US10427244B2 - Control in generative production - Google Patents

Control in generative productionDownload PDFInfo

- Publication number

- US10427244B2 US10427244B2US14/325,458US201414325458AUS10427244B2US 10427244 B2US10427244 B2US 10427244B2US 201414325458 AUS201414325458 AUS 201414325458AUS 10427244 B2US10427244 B2US 10427244B2

- Authority

- US

- United States

- Prior art keywords

- eddy current

- current testing

- layer

- coil

- energy beam

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related, expires

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/10—Sintering only

- B22F3/105—Sintering only by using electric current other than for infrared radiant energy, laser radiation or plasma ; by ultrasonic bonding

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/20—Direct sintering or melting

- B22F10/28—Powder bed fusion, e.g. selective laser melting [SLM] or electron beam melting [EBM]

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/003—Apparatus, e.g. furnaces

- B22F3/1055—

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K15/00—Electron-beam welding or cutting

- B23K15/002—Devices involving relative movement between electronbeam and workpiece

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K15/00—Electron-beam welding or cutting

- B23K15/0046—Welding

- B23K15/0086—Welding welding for purposes other than joining, e.g. built-up welding

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/08—Devices involving relative movement between laser beam and workpiece

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K26/00—Working by laser beam, e.g. welding, cutting or boring

- B23K26/352—Working by laser beam, e.g. welding, cutting or boring for surface treatment

- B23K26/354—Working by laser beam, e.g. welding, cutting or boring for surface treatment by melting

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y10/00—Processes of additive manufacturing

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y30/00—Apparatus for additive manufacturing; Details thereof or accessories therefor

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N27/00—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means

- G01N27/72—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means by investigating magnetic variables

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/30—Process control

- B22F10/32—Process control of the atmosphere, e.g. composition or pressure in a building chamber

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F10/00—Additive manufacturing of workpieces or articles from metallic powder

- B22F10/30—Process control

- B22F10/36—Process control of energy beam parameters

- B22F2003/1057—

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y50/00—Data acquisition or data processing for additive manufacturing

- B33Y50/02—Data acquisition or data processing for additive manufacturing for controlling or regulating additive manufacturing processes

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P10/00—Technologies related to metal processing

- Y02P10/25—Process efficiency

- Y02P10/295—

Definitions

- the present inventionrelates to a method for producing a component by means of a generative production process, in which material is repeatedly applied layer by layer to a base plate or an already correspondingly generated semifinished product and is bonded with the semifinished product, wherein radiation energy which is introduced into the material by at least one beam that is moved in relation to and over the surface of the semifinished product is used for the bonding of the material with the semifinished product.

- the inventionalso relates to a corresponding apparatus for carrying out the method.

- Generative production processes for producing a componentare used in industry for so-called rapid tooling, rapid prototyping or else for the production of series products in rapid manufacturing.

- such processesmay also be used for the production of turbine parts, in particular parts of aircraft engines, in the case of which such generative production processes are advantageous for example because of the material used.

- An example of thiscan be found in DE 10 2010 050 531 A1, the entire disclosure of which is incorporated by reference herein.

- the given properties of the material and componentcause variations in the process, which may lead to inhomogeneities.

- the geometry of the componentmay cause the irregular removal of process gases, resulting in instability.

- the present inventionprovides a method for generatively producing components by layer-by-layer building from a powder material by selective material bonding of powder particles by a high-energy beam. An eddy current testing is carried out concurrently with the material bonding.

- the material bondingmay take place by at least one of welding and sintering.

- the high-energy beammay be a laser beam or an electron beam.

- the high-energy beammay be passed in any desired pattern over a surface with powder particles to be subjected to material bonding.

- an eddy current measuring arrangementwith at least one coil arrangement comprising at least one transmitter coil and at least one integrated or separate receiver coil, e.g., a differential or multi-differential coil may be used for the eddy current testing.

- the coil arrangementin the eddy current testing with the high-energy beam, may be passed over the surface of a powder layer.

- the coil arrangementin the eddy current testing, may surround the high-energy beam.

- one or more measured values of the eddy current testingmay be used for controlling the layer-by-layer building, for example, the material bonding.

- one or more measured values of the eddy current testingmay be used for automatic control of parameters of the layer-by-layer building, for example, the material bonding, and/or may be used for determining whether and/or how a finishing is carried out.

- measured values of the eddy current testingmay be filtered by a high-pass filter on the basis of a different speed of movement of the coil arrangement and the high-energy beam.

- the present inventionalso provides an apparatus for the generative production of a component with a beam generating device and a powder arranging unit.

- the apparatusis set up in such a way that a high-energy beam of the beam generating device is passed in any desired pattern over a surface with a powder particle layer provided by the powder arranging unit, in order for the surface to undergo material bonding with powder particles in predetermined regions of the powder particle layer.

- the apparatusfurther comprises an eddy current measuring arrangement which is capable of carrying out an eddy current testing during the material bonding by the high-energy beam.

- the beam generating devicemay comprise a laser beam or electron beam unit which comprises a deflecting device with which a respective beam can be passed over the surface provided with powder.

- the eddy current measuring arrangementmay comprise at least one coil arrangement comprising at least one transmitter coil and at least one integrated or separate receiver coil, for example, a differential or multi-differential coil.

- the apparatusmay further comprise a control unit which receives measured values of the eddy current measuring arrangement and outputs control data for the beam generating device and/or the powder arranging unit.

- the present inventionproposes carrying out at the same time as the generative building an eddy current testing, in order to obtain knowledge of the machining process and the layer structure by means of the eddy current testing, so that the homogeneity, and the quality in general, of the layer structure and of the component generated can be improved on the basis of the knowledge acquired about the course of the generative building and/or the properties of the layers deposited.

- an apparatus for the generative production of componentsnot only a radiation-generating device for providing a high-energy beam and a powder-arranging unit, by which a layer of powder is provided for the layer-by-layer building of the component to be generated, but also an eddy current measuring arrangement is provided, with which an eddy current testing can be carried out during the material bonding of the powder particles by means of the high-energy beam.

- the eddy current measuring arrangementmay be equipped with at least one coil arrangement comprising at least one transmitter coil and at least one integrated or separate receiver coil, preferably with a differential or multi-differential coil.

- the transmitter coil and the receiver coilare realized by one coil, whereas, in the case of separate transmitter and receiver coils, there are separate coils for transmitting and receiving.

- eddy currentsare generated by the transmitter coil in the material to be investigated and in turn generate alternating electromagnetic fields, which can be detected by the receiver coil.

- the detected electromagnetic fieldsconclusions about the material investigated can be drawn and a characterization of the material built up can be carried out.

- differential or multi-differential coilin which at least two separate receiver coils are provided, external influences on the measurement result, such as for example temperature changes, can be ruled out.

- the measured values obtained in the eddy current testing, or at least one corresponding measured valuecan be used for the control, and in particular automatic control, of the layer-by-layer building, or in particular the material bonding, in that corresponding parameters of the layer-by-layer building, such as for example the radiation power, setting of the beam diameter, setting of the speed of movement of the beam over the surface to be machined, settings for the exposure strategy, such as for example the exposure sequence, settings for a possible preheating of the powder and/or of the component to be formed, settings for the layer thickness of the powder particles applied and the like, can be varied in dependence on the measurement results.

- corresponding parameters of the layer-by-layer buildingsuch as for example the radiation power, setting of the beam diameter, setting of the speed of movement of the beam over the surface to be machined

- settings for the exposure strategysuch as for example the exposure sequence

- settings for a possible preheating of the powder and/or of the component to be formedsettings for the layer thickness of the powder particles applied and the like

- the apparatus for the generative production of componentsmay comprise a control unit, which receives the measured values of the eddy current measuring arrangement and outputs control data for the radiation generating device and/or the powder arranging unit. Consequently, the control or operation of the apparatus for the generative production of components can be adapted in situ to the given conditions.

- results of the eddy current testingcan also be used for an optional finishing of the layers applied by the high-energy beam, so that corresponding defects can be repaired or eliminated in finishing with the high-energy beam.

- the high-energy beamis usually moved in relation to the surface of the powder particle layer or the component already generated, in order to produce material bonding in the corresponding regions in which the beam impinges on the powder layer.

- the coil arrangement for the eddy current testing with the high-energy beammay be passed over the surface of the powder layer, wherein the speed of movement of the high-energy beam may be greater than the speed of movement of the coil arrangement, since the high-energy beam may be moved additionally in relation to the coil arrangement.

- the measured values of the eddy current measuring arrangementmay be subjected to high-pass filtering, in order in this way to improve the signal-to-noise ratio of the measured values.

- the coil arrangementmay surround the high-energy beam, so that specifically the machining region of the high-energy beam is subjected to the eddy current testing.

- the high-energy beammay be a laser beam or an electron beam or some other suitable beam of an electromagnetic radiation or a corresponding particle beam.

- the material bonding between the powder particles or the powder particles and the already existing componentmay take place by welding or sintering.

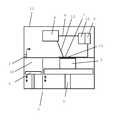

- FIG. 1shows a schematic representation of an apparatus according to the invention for the generative production of components by the example of selective laser melting

- FIG. 2shows a plan view of a surface of a powder particle layer with a laser beam and a coil arrangement during the application of a layer.

- FIG. 1shows in a purely schematic representation an apparatus 1 according to the invention, as may be used for example for selective laser melting for the generative production of a component.

- the apparatus 1comprises a lifting table 2 , on the platform of which there is arranged a semifinished product 3 , on which material is deposited layer by layer in order to generate a three-dimensional component.

- powder 10which is located above a lifting table 9 in a powder store, is pushed by means of the pusher 8 layer by layer over the semifinished product 3 and subsequently bonded with the already present semifinished product 3 by melting or sintering by the laser beam 13 of a laser 4 .

- the bonding of the powder material in a powder layer with the semifinished product 3takes place by the laser 4 in a way depending on the desired contour of the component to be produced, so that any desired, three-dimensional forms can be generated.

- the processmay take place in an enclosed space, which is provided by a housing 11 of the apparatus 1 , and moreover an inert gas atmosphere may also be provided, in order for example to avoid oxidation of the powder material during the depositing and the like.

- the laser beam 13moves over the powder layer 14 arranged over the component 3 , in order to melt the powder material at the locations at which the component 3 is to be generated layer by layer and to enter into a material bond with the already existing component 3 .

- the powder materialmay also merely be heated up to the extent that a sintering process takes place.

- the laser beam 13 generated by the beam generating unit 4is deflected in two directions that are independent of one another in such a way that every location of the surface of the powder particle layer 14 can be reached. In this way it is possible to realize any desired three-dimensional form of the component 3 to be produced.

- a coil arrangement 7with which an eddy current testing can be carried out during the melting or sintering of the powder, is provided around the laser beam 13 .

- the coil arrangement 7comprises a transmitter coil and at least one receiver coil, preferably two separate receiver coils (not represented), wherein eddy currents are generated by the transmitter coil in the machining region of the laser beam 7 and the magnetic fields induced by the eddy currents are measured by the receiver coil.

- the measurement of the magnetic fields generated by the eddy currentsallows the state of the material in the machining region of the laser beam 13 to be inferred. This knowledge in turn makes it possible to set the settings and parameters of the apparatus for the generative production of the component in dependence on the eddy current testing.

- the coil arrangement 7is connected to an actuating unit 5 of the eddy current measuring arrangement, which on the one hand provides the coil current for the coil arrangement 7 and on the other hand receives the measurement data of the coil arrangement 7 . Furthermore, the actuating unit 5 brings about the movement of the coil arrangement 7 together with the laser beam 13 , wherein the coil arrangement with a single integrated transmitter and receiver coil or separate transmitter and receiver coils can move at a small distance from the machining surface in parallel above the powder layer 14 in two independent directions.

- the actuating unit 5 of the eddy current measuring arrangementis connected to a control unit 12 , which receives the measurement data of the eddy current testing and, in dependence on these measurement data, generates control data for the laser beam generating device 4 and transmits them to the latter via the control data line 6 .

- the control unit 12may also supply the lifting tables 2 and 9 and the pusher 8 with control data, in order for example to influence the arrangement of the powder in the powder layer 14 or the thickness of the powder layer 14 or the like in dependence on the eddy current testing.

- control unit 12can be used to realize automatic control, with which, by means of eddy current testing using the coil arrangement 7 , the state of the layer structure on the component 3 is detected and the parameters for the generative production, such as for example beam power, speed of movement of the beam over the surface of the powder layer 14 or the component 3 , thickness of the powder layer 14 , size of the focal point of the beam, movement sequence of the laser beam 13 (scanning strategy), possible preheating of the powder layer 14 and/or the component 3 , for example by inductive heating and the like, are set in situ.

- parameters for the generative productionsuch as for example beam power, speed of movement of the beam over the surface of the powder layer 14 or the component 3 , thickness of the powder layer 14 , size of the focal point of the beam, movement sequence of the laser beam 13 (scanning strategy), possible preheating of the powder layer 14 and/or the component 3 , for example by inductive heating and the like, are set in situ.

- the knowledge obtained from the eddy current testingmay also be used for finishing a layer, that is to say exposing it with the laser beam 13 for a second time, in order to heal defects established in the eddy current testing.

- FIG. 2shows a plan view of the powder layer 14 during machining with the laser beam 13 .

- a coil arrangement 7which moves with the laser beam 13 over the surface of the powder layer 14 .

- an eddy current testingcan be carried out, as described above, in order to be able to adapt the conditions for the generative growth of the layers during the production of the component 3 .

- the coil of the coil arrangement 7may have a diameter of up to 5 cm and be moved at a distance of from 0.1 mm to 1 mm from the surface of the powder layer 14 at a speed in the range from 50 mm per second to 2000 mm per second.

- the laser beam 13may be additionally moved within the coil arrangement 7 in relation to the coil arrangement 7 , for example by a back and forth movement transversely with respect to the forward movement of the laser beam 13 in the machining direction.

- the speed of movement of the lasermay be higher than the speed of movement of the coil arrangement 7 .

- the relative movementmay also be realized by a movement of the semifinished product with respect to the beam and the coil arrangement.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Optics & Photonics (AREA)

- Plasma & Fusion (AREA)

- Health & Medical Sciences (AREA)

- Electrochemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Life Sciences & Earth Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Powder Metallurgy (AREA)

- Sampling And Sample Adjustment (AREA)

Abstract

Description

Claims (20)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102013213370.7ADE102013213370A1 (en) | 2013-07-09 | 2013-07-09 | Control in generative production |

| DE102013213370.7 | 2013-07-09 | ||

| DE102013213370 | 2013-07-09 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| US20150017054A1 US20150017054A1 (en) | 2015-01-15 |

| US10427244B2true US10427244B2 (en) | 2019-10-01 |

Family

ID=51210234

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US14/325,458Expired - Fee RelatedUS10427244B2 (en) | 2013-07-09 | 2014-07-08 | Control in generative production |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US10427244B2 (en) |

| EP (1) | EP2823917B1 (en) |

| DE (1) | DE102013213370A1 (en) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10488852B2 (en)* | 2015-03-12 | 2019-11-26 | Limacorporate S.P.A. | Quality control method for regulating the operation of an electromechanical apparatus, for example an EBM apparatus, in order to obtain certified processed products |

| US11478983B2 (en) | 2015-06-19 | 2022-10-25 | General Electric Company | Additive manufacturing apparatus and method for large components |

| US10449606B2 (en)* | 2015-06-19 | 2019-10-22 | General Electric Company | Additive manufacturing apparatus and method for large components |

| DE102015110264A1 (en)* | 2015-06-25 | 2016-12-29 | Cl Schutzrechtsverwaltungs Gmbh | Device for the generative production of at least one three-dimensional object |

| CN105382259A (en)* | 2015-12-03 | 2016-03-09 | 大连理工大学 | A selective laser melting compound manufacturing machine tool and workpiece compound manufacturing method |

| CN105397494A (en)* | 2015-12-03 | 2016-03-16 | 大连理工大学 | Laser coaxial powder feeding composite manufacturing machine tool and workpiece composite manufacturing method |

| DE102016201289A1 (en) | 2016-01-28 | 2017-08-03 | Siemens Aktiengesellschaft | Process for additive production and device |

| DE102016201290A1 (en) | 2016-01-28 | 2017-08-17 | Siemens Aktiengesellschaft | Method of quality assurance and device |

| US20180036964A1 (en)* | 2016-08-08 | 2018-02-08 | General Electric Company | Method and system for inspection of additive manufactured parts |

| DE102016216682A1 (en)* | 2016-09-02 | 2018-03-08 | Eos Gmbh Electro Optical Systems | Method and device for generatively producing a three-dimensional object |

| US10926328B2 (en) | 2016-10-20 | 2021-02-23 | Huntington Ingalls Incorporated | System and method for in-situ inspection of additive manufacturing materials and builds |

| US11766824B2 (en) | 2017-05-26 | 2023-09-26 | Ihi Corporation | Apparatus for producing three-dimensional multilayer model, method for producing three-dimensional multilayer model, and flaw detector |

| JP7007152B2 (en) | 2017-10-19 | 2022-01-24 | 株式会社アドバンテスト | Three-dimensional laminated modeling equipment and laminated modeling method |

| EP3765936A4 (en)* | 2018-03-12 | 2021-12-08 | Creator, Inc. | Control system architecture and distributed human-machine interface for robot control |

| JP7096702B2 (en)* | 2018-05-11 | 2022-07-06 | 株式会社アドバンテスト | Manufacturing equipment, inspection methods, manufacturing methods and programs |

| FR3087270A1 (en)* | 2018-10-16 | 2020-04-17 | Commissariat A L'energie Atomique Et Aux Energies Alternatives | METHOD AND DEVICE FOR CONTROLLING THE QUALITY OF A BED OF POWDERS IN ADDITIVE MANUFACTURING PROCESSES |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4002633A1 (en) | 1990-01-30 | 1991-08-01 | Schiebold Gerald | Virtual rotation-motion sensor for non-destructive material test - has field generating coils and sensor segments with successive electronic scanning |

| US5684616A (en)* | 1988-04-18 | 1997-11-04 | Brotz; Gregory R. | Moving mirror apparatus |

| DE19835860C1 (en) | 1998-08-07 | 2000-04-20 | Siemens Ag | Circuit for device used for material investigation using eddy current |

| US20060244443A1 (en)* | 2005-01-28 | 2006-11-02 | Goldfine Neil J | Material condition assessment with eddy current sensors |

| US20070176312A1 (en)* | 2006-02-01 | 2007-08-02 | Daniel Clark | Method and apparatus for examination of objects and structures |

| US20080241392A1 (en) | 2007-03-27 | 2008-10-02 | Eos Gmbh Electro Optical Systems | Method and Device for Manufacturing a Three-Dimensional Object |

| US20090091318A1 (en)* | 2007-09-11 | 2009-04-09 | Benoit Lepage | Phased scan eddy current array probe and a phased scanning method which provide complete and continuous coverage of a test surface without mechanical scanning |

| DE102010050531A1 (en) | 2010-09-08 | 2012-03-08 | Mtu Aero Engines Gmbh | Generatively producing portion of component, which is constructed from individual powder layers, comprises heating powder layer locally on melting temperature, forming molten bath, reheating zone downstream to the molten bath |

| DE102011008774A1 (en) | 2011-01-18 | 2012-07-19 | Mtu Aero Engines Gmbh | Method and device for testing the generative production of a component |

| DE102011009624A1 (en) | 2011-01-28 | 2012-08-02 | Mtu Aero Engines Gmbh | Method and device for process monitoring |

| DE102011111818A1 (en) | 2011-08-27 | 2013-02-28 | Mtu Aero Engines Gmbh | Method and device for the generative production of a component |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7906935B2 (en)* | 2007-06-06 | 2011-03-15 | Kissel Jr Waldemar F | Method and apparatus for charging electric devices |

- 2013

- 2013-07-09DEDE102013213370.7Apatent/DE102013213370A1/ennot_activeCeased

- 2014

- 2014-06-27EPEP14174634.7Apatent/EP2823917B1/ennot_activeNot-in-force

- 2014-07-08USUS14/325,458patent/US10427244B2/ennot_activeExpired - Fee Related

Patent Citations (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5684616A (en)* | 1988-04-18 | 1997-11-04 | Brotz; Gregory R. | Moving mirror apparatus |

| DE4002633A1 (en) | 1990-01-30 | 1991-08-01 | Schiebold Gerald | Virtual rotation-motion sensor for non-destructive material test - has field generating coils and sensor segments with successive electronic scanning |

| DE19835860C1 (en) | 1998-08-07 | 2000-04-20 | Siemens Ag | Circuit for device used for material investigation using eddy current |

| US20060244443A1 (en)* | 2005-01-28 | 2006-11-02 | Goldfine Neil J | Material condition assessment with eddy current sensors |

| US20070176312A1 (en)* | 2006-02-01 | 2007-08-02 | Daniel Clark | Method and apparatus for examination of objects and structures |

| US8034279B2 (en) | 2007-03-27 | 2011-10-11 | Eos Gmbh Electro Optical Systems | Method and device for manufacturing a three-dimensional object |

| DE102007014683A1 (en) | 2007-03-27 | 2008-10-09 | Eos Gmbh Electro Optical Systems | Method and device for producing a three-dimensional object |

| US20080241392A1 (en) | 2007-03-27 | 2008-10-02 | Eos Gmbh Electro Optical Systems | Method and Device for Manufacturing a Three-Dimensional Object |

| US20090091318A1 (en)* | 2007-09-11 | 2009-04-09 | Benoit Lepage | Phased scan eddy current array probe and a phased scanning method which provide complete and continuous coverage of a test surface without mechanical scanning |

| DE102010050531A1 (en) | 2010-09-08 | 2012-03-08 | Mtu Aero Engines Gmbh | Generatively producing portion of component, which is constructed from individual powder layers, comprises heating powder layer locally on melting temperature, forming molten bath, reheating zone downstream to the molten bath |

| US20130233846A1 (en) | 2010-09-08 | 2013-09-12 | Andreas Jakimov | Method and device for generatively producing at least one component area |

| DE102011008774A1 (en) | 2011-01-18 | 2012-07-19 | Mtu Aero Engines Gmbh | Method and device for testing the generative production of a component |

| DE102011009624A1 (en) | 2011-01-28 | 2012-08-02 | Mtu Aero Engines Gmbh | Method and device for process monitoring |

| US20130343947A1 (en) | 2011-01-28 | 2013-12-26 | MTU Aero Engines AG | Method and device for process monitoring |

| DE102011111818A1 (en) | 2011-08-27 | 2013-02-28 | Mtu Aero Engines Gmbh | Method and device for the generative production of a component |

| US20140159266A1 (en)* | 2011-08-27 | 2014-06-12 | MTU Aero Engines AG | Method and device for the generative production of a component |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2823917B1 (en) | 2019-01-16 |

| DE102013213370A1 (en) | 2015-01-15 |

| EP2823917A2 (en) | 2015-01-14 |

| EP2823917A3 (en) | 2015-09-16 |

| US20150017054A1 (en) | 2015-01-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10427244B2 (en) | Control in generative production | |

| US11648730B2 (en) | System and method for calibrating an acoustic monitoring system of an additive manufacturing machine | |

| CN105965015B (en) | Method and device for producing three-dimensional workpieces using thermal focus offset compensation | |

| US9839977B2 (en) | Apparatus for laser materials processing | |

| JP6961926B2 (en) | Acoustic monitoring methods for additive manufacturing processes | |

| US10201853B2 (en) | Multiple coil arrangement for a device for generative production of components and corresponding production method | |

| US11014164B2 (en) | Lamination molding apparatus and method for producing three-dimensional molded object | |

| US11975481B2 (en) | Adaptive closed-loop control of additive manufacturing for producing a workpiece | |

| JP7487102B2 (en) | DMLM Build Platform and Surface Planarization | |

| US10507525B2 (en) | Method and device for manufacturing at least a portion of a component | |

| US11638955B2 (en) | Applying electric pulses through a laser induced plasma channel for use in a 3-D metal printing process | |

| CN105555442A (en) | Device and method for additively producing at least one component region of a component | |

| US20190366480A1 (en) | Additive manufacturing with metal wire | |

| DE19953000A1 (en) | Rapid e.g. tool, prototype, mold and undercut section production by stereolithographic powder processing employs two beams for welding or sintering | |

| US20240033820A1 (en) | Method and System for Processing a Powder Material for Additive Production of a Workpiece | |

| Wagiman et al. | Effect of GMAW-CMT heat input on weld bead profile geometry for freeform fabrication of aluminium parts | |

| CN104900469A (en) | A real-time monitoring rapid prototyping manufacturing device based on electron beam and ion beam composite technology and a method for preparing parts using it | |

| RU2669953C1 (en) | Device for hybrid laser-acoustic creation of functional-gradient material | |

| JP7396613B2 (en) | Laminated manufacturing equipment, processing method for three-dimensional shaped objects, three-dimensional shaped objects and molds | |

| JP7041042B2 (en) | Method of laminating the hardened layer and method of manufacturing the laminated model | |

| US20220241861A1 (en) | Method for operating a device for additive manufacturing of a three-dimensional object | |

| CN112203858A (en) | Apparatus for heating a component material, additive manufacturing facility and method of additive manufacturing | |

| WO2022214637A1 (en) | Method and apparatus for additive manufacturing | |

| Rodrigues | Wire and arc additive manufacturing: equipment development and parts characterization | |

| EP4197686A1 (en) | Method of controlling performance of an apparatus |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| AS | Assignment | Owner name:MTU AERO ENGINES AG, GERMANY Free format text:ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNORS:JAKIMOV, ANDREAS;SCHLICK, GEORG;BAMBERG, JOACHIM;AND OTHERS;REEL/FRAME:033408/0487 Effective date:20140728 | |

| STCV | Information on status: appeal procedure | Free format text:NOTICE OF APPEAL FILED | |

| STCV | Information on status: appeal procedure | Free format text:APPEAL BRIEF (OR SUPPLEMENTAL BRIEF) ENTERED AND FORWARDED TO EXAMINER | |

| STPP | Information on status: patent application and granting procedure in general | Free format text:NOTICE OF ALLOWANCE MAILED -- APPLICATION RECEIVED IN OFFICE OF PUBLICATIONS | |

| STPP | Information on status: patent application and granting procedure in general | Free format text:PUBLICATIONS -- ISSUE FEE PAYMENT VERIFIED | |

| STCF | Information on status: patent grant | Free format text:PATENTED CASE | |

| FEPP | Fee payment procedure | Free format text:MAINTENANCE FEE REMINDER MAILED (ORIGINAL EVENT CODE: REM.); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY | |

| LAPS | Lapse for failure to pay maintenance fees | Free format text:PATENT EXPIRED FOR FAILURE TO PAY MAINTENANCE FEES (ORIGINAL EVENT CODE: EXP.); ENTITY STATUS OF PATENT OWNER: LARGE ENTITY | |

| STCH | Information on status: patent discontinuation | Free format text:PATENT EXPIRED DUE TO NONPAYMENT OF MAINTENANCE FEES UNDER 37 CFR 1.362 | |

| FP | Lapsed due to failure to pay maintenance fee | Effective date:20231001 |