US10820650B2 - Surface projection for apparel in an apparel design system - Google Patents

Surface projection for apparel in an apparel design systemDownload PDFInfo

- Publication number

- US10820650B2 US10820650B2US16/288,047US201916288047AUS10820650B2US 10820650 B2US10820650 B2US 10820650B2US 201916288047 AUS201916288047 AUS 201916288047AUS 10820650 B2US10820650 B2US 10820650B2

- Authority

- US

- United States

- Prior art keywords

- garment

- laser

- image

- preview image

- pattern

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active, expires

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q10/00—Administration; Management

- G06Q10/06—Resources, workflows, human or project management; Enterprise or organisation planning; Enterprise or organisation modelling

- G06Q10/063—Operations research, analysis or management

- G06Q10/0631—Resource planning, allocation, distributing or scheduling for enterprises or organisations

- G06Q10/06315—Needs-based resource requirements planning or analysis

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M10/00—Physical treatment of fibres, threads, yarns, fabrics, or fibrous goods made from such materials, e.g. ultrasonic, corona discharge, irradiation, electric currents, or magnetic fields; Physical treatment combined with treatment with chemical compounds or elements

- D06M10/005—Laser beam treatment

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41D—OUTERWEAR; PROTECTIVE GARMENTS; ACCESSORIES

- A41D1/00—Garments

- A41D1/06—Trousers

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41D—OUTERWEAR; PROTECTIVE GARMENTS; ACCESSORIES

- A41D27/00—Details of garments or of their making

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41D—OUTERWEAR; PROTECTIVE GARMENTS; ACCESSORIES

- A41D27/00—Details of garments or of their making

- A41D27/08—Trimmings; Ornaments

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41H—APPLIANCES OR METHODS FOR MAKING CLOTHES, e.g. FOR DRESS-MAKING OR FOR TAILORING, NOT OTHERWISE PROVIDED FOR

- A41H3/00—Patterns for cutting-out; Methods of drafting or marking-out such patterns, e.g. on the cloth

- A41H3/007—Methods of drafting or marking-out patterns using computers

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41H—APPLIANCES OR METHODS FOR MAKING CLOTHES, e.g. FOR DRESS-MAKING OR FOR TAILORING, NOT OTHERWISE PROVIDED FOR

- A41H3/00—Patterns for cutting-out; Methods of drafting or marking-out such patterns, e.g. on the cloth

- A41H3/08—Patterns on the cloth, e.g. printed

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41H—APPLIANCES OR METHODS FOR MAKING CLOTHES, e.g. FOR DRESS-MAKING OR FOR TAILORING, NOT OTHERWISE PROVIDED FOR

- A41H43/00—Other methods, machines or appliances

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/352—Working by laser beam, e.g. welding, cutting or boring for surface treatment

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D1/00—Woven fabrics designed to make specified articles

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06B—TREATING TEXTILE MATERIALS USING LIQUIDS, GASES OR VAPOURS

- D06B11/00—Treatment of selected parts of textile materials, e.g. partial dyeing

- D06B11/0093—Treatments carried out during or after a regular application of treating materials, in order to get differentiated effects on the textile material

- D06B11/0096—Treatments carried out during or after a regular application of treating materials, in order to get differentiated effects on the textile material to get a faded look

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06C—FINISHING, DRESSING, TENTERING OR STRETCHING TEXTILE FABRICS

- D06C23/00—Making patterns or designs on fabrics

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06C—FINISHING, DRESSING, TENTERING OR STRETCHING TEXTILE FABRICS

- D06C23/00—Making patterns or designs on fabrics

- D06C23/02—Making patterns or designs on fabrics by singeing, teasing, shearing, etching or brushing

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06P—DYEING OR PRINTING TEXTILES; DYEING LEATHER, FURS OR SOLID MACROMOLECULAR SUBSTANCES IN ANY FORM

- D06P5/00—Other features in dyeing or printing textiles, or dyeing leather, furs, or solid macromolecular substances in any form

- D06P5/13—Fugitive dyeing or stripping dyes

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06P—DYEING OR PRINTING TEXTILES; DYEING LEATHER, FURS OR SOLID MACROMOLECULAR SUBSTANCES IN ANY FORM

- D06P5/00—Other features in dyeing or printing textiles, or dyeing leather, furs, or solid macromolecular substances in any form

- D06P5/15—Locally discharging the dyes

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06P—DYEING OR PRINTING TEXTILES; DYEING LEATHER, FURS OR SOLID MACROMOLECULAR SUBSTANCES IN ANY FORM

- D06P5/00—Other features in dyeing or printing textiles, or dyeing leather, furs, or solid macromolecular substances in any form

- D06P5/20—Physical treatments affecting dyeing, e.g. ultrasonic or electric

- D06P5/2005—Treatments with alpha, beta, gamma or other rays, e.g. stimulated rays

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B19/00—Programme-control systems

- G05B19/02—Programme-control systems electric

- G05B19/18—Numerical control [NC], i.e. automatically operating machines, in particular machine tools, e.g. in a manufacturing environment, so as to execute positioning, movement or co-ordinated operations by means of programme data in numerical form

- G05B19/4097—Numerical control [NC], i.e. automatically operating machines, in particular machine tools, e.g. in a manufacturing environment, so as to execute positioning, movement or co-ordinated operations by means of programme data in numerical form characterised by using design data to control NC machines, e.g. CAD/CAM

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F3/00—Input arrangements for transferring data to be processed into a form capable of being handled by the computer; Output arrangements for transferring data from processing unit to output unit, e.g. interface arrangements

- G06F3/01—Input arrangements or combined input and output arrangements for interaction between user and computer

- G06F3/011—Arrangements for interaction with the human body, e.g. for user immersion in virtual reality

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F3/00—Input arrangements for transferring data to be processed into a form capable of being handled by the computer; Output arrangements for transferring data from processing unit to output unit, e.g. interface arrangements

- G06F3/01—Input arrangements or combined input and output arrangements for interaction between user and computer

- G06F3/048—Interaction techniques based on graphical user interfaces [GUI]

- G06F3/0481—Interaction techniques based on graphical user interfaces [GUI] based on specific properties of the displayed interaction object or a metaphor-based environment, e.g. interaction with desktop elements like windows or icons, or assisted by a cursor's changing behaviour or appearance

- G06F3/0482—Interaction with lists of selectable items, e.g. menus

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F30/00—Computer-aided design [CAD]

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F30/00—Computer-aided design [CAD]

- G06F30/10—Geometric CAD

- G06F30/12—Geometric CAD characterised by design entry means specially adapted for CAD, e.g. graphical user interfaces [GUI] specially adapted for CAD

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F30/00—Computer-aided design [CAD]

- G06F30/10—Geometric CAD

- G06F30/17—Mechanical parametric or variational design

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F30/00—Computer-aided design [CAD]

- G06F30/20—Design optimisation, verification or simulation

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q30/00—Commerce

- G06Q30/06—Buying, selling or leasing transactions

- G06Q30/0601—Electronic shopping [e-shopping]

- G06Q30/0621—Electronic shopping [e-shopping] by configuring or customising goods or services

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q30/00—Commerce

- G06Q30/06—Buying, selling or leasing transactions

- G06Q30/0601—Electronic shopping [e-shopping]

- G06Q30/0641—Electronic shopping [e-shopping] utilising user interfaces specially adapted for shopping

- G06Q30/0643—Electronic shopping [e-shopping] utilising user interfaces specially adapted for shopping graphically representing goods, e.g. 3D product representation

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T11/00—2D [Two Dimensional] image generation

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T19/00—Manipulating 3D models or images for computer graphics

- G06T19/006—Mixed reality

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T19/00—Manipulating 3D models or images for computer graphics

- G06T19/20—Editing of 3D images, e.g. changing shapes or colours, aligning objects or positioning parts

- G06T3/005—

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T3/00—Geometric image transformations in the plane of the image

- G06T3/08—Projecting images onto non-planar surfaces, e.g. geodetic screens

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41D—OUTERWEAR; PROTECTIVE GARMENTS; ACCESSORIES

- A41D2500/00—Materials for garments

- A41D2500/20—Woven

- D03D2700/0174—

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06C—FINISHING, DRESSING, TENTERING OR STRETCHING TEXTILE FABRICS

- D06C2700/00—Finishing or decoration of textile materials, except for bleaching, dyeing, printing, mercerising, washing or fulling

- D06C2700/31—Methods for making patterns on fabrics, e.g. by application of powder dye, moiréing, embossing

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2201/00—Cellulose-based fibres, e.g. vegetable fibres

- D10B2201/01—Natural vegetable fibres

- D10B2201/02—Cotton

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2501/00—Wearing apparel

- D10B2501/04—Outerwear; Protective garments

- D—TEXTILES; PAPER

- D10—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B—INDEXING SCHEME ASSOCIATED WITH SUBLASSES OF SECTION D, RELATING TO TEXTILES

- D10B2501/00—Wearing apparel

- D10B2501/06—Details of garments

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/35—Nc in input of data, input till input file format

- G05B2219/35008—Www cad, world wide design and manufacturing

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/35—Nc in input of data, input till input file format

- G05B2219/35012—Cad cam

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/45—Nc applications

- G05B2219/45222—Cloth making

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F2111/00—Details relating to CAD techniques

- G06F2111/20—Configuration CAD, e.g. designing by assembling or positioning modules selected from libraries of predesigned modules

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F2113/00—Details relating to the application field

- G06F2113/12—Cloth

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F3/00—Input arrangements for transferring data to be processed into a form capable of being handled by the computer; Output arrangements for transferring data from processing unit to output unit, e.g. interface arrangements

- G06F3/01—Input arrangements or combined input and output arrangements for interaction between user and computer

- G06F3/048—Interaction techniques based on graphical user interfaces [GUI]

- G06F3/0481—Interaction techniques based on graphical user interfaces [GUI] based on specific properties of the displayed interaction object or a metaphor-based environment, e.g. interaction with desktop elements like windows or icons, or assisted by a cursor's changing behaviour or appearance

- G06F3/04817—Interaction techniques based on graphical user interfaces [GUI] based on specific properties of the displayed interaction object or a metaphor-based environment, e.g. interaction with desktop elements like windows or icons, or assisted by a cursor's changing behaviour or appearance using icons

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F3/00—Input arrangements for transferring data to be processed into a form capable of being handled by the computer; Output arrangements for transferring data from processing unit to output unit, e.g. interface arrangements

- G06F3/01—Input arrangements or combined input and output arrangements for interaction between user and computer

- G06F3/048—Interaction techniques based on graphical user interfaces [GUI]

- G06F3/0484—Interaction techniques based on graphical user interfaces [GUI] for the control of specific functions or operations, e.g. selecting or manipulating an object, an image or a displayed text element, setting a parameter value or selecting a range

- G06F3/04845—Interaction techniques based on graphical user interfaces [GUI] for the control of specific functions or operations, e.g. selecting or manipulating an object, an image or a displayed text element, setting a parameter value or selecting a range for image manipulation, e.g. dragging, rotation, expansion or change of colour

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T2207/00—Indexing scheme for image analysis or image enhancement

- G06T2207/10—Image acquisition modality

- G06T2207/10024—Color image

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T2207/00—Indexing scheme for image analysis or image enhancement

- G06T2207/20—Special algorithmic details

- G06T2207/20212—Image combination

- G06T2207/20221—Image fusion; Image merging

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T2210/00—Indexing scheme for image generation or computer graphics

- G06T2210/16—Cloth

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P90/00—Enabling technologies with a potential contribution to greenhouse gas [GHG] emissions mitigation

- Y02P90/02—Total factory control, e.g. smart factories, flexible manufacturing systems [FMS] or integrated manufacturing systems [IMS]

Definitions

- the present inventionrelates to apparel finishing and, more specifically, the use of a laser in the finishing of garments, especially denim including jeans, shirts, shorts, jackets, vests, and skirts, to obtain a faded, distressed, washed, or worn finish or appearance.

- jeans at the time of the Gold Rushwere used as work clothes, jeans have evolved to be fashionably worn everyday by men and women, showing up on billboards, television commercials, and fashion runways. Fashion is one of the largest consumer industries in the U.S. and around the world. Jeans and related apparel are a significant segment of the industry.

- a typical process to produce jeansuses significant amounts of water, chemicals (e.g., bleaching or oxidizing agents), ozone, enzymes, and pumice stone. For example, it may take about twenty to sixty liters of water to finish each pair of jeans.

- a toolallows a user to create new designs for apparel and preview these designs before manufacture.

- Software and lasersare used in finishing apparel to produce a desired wear pattern or other design. Based on a laser input file with a pattern, a laser will burn the pattern onto apparel. With the tool, the user will be able to create, make changes, and view images of a design, in real time, before burning by a laser.

- Input to the toolincludes fabric template images, laser input files, and damage input.

- the toolallows adding of tinting and adjusting of intensity and bright point. The user can also move, rotate, scale, and warp the image input.

- a method for surface projection in an apparel design systemincludes providing a garment previewing tool that allows previewing on a computer screen of a garment base customized by a user with a finishing pattern, where the garment previewing tool includes: providing an option for the user to select the garment base and upon the user's selection, showing a first garment preview image on the computer screen including a jeans base image for the selected garment base, providing an option for the user to select a wear pattern from a menu of wear patterns, where each wear pattern is associated with a laser input file to be used by a laser to produce that wear pattern onto a jeans garment, after the wear pattern is selected, showing a second garment preview image on the computer screen including the selected wear pattern in combination with the jeans base image, where the second garment preview image replaces the first garment preview image, in the second garment preview image, allowing the user to select the wear pattern and modify a sizing of the wear pattern relative to the jeans base image, where as the user makes changes, the modified sizing of the wear pattern is displayed to the user in response to selecting the wear pattern

- the methodincludes applying a distortion to the third garment preview image, where the distortion approximates how the jeans base image and selected wear pattern, with modified sizing or modified positioning, or a combination, needs to be modified to appear on a three-dimensional mannequin.

- the methodincludes projecting, using a light projector, onto the three-dimensional mannequin the distorted garment preview image and receiving a first captured image of the distorted garment preview image as projected onto the three-dimensional mannequin.

- the methodincludes refining, based on the first captured image, the distorted garment preview image.

- the methodincludes providing a target garment corresponding to the garment base selected by the user; and based on a laser input file associated with a selected wear pattern with modified sizing or modified positioning, or a combination, using a laser to create a finishing pattern on an outer surface of the target garment.

- the methodmay include calibration techniques.

- the methodincludes before projecting, using a structured light technique to determine contours of the three-dimensional mannequin.

- the methodmay include the third garment preview image with different garment features.

- the methodincludes where the third garment preview image includes at least one of a label, fastener, buckle, embellishment, embroidery, grommet, heat transfer pattern, lace, patch, printing, foil, ribbon, tab, foil, rivet, sequin, pocket, thread, or zipper.

- the methodmay include refining images using various techniques.

- the methodincludes where the step of refining the distorted garment preview image is repeated using subsequent captured images.

- the methodincludes before refining the distorted garment preview image, comparing the first captured image and the third garment preview image without distortions to calculate a difference ratio, where the step of refining the distorted garment preview image is in response to determining the difference ratio is higher than a threshold ratio.

- the methodincludes where refining the distorted garment preview image includes modifying the distorted garment preview image based on at least one of a contour of the three-dimensional mannequin, warp, brightness level of the first captured image, color balance, saturation level, or hue.

- the methodincludes use with different types of three-dimensional mannequins.

- the methodincludes the three-dimensional mannequin including a full-body, legs, torso, head, or any combination of body parts.

- the methodincludes where the third garment preview image is generated before using the laser to create the finishing pattern.

- the methodincludes a jeans garment.

- the methodincludes where a method of manufacturing the target garment includes: assembling the target garment from fabric panels of a woven first material including a warp including indigo ring-dyed cotton yarn, where the fabric panels are sewn together using thread.

- the methodincludes where based on the laser input file, the laser removes selected amounts of material from the surface of a material of the target garment at different pixel locations of the garment, and for lighter pixel locations of the finishing pattern, a greater amount of the indigo ring-dyed cotton warp yarn is removed, while for darker pixel locations of the finishing pattern, a lesser amount of the indigo ring-dyed cotton warp yarn is removed.

- the methodincludes where when using the laser to create a finishing pattern, different laser levels are obtained by varying an output of the laser beam by altering a characteristic of the laser including at least one of a frequency, period, pulse width, power, duty cycle, or burning speed.

- the methodincludes where the target garment is made of at least one of a twill material or a cotton twill material.

- the methodincludes where the garment base corresponds to a base fit fabric and the base fit fabric includes known characteristics regarding the suitability of the base fit fabric for finishing using the laser.

- FIG. 1shows a block diagram of a system for creating, designing, producing apparel products with laser finishing.

- FIG. 2shows a flow for a finishing technique that includes the use of a laser.

- FIG. 3shows a weave pattern for a denim fabric.

- FIGS. 4-7show how the laser alters the color of ring-dyed yarn.

- FIG. 8shows a flow for finishing in two finishing steps and using base templates.

- FIG. 9shows multiple base templates and multiple resulting finished products from each of these templates.

- FIG. 10shows a distributed computer network.

- FIG. 11shows a computer system that can be used in laser finishing.

- FIG. 12shows a system block diagram of the computer system.

- FIGS. 13-14show examples of mobile devices.

- FIG. 15shows a system block diagram of a mobile device.

- FIG. 16shows a block diagram of a system for creating, designing, producing apparel products with laser finishing.

- FIG. 17shows a block diagram of a specific implementation of a preview tool.

- FIG. 18shows a block diagram of a brief tool.

- FIG. 19shows a technique of generating a preview of a finished image using a brief tool.

- FIG. 20shows a block diagram of a technique of generating a preview of a laser finishing pattern on a garment.

- FIG. 21shows a system for apparel manufacturing and sales.

- FIG. 22shows block diagram of a digital showroom system.

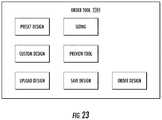

- FIG. 23shows an order tool

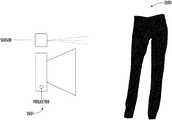

- FIG. 24shows a system diagram for a system including a projector preview tool.

- FIG. 25shows a flow diagram for a system including the projector preview tool.

- FIG. 26shows a projector used to project a wear pattern onto jeans.

- FIG. 27shows flow for a projector preview tool.

- FIG. 28shows of a technique of shape projection.

- FIG. 29shows a feedback technique to optimize or enhance the accuracy of the projector preview.

- FIG. 1shows a process flow 101 for manufacturing apparel such as jeans, where garments are finished using a laser.

- the fabric or material for various apparel including jeansis made from natural or synthetic fibers 106 , or a combination of these.

- a fabric milltakes fibers and processes 109 these fibers to produce a laser-sensitive finished fabric 112 , which has enhanced response characteristics for laser finishing.

- Some examples of natural fibersinclude cotton, flax, hemp, sisal, jute, kenaf, and coconut; fibers from animal sources include silk, wool, cashmere, and mohair.

- Some examples of synthetic fibersinclude polyester, nylon, spandex or elastane, and other polymers.

- Some examples of semisynthetic fibersinclude rayon, viscose, modal, and lyocell, which are made from a regenerated cellulose fiber.

- a fabriccan be a natural fiber alone (e.g., cotton), a synthetic fiber alone (e.g., polyester alone), a blend of natural and synthetic fibers (e.g., cotton and polyester blend, or cotton and spandex), or a blend of natural and semisynthetic fibers, or any combination of these or other fibers.

- the fabricis typically a denim, which is a sturdy cotton warp-faced textile in which a weft passes under two or more warp threads. This twill weaving produces a diagonal ribbing.

- the yarnse.g., warp yarns

- the yarnsare dyed using an indigo or blue dye, which is characteristic of blue jeans.

- the inventionis not limited jeans or denim products, such as shirts, shorts, jackets, vests, and skirts.

- the techniques and approaches describedare applicable to other apparel and products, including non-denim products and products made from knit materials.

- Some examplesinclude T-shirts, sweaters, coats, sweatshirts (e.g., hoodies), casual wear, athletic wear, outerwear, dresses, evening wear, sleepwear, loungewear, underwear, socks, bags, backpacks, uniforms, umbrellas, swimwear, bed sheets, scarves, and many others.

- a manufacturercreates a design 115 (design I) of its product.

- the designcan be for a particular type of clothing or garment (e.g., men's or women's jean, or jacket), sizing of the garment (e.g., small, medium, or large, or waist size and inseam length), or other design feature.

- the designcan be specified by a pattern or cut used to form pieces of the pattern.

- a fabricis selected and patterned and cut 118 based on the design.

- the pattern piecesare assembled together 121 into the garment, typically by sewing, but can be joined together using other techniques (e.g., rivets, buttons, zipper, hoop and loop, adhesives, or other techniques and structures to join fabrics and materials together).

- Some garmentscan be complete after assembly and ready for sale. However, other garments are unfinished 122 and have additional finishing 124 , which includes laser finishing.

- the finishingmay include tinting, washing, softening, and fixing.

- the finishingcan include using a laser to produce a wear pattern according to a design 127 (design II).

- Design 127is for postassembly aspects of a garment while design 115 is for preassembly aspects of a garment.

- a finished product 130e.g., a pair of jeans

- the finished productis inventoried and distributed 133 , delivered to stores 136 , and sold to consumers or customers 139 .

- the consumercan buy and wear worn blue jeans without having to wear out the jeans themselves, which usually takes significant time and effort.

- finishing techniquesinclude dry abrasion, wet processing, oxidation, or other techniques, or combinations of these, to accelerate wear of the material in order to produce a desired wear pattern.

- Dry abrasioncan include sandblasting or using sandpaper. For example, some portions or localized areas of the fabric are sanded to abrade the fabric surface.

- Wet processingcan include washing in water, washing with oxidizers (e.g., bleach, peroxide, ozone, or potassium permanganate), spraying with oxidizers, washing with abrasives (e.g., pumice, stone, or grit).

- oxidizerse.g., bleach, peroxide, ozone, or potassium permanganate

- abrasivese.g., pumice, stone, or grit

- FIG. 2shows a finishing technique that includes the use of a laser 207 .

- a laseris a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. Lasers are used for bar code scanning, medical procedures such as corrective eye surgery, and industrial applications such as welding.

- a particular type of laser for finishing apparelis a carbon dioxide laser, which emits a beam of infrared radiation.

- the laseris controlled by an input file 210 and control software 213 to emit a laser beam onto fabric at a particular position or location at a specific power level for a specific amount of time. Further, the power of the laser beam can be varied according to a waveform such as a pulse wave with a particular frequency, period, pulse width, or other characteristic. Some aspects of the laser that can be controlled include the duty cycle, frequency, marking or burning speed, and other parameters.

- the duty cycleis a percentage of laser emission time. Some examples of duty cycle percentages include 40, 45, 50, 55, 60, 80, and 100 percent.

- the frequencyis the laser pulse frequency. A low frequency might be, for example, 5 kilohertz, while a high frequency might be, for example, 25 kilohertz. Generally, lower frequencies will have higher surface penetration than high frequencies, which has less surface penetration.

- the laseracts like a printer and “prints,” “marks,” or “burns” a wear pattern (specified by input file 210 ) onto the garment.

- the fabric that is exposed to the laser beame.g., infrared beam

- the lasercontinues from position to position until the wear pattern is completely printed on the garment.

- the laserhas a resolution of about 34 dots per inch (dpi), which on the garment is about 0.7 millimeters per pixel.

- dpidots per inch

- the technique described in this patentis not dependent on the laser's resolution, and will work with lasers have more or less resolution than 34 dots per inch.

- the lasercan have a resolution of 10, 15, 20, 25, 30, 40, 50, 60, 72, 80, 96, 100, 120, 150, 200, 300, or 600 dots per inch, or more or less than any of these or other values.

- the greater the resolutionthe finer the features that can be printed on the garment in a single pass.

- multiple passese.g., 2, 3, 4, 5, or more passes

- multiple laser passesare used.

- Jeansare dyed using an indigo dye, which results in a blue colored fabric.

- the blue coloris caused by chromophores trapped in the fabric which reflect light as a blue color.

- U.S. patent application 62/433,739filed Dec. 13, 2016, which is incorporated by reference, describes a denim material with enhanced response characteristics to laser finishing. Using a denim material made from indigo ring-dyed yarn, variations in highs and lows in indigo color shading is achieved by using a laser.

- FIG. 3shows a weave pattern of a denim fabric 326 .

- a loomdoes the weaving.

- warpis the lengthwise or longitudinal yarn or thread in a roll, while weft or woof is the transverse thread.

- the weft yarnis drawn through the warp yarns to create the fabric.

- the warpsextend in a first direction 335 (e.g., north and south) while the wefts extend in a direction 337 (e.g., east and west).

- the weftsare shown as a continuous yarn that zigzags across the wefts (e.g., carried across by a shuttle or a rapier of the loom).

- the weftscould be separate yarns.

- the warp yarnhas a different weight or thickness than the weft yarns.

- warp yarnscan be coarser than the weft yarns.

- the weft yarnFor denim, dyed yarn is used for the warp, and undyed or white yarn is typically used for the weft yarn. In some denim fabrics, the weft yarn can be dyed and have a color other than white, such as red.

- the weftpasses under two or more warp threads.

- FIG. 3shows a weave with the weft passing under two warp threads.

- the fabric weaveis known as a 2 ⁇ 1 right-hand twill. For a right-hand twill, a direction of the diagonal is from a lower left to an upper right. For a left-hand twill, a direction of the diagonal is from a lower right to an upper left.

- the weftcan pass under a different number of warp threads, such as 3, 4, 5, 6, 7, 8, or more.

- the denimis a 3 ⁇ 1 right-hand twill, which means the weft passes under three warp threads.

- one side of the fabricexposes more of the warp yarns (e.g., warp-faced side), while the other side exposes more of the weft yarns (e.g., weft-faced side).

- the warp yarnsare blue and weft yarns are white

- a result of the weaveis the warp-faced side will appear mostly blue while the reverse side, weft-faced side, will appear mostly white.

- the warpis typically 100 percent cotton.

- some warp yarnscan be a blend with, for example, elastane to allow for warp stretch.

- some yarns for other fabricsmay contain other fibers, such as polyester or elastane as examples.

- the indigodoes not fully penetrate to a core of the yarn. Rather, the indigo dye is applied at a surface of the cotton yarn and diffuses toward the interior of the yarn. So when the yarn is viewed cross-sectionally, the indigo dyed material will appear as a ring on around an outer edge of the yarn. The shading of the indigo dye will generally lighten in a gradient as a distance increases from the surface of the yarn to the center (or core) of the yarn.

- the laserremoves a selected amount of the surface of the indigo dyed yarn (e.g., blue color) to reveal a lighter color (e.g., white color) of the inner core of the ring-dyed yarn.

- a lighter colore.g., white color

- the more of the indigo dyed material that is removedthe lighter the color (e.g., lighter shade of blue).

- the lasercan be controlled precisely to remove a desired amount of material to achieve a desired shade of blue in a desired place or position on the material.

- a finishcan be applied (e.g., printed or burned via the laser) onto apparel (e.g., jeans and denim garments) that will appear similar to or indistinguishable from a finish obtained using traditional processing techniques (e.g., dry abrasion, wet processing, and oxidation).

- traditional processing techniquese.g., dry abrasion, wet processing, and oxidation.

- Laser finishing of apparelis less costly and is faster than traditional finishing techniques and also has reduced environmental impact (e.g., eliminating the use of harsh chemical agents and reducing waste).

- FIGS. 4-7show how the laser alters the color of ring-dyed yarn.

- FIG. 4shows a laser beam 407 striking a ring-dyed yarn 413 having indigo-dyed fibers 418 and white core fibers 422 .

- the laserremoves the dyed fibers, which can be by vaporizing or otherwise destroying the cotton fiber via heat or high temperature that the laser beam causes.

- FIG. 5shows the laser using a first power level setting or first exposure time setting, or a combination of these, to remove some of the dyed fibers, but not revealing any of the white core fibers. The undyed fibers remain covered. There is no color change.

- FIG. 6shows the laser using a second power level setting or second exposure time setting, or a combination of these, to remove more of the dyed fibers than in FIG. 5 .

- the second power levelis greater than the first power level, or the second exposure time setting is greater than the first exposure time setting, or a combination of these.

- the resultis some of the undyed fibers are revealed. There is a color change, subtle highlighting.

- FIG. 7shows the laser using a third power level setting or third exposure time setting, or a combination of these, to remove even more of the dyed fibers than in FIG. 6 .

- the third power levelis greater than the second power level, or the third exposure time setting is greater than the second exposure time setting, or a combination of these.

- the resultis more of the undyed fibers are revealed. There is a color change, brighter highlighting.

- the fabriccan be prepared 216 for the laser, which may be referred to as a base preparation, and can include a prelaser wash. This step helps improves the results of the laser.

- a postlaser wash 219This wash can clean or remove any residue caused by the laser, such as removing any charring (which would appear as brown or slightly burning).

- additional finish 221which may be including tinting, softening, or fixing, to complete finishing.

- FIG. 8shows a technique where finishing 124 is divided into two finishing steps, finishing I and finishing II.

- Finishing I 808is an initial finishing to create base templates 811 .

- finishing II 814each base template can be used to manufacture multiple final finishes 817 .

- FIG. 9shows multiple base templates, base A, base B, and base C. These base templates may be referred to as base fit fabrics or BFFs.

- the base templatescan be created during base prep and prelaser wash 216 (see FIG. 2 ). During finishing I, by using different wash 216 methods or recipes, each different base template can be created.

- Finishing IIcan include laser finishing.

- Base Ais lasered with different designs to obtain various final product based on base A (e.g., FP(A) 1 to FP(A)i, where i is an integer).

- Base Bis lasered with different designs to obtain various final products based on base B (e.g., FP(B) 1 to FP(B)j, where j is an integer).

- Base Cis lasered with different designs to obtain various final products based on base C (e.g., FP(C) 1 to FP(C)k, where k is an integer).

- Each basecan be used to obtain a number of different final designs.

- the integers i, j, and kcan have different values.

- finishing IIthere can be additional finishing during post laser wash 219 and additional finishing 221 .

- additional finishingfor example, during the postlaser wash, there may be additional tinting to the lasered garments. This tinting can result in an overall color cast to change the look of the garment.

- laser finishingis used to create many different finishes (each a different product) easily and quickly from the same fabric template or BFF or “blank.” For each fabric, there will be a number of base fit fabrics. These base fit fabrics are lasered to produce many different finishes, each being a different product for a product line. Laser finishing allows greater efficiency because by using fabric templates (or base fit fabrics), a single fabric or material can be used to create many different products for a product line, more than is possible with traditional processing. This reduces the inventory of different fabric and finish raw materials.

- a base fit fabrice.g., FP(B) 1

- FP(B) 2there can be two different fabrics, such as base B and base C of FIG. 9 .

- the fabricscan be part of a fabric tool kit.

- base Bthere are multiple base fit fabrics, FP(B) 1 , FP(B) 2 , and so forth.

- a base fit fabrice.g., FP(B) 1

- FP(B) 1can be used to product any number of different finishes (e.g., eight different finishes), each of which would be considered a different product model.

- FP(B) 1can be laser finished using different laser files (e.g., laser file 1, laser file 2, laser file 3, or others) or have different postlaser wash (e.g., postlaser wash recipe 1, postlaser wash recipe 2, postlaser wash recipe 3, or others), or any combination of these.

- a first productwould be base fit fabric FP(B) 1 lasered using laser file 1 and washed using postlaser wash recipe 1.

- a second productwould be base fit fabric FP(B) 1 lasered using laser file 2 and washed using postlaser wash recipe 1.

- a third productwould be base fit fabric FP(B) 1 lasered using laser file 2 and washed using postlaser wash recipe 2.

- Eachcan have a different product identifier or unique identifier, such as a different PC9 or nine-digit product code.

- a system incorporating laser finishingcan include a computer to control or monitor operation, or both.

- FIG. 10shows an example of a computer that is component of a laser finishing system.

- the computermay be a separate unit that is connected to a system, or may be embedded in electronics of the system.

- the inventionincludes software that executes on a computer workstation system or server, such as shown in FIG. 10 .

- FIG. 10is a simplified block diagram of a distributed computer network 1000 incorporating an embodiment of the present invention.

- Computer network 1000includes a number of client systems 1013 , 1016 , and 1019 , and a server system 1022 coupled to a communication network 1024 via a plurality of communication links 1028 .

- Communication network 1024provides a mechanism for allowing the various components of distributed network 1000 to communicate and exchange information with each other.

- Communication network 1024may itself be comprised of many interconnected computer systems and communication links.

- Communication links 1028may be hardwire links, optical links, satellite or other wireless communications links, wave propagation links, or any other mechanisms for communication of information.

- Communication links 1028may be DSL, Cable, Ethernet or other hardwire links, passive or active optical links, 3G, 3.5G, 4G and other mobility, satellite or other wireless communications links, wave propagation links, or any other mechanisms for communication of information.

- communication protocolsmay be used to facilitate communication between the various systems shown in FIG. 10 .

- These communication protocolsmay include VLAN, MPLS, TCP/IP, Tunneling, HTTP protocols, wireless application protocol (WAP), vendor-specific protocols, customized protocols, and others.

- communication network 1024is the Internet, in other embodiments, communication network 1024 may be any suitable communication network including a local area network (LAN), a wide area network (WAN), a wireless network, an intranet, a private network, a public network, a switched network, and combinations of these, and the like.

- Distributed computer network 1000 in FIG. 10is merely illustrative of an embodiment incorporating the present invention and does not limit the scope of the invention as recited in the claims.

- more than one server system 1022may be connected to communication network 1024 .

- a number of client systems 1013 , 1016 , and 1019may be coupled to communication network 1024 via an access provider (not shown) or via some other server system.

- Client systems 1013 , 1016 , and 1019typically request information from a server system which provides the information. For this reason, server systems typically have more computing and storage capacity than client systems. However, a particular computer system may act as both as a client or a server depending on whether the computer system is requesting or providing information. Additionally, although aspects of the invention have been described using a client-server environment, it should be apparent that the invention may also be embodied in a stand-alone computer system.

- Server 1022is responsible for receiving information requests from client systems 1013 , 1016 , and 1019 , performing processing required to satisfy the requests, and for forwarding the results corresponding to the requests back to the requesting client system.

- the processing required to satisfy the requestmay be performed by server system 1022 or may alternatively be delegated to other servers connected to communication network 1024 .

- Client systems 1013 , 1016 , and 1019enable users to access and query information stored by server system 1022 .

- the client systemscan run as a standalone application such as a desktop application or mobile smartphone or tablet application.

- a “Web browser” application executing on a client systemenables users to select, access, retrieve, or query information stored by server system 1022 .

- Examples of Web browsersinclude the Internet Explorer browser program provided by Microsoft Corporation, Firefox browser provided by Mozilla, Chrome browser provided by Google, Safari browser provided by Apple, and others.

- some resourcese.g., files, music, video, or data

- resourcese.g., files, music, video, or data

- the user's datacan be stored in the network or “cloud.”

- the usercan work on documents on a client device that are stored remotely on the cloud (e.g., server). Data on the client device can be synchronized with the cloud.

- FIG. 11shows an exemplary client or server system of the present invention.

- a userinterfaces with the system through a computer workstation system, such as shown in FIG. 11 .

- FIG. 11shows a computer system 1101 that includes a monitor 1103 , screen 1105 , enclosure 1107 (may also be referred to as a system unit, cabinet, or case), keyboard or other human input device 1109 , and mouse or other pointing device 1111 .

- Mouse 1111may have one or more buttons such as mouse buttons 1113 .

- the present inventionis not limited any computing device in a specific form factor (e.g., desktop computer form factor), but can include all types of computing devices in various form factors.

- a usercan interface with any computing device, including smartphones, personal computers, laptops, electronic tablet devices, global positioning system (GPS) receivers, portable media players, personal digital assistants (PDAs), other network access devices, and other processing devices capable of receiving or transmitting data.

- GPSglobal positioning system

- PDAspersonal digital assistants

- other network access devicesand other processing devices capable of receiving or transmitting data.

- the client devicecan be a smartphone or tablet device, such as the Apple iPhone (e.g., Apple iPhone 6), Apple iPad (e.g., Apple iPad, Apple iPad Pro, or Apple iPad mini), Apple iPod (e.g., Apple iPod Touch), Samsung Galaxy product (e.g., Galaxy S series product or Galaxy Note series product), Google Nexus and Pixel devices (e.g., Google Nexus 6, Google Nexus 7, or Google Nexus 9), and Microsoft devices (e.g., Microsoft Surface tablet).

- a smartphoneincludes a telephony portion (and associated radios) and a computer portion, which are accessible via a touch screen display.

- Nonvolatile memoryto store data of the telephone portion (e.g., contacts and phone numbers) and the computer portion (e.g., application programs including a browser, pictures, games, videos, and music).

- the smartphonetypically includes a camera (e.g., front facing camera or rear camera, or both) for taking pictures and video.

- a smartphone or tabletcan be used to take live video that can be streamed to one or more other devices.

- Enclosure 1107houses familiar computer components, some of which are not shown, such as a processor, memory, mass storage devices 1117 , and the like.

- Mass storage devices 1117may include mass disk drives, floppy disks, magnetic disks, optical disks, magneto-optical disks, fixed disks, hard disks, CD-ROMs, recordable CDs, DVDs, recordable DVDs (e.g., DVD-R, DVD+R, DVD-RW, DVD+RW, HD-DVD, or Blu-ray Disc), flash and other nonvolatile solid-state storage (e.g., USB flash drive or solid state drive (SSD)), battery-backed-up volatile memory, tape storage, reader, and other similar media, and combinations of these.

- mass disk drivesfloppy disks, magnetic disks, optical disks, magneto-optical disks, fixed disks, hard disks, CD-ROMs, recordable CDs, DVDs, recordable DVDs (e.g., DVD-R, DVD+R, DVD-RW

- a computer-implemented or computer-executable version or computer program product of the inventionmay be embodied using, stored on, or associated with computer-readable medium.

- a computer-readable mediummay include any medium that participates in providing instructions to one or more processors for execution. Such a medium may take many forms including, but not limited to, nonvolatile, volatile, and transmission media.

- Nonvolatile mediaincludes, for example, flash memory, or optical or magnetic disks.

- Volatile mediaincludes static or dynamic memory, such as cache memory or RAM.

- Transmission mediaincludes coaxial cables, copper wire, fiber optic lines, and wires arranged in a bus. Transmission media can also take the form of electromagnetic, radio frequency, acoustic, or light waves, such as those generated during radio wave and infrared data communications.

- a binary, machine-executable version, of the software of the present inventionmay be stored or reside in RAM or cache memory, or on mass storage device 1117 .

- the source code of the software of the present inventionmay also be stored or reside on mass storage device 1117 (e.g., hard disk, magnetic disk, tape, or CD-ROM).

- code of the inventionmay be transmitted via wires, radio waves, or through a network such as the Internet.

- FIG. 12shows a system block diagram of computer system 1101 used to execute the software of the present invention.

- computer system 1101includes monitor 1103 , keyboard 1109 , and mass storage devices 1117 .

- Computer system 1101further includes subsystems such as central processor 1202 , system memory 1204 , input/output (I/O) controller 1206 , display adapter 1208 , serial or universal serial bus (USB) port 1212 , network interface 1218 , and speaker 1220 .

- the inventionmay also be used with computer systems with additional or fewer subsystems.

- a computer systemcould include more than one processor 1202 (i.e., a multiprocessor system) or a system may include a cache memory.

- Arrows such as 1222represent the system bus architecture of computer system 1101 . However, these arrows are illustrative of any interconnection scheme serving to link the subsystems.

- speaker 1220could be connected to the other subsystems through a port or have an internal direct connection to central processor 1202 .

- the processormay include multiple processors or a multicore processor, which may permit parallel processing of information.

- Computer system 1101 shown in FIG. 12is but an example of a computer system suitable for use with the present invention. Other configurations of subsystems suitable for use with the present invention will be readily apparent to one of ordinary skill in the art.

- Computer software productsmay be written in any of various suitable programming languages, such as C, C++, C#, Pascal, Fortran, Perl, MATLAB (from MathWorks, www.mathworks.com), SAS, SPSS, JavaScript, AJAX, Java, Python, Erlang, and Ruby on Rails.

- the computer software productmay be an independent application with data input and data display modules.

- the computer software productsmay be classes that may be instantiated as distributed objects.

- the computer software productsmay also be component software such as Java Beans (from Oracle Corporation) or Enterprise Java Beans (EJB from Oracle Corporation).

- An operating system for the systemmay be one of the Microsoft Windows® family of systems (e.g., Windows 95, 98, Me, Windows NT, Windows 2000, Windows XP, Windows XP x64 Edition, Windows Vista, Windows 7, Windows 8, Windows 10, Windows CE, Windows Mobile, Windows RT), Symbian OS, Tizen, Linux, HP-UX, UNIX, Sun OS, Solaris, Mac OS X, Apple iOS, Android, Alpha OS, AIX, IRIX32, or IRIX64. Other operating systems may be used.

- Microsoft Windowsis a trademark of Microsoft Corporation.

- the computermay be connected to a network and may interface to other computers using this network.

- the networkmay be an intranet, internet, or the Internet, among others.

- the networkmay be a wired network (e.g., using copper), telephone network, packet network, an optical network (e.g., using optical fiber), or a wireless network, or any combination of these.

- data and other informationmay be passed between the computer and components (or steps) of a system of the invention using a wireless network using a protocol such as Wi-Fi (IEEE standards 802.11, 802.11a, 802.11b, 802.11e, 802.11g, 802.11i, 802.11n, 802.11ac, and 802.11ad, just to name a few examples), near field communication (NFC), radio-frequency identification (RFID), mobile or cellular wireless (e.g., 2G, 3G, 4G, 3GPP LTE, WiMAX, LTE, LTE Advanced, Flash-OFDM, HIPERMAN, iBurst, EDGE Evolution, UMTS, UMTS-TDD, 1xRDD, and EV-DO).

- Wi-FiIEEE standards 802.11, 802.11a, 802.11b, 802.11e, 802.11g, 802.11i, 802.11n, 802.11ac, and 802.11ad, just to name a few examples

- a useraccesses a system on the World Wide Web (WWW) through a network such as the Internet.

- WWWWorld Wide Web

- the Web browseris used to download Web pages or other content in various formats including HTML, XML, text, PDF, and postscript, and may be used to upload information to other parts of the system.

- the Web browsermay use uniform resource identifiers (URLs) to identify resources on the Web and hypertext transfer protocol (HTTP) in transferring files on the Web.

- URLsuniform resource identifiers

- HTTPhypertext transfer protocol

- the useraccesses the system through either or both of native and nonnative applications.

- Native applicationsare locally installed on the particular computing system and are specific to the operating system or one or more hardware devices of that computing system, or a combination of these.

- These applications(which are sometimes also referred to as “apps”) can be updated (e.g., periodically) via a direct internet upgrade patching mechanism or through an applications store (e.g., Apple iTunes and App store, Google Play store, Windows Phone store, and Blackberry App World store).

- an applications storee.g., Apple iTunes and App store, Google Play store, Windows Phone store, and Blackberry App World store.

- the systemcan run in platform-independent, nonnative applications.

- clientcan access the system through a Web application from one or more servers using a network connection with the server or servers and load the Web application in a Web browser.

- a Web applicationcan be downloaded from an application server over the Internet by a Web browser.

- Nonnative applicationscan also be obtained from other sources, such as a disk.

- FIGS. 13-14show examples of mobile devices, which can be mobile clients.

- Mobile devicesare specific implementations of a computer, such as described above.

- FIG. 13shows a smartphone device 1301

- FIG. 14shows a tablet device 1401 .

- smartphonesinclude the Apple iPhone, Samsung Galaxy, and Google Nexus family of devices.

- tablet devicesinclude the Apple iPad, Apple iPad Pro, Samsung Galaxy Tab, and Google Nexus family of devices.

- Smartphone 1301has an enclosure that includes a screen 1303 , button 1309 , speaker 1311 , camera 1313 , and proximity sensor 1335 .

- the screencan be a touch screen that detects and accepts input from finger touch or a stylus.

- the technology of the touch screencan be a resistive, capacitive, infrared grid, optical imaging, or pressure-sensitive, dispersive signal, acoustic pulse recognition, or others.

- the touch screenis screen and a user input device interface that acts as a mouse and keyboard of a computer.

- Button 1309is sometimes referred to as a home button and is used to exit a program and return the user to the home screen.

- the phonemay also include other buttons (not shown) such as volume buttons and on-off button on a side.

- the proximity detectorcan detect a user's face is close to the phone, and can disable the phone screen and its touch sensor, so that there will be no false inputs from the user's face being next to screen when talking.

- Tablet 1401is similar to a smartphone.

- Tablet 1401has an enclosure that includes a screen 1403 , button 1409 , and camera 1413 .

- the screene.g., touch screen

- the screen of a tabletis larger than a smartphone, usually 7, 8, 9, 10, 12, 13, or more inches (measured diagonally).

- FIG. 15shows a system block diagram of mobile device 1501 used to execute the software of the present invention.

- This block diagramis representative of the components of smartphone or tablet device.

- the mobile device systemincludes a screen 1503 (e.g., touch screen), buttons 1509 , speaker 1511 , camera 1513 , motion sensor 1515 , light sensor 1517 , microphone 1519 , indicator light 1521 , and external port 1523 (e.g., USB port or Apple Lightning port). These components can communicate with each other via a bus 1525 .

- a bus 1525e.g., USB port or Apple Lightning port

- the systemincludes wireless components such as a mobile network connection 1527 (e.g., mobile telephone or mobile data), Wi-Fi 1529 , Bluetooth 1531 , GPS 1533 (e.g., detect GPS positioning), other sensors 1535 such as a proximity sensor, CPU 1537 , RAM memory 1539 , storage 1541 (e.g. nonvolatile memory), and battery 1543 (lithium ion or lithium polymer cell).

- the batterysupplies power to the electronic components and is rechargeable, which allows the system to be mobile.

- FIG. 16shows a block diagram of a system for creating, designing, producing apparel products with laser finishing.

- a box line plan 1602is an internal and interim tool for communication between a merchandising group and design group. Through the box line plan, merchandising can communicate what needs to be designed by the design group.

- the box line plancan have open slots to be designed 1609 .

- a digital design tool 1616merchants and design can use to click and drag finish effects (e.g., laser files) and tint casts over images of base washes in order to visualize possible combinations and build the line visually before the garment finish is actually finished by the laser.

- the visualizationscan be by rendering on a computer system, such as using three-dimensional (3D) graphics.

- Laser finishing of apparel productsallows an operating model that reduces finishing cost, lowers carrying costs, increases productivity, shortens time to market, be more reactive to trends, reduce product constraints, reduces lost sales and dilution, and more.

- Improved aspectsinclude design, development, planning, merchandising, selling, making, and delivering.

- the modeluses fabric templates, each of which can be used be produce a multitude of laser finishes. Operational efficiency is improved.

- Design toolscan use the digital design tool to design products that are used to satisfy the requests in open slots 1609 .

- Designs created using the digital design toolcan be stored in a digital library 1622 .

- Input to the digital design toolinclude fabric templates or blanks 1627 (e.g., base fit fabrics or BFFs), existing finishes 1633 (e.g., can be further modified by the tool 1616 ), and new finishes 1638 .

- New finishescan be from designs 1641 (e.g., vintage design) captured using a laser finish software tool 1645 , examples of which are described in U.S. patent applications 62/377,447, filed Aug. 19, 2016, and Ser. No. 15/682,507, filed Aug. 21, 2017.

- Digital library 1622can be accessible by the region assorting and sell-in 1650 . And the digital library can be used populate or satisfy the box line plan.

- FIG. 17shows a block diagram of a specific implementation of a digital design tool, a preview tool 1703 .

- Digital design tool 1616can be representative of a collection of tools, such as an application suite, including desktop or mobile apps, or a combination.

- Preview tool 1703can be a single tool in a toolbox or toolkit used for laser finishing of garments, or the tool can be incorporated as a feature of another tool.

- the preview toolallows a user such as a clothing designer to preview on a computer screen or to generate a digital representation (e.g., image file, JPEG file, BMP file, TIFF file, GIF file, PNG file, PSD file, or others) of jeans in a selected base fit fabric or fabric template 1706 with a selected laser pattern 1709 (e.g., from a laser input file).

- a digital representatione.g., image file, JPEG file, BMP file, TIFF file, GIF file, PNG file, PSD file, or others

- the userwill be able to see or preview the jeans in the selected base fit fabric as if it had been burned with the selected laser input file, without needing to actually laser or burn the jeans.

- Some filesare described as being of an image file type.

- image file types or file formatsinclude bitmap or raster graphics formats including IMG, TIFF, EXIF, JPEG, GIF, PNG, PBM, PGM, PPM, BMP, and RAW.

- the compression for the filecan be lossless (e.g., TIFF) or lossy (e.g., JPEG).

- image file types or file formatsinclude vector graphics including DXF, SVG, and the like.

- Bitmaps or raster graphicsare resolution dependent while vector graphics are resolution independent. Raster graphics generally cannot scale up to an arbitrary resolution without loss of apparent quality. This property contrasts with the capabilities of vector graphics, which generally easily scale up to the quality of the device rendering them.

- a raster graphics imageis a dot matrix data structure representing a generally rectangular grid of pixels, or points of color, viewable via a monitor, paper, or other display medium.

- a bitmapsuch as a single-bit raster, corresponds bit-for-bit with an image displayed on a screen or output medium.

- a rasteris characterized by the width and height of the image in pixels and by the number of bits per pixel (or color depth, which determines the number of colors it can represent).

- the BMP file formatis an example of a bitmap.

- the BMP file formatalso known as bitmap image file or device independent bitmap (DIB) file format or simply a bitmap, is a raster graphics image file format used to store bitmap digital images, independently of the display device.

- DIBdevice independent bitmap

- the BMP file formatis capable of storing two-dimensional digital images of arbitrary width, height, and resolution, both monochrome and color, in various color depths, and optionally with data compression, alpha channels, and color profiles.

- the fabric templatecan be selected from a library of fabric template images 1716 or may be a new image uploaded or provided by the user.

- Each fabric template imagesis an image file of a jeans in a base fit fabric or other material.

- For each jeans model or fite.g., models or fits 311, 501, 505, 511, 515, 541, 569, 721, and others, there would be one image in each different material or base fit fabric.

- the laser input filecan be selected from a library of laser input files 1722 (e.g., files created from vintage jeans or from a group of designers), may be a file 1718 created by the user, or may be a file uploaded or provided by the user.

- a library of laser input files 1722e.g., files created from vintage jeans or from a group of designers

- the usermay have created the laser pattern (contained within a laser input file) manually using a graphical or image editing tool (e.g., Adobe Photoshop and similar photo editing programs).

- the laser patternmay have been created by another, such as selected from a library of laser files.

- the laser patternmay be generated by a computer or automated process, such as may be used to obtain a laser pattern from vintage jeans.

- the userwill be able to see the results of a burn, make any manual changes or alterations to the pattern (such as additional changes to a vintage jean pattern in a digital image file) and preview the results again.

- the preview toolallows a user to make and see changes, to the user can obtain feedback faster than having to laser jeans to see the results and also avoiding unneeded waste (e.g., preliminary versions of burned jeans).

- Each digital representationcan be saved in a separate images, and a group or set of the images can be a called brief of collection of jeans.

- the preview toolcan be used for merchandising, such as generating images of a proposed line of products for a particular season, and these images can be shared among members of a team to discuss any additions, changes, or deletions to a collection.

- a specific version of the preview tooloverlays a fabric template input file and a laser input file, and then generates an image to display them together as a representation of the laser-finished apparel.

- the laser input fileis aligned to the garment in the fabric template input file, so that the positioning of features in the laser input file and at appropriate positions or places on the garment.

- the alignmentmay be by using alignment marks that are in the input files.

- the alignmentmay be an automated alignment or scaling, or a combination.

- Brightness, intensity, opacity, blending, transparency, or other adjustable parameters for an image layer, or any combination of these,are selected or adjusted for the laser input file, so that when the laser input file is overlaid above the fabric template image, the look of the garment will appear of simulate the look of a garment had been burned by a laser using that laser input file.

- Adjustable parameters such as opacitycan be used to blend two or more image layers together. For example, a layer's overall opacity determines to what degree it obscures or reveals the layer beneath it. For example, a layer with 1 percent opacity appears nearly transparent, while one with 100 percent opacity appears completely opaque.

- a dots per inch (dpi) of the combined imagecan be adjusted to also more properly simulate the look of a garment more closely with a burned garment.

- Dots per inchrefers to the number of dots in a printed inch. The more dots, the higher the quality of the print (e.g., more sharpness and detail). By reducing the dpi of the image, this will reduce the image quality, resulting a blurring of the image.

- the preview toolreduces a dpi of the combined image, to be of less dpi than the fabric template input file or the laser input file. By blurring the preview image, this results in improved simulation that corresponds better to a burned laser garment. When burning a garment, the garment material or fabric typically limits the resolution of the result to less than that of the input file.

- the dpi of the laser input fileis about 72 dpi, while the dpi of the preview image is about 34 dpi.

- the dpi of the fabric template input file and laser input fileare about 36 dpi or above, while the dpi of the preview image is about 36 dpi or lower.

- FIG. 18shows a block diagram of a digital brief tool 1803 , which also like preview tool 1703 , provides a real-time preview of an appearance of pair of jeans when a finishing pattern is applied by burning using a laser input file.

- the digital brief toolhas additional features to allow more flexible designing of jeans.

- the digital brief tooltakes as input three types of digital assets 1805 , fabric template input 1816 , damage input 1819 , and laser input file 1822 .

- Fabric template input 1816 and laser input file 1822are similar to the inputs for the preview tool.

- Damage input 1819is an image of damage (e.g., holes, rips, shredded regions, or openings of various shapes and sizes) that can be burned by a laser into jeans.

- the digital brief tooloverlays the damage and laser input files over the fabric template.

- the userselects a fabric template input, which an image of a jeans style in a particular base fit fabric.

- the usercan optionally select one or more damage inputs. If a damage input is selected, the damage input will be a layer that overlays the fabric template layer.

- the preview toolthe user selects a laser input file with laser pattern and overlays the fabric template layer. As the user selects the inputs, the user will be able to see in real time the inputs and any changes or updates in a preview image or brief.

- the usercan select and perform one or more operations 1826 on the inputs using the digital brief tool. These operations including adding tint 1831 , adjusting intensity 1834 , adjusting bright point 1837 , move digital asset 1842 , rotate digital asset 1845 , scale digital asset 1848 , and warp digital asset 1852 . As the user selects and performs one or more operations, the user will be able to see in real time the changes or updates in the preview image or brief.

- Tintingwill adjust the hue of the color of the fabric template input. Tinting is representative of the tinting which can be added during the postlaser wash or finishing II, described above. The user will be able to select a tint color, and this tint color will be blended with the existing color of the fabric template input. The amount or intensity of the tinting can be increased or decreased, such as by using a slider bar.

- intensity 1834adjusts a weight matrix by a percentage of each value in the array.

- intensity (or brightness)adjusts an opacity of a generated adjustment layer (see hue saturation lightness adjustment layer described below). The greater the opacity, the more opaque this layer will appear in the preview or brief image. The less the opacity, the less opaque this layer will appear in the preview or brief image; the layer will appear more transparent so that the layer beneath will show through more.

- the opacity of the adjustment layerincreases, and since the adjustment layer is above the fabric template input, the generated adjustment layer will become more prominent or visible, thus making this layer (which has the wear pattern) brighter. Similarly, when decreasing brightness, the opacity of the adjustment layer decreases, the generated adjustment layer will become less prominent or visible, thus making this layer (which has the wear pattern) less bright or fainter.

- the amount of the intensitycan be increased or decreased, such as by using a slider bar.

- Bright point 1837adjusts the effect of the laser input file on the fabric template input.

- bright point adjustmentchanges a midpoint of a grayscale, creating a piecewise linear mapping of the pattern file.

- the bright point adjustmentcan be analogous to changing a pixel time or the time that the laser stays at a particular position for a given input from the laser input file.

- the amount of the bright pointcan be increased or decreased, such as by using a slider bar.

- the usercan move 1842 or reposition a selected digital asset.

- a damage inputor fabric template or laser file

- the usercan rotate 1845 a selected digital asset.

- a damage inputor fabric template or laser file

- the usercan scale 1848 a selected digital asset. This scaling can be locked, maintaining the original aspect ratio of the digital asset, or can be unlocked, such that the user can change the aspect ratio.

- the usercan warp 1852 a selected digital asset. With warping, the user can adjust an aspect ratio of a portion of the digital asset differently from another portion. For example, one portion of a damage input (or fabric template or laser file) can be squished (e.g., right and left edges of image pushed toward each other) while another portion is expanded (e.g., right and left edges of image pulled away from each other).

- the digital brief toolshows an image of the jeans with the laser finishing pattern, including any tinting, damage, or other adjustments, as created by the user. This image can be saved and viewed again later. A user can create multiple designs, and these can be saved together as part of a collection.

- FIG. 19shows a technique of generating a preview of a finished image using a digital brief tool.

- a base image(or fabric template input) is selected.

- a hue saturation lightness (HSL) adjustment layeris created or generated for the selected base image.

- the HSL adjustment layercan be the base layer with an adjustment for hue saturation lightness.

- a solid color adjustment layeris created or generated.

- the solid color adjustment layerhas a solid color (e.g., yellow, green, red, blue, or other color that is used for tinting the garment) that is in the same form or outline as the garment (e.g., pants), as indicated by the dotted lines in the figure.

- a laser pattern maskis combined with the base image and HSL adjustment layer.

- a resulting combinationwill be based on intensity and bright point settings.

- the laser pattern maskis a negative image or reverse image of the laser input file.

- a white pixelmeans the pixel is not lasered (which results in the original indigo color of the fabric), and a black pixel means the pixel will be lasered at highest level (which results in the whitest color that can be achieved on the fabric).

- the laser input filehas 256 levels of gray, and for levels between 0 (e.g., black) and 255 (e.g., white), then the amount of laser burning will be proportionally somewhere in between.

- FIG. 20shows a block diagram of a technique of generating a preview of a laser finishing pattern on a garment, such as jeans.

- the techniquemay be embodied in a preview generation tool 2001 .

- Inputs to a create preview image process 2002include a base template image 2007 and laser input file 2009 .

- the base template imageis used to create an adjusted base template image 2017 , which is also input to the create preview image process.

- These create preview image processuses these three inputs to create a preview image 2027 , which can be displayed on a computer screen for the user.