US10843517B2 - Isolated lift assembly for vehicle auxiliary suspension arrangement - Google Patents

Isolated lift assembly for vehicle auxiliary suspension arrangementDownload PDFInfo

- Publication number

- US10843517B2 US10843517B2US15/913,273US201815913273AUS10843517B2US 10843517 B2US10843517 B2US 10843517B2US 201815913273 AUS201815913273 AUS 201815913273AUS 10843517 B2US10843517 B2US 10843517B2

- Authority

- US

- United States

- Prior art keywords

- actuator

- trailing arm

- vehicle suspension

- suspension assembly

- state

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active, expires

Links

- 239000000725suspensionSubstances0.000titleclaimsabstractdescription64

- 230000008878couplingEffects0.000claimsdescription3

- 238000010168coupling processMethods0.000claimsdescription3

- 238000005859coupling reactionMethods0.000claimsdescription3

- 230000000712assemblyEffects0.000description11

- 238000000429assemblyMethods0.000description11

- 230000009977dual effectEffects0.000description2

- 238000004519manufacturing processMethods0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 238000010408sweepingMethods0.000description2

- 239000004677NylonSubstances0.000description1

- 238000010276constructionMethods0.000description1

- 239000000446fuelSubstances0.000description1

- 238000000034methodMethods0.000description1

- 229920001778nylonPolymers0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G3/00—Resilient suspensions for a single wheel

- B60G3/18—Resilient suspensions for a single wheel with two or more pivoted arms, e.g. parallelogram

- B60G3/20—Resilient suspensions for a single wheel with two or more pivoted arms, e.g. parallelogram all arms being rigid

- B60G3/26—Means for maintaining substantially-constant wheel camber during suspension movement ; Means for controlling the variation of the wheel position during suspension movement

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G9/00—Resilient suspensions of a rigid axle or axle housing for two or more wheels

- B60G9/02—Resilient suspensions of a rigid axle or axle housing for two or more wheels the axle or housing being pivotally mounted on the vehicle, e.g. the pivotal axis being parallel to the longitudinal axis of the vehicle

- B60G9/022—Resilient suspensions of a rigid axle or axle housing for two or more wheels the axle or housing being pivotally mounted on the vehicle, e.g. the pivotal axis being parallel to the longitudinal axis of the vehicle the axle having an imaginary pivotal point

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G11/00—Resilient suspensions characterised by arrangement, location or kind of springs

- B60G11/26—Resilient suspensions characterised by arrangement, location or kind of springs having fluid springs only, e.g. hydropneumatic springs

- B60G11/27—Resilient suspensions characterised by arrangement, location or kind of springs having fluid springs only, e.g. hydropneumatic springs wherein the fluid is a gas

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G17/00—Resilient suspensions having means for adjusting the spring or vibration-damper characteristics, for regulating the distance between a supporting surface and a sprung part of vehicle or for locking suspension during use to meet varying vehicular or surface conditions, e.g. due to speed or load

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G17/00—Resilient suspensions having means for adjusting the spring or vibration-damper characteristics, for regulating the distance between a supporting surface and a sprung part of vehicle or for locking suspension during use to meet varying vehicular or surface conditions, e.g. due to speed or load

- B60G17/005—Suspension locking arrangements

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G3/00—Resilient suspensions for a single wheel

- B60G3/18—Resilient suspensions for a single wheel with two or more pivoted arms, e.g. parallelogram

- B60G3/20—Resilient suspensions for a single wheel with two or more pivoted arms, e.g. parallelogram all arms being rigid

- B—PERFORMING OPERATIONS; TRANSPORTING

- B62—LAND VEHICLES FOR TRAVELLING OTHERWISE THAN ON RAILS

- B62D—MOTOR VEHICLES; TRAILERS

- B62D61/00—Motor vehicles or trailers, characterised by the arrangement or number of wheels, not otherwise provided for, e.g. four wheels in diamond pattern

- B62D61/12—Motor vehicles or trailers, characterised by the arrangement or number of wheels, not otherwise provided for, e.g. four wheels in diamond pattern with variable number of ground engaging wheels, e.g. with some wheels arranged higher than others, or with retractable wheels

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2200/00—Indexing codes relating to suspension types

- B60G2200/10—Independent suspensions

- B60G2200/13—Independent suspensions with longitudinal arms only

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2200/00—Indexing codes relating to suspension types

- B60G2200/10—Independent suspensions

- B60G2200/14—Independent suspensions with lateral arms

- B60G2200/144—Independent suspensions with lateral arms with two lateral arms forming a parallelogram

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2200/00—Indexing codes relating to suspension types

- B60G2200/30—Rigid axle suspensions

- B60G2200/314—Rigid axle suspensions with longitudinally arranged arms articulated on the axle

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2200/00—Indexing codes relating to suspension types

- B60G2200/40—Indexing codes relating to the wheels in the suspensions

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2202/00—Indexing codes relating to the type of spring, damper or actuator

- B60G2202/10—Type of spring

- B60G2202/15—Fluid spring

- B60G2202/152—Pneumatic spring

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2204/00—Indexing codes related to suspensions per se or to auxiliary parts

- B60G2204/40—Auxiliary suspension parts; Adjustment of suspensions

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2204/00—Indexing codes related to suspensions per se or to auxiliary parts

- B60G2204/40—Auxiliary suspension parts; Adjustment of suspensions

- B60G2204/47—Means for retracting the suspension

- B60G2204/4702—Means for retracting the suspension pneumatically

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G2300/00—Indexing codes relating to the type of vehicle

- B60G2300/02—Trucks; Load vehicles

Definitions

- the present inventionrelates to heavy-duty vehicle suspensions and assemblies, and particularly to suspension assemblies incorporating a trailing arm-type configuration. More particularly, the present invention relates to an auxiliary vehicle suspension assembly that includes a lift assembly for operating an auxiliary suspension arrangement between an in use position and a stored position, wherein the lift assembly is isolated from an associated axle assembly when the auxiliary suspension arrangement is in the stored position.

- One aspect of the present inventionis a vehicle suspension assembly that includes a first mounting bracket adapted to couple to a vehicle frame assembly, a first trailing arm having a first end pivotably coupled to the first mounting bracket, and a second end, a second mounting bracket adapted to couple to a vehicle frame assembly, and a second trailing arm having a first end pivotably coupled to the second mounting bracket, and a second end.

- the present inventionfurther includes an axle member having a first end operably coupled to the second end of the first trailing arm and a second end operably coupled to the second end of the second trailing arm, the axle member configured to support a tire, and a pneumatic actuator operably coupled to at least one of the first trailing arm and the second trailing arm and operable between an inflated position configure to lift the tire away from a ground surface and a deflated position configured for the tire to contact the ground surface.

- the present inventionstill further includes a lever arm operably coupling the pneumatic actuator and the at least one of the first trailing arm and the second trailing arm, wherein the lever arm abuts the at least one of the first trailing arm and the second trailing arm when the pneumatic actuator is in the inflated position, and wherein the lever arm is spaced from the at least one of the first trailing arm and the second trailing arm when the pneumatic actuator is in the deflated position thereby decoupling the pneumatic actuator from the at least one of the first trailing arm and the second trailing arm when the pneumatic actuator is in the deflated position.

- a vehicle suspension assemblythat includes a mounting bracket adapted to couple to a vehicle fame assembly, a trailing arm having a first end pivotably coupled to the first mounting bracket, and a second end, an axle member coupled to the second end of the trailing arm, the axle member configured to support a tire, an actuator operably coupled to the trailing arm and operable between a first state configured to lift the tire away from a ground surface and a second state configured for the tire to contact the ground surface, and an actuator arrangement configured to move from a first position where the actuator arrangement couples the actuator to the trailing arm when the actuator is in the first state, and a second position where the actuator arrangement uncouples the actuator from the trailing arm when the actuator is in the second state.

- Still another aspect of the present inventionincludes a vehicle suspension assembly that includes an attachment member adapted to couple to a vehicle frame assembly, a support member having a first portion coupled to the attachment member, and a second portion, an axle member coupled to the second portion of the support member, the axle member configured to support a tire, an actuator operably coupled to the support member and operable between a first state configured to lift the tire away from a ground surface and a second state configured for the tire to contact the ground surface, and an actuator arrangement configured to move from a first position where the actuator arrangement couples the actuator to the support member when the actuator is in the first state, and a second position where the actuator arrangement uncouples the actuator from the support member when the actuator is in the second state such that vertical movement of the axle member is not transmitted to the actuator when the actuator arrangement is in the second position.

- the present inventive vehicle suspension assemblyprovides a durable, uncomplicated design that can be easily and quickly assembled, while simultaneously reducing manufacturing costs.

- the inventionis efficient in use, economical to manufacture, capable of a long operating life, and is particularly well adapted for the proposed use.

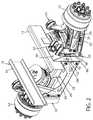

- FIG. 1is a rear perspective view of a suspension arrangement embodying the present invention

- FIG. 2is a front perspective view of the suspension arrangement

- FIG. 3is a side elevational view of the suspension arrangement

- FIG. 4is a perspective view of a trailing arm

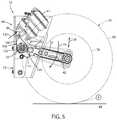

- FIG. 5is a side elevational view of the suspension arrangement in an in use position

- FIG. 6is a side elevational view of the suspension arrangement in a lowered position in solid line and in a raised position in dashed line;

- FIG. 7is a cross-sectional view of a dual-diaphragm chamber assembly

- FIG. 8is a side elevational view of an alternative embodiment of a mounting member

- FIG. 9is a side elevational view of an alternative embodiment of an actuator.

- FIG. 10is an end elevational view of the alternative embodiment of the actuator.

- the terms “upper,” “lower,” “right,” “left,” “rear,” “front,” “vertical,” “horizontal,” and derivatives thereofshall relate to the invention as oriented in FIGS. 1 and 2 .

- the inventionmay assume various alternative orientations, except where expressly specified to the contrary.

- the specific devices and processes illustrated in the attached drawings, and described in the following specificationare simply exemplary embodiments of the inventive concepts defined in the appended claims. Hence, specific dimensions and other characteristics relating to the embodiments disclosed herein are not to be considered as limiting, unless the claims expressly state otherwise.

- a suspension assembly 10( FIGS. 1 and 2 ) comprises a pair of mounting brackets 12 fixedly connected to a pair of longitudinally-extending frame members 14 of a vehicle frame assembly 16 by a plurality of mechanical fasteners (not shown) and coupled to one another by a cross member 18 , a plurality of trailing arm assemblies including a pair of upper trailing arms 20 ( FIG. 3 ) and a pair of lower trailing arms 22 , an axle assembly 24 , and a pair of air spring assemblies 23 extending between the axle assembly 24 and the corresponding frame members 14 .

- each upper trailing arm 20( FIGS. 3 and 4 ) includes a first end 26 pivotably coupled to one of the mounting brackets 12 via a bushing arrangement 28 for rotation about a pivot axis 30 and a second end 32 pivotably coupled to the axle assembly 24 via a bushing arrangement 33 for rotation about a pivot axis 34 , as described below.

- Each lower trailing arm 22includes a first end 36 secured to the mounting bracket 12 via a bushing arrangement 38 for pivoting about a pivot axis 40 , and a second end 42 pivotably coupled via a bushing arrangement 44 to the axle assembly 24 for pivotable movement about a pivot axis 46 , also as described below.

- each bushing arrangement 28 , 33 , 38 , 44comprise an elastically resilient bushing member, a bushing pin and nylon washers received within a corresponding bore.

- the second end 32 , 42 of each upper trailing arm 20 and lower trailing arm 22are pivotably coupled to the axle assembly 24 via an integrated corresponding mounting arrangement 50 .

- the mounting arrangement 50is described in detail in currently pending U.S. patent application Ser. No. 15/205,711, entitled Auxiliary Axle and Suspension Assembly, the entire contents of which are incorporated herein by reference.

- the mounting arrangement 50provides a coupling interface between the second end 32 , 42 of the upper trailing arm 20 and lower trailing arm 22 , associated spindle arrangements (not shown) to support the hub assemblies 52 , and the air spring assemblies 23 .

- the hub assemblies 52 , associated braking assemblies 54 and wheel assemblies 56including wheels 58 and tires 60 , are coupled to each spindle (not shown).

- the outwardly-sweeping configuration of the trailing arms 20 , 22 in conjunction with the configuration and construction of the mounting arrangements 50 ,provides for attachment of the trailing arms 20 , 22 to the spindles (not shown) the air spring assemblies 23 in close proximity to one another and in close proximity to the ends of the axle member 62 of the axle assembly 24 .

- the vehicle suspension assembly 10is a vertically adjustable. Specifically, the axle assembly 24 is movable from a lowered position A as shown in FIG. 5 , wherein the tires 60 contact a ground surface 64 , thereby assisting in supporting the load of the vehicle, and a raised position B as shown in FIG. 6 , wherein the tires 60 are spaced from the ground surface 64 , thereby reducing tire wear and fuel consumption.

- the vehicle suspension assembly 10includes a pair of lift arrangements 66 operably coupled with the associated trailing arms 20 and mounting brackets 12 . Each lift arrangement 66 includes a pneumatic actuator, which in the illustrated example includes a dual diaphragm chamber assembly 67 ( FIG.

- Each diaphragm chamber 70 , 72includes a housing 74 divided into an upper chamber 76 and a lower chamber 78 by a deformable diaphragm 80 and a push plate 82 , wherein the upper chamber 76 may be pressurized via an air inlet 84 .

- Each push plate 82is secured to a pushrod 86 such that the pushrods 86 are each forced in a direction 88 as the upper chamber 76 is pressurized. It is noted that in the illustrated example, the longitudinal axis 90 of each of the pushrods 88 are aligned with one another.

- the dual pushrods 86may be replaced by a single pushrod that extends through both the first diaphragm chamber 70 and the second diaphragm chamber 72 .

- a pneumatic actuatoris shown in the illustrated examples and described herein, other actuators may also be utilized, including electric motors, gearing arrangements, and the like.

- the lift arrangement 66further includes a mounting member 92 ( FIGS. 1-3 ) that mounts the diaphragm chamber assembly 67 to an outer wall 94 of the associated mounting bracket 12 .

- the mounting member 92includes an inner wall 96 mounted to the outer wall of the mounting bracket 12 , an outer wall 98 and an upper wall 100 extending between the inner wall 96 and the outer wall 98 to which the diaphragm chamber assembly 67 is mounted via a plurality of mechanical fasteners 102 .

- Each lift arrangement 66further includes an actuator 104 operably coupled to the diaphragm chamber assembly 67 .

- the actuator 104includes a lever arm 106 having a first end 108 pivotably coupled to an end 110 of the pushrod 86 of the diaphragm chamber assembly 67 , and a second end 111 configured to abut a lug 112 extending outwardly from the upper trailing arm 20 .

- the lug 112may be formed integrally with the trailing arm 20 or separately therefrom.

- the lever arm 106is configured so as to couple and uncouple the lift arrangement 66 from the upper trailing arm 20 depending upon whether the axle assembly 24 is in the lowered position A or the raised position B. In the raised position B (as shown in FIG.

- the diaphragm chamber assembly 67is pressurized such that the pushrod 86 is actuated in a direction 114 , thereby causing the lever arm 106 to pivot about the pivot axis 30 in a direction 116 until the second end 111 abuts the lug 112 , thereby in turn forcing the trailing arm 20 in the direction 118 until the tire 60 is lifted from engagement with the ground surface 64 .

- the lift arrangement 66remains in this position thereby preventing the tire 60 from engaging the ground surface 64 until the auxiliary suspension arrangement 10 is required to support the load of the vehicle.

- the diaphragm chamber assembly 67is actuated so that the pushrod 86 is actuated in a direction 120 thereby causing the lever arm 106 to rotate in the direction 122 , thereby allowing the trailing arm 20 to rotate in a direction 124 until the tire 60 abuts the ground surface 64 .

- the second end 111 of the lever arm 106is spaced from the lug 112 such that a gap 126 is formed therebetween.

- This gap 126allows the trailing arm 20 to pivot about to the pivot axis 30 and the second end 42 to move in a vertical direction 128 without transmitting the vertical movement of the trailing arm 20 to the lift arrangement 66 .

- the decoupling of the lifting arrangement 66 from the trailing arm 20reduces the forces exerted on the lift arrangement 66 and the resulting mechanical wear to the lift arrangement 66 and the components thereof, thereby reducing the potential of a failure and increasing the operating life thereof.

- the mounting member 92 amay be provided with a stop arrangement 136 that limits the overall travel of the assembly between the fully lowered position A and the fully raised position B.

- the reference numeral 66 a( FIG. 8 ) generally designates the alternative embodiment of the lift arrangement. Since the lift arrangement 66 a is similar to the previously described lift arrangement 66 , similar parts appearing in FIGS. 1-7 and FIG. 8 , respectively, represent the same, corresponding reference, except for the suffix “a” in the numerals of the latter.

- the mounting member 92 ais provided with an arcuately-shaped relief that receives a stop portion 134 fixedly attached to the first end 108 a of the lever arm 106 a such that the stop portion 134 tracks along the relief 132 thereby limiting the overall travel of the end 110 a of the pushrod 86 and the second end 108 a of the lever arm 106 a.

- each lift arrangement 66 bfurther includes an actuator 104 b operably coupled to the diaphragm chamber assembly 67 b .

- the actuator 104 bincludes a lever arm 106 b having a first end 108 b pivotably coupled to an end 110 b of the pushrod 86 b (not shown) of the diaphragm chamber assembly 67 b , and a second end 111 b configured to abut an underside 113 of the upper trailing arm 20 b .

- the lever arm 106 bis configured so as to couple and uncouple the lift arrangement 66 b from the upper trailing arm 20 b depending upon whether the axle assembly 24 b is in the lowered position or the raised position.

- the diaphragm chamber assembly 67 bis pressurized such that the pushrod 86 b is actuated in a direction 114 b , thereby causing the lever arm 106 b to pivot about the pivot axis 30 b in a direction 116 b until the second end 111 b abuts the underside 113 of the trailing arm 20 b , thereby in turn forcing the trailing arm 20 b in the direction 118 b until the associated tire (not shown) is lifted from engagement with the ground surface.

- the lift arrangement 66 bremains in this position thereby preventing the tire from engaging the ground surface until the auxiliary suspension arrangement 10 b is required to support the load of the vehicle.

- the diaphragm chamber assembly 67 bis actuated so that the pushrod 86 b is actuated in a direction 120 b thereby causing the lever arm 106 b to rotate in the direction 122 b , thereby allowing the trailing arm 20 b to rotate in a direction 124 b until the tire abuts the ground surface.

- the second end 111 b of the lever arm 106 bis spaced from the underside 113 of the trailing arm 120 b such that a gap is formed therebetween.

- This gapallows the trailing arm 20 b to pivot about to the pivot axis 30 b and the second end 42 b to move in a vertical direction 128 b without transmitting the vertical movement of the trailing arm 20 b to the lift arrangement 66 b .

- the decoupling of the lifting arrangement 66 b from the trailing arm 20 breduces the forces exerted on the lift arrangement 66 b and the resulting mechanical wear to the lift arrangement 66 b and the components thereof, thereby reducing the potential of a failure and increasing the operating life thereof.

- the vehicle suspension assembly 10comprises a self-steer assembly which pivots the spindles (not shown) and the supported tires between an in-line orientation and a turning orientation. While the illustrated example includes a self-steer assembly, the present invention may be utilized with non-self-steer assemblies or any suitable suspension arrangement including trailing arm type suspensions, leaf spring type suspensions, or other suspension systems. Further, the vehicle suspension assembly 10 may be pre-assembled and then attached to the associated frame rails 14 as a modular unit.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Transportation (AREA)

- Vehicle Body Suspensions (AREA)

Abstract

Description

Claims (31)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US15/913,273US10843517B2 (en) | 2017-03-27 | 2018-03-06 | Isolated lift assembly for vehicle auxiliary suspension arrangement |

| MX2019011582AMX2019011582A (en) | 2017-03-27 | 2018-03-26 | Isolated lift assembly for vehicle auxiliary suspension arrangement. |

| EP18774907.2AEP3600922A4 (en) | 2017-03-27 | 2018-03-26 | ISOLATED ELEVATOR ARRANGEMENT FOR AUXILIARY SUSPENSION ARRANGEMENT OF A VEHICLE |

| CA3057843ACA3057843A1 (en) | 2017-03-27 | 2018-03-26 | Isolated lift assembly for vehicle auxiliary suspension arrangement |

| PCT/US2018/024327WO2018183188A1 (en) | 2017-03-27 | 2018-03-26 | Isolated lift assembly for vehicle auxiliary suspension arrangement |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201762477170P | 2017-03-27 | 2017-03-27 | |

| US15/913,273US10843517B2 (en) | 2017-03-27 | 2018-03-06 | Isolated lift assembly for vehicle auxiliary suspension arrangement |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| US20180272818A1 US20180272818A1 (en) | 2018-09-27 |

| US10843517B2true US10843517B2 (en) | 2020-11-24 |

Family

ID=63581564

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US15/913,273Active2038-11-16US10843517B2 (en) | 2017-03-27 | 2018-03-06 | Isolated lift assembly for vehicle auxiliary suspension arrangement |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US10843517B2 (en) |

| EP (1) | EP3600922A4 (en) |

| CA (1) | CA3057843A1 (en) |

| MX (1) | MX2019011582A (en) |

| WO (1) | WO2018183188A1 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7056115B2 (en)* | 2017-12-08 | 2022-04-19 | いすゞ自動車株式会社 | Suspension device |

| US10953939B2 (en) | 2018-03-08 | 2021-03-23 | Oshkosh Corporation | Load span tag axle system |

Citations (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4202276A (en)* | 1977-06-27 | 1980-05-13 | Bi-Modal Corporation | Self-steering wheel-set for convertible railway vehicle |

| US4311244A (en)* | 1980-02-28 | 1982-01-19 | Bi-Modal Corporation | Automatic coupler to connect convertible rail-highway vehicles end to end |

| US4316418A (en)* | 1980-05-01 | 1982-02-23 | Bi-Modal Corporation | Convertible rail highway semi-trailer air controlled suspension shifting system |

| EP0401100A1 (en)* | 1989-05-30 | 1990-12-05 | S.E.S.R. - Societe Europeenne De Semi-Remorques | Trailer suspensions |

| EP0450942A2 (en) | 1990-04-05 | 1991-10-09 | Ror Rockwell Limited | Locking mechanism on a vehicle |

| US5058916A (en)* | 1990-06-18 | 1991-10-22 | Lear Siegler Truck Products Corp. | Apparatus for providing additional lift in a retractable suspension |

| US5058917A (en)* | 1990-10-01 | 1991-10-22 | Neway Corp. | Two-stage retractable suspension |

| US5090495A (en)* | 1990-12-03 | 1992-02-25 | Mcneilus Truck And Manufacturing, Inc. | Tag axle for refuse truck |

| US5192101A (en)* | 1991-10-15 | 1993-03-09 | Neway Corp. | Lock mechanism for an axle lift suspension |

| US5332258A (en)* | 1990-03-10 | 1994-07-26 | Otto Sauer Achsenfabrik Keilberg | Motor vehicle axle suspension |

| US5655788A (en)* | 1993-03-09 | 1997-08-12 | Ror Rockwell Limited | Vehicle air suspension having a lifting system |

| US6182984B1 (en)* | 1999-04-06 | 2001-02-06 | Watson & Chalin Manufacturing, Inc. | Reversible caster steerable suspension system |

| US20040178594A1 (en)* | 2003-03-11 | 2004-09-16 | Keeler Michael J. | In line lift axle suspension system |

| US6994358B2 (en)* | 2000-07-21 | 2006-02-07 | Gibbs Technologies Limited | Bump stop |

| US7854436B2 (en)* | 2006-01-13 | 2010-12-21 | SAF-Holland, GmbH | Axle lifting device for a vehicle |

| US20120126504A1 (en) | 2010-11-22 | 2012-05-24 | Hendrickson Usa, L.L.C. | Side-beam lift assembly for heavy-duty vehicles |

| US8226098B2 (en)* | 2009-04-22 | 2012-07-24 | Air Suspensions, Inc. | Suspension system with a retrofit suspension kit |

| EP2647512A2 (en)* | 2012-04-02 | 2013-10-09 | BPW Bergische Achsen KG | Axle guide |

| US8967639B2 (en)* | 2013-01-28 | 2015-03-03 | Saf-Holland, Inc. | Auxiliary axle and suspension assembly |

| EP2873596A1 (en)* | 2013-11-18 | 2015-05-20 | BPW Bergische Achsen KG | Axle lift for a vehicle axle |

| US20150197130A1 (en)* | 2013-12-18 | 2015-07-16 | Dallas Smith Corporation | Suspension for a multiple height vehicle |

| WO2016022024A1 (en)* | 2014-08-08 | 2016-02-11 | Vdl Weweler B.V. | Mounting of an axle lift |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| HU9701139D0 (en) | 1997-02-28 | 1997-08-28 | Bpw Bergische Achsen Kg | Lift for shafts of vehicles with air spring |

| DE102011001431B4 (en)* | 2011-03-21 | 2022-09-29 | Bpw Bergische Achsen Kg | Axle lift for a vehicle axle |

- 2018

- 2018-03-06USUS15/913,273patent/US10843517B2/enactiveActive

- 2018-03-26MXMX2019011582Apatent/MX2019011582A/enunknown

- 2018-03-26EPEP18774907.2Apatent/EP3600922A4/ennot_activeWithdrawn

- 2018-03-26WOPCT/US2018/024327patent/WO2018183188A1/ennot_activeCeased

- 2018-03-26CACA3057843Apatent/CA3057843A1/enactivePending

Patent Citations (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4202276A (en)* | 1977-06-27 | 1980-05-13 | Bi-Modal Corporation | Self-steering wheel-set for convertible railway vehicle |

| US4311244A (en)* | 1980-02-28 | 1982-01-19 | Bi-Modal Corporation | Automatic coupler to connect convertible rail-highway vehicles end to end |

| US4316418A (en)* | 1980-05-01 | 1982-02-23 | Bi-Modal Corporation | Convertible rail highway semi-trailer air controlled suspension shifting system |

| EP0401100A1 (en)* | 1989-05-30 | 1990-12-05 | S.E.S.R. - Societe Europeenne De Semi-Remorques | Trailer suspensions |

| US5332258A (en)* | 1990-03-10 | 1994-07-26 | Otto Sauer Achsenfabrik Keilberg | Motor vehicle axle suspension |

| EP0450942A2 (en) | 1990-04-05 | 1991-10-09 | Ror Rockwell Limited | Locking mechanism on a vehicle |

| US5058916A (en)* | 1990-06-18 | 1991-10-22 | Lear Siegler Truck Products Corp. | Apparatus for providing additional lift in a retractable suspension |

| US5058917A (en)* | 1990-10-01 | 1991-10-22 | Neway Corp. | Two-stage retractable suspension |

| US5090495A (en)* | 1990-12-03 | 1992-02-25 | Mcneilus Truck And Manufacturing, Inc. | Tag axle for refuse truck |

| US5192101A (en)* | 1991-10-15 | 1993-03-09 | Neway Corp. | Lock mechanism for an axle lift suspension |

| US5655788A (en)* | 1993-03-09 | 1997-08-12 | Ror Rockwell Limited | Vehicle air suspension having a lifting system |

| US6182984B1 (en)* | 1999-04-06 | 2001-02-06 | Watson & Chalin Manufacturing, Inc. | Reversible caster steerable suspension system |

| US6994358B2 (en)* | 2000-07-21 | 2006-02-07 | Gibbs Technologies Limited | Bump stop |

| US20040178594A1 (en)* | 2003-03-11 | 2004-09-16 | Keeler Michael J. | In line lift axle suspension system |

| US6880839B2 (en)* | 2003-03-11 | 2005-04-19 | Boler Company | In-line lift axle suspension system |

| US7854436B2 (en)* | 2006-01-13 | 2010-12-21 | SAF-Holland, GmbH | Axle lifting device for a vehicle |

| US8226098B2 (en)* | 2009-04-22 | 2012-07-24 | Air Suspensions, Inc. | Suspension system with a retrofit suspension kit |

| US20120126504A1 (en) | 2010-11-22 | 2012-05-24 | Hendrickson Usa, L.L.C. | Side-beam lift assembly for heavy-duty vehicles |

| EP2647512A2 (en)* | 2012-04-02 | 2013-10-09 | BPW Bergische Achsen KG | Axle guide |

| US8967639B2 (en)* | 2013-01-28 | 2015-03-03 | Saf-Holland, Inc. | Auxiliary axle and suspension assembly |

| US20160318567A1 (en) | 2013-01-28 | 2016-11-03 | Saf-Holland, Inc. | Auxiliary Axle and Suspension Assembly |

| EP2873596A1 (en)* | 2013-11-18 | 2015-05-20 | BPW Bergische Achsen KG | Axle lift for a vehicle axle |

| US20150197130A1 (en)* | 2013-12-18 | 2015-07-16 | Dallas Smith Corporation | Suspension for a multiple height vehicle |

| WO2016022024A1 (en)* | 2014-08-08 | 2016-02-11 | Vdl Weweler B.V. | Mounting of an axle lift |

Also Published As

| Publication number | Publication date |

|---|---|

| CA3057843A1 (en) | 2018-10-04 |

| MX2019011582A (en) | 2020-10-15 |

| WO2018183188A1 (en) | 2018-10-04 |

| US20180272818A1 (en) | 2018-09-27 |

| EP3600922A4 (en) | 2020-12-23 |

| EP3600922A1 (en) | 2020-02-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9688327B2 (en) | Auxiliary axle and suspension assembly | |

| KR0137575B1 (en) | Parallelogram lift axle suspension with control for adjusting axle casters | |

| CA2754287C (en) | Vehicle suspension | |

| CN106457939B (en) | vehicle suspension | |

| EP1977915B1 (en) | Wheel suspension for wheeled vehicle | |

| KR20050117582A (en) | Axle clamp assembly top pad and air spring mounting assembly | |

| US11207934B2 (en) | Vehicle suspension assembly | |

| US7618049B2 (en) | Trailing arm suspension | |

| US10843517B2 (en) | Isolated lift assembly for vehicle auxiliary suspension arrangement | |

| CN110667703A (en) | Independent suspension axle system for commercial vehicle | |

| KR20180066517A (en) | Adjustable trailing arm | |

| CN210284486U (en) | Swing device for scooter and scooter | |

| US7997598B2 (en) | Vehicle suspension system | |

| CN211543681U (en) | Linkage adjusting wheel camber angle parameter suspension | |

| US8955860B2 (en) | Vehicle suspension assembly with integrated torque member and trailing arm mount | |

| CN220562494U (en) | Double-cross arm independent suspension structure | |

| KR0153195B1 (en) | Car suspension structure | |

| US20080169622A1 (en) | Linkage system for suspension | |

| HK1234707A1 (en) | Vehicle suspension | |

| KR200260742Y1 (en) | An axle suspension system for automobile | |

| KR20050014031A (en) | Independent suspension system of one body with horizontal mounting type leaf spring for vehicle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AS | Assignment | Owner name:SAF-HOLLAND, INC., MICHIGAN Free format text:ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:JOHNSON, MARC R.;REEL/FRAME:045122/0459 Effective date:20180301 | |

| FEPP | Fee payment procedure | Free format text:ENTITY STATUS SET TO UNDISCOUNTED (ORIGINAL EVENT CODE: BIG.); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY | |

| STPP | Information on status: patent application and granting procedure in general | Free format text:DOCKETED NEW CASE - READY FOR EXAMINATION | |

| STPP | Information on status: patent application and granting procedure in general | Free format text:NON FINAL ACTION MAILED | |

| STPP | Information on status: patent application and granting procedure in general | Free format text:NON FINAL ACTION MAILED | |

| STPP | Information on status: patent application and granting procedure in general | Free format text:NOTICE OF ALLOWANCE MAILED -- APPLICATION RECEIVED IN OFFICE OF PUBLICATIONS | |

| STPP | Information on status: patent application and granting procedure in general | Free format text:PUBLICATIONS -- ISSUE FEE PAYMENT VERIFIED | |

| STCF | Information on status: patent grant | Free format text:PATENTED CASE | |

| CC | Certificate of correction | ||

| MAFP | Maintenance fee payment | Free format text:PAYMENT OF MAINTENANCE FEE, 4TH YEAR, LARGE ENTITY (ORIGINAL EVENT CODE: M1551); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY Year of fee payment:4 |