/814—General aspects of the pressing elements, i.e. the elements applying pressure on the parts to be joined in the area to be joined, e.g. the welding jaws or clamps characterised by the design of the pressing elements, e.g. of the welding jaws or clamps

- B29C66/8141—General aspects of the pressing elements, i.e. the elements applying pressure on the parts to be joined in the area to be joined, e.g. the welding jaws or clamps characterised by the design of the pressing elements, e.g. of the welding jaws or clamps characterised by the surface geometry of the part of the pressing elements, e.g. welding jaws or clamps, coming into contact with the parts to be joined

- B29C66/81411—General aspects of the pressing elements, i.e. the elements applying pressure on the parts to be joined in the area to be joined, e.g. the welding jaws or clamps characterised by the design of the pressing elements, e.g. of the welding jaws or clamps characterised by the surface geometry of the part of the pressing elements, e.g. welding jaws or clamps, coming into contact with the parts to be joined characterised by its cross-section, e.g. transversal or longitudinal, being non-flat

- B29C66/81421—General aspects of the pressing elements, i.e. the elements applying pressure on the parts to be joined in the area to be joined, e.g. the welding jaws or clamps characterised by the design of the pressing elements, e.g. of the welding jaws or clamps characterised by the surface geometry of the part of the pressing elements, e.g. welding jaws or clamps, coming into contact with the parts to be joined characterised by its cross-section, e.g. transversal or longitudinal, being non-flat being convex or concave

- B29C66/81423—General aspects of the pressing elements, i.e. the elements applying pressure on the parts to be joined in the area to be joined, e.g. the welding jaws or clamps characterised by the design of the pressing elements, e.g. of the welding jaws or clamps characterised by the surface geometry of the part of the pressing elements, e.g. welding jaws or clamps, coming into contact with the parts to be joined characterised by its cross-section, e.g. transversal or longitudinal, being non-flat being convex or concave being concave

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/80—General aspects of machine operations or constructions and parts thereof

- B29C66/83—General aspects of machine operations or constructions and parts thereof characterised by the movement of the joining or pressing tools

- B29C66/834—General aspects of machine operations or constructions and parts thereof characterised by the movement of the joining or pressing tools moving with the parts to be joined

- B29C66/8351—Jaws mounted on rollers, cylinders, drums, bands, belts or chains; Flying jaws

- B29C66/83511—Jaws mounted on rollers, cylinders, drums, bands, belts or chains; Flying jaws jaws mounted on rollers, cylinders or drums

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/80—General aspects of machine operations or constructions and parts thereof

- B29C66/84—Specific machine types or machines suitable for specific applications

- B29C66/841—Machines or tools adaptable for making articles of different dimensions or shapes or for making joints of different dimensions

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/80—General aspects of machine operations or constructions and parts thereof

- B29C66/84—Specific machine types or machines suitable for specific applications

- B29C66/851—Bag or container making machines

- B29C66/8511—Bag making machines

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B70/00—Making flexible containers, e.g. envelopes or bags

- B31B70/74—Auxiliary operations

- B31B70/81—Forming or attaching accessories, e.g. opening devices, closures or tear strings

- B31B70/812—Applying patches, strips or strings on sheets or webs

- B31B70/8122—Applying patches

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/71—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the composition of the plastics material of the parts to be joined

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2023/00—Use of polyalkenes or derivatives thereof as moulding material

- B29K2023/04—Polymers of ethylene

- B29K2023/06—PE, i.e. polyethylene

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/712—Containers; Packaging elements or accessories, Packages

- B29L2031/7128—Bags, sacks, sachets

- B29L2031/7129—Bags, sacks, sachets open

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B2155/00—Flexible containers made from webs

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B2155/00—Flexible containers made from webs

- B31B2155/001—Flexible containers made from webs by folding webs longitudinally

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B2155/00—Flexible containers made from webs

- B31B2155/001—Flexible containers made from webs by folding webs longitudinally

- B31B2155/0012—Flexible containers made from webs by folding webs longitudinally having their openings facing in the direction of movement

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B2155/00—Flexible containers made from webs

- B31B2155/003—Flexible containers made from webs starting from tubular webs

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B2160/00—Shape of flexible containers

- B31B2160/10—Shape of flexible containers rectangular and flat, i.e. without structural provision for thickness of contents

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B2160/00—Shape of flexible containers

- B31B2160/20—Shape of flexible containers with structural provision for thickness of contents

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B2170/00—Construction of flexible containers

- B31B2170/20—Construction of flexible containers having multi-layered walls, e.g. laminated or lined

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B70/00—Making flexible containers, e.g. envelopes or bags

- B31B70/14—Cutting, e.g. perforating, punching, slitting or trimming

- B31B70/16—Cutting webs

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B70/00—Making flexible containers, e.g. envelopes or bags

- B31B70/26—Folding sheets, blanks or webs

- B31B70/262—Folding sheets, blanks or webs involving longitudinally folding, i.e. along a line parallel to the direction of movement

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B70/00—Making flexible containers, e.g. envelopes or bags

- B31B70/26—Folding sheets, blanks or webs

- B31B70/262—Folding sheets, blanks or webs involving longitudinally folding, i.e. along a line parallel to the direction of movement

- B31B70/266—Folding sheets, blanks or webs involving longitudinally folding, i.e. along a line parallel to the direction of movement involving gusset-forming

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B70/00—Making flexible containers, e.g. envelopes or bags

- B31B70/26—Folding sheets, blanks or webs

- B31B70/56—Folding sheets, blanks or webs by rotary members co-operating with blades

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B70/00—Making flexible containers, e.g. envelopes or bags

- B31B70/60—Uniting opposed surfaces or edges; Taping

- B31B70/62—Uniting opposed surfaces or edges; Taping by adhesives

- B31B70/628—Applying glue on moving webs to form tubular webs

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B70/00—Making flexible containers, e.g. envelopes or bags

- B31B70/60—Uniting opposed surfaces or edges; Taping

- B31B70/64—Uniting opposed surfaces or edges; Taping by applying heat or pressure

- B31B70/644—Making seals parallel to the direction of movement, i.e. longitudinal sealing

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B70/00—Making flexible containers, e.g. envelopes or bags

- B31B70/60—Uniting opposed surfaces or edges; Taping

- B31B70/64—Uniting opposed surfaces or edges; Taping by applying heat or pressure

- B31B70/645—Making seals transversally to the direction of movement

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B70/00—Making flexible containers, e.g. envelopes or bags

- B31B70/60—Uniting opposed surfaces or edges; Taping

- B31B70/64—Uniting opposed surfaces or edges; Taping by applying heat or pressure

- B31B70/649—Uniting opposed surfaces or edges; Taping by applying heat or pressure using tools mounted on a drum

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B70/00—Making flexible containers, e.g. envelopes or bags

- B31B70/74—Auxiliary operations

- B31B70/81—Forming or attaching accessories, e.g. opening devices, closures or tear strings

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B70/00—Making flexible containers, e.g. envelopes or bags

- B31B70/74—Auxiliary operations

- B31B70/92—Delivering

- B31B70/98—Delivering in stacks or bundles

Definitions

- the present disclosuregenerally relates to reinforced packages for holding products and to methods of forming the packages. More specifically, the present disclosure is directed to methods and systems for forming the packages including a reinforcing sleeve for supporting a bag.

- Bagssuch as paper or plastic bags, traditionally have been used for the packaging and transport of products from bulk materials such as rice or sand to larger items. Bags generally are cheap and easy to manufacture and can be formed in different configurations and sizes, and can be used for storage and transport of a wide variety of products. In particular, in the Fast Food industry, bags are frequently used for packaging of prepared food items, such as sandwiches, etc. Currently, there is a growing demand for bags or similar packages for use in packaging various products, including sandwiches, French fries, and other prepared food items, that a worker can easily open, such as with one hand, and have the bag supported in an open configuration to enhance the efficiency of packaging of such products. However, it is equally important that the costs of such bags necessarily must be minimized as much as possible. While various bag designs including reinforcing or supporting materials have been developed, often, the manufacture of such specialty bags having reinforcing layers or materials supplied thereto has required multiple stages or operations, which can significantly increase the cost of manufacture of such bags.

- one aspect of the disclosureis directed to a method of forming reinforced packages.

- the methodcan comprise forming an attached web by adhering a blank to a web of material and moving the attached web in a downstream direction through at least a tube forming assembly and a carton forming assembly.

- the moving the attached webcan comprise moving the blank with the web of material.

- the methodalso can comprise at least partially forming a tube by folding at least a portion of the web of material as the attached web moves through the tube forming assembly, forming a reinforcement sleeve by folding at least a portion of the blank so that the reinforcement sleeve extends at least partially around the tube as the attached web moves through the carton forming assembly, and forming a reinforced package comprising the reinforcement sleeve and a tube portion by separating the tube portion from a remainder of the tube, the reinforcement sleeve being adhered to the tube portion.

- the disclosureis generally directed to a system for forming reinforced packages.

- the systemcan comprise an attachment assembly receiving a web of material and a blank.

- the attachment assemblycan bring the blank into engagement with the web of material for forming an attached web.

- a tube forming assemblycan be disposed downstream from the attachment assembly.

- the tube forming assemblycan receive the attached web and can comprise web folding features for folding at least a portion of the web of material to at least partially form a tube.

- a carton forming assemblycan be disposed downstream from the attachment assembly.

- the carton forming assemblycan receive the attached web and can comprise carton folding features for folding at least portion of the blank over the tube to form a reinforcement sleeve.

- the systemfurther can comprise a cutting assembly comprising cutting features for separating a tube portion from the web of material to at least partially form a reinforced package comprising the tube portion attached to the reinforcement sleeve.

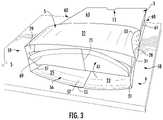

- FIG. 1is a perspective side view of a reinforced package in a flattened condition formed according to a system and method of forming reinforced packages according to an exemplary embodiment of the disclosure

- FIG. 2is a plan view of a blank for forming a reinforcing construct of the reinforced package of FIG. 1 .

- FIGS. 3 and 4are perspective views of the reinforced package of FIG. 1 in an opened condition.

- FIG. 5is a schematic illustration of the system and method of forming the reinforced packages of FIG. 1 according to the exemplary embodiment of the disclosure.

- FIGS. 6A-8are perspective views of a carton feeder, an adhesive applicator, and an attachment assembly of the system of FIG. 5 schematically showing the carton feeder, the adhesive applicator, and the attachment assembly feeding blanks and attaching the blanks to a web of material to form an attached web according to the exemplary embodiment of the disclosure.

- FIGS. 9-11are perspective views of a tube forming assembly of the system of FIG. 5 schematically showing the tube forming assembly forming a tube of the web of material according to the exemplary embodiment of the disclosure.

- FIGS. 12 and 13are perspective views of a carton forming assembly of the system of FIG. 5 schematically showing the carton forming assembly folding the blanks over the tube according to the exemplary embodiment of the disclosure.

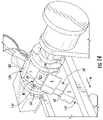

- FIGS. 14 and 15are perspective views of a heat sealer assembly of the system of FIG. 5 schematically showing the heat sealer assembly forming a transverse seal in the tube according to the exemplary embodiment of the disclosure.

- FIG. 16is a schematic side view of the heat sealer assembly of FIGS. 14 and 15 .

- FIGS. 17 and 18are perspective views of a cutter assembly and a conveyor assembly of the system of FIG. 5 schematically showing the cutting of the attached web into individual reinforced packages according to the exemplary embodiment of the disclosure.

- FIG. 19is a perspective view of a carton feeder according to an alternative embodiment of the disclosure.

- FIG. 20is a schematic illustration of a system and method of forming the reinforced packages of FIG. 1 according to the a further alternative embodiment of the disclosure

- the present disclosuregenerally relates to a system and method of forming reinforced packages for holding products such as food products or other articles.

- Packages according to the present disclosurecan accommodate articles of any shape.

- the packagescan comprise a bag or liner comprising a relatively flexible material attached to a reinforcing construct comprising a relatively rigid material (e.g., paperboard).

- the bagscan generally be made from a paper, plastic, laminate, or other stock material and can be attached to the reinforcing construct that can be located between the opened end and sealed or closed end of the bag.

- the bagscomprise polyethylene material or any other suitable heat-sealable material.

- the reinforcing constructcan be of varying widths and can extend about or over the closed ends of the bags, in some embodiments enclosing such closed ends, and will provide support for the bags upon loading with a product or article or series of articles therein.

- the reinforcing constructscan be folded with their bags into a configuration supporting the bags in a freestanding, upright, and opened condition for ease of loading.

- FIG. 1illustrates a reinforced package generally indicated at 1 that can be formed by one embodiment of the system and method of the present disclosure.

- the package 1includes a bag 3 and a reinforcing construct or sleeve 5 attached to the bag 3 .

- the baghas an open end 7 , a closed end 9 ( FIG. 3 ), and an interior space 17 for holding a product.

- the bag 3has gusseted sides 60 including a fold line 61 ( FIGS. 3 and 4 ) extending the length of the bag on each side to facilitate forming the gusseted side.

- the gussets 60can extend between a central portion 63 (e.g., the front of the bag 3 ) and respective marginal portions 65 , 67 , which can form the back of the bag 3 .

- the marginal portions 65 , 67can be at least partially overlapped with one another and adhered to one another to form a longitudinal seam 71 extending along the height of the bag 3 ( FIG. 4 ).

- the closed end 9can be at least partially closed by a transverse seal or seam 69 where the walls (e.g., the gussets 60 , the central portion 63 , and the marginal portions 65 , 67 ) have been heat sealed and/or adhered together along a section of the bag 3 .

- the interior space 17may be accessible through a notch 15 in the bag 3 .

- the reinforcing sleeve 5is configured to at least partially receive a portion 11 of the closed end 9 of the bag 3 .

- the reinforcing sleeve 5could be positioned to extend around the middle portion or top portion of the bag 3 without departing from the disclosure.

- FIG. 2illustrates a blank 10 for forming the reinforcing sleeve 5 .

- the blankhas a lateral axis L 1 and a longitudinal axis L 2 .

- the blank 10has a front panel 21 foldably connected to a first side panel 28 at a first arcuate fold line 33 .

- the first side panel 28includes two individual panel portions 28 A, 28 B foldably connected to one another at a lateral fold line 26 .

- a first back panel 23is foldably connected to the first side panel 28 at a second arcuate fold line 31 .

- a second side panel 29is foldably connected to the front panel 21 at a third arcuate fold line 35 .

- the second side panel 29includes two individual panel portions 29 A, 29 B foldably connected to one another at a lateral fold line 27 .

- a second back panel 25is foldably connected to the second side panel 29 at a fourth arcuate fold line 37 .

- the arcuate fold lines 31 , 33are spaced apart from the lateral fold line 26 and are concave with respect to the lateral fold line 26 .

- the arcuate fold lines 35 , 37are spaced apart from the lateral fold line 27 and are concave with respect to the lateral fold line 27 .

- the blank 10can have alternative panel, fold line, and/or panel portion arrangements.

- U.S. patent application Ser. No. 13/826,937, filed Mar. 14, 2013,is incorporated by reference herein for all purposes, and illustrates various reinforced packages including various reinforcing constructs 5 , blanks 10 , and bags 3 that can be formed from the method and system of the present disclosure.

- the blank 10can include one or more adhesive regions 41 , 43 , and 45 on the first back panel 23 , front panel 21 , and/or second back panel 25 , respectively, for receiving adhesive and being fixedly attached to an exterior surface of the bag 3 .

- the blank 10has a first edge 52 and a second edge 53 extending in the longitudinal direction L 2 .

- the adhesive regions 41 , 43 , 45are separated from the first edge 52 by a first distance D 1 and are separated from the second edge 53 by a second distance D 2 .

- the first distance D 1is less than the second distance D 2 .

- the first and second side panels 28 , 29 and regions separate from the adhesive regions 41 , 43 , 45may be generally free from adhesive in some embodiments, or may include adhesive in alternative embodiments. Additionally, the first and second distances D 1 , D 2 , adhesive regions 41 , 43 , 45 , and/or edges 52 , 53 can be otherwise arranged, shaped, modified, or omitted without departing from the scope of this disclosure. For example, the first distance D 1 and the second distance D 2 could be generally equal or the first distance D 1 could be greater than the second distance D 2 .

- the blank 10may be folded about fold lines 26 , 27 to create the reinforcing sleeve 5 .

- distal ends 55 , 57 of the first and second back panels 23 , 25may be overlapped, and the sleeve 5 attached to the bag 3 as illustrated in FIGS. 1, 3, and 4 .

- the glue regions or another adhesivecan extend into one or both of the distal ends 55 , 57 so that the overlapped portions of the back panels 23 , 25 are adhered to one another when the reinforcement sleeve 5 is formed.

- the individual panel portions 28 A, 28 B, 29 A, and 29 Bmay be in face-to-face registration in a first, non-erect position of the bag 3 as illustrated in FIG. 1 .

- the first, non-erect position illustratedreduces and/or minimizes a volume of the interior space 17 such that the package 1 is in a non-erect or flattened state.

- the non-erect statemay facilitate easy stacking of a plurality of packages into, for example, a shipment container and subsequent organization at a destination facility.

- the individual panel portions 28 A, 28 B, 29 A, and 29 Bmay be flexed or positioned to form first and second sides 58 , 59 of the package 1 in a second, erect position of the bag 3 as illustrated in FIGS. 3 and 4 .

- the second, erect position illustratedincreases and/or maximizes a volume of the interior space 17 such that the package 1 is in an erect or self-supporting state.

- the closed end 9 of the bag 3can extend upwardly into an interior 56 of the sleeve 5 in the direction of arrow A 1 while the package is in the erect state ( FIG. 3 ). Furthermore, the bottom edge 53 forms a support when the package 1 is in the erect state for contacting a surface S ( FIG. 4 ). The support formed of the bottom edge 53 maintains the package in an upright position on the surface S. As further illustrated in FIGS. 3 and 4 , the gusseted sides 60 of the bag 3 may be maintained extended when the package 1 is in the erect state. Other intervening states of the package 1 including intermediate states whereby the package 1 is not fully erected are also applicable according to some embodiments. Furthermore, additional reinforcing sleeves of differing configurations are also applicable according to some embodiments. The reinforced package 1 may be otherwise shaped, arranged, and configured without departing from the disclosure.

- FIG. 5generally illustrates an example embodiment of a system and method 100 for forming the reinforced packages (e.g., reinforced packages 1 ) in accordance with the disclosure.

- the packaging system 100attaches a web of material 101 for forming the bags 3 of the packages 1 to the blanks 10 , and the attached blanks and web move through a respective packaging system from an upstream end 103 to a downstream end 105 generally in a machine direction M (e.g., the downstream direction), and are formed into the individual packages by various portions and components of the system as discussed further below.

- a machine direction Me.g., the downstream direction

- the web of bag material 101which can include preprinted or imprinted paper, polyethylene, laminates, or other material including flexible and heat-sealable materials, for example, is fed from a roll or supply 102 .

- the bag material 101can be pre-printed with various designs, lettering, labels and/or other graphics and can be perforated, printed roll stock that can include patterned adhesive that is positioned to facilitate forming the web 101 into bags 3 in the formed packages 1 .

- a carton feeder 107is positioned at the upstream end 103 of the system 100 and includes a stack 108 of carton blanks 10 that are fed to a blank conveyor 109 .

- the carton feeder 107is a pick and place type carton feeder that includes an arm 110 with suction cups 110 a or any other suitable actuator for holding a blank 10 .

- the arm 110is positioned adjacent a blank 10 in the stack 108 and the suction cups 110 a can engage the blank 10 (e.g., with vacuum pressure) so that the arm 110 can carry the blank.

- the arm 110can be moved to the position shown in FIG.

- the carton feedercould comprise other types of feeders such as mechanisms that convey blanks 10 directed from a blank cutting station, or any other suitable types of feeders or other mechanisms without departing from the disclosure.

- the blank conveyor 109includes two spaced apart lug belts or tracks 111 with lugs 113 for engaging a series of blanks 10 and conveying the blanks in the machine direction M.

- the lug belts 111can be endless belts, each with a plurality of the lugs 113 spaced along the respective belt.

- the lugs 113can be spaced on the lug belts 111 by approximately the height of the bags 3 in the reinforced packages 1 .

- the blank conveyor 109receives the blanks 10 from the carton feeder 107 ( FIG.

- the blank conveyor 109can include one or more brushes 114 or other suitable features that can engage the blanks 10 as the lug belts 111 move the blanks 10 past the brushes 114 . Accordingly, as the lug belts 111 move the blanks 10 downstream, the brushes 114 can drag against the blanks 10 and push the blanks against the respectively adjacent lugs 113 so that, for example, the blanks 10 can be properly positioned for attachment to the web of material 101 in the attachment assembly 115 . Subsequently, the lugs 113 can push the respective blanks 10 toward the attachment assembly 115 overcoming the resistance of the brushes 114 .

- the attachment assembly 115 of the system 100includes an adhesive applicator 116 ( FIGS. 5-8 ) for applying adhesive to the blanks 10 (e.g., at the adhesive region 43 ).

- the adhesive applicator 116can include one or more adhesive outlets 116 a mounted on a frame 116 b above the blank conveyor 109 so that the adhesive applicator 116 can apply an adhesive (e.g., adhesive 118 shown schematically in FIGS. 6A and 8 ) to the upper surfaces of the blanks 10 as they pass under the adhesive applicator 116 and prior to engaging the blanks 10 with the web of material 101 .

- an adhesivee.g., adhesive 118 shown schematically in FIGS. 6A and 8

- the web of material 101can be unrolled from the roll 102 over one or more rollers and directed to move in the machine direction over (e.g., generally parallel to) the lug belts 111 so that the web of material 101 can be brought into contact with the blanks 10 in the attachment assembly 115 .

- the attachment assembly 115can include an adhesive compression nip roller 117 ( FIGS. 5 and 8 ) downstream from the adhesive applicator 116 over the web of material 101 .

- An opposing nip roller or other surfacecan be disposed below the blanks 10 .

- the nip rollerscan receive the web of material 101 and the blanks 10 and press the web of material 101 against the blanks 10 to adhesively attach the web to the blanks via the adhesive 118 , for example.

- the nip roller 117 and the opposing rollercan be disposed between the lug belts 111 so that the lugs 113 can pass by the rollers.

- the blank 10can be attached to the web 101 by other suitable mechanisms without departing from the disclosure.

- the web 101 with blanks 10 attachedtravels from the blank conveyor 109 through a series of rollers 121 , 123 and to a tube forming assembly 125 of the system 100 .

- the tube forming assembly 125can include web folding features for forming the web of material 101 into an open-ended tube 101 ′.

- the tube forming assembly 125can include a forming roll 126 , guide rollers 128 a , an inner forming plate 129 , and two outer guide plates 130 that form and shape the web 101 into the tube 101 ′ having the side gussets 60 and fold lines 61 ( FIGS.

- the forming roll 126can engage the central portion 63 of the web of material 101 , and the marginal portions 65 , 67 of the web of material 101 can fold upwardly at the forming roll 126 to the guide rollers 128 a .

- the guide rollers 128 acan direct the marginal portions 65 , 67 over the inner forming plate 129 and between the outer guide plates 130 .

- Additional guide rollers 128 b ( FIG. 10 ) downstream from the guide rollers 128 acan further direct the marginal portions 65 , 67 to overlap one another on the inner forming plate 129 .

- the inner forming plate 129can be spaced apart from the central portion 63 of the web of material so that the gusset portions 60 extend generally vertically between the central portion 63 and the respective marginal portions 65 , 67 and adjacent to the respective outer guide plates 130 . Accordingly, the marginal portions 65 , 67 of the web of material 101 are engaged between the inner forming plate 129 and the guide rollers 128 a , 128 b to move the marginal portions from being generally planar with the central portion 63 (e.g., upstream from the forming roll 126 ) to being at least partially overlapped with one another and extending over the central portion 63 downstream from the guide rollers 128 a.

- the central portion 63e.g., upstream from the forming roll 126

- the tube forming assembly 125includes a web adhesive applicator 127 that applies adhesive (e.g., an adhesive 72 schematically shown in FIG. 10 ) to the web 101 as the web is being formed into the tube 101 ′.

- adhesivee.g., an adhesive 72 schematically shown in FIG. 10

- the adhesive 72can be applied to one or both of the marginal portions 65 , 67 by the adhesive applicator 127 as they are overlapped to form a longitudinal seam 71 in the tube 101 ′ ( FIGS. 10 and 11 ).

- the longitudinal seam 71can form a back of the bag 3 in the formed package 1 .

- the seam 71could be otherwise formed without departing from the scope of the invention.

- FIG. 10the longitudinal seam 71

- the gussets 60 of the tube 101 ′can be formed by the inner forming plate 129 , the outer guide plates 130 , and a flexible plate 132 disposed downstream from the inner forming plate and the outer guide plates.

- the inner forming plate 129can be angled downwardly so that the upstream end of the inner forming plate 129 ( FIG. 9 ) is spaced farther from the central portion 63 of the web of material 101 than the downstream end of the forming plate (not shown).

- the outer guide plates 130can each include an inwardly-directly horizontal plate 130 a ( FIGS.

- the outer guide plates 130 with the horizontal plates 130 acan be angled inwardly so that the outer guide plates 130 are spaced farther apart from one another at the upstream end ( FIG. 9 ) of the outer guide plates than at the downstream end ( FIG. 11 ) of the outer guide plates. Accordingly, in one embodiment, as the attached web W′ moves in the machine direction M, the inner forming plate 129 can lower the overlapped marginal portions 65 , 67 and the longitudinal seam 71 toward the central portion 63 of the tube 101 ′ while the horizontal plates 130 a push the gusset portions 60 of the tube 101 ′ inwardly. As shown in FIG.

- the portions of the gussets 60 adjacent the respective marginal portions 65 , 67overlap the portions of the gussets 60 adjacent the central portion 63 between the central portion 63 and the respective marginal portions 65 , 67 .

- the flexible plate 132can apply downward pressure on the tube 101 ′ to help form the fold lines of the gussets 60 , to help adhere the marginal portions 65 , 67 together via the adhesive 72 , and/or to generally flatten the tube 101 ′.

- the tube forming assembly 125could be otherwise configured without departing from the disclosure.

- the attached web W′moves from the tube forming assembly 125 to a carton forming assembly 131 of the system 100 .

- the carton forming assembly 131includes carton folding features ( FIGS. 12 and 13 ) that position the various flaps and panels of the blank 10 .

- the system 100can include folders (not shown) for breaking the fold lines of the blank 10 (e.g., the arcuate fold lines 31 , 33 , 35 , 37 ) between the tube forming assembly 125 and the carton forming assembly 131 .

- the carton forming assembly 131includes a carton adhesive applicator 135 ( FIG. 12 ) that applies adhesive (e.g., an adhesive 136 shown schematically in FIG.

- the carton forming assembly 131can include folding plates including outer wedge plates 133 a , inner guide plates 133 b , and forming plates 134 .

- the inner guide plates 133 bcan extend over the blank 10 (e.g., adjacent and inward of the lateral fold lines 26 , 27 — FIG.

- the outer wedge plates 133 acan push the back panels 23 , 25 of the blank upwardly to extend generally vertically between the respective outer wedge plates 133 a and the respective inner guide plates 133 b , folding the blank 10 at the lateral fold lines 26 , 27 in one embodiment.

- the forming plates 134can have an inner edge that is angled inwardly to further fold the back panels 23 , 25 downwardly over the tube 101 ′. Additionally, the forming plates 134 can press the back panels 23 , 25 against the tube so that the adhesive 136 can attach the back panels to the tube. In one embodiment, the back panels 23 , 25 can at least partially overlap and can be adhered to one another.

- the carton forming assembly 131could be otherwise configured without departing from the disclosure. For example, the carton forming assembly 131 could use forming belts instead of or in addition to the folding plates shown in FIGS. 12 and 13 .

- the attached web W′moves from the carton forming assembly 131 through two drive rollers 135 , 137 and into a rotary bag sealer assembly 139 that is downstream from the drive rollers.

- the attached web W′moves upward from the drive rollers 135 , 137 to the rotary bag sealer assembly 139 that includes a heat seal roller 141 and a heat seal arm 143 .

- the roller 141has a square or other suitable polygonal cross-sectional shape (shown schematically in FIG. 16 ) so that the roller includes four edges 144 or corners around the circumference of the roller.

- the rollercould have any suitable number of edges without departing from the disclosure.

- the roller 141rotates and the edges 144 move into engagement with a respective section of the attached web corresponding to the bottom transverse seal 69 at the closed end 9 of the bag 3 .

- the heat seal arm 143is urged against the roller 141 and rides along the square shaped outer surface of the roller. As the corresponding edges 144 of the roller bring the corresponding section of the attached web W′ into engagement with the heat seal arm 143 , the arm moves away from the roller 141 but stays in contact with the roller to heat the web material and join the two layers of overlapped material at the section of the tube 101 ′ to form the transverse seal 69 .

- the heat from the heat seal arm 143can activate a previously-applied heat-activate glue and/or at least partially melt or weld the walls of the tube 101 ′ together to form the transverse seal 69 .

- the sequential transverse seals 69 disposed between each of the reinforcement sleeves 5 on the attached web W′ moving downstream from the roller 141can form tube portions 147 in the tube 101 ′.

- the tube portions 147can extend from one transverse seal 69 to another and can generally correspond to the bags 3 in the packages 1 .

- the size of the roller 141can be adjusted to change the distance between the respective edges to adjust to location of the bottom seal 9 of the bag 3 based on the size of the bag needed.

- the seal arm 143is generally arcuate with a curved interior surface 146 that contacts the web of material 101 and presses the web of material against a respective edge 144 .

- the attached web W′After leaving the rotary bag sealer assembly 139 , the attached web W′ includes a series of formed reinforced packages (e.g., including the reinforcement sleeves 5 attached to the tube portions 147 , which generally correspond to the bags 3 in the separate packages 1 ) that are connected together via the tube 101 ′.

- the rotary bag sealer assembly 139could be otherwise shaped, arranged, configured, and/or omitted without departing from the disclosure.

- the sealer assembly 139could include rollers with a generally cylindrical body having a series of raised heating elements arranged at spaced locations about the circumference of the roller so that the bottom transverse seals 69 of the bags 3 are provided by pressing the portion of the attached web W′ against the raised heating elements.

- the system 100includes a cutting assembly 151 with one or more cutting features downstream from the rotary bag sealer assembly 139 .

- the cutting assemblyis a rotary cutting assembly 151 that includes a cutting roller 153 and a base roller 155 that cut the attached web W′ into the individual reinforced packages 1 .

- the attached web W′is cut and separated into individual packages 1 by cutting the web material 101 at the location corresponding to the top edge 7 of the package 1 and the location corresponding to the bottom edge 9 of the package (e.g., adjacent the transverse seal 69 ).

- the cutting roller 153can have an edge 157 or other cutting feature that is configured to cut the tube 101 ′ after the transverse seam 69 of a tube portion 147 passes the cutting roller 153 so that the cut is made just upstream from transverse seam 69 .

- the package 1is now separated from the remainder of the attached web W′ and the tube portion 147 is now the bag 3 .

- the attached web W′can be cut and formed into the packages 1 by other mechanisms without departing from the disclosure.

- the rotary cutting assembly 151could be otherwise shaped, arranged, and/or configured without departing from the disclosure.

- a conveyor assembly 161is located downstream of the rotary bag sealer assembly 139 and the cutting assembly 151 to transport the separate packages 1 for collection and further handling and/or packaging for shipping to a customer.

- the conveyor assembly 161can include several belts driven by and guided by rollers to move the packages 1 away from the cutting assembly 151 and to output the packages onto a stack or another conveyor, for example.

- the packages 1could be otherwise moved away from the cutting assembly 151 without departing from the disclosure.

- the carton feeder 107could be replaced by a belt driven carton feeder 107 ′ that conveys a blank 10 from the stack at relatively higher speeds than the pick and place type carton feeder 107 of FIGS. 6A and 6B .

- the carton feeder 107 ′can move the blanks 10 from the stack 108 between an upper series of belts 171 and a lower series of belts 173 .

- the belts 171 , 173can be endless belts that extend around and are driven by a plurality of rollers 175 , for example.

- the carton feeder 107 ′can be timed to output a blank 10 onto the lug belts 111 ahead of respective lugs 113 , and a drag feature (e.g., the brushes 114 shown in FIGS. 7 and 8 ) can engage the blank 10 until the adjacent lugs 113 move downstream and engage an edge of the blank. As described above, the lugs 113 can then move the blank 10 downstream to the adhesive applicator 116 .

- the blanks 10could be otherwise fed to the blank conveyor 109 without departing from the disclosure.

- the carton feedercould include a shuttle feeder or other suitable features.

- FIG. 20is a schematic view of a system 200 of a second embodiment that is similar to the system 100 of the first embodiment.

- the system 200is for forming the reinforced packages 1 in a similar manner as the system 100 except system 200 includes a different sealing mechanism 203 for forming the transverse seals 69 the bottom ends 9 of the bags 3 .

- like or similar references numbersare used to indicate like or similar features of the two embodiments.

- the rotary bag sealer assembly 139FIGS. 5 and 14-16

- the sealing mechanism 203heat seals the bottom end portions 9 of the bags 3 after the attached web W′ has been separated at the rotary cutting assembly 151 .

- Separated but unsealed packages 210can be fed to the sealing mechanism 203 and the bottom end portions 9 of the bags can be heat sealed to form the transverse seals 69 ( FIG. 3 ) of the reinforced packages 1 .

- the heat sealing mechanism 203can be any suitable heat sealer machine for heat sealing the bag material 101 , or any other suitable mechanism for forming the transverse seal 69 of the bag 3 .

- the system 100 , 200 for forming the reinforced packages 1 of the present disclosureform the packages in a highly efficient manner by first attaching the web 101 to the blanks 10 to form the attached web W′, and then forming the tube 101 ′ from the web 101 including the side gussets 60 on each side of the tube.

- the blank 10is then folded to form the reinforced construct or sleeve 5 .

- the attached web W′ including the tube 101 ′ and the sleeves 5is then further processed to form the bottom transverse seal 69 of the bags and to cut and separate the attached web into individual reinforced packages 1 .

- the system 100 , 200 of the present disclosureis more efficient than other systems that separately form the bags 3 and attach the formed bags to the blanks at least because once the blanks 10 are attached to the web 101 to create the attached web W′ of the systems 100 , 200 of the present disclosure, the blanks move with the web 101 in an aligned manner and twisting or turning of the blanks during processing is prevented by the secure attachment to the web. Furthermore, alignment of the separate blanks 10 and formed bags 3 is no longer needed as the packages 1 formed by the systems 100 , 200 are formed from the attached web W′ including the blanks 10 attached to the web 101 .

- bagscan be formed from a paper stock material, although various plastic or other bag materials also can be used, and can be lined or coated with a desired material.

- the reinforcing sleeves described hereincan be made from a more rigid material such as a clay-coated natural kraft (“CCNK”).

- CCNKclay-coated natural kraft

- Other materialssuch various card-stock, paper, plastic or other synthetic or natural materials also can be used to form the components of the packages described herein.

- the blanks of the present disclosuremay be constructed from paperboard having a caliper so that it is heavier and more rigid than ordinary paper.

- the blankcan also be constructed of other materials, such as cardboard, or any other material having properties suitable for enabling the carton to function at least generally as described above.

- the blankcan be coated with, for example, a clay coating.

- the clay coatingmay then be printed over with product, advertising, and other information or images.

- the blanksmay then be coated with a varnish to protect information printed on the blanks.

- the blanksmay also be coated with, for example, a moisture barrier layer, on either or both sides of the blanks.

- the blankscan also be laminated to or coated with one or more sheet-like materials at selected panels or panel sections.

- a tear linecan include: a slit that extends partially into the material along the desired line of weakness, and/or a series of spaced apart slits that extend partially into and/or completely through the material along the desired line of weakness, or various combinations of these features.

- one type tear lineis in the form of a series of spaced apart slits that extend completely through the material, with adjacent slits being spaced apart slightly so that a nick (e.g., a small somewhat bridging-like piece of the material) is defined between the adjacent slits for typically temporarily connecting the material across the tear line. The nicks are broken during tearing along the tear line.

- the nickstypically are a relatively small percentage of the tear line, and alternatively the nicks can be omitted from or torn in a tear line such that the tear line is a continuous cut line. That is, it is within the scope of the present disclosure for each of the tear lines to be replaced with a continuous slit, or the like.

- a cut linecan be a continuous slit or could be wider than a slit without departing from the present disclosure.

- a fold linecan be any substantially linear, although not necessarily straight, form of weakening that facilitates folding there along. More specifically, but not for the purpose of narrowing the scope of the present disclosure, fold lines include: a score line, such as lines formed with a blunt scoring knife, or the like, which creates a crushed or depressed portion in the material along the desired line of weakness; a cut that extends partially into a material along the desired line of weakness, and/or a series of cuts that extend partially into and/or completely through the material along the desired line of weakness; and various combinations of these features. In situations where cutting is used to create a fold line, typically the cutting will not be overly extensive in a manner that might cause a reasonable user to incorrectly consider the fold line to be a tear line.

- the above embodimentsmay be described as having one or more panels adhered together by glue during erection of the carton embodiments.

- glueis intended to encompass all manner of adhesives commonly used to secure carton panels in place.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Making Paper Articles (AREA)

- Separation Using Semi-Permeable Membranes (AREA)

- Containers And Plastic Fillers For Packaging (AREA)

Abstract

Description

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/720,126US11325336B2 (en) | 2015-04-29 | 2019-12-19 | Method and system for forming packages |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201562179172P | 2015-04-29 | 2015-04-29 | |

| US15/142,103US10562675B2 (en) | 2015-04-29 | 2016-04-29 | Method and system for forming packages |

| US16/720,126US11325336B2 (en) | 2015-04-29 | 2019-12-19 | Method and system for forming packages |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US15/142,103DivisionUS10562675B2 (en) | 2015-04-29 | 2016-04-29 | Method and system for forming packages |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| US20200122895A1 US20200122895A1 (en) | 2020-04-23 |

| US11325336B2true US11325336B2 (en) | 2022-05-10 |

Family

ID=57198797

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US15/142,103Active2037-11-23US10562675B2 (en) | 2015-04-29 | 2016-04-29 | Method and system for forming packages |

| US16/720,126Active2036-11-04US11325336B2 (en) | 2015-04-29 | 2019-12-19 | Method and system for forming packages |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US15/142,103Active2037-11-23US10562675B2 (en) | 2015-04-29 | 2016-04-29 | Method and system for forming packages |

Country Status (9)

| Country | Link |

|---|---|

| US (2) | US10562675B2 (en) |

| EP (1) | EP3288834B1 (en) |

| CN (1) | CN107530998B (en) |

| AU (1) | AU2016254135B2 (en) |

| BR (1) | BR112017022499B1 (en) |

| CA (1) | CA2980354C (en) |

| ES (1) | ES2789648T3 (en) |

| MX (1) | MX392619B (en) |

| WO (1) | WO2016176540A1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD1042113S1 (en)* | 2020-01-24 | 2024-09-17 | Graphic Packaging International, Llc | Reinforcing carton |

| US12172405B2 (en) | 2021-12-01 | 2024-12-24 | Graphic Packaging International, Llc | Methods and systems for forming trays |

| US12304677B2 (en) | 2021-12-21 | 2025-05-20 | Graphic Packaging International, Llc | Reconfigurable tray engaging assembly |

Families Citing this family (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2789648T3 (en) | 2015-04-29 | 2020-10-26 | Graphic Packaging Int Llc | Container formation procedure and system |

| CA2980192C (en) | 2015-04-29 | 2019-05-07 | Graphic Packaging International, Inc. | Method and system for forming packages |

| ES2954919T3 (en)* | 2015-07-14 | 2023-11-27 | Graphic Packaging Int Llc | Procedure and system to form containers |

| WO2019032436A1 (en)* | 2017-08-09 | 2019-02-14 | Graphic Packaging International, Llc | Method and system for forming packages |

| CA3098648C (en)* | 2018-05-14 | 2023-02-28 | Graphic Packaging International, Llc | Method and system for forming packages |

| MX2021000248A (en) | 2018-07-09 | 2021-03-25 | Graphic Packaging Int Llc | Method and system for forming packages. |

| US11667097B2 (en) | 2018-11-06 | 2023-06-06 | Graphic Packaging International, Llc | Method and system for processing blanks for forming constructs |

| CN109649745B (en)* | 2018-12-28 | 2024-02-02 | 浙江旭翔机械科技有限公司 | Hot-melt adhesive tape coating device for filling machine |

| EP3917848B1 (en) | 2019-01-28 | 2025-09-17 | Graphic Packaging International, LLC | Reinforced package |

| GB201902604D0 (en)* | 2019-02-27 | 2019-04-10 | Intercontinental Great Brands Llc | Apparatus and methods for packaging |

| WO2021102102A1 (en) | 2019-11-22 | 2021-05-27 | Graphic Packaging International, Llc | Container with liner |

| MX2023004338A (en)* | 2020-10-14 | 2023-05-04 | Graphic Packaging Int Llc | Method and system for preparing blanks for forming cartons. |

| CA3204463A1 (en) | 2020-12-22 | 2022-06-30 | Graphic Packaging International, Llc | End flap engagement assembly for erecting cartons and related systems and methods |

| CN112960203A (en)* | 2021-03-23 | 2021-06-15 | 安庆市恒昌机械制造有限责任公司 | Packaging bag heat sealing structure and production device and technological method thereof |

| CN113334859B (en)* | 2021-06-08 | 2022-11-18 | 惠州益栢科技有限公司 | Center-sealed packaging bag production method based on bag making machine |

Citations (380)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1474088A (en) | 1920-07-26 | 1923-11-13 | Richard S Reynolds | Collapsible metal box |

| US1516090A (en) | 1923-03-28 | 1924-11-18 | Benjamin L Gary | Carton |

| US1664111A (en) | 1927-03-23 | 1928-03-27 | W H Marvin Company | Carton |

| US2092858A (en) | 1934-03-12 | 1937-09-14 | Johnson Automatic Sealer Co Lt | Bag and method of making same |

| US2095910A (en) | 1936-07-08 | 1937-10-12 | Edna May Bergstein | Method of forming containers |

| US2099257A (en)* | 1935-10-04 | 1937-11-16 | Edna May Bergstein | Container |

| US2107946A (en) | 1936-09-15 | 1938-02-08 | Bloomer Bros Co | Carton construction |

| US2114625A (en) | 1937-05-01 | 1938-04-19 | Edna May Bergstein | Method of forming containers |

| US2132966A (en) | 1937-03-19 | 1938-10-11 | Edson A O'brien | Contection |

| US2134057A (en) | 1936-10-27 | 1938-10-25 | Potdevin Machine Co | Bag making machine |

| US2166388A (en) | 1937-12-20 | 1939-07-18 | Edna May Bergstein | Machine for combining bags and cartons |

| US2197113A (en) | 1938-04-30 | 1940-04-16 | Marshall & Ilsley Bank | Bag assemblage |

| US2250249A (en) | 1936-02-04 | 1941-07-22 | Bergstein Robert Morris | Container |

| US2273470A (en) | 1941-04-08 | 1942-02-17 | Wingfoot Corp | Method of lining cartons |

| US2282207A (en) | 1939-01-06 | 1942-05-05 | Kraft Cheese Company | Container and method of making the same |

| US2286465A (en) | 1941-02-06 | 1942-06-16 | Clement Erlin | Paper cup opener |

| USRE23096E (en) | 1949-04-05 | Moisturepboof package | ||

| GB632554A (en) | 1946-09-02 | 1949-11-28 | Johannes Wilhelmus Boon | Improvements in machines for the manufacture of bags |

| US2502117A (en) | 1948-03-17 | 1950-03-28 | Gen Mills Inc | Method and apparatus for lining blanks |

| US2553923A (en) | 1948-09-11 | 1951-05-22 | Ralph E Lambert | Wrapping paper comprising single face corrugated board and integral fly webs |

| FR1048714A (en) | 1950-11-06 | 1953-12-23 | Ici Ltd | Lined boxes and their manufacture |

| US2758520A (en) | 1950-11-06 | 1956-08-14 | Ici Ltd | Method for the manufacture of lined cartons |

| US2799211A (en)* | 1954-10-12 | 1957-07-16 | Jagenberg Werk Akt Ges | Method and apparatus for manufacturing blanks for tubular containers having moisture resistant linings |

| NL87840C (en) | 1951-07-04 | 1958-04-15 | ||

| US2835435A (en) | 1950-09-05 | 1958-05-20 | Charles D Mullinix | Packaging means |

| US2870023A (en) | 1951-07-05 | 1959-01-20 | Clarence W Vogt | Enwrapments for plastic and like substances |

| DE1060313B (en) | 1957-02-05 | 1959-06-25 | Hansjuergen Mensing | Packaging in the form of a folding box |

| US2913161A (en) | 1953-06-15 | 1959-11-17 | Waldorf Paper Products Co | Plant package |

| US2987402A (en) | 1958-07-11 | 1961-06-06 | Milprint Inc | Composite food package and method of making same |

| DE1147379B (en) | 1960-11-16 | 1963-04-18 | Windmoeller & Hoelscher | Device for producing flat bags from thermoplastic plastic webs |

| US3104596A (en)* | 1960-10-17 | 1963-09-24 | Interstate Folding Box Co | Process and apparatus for the manufacture of multiple-cell inner-lined containers |

| US3105417A (en) | 1959-11-21 | 1963-10-01 | Hammer Steffen | Method for production of reinforced bags, tobacco pouches, etc. of synthetic foil |

| US3142231A (en) | 1960-05-23 | 1964-07-28 | Christensson Od Wikar | Arrangement in machines for the production of lined packages |

| US3142430A (en) | 1963-03-15 | 1964-07-28 | American Can Co | Carton |

| US3153991A (en) | 1963-03-04 | 1964-10-27 | St Regis Paper Co | Apparatus for the manufacture of composite carton blanks |

| US3194471A (en) | 1964-06-04 | 1965-07-13 | Inland Container Corp | Bulk container device |

| US3218961A (en) | 1961-02-10 | 1965-11-23 | Phillips Petroleum Co | Thermoplastic bag sealer |

| US3240419A (en) | 1964-09-15 | 1966-03-15 | American Can Co | Carton with integral tear-strip sealing means |

| US3249286A (en) | 1964-09-28 | 1966-05-03 | Monsanto Co | Reinforced plastic bag |

| US3250454A (en) | 1963-11-27 | 1966-05-10 | Steiger A G | Carton and blank for its fabrication |

| US3272423A (en) | 1961-12-05 | 1966-09-13 | Bjarno Knud Maro Henrik | Container structures |

| US3324998A (en) | 1965-10-23 | 1967-06-13 | Reynolds Metals Co | Container and blanks for making same |

| US3336846A (en) | 1963-07-18 | 1967-08-22 | Berghgracht Marius | Process and apparatus for the continuous manufacture of boxes comprising a cardboard sheath folded flat around an inner tubular lining |

| US3357631A (en) | 1963-12-03 | 1967-12-12 | Continental Can Co | Recessed ice-cream carton with tuck-in reclosure |

| US3395623A (en) | 1964-12-08 | 1968-08-06 | Continental Can Co | Liquid-tight container and method of forming same |

| US3399818A (en) | 1966-05-17 | 1968-09-03 | Douglass M. Stegner | Container |

| US3412925A (en) | 1967-12-13 | 1968-11-26 | Albemarle Paper Co | Flat bottom multi-ply bag |

| US3428235A (en) | 1967-09-22 | 1969-02-18 | Pasquale Randazzo | Can carriers |

| US3459357A (en) | 1967-01-05 | 1969-08-05 | Union Camp Corp | Bag-in-a-box |

| US3461642A (en) | 1966-10-21 | 1969-08-19 | American Can Co | Method and machine for forming and sealing a carton |

| US3482758A (en) | 1968-01-12 | 1969-12-09 | Interstate Folding Box Co | Prelined two wall packet |

| US3515333A (en) | 1969-02-13 | 1970-06-02 | Eastman Kodak Co | Combination wrap-base roll box |

| DE1810965A1 (en) | 1968-11-26 | 1970-10-15 | Sengewald Dr Karl H | Thermoplastic synthetic foil carrier bag |

| US3543469A (en) | 1966-04-25 | 1970-12-01 | Huntingdon Ind Inc | Packaging apparatus |

| US3552640A (en) | 1969-04-14 | 1971-01-05 | Frank L Young | Expansible gusset envelope with side flap seams |

| US3554434A (en) | 1968-11-08 | 1971-01-12 | Dave Chapman | Free-standing flexible package |

| US3570751A (en) | 1969-07-03 | 1971-03-16 | Wyomissing Corp | Tear-open package |

| US3575409A (en) | 1968-12-03 | 1971-04-20 | Mead Corp | Feeder mechanism |

| US3576290A (en) | 1969-08-01 | 1971-04-27 | Union Camp Corp | Bag in a box for frozen eggs or the like |

| US3616027A (en) | 1966-12-23 | 1971-10-26 | Honsel Karl Heinz | Method for applying cardboard reinforcements onto a paper web or the like |

| US3627541A (en) | 1968-11-21 | 1971-12-14 | Reynolds Metals Co | Method of packaging a food product in a carton |

| US3637130A (en) | 1970-08-10 | 1972-01-25 | Reynolds Metals Co | Container and blanks for making same |

| US3659777A (en) | 1969-06-30 | 1972-05-02 | Takahi Kanada | Reinforced package |

| US3739545A (en) | 1971-05-19 | 1973-06-19 | Emhart Corp | Method and apparatus for packaging articles |

| US3800677A (en) | 1971-05-03 | 1974-04-02 | Xepex Ind Inc | Apparatus for forming carton |

| US3878771A (en) | 1972-06-26 | 1975-04-22 | James A Malcolm | Manufacture of paperboard cartons with liquid-proof liners |

| USRE28554E (en) | 1966-12-06 | 1975-09-16 | Flexible wrapping material | |

| US3945870A (en) | 1973-07-24 | 1976-03-23 | Johnsen Edward L | Method of making multi-layer composite and articles therefrom |

| US3959950A (en) | 1975-03-17 | 1976-06-01 | Nobuyoshi Fukuda | Packaging system |

| US3964669A (en) | 1975-09-02 | 1976-06-22 | Milprint, Inc. | Composite wrapper combining rigid and flexible elements |

| US3981494A (en) | 1975-05-08 | 1976-09-21 | Prestegaard Paul G | Blank feeder apparatus |

| US4011983A (en) | 1976-02-24 | 1977-03-15 | William Henry Greene | Bag container |

| US4034658A (en) | 1975-10-28 | 1977-07-12 | Olinkraft, Inc. | Tray feeder system |

| US4082216A (en) | 1977-02-07 | 1978-04-04 | Eli Lilly And Company | Carton and bag container |

| US4164171A (en) | 1977-10-25 | 1979-08-14 | American Can Company | Carton forming apparatus |

| US4170928A (en) | 1977-11-29 | 1979-10-16 | Sonoco Products Company | Apparatus for fabricating and assembling multi-cell partitions |

| US4196035A (en) | 1977-05-12 | 1980-04-01 | Tetra Pak Development S.A. | Apparatus for applying strips to coated web material |

| US4228945A (en) | 1979-03-05 | 1980-10-21 | Champion International Corporation | Food carton for microwave heating |

| US4244281A (en) | 1979-01-19 | 1981-01-13 | Ex-Cell-O Corporation | Carton, feeder apparatus for packaging machines |

| US4267955A (en) | 1979-07-25 | 1981-05-19 | Diamond International Corporation | Quickly erected scoop-type carton and layout for cutting |

| US4284205A (en) | 1978-10-11 | 1981-08-18 | Tokai Metals Company, Limited | Foldable cup |

| US4312451A (en) | 1979-07-20 | 1982-01-26 | Westvaco Corporation | Self standing flanged tray with integral lid |

| US4313542A (en) | 1979-07-13 | 1982-02-02 | Champion International Corporation | Single-serving pie carton and blank |

| US4331434A (en) | 1979-07-27 | 1982-05-25 | Pneumatic Scale Corporation | Method and apparatus for forming a container for liquids |

| FR2516481A1 (en) | 1981-11-13 | 1983-05-20 | Mead Corp | OBJECT HOLDER AND BLANK FOR ITS MANUFACTURE |

| US4457483A (en) | 1981-10-08 | 1984-07-03 | Laureat Gagne | Collapsible support for garbage bags |

| US4477014A (en) | 1983-05-04 | 1984-10-16 | Container Corporation Of America | Triangular carton and opening means therefor |

| US4478351A (en) | 1981-11-11 | 1984-10-23 | Hokkai Can Co., Ltd. | Compound packing container |

| US4484683A (en) | 1982-02-19 | 1984-11-27 | Ralston Purina Company | Reclosable carton |

| US4490960A (en) | 1980-07-25 | 1985-01-01 | Doboy Packaging Machinery, Inc. | Apparatus and method for closing reclosable bags |

| US4494785A (en) | 1983-06-20 | 1985-01-22 | Song Ho K | Adjustable handheld round sandwich holder |

| US4520615A (en) | 1983-02-28 | 1985-06-04 | Doboy Packaging Machinery, Inc. | Tube forming apparatus for packaging |

| US4575000A (en) | 1984-11-09 | 1986-03-11 | International Paper Company | Food wrapper package |

| US4577746A (en) | 1981-07-20 | 1986-03-25 | Rengo Co., Ltd. | Control system for blank presser |

| US4578929A (en) | 1984-02-16 | 1986-04-01 | Tisma Machine Corporation | Automatic form and fill packaging machine using cardboard blanks |

| US4582315A (en) | 1981-06-22 | 1986-04-15 | R. A. Jones & Co. Inc. | High speed carton feeder |

| US4600346A (en) | 1985-11-22 | 1986-07-15 | Dennison National Company | Binder cover and method of manufacture thereof |

| US4605464A (en) | 1983-05-25 | 1986-08-12 | Slevin Julian B | Method and machine for producing complance carrier cartons |

| US4608259A (en) | 1984-11-21 | 1986-08-26 | Taco Bell | Pocket wrap |

| JPS61232175A (en) | 1985-04-05 | 1986-10-16 | 平田 勲 | Simple vessel |

| US4627223A (en) | 1982-02-05 | 1986-12-09 | Janhonen Veikko Ilmari | Package blank and packaging method |

| JPS6216319A (en) | 1985-07-11 | 1987-01-24 | 呉羽化学工業株式会社 | Automatic filling packaging device |

| WO1987003249A1 (en) | 1985-11-26 | 1987-06-04 | Wilverley Mansions I.B.V. | Plastic bag and method and apparatus of manufacture |

| US4726170A (en) | 1985-07-11 | 1988-02-23 | Kureha Chemical Industry Co., Ltd. | Automatic filling and packaging system |

| US4747703A (en) | 1985-02-28 | 1988-05-31 | Societe Generale Des Eaux Minerales De Vittel | Bag made of flexible synthetic material and possessing a stiffening and stabilizing means |

| US4754914A (en) | 1986-09-26 | 1988-07-05 | Rock-Tenn Company | Package for wrapping food or other articles |

| US4775771A (en) | 1987-07-30 | 1988-10-04 | James River Corporation | Sleeve for crisping and browning of foods in a microwave oven and package and method utilizing same |

| US4785696A (en) | 1987-04-03 | 1988-11-22 | Kraft, Inc. | High-speed apparatus for forming sheets from a web |

| US4793117A (en) | 1987-05-06 | 1988-12-27 | Standard Knapp, Inc. | Continuous motion tray type packaging machine |

| US4802664A (en) | 1986-01-20 | 1989-02-07 | Ab Tetra Pak | Arrangement for the feeding of sheets to a magazine |

| US4854983A (en) | 1987-09-22 | 1989-08-08 | Mobil Oil Corporation | Rotary heat sealing method and apparatus |

| US4865921A (en) | 1987-03-10 | 1989-09-12 | James Riker Corporation Of Virginia | Microwave interactive laminate |

| US4881934A (en) | 1988-02-27 | 1989-11-21 | Kliklok Corporation | Rotary transfer mechanism |

| US4890439A (en) | 1988-11-09 | 1990-01-02 | James River Corporation | Flexible disposable material for forming a food container for microwave cooking |

| US4919785A (en) | 1988-04-28 | 1990-04-24 | Kraft General Foods, Inc. | Microwave carton |

| US4930639A (en) | 1989-08-02 | 1990-06-05 | Westvaco Corporation | Ovenable food container with removable lid |

| US4936935A (en) | 1988-05-20 | 1990-06-26 | Beckett Industries Inc. | Microwave heating material |

| US4940200A (en) | 1989-01-13 | 1990-07-10 | Wilmarc, Inc. | Support for a non-self supporting container |

| US4986522A (en) | 1989-09-27 | 1991-01-22 | Paulson Harold E | Printing press feed mechanism |

| US4995217A (en) | 1987-12-22 | 1991-02-26 | Francis Jr Sam E | Method of making a chemical thermal pack |

| US5014582A (en) | 1987-12-17 | 1991-05-14 | Komori-Chambon Sa | Carton blank deceleration unit |

| US5019029A (en) | 1989-11-13 | 1991-05-28 | The Mead Corporation | Machine for erecting sleeve type cartons |

| US5028147A (en) | 1988-08-25 | 1991-07-02 | Bell Paper Company | Integrated container for meat products |

| US5034234A (en) | 1988-03-15 | 1991-07-23 | Golden Valley Microwave Foods Inc. | Microwave heating and serving package |

| US5071062A (en) | 1991-01-28 | 1991-12-10 | Bradley David E | Reducible carton for pizza pies and the like |

| US5078273A (en) | 1991-02-12 | 1992-01-07 | James River Corporation Of Virginia | Microwave carton and blank for forming the same |

| US5080643A (en) | 1988-03-21 | 1992-01-14 | Dow Brands Inc. | Method of making a stand-up plastic bag |

| FR2665882A1 (en) | 1990-03-14 | 1992-02-21 | Vataire Fabienne | Hygienic packaging case for the consumption of sandwiches in fast food situations |

| US5093364A (en) | 1988-08-24 | 1992-03-03 | Schering Agrochemicals Limited | 5-fluoroanthranilic fungicides |

| US5096723A (en) | 1990-07-23 | 1992-03-17 | Golden Valley Microwave Foods Inc. | Microwave food heating package with serving tray |

| US5097651A (en) | 1988-09-26 | 1992-03-24 | Societe Generale Des Eaux Minerales De Vittel | Process and device for improving the rigidity of a container made of synthetic material |

| US5102385A (en) | 1991-03-05 | 1992-04-07 | The Mead Corporation | Feeder mechanism for sleeve type cartons |

| US5102485A (en) | 1989-02-01 | 1992-04-07 | International Paper Company | Apparatus for continuous feeding and synchronized application of fitments to carton blanks and related method |

| US5108355A (en) | 1990-09-07 | 1992-04-28 | Graphic Packaging Corporation | Method and apparatus for attaching insert panels to carton blanks |

| US5117078A (en) | 1990-02-02 | 1992-05-26 | Beckett Industries Inc. | Controlled heating of foodstuffs by microwave energy |

| US5132124A (en) | 1990-05-18 | 1992-07-21 | Pokka Corporation | Powdered drink brewing bag |

| US5154041A (en) | 1991-07-08 | 1992-10-13 | Schneider Packaging Equipment Co., Inc. | Wrap-around carton packing apparatus and method |

| US5175404A (en) | 1988-03-15 | 1992-12-29 | Golden Valley Microwave Foods Inc. | Microwave receptive heating sheets and packages containing them |