US11008517B2 - Non-perpendicular connections between coke oven uptakes and a hot common tunnel, and associated systems and methods - Google Patents

Non-perpendicular connections between coke oven uptakes and a hot common tunnel, and associated systems and methodsDownload PDFInfo

- Publication number

- US11008517B2 US11008517B2US16/026,363US201816026363AUS11008517B2US 11008517 B2US11008517 B2US 11008517B2US 201816026363 AUS201816026363 AUS 201816026363AUS 11008517 B2US11008517 B2US 11008517B2

- Authority

- US

- United States

- Prior art keywords

- uptake

- common tunnel

- common

- flow

- tunnel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10B—DESTRUCTIVE DISTILLATION OF CARBONACEOUS MATERIALS FOR PRODUCTION OF GAS, COKE, TAR, OR SIMILAR MATERIALS

- C10B15/00—Other coke ovens

- C10B15/02—Other coke ovens with floor heating

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10B—DESTRUCTIVE DISTILLATION OF CARBONACEOUS MATERIALS FOR PRODUCTION OF GAS, COKE, TAR, OR SIMILAR MATERIALS

- C10B45/00—Other details

Definitions

- the present technologyis generally directed to non-perpendicular connections between coke oven uptakes and a hot common tunnel, and associated systems and methods.

- Cokeis a solid carbonaceous fuel that is derived from coal. Coke is a favored energy source in a variety of useful applications. For example, coke is often used to smelt iron ore during the steelmaking process. As a further example, coke may also be used to heat commercial buildings or power industrial boilers.

- an amount of coalis baked in a coke oven at temperatures that generally exceed 2,000 degrees Fahrenheit.

- the baking processtransforms the relatively impure coal into coke, which contains relatively few impurities.

- the coketypically emerges from the coke oven as a substantially intact piece.

- the coketypically is removed from the coke oven, loaded into one or more train cars, and transported to a quench tower in order to cool or “quench” the coke before it is made available for distribution for use as a fuel source.

- the hot exhaust (i.e. flue gas) emitted during bakingis extracted from the coke ovens through a network of ducts, intersections, and transitions.

- the intersections in the flue gas flow path of a coke plantcan lead to significant pressure drop losses, poor flow zones (e.g. dead, stagnant, recirculation, separation, etc.), and poor mixing of air and volatile matter.

- the high pressure drop lossescan lead to higher required draft, leaks, and problems with system control.

- poor mixing and resulting localized hot spotscan lead to earlier structural degradation due to accelerated localized erosion and thermal wear. Erosion includes deterioration due to high velocity flow eating away at material. Hot spots can lead to thermal degradation of material, which can eventually cause thermal/structural failure.

- the localized erosion and/or hot spotscan, in turn, lead to failures at duct intersections.

- FIG. 1is a schematic illustration of a horizontal heat recovery coke plant, configured in accordance with embodiments of the technology.

- FIG. 2is an isometric, partial cut-away view of a portion of the horizontal heat recovery coke plant of FIG. 1 configured in accordance with embodiments of the technology.

- FIG. 3is a sectional view of a horizontal heat recovery coke oven configured in accordance with embodiments of the technology.

- FIG. 4is a top view of a portion of a horizontal heat recovery coke plant configured in accordance with embodiments of the technology.

- FIG. 5Ais a cross-sectional top view of a perpendicular interface between an uptake duct and a common tunnel configured in accordance with embodiments of the technology.

- FIG. 5Bis a cross-sectional top view of a non-perpendicular interface between an uptake duct and a common tunnel configured in accordance with embodiments of the technology.

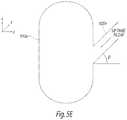

- FIG. 5Cis a cross-sectional end view of a non-perpendicular interface between an uptake duct and a common tunnel configured in accordance with embodiments of the technology.

- FIG. 5Dis a cross-sectional end view of a non-perpendicular interface between an uptake duct and a common tunnel configured in accordance with embodiments of the technology.

- FIG. 5Eis a cross-sectional end view of a non-perpendicular interface between an uptake duct and a common tunnel configured in accordance with embodiments of the technology.

- FIGS. 6A-6Iare top views of various configurations of interfaces between uptake ducts and a common tunnel configured in accordance with embodiments of the technology.

- FIG. 7Ais a cross-sectional top view of a non-perpendicular interface retrofitted between an uptake and a common tunnel configured in accordance with embodiments of the technology.

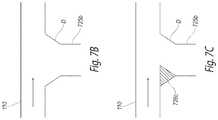

- FIG. 7Bis a cross-sectional top view of an interface between an uptake and a common tunnel configured in accordance with embodiments of the technology.

- FIG. 7Cis a cross-sectional top view of a non-perpendicular interface retrofitted between the uptake and common tunnel of FIG. 7B configured in accordance with embodiments of the technology.

- FIG. 8is a cross-sectional top view of a non-perpendicular interface between an uptake and a common tunnel configured in accordance with embodiments of the technology.

- FIG. 9is a plot showing the spatial distribution of gas static pressure along the length of the common tunnel.

- a coking systemincludes a coke oven and an uptake duct in fluid communication with the coke oven.

- the uptake ducthas an uptake flow vector of exhaust gas from the coke oven.

- the systemalso includes a common tunnel in fluid communication with the uptake duct.

- the common tunnelhas a common flow vector and can be configured to transfer the exhaust gas to a venting system.

- the uptake flow vector and common flow vectorcan meet at a non-perpendicular interface to improve mixing between the flow vectors and reduce draft loss in the common tunnel.

- FIG. 1is a schematic illustration of a horizontal heat recovery (HHR) coke plant 100 , configured in accordance with embodiments of the technology.

- the HHR coke plant 100comprises ovens 105 , along with heat recovery steam generators (HRSGs) 120 and an air quality control system 130 (e.g., an exhaust or flue gas desulfurization (FGD) system), both of which are positioned fluidly downstream from the ovens 105 and both of which are fluidly connected to the ovens 105 by suitable ducts.

- the HHR coke plant 100also includes one or more common tunnels 110 A, 110 B (collectively “common tunnel 110 ”) fluidly connecting individual ovens 105 to the HRSGs 120 via one or more individual uptake ducts 225 .

- common tunnel 110collectively connecting individual ovens 105 to the HRSGs 120 via one or more individual uptake ducts 225 .

- two or more uptake ducts 225connect each individual oven 105 to the common tunnel 110 .

- a first crossover duct 290fluidly connects the common tunnel 110 A to the HRSGs 120 and a second crossover duct 295 fluidly connects the common tunnel 110 B to the HRSGs 120 at respective intersections 245 .

- the common tunnel 110can further be fluidly connected to one or more bypass exhaust stacks 240 .

- a cooled gas duct 125transports the cooled gas from the HRSGs to the FGD system 130 .

- Fluidly connected and further downstreamare a baghouse 135 for collecting particulates, at least one draft fan 140 for controlling air pressure within the system, and a main gas stack 145 for exhausting cooled, treated exhaust into the environment.

- Various coke plants 100can have different proportions of ovens 105 , HRSGs 120 , uptake ducts 225 , common tunnels 110 , and other structures.

- each oven 105 illustrated in FIG. 1can represent ten actual ovens.

- the uptake ducts 225meet the common tunnel 110 at non-perpendicular interfaces.

- the non-perpendicular interfacesmay comprise a fitting within the uptake ducts 225 , a fitting within the common tunnel 110 , a non-perpendicular uptake duct 225 , a non-perpendicular portion of the uptake duct 225 , or other feature.

- the non-perpendicular interfacescan lower the mixing draft loss at the uptake/common tunnel connection by angling the connection in the direction of the common tunnel flow.

- the uptake ducts 225have an uptake flow having an uptake flow vector (having x, y, and z orthogonal components) and the common tunnel 110 has a common flow having a common flow vector (having x, y, and z orthogonal components).

- the interfacecan act as a vacuum aspirator which uses mass flow to pull a vacuum.

- a coke plantcan achieve more vacuum pull and lower draft loss, which can potentially cause a draft increase.

- the reduced draft losscan be used to reduce the common tunnel 110 size (e.g., diameter) or lower the required overall system draft.

- any connection where the gas flow undergoes a significant change in directioncan be improved to have a lower draft loss by using a non-perpendicular connection.

- any of the connections in the exhaust flow pathe.g., between the common tunnel 110 and the bypass exhaust stacks 240

- FIGS. 2 and 3provide further detail regarding the structure and operation of the coke plant 100 . More specifically, FIGS. 2 and 3 illustrate further details related to the structure and mechanics of exhaust flow from the ovens to the common tunnel. FIGS. 4 through 9 provide further details regarding various embodiments of non-perpendicular connections between coke oven uptakes ducts and the common tunnel.

- FIG. 2is an isometric, partial cut-away view of a portion of the HHR coke plant 100 of FIG. 1 configured in accordance with embodiments of the technology.

- FIG. 3is a sectional view of an HHR coke oven 105 configured in accordance with embodiments of the technology.

- each oven 105can include an open cavity defined by a floor 160 , a front door 165 forming substantially the entirety of one side of the oven, a rear door 170 opposite the front door 165 forming substantially the entirety of the side of the oven opposite the front door, two sidewalls 175 extending upwardly from the floor 160 intermediate the front 165 and rear 170 doors, and a crown 180 which forms the top surface of the open cavity of an oven chamber 185 .

- Controlling air flow and pressure inside the oven chamber 185can be critical to the efficient operation of the coking cycle, and therefore the front door 165 includes one or more primary air inlets 190 that allow primary combustion air into the oven chamber 185 .

- Each primary air inlet 190includes a primary air damper 195 which can be positioned at any of a number of positions between fully open and fully closed to vary the amount of primary air flow into the oven chamber 185 .

- the one or more primary air inlets 190are formed through the crown 180 .

- volatile gases emitted from the coal positioned inside the oven chamber 185collect in the crown and are drawn downstream in the overall system into downcomer channels 200 formed in one or both sidewalls 175 .

- the downcomer channelsfluidly connect the oven chamber 185 with a sole flue 205 positioned beneath the oven floor 160 .

- the sole flue 205forms a circuitous path beneath the oven floor 160 .

- Volatile gases emitted from the coalcan be combusted in the sole flue 205 thereby generating heat to support the carbonization of coal into coke.

- the downcomer channels 200are fluidly connected to chimneys or uptake channels 210 formed in one or both sidewalls 175 .

- a secondary air inlet 215is provided between the sole flue 205 and the atmosphere; the secondary air inlet 215 includes a secondary air damper 220 that can be positioned at any of a number of positions between fully open and fully closed to vary the amount of secondary air flow into the sole flue 205 .

- the uptake channels 210are fluidly connected to the common tunnel 110 by the one or more uptake ducts 225 .

- a tertiary air inlet 227is provided between the uptake duct 225 and atmosphere.

- the tertiary air inlet 227includes a tertiary air damper 229 which can be positioned at any of a number of positions between fully open and fully closed to vary the amount of tertiary air flow into the uptake duct 225 .

- each uptake duct 225also includes an uptake damper 230 .

- the uptake damper 230can be positioned at any number of positions between fully open and fully closed to vary the amount of oven draft in the oven 105 .

- the uptake damper 230can comprise any automatic or manually-controlled flow control or orifice blocking device (e.g., any plate, seal, block, etc.).

- “draft”indicates a negative pressure relative to atmosphere. For example, a draft of 0.1 inches of water indicates a pressure of 0.1 inches of water below atmospheric pressure.

- Inches of wateris a non-SI unit for pressure and is conventionally used to describe the draft at various locations in a coke plant.

- the draftranges from about 0.12 to about 0.16 inches of water in the oven 105 . If a draft is increased or otherwise made larger, the pressure moves further below atmospheric pressure. If a draft is decreased, drops, or is otherwise made smaller or lower, the pressure moves towards atmospheric pressure.

- the oven draftBy controlling the oven draft with the uptake damper 230 , the air flow into the oven 105 from the air inlets 190 , 215 , 227 as well as air leaks into the oven 105 can be controlled.

- an individual oven 105includes two uptake ducts 225 and two uptake dampers 230 , but the use of two uptake ducts and two uptake dampers is not a necessity; a system can be designed to use just one or more than two uptake ducts and two uptake dampers. All of the ovens 105 are fluidly connected by at least one uptake duct 225 to the common tunnel 110 which is in turn fluidly connected to each HRSG 120 by the crossover ducts 290 , 295 . The exhaust gases from each oven 105 flow through the common tunnel 110 to the crossover ducts 290 , 295 .

- cokeis produced in the ovens 105 by first loading coal into the oven chamber 185 , heating the coal in an oxygen depleted environment, driving off the volatile fraction of coal, and then oxidizing the VM within the oven 105 to capture and utilize the heat given off.

- the coal volatilesare oxidized within the ovens over an extended coking cycle, and release heat to regeneratively drive the carbonization of the coal to coke.

- the coking cyclebegins when the front door 165 is opened and coal is charged onto the oven floor 160 .

- the coal on the oven floor 160is known as the coal bed. Heat from the oven (due to the previous coking cycle) starts the carbonization cycle. As discussed above, in some embodiments, no additional fuel other than that produced by the coking process is used.

- each oven 105is operated at negative pressure so air is drawn into the oven during the reduction process due to the pressure differential between the oven 105 and atmosphere.

- Primary air for combustionis added to the oven chamber 185 to partially oxidize the coal volatiles, but the amount of this primary air is controlled so that only a portion of the volatiles released from the coal are combusted in the oven chamber 185 , thereby releasing only a fraction of their enthalpy of combustion within the oven chamber 185 .

- the primary airis introduced into the oven chamber 185 above the coal bed through the primary air inlets 190 with the amount of primary air controlled by the primary air dampers 195 .

- the primary air dampers 195can also be used to maintain the desired operating temperature inside the oven chamber 185 .

- the partially combusted gasespass from the oven chamber 185 through the downcomer channels 200 into the sole flue 205 , where secondary air is added to the partially combusted gases.

- the secondary airis introduced through the secondary air inlet 215 .

- the amount of secondary air that is introducedis controlled by the secondary air damper 220 .

- the partially combusted gasesare more fully combusted in the sole flue 205 , thereby extracting the remaining enthalpy of combustion which is conveyed through the oven floor 160 to add heat to the oven chamber 185 .

- the fully or nearly-fully combusted exhaust gasesexit the sole flue 205 through the uptake channels 210 and then flow into the uptake duct 225 .

- Tertiary airis added to the exhaust gases via the tertiary air inlet 227 , where the amount of tertiary air introduced is controlled by the tertiary air damper 229 so that any remaining fraction of uncombusted gases in the exhaust gases are oxidized downstream of the tertiary air inlet 227 .

- the coalhas coked out and has carbonized to produce coke.

- the cokeis preferably removed from the oven 105 through the rear door 170 utilizing a mechanical extraction system. Finally, the coke is quenched (e.g., wet or dry quenched) and sized before delivery to a user.

- FIG. 4is a top view of a portion of a horizontal heat recovery coke plant 400 configured in accordance with embodiments of the technology.

- the coke plant 400includes several features generally similar to the coke plant 100 described above with reference to FIG. 1 .

- the plant 400includes numerous uptake ducts 425 in fluid communication with coke ovens (not shown) and the hot common tunnel 110 .

- the uptake ducts 425can include “corresponding” uptake ducts 425 a , 425 b opposite one another on opposing lateral sides of the common tunnel 110 and a most-upstream or “end” uptake duct 425 c .

- the uptake ducts 425can channel exhaust gas to the common tunnel 110 .

- the exhaust gas in the common tunnel 110moves from an “upstream” end toward a “downstream” end.

- the uptake ducts 425meet the common tunnel 110 at a non-perpendicular interface. More specifically, the uptake ducts 425 have an upstream angle ⁇ relative to the common tunnel 110 . While the upstream angle ⁇ is shown to be approximately 45°, it can be lesser or greater in other embodiments. Further, as will be discussed in more detail below, in some embodiments different uptake ducts 425 can have different upstream angles ⁇ from one another. For example, there may be a combination of perpendicular (90°) and non-perpendicular (less than 90°) interfaces. The non-perpendicular interfaces between the uptake ducts 425 and the common tunnel 110 can improve flow and reduce draft loss in the manner described above.

- FIG. 5Ais a cross-sectional top view of a perpendicular interface between an uptake duct 525 a and the common tunnel 110 configured in accordance with embodiments of the technology.

- An uptake flow of exhaust gas in the uptake duct 525 aintersects a common flow of exhaust gas in the common tunnel 110 to form a combined flow.

- the uptake duct 525 a and the common tunnel 110meet at an interface having an upstream angle ⁇ 1 and a downstream angle ⁇ 2 which are each approximately 90°.

- a direction of the uptake flow vectorcomprises an azimuthal y-component but no azimuthal x-component

- a direction of the common flow vector and combined flow vectorcomprises an x-component but no y-component

- FIG. 5Bis a cross-sectional top view of a non-perpendicular interface between an uptake duct 525 b and the common tunnel 110 configured in accordance with embodiments of the technology.

- the uptake flow from the uptake duct 525 bintersects the common flow in the common tunnel 110 to form a combined flow.

- the uptake duct 525 b and the common tunnel 110meet at an interface having an upstream angle ⁇ 1 less than 90° and a downstream angle ⁇ 2 greater than 90°.

- the non-perpendicular interfacethus provides an azimuthal commonality between the uptake flow vector and the common flow vector.

- the uptake flow vectorcomprises an x-component having a direction in common with an x-component of the common flow vector, and the exhaust gas accordingly loses less momentum at the uptake duct 525 b and common tunnel 110 interface as compared to the arrangement of FIG. 5A .

- the reduced momentum losscan lower the draft loss at the interface or, in some embodiments, can even increase the draft in the common tunnel 110 .

- FIG. 5Cis a cross-sectional end view of a non-perpendicular interface between an uptake duct 525 c and a common tunnel 510 c configured in accordance with embodiments of the technology. While previous embodiments have shown the common tunnel to have a generally circular cross-sectional shape, in the embodiment shown in FIG. 5C the common tunnel 510 c has a generally oval or egg-shaped cross-sectional shape. For example, the common tunnel 510 has a height H between a base B and a top T.

- the egg-shaped cross-sectioncan be asymmetrical (i.e., top-heavy), such that the common tunnel 510 c has a greater cross-sectional area above a midpoint M between the top T and base B than below the midpoint M.

- a top-heavy designcan provide for more room in the upper portion of the common tunnel 510 c for combustion to occur, as the buoyancy of hot exhaust gas tends to urge combustion upward.

- the oblong shape of the illustrated common tunnel 510 ccan thus minimize flame impingement along the upper surface of the interior of the common tunnel 510 c .

- the uptake duct 525 ccan comprise any of the circular or non-circular cross-sectional shapes described above with reference to the common tunnel 510 c , and the uptake duct 525 c and common tunnel 510 c need not have the same cross-sectional shape.

- the uptake flow from the uptake duct 525 cintersects the common flow in the common tunnel 510 c to form a combined flow.

- the uptake duct 525 cmeets the common tunnel 510 c at an interface having a negative altitude angle ⁇ less than 90° with respect to the horizon (e.g., with respect to the x-y plane).

- the non-perpendicular interfacethus provides an altitudinal difference between the uptake flow vector and the common flow vector.

- the uptake flow vectorcomprises a z-component that differs from a z-component of the common flow vector.

- the altitude angle ⁇is a positive angle, greater than 90°, or approximately equal to 90°.

- the uptake duct 525 ccan interface with the common tunnel 510 c at any height between the top T and bottom B of the common tunnel 510 c .

- the uptake duct 525 cintersects with the common tunnel 510 c in the lower portion of the common tunnel 510 c (i.e., below or substantially below the midpoint M).

- the uptake duct 525 cintersects with the common tunnel 510 c in the upper portion of the common tunnel 510 c , at the midpoint M, at a top T or bottom B of the common tunnel 510 c , or in multiple locations around the cross-sectional circumference of the common tunnel 510 c .

- one or more uptake ducts 525 cmay intersect with the common tunnel 510 c in the lower portion and one or more other uptake ducts 525 c may intersect with the common tunnel 510 c in the upper portion.

- FIG. 5Dis a cross-sectional end view of a non-perpendicular interface between an uptake duct 525 d and the common tunnel 510 d configured in accordance with embodiments of the technology.

- the common tunnel 510 dhas a generally square or rectangular cross-sectional shape. Other embodiments can have other cross-sectional shapes.

- the uptake flow from the uptake duct 525 dintersects the common flow in the common tunnel 510 d to form a combined flow.

- the uptake duct 525 d and the common tunnel 510 dmeet at an interface having a positive altitude angle ⁇ less than 90° with respect to the horizon.

- the uptake flow vectorcomprises a z-component that differs from a z-component of the common flow vector.

- mixing draft losscan be reduced and combustion can be encouraged to occur at a height that does not burn the interior surfaces of the common tunnel 510 d .

- the downward altitudinal introduction of flow from the uptake duct 525 dcan counter the buoyancy of the hot exhaust gas to encourage combustion to occur toward the bottom of the common tunnel 510 d so as not to burn the top of the common tunnel 501 d.

- FIG. 5Eis a cross-sectional end view of a non-perpendicular interface between an uptake duct 525 e and a common tunnel 510 e configured in accordance with embodiments of the technology.

- the interfacehas several features generally similar to those discussed above with reference to FIGS. 5A-5D .

- the common tunnel 510 ecomprises a symmetrical, elongated oval. More specifically, the common tunnel 510 e includes a semi-circular shape at top and bottom positions of the common tunnel 510 e , and generally straight, parallel, elongated sides between the top and bottom semi-circles.

- the elongated shapecan provide several of the advantages described above.

- the designcan provide for more room in the mid-section of the common tunnel 510 e for combustion to occur, as the buoyancy of hot exhaust gas tends to urge combustion upward.

- the downward altitudinal introduction of flow from the uptake duct 525 e at angle ⁇can further counter the buoyancy of the hot exhaust gas to encourage combustion to occur toward the bottom of the common tunnel 510 e .

- the oblong shape of the illustrated common tunnel 510 ecan thus minimize flame impingement along the upper surface of the interior of the common tunnel 510 e .

- the common tunnel 510 ecan be symmetrical or asymmetrical and have the same or different shapes.

- the azimuthal angle of interface, the altitudinal angle of interface, the height of interface, the shape of the common tunnel and/or uptake duct, or other featurecan be selected to achieve the desired thermal and draft conditions at the interface.

- Various parameterssuch as common tunnel draft, desired degree of common tunnel combustion, exhaust gas buoyancy conditions, total pressure, etc. can be some of the considerations in selecting the features of the uptake duct and common tunnel interface.

- FIGS. 6A-6Iare top views of various configurations of interfaces between uptake ducts and a common tunnel configured in accordance with embodiments of the technology.

- the uptake ductscan comprise various patterns of perpendicular and non-perpendicular interfaces with the common tunnel, or can comprise various non-perpendicular angles relative to the common tunnel. While the embodiments shown and discussed with reference to FIGS. 6A-6I include numerous features and arrangements, in further embodiments any of these features and/or arrangements can be used independently or in any combination with other features and/or arrangements described herein.

- each of several uptake ducts 625 ameets the common tunnel 110 at a less-than-90° upstream angle ⁇ .

- the uptake ducts 625 athus reduce mixing loss at the combination of common flow and uptake flow in the manner described above.

- corresponding (i.e., opposing) uptake ducts 625 aare laterally offset from one another and are not directly opposing. This is shown in the two most-downstream uptake ducts 625 a shown in FIG. 6A .

- the spacing between individual uptake ducts 625 ai.e., along the length of the common tunnel 110 ) can likewise be variable.

- the distance d between the two most downstream uptake ducts 625 a along one side of the common tunnel 110is greater than the distance between the other uptake ducts 625 a .

- the spacingis constant between all uptake ducts 625 a.

- FIG. 6Billustrates an embodiment where uptake ducts 625 b meet the common tunnel 110 at decreasing upstream angles ⁇ .

- the uptake ductsmay be perpendicular or nearly-perpendicular to the common tunnel 110 .

- the upstream angles ⁇ between the uptake ducts 625 b and the common tunnel 110become progressively smaller.

- the range of upstream angles ⁇varies from about 15° to about 90°. Since the draft pull is weaker farther upstream, this arrangement can progressively reduce the barrier to entry of the uptake flow into the common flow and thereby reduce draft loss due to mixing or stagnant flow regions.

- one or more uptake ducts 625 bcan be positioned at an upstream angle ⁇ that is greater than 90°.

- the trend shown in FIG. 6Bcan be reversed. More specifically, the uptake ducts 625 b can meet the common tunnel 110 at increasing upstream angles, wherein the most-upstream angle can be near or approaching 90°. Such an arrangement can be useful in embodiments where mixing flow losses are potentially greater at downstream positions having higher accumulated common flow.

- FIG. 6Cillustrates an embodiment having a combination of uptake ducts 625 c meeting the common tunnel 110 at non-perpendicular angles ⁇ 1 and perpendicular angles ⁇ 2 .

- the illustrated embodimentincludes pairs of non-perpendicular ducts 625 c along a side of the common tunnel 110 followed by pairs of perpendicular ducts 625 c , and so on. In further embodiments, there can be more or fewer perpendicular or non-perpendicular uptake ducts 625 c in a row.

- FIG. 6Dillustrates an embodiment having a combination of uptake ducts 625 d meeting the common tunnel 110 at non-perpendicular angles ⁇ 1 and perpendicular angles ⁇ 2 .

- the illustrated embodimentincludes alternating non-perpendicular ducts 625 d and perpendicular ducts 625 d along a side of the common tunnel 110 .

- FIG. 6Eillustrates an embodiment having a combination of uptake ducts 625 e meeting the common tunnel 110 at non-perpendicular angles ⁇ l and perpendicular angles ⁇ 2 .

- the illustrated embodimentincludes individual perpendicular uptake ducts 625 e alternating with non-perpendicular uptake ducts 625 e , followed by pairs of non-perpendicular ducts 625 e , followed by pairs of perpendicular ducts 625 e , and so on. This pattern or a portion of this pattern can repeat along further sections of the common tunnel 110 . In further embodiments, there can be different combinations of perpendicular and non-perpendicular uptake ducts.

- FIG. 6Fillustrates an embodiment having a combination of uptake ducts 625 f meeting the common tunnel 110 at non-perpendicular angles ⁇ l and perpendicular angles ⁇ 2 .

- the illustrated embodimentincludes a series of non-perpendicular uptake ducts 625 f , followed by a perpendicular duct 625 f , followed by another series of non-perpendicular ducts 625 f , and so on.

- FIG. 6Gillustrates an embodiment having a combination of uptake ducts 625 g meeting the common tunnel 110 at non-perpendicular angles ⁇ l and perpendicular angles ⁇ 2 .

- the illustrated embodimentincludes non-perpendicular uptake ducts 625 g on a first lateral side of the common tunnel 110 , and perpendicular ducts 625 g along a second, opposing, lateral side of the common tunnel 110 .

- FIG. 6Hillustrates an embodiment having a combination of uptake ducts 625 h meeting the common tunnel 110 at non-perpendicular angles ⁇ l and perpendicular angles ⁇ 2 .

- the illustrated embodimentincludes alternating non-perpendicular ducts 625 h and perpendicular ducts 625 h along a side of the common tunnel 110 , where the non-perpendicular uptake ducts 625 h are opposite perpendicular ducts 625 h and vice-versa.

- FIG. 6Iillustrates an embodiment having uptake ducts 625 i along only one lateral side of the common tunnel 110 , with no uptake ducts on the opposing lateral side.

- two single-sided common tunnels 110can be operated in a coke plant in a side-by-side parallel arrangement.

- the uptake ducts 625 ican be angled at non-perpendicular angle ⁇ relative to the common tunnel 110 in the manner described above.

- FIG. 7Ais a cross-sectional top view of a non-perpendicular interface retrofitted between a perpendicular uptake duct 725 a and the common tunnel 110 configured in accordance with embodiments of the technology.

- the uptake duct 725 a and the common tunnel 110can originally have the same arrangement as the embodiment discussed above with reference to FIG. 5A , but can be retrofitted to include one or more non-perpendicular interface features.

- the interfacehas been fitted with an internal baffle 726 a to alter the flow pattern and create a non-perpendicular interface.

- the baffle 726 ais placed in a lumen of the uptake duct 725 a and modifies a perpendicular interface into an angled interface that reduces draft loss due to mixing.

- the baffle 726 ais triangle-shaped and converges the uptake flow by reducing an inner characteristic dimension of the uptake duct 725 a . This converged flow can act as a nozzle and minimize flow energy losses of the uptake flow and/or common flow.

- the baffle 726 acan be adjustable (i.e., movable to adjust the flow and interface pattern), can have different shapes and/or sizes, and/or can converge and/or diverge flow to other degrees. Further, the baffle can extend around more or less of the lumen of the uptake duct 725 a.

- the common tunnel 110can further be retrofitted with a flow modifier 703 positioned on an interior surface of the common tunnel 110 and configured to interrupt or otherwise modify flow in the common tunnel 110 , or improve the interface (i.e., reduce draft loss) at the junction of the uptake flow and the common flow.

- the uptake duct 725 ahas further been modified with a bumped-out diverging flow plate D.

- the diverging flow plate Dmodifies the uptake flow vector to have an x-component in common with a common flow vector, thus reducing draft loss between the uptake flow and the common flow. While the diverging flow plate D, the baffle 726 a , and the flow modifier 703 are shown in use together, in further embodiments, any of these features can be used independently or in any combination with any other features described herein.

- baffle 726 a and “flow modifier” 703are used herein, the additions to the uptake duct 726 a or common tunnel 110 can comprise any insulation material, refractory material, or other thermally-suitable material.

- the flow modifier 703 and/or baffle 726 amay comprise a single or multilayer lining that is built up with a relatively inexpensive material and covered with a skin.

- refractory or similar materialcan be shaped via gunning (i.e. spraying). Better control of shaping via gunning may be accomplished by gunning in small increments or layers.

- a template or moldmay be used to aid the shaping via gunning.

- a template, mold, or advanced cutting techniquesmay be used to shape the refractory (e.g. even in the absence of gunning for the main shape of an internal insert) for insertion into the duct and then attached via gunning to the inner lining of the duct.

- the flow modifier 703 and/or baffle 726 amay be integrally formed along the duct.

- the uptake duct 725 a wallmay be formed or “dented” to provide a convex surface along the interior surface of the duct.

- convexdoes not require a continuous smooth surface, although a smooth surface may be desirable.

- the flow modifier 703 and/or baffle 726 amay be in the form of a multi-faceted protrusion extending into the flow path. Such a protrusion may be comprised of multiple discontinuous panels and/or surfaces.

- the flow modifier 703 and/or baffle 726 aare not limited to convex surfaces.

- the contours of the flow modifier 703 and/or baffle 726 amay have other complex surfaces, and can be determined by design considerations such as cost, space, operating conditions, etc.

- the flow modifier 703is shown in the common tunnel 110 , in further embodiments the flow modifier 703 can be positioned at other locations (e.g., entirely or partially extending into the uptake duct 725 a , or around the inner circumference of the common tunnel 110 .

- FIG. 7Bis a cross-sectional top view of an interface between an uptake duct 725 b and a common tunnel 110 configured in accordance with embodiments of the technology.

- FIG. 7Cis a cross-sectional top view of a non-perpendicular interface retrofitted between the uptake duct 725 b and common tunnel 110 of FIG. 7B .

- the uptake duct 725 bincludes a diverging uptake end D that flares at the interface with the common tunnel 110 .

- the uptake duct 725 bcan be retrofitted with an internal baffle 726 c generally similar to the internal baffle 726 a described above with reference to FIG. 7A .

- the baffle 726 ccan minimize flow energy losses as the uptake flow meets the common flow in the common tunnel 110 .

- FIG. 8is a cross-sectional top view of a non-perpendicular interface between an uptake duct 825 and the common tunnel 110 configured in accordance with embodiments of the technology.

- the uptake duct 825includes a converging portion C followed by a diverging portion D.

- the converging portion Ccan minimize flow energy losses as the exhaust gas from the uptake duct 825 meets the common flow in the common tunnel 110 .

- the diverging portionprovides an interface that modifies the uptake flow vector to have an x-component in common with a common flow vector, thus reducing draft loss between the pressurized uptake flow and the common flow.

- the diverging and converging portionscan have smooth or sharp transitions, and there can be more or fewer converging or diverging nozzles in the uptake duct 825 or common tunnel 110 .

- the converging portion Cis adjacent to the common tunnel 110 and the diverging portion D is upstream in the uptake duct 825 .

- the converging portion Ccan be used independently from the diverging portion D, and vice versa.

- the interface of FIG. 8further includes a jet 803 configured to introduce a pressurized fluid such as air, exhaust gas, water, steam, fuel, oxidizer, inert, or other fluid (or combination of fluids) to the uptake flow or common flow as a way to improve flow and reduce draft loss.

- a pressurized fluidsuch as air, exhaust gas, water, steam, fuel, oxidizer, inert, or other fluid (or combination of fluids)

- the fluidcan be gaseous, liquid, or multiphase.

- the jet 803can stem from or be supported by any external or internal pressurized source (e.g., a pressurized vessel, a pressurized line, a compressor, a chemical reaction or burning within the coking oven system that supports energy to create pressure, etc.).

- the jet 803is shown as penetrating the common tunnel 110 at a position downstream of the uptake duct 825 , in further embodiments the jet 803 can be positioned in the uptake duct 825 , upstream of the uptake duct 825 in the common tunnel 110 , in multiple locations (e.g., a ring) around the circumference of the common tunnel 110 or uptake duct 825 a , a combination of these positions, or other positions. In a particular embodiment, the jet 803 can be positioned in the uptake duct 825 upstream of the converging portion C. The jet 803 can act as an ejector, and can pull a vacuum draft behind the pressurized fluid.

- the jet 803can thus modify flow to create improved draft conditions, energize flow or mixing, or can reduce stagnant air or “dead” zones.

- the jet 803can pulse the fluid, provide constant fluid, or be run on a timer.

- the jet 803can be controlled manually, in response to conditions in the common tunnel 110 , uptake duct 825 , or other portion of the exhaust system, or as part of an advanced control regime. While the jet 803 is shown in use with the particular uptake duct 825 arrangement illustrated in FIG. 8 , in further embodiments, the jet 803 and uptake duct 825 could be employed independently or in any combination with any other features described herein.

- the jet 803could be used in combination with the flow modifier 703 shown in FIG. 7A , and could be proximate to or protrude through such a flow modifier 703 .

- FIG. 9is a plot showing the spatial distribution of the difference in static pressure (in inches-water) along the length of the common tunnel.

- the plotillustrates the difference in static pressure at downstream positions in the common tunnel compared to the static pressure at the upstream end.

- the 45 degree uptakehas a much lower draft loss over the same length of common tunnel as compared to the perpendicular uptake. This is because the angled uptake has less mixing loss than the perpendicular uptake.

- a coking systemcomprising:

- non-perpendicular interfacecomprises at least one of an altitudinal difference or an azimuthal commonality between the uptake flow vector and the common flow vector.

- non-perpendicular interfacecomprises at least one of a baffle, gunned surface, contoured duct liner, or convex flow modifier inside at least one of the uptake duct or common tunnel and configured to alter at least one of the uptake flow vector or common flow vector.

- the uptake ductcomprises a first uptake duct in fluid communication with a first coke oven and having a first uptake flow vector

- the systemfurther comprises a second uptake duct in fluid communication with the first coke oven or a second coke oven and having a second uptake flow vector of exhaust gas.

- first uptake ductis positioned on a first lateral side of the common tunnel and the second uptake duct is positioned on a second lateral side of the common tunnel opposite the first lateral side, and wherein the first uptake duct and second uptake duct are laterally offset from one another.

- a method of reducing draft losses in a common tunnel in a coking systemcomprising:

- biasing the exhaust gascomprises biasing the exhaust gas with a baffle in the uptake duct.

- biasing the exhaust gascomprises biasing the exhaust gas within the uptake duct, wherein the uptake duct is at least partially non-perpendicular to the common tunnel.

- a coking systemcomprising:

- the non-perpendicular interfaces disclosed hereincan lower the mixing draft loss at the uptake/common tunnel connection by angling the connection in the direction of the common tunnel flow.

- the draft losscan be lowered, which then can be used to reduce the common tunnel size or lower the required draft.

- the technology described hereincan reduce the common tunnel insider diameter to 7-9 feet. The technology could similarly allow a longer common tunnel that would traditionally have been prohibitive due to draft losses.

- the common tunnelcan be long enough to support 30, 45, 60, or more ovens per side.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Organic Chemistry (AREA)

- Waste-Gas Treatment And Other Accessory Devices For Furnaces (AREA)

- Combustion & Propulsion (AREA)

Abstract

Description

- a coke oven;

- an uptake duct in fluid communication with the coke oven and having an uptake flow vector of exhaust gas from the coke oven; and

- a common tunnel in fluid communication with the uptake duct, the common tunnel having a common flow vector of exhaust gas and configured to transfer the exhaust gas to a venting system, wherein the uptake flow vector and common flow vector meet at a non-perpendicular interface.

- the system further comprises a third uptake duct in fluid communication with the first coke oven, the second coke oven, or a third coke oven and having a third uptake flow vector of exhaust gas;

- the first uptake duct, second uptake duct, and third uptake duct are positioned along a lateral side of the common tunnel; and

- there is a first distance between the first uptake duct and second uptake duct and a second distance different from the first distance between the second uptake duct and the third uptake duct.

- flowing exhaust gas from a coke oven through an uptake duct;

- biasing the exhaust gas exiting the uptake duct toward a common flow in the common tunnel; and

- merging the exhaust gas and common flow at a non-perpendicular interface.

- a common tunnel configured to direct a gas from one or more coke ovens to a common stack, wherein the common tunnel has a common tunnel flow with a common tunnel flow vector, and wherein the common tunnel flow vector has an x-component and a y-component;

- a coke oven in fluid connection with the common tunnel via an uptake, wherein—

- the uptake connects to the common tunnel at an intersection, and

- the uptake includes an uptake flow having an uptake flow vector with an x-component and a y-component; and

- wherein the uptake flow vector x-component has a same direction as the x-component of the common tunnel flow vector.

Claims (5)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/026,363US11008517B2 (en) | 2012-12-28 | 2018-07-03 | Non-perpendicular connections between coke oven uptakes and a hot common tunnel, and associated systems and methods |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13/730,673US9476547B2 (en) | 2012-12-28 | 2012-12-28 | Exhaust flow modifier, duct intersection incorporating the same, and methods therefor |

| US13/830,971US10047295B2 (en) | 2012-12-28 | 2013-03-14 | Non-perpendicular connections between coke oven uptakes and a hot common tunnel, and associated systems and methods |

| US16/026,363US11008517B2 (en) | 2012-12-28 | 2018-07-03 | Non-perpendicular connections between coke oven uptakes and a hot common tunnel, and associated systems and methods |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US13/830,971ContinuationUS10047295B2 (en) | 2012-12-28 | 2013-03-14 | Non-perpendicular connections between coke oven uptakes and a hot common tunnel, and associated systems and methods |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| US20190169503A1 US20190169503A1 (en) | 2019-06-06 |

| US11008517B2true US11008517B2 (en) | 2021-05-18 |

Family

ID=51015912

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US13/830,971Active2034-01-03US10047295B2 (en) | 2012-12-28 | 2013-03-14 | Non-perpendicular connections between coke oven uptakes and a hot common tunnel, and associated systems and methods |

| US16/026,363ActiveUS11008517B2 (en) | 2012-12-28 | 2018-07-03 | Non-perpendicular connections between coke oven uptakes and a hot common tunnel, and associated systems and methods |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US13/830,971Active2034-01-03US10047295B2 (en) | 2012-12-28 | 2013-03-14 | Non-perpendicular connections between coke oven uptakes and a hot common tunnel, and associated systems and methods |

Country Status (1)

| Country | Link |

|---|---|

| US (2) | US10047295B2 (en) |

Cited By (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20210371752A1 (en)* | 2018-12-28 | 2021-12-02 | Suncoke Technology And Development Llc | Coke plant tunnel repair and flexible joints |

| US11261381B2 (en) | 2018-12-28 | 2022-03-01 | Suncoke Technology And Development Llc | Heat recovery oven foundation |

| US11359146B2 (en) | 2013-12-31 | 2022-06-14 | Suncoke Technology And Development Llc | Methods for decarbonizing coking ovens, and associated systems and devices |

| US11359145B2 (en) | 2012-12-28 | 2022-06-14 | Suncoke Technology And Development Llc | Systems and methods for maintaining a hot car in a coke plant |

| US11395989B2 (en) | 2018-12-31 | 2022-07-26 | Suncoke Technology And Development Llc | Methods and systems for providing corrosion resistant surfaces in contaminant treatment systems |

| US11441077B2 (en) | 2012-08-17 | 2022-09-13 | Suncoke Technology And Development Llc | Coke plant including exhaust gas sharing |

| US11486572B2 (en) | 2018-12-31 | 2022-11-01 | Suncoke Technology And Development Llc | Systems and methods for Utilizing flue gas |

| US11508230B2 (en) | 2016-06-03 | 2022-11-22 | Suncoke Technology And Development Llc | Methods and systems for automatically generating a remedial action in an industrial facility |

| US11643602B2 (en) | 2018-12-28 | 2023-05-09 | Suncoke Technology And Development Llc | Decarbonization of coke ovens, and associated systems and methods |

| US11680208B2 (en) | 2018-12-28 | 2023-06-20 | Suncoke Technology And Development Llc | Spring-loaded heat recovery oven system and method |

| US11692138B2 (en) | 2012-08-17 | 2023-07-04 | Suncoke Technology And Development Llc | Automatic draft control system for coke plants |

| US11746296B2 (en) | 2013-03-15 | 2023-09-05 | Suncoke Technology And Development Llc | Methods and systems for improved quench tower design |

| US11760937B2 (en) | 2018-12-28 | 2023-09-19 | Suncoke Technology And Development Llc | Oven uptakes |

| US11767482B2 (en) | 2020-05-03 | 2023-09-26 | Suncoke Technology And Development Llc | High-quality coke products |

| US11788012B2 (en) | 2015-01-02 | 2023-10-17 | Suncoke Technology And Development Llc | Integrated coke plant automation and optimization using advanced control and optimization techniques |

| US11795400B2 (en) | 2014-09-15 | 2023-10-24 | Suncoke Technology And Development Llc | Coke ovens having monolith component construction |

| US11807812B2 (en) | 2012-12-28 | 2023-11-07 | Suncoke Technology And Development Llc | Methods and systems for improved coke quenching |

| US11845898B2 (en) | 2017-05-23 | 2023-12-19 | Suncoke Technology And Development Llc | System and method for repairing a coke oven |

| US11845037B2 (en) | 2012-12-28 | 2023-12-19 | Suncoke Technology And Development Llc | Systems and methods for removing mercury from emissions |

| US11851724B2 (en) | 2021-11-04 | 2023-12-26 | Suncoke Technology And Development Llc. | Foundry coke products, and associated systems, devices, and methods |

| US11939526B2 (en) | 2012-12-28 | 2024-03-26 | Suncoke Technology And Development Llc | Vent stack lids and associated systems and methods |

| US11946108B2 (en) | 2021-11-04 | 2024-04-02 | Suncoke Technology And Development Llc | Foundry coke products and associated processing methods via cupolas |

| US12110458B2 (en) | 2022-11-04 | 2024-10-08 | Suncoke Technology And Development Llc | Coal blends, foundry coke products, and associated systems, devices, and methods |

| US12227699B2 (en) | 2019-12-26 | 2025-02-18 | Suncoke Technology And Development Llc | Oven health optimization systems and methods |

| US12325828B2 (en) | 2012-12-28 | 2025-06-10 | Suncoke Technology And Development Llc | Exhaust flow modifier, duct intersection incorporating the same, and methods therefor |

| US12338394B2 (en) | 2014-12-31 | 2025-06-24 | Suncoke Technology And Development Llc | Multi-modal beds of coking material |

| US12410369B2 (en) | 2023-11-21 | 2025-09-09 | Suncoke Technology And Development Llc | Flat push hot car for foundry coke and associated systems and methods |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10160531A1 (en)* | 2001-12-10 | 2003-06-12 | Siemens Ag | Share based incentive system similar to frequent flier air mile schemes, whereby customers, employees or suppliers of a company receive shares in return for services, business, work, etc. carried out with the company |

| US7998316B2 (en) | 2009-03-17 | 2011-08-16 | Suncoke Technology And Development Corp. | Flat push coke wet quenching apparatus and process |

| US9200225B2 (en) | 2010-08-03 | 2015-12-01 | Suncoke Technology And Development Llc. | Method and apparatus for compacting coal for a coal coking process |

| EP3531018B1 (en) | 2012-07-31 | 2024-03-20 | SunCoke Technology and Development LLC | System for handling coal processing emissions |

| US9249357B2 (en) | 2012-08-17 | 2016-02-02 | Suncoke Technology And Development Llc. | Method and apparatus for volatile matter sharing in stamp-charged coke ovens |

| US9169439B2 (en) | 2012-08-29 | 2015-10-27 | Suncoke Technology And Development Llc | Method and apparatus for testing coal coking properties |

| CN110283604A (en) | 2012-09-21 | 2019-09-27 | 太阳焦炭科技和发展有限责任公司 | Extend the shared coking technique for reducing output rating of gas of process cycle through providing |

| US9273249B2 (en) | 2012-12-28 | 2016-03-01 | Suncoke Technology And Development Llc. | Systems and methods for controlling air distribution in a coke oven |

| US9238778B2 (en) | 2012-12-28 | 2016-01-19 | Suncoke Technology And Development Llc. | Systems and methods for improving quenched coke recovery |

| US10047295B2 (en)* | 2012-12-28 | 2018-08-14 | Suncoke Technology And Development Llc | Non-perpendicular connections between coke oven uptakes and a hot common tunnel, and associated systems and methods |

| US9193915B2 (en) | 2013-03-14 | 2015-11-24 | Suncoke Technology And Development Llc. | Horizontal heat recovery coke ovens having monolith crowns |

| UA123141C2 (en) | 2014-06-30 | 2021-02-24 | Санкоук Текнолоджі Енд Дівелепмент Ллк | Horizontal heat recovery coke ovens having monolith crowns |

| CA2959367C (en) | 2014-08-28 | 2018-02-20 | John Francis Quanci | Coke oven charging system |

| US11060032B2 (en) | 2015-01-02 | 2021-07-13 | Suncoke Technology And Development Llc | Integrated coke plant automation and optimization using advanced control and optimization techniques |

| CN108463536B (en) | 2015-12-28 | 2021-06-01 | 太阳焦炭科技和发展有限责任公司 | Method and system for a dynamic charging coke oven |

| JP6956536B2 (en)* | 2017-06-26 | 2021-11-02 | 株式会社デンソー | Three-way valve |

| US11071935B2 (en) | 2018-12-28 | 2021-07-27 | Suncoke Technology And Development Llc | Particulate detection for industrial facilities, and associated systems and methods |

Citations (522)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US425797A (en) | 1890-04-15 | Charles w | ||

| US469868A (en) | 1892-03-01 | Apparatus for quenching coke | ||

| US845719A (en) | 1899-08-01 | 1907-02-26 | United Coke & Gas Company | Apparatus for charging coke-ovens. |

| DE201729C (en) | 1956-08-25 | 1908-09-19 | Franz Meguin & Co Ag | DEVICE FOR SCRAPING GRAPHITE APPROACHES AND THE DIGITAL VOCES OF KOKS CHAMBERS |

| DE212176C (en) | 1908-04-10 | 1909-07-26 | ||

| US976580A (en) | 1909-07-08 | 1910-11-22 | Stettiner Chamotte Fabrik Actien Ges | Apparatus for quenching incandescent materials. |

| US1140798A (en) | 1915-01-02 | 1915-05-25 | Riterconley Mfg Company | Coal-gas-generating apparatus. |

| US1424777A (en) | 1915-08-21 | 1922-08-08 | Schondeling Wilhelm | Process of and device for quenching coke in narrow containers |

| US1430027A (en) | 1920-05-01 | 1922-09-26 | Plantinga Pierre | Oven-wall structure |

| US1486401A (en) | 1924-03-11 | van ackeren | ||

| US1530995A (en) | 1922-09-11 | 1925-03-24 | Geiger Joseph | Coke-oven construction |

| US1572391A (en) | 1923-09-12 | 1926-02-09 | Koppers Co Inc | Container for testing coal and method of testing |

| US1677973A (en) | 1925-08-08 | 1928-07-24 | Frank F Marquard | Method of quenching coke |

| US1705039A (en) | 1926-11-01 | 1929-03-12 | Thornhill Anderson Company | Furnace for treatment of materials |

| US1721813A (en) | 1926-03-04 | 1929-07-23 | Geipert Rudolf | Method of and apparatus for testing coal |

| US1757682A (en) | 1928-05-18 | 1930-05-06 | Palm Robert | Furnace-arch support |

| US1818370A (en) | 1929-04-27 | 1931-08-11 | William E Wine | Cross bearer |

| US1818994A (en) | 1924-10-11 | 1931-08-18 | Combustion Eng Corp | Dust collector |

| US1830951A (en) | 1927-04-12 | 1931-11-10 | Koppers Co Inc | Pusher ram for coke ovens |

| GB364236A (en) | 1929-11-25 | 1932-01-07 | Stettiner Chamotte Fabrik Ag | Improvements in processes and apparatus for extinguishing coke |

| US1848818A (en) | 1932-03-08 | becker | ||

| GB368649A (en) | 1930-10-04 | 1932-03-10 | Ig Farbenindustrie Ag | Process for the treatment of welded structural members, of light metal, with closed, hollow cross section |

| US1947499A (en) | 1930-08-12 | 1934-02-20 | Semet Solvay Eng Corp | By-product coke oven |

| US1955962A (en) | 1933-07-18 | 1934-04-24 | Carter Coal Company | Coal testing apparatus |

| GB441784A (en) | 1934-08-16 | 1936-01-27 | Carves Simon Ltd | Process for improvement of quality of coke in coke ovens |

| US2075337A (en) | 1936-04-03 | 1937-03-30 | Harold F Burnaugh | Ash and soot trap |

| US2141035A (en) | 1935-01-24 | 1938-12-20 | Koppers Co Inc | Coking retort oven heating wall of brickwork |

| US2195466A (en)* | 1936-07-28 | 1940-04-02 | Otto Wilputte Ovenbouw Mij N V | Operating coke ovens |

| US2235970A (en) | 1940-06-19 | 1941-03-25 | Wilputte Coke Oven Corp | Underfired coke oven |

| US2340981A (en) | 1941-05-03 | 1944-02-08 | Fuel Refining Corp | Coke oven construction |

| US2394173A (en) | 1943-07-26 | 1946-02-05 | Albert B Harris | Locomotive draft arrangement |

| US2424012A (en) | 1942-07-07 | 1947-07-15 | C D Patents Ltd | Manufacture of molded articles from coal |

| GB606340A (en) | 1944-02-28 | 1948-08-12 | Waldemar Amalius Endter | Latch devices |

| GB611524A (en) | 1945-07-21 | 1948-11-01 | Koppers Co Inc | Improvements in or relating to coke oven door handling apparatus |

| US2609948A (en) | 1949-08-12 | 1952-09-09 | Koppers Co Inc | Pusher machine with articulated pusher bar |

| US2641575A (en) | 1949-01-21 | 1953-06-09 | Otto Carl | Coke oven buckstay structure |

| US2649978A (en) | 1950-10-07 | 1953-08-25 | Smith Henry Such | Belt charging apparatus |

| US2667185A (en) | 1950-02-13 | 1954-01-26 | James L Beavers | Fluid diverter |

| GB725865A (en) | 1952-04-29 | 1955-03-09 | Koppers Gmbh Heinrich | Coke-quenching car |

| US2723725A (en) | 1954-05-18 | 1955-11-15 | Charles J Keiffer | Dust separating and recovering apparatus |

| US2756842A (en) | 1954-08-27 | 1956-07-31 | Research Corp | Electrostatic gas cleaning method |

| US2813708A (en) | 1951-10-08 | 1957-11-19 | Frey Kurt Paul Hermann | Devices to improve flow pattern and heat transfer in heat exchange zones of brick-lined furnaces |

| US2827424A (en) | 1953-03-09 | 1958-03-18 | Koppers Co Inc | Quenching station |

| US2873816A (en) | 1954-09-27 | 1959-02-17 | Ajem Lab Inc | Gas washing apparatus |

| US2902991A (en) | 1957-08-15 | 1959-09-08 | Howard E Whitman | Smoke generator |

| US2907698A (en) | 1950-10-07 | 1959-10-06 | Schulz Erich | Process of producing coke from mixture of coke breeze and coal |

| GB871094A (en) | 1959-04-29 | 1961-06-21 | Didier Werke Ag | Coke cooling towers |

| US3015893A (en) | 1960-03-14 | 1962-01-09 | Mccreary John | Fluid flow control device for tenter machines utilizing super-heated steam |

| US3033764A (en) | 1958-06-10 | 1962-05-08 | Koppers Co Inc | Coke quenching tower |

| GB923205A (en) | 1959-02-06 | 1963-04-10 | Stanley Pearson Winn | Roller blind for curved windows |

| US3224805A (en) | 1964-01-30 | 1965-12-21 | Glen W Clyatt | Truck top carrier |

| DE1212037B (en) | 1963-08-28 | 1966-03-10 | Still Fa Carl | Sealing of the extinguishing area of coke extinguishing devices |

| US3448012A (en) | 1967-02-01 | 1969-06-03 | Marathon Oil Co | Rotary concentric partition in a coke oven hearth |

| US3462345A (en) | 1967-05-10 | 1969-08-19 | Babcock & Wilcox Co | Nuclear reactor rod controller |

| US3511030A (en) | 1967-02-06 | 1970-05-12 | Cottrell Res Inc | Methods and apparatus for electrostatically cleaning highly compressed gases |

| US3542650A (en) | 1966-12-17 | 1970-11-24 | Gvi Proekt Predpriaty Koksokhi | Method of loading charge materials into a horizontal coke oven |

| US3545470A (en) | 1967-07-24 | 1970-12-08 | Hamilton Neil King Paton | Differential-pressure flow-controlling valve mechanism |

| US3592742A (en) | 1970-02-06 | 1971-07-13 | Buster R Thompson | Foundation cooling system for sole flue coking ovens |

| US3616408A (en) | 1968-05-29 | 1971-10-26 | Westinghouse Electric Corp | Oxygen sensor |

| US3623511A (en) | 1970-02-16 | 1971-11-30 | Bvs | Tubular conduits having a bent portion and carrying a fluid |

| US3630852A (en) | 1968-07-20 | 1971-12-28 | Still Fa Carl | Pollution-free discharging and quenching apparatus |

| US3652403A (en) | 1968-12-03 | 1972-03-28 | Still Fa Carl | Method and apparatus for the evacuation of coke from a furnace chamber |

| US3676305A (en) | 1968-12-05 | 1972-07-11 | Koppers Gmbh Heinrich | Dust collector for a by-product coke oven |

| US3709794A (en) | 1971-06-24 | 1973-01-09 | Koppers Co Inc | Coke oven machinery door extractor shroud |

| US3710551A (en) | 1970-06-18 | 1973-01-16 | Pollution Rectifiers Corp | Gas scrubber |

| US3746626A (en) | 1970-05-14 | 1973-07-17 | Dravo Corp | Pollution control system for discharging operations of coke oven |

| US3748235A (en) | 1971-06-10 | 1973-07-24 | Otto & Co Gmbh Dr C | Pollution free discharging and quenching system |

| US3784034A (en) | 1972-04-04 | 1974-01-08 | B Thompson | Coke oven pushing and charging machine and method |

| US3806032A (en) | 1971-11-02 | 1974-04-23 | Otto & Co Gmbh Dr C | Coke quenching tower |

| US3811572A (en) | 1970-04-13 | 1974-05-21 | Koppers Co Inc | Pollution control system |

| US3836161A (en) | 1973-01-08 | 1974-09-17 | Midland Ross Corp | Leveling system for vehicles with optional manual or automatic control |

| US3839156A (en) | 1971-12-11 | 1974-10-01 | Koppers Gmbh Heinrich | Process and apparatus for controlling the heating of a horizontal by-product coke oven |

| US3844900A (en) | 1972-10-16 | 1974-10-29 | Hartung Kuhn & Co Maschf | Coking installation |

| US3857758A (en) | 1972-07-21 | 1974-12-31 | Block A | Method and apparatus for emission free operation of by-product coke ovens |

| US3875016A (en) | 1970-10-13 | 1975-04-01 | Otto & Co Gmbh Dr C | Method and apparatus for controlling the operation of regeneratively heated coke ovens |

| US3876143A (en) | 1973-03-15 | 1975-04-08 | Otto & Co Gmbh Dr C | Process for quenching hot coke from coke ovens |

| US3876506A (en) | 1972-09-16 | 1975-04-08 | Wolff Kg G Jr | Coke oven door |

| US3878053A (en) | 1973-09-04 | 1975-04-15 | Koppers Co Inc | Refractory shapes and jamb structure of coke oven battery heating wall |

| US3894302A (en) | 1972-03-08 | 1975-07-15 | Tyler Pipe Ind Inc | Self-venting fitting |

| US3897312A (en) | 1974-01-17 | 1975-07-29 | Interlake Inc | Coke oven charging system |

| US3906992A (en) | 1974-07-02 | 1975-09-23 | John Meredith Leach | Sealed, easily cleanable gate valve |

| US3912091A (en) | 1972-04-04 | 1975-10-14 | Buster Ray Thompson | Coke oven pushing and charging machine and method |

| US3912597A (en) | 1974-03-08 | 1975-10-14 | James E Macdonald | Smokeless non-recovery type coke oven |

| US3917458A (en) | 1972-07-21 | 1975-11-04 | Nicoll Jr Frank S | Gas filtration system employing a filtration screen of particulate solids |

| JPS50148405A (en) | 1974-05-18 | 1975-11-28 | ||

| US3928144A (en) | 1974-07-17 | 1975-12-23 | Nat Steel Corp | Pollutants collection system for coke oven discharge operation |

| US3930961A (en) | 1974-04-08 | 1976-01-06 | Koppers Company, Inc. | Hooded quenching wharf for coke side emission control |

| US3933443A (en) | 1971-05-18 | 1976-01-20 | Hugo Lohrmann | Coking component |

| US3957591A (en) | 1973-05-25 | 1976-05-18 | Hartung, Kuhn & Co., Maschinenfabrik Gmbh | Coking oven |

| US3959084A (en) | 1974-09-25 | 1976-05-25 | Dravo Corporation | Process for cooling of coke |

| US3963582A (en) | 1974-11-26 | 1976-06-15 | Koppers Company, Inc. | Method and apparatus for suppressing the deposition of carbonaceous material in a coke oven battery |

| US3969191A (en) | 1973-06-01 | 1976-07-13 | Dr. C. Otto & Comp. G.M.B.H. | Control for regenerators of a horizontal coke oven |

| US3975148A (en) | 1974-02-19 | 1976-08-17 | Onoda Cement Company, Ltd. | Apparatus for calcining cement |

| US3979870A (en) | 1975-01-24 | 1976-09-14 | Moore Alvin E | Light-weight, insulated construction element and wall |

| US3984289A (en) | 1974-07-12 | 1976-10-05 | Koppers Company, Inc. | Coke quencher car apparatus |

| US4004983A (en) | 1974-04-04 | 1977-01-25 | Dr. C. Otto & Comp. G.M.B.H. | Coke oven battery |

| US4004702A (en) | 1975-04-21 | 1977-01-25 | Bethlehem Steel Corporation | Coke oven larry car coal restricting insert |

| US4025395A (en) | 1974-02-15 | 1977-05-24 | United States Steel Corporation | Method for quenching coke |

| US4040910A (en) | 1975-06-03 | 1977-08-09 | Firma Carl Still | Apparatus for charging coke ovens |

| FR2339664A1 (en) | 1976-01-31 | 1977-08-26 | Saarbergwerke Ag | Charging ram locking in coke oven opening - using sliding plate arranged in guideway |

| US4045056A (en) | 1975-10-14 | 1977-08-30 | Gennady Petrovich Kandakov | Expansion compensator for pipelines |

| US4045299A (en) | 1975-11-24 | 1977-08-30 | Pennsylvania Coke Technology, Inc. | Smokeless non-recovery type coke oven |

| US4059885A (en) | 1975-03-19 | 1977-11-29 | Dr. C. Otto & Comp. G.M.B.H. | Process for partial restoration of a coke oven battery |

| US4067462A (en) | 1974-01-08 | 1978-01-10 | Buster Ray Thompson | Coke oven pushing and charging machine and method |

| US4083753A (en) | 1976-05-04 | 1978-04-11 | Koppers Company, Inc. | One-spot coke quencher car |

| US4086231A (en) | 1974-10-31 | 1978-04-25 | Takatoshi Ikio | Coke oven door construction |

| US4093245A (en) | 1977-06-02 | 1978-06-06 | Mosser Industries, Inc. | Mechanical sealing means |

| US4100491A (en) | 1977-02-28 | 1978-07-11 | Southwest Research Institute | Automatic self-cleaning ferromagnetic metal detector |

| US4100033A (en) | 1974-08-21 | 1978-07-11 | Hoelter H | Extraction of charge gases from coke ovens |

| US4111757A (en) | 1977-05-25 | 1978-09-05 | Pennsylvania Coke Technology, Inc. | Smokeless and non-recovery type coke oven battery |

| US4135948A (en) | 1976-12-17 | 1979-01-23 | Krupp-Koppers Gmbh | Method and apparatus for scraping the bottom wall of a coke oven chamber |

| US4141796A (en) | 1977-08-08 | 1979-02-27 | Bethlehem Steel Corporation | Coke oven emission control method and apparatus |

| US4145195A (en) | 1976-06-28 | 1979-03-20 | Firma Carl Still | Adjustable device for removing pollutants from gases and vapors evolved during coke quenching operations |

| US4147230A (en) | 1978-04-14 | 1979-04-03 | Nelson Industries, Inc. | Combination spark arrestor and aspirating muffler |

| JPS5453103A (en) | 1977-10-04 | 1979-04-26 | Nippon Kokan Kk <Nkk> | Production of metallurgical coke |

| JPS5454101A (en) | 1977-10-07 | 1979-04-28 | Nippon Kokan Kk <Nkk> | Charging of raw coal for sintered coke |

| US4162546A (en) | 1977-10-31 | 1979-07-31 | Carrcraft Manufacturing Company | Branch tail piece |

| US4181459A (en) | 1978-03-01 | 1980-01-01 | United States Steel Corporation | Conveyor protection system |

| US4189272A (en) | 1978-02-27 | 1980-02-19 | Gewerkschaft Schalker Eisenhutte | Method of and apparatus for charging coal into a coke oven chamber |

| US4194951A (en) | 1977-03-19 | 1980-03-25 | Dr. C. Otto & Comp. G.M.B.H. | Coke oven quenching car |

| US4196053A (en) | 1977-10-04 | 1980-04-01 | Hartung, Kuhn & Co. Maschinenfabrik Gmbh | Equipment for operating coke oven service machines |

| US4211608A (en) | 1977-09-28 | 1980-07-08 | Bethlehem Steel Corporation | Coke pushing emission control system |

| US4211611A (en) | 1978-02-06 | 1980-07-08 | Firma Carl Still | Coke oven coal charging device |

| US4213489A (en) | 1979-01-10 | 1980-07-22 | Koppers Company, Inc. | One-spot coke quench car coke distribution system |

| US4213828A (en) | 1977-06-07 | 1980-07-22 | Albert Calderon | Method and apparatus for quenching coke |

| US4222748A (en) | 1979-02-22 | 1980-09-16 | Monsanto Company | Electrostatically augmented fiber bed and method of using |

| US4222824A (en) | 1978-02-25 | 1980-09-16 | Didier Engineering Gmbh | Recuperative coke oven and process for the operation thereof |

| US4224109A (en) | 1977-04-07 | 1980-09-23 | Bergwerksverband Gmbh | Process and apparatus for the recovery of waste heat from a coke oven operation |

| US4225393A (en) | 1977-12-10 | 1980-09-30 | Gewerkschaft Schalker Eisenhutte | Door-removal device |

| US4235830A (en) | 1978-09-05 | 1980-11-25 | Aluminum Company Of America | Flue pressure control for tunnel kilns |

| US4239602A (en) | 1979-07-23 | 1980-12-16 | Insul Company, Inc. | Ascension pipe elbow lid for coke ovens |

| US4248671A (en) | 1979-04-04 | 1981-02-03 | Envirotech Corporation | Dry coke quenching and pollution control |

| US4249997A (en) | 1978-12-18 | 1981-02-10 | Bethlehem Steel Corporation | Low differential coke oven heating system |

| US4263099A (en) | 1979-05-17 | 1981-04-21 | Bethlehem Steel Corporation | Wet quenching of incandescent coke |

| US4268360A (en) | 1980-03-03 | 1981-05-19 | Koritsu Machine Industrial Limited | Temporary heat-proof apparatus for use in repairing coke ovens |

| US4271814A (en) | 1977-04-29 | 1981-06-09 | Lister Paul M | Heat extracting apparatus for fireplaces |

| US4284478A (en) | 1977-08-19 | 1981-08-18 | Didier Engineering Gmbh | Apparatus for quenching hot coke |

| US4285772A (en) | 1979-02-06 | 1981-08-25 | Kress Edward S | Method and apparatus for handlng and dry quenching coke |

| US4287024A (en) | 1978-06-22 | 1981-09-01 | Thompson Buster R | High-speed smokeless coke oven battery |

| US4289584A (en) | 1979-03-15 | 1981-09-15 | Bethlehem Steel Corporation | Coke quenching practice for one-spot cars |

| US4289479A (en) | 1980-06-19 | 1981-09-15 | Johnson Jr Allen S | Thermally insulated rotary kiln and method of making same |

| US4289585A (en) | 1979-04-14 | 1981-09-15 | Didier Engineering Gmbh | Method and apparatus for the wet quenching of coke |

| US4296938A (en) | 1979-05-17 | 1981-10-27 | Firma Carl Still Gmbh & Kg | Immersion-type seal for the standpipe opening of coke ovens |

| US4299666A (en) | 1979-04-10 | 1981-11-10 | Firma Carl Still Gmbh & Co. Kg | Heating wall construction for horizontal chamber coke ovens |

| US4302935A (en) | 1980-01-31 | 1981-12-01 | Cousimano Robert D | Adjustable (D)-port insert header for internal combustion engines |

| US4303615A (en) | 1980-06-02 | 1981-12-01 | Fisher Scientific Company | Crucible with lid |

| US4307673A (en) | 1979-07-23 | 1981-12-29 | Forest Fuels, Inc. | Spark arresting module |

| US4314787A (en) | 1979-06-02 | 1982-02-09 | Dr. C. Otto & Comp. Gmbh | Charging car for coke ovens |

| JPS5751786A (en) | 1980-09-11 | 1982-03-26 | Nippon Steel Corp | Apparatus for pressurizing and vibration-packing pulverized coal in coke oven |

| JPS5751787A (en) | 1980-09-11 | 1982-03-26 | Nippon Steel Corp | Apparatus for pressurizing and vibration-packing pulverized coal in coke oven |

| US4324568A (en) | 1980-08-11 | 1982-04-13 | Flanders Filters, Inc. | Method and apparatus for the leak testing of filters |

| US4330372A (en) | 1981-05-29 | 1982-05-18 | National Steel Corporation | Coke oven emission control method and apparatus |

| JPS5783585A (en) | 1980-11-12 | 1982-05-25 | Ishikawajima Harima Heavy Ind Co Ltd | Method for charging stock coal into coke oven |

| JPS5790092A (en) | 1980-11-27 | 1982-06-04 | Ishikawajima Harima Heavy Ind Co Ltd | Method for compacting coking coal |

| US4334963A (en) | 1979-09-26 | 1982-06-15 | Wsw Planungs-Gmbh | Exhaust hood for unloading assembly of coke-oven battery |

| US4336843A (en) | 1979-10-19 | 1982-06-29 | Odeco Engineers, Inc. | Emergency well-control vessel |

| US4340445A (en) | 1981-01-09 | 1982-07-20 | Kucher Valery N | Car for receiving incandescent coke |

| US4342195A (en) | 1980-08-15 | 1982-08-03 | Lo Ching P | Motorcycle exhaust system |

| US4344822A (en) | 1979-10-31 | 1982-08-17 | Bethlehem Steel Corporation | One-spot car coke quenching method |

| US4353189A (en) | 1978-08-15 | 1982-10-12 | Firma Carl Still Gmbh & Co. Kg | Earthquake-proof foundation for coke oven batteries |

| JPS57172978A (en) | 1981-04-17 | 1982-10-25 | Kawatetsu Kagaku Kk | Apparatus for feeding pressure molded briquette into oven chamber |

| US4366029A (en) | 1981-08-31 | 1982-12-28 | Koppers Company, Inc. | Pivoting back one-spot coke car |

| US4373244A (en) | 1979-05-25 | 1983-02-15 | Dr. C. Otto & Comp. G.M.B.H. | Method for renewing the brickwork of coke ovens |

| US4375388A (en) | 1979-10-23 | 1983-03-01 | Nippon Steel Corporation | Apparatus for filling carbonizing chamber of coke oven with powered coal with vibration applied thereto |

| JPS5891788A (en) | 1981-11-27 | 1983-05-31 | Ishikawajima Harima Heavy Ind Co Ltd | Coal compaction block charging equipment into coke oven |

| US4391674A (en) | 1981-02-17 | 1983-07-05 | Republic Steel Corporation | Coke delivery apparatus and method |

| US4392824A (en) | 1980-10-08 | 1983-07-12 | Dr. C. Otto & Comp. G.M.B.H. | System for improving the flow of gases to a combustion chamber of a coke oven or the like |

| US4394217A (en) | 1980-03-27 | 1983-07-19 | Ruhrkohle Aktiengesellschaft | Apparatus for servicing coke ovens |

| US4395269A (en) | 1981-09-30 | 1983-07-26 | Donaldson Company, Inc. | Compact dust filter assembly |

| US4396394A (en) | 1981-12-21 | 1983-08-02 | Atlantic Richfield Company | Method for producing a dried coal fuel having a reduced tendency to spontaneously ignite from a low rank coal |

| US4396461A (en) | 1979-10-31 | 1983-08-02 | Bethlehem Steel Corporation | One-spot car coke quenching process |

| US4407237A (en) | 1981-02-18 | 1983-10-04 | Applied Engineering Co., Inc. | Economizer with soot blower |

| US4421070A (en) | 1982-06-25 | 1983-12-20 | Combustion Engineering, Inc. | Steam cooled hanger tube for horizontal superheaters and reheaters |

| DE3231697C1 (en) | 1982-08-26 | 1984-01-26 | Didier Engineering Gmbh, 4300 Essen | Extinguishing tower |

| JPS5919301A (en) | 1982-07-24 | 1984-01-31 | 株式会社井上ジャパックス研究所 | pressure sensitive resistor |

| US4431484A (en) | 1981-05-20 | 1984-02-14 | Firma Carl Still Gmbh & Co. Kg | Heating system for regenerative coke oven batteries |

| DE3315738C2 (en) | 1982-05-03 | 1984-03-22 | WSW Planungsgesellschaft mbH, 4355 Waltrop | Process and device for dedusting coke oven emissions |

| JPS5951978A (en) | 1982-09-16 | 1984-03-26 | Kawasaki Heavy Ind Ltd | Self-supporting carrier case for compression-molded coal |

| US4439277A (en) | 1981-08-01 | 1984-03-27 | Dix Kurt | Coke-oven door with Z-profile sealing frame |

| JPS5953589A (en) | 1982-09-22 | 1984-03-28 | Kawasaki Steel Corp | Manufacture of compression-formed coal |

| US4440098A (en) | 1982-12-10 | 1984-04-03 | Energy Recovery Group, Inc. | Waste material incineration system and method |

| JPS5971388A (en) | 1982-10-15 | 1984-04-23 | Kawatetsu Kagaku Kk | Operating station for compression molded coal case in coke oven |

| US4446018A (en) | 1980-05-01 | 1984-05-01 | Armco Inc. | Waste treatment system having integral intrachannel clarifier |

| US4445977A (en) | 1983-02-28 | 1984-05-01 | Furnco Construction Corporation | Coke oven having an offset expansion joint and method of installation thereof |

| US4448541A (en) | 1982-09-22 | 1984-05-15 | Mediminder Development Limited Partnership | Medical timer apparatus |

| US4452749A (en) | 1982-09-14 | 1984-06-05 | Modern Refractories Service Corp. | Method of repairing hot refractory brick walls |

| JPS59108083A (en) | 1982-12-13 | 1984-06-22 | Kawasaki Heavy Ind Ltd | Transportation of compression molded coal and its device |

| US4459103A (en) | 1982-03-10 | 1984-07-10 | Hazen Research, Inc. | Automatic volatile matter content analyzer |

| JPS59145281A (en) | 1983-02-08 | 1984-08-20 | Ishikawajima Harima Heavy Ind Co Ltd | Powdered coal compaction cake manufacturing equipment |

| CA1172895A (en) | 1981-08-27 | 1984-08-21 | James Ross | Energy saving chimney cap assembly |

| US4469446A (en) | 1982-06-24 | 1984-09-04 | Joy Manufacturing Company | Fluid handling |

| US4474344A (en) | 1981-03-25 | 1984-10-02 | The Boeing Company | Compression-sealed nacelle inlet door assembly |

| EP0126399A1 (en) | 1983-05-13 | 1984-11-28 | Robertson GAL Gesellschaft für angewandte Lufttechnik mbH | Fluid duct presenting a reduced construction |

| DE3329367C1 (en) | 1983-08-13 | 1984-11-29 | Gewerkschaft Schalker Eisenhütte, 4650 Gelsenkirchen | Coking furnace |

| US4487137A (en) | 1983-01-21 | 1984-12-11 | Horvat George T | Auxiliary exhaust system |

| JPS604588A (en) | 1983-06-22 | 1985-01-11 | Nippon Steel Corp | Horizontal chamber coke oven and method for controlling heating of said oven |

| US4498786A (en) | 1980-11-15 | 1985-02-12 | Balcke-Durr Aktiengesellschaft | Apparatus for mixing at least two individual streams having different thermodynamic functions of state |

| DE3328702A1 (en) | 1983-08-09 | 1985-02-28 | FS-Verfahrenstechnik für Industrieanlagen GmbH, 5110 Alsorf | Process and equipment for quenching red-hot coke |

| US4506025A (en) | 1984-03-22 | 1985-03-19 | Dresser Industries, Inc. | Silica castables |