TWI872340B - Liquid recycle assembly, single wafer processing equipment and control method thereof - Google Patents

Liquid recycle assembly, single wafer processing equipment and control method thereofDownload PDFInfo

- Publication number

- TWI872340B TWI872340BTW111120727ATW111120727ATWI872340BTW I872340 BTWI872340 BTW I872340BTW 111120727 ATW111120727 ATW 111120727ATW 111120727 ATW111120727 ATW 111120727ATW I872340 BTWI872340 BTW I872340B

- Authority

- TW

- Taiwan

- Prior art keywords

- ring

- lifting mechanism

- recovery

- distance

- door

- Prior art date

Links

- 239000007788liquidSubstances0.000titleclaimsabstractdescription133

- 238000000034methodMethods0.000titleclaimsabstractdescription95

- 230000007246mechanismEffects0.000claimsabstractdescription164

- 238000011084recoveryMethods0.000claimsdescription171

- 230000008569processEffects0.000claimsdescription71

- 239000000758substrateSubstances0.000claimsdescription65

- 230000001174ascending effectEffects0.000claimsdescription12

- 238000004064recyclingMethods0.000description16

- 238000010586diagramMethods0.000description6

- 101100233916Saccharomyces cerevisiae (strain ATCC 204508 / S288c) KAR5 geneProteins0.000description5

- 101001121408Homo sapiens L-amino-acid oxidaseProteins0.000description3

- 102100026388L-amino-acid oxidaseHuman genes0.000description3

- 101100012902Saccharomyces cerevisiae (strain ATCC 204508 / S288c) FIG2 geneProteins0.000description3

- 239000004065semiconductorSubstances0.000description3

- 238000004140cleaningMethods0.000description2

- 238000005530etchingMethods0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 230000000630rising effectEffects0.000description2

- 230000005540biological transmissionEffects0.000description1

- 238000011109contaminationMethods0.000description1

- 238000004519manufacturing processMethods0.000description1

Images

Landscapes

- Coating Apparatus (AREA)

- Cleaning Or Drying Semiconductors (AREA)

- Weting (AREA)

Abstract

Description

Translated fromChinese本揭示是關於一種濕處理設備,特別是關於一種液體回收組件、單晶圓處理設備及其控制方法。The present disclosure relates to a wet processing device, and more particularly to a liquid recovery component, a single wafer processing device and a control method thereof.

在半導體基板的製程中,需要對半導體基板的元件設置面進行多道處理步驟,包含蝕刻、清洗等濕式處理程序。隨著半導體基板的製程複雜度增加,現已發展出一種單晶圓處理設備,其包含旋轉台和回收環。單晶圓處理設備可對旋轉台上的基板施加製程液體,並且通過回收環收集該製程液體。In the process of manufacturing semiconductor substrates, it is necessary to perform multiple processing steps on the component setting surface of the semiconductor substrate, including wet processing procedures such as etching and cleaning. As the complexity of the process of semiconductor substrates increases, a single wafer processing equipment has been developed, which includes a turntable and a recovery ring. The single wafer processing equipment can apply a process liquid to the substrate on the turntable and collect the process liquid through the recovery ring.

在傳統的單晶圓處理設備中,回收環是採用單一昇降機構。然而,如果待處理基板不是平坦表面,而是具有複數晶片堆疊於晶圓表面的凸塊結構,此時當回收環的上升高度不足時,製程液體可能會噴濺超過回收環的高度,進而越過回收環而污染到周圍元件。另一方面,如果為了防止液體飛濺而增加回收環的高度差,當回收環下降到原點時,回收環容易與機械手臂互相干涉,進而導致機械手臂難以順利地夾取或放入晶圓。In traditional single-wafer processing equipment, the recycling ring uses a single lifting mechanism. However, if the substrate to be processed is not a flat surface, but a bump structure with multiple chips stacked on the wafer surface, when the lifting height of the recycling ring is insufficient, the process liquid may splash over the height of the recycling ring, and then cross the recycling ring and contaminate the surrounding components. On the other hand, if the height difference of the recycling ring is increased to prevent liquid splashing, when the recycling ring descends to the origin, the recycling ring is easy to interfere with the robot arm, making it difficult for the robot arm to smoothly clamp or put in the wafer.

有鑑於此,有必要提供一種單晶圓處理設備,以解決上述技術問題。In view of this, it is necessary to provide a single wafer processing equipment to solve the above technical problems.

為解決上述習知技術之問題,本申請之目的在於提供一種液體回收組件、單晶圓處理設備及其控制方法,其藉由在回收環上增設一個門環,防止了液體飛濺越過回收環上方而污染周圍元件。In order to solve the above-mentioned problems of the prior art, the purpose of this application is to provide a liquid recovery component, a single wafer processing equipment and a control method thereof, which prevents liquid splashing over the recovery ring and contaminating surrounding components by adding a door ring to the recovery ring.

為達成上述目的,本申請提供一種液體回收組件,包括:一承載台;一回收環,與該承載台間隔設置;一第一昇降機構,連接該承載台和該回收環,其中該回收環藉由該第一昇降機構沿著一垂直方向與該承載台相對地移動;一門環,設置在該回收環遠離該承載台之一側;以及一第二昇降機構,連接該門環和該回收環,其中該門環藉由該第二昇降機構沿著該垂直方向與該回收環相對地移動。To achieve the above-mentioned purpose, the present application provides a liquid recovery assembly, comprising: a supporting platform; a recovery ring, spaced apart from the supporting platform; a first lifting mechanism, connecting the supporting platform and the recovery ring, wherein the recovery ring moves relative to the supporting platform along a vertical direction by the first lifting mechanism; a door ring, arranged on a side of the recovery ring away from the supporting platform; and a second lifting mechanism, connecting the door ring and the recovery ring, wherein the door ring moves relative to the recovery ring along the vertical direction by the second lifting mechanism.

在一些實施例中,該第一昇降機構包括第一起始態和第一上昇態,當該第一昇降機構處於該第一起始態時,該回收環與該承載台相隔第一距離,以及當該第一昇降機構處於該第一上昇態時,該回收環與該承載台相隔第二距離,其中該第二距離大於該第一距離。In some embodiments, the first lifting mechanism includes a first starting state and a first ascending state. When the first lifting mechanism is in the first starting state, the recovery ring is separated from the supporting platform by a first distance, and when the first lifting mechanism is in the first ascending state, the recovery ring is separated from the supporting platform by a second distance, wherein the second distance is greater than the first distance.

在一些實施例中,該第二昇降機構包括第二起始態和第二上昇態,當該第二昇降機構處於該第二起始態時,該門環與該回收環相隔第三距離,以及當該第二昇降機構處於該第二上昇態時,該門環與該回收環相隔第四距離,其中該第四距離大於該第三距離。In some embodiments, the second lifting mechanism includes a second starting state and a second ascending state, when the second lifting mechanism is in the second starting state, the door ring is separated from the recovery ring by a third distance, and when the second lifting mechanism is in the second ascending state, the door ring is separated from the recovery ring by a fourth distance, wherein the fourth distance is greater than the third distance.

在一些實施例中,當該第一昇降機構處於該第一起始態和該第二昇降機構處於該第二起始態時,該門環與該承載台的距離為該第一距離和該第三距離的和,以及當該第一昇降機構處於該第一上昇態和該第二昇降機構處於該第二上昇態時,該門環與該承載台的距離為該第二距離和該第四距離的和。In some embodiments, when the first lifting mechanism is in the first starting state and the second lifting mechanism is in the second starting state, the distance between the door ring and the supporting platform is the sum of the first distance and the third distance, and when the first lifting mechanism is in the first upward lifting state and the second lifting mechanism is in the second upward lifting state, the distance between the door ring and the supporting platform is the sum of the second distance and the fourth distance.

本申請還提供一種單晶圓處理設備,包括:一旋轉台,配置為放置一基板;一液體供應裝置,設置在該旋轉台上方,且配置為對該基板施加一製程液體;以及一液體回收組件,環繞地設置在該旋轉台的周圍,並且可沿著一垂直方向相對該旋轉台移動。該液體回收組件包括:一承載台;一回收環,與該承載台間隔設置,並且配置為收集從該基板飛濺出的該製程液體;一第一昇降機構,連接該承載台和該回收環,其中該回收環藉由該第一昇降機構沿著該垂直方向與該承載台相對地移動;一門環,設置在該回收環遠離該承載台之一側,並且配置為收集部分越過該回收環而噴濺至該回收環外部的該製程液體;以及一第二昇降機構,連接該門環和該回收環,其中該門環藉由該第二昇降機構沿著該垂直方向與該回收環相對地移動。The present application also provides a single wafer processing equipment, including: a turntable configured to place a substrate; a liquid supply device disposed above the turntable and configured to apply a process liquid to the substrate; and a liquid recovery assembly disposed around the turntable and movable relative to the turntable in a vertical direction. The liquid recovery assembly includes: a supporting platform; a recovery ring, which is spaced apart from the supporting platform and configured to collect the process liquid splashed from the substrate; a first lifting mechanism, which connects the supporting platform and the recovery ring, wherein the recovery ring moves relative to the supporting platform along the vertical direction by the first lifting mechanism; a door ring, which is arranged on a side of the recovery ring away from the supporting platform and configured to collect part of the process liquid that splashes over the recovery ring to the outside of the recovery ring; and a second lifting mechanism, which connects the door ring and the recovery ring, wherein the door ring moves relative to the recovery ring along the vertical direction by the second lifting mechanism.

在一些實施例中,當取放該基板時,該回收環和該門環的水平高度低於該旋轉台的水平高度,以及當該旋轉台旋轉時,該回收環和該門環的水平高度高於該旋轉台的水平高度。In some embodiments, when the substrate is placed or retrieved, the levels of the recycling ring and the door ring are lower than the level of the turntable, and when the turntable rotates, the levels of the recycling ring and the door ring are higher than the level of the turntable.

在一些實施例中,該單晶圓處理設備還包含第一排放管和第二排放管,其中該第一排放管與該回收環的內部空間連通並且配置為排放該回收環收集的該製程液體,以及該第二排放管與該門環的內部空間連通並且配置為排放該門環收集的該部分的該製程液體。In some embodiments, the single wafer processing equipment further includes a first drain pipe and a second drain pipe, wherein the first drain pipe is connected to the internal space of the recovery ring and is configured to discharge the process liquid collected by the recovery ring, and the second drain pipe is connected to the internal space of the door ring and is configured to discharge the portion of the process liquid collected by the door ring.

在一些實施例中,該第一昇降機構包括第一起始態和第一上昇態,當該第一昇降機構處於該第一起始態時,該回收環與該承載台相隔第一距離,以及當該第一昇降機構處於該第一上昇態時,該回收環與該承載台相隔第二距離,其中該第二距離大於該第一距離。In some embodiments, the first lifting mechanism includes a first starting state and a first ascending state. When the first lifting mechanism is in the first starting state, the recovery ring is separated from the supporting platform by a first distance, and when the first lifting mechanism is in the first ascending state, the recovery ring is separated from the supporting platform by a second distance, wherein the second distance is greater than the first distance.

在一些實施例中,該第二昇降機構包括第二起始態和第二上昇態,當該第二昇降機構處於該第二起始態時,該門環與該回收環相隔第三距離,以及當該第二昇降機構處於該第二上昇態時,該門環與該回收環相隔第四距離,其中該第四距離大於該第三距離。In some embodiments, the second lifting mechanism includes a second starting state and a second ascending state, when the second lifting mechanism is in the second starting state, the door ring is separated from the recovery ring by a third distance, and when the second lifting mechanism is in the second ascending state, the door ring is separated from the recovery ring by a fourth distance, wherein the fourth distance is greater than the third distance.

在一些實施例中,當該第一昇降機構處於該第一起始態和該第二昇降機構處於該第二起始態時,該門環與該承載台的距離為該第一距離和該第三距離的和,以及當該第一昇降機構處於該第一上昇態和該第二昇降機構處於該第二上昇態時,該門環與該承載台的距離為該第二距離和該第四距離的和。In some embodiments, when the first lifting mechanism is in the first starting state and the second lifting mechanism is in the second starting state, the distance between the door ring and the supporting platform is the sum of the first distance and the third distance, and when the first lifting mechanism is in the first upward lifting state and the second lifting mechanism is in the second upward lifting state, the distance between the door ring and the supporting platform is the sum of the second distance and the fourth distance.

在一些實施例中,當取放該基板時,該第一昇降機構處於該第一起始態和該第二昇降機構處於該第二起始態,以及當該旋轉台旋轉時,該第一昇降機構處於該第一上昇態和該第二昇降機構處於該第二上昇態。In some embodiments, when the substrate is placed or picked up, the first lifting mechanism is in the first starting state and the second lifting mechanism is in the second starting state, and when the turntable rotates, the first lifting mechanism is in the first upward lifting state and the second lifting mechanism is in the second upward lifting state.

本申請還提供一種單晶圓處理設備的控制方法,其中該單晶圓處理設備包括一旋轉台、一液體供應裝置、一承載台、一回收環、一第一昇降機構、一門環和一第二昇降機構,以及該控制方法包括:在該旋轉台上放置一基板;藉由該第一昇降機構控制該回收環同步帶動該門環一起沿著一垂直方向朝遠離該承載台的方向移動;藉由該第二昇降機構控制該門環沿著該垂直方向朝遠離該回收環的方向移動;以及控制該旋轉台旋轉以及控制該液體供應裝置對該基板施加一製程液體,其中該回收環配置為收集從該基板飛濺出的該製程液體,以及該門環配置為收集部分越過該回收環而噴濺至該回收環外部的該製程液體。The present application also provides a control method for a single wafer processing device, wherein the single wafer processing device includes a rotating table, a liquid supply device, a carrier table, a recycling ring, a first lifting mechanism, a door ring and a second lifting mechanism, and the control method includes: placing a substrate on the rotating table; controlling the recycling ring by the first lifting mechanism to synchronously drive the door ring along a vertical direction away from the carrier table; The invention relates to a process liquid supply device, wherein the rotary table is controlled to rotate and the liquid supply device is controlled to apply a process liquid to the substrate, wherein the recovery ring is configured to collect the process liquid splashed from the substrate, and the door ring is configured to collect part of the process liquid that passes over the recovery ring and splashes to the outside of the recovery ring.

在一些實施例中,該第一昇降機構包括第一起始態和第一上昇態並且該第二昇降機構包括第二起始態和第二上昇態,以及在該旋轉台上放置該基板之前,該控制方法還包括:控制該第一昇降機構處於該第一起始態以及控制該第二昇降機構處於該第二起始態,使得該回收環和該門環的水平高度低於該旋轉台的水平高度。In some embodiments, the first lifting mechanism includes a first starting state and a first upward lifting state and the second lifting mechanism includes a second starting state and a second upward lifting state, and before placing the substrate on the turntable, the control method further includes: controlling the first lifting mechanism to be in the first starting state and controlling the second lifting mechanism to be in the second starting state, so that the horizontal heights of the recovery ring and the door ring are lower than the horizontal height of the turntable.

在一些實施例中,在控制該旋轉台旋轉以及控制該液體供應裝置對該基板施加該製程液體之前,該控制方法還包括:控制該第一昇降機構處於該第一上昇態以及控制該第二昇降機構處於該第二上昇態,使得該回收環和該門環的水平高度高於該旋轉台的水平高度。In some embodiments, before controlling the turntable to rotate and controlling the liquid supply device to apply the process liquid to the substrate, the control method further includes: controlling the first lifting mechanism to be in the first upward state and controlling the second lifting mechanism to be in the second upward state, so that the horizontal heights of the recovery ring and the door ring are higher than the horizontal height of the turntable.

在一些實施例中,控制該旋轉台旋轉以及控制該液體供應裝置對該基板施加該製程液體之後,該控制方法還包括:控制該旋轉台停止旋轉以及控制該液體供應裝置停止對該基板施加該製程液體;藉由該第二昇降機構控制該門環沿著該垂直方向朝靠近該回收環的方向移動;藉由該第一昇降機構控制該回收環同步帶動該門環一起沿著該垂直方向朝靠近該承載台的方向移動;以及從該旋轉台取走該基板。In some embodiments, after controlling the turntable to rotate and controlling the liquid supply device to apply the process liquid to the substrate, the control method further includes: controlling the turntable to stop rotating and controlling the liquid supply device to stop applying the process liquid to the substrate; controlling the door ring to move along the vertical direction toward the recovery ring by the second lifting mechanism; controlling the recovery ring to synchronously drive the door ring to move along the vertical direction toward the supporting platform by the first lifting mechanism; and removing the substrate from the turntable.

在一些實施例中,該單晶圓處理設備還包含第一排放管和第二排放管,該控制方法還包括:當控制該旋轉台旋轉以及控制該液體供應裝置對該基板施加該製程液體時,藉由該第一排放管排放該回收環收集的該製程液體,以及藉由該第二排放管排放該門環收集的該部分的該製程液體。In some embodiments, the single wafer processing equipment further includes a first drain pipe and a second drain pipe, and the control method further includes: when controlling the rotation of the turntable and controlling the liquid supply device to apply the process liquid to the substrate, the process liquid collected by the recovery ring is discharged through the first drain pipe, and the portion of the process liquid collected by the door ring is discharged through the second drain pipe.

相較於先前技術,本申請之單晶圓處理設備藉由在回收環上增設門環,並且藉由兩個昇降機構以兩階段的方式將回收環和門環進行昇降,進而提高液體回收組件的整體高度差,防止藥水飛濺越過回收環上方而污染設備。Compared to the prior art, the single wafer processing equipment of the present application increases the overall height difference of the liquid recovery assembly by adding a door ring to the recovery ring and raising and lowering the recovery ring and the door ring in two stages by two lifting mechanisms, thereby preventing the liquid from splashing over the recovery ring and contaminating the equipment.

爲了讓本申請之上述及其他目的、特徵、優點能更明顯易懂,下文將特舉本申請較佳實施例,並配合所附圖式,作詳細說明如下。In order to make the above and other purposes, features, and advantages of this application more clearly understood, the following will specifically cite the preferred embodiments of this application and provide a detailed description in conjunction with the attached drawings as follows.

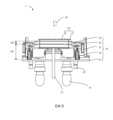

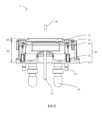

請參照圖1至圖3,圖1顯示本申請之實施例之單晶圓處理設備之第一示意圖,圖2顯示本申請之實施例之單晶圓處理設備之第二示意圖,以及圖3顯示本申請之實施例之單晶圓處理設備之第三示意圖。單晶圓處理設備1包括旋轉台10、液體供應裝置20以及液體回收組件30。旋轉台10配置為放置一基板50。在本申請中,單晶圓處理設備1適用於對單晶圓進行濕處理,尤其是對表面具有凸塊結構的單晶圓進行濕處理。舉例來說,基板50包含鍵合的3D-IC晶片52與晶圓51(Chip on Wafer),因此基板50的待處理表面具有多個以3D-IC晶片52形成的凸塊結構。在對基板50進行濕製程時,表面的凸塊結構會加重製程液體的飛濺程度。本申請的單晶圓處理設備1可確實地回收飛濺的製程液體以避免製程液體噴濺到周圍設備,具體說明如下。Please refer to Figures 1 to 3, Figure 1 shows a first schematic diagram of a single wafer processing equipment of an embodiment of the present application, Figure 2 shows a second schematic diagram of a single wafer processing equipment of an embodiment of the present application, and Figure 3 shows a third schematic diagram of a single wafer processing equipment of an embodiment of the present application. The single

如圖1所示,在本實施例中,當基板50放置在旋轉台10上之後,基板50可被進一步固定在旋轉台10上,例如採用真空吸盤或夾持裝置等方式進行固定。旋轉台10配置有驅動機構,用於驅使旋轉台10繞軸旋轉。再者,液體供應裝置20設置在旋轉台10上方,用於對基板50施加製程液體。可選地,液體供應裝置20的藥液供應旋轉懸臂可包含有一個或複數個噴嘴,使得液體供應裝置20可對基板50施加一種或多種製程液體。噴嘴設置爲與旋轉台10的頂部對準,以及液體傳輸管線的一端與對應的噴嘴連接,另一端連接至對應的製程液體的供應端。藉此設計,可根據製程需求來控制液體供應裝置20施加對應的製程液體至旋轉台10上的基板50,以對基板50進行蝕刻或清洗等作業。As shown in FIG. 1 , in this embodiment, after the

如圖1至圖3所示,液體回收組件30環繞地設置在旋轉台10的周圍,並且可沿著一垂直方向相對旋轉台10移動。液體回收組件30用於收集從旋轉台10上的基板50的表面因離心力甩出的製程液體,並且將該製程液體排出。液體回收組件30包括承載台31、回收環32、門環33、第一昇降機構34以及第二昇降機構35。如圖3所示,回收環32與承載台31間隔設置,並且配置為收集大部分的從基板50飛濺出的製程液體21。門環33設置在回收環32環遠離承載台31之一側,並且配置為收集其餘部分越過回收環32而噴濺至回收環32外部的製程液體22。在本實施例中,回收環32的頂部包含朝中心傾斜的遮擋壁,以及門環33的頂部也包含朝中心傾斜的遮擋壁。藉由遮擋壁的設計,可有效地將飛濺的液體檔下,並且驅使液體沿著傾斜的遮擋壁向下流動。As shown in FIGS. 1 to 3 , the

如圖1至圖3所示,第一昇降機構34包括第一起始態和第一上昇態,以及第二昇降機構35包括第二起始態和第二上昇態。第一昇降機構34連接承載台31和回收環32。回收環32藉由第一昇降機構34沿著垂直方向與承載台31相對地移動。第二昇降機構35連接門環33和回收環32。門環33藉由第二昇降機構35沿著垂直方向與回收環32相對地移動。應當注意的是,當第一昇降機構34昇降時,回收環32會同步帶動門環33一起運動。As shown in FIGS. 1 to 3 , the

如圖1所示,當第一昇降機構34處於第一起始態時,回收環32與承載台31相隔第一距離D1。如圖2和圖3所示,當第一昇降機構34處於第一上昇態時,回收環32與承載台31相隔第二距離D2。第二距離D2大於第一距離D1。在一些實施例中,第二距離D2與第一距離D1的差值為60 mm。As shown in FIG1 , when the

如圖1和圖2所示,當第二昇降機構35處於第二起始態時,門環33與回收環32相隔第三距離D3。如圖3所示,當第二昇降機構35處於第二上昇態時,門環33與回收環32相隔第四距離D4。第四距離D4大於第三距離D3。在一些實施例中,第四距離D4與第三距離D3的差值為30 mm。As shown in FIGS. 1 and 2 , when the

如圖1所示,當第一昇降機構34處於第一起始態和第二昇降機構35處於第二起始態時時,門環33與承載台31的距離為第一距離D1和第三距離D3的和。如圖3所示,當第一昇降機構34處於第一上昇態和第二昇降機構35處於第二上昇態時,門環33與承載台31的距離為第二距離D2和第四距離D4的和。As shown in Fig. 1, when the

如圖1所示,當從旋轉台10取放基板50時,第一昇降機構34處於第一起始態以及第二昇降機構35處於第二起始態。此時,門環33與回收環32的水平高度皆低於旋轉台10的用於放置基板50的台面。應當注意的是,當門環33與回收環32下降至最低點時(即,第一昇降機構34處於第一起始態和第二昇降機構35處於第二起始態),機械手臂能順利夾取或放入基板50,不會受到門環33和回收環32阻擋。也就是說,機械手臂在橫移時不會與液體回收組件30產生結構上的干涉。As shown in FIG1 , when the

如圖2所示,當待處理的基板50放置在旋轉台10上時,第一昇降機構34開始上升,使得第一昇降機構34處於第一上昇態以及第二昇降機構35處於第二起始態。此時,門環33與回收環32的水平高度皆高於旋轉台10的台面。As shown in FIG2 , when the

如圖3所示,當第一昇降機構34上升之後,第二昇降機構35開始上升,使得第一昇降機構34處於第一上昇態以及第二昇降機構35處於第二上昇態時。此時,門環33與回收環32的水平高度也皆高於旋轉台10的台面。再者,當第二昇降機構35上升時,回收環32與旋轉台10的距離不變,而門環33相較於回收環32進一步增加與旋轉台10之間的距離。藉由門環33的高度提升,可提高液體回收組件30的整體高度差(即門環33與回收環32的高度差),確保了飛濺越過回收環32上方的製程液體22可被門環33收集而不會造成周圍設備的污染。一般而言,現有的單晶圓處理設備僅包含單一昇降機構和回收環。當回收環的上升高度不足時,液體容易噴濺超過回收環的高度,進而從回收環上方飛濺而污染周圍設備。相較於現有的單晶圓處理設備,本申請的單晶圓處理設備可確保飛濺越過回收環32上方的製程液體22可被門環33收集而不會造成周圍設備的污染。As shown in FIG3 , after the

在本實施例中,如圖3所示,當第一昇降機構34和第二昇降機構35皆上升後,旋轉台10開始旋轉以及液體供應裝置20開始對基板50施加製程液體。也就是說,當旋轉台10旋轉時,第一昇降機構34處於第一上昇態和第二昇降機構35處於第二上昇態。In this embodiment, as shown in FIG3 , after the

如圖1至圖3所示,單晶圓處理設備1還包含第一排放管41和第二排放管42。第一排放管41與回收環32的內部空間連通並且配置為排放回收環32收集的製程液體。第二排放管42與門環33的內部空間連通並且配置為排放門環33收集的部分的製程液體。液體供應裝置20所噴灑之製程液體被回收環32和門環33檔下後,製程液體直接沿著回收環32和門環33的內部往下方流動並且收集至腔體空間的底部,接著分別由連接至各別腔體空間的底部的第一排放管41和第二排放管42排出或回收。As shown in FIGS. 1 to 3 , the single

本申請的實施例還提供一種單晶圓處理設備的控制方法。本實施例的單晶圓處理設備包含上述的單晶圓處理設備1。單晶圓處理設備1包括旋轉台10、液體供應裝置20、承載台31、回收環32、門環33、第一昇降機構34和第二昇降機構35,該些元件的具體結構如上所述,在此不加以贅述。本申請的單晶圓處理設備的控制方法包括以下步驟。The embodiment of the present application also provides a control method for a single wafer processing device. The single wafer processing device of the present embodiment includes the above-mentioned single

首先,如圖1所示,在旋轉台10上放置基板50。在本實施例中,第一昇降機構34包括第一起始態和第一上昇態,以及第二昇降機構35包括第二起始態和第二上昇態。當從旋轉台10取放基板50之前,控制第一昇降機構34處於第一起始態以及控制第二昇降機構35處於該第二起始態。此時,門環33與回收環32的水平高度皆低於旋轉台10的用於放置基板50的台面(即,旋轉台10的水平高度)。應當注意的是,當門環33與回收環32下降至最低點時,第一昇降機構34處於第一起始態和第二昇降機構35處於第二起始態。因此,機械手臂能順利夾取或放入基板50,不會受到門環33和回收環32阻擋。也就是說,機械手臂在橫移時不會與液體回收組件30產生結構上的干涉。First, as shown in FIG. 1 , a

如圖2所示,將基板50固定在旋轉台10上之後,藉由第一昇降機構34控制回收環32同步帶動該門環一起沿著垂直方向朝遠離承載台31的方向移動。在此步驟中,第一昇降機構34開始上升,使得第一昇降機構34處於第一上昇態以及第二昇降機構35處於第二起始態。此時,門環33與回收環32的水平高度皆高於旋轉台10的台面。As shown in FIG. 2 , after the

如圖3所示,當第一昇降機構34上升之後,藉由第二昇降機構35控制門環33沿著該垂直方向朝遠離回收環32方向移動。在此步驟中,第二昇降機構35開始上升,使得第一昇降機構34處於第一上昇態以及第二昇降機構35處於第二上昇態時。此時,門環33與回收環32的水平高度也皆高於旋轉台10的台面。再者,當第二昇降機構35上升時,回收環32與旋轉台10的距離不變,而門環33相較於回收環32進一步增加與旋轉台10之間的距離。As shown in FIG3 , after the

如圖3所示,當第一昇降機構34和第二昇降機構35皆上升後,控制旋轉台10旋轉以及控制液體供應裝置20對基板50施加製程液體。也就是說,在控制旋轉台10旋轉以及控制液體供應裝置20對基板50施加製程液體之前,控制第一昇降機構34處於第一上昇態以及控制第二昇降機構35處於第二上昇態,使得回收環32和門環33沿的水平高度高於旋轉台10的水平高度。當旋轉台10旋轉時,回收環32配置為收集大部分的從基板50飛濺出的製程液體21。門環33配置為收集其餘部分越過回收環32而噴濺至回收環32外部的製程液體22。在此步驟中,由於門環33的高度進一步提升,提高了液體回收組件30的整體高度差(即門環33與回收環32的高度差),進而確保飛濺越過回收環32上方的製程液體22可被門環33收集而不會造成周圍設備的污染。一般而言,現有的單晶圓處理設備僅包含單一昇降機構和回收環。當回收環的上升高度不足時,液體容易噴濺超過回收環的高度,進而從回收環上方飛濺而污染周圍設備。相較於現有的單晶圓處理設備,本申請的單晶圓處理設備可確保飛濺越過回收環32上方的製程液體22可被門環33收集而不會造成周圍設備的污染。As shown in FIG3 , after the

如圖1至圖3所示,單晶圓處理設備1還包含第一排放管41和第二排放管42。第一排放管41與回收環32的內部空間連通並且配置為排放回收環32收集的製程液體。第二排放管42與門環33的內部空間連通並且配置為排放門環33收集的部分的製程液體。也就是說,當控制旋轉台10旋轉以及控制液體供應裝置20對基板50施加製程液體時,藉由第一排放管排41放回收環32收集的製程液體,以及藉由第二排放管42排放門環33收集的部分的製程液體。液體供應裝置20所噴灑之製程液體被回收環32和門環33檔下後,製程液體直接沿著回收環32和門環33的內部往下方流動並且收集至腔體空間的底部,接著分別由連接至各別腔體空間的底部的第一排放管41和第二排放管42排出或回收。As shown in FIGS. 1 to 3 , the single

當對基板50濕處理完畢之後,控制旋轉台10停止旋轉以及控制液體供應裝置20停止對基板50施加製程液體。接著,如圖2所示,藉由第二昇降機構35控制門環33沿著垂直方向朝靠近回收環32的方向移動。接著,如圖1所示,藉由第一昇降機構34控制回收環32同步帶動門環33一起沿著垂直方向朝靠近承載台31的方向移動。最後,藉由機械手臂從旋轉台10取走基板50。After the wet treatment of the

相較於現有技術,在本申請的液體回收組件、單晶圓處理設備及其控制方法中,藉由兩個昇降機構以兩階段的方式將回收環和門環進行昇降。當回收環和門環上升時,提高了液體回收組件的整體高度差確保了飛濺越過回收環上方的製程液體可被門環收集而不會造成周圍設備的污染。當回收環和門環下降時,機械手臂能順利夾取或放入基板,不會受到門環和回收環阻擋。Compared to the prior art, in the liquid recovery assembly, single wafer processing equipment and control method thereof of the present application, the recovery ring and the door ring are raised and lowered in two stages by two lifting mechanisms. When the recovery ring and the door ring are raised, the overall height difference of the liquid recovery assembly is increased to ensure that the process liquid splashing over the recovery ring can be collected by the door ring without causing contamination of surrounding equipment. When the recovery ring and the door ring are lowered, the robot arm can smoothly clamp or place the substrate without being blocked by the door ring and the recovery ring.

以上僅是本揭示的較佳實施方式,應當指出,對於所屬領域技術人員,在不脫離本揭示原理的前提下,還可以做出若干改進和潤飾,這些改進和潤飾也應視爲本揭示的保護範圍。The above is only the preferred implementation of the present disclosure. It should be pointed out that technical personnel in the relevant field can make several improvements and modifications without departing from the principles of the present disclosure. These improvements and modifications should also be regarded as the protection scope of the present disclosure.

1:單晶圓處理設備 10:旋轉台 20:液體供應裝置 21、22:製程液體 30:液體回收組件 31:承載台 32:回收環 33:門環 34:第一昇降機構 35:第二昇降機構 41:第一排放管 42:第二排放管 50:基板 51:晶圓 52:晶片 D1:第一距離 D2:第二距離 D3:第三距離 D4:第四距離1: Single wafer processing equipment10: Rotating table20:

圖1顯示本申請之實施例之單晶圓處理設備之第一示意圖; 圖2顯示本申請之實施例之單晶圓處理設備之第二示意圖; 圖3顯示本申請之實施例之單晶圓處理設備之第三示意圖。FIG. 1 shows a first schematic diagram of a single wafer processing device according to an embodiment of the present application;FIG. 2 shows a second schematic diagram of a single wafer processing device according to an embodiment of the present application;FIG. 3 shows a third schematic diagram of a single wafer processing device according to an embodiment of the present application.

1:單晶圓處理設備1: Single wafer processing equipment

10:旋轉台10: Rotating table

20:液體供應裝置20: Liquid supply device

30:液體回收組件30: Liquid recovery components

31:承載台31: Carrier platform

32:回收環32: Recycling Ring

33:門環33: Door knocker

34:第一昇降機構34: The first lifting mechanism

35:第二昇降機構35: Second lifting mechanism

41:第一排放管41: First discharge pipe

42:第二排放管42: Second discharge pipe

50:基板50: Substrate

51:晶圓51: Wafer

52:晶片52: Chip

D1:第一距離D1: First distance

D3:第三距離D3: The third distance

Claims (16)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| TW111120727ATWI872340B (en) | 2022-06-02 | 2022-06-02 | Liquid recycle assembly, single wafer processing equipment and control method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| TW111120727ATWI872340B (en) | 2022-06-02 | 2022-06-02 | Liquid recycle assembly, single wafer processing equipment and control method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| TW202349474A TW202349474A (en) | 2023-12-16 |

| TWI872340Btrue TWI872340B (en) | 2025-02-11 |

Family

ID=90039212

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| TW111120727ATWI872340B (en) | 2022-06-02 | 2022-06-02 | Liquid recycle assembly, single wafer processing equipment and control method thereof |

Country Status (1)

| Country | Link |

|---|---|

| TW (1) | TWI872340B (en) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107871686A (en)* | 2016-09-26 | 2018-04-03 | 株式会社斯库林集团 | Substrate processing method using same and substrate board treatment |

| TW201824444A (en)* | 2016-12-15 | 2018-07-01 | 辛耘企業股份有限公司 | Substrate processing device |

| CN112655074A (en)* | 2018-09-10 | 2021-04-13 | 东京毅力科创株式会社 | Coating film forming method and coating film forming apparatus |

| TW202216271A (en)* | 2020-10-20 | 2022-05-01 | 凱爾迪科技股份有限公司 | Device for gas-liquid separation and layered independent recovery Capable of effectively reducing the burden of subsequent processing and avoiding the generation of toxic substances or further caused pollution |

- 2022

- 2022-06-02TWTW111120727Apatent/TWI872340B/enactive

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107871686A (en)* | 2016-09-26 | 2018-04-03 | 株式会社斯库林集团 | Substrate processing method using same and substrate board treatment |

| TW201824444A (en)* | 2016-12-15 | 2018-07-01 | 辛耘企業股份有限公司 | Substrate processing device |

| CN112655074A (en)* | 2018-09-10 | 2021-04-13 | 东京毅力科创株式会社 | Coating film forming method and coating film forming apparatus |

| TW202216271A (en)* | 2020-10-20 | 2022-05-01 | 凱爾迪科技股份有限公司 | Device for gas-liquid separation and layered independent recovery Capable of effectively reducing the burden of subsequent processing and avoiding the generation of toxic substances or further caused pollution |

Also Published As

| Publication number | Publication date |

|---|---|

| TW202349474A (en) | 2023-12-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5677000A (en) | Substrate spin treating method and apparatus | |

| CN1246092C (en) | Solution processing unit and method | |

| JP5420222B2 (en) | Substrate processing equipment | |

| TW201312678A (en) | Liquid treatment device, liquid treatment method, and computer readable memory medium stored with program | |

| CN105319871B (en) | Developing device and method for semiconductor substrate | |

| KR20130103378A (en) | Liquid processing apparatus | |

| CN109545703B (en) | Substrate processing apparatus and substrate processing method | |

| CN217426691U (en) | Liquid recovery module and single wafer processing apparatus | |

| JP3837017B2 (en) | Substrate processing apparatus, substrate processing method, and substrate processing apparatus cleaning method | |

| US20250058363A1 (en) | Wafer processing method | |

| TWI872340B (en) | Liquid recycle assembly, single wafer processing equipment and control method thereof | |

| TWI861585B (en) | Single wafer spin cleaner with soaking, cleaning, and etching functions | |

| CN118848714A (en) | Epitaxial wafer back side flatness processing device and processing method | |

| JP2009158564A (en) | Substrate treatment apparatus and substrate treatment method | |

| TWM632763U (en) | Liquid recycle assembly and single wafer processing equipment | |

| CN117219533A (en) | Liquid recovery assembly, single wafer processing apparatus and control method thereof | |

| JP2010177372A (en) | Substrate treatment device | |

| JP4093878B2 (en) | Multistage processing equipment | |

| JP6236328B2 (en) | Substrate processing equipment | |

| CN119609901B (en) | Anti-drip lifting mechanism, chemical mechanical polishing unit and chemical mechanical polishing equipment | |

| JP4504859B2 (en) | Substrate processing equipment | |

| CN218887160U (en) | Single-wafer rotary cleaning equipment with soaking, cleaning and etching functions | |

| TWI711491B (en) | Substrate wet processing apparatus and recycle ring | |

| KR101485579B1 (en) | Apparatus to clean substrate | |

| JPH1012540A (en) | Treating apparatus |