TWI730974B - Medicine dispensing device - Google Patents

Medicine dispensing deviceDownload PDFInfo

- Publication number

- TWI730974B TWI730974BTW105124961ATW105124961ATWI730974BTW I730974 BTWI730974 BTW I730974BTW 105124961 ATW105124961 ATW 105124961ATW 105124961 ATW105124961 ATW 105124961ATW I730974 BTWI730974 BTW I730974B

- Authority

- TW

- Taiwan

- Prior art keywords

- container

- medicine

- powder

- moving device

- medicine container

- Prior art date

Links

Images

Classifications

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61J—CONTAINERS SPECIALLY ADAPTED FOR MEDICAL OR PHARMACEUTICAL PURPOSES; DEVICES OR METHODS SPECIALLY ADAPTED FOR BRINGING PHARMACEUTICAL PRODUCTS INTO PARTICULAR PHYSICAL OR ADMINISTERING FORMS; DEVICES FOR ADMINISTERING FOOD OR MEDICINES ORALLY; BABY COMFORTERS; DEVICES FOR RECEIVING SPITTLE

- A61J3/00—Devices or methods specially adapted for bringing pharmaceutical products into particular physical or administering forms

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B1/00—Packaging fluent solid material, e.g. powders, granular or loose fibrous material, loose masses of small articles, in individual containers or receptacles, e.g. bags, sacks, boxes, cartons, cans, or jars

- B65B1/04—Methods of, or means for, filling the material into the containers or receptacles

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B1/00—Packaging fluent solid material, e.g. powders, granular or loose fibrous material, loose masses of small articles, in individual containers or receptacles, e.g. bags, sacks, boxes, cartons, cans, or jars

- B65B1/30—Devices or methods for controlling or determining the quantity or quality or the material fed or filled

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B35/00—Supplying, feeding, arranging or orientating articles to be packaged

- B65B35/30—Arranging and feeding articles in groups

- B65B35/34—Arranging and feeding articles in groups by agitators or vibrators

Landscapes

- Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Mechanical Engineering (AREA)

- Pharmacology & Pharmacy (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Medicinal Chemistry (AREA)

- Quality & Reliability (AREA)

- Chemical & Material Sciences (AREA)

- Medical Preparation Storing Or Oral Administration Devices (AREA)

- Basic Packing Technique (AREA)

- Supply Of Fluid Materials To The Packaging Location (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese本發明係有關於藥劑配發裝置,特別是有關於將散劑按照一次服用量一包一包分別進行包裝並配發之藥劑配發裝置。The present invention relates to a medicament dispensing device, in particular to a medicament dispensing device in which powders are packaged and dispensed according to the dosage of one package per package.

近年來,於大醫院或大規模藥店中引進了散劑分包裝置或具有散劑分包功能之藥劑配發裝置。於此,所謂“散劑分包裝置”,係指根據處方資訊將散劑按照一次服用量一包一包分別進行包裝之裝置。在使用散劑分包裝置之情況下,能夠自動化地進行將散劑按照一次服用量一包一包分別進行包裝之作業中的大半作業。In recent years, large hospitals or large-scale pharmacies have introduced powder sub-packaging devices or pharmaceutical dispensing devices with powder sub-packaging functions. Here, the so-called "powder sub-packaging device" refers to a device that separately packs powders according to the prescription information, one package per package at a time. In the case of using the powder packaging device, it is possible to automatically perform most of the operations of packaging the powders according to the amount of one package per package.

先前之藥劑配發裝置例如如專利文獻1所揭示,係由將散劑按照一次服用量一包一包分別進行分配之散劑分配部與將分配好之散劑分別進行包裝之包裝裝置構成。另外,散劑分配部係具有粉體送料器、分配盤以及刮出裝置。在先前之藥劑配發裝置之情況下,由藥劑師確認醫生的處方,從藥架上取出裝有處方開出的散劑之藥瓶,然後,使用天平等秤秤量處方開出之特定散劑之總重量。然後,將秤量出的散劑投入粉體送料器之料斗中,使粉體送料器之濾槽振動而使散劑落入分配盤中。另外,同時使分配盤以固定轉速連續地旋轉,使得散劑均勻地分散於分配盤之槽中。The conventional medicine dispensing device, for example, as disclosed in Patent Document 1, is composed of a powder dispensing unit that dispenses powders in a single dose, one packet per packet, and a packaging device that separately packages the dispensed powders. In addition, the powder distribution unit has a powder feeder, a distribution plate, and a scraping device. In the case of the previous medicine dispensing device, the pharmacist confirms the doctor's prescription, takes out the medicine bottle containing the prescription powder from the medicine rack, and then uses the balance to weigh the total of the prescribed powder weight. Then, put the weighed powder into the hopper of the powder feeder, and vibrate the filter trough of the powder feeder to make the powder fall into the distribution tray. In addition, at the same time, the distribution plate is continuously rotated at a fixed speed, so that the powder is evenly dispersed in the groove of the distribution plate.

在這之後,使刮出裝置之刮攏板落入分配盤之槽內,並使分配盤僅旋轉與分配個數對應之角度,從而使一次服用量之散劑聚積於刮攏板之前面側。然後,旋轉刮攏板,藉由刮出板將散劑刮出至分配盤外部並輸送至包裝裝置側,然後藉由包裝裝置按照一次服用量一包一包地進行包裝。After that, the scraping plate of the scraping device is dropped into the groove of the distribution plate, and the distribution plate is rotated only at an angle corresponding to the number of dispensing, so that the powder for one dose is accumulated on the front side of the scraping plate. Then, the scraping plate is rotated, and the powder is scraped out to the outside of the distribution tray by the scraping plate and transported to the side of the packaging device, and then the packaging device is used for packaging according to the dosage of one packet at a time.

在先前之藥劑配發裝置之情況下,需要由藥劑師進行從藥架上取出裝有所需散劑之藥瓶,並從該藥瓶中秤量出規定量的散劑這一作業,本申請人成功地開發出使該作業自動化之藥劑配發裝置(專利文獻2)。In the case of the previous medicine dispensing device, the pharmacist needs to take out the medicine bottle containing the required powder from the medicine rack and weigh out the prescribed amount of the powder from the medicine bottle. The applicant succeeded We have developed a medicine dispensing device that automates this operation (Patent Document 2).

本申請人開發之揭示於專利文獻2之藥劑配發裝置,在分配盤的周圍配置有振動臺。在專利文獻2所揭示之藥劑配發裝置中,於振動臺上設置有作為計量結構之測力感測器。The medicine dispensing device disclosed in

此外,在專利文獻2所揭示之藥劑配發裝置中係設有:收容多個藥劑容器之容器架,以及從容器架取出藥劑容器並將其配置於振動臺上之機械手(robot)。In addition, the medicine dispensing device disclosed in

在專利文獻2所揭示之藥劑配發裝置中,藉由機械手將藥劑容器從容器架上取出並移動至振動臺上,然後使藥劑容器振動而使散劑從藥劑容器直接落入分配盤中。另外,藉由振動臺上所安裝之測力感測器對藥劑容器的重量進行監視,藉此檢測散劑之落下量。In the medicine dispensing device disclosed in

之後的工序同先前技術的工序,使分配盤以固定轉速連續地旋轉,而將散劑均勻地分散(分配)至分配盤之槽中。然後,使刮出裝置之刮攏板落入分配盤之槽內,並使分配盤僅旋轉與分配個數對應之角度,從而使一次服用量的散劑聚積於刮攏板之前面側,然後,藉由刮出板將散劑刮出至分配盤外部並輸送至包裝裝置側,藉由包裝裝置按照一次服用量一包一包地進行包裝。 [先前技術文獻] [專利文獻]The subsequent process is the same as that of the prior art, which makes the distribution plate rotate continuously at a fixed speed, and the powder is evenly dispersed (distributed) into the groove of the distribution plate. Then, the scraping plate of the scraping device is dropped into the groove of the distribution plate, and the distribution plate is rotated only by the angle corresponding to the number of dispensing, so that the powder for one dose is accumulated on the front side of the scraping plate, and then, The powder is scraped out by the scraping plate to the outside of the distribution tray and transported to the packaging device side, and the packaging device is used to pack the dosage per packet by packet. [Prior Technical Documents] [Patent Documents]

專利文獻1:日本專利特開平7-80043號公報 專利文獻2:國際公開公報WO2014-46148號Patent Document 1: Japanese Patent Laid-Open No. 7-80043 Patent Document 2: International Publication No. WO2014-46148

[發明所欲解決之問題] 依本申請人所揭示之藥劑配發裝置,不僅能夠大幅地減少藥劑師的作業量,而且能夠以短時間準確地進行藥劑分包。[Problem to be solved by the invention] According to the medicine dispensing device disclosed by the applicant, not only the workload of the pharmacist can be greatly reduced, but also the medicine can be subcontracted accurately in a short time.

但是,市場上需要進一步的改良。具體而言,市場上需要開發下述藥劑配發裝置,即,能夠更迅速、更準確地進行藥劑分包,並且能夠在不減少可收容之藥劑容器數量之前提下謀求裝置整體的小型化這一藥劑配發裝置。However, further improvements are needed in the market. Specifically, there is a need in the market for the development of a medicine dispensing device that can more quickly and accurately dispense medicines, and that can reduce the size of the entire device without reducing the number of medicine containers that can be stored. A medicament dispensing device.

另外,先前技術下的藥劑配發裝置係使用分配盤之裝置,但是,使用分配盤之藥劑配發裝置不適合用於少量且小包的面向兒童之處方散劑之分包。In addition, the medicament dispensing device in the prior art is a device that uses a distribution plate, but the medicament dispensing device using a distribution plate is not suitable for sub-packing small amounts and small packages of prescription powders for children.

即,分配盤之大小(直徑)與一次包裝之最大容量相對應。具體而言,分配盤之大小(直徑)被設計成能夠應對收容於一包之散劑的量多且服用次數多之情況。That is, the size (diameter) of the distribution tray corresponds to the maximum capacity of a package. Specifically, the size (diameter) of the distribution tray is designed to be able to cope with the situation where the amount of powder contained in a packet is large and the number of doses is large.

因此,相反地在如針對面向兒童之處方進行分包那樣、收容於一包之散劑的量少且服用次數也少之情況下,當將散劑分散(分配)於分配盤之槽中時,呈藥劑薄薄地積存於槽的底部之狀態,從而成為藉由刮出裝置難以將散劑排出之狀態。Therefore, on the contrary, when the amount of the powder contained in one packet is small and the number of times of taking is small, as in the case of sub-packaging for children-oriented places, when the powder is dispersed (distributed) in the slot of the distribution tray, the result is The medicament is stored thinly at the bottom of the tank, so that it is difficult to discharge the powder by the scraping device.

因此,在使用分配盤之藥劑配發裝置之情況下,能夠分包的散劑量存在下限,難以對少量的散劑進行分包。Therefore, in the case of using the medicine dispensing device of the distribution tray, there is a lower limit on the amount of powder that can be packaged, and it is difficult to package a small amount of powder.

本發明係為了回應上述的市場需求而開發者,其課題係在於開發能夠實現上述任一目的之藥劑配發裝置。The present invention was developed in response to the above-mentioned market demand, and its subject is to develop a medicine dispensing device that can achieve any of the above-mentioned objectives.

作為藥劑配發裝置之形態,該藥劑配發裝置係包括收容散劑之藥劑容器、保管多個藥劑容器之藥劑容器收容部、容器移動裝置、以及包裝裝置,並且,藉由容器移動裝置使藥劑容器收容部中的藥劑容器移動,從藥劑容器中排出散劑,並藉由包裝裝置將散劑按照一次服用量一包一包地分別進行包裝;該藥劑配發裝置之特徵係在於,容器移動裝置包括:保持藥劑容器之容器保持組件、使容器保持組件移動之輸送結構、以及使散劑從藥劑容器中排出之排出結構;藉由容器移動裝置取出藥劑容器收容部中所保管之藥劑容器,並且藉由容器移動裝置之容器保持組件保持藥劑容器並藉由輸送結構將藥劑容器移動至規定位置,在藉由容器移動裝置之容器保持組件保持著藥劑容器之狀態下,藉由上述排出結構將散劑從藥劑容器中排出。As a form of the medicine dispensing device, the medicine dispensing device includes a medicine container for storing powder, a medicine container accommodating part for storing a plurality of medicine containers, a container moving device, and a packaging device, and the medicine container is moved by the container moving device. The medicament container in the accommodating part moves to discharge the powder from the medicament container, and the powder is separately packaged by the packaging device according to the amount of one-time dose; the medicine dispensing device is characterized in that the container moving device includes: The container holding assembly for holding the medicine container, the conveying structure for moving the container holding assembly, and the discharging structure for discharging the powder from the medicine container; the medicine container stored in the medicine container receiving part is taken out by the container moving device, and the medicine container is taken out by the container The container holding component of the moving device holds the medicine container and moves the medicine container to a predetermined position by the conveying structure. In the state where the medicine container is held by the container holding component of the container moving device, the powder is removed from the medicine container by the above-mentioned discharge structure In the discharge.

在本形態之藥劑配發裝置中,容器移動裝置係具有排出結構,在藉由容器移動裝置之容器保持組件保持著藥劑容器之狀態下,能夠藉由排出結構將散劑從藥劑容器中排出。因此,亦可不設置另外的振動臺,從而能夠實現裝置之小型化。In the medicine dispensing device of this aspect, the container moving device has a discharge structure, and the powder can be discharged from the medicine container by the discharge structure while the medicine container is held by the container holding assembly of the container moving device. Therefore, another vibration table may not be provided, so that the miniaturization of the device can be achieved.

較佳係容器移動裝置具有計量結構,且能夠藉由上述排出結構將散劑按照一次服用量為單位從藥劑容器中定量地排出。Preferably, the container moving device has a metering structure, and the powder can be quantitatively discharged from the medicine container in units of a single dose by the above-mentioned discharge structure.

依本形態,可以不需要分配盤,從而能夠實現裝置之小型化。According to this form, the distribution disk is not required, so that the miniaturization of the device can be realized.

亦可構成為:具有暫時儲存從藥劑容器中排出的散劑之臨時放置容器,並且在臨時放置容器中設有計量結構,當臨時放置容器中積存有一次服用量之散劑時,能夠將臨時放置容器中之散劑轉移至包裝裝置。It can also be configured as: a temporary storage container for temporarily storing powders discharged from the medicine container, and a metering structure is provided in the temporary storage container. When the temporary storage container stores a single dose of powders, the temporary storage container can be placed The powder is transferred to the packaging device.

依本形態,可以不需要分配盤,從而能夠實現裝置之小型化。另外,透過在容器移動裝置中設置計量結構,進而在臨時放置容器中也設置計量結構,藉此能夠更準確地計量藥劑的量。According to this form, the distribution disk is not required, so that the miniaturization of the device can be realized. In addition, by providing a metering structure in the container moving device, and further providing a metering structure in the temporary container, the amount of medicine can be measured more accurately.

另外,其他形態之藥劑配發裝置係包括收容散劑之藥劑容器、保管多個藥劑容器之藥劑容器收容部、以及容器移動裝置,並且,藉由容器移動裝置使藥劑容器收容部中的藥劑容器移動,從藥劑容器中排出散劑,該藥劑配發裝置之特徵係在於,容器移動裝置包括:保持藥劑容器之容器保持組件、使容器保持組件移動之輸送結構,以及能夠對處於被上述容器保持組件保持之狀態之藥劑容器的重量進行計量之計量結構;能夠藉由容器移動裝置取出藥劑容器收容部中所保管之藥劑容器,並且藉由容器移動裝置之容器保持組件保持藥劑容器並藉由輸送結構將藥劑容器移動至規定位置,並且,在任一階段藉由計量結構對藥劑容器的重量進行計量。In addition, other forms of the medicine dispensing device include a medicine container for storing powders, a medicine container accommodating part for storing a plurality of medicine containers, and a container moving device, and the medicine container in the medicine container accommodating part is moved by the container moving device Discharge the powder from the medicament container, the medicament dispensing device is characterized in that the container moving device includes: a container holding assembly for holding the medicament container, a conveying structure for moving the container holding assembly, and a device capable of being held by the container holding assembly. A measuring structure for measuring the weight of the medicine container in the state; the medicine container stored in the medicine container accommodating part can be taken out by the container moving device, and the medicine container is held by the container holding component of the container moving device, and the medicine container is held by the conveying structure The medicine container moves to a predetermined position, and the weight of the medicine container is measured by the measuring structure at any stage.

依本形態,可以不需要分配盤,從而能夠實現裝置之小型化。另外,在具有分配盤之藥劑配發裝置中也能夠適用本發明。該情況下,能夠省略其他的計量結構。另外,亦可藉由其他的計量結構和容器移動裝置中所設置之計量結構對藥劑之量進行雙重檢測,從而能夠更準確地計量藥劑之量。According to this form, the distribution disk is not required, so that the miniaturization of the device can be realized. In addition, the present invention can also be applied to a medicine dispensing device having a dispensing tray. In this case, other measurement structures can be omitted. In addition, other metering structures and the metering structure provided in the container moving device can double-detect the amount of medicine, so that the amount of medicine can be measured more accurately.

亦可將下述結構與上述各構成進行組合,該結構係指:設有容器設置臺,容器設置臺具有使散劑從藥劑容器中排出之排出結構,藉由上述容器移動裝置使藥劑容器移動至容器設置臺上,並且藉由排出結構將散劑從藥劑容器中排出。The following structure can also be combined with each of the above-mentioned structures. The structure means: a container setting table is provided, and the container setting table has a discharge structure for discharging the powder from the medicine container, and the medicine container is moved to the container by the container moving device. The container is set on the platform, and the powder is discharged from the medicine container by the discharge structure.

亦可採用下述結構:即,設有容器設置臺,容器設置臺具有使散劑從藥劑容器中排出之排出結構,藉由上述容器移動裝置使藥劑容器移動至容器設置臺上,並且藉由排出結構將散劑從藥劑容器中排出,容器設置臺具有計量結構,藉由容器移動裝置之計量結構對被設置於容器設置臺上之前的藥劑容器之重量進行測量,一邊藉由排出結構將散劑從藥劑容器中排出,一邊藉由容器設置臺之計量結構對散劑之排出量進行監視,在排出了一次服用量的散劑之後,藉由容器移動裝置從容器設置臺上拆下藥劑容器,並藉由容器移動裝置之計量結構再次測量藥劑容器之重量,重複進行該一系列動作,而將多次服用量之散劑按照一次服用量為單位定量地排出。The following structure may also be adopted: that is, a container setting table is provided, and the container setting table has a discharge structure for discharging the powder from the medicine container, and the medicine container is moved to the container setting table by the container moving device, and the medicine container is moved to the container setting table by the container moving device. The structure discharges the powder from the medicine container. The container setting table has a measuring structure. The weight of the medicine container before it is set on the container setting table is measured by the measuring structure of the container moving device. The powder is discharged from the medicine by the discharge structure. Discharge from the container, while monitoring the discharge amount of the powder by the metering structure of the container setting table, after discharging a single dose of powder, use the container moving device to remove the medicine container from the container setting table, and use the container to remove the medicine container from the container setting table. The metering structure of the mobile device measures the weight of the medicine container again, repeats the series of actions, and discharges the powders of multiple doses in units of one dose.

亦可採用下述結構:即,設有容器設置臺,容器設置臺具有使散劑從藥劑容器中排出之排出結構,藉由上述容器移動裝置使藥劑容器移動至容器設置臺上,並且藉由排出結構將散劑從藥劑容器中排出,容器設置臺具有計量結構,藉由容器移動裝置之計量結構對被設置於容器設置臺上之前的藥劑容器之重量進行測量,一邊藉由排出結構將散劑從藥劑容器中排出,一邊藉由容器設置臺之計量結構對散劑的排出量進行監視,在排出了一次服用量或多次服用量的散劑之後,藉由容器移動裝置從容器設置臺上拆下藥劑容器,並藉由容器移動裝置之計量結構再次測量藥劑容器的重量。The following structure may also be adopted: that is, a container setting table is provided, and the container setting table has a discharge structure for discharging the powder from the medicine container, and the medicine container is moved to the container setting table by the container moving device, and the medicine container is moved to the container setting table by the container moving device. The structure discharges the powder from the medicine container. The container setting table has a measuring structure. The weight of the medicine container before it is set on the container setting table is measured by the measuring structure of the container moving device. The powder is discharged from the medicine by the discharge structure. Discharge from the container, while monitoring the discharge amount of the powder by the metering structure of the container setting table, after discharging the single dose or multiple doses of the powder, the drug container is removed from the container setting table by the container moving device , And measure the weight of the medicine container again by the measuring structure of the container moving device.

容器移動裝置亦可具有使散劑從藥劑容器排出之排出結構,在藉由容器移動裝置之容器保持組件保持著藥劑容器之狀態下,能夠藉由排出結構將散劑從藥劑容器中排出。The container moving device may also have a discharge structure for discharging the powder from the medicine container, and the powder can be discharged from the medicine container by the discharge structure while the medicine container is held by the container holding assembly of the container moving device.

另外,其他形態之藥劑配發裝置係包括收容散劑之藥劑容器、使散劑從藥劑容器排出之排出裝置、以及包裝裝置,該藥劑配發裝置之特徵係在於,排出裝置中具有排出側計量結構;藥劑配發裝置具有暫時儲存從藥劑容器中排出的散劑之臨時放置容器,臨時放置容器中設有接收側計量結構,藉由排出裝置將藥劑從藥劑容器中排出並臨時放置於臨時放置容器中,當臨時放置容器中積存有一次服用量之散劑時,將臨時放置容器中的散劑轉移至包裝裝置。In addition, other forms of medicament dispensing device include a medicament container containing powder, a discharging device for discharging the powder from the medicament container, and a packaging device. The medicament dispensing device is characterized in that the discharging device has a discharge side metering structure; The medicine dispensing device has a temporary storage container for temporarily storing the powder discharged from the medicine container. The temporary storage container is equipped with a receiving side metering structure. The medicine is discharged from the medicine container by the discharge device and temporarily placed in the temporary storage container. When a single dose of powder is stored in the temporary container, the powder in the temporary container is transferred to the packaging device.

依本形態,可以不需要分配盤,從而能夠實現裝置之小型化。 [發明功效]According to this form, the distribution disk is not required, so that the miniaturization of the device can be realized. [Efficacy of invention]

與先前之藥劑配發裝置相比,本發明之藥劑配發裝置具有能夠謀求迅速性、準確性、小型化之至少一方面的提高這一效果。Compared with the conventional medicine dispensing device, the medicine dispensing device of the present invention has the effect of improving at least one of speed, accuracy, and miniaturization.

以下進一步對本發明之實施方式進行說明。The embodiments of the present invention will be further described below.

本實施方式之藥劑配發裝置1係被框體2包圍,且在內部設有保管多個藥劑容器30之藥劑容器收容部3、容器移動裝置5以及包裝裝置6。在被保管於藥劑容器收容部3之藥劑容器30中,分別收納有所需的散劑。The medicine dispensing device 1 of the present embodiment is surrounded by a

在本實施方式中,框體2主要分為上下兩段,藥劑容器收容部3和容器移動裝置5存在於上段側,包裝裝置6存在於下段側。In the present embodiment, the

藥劑容器收容部3中具有沿大致水平方向旋轉之立式滾筒組件7,在滾筒組件7的外周面上設有多個容器設置部13。The medicine

在滾筒組件7之容器設置部13上安裝有所需的藥劑容器30。而且,使後述之容器移動裝置5之機械手10與藥劑容器30靠近,藉由機械手10安裝或拆卸藥劑容器30。The

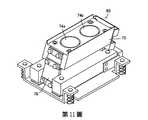

如第2圖所示,容器移動裝置5係由昇降結構8和機械手10構成。另外,在本實施方式中,藉由昇降結構8和機械手10構成輸送結構,且藉由機械手10的手部18構成容器保持組件。As shown in FIG. 2, the

昇降結構8係設置於垂直方向之直線導軌,且由直線軌道11和昇降臺12構成。在直線軌道11上形成有未圖示之齒條,在昇降臺12上設有未圖示之電動機和齠輪。The lifting

透過使未圖示之電動機工作,昇降臺12在上下方向上移動。By operating a motor (not shown), the

機械手10係包括兩根臂組件15、16和手部18。The

即,第一臂組件15經由未圖示之垂直軸安裝在昇降臺12上,並且,在安裝於昇降臺12之電動機之驅動下,第一臂組件15以昇降臺12為中心在水平方向上轉動。That is, the

第二臂組件16經由未圖示之垂直軸安裝在第一臂組件15之前端,並且,在安裝於第一臂組件15前端之電動機之驅動下,第二臂組件16以第一臂組件15之前端為中心在水平方向上轉動。The

在本實施方式中,手部18具有以下功能:即,保持藥劑容器30並且改變姿勢之功能、保持藥劑容器並使其振動之振動功能(排出結構),以及對藥劑容器之重量進行測量之重量測量功能(計量結構)。In this embodiment, the

如第4圖所示,手部18具有容器保持掌部21。另外,在容器保持掌部21上安裝有電磁鐵24。As shown in FIG. 4, the

手部18經由未圖示之水平軸安裝在第二臂組件16之前端,並且,在電動機之驅動下,手部18以第二臂組件16之前端為中心在垂直方向上轉動。The

因此,容器保持掌部21既能夠呈平行姿勢,也能夠呈垂直姿勢。另外,能夠藉由電磁鐵24保持藥劑容器30。Therefore, the

在本實施方式中,在容器保持掌部21與手部18之主體部分23之間,配置有激振組件22a、22b和第一重量測量裝置(計量結構)25。In this embodiment, between the container holding

激振組件22a、22b為壓電元件。重量測量裝置25為計量結構,具體為測力感測器。在激振組件22a、22b與重量測量裝置25之間配設有防振組件38,激振組件22a、22b之振動不會直接傳遞至重量測量裝置25。The

在本實施方式中,藉由激振組件22a、22b使藥劑容器30振動,藉此將藥劑容器30內的藥劑排出。在本實施方式中,由激振組件22a、22b構成排出結構,容器移動裝置5具有排出功能。In the present embodiment, the

另外,在本實施方式中,藉由第一重量測量裝置25構成計量結構,容器移動裝置5具有計量功能。In addition, in this embodiment, the first

與習知包裝裝置同樣地,包裝裝置6係將藥劑按照一次服用量一包一包地分別進行包裝之機械,如眾所周知由分包紙供給裝置32和製袋裝置33構成。另外,設有對包裝裝置6投入藥劑之散劑投入料斗31。散劑投入料斗31係由主料斗26和輔助料斗27構成。Similar to the conventional packaging device, the

分包紙供給裝置32係對分包部供給薄片狀分包紙28之部位。The packaging

製袋裝置33係透過將薄片狀分包紙28彎折並將散劑導入其中後,將薄片的邊緣熱黏接而成形為袋狀之部位。本實施方式中所採用之分包紙供給裝置32及製袋裝置33均為習知裝置,故省略其詳細說明。The bag-making

散劑投入料斗31之主料斗26為接收從藥劑容器30落下之散劑之裝置。主料斗26發揮作為臨時放置容器之功能。The

另一方面,輔助料斗27係將主料斗26和包裝裝置6連接之裝置,且是將散劑導入包裝裝置6側之裝置。On the other hand, the

主料斗26呈漏斗狀。即,主料斗26具有開口面積大的導入側開口和開口面積小的排出側開口。排出側開口係位於主料斗26之下端,且設置有開閉板35。開閉板35能夠藉由動力進行開關,從而能夠將排出側開口打開或關閉。The

在本實施方式中,在主料斗26中設置有第二重量測量裝置36。第二重量測量裝置36為計量結構,具體為測力感測器。In this embodiment, the second

輔助料斗27為簡單的漏斗狀組件,其上部係位於主料斗26之排出側開口附近,下部則到達至包裝裝置6,且是向被彎折的薄片狀分包紙28內導入散劑之部位。The

接下來,參照第3圖對藥劑容器30進行說明。Next, the

藥劑容器30為密閉型容器,由容器主體40和蓋組件43構成。The

容器主體40係由樹脂製成之縱長形容器。The

另外,在容器主體40上設有輸送用鐵板部。在本實施方式中,輸送用鐵板部係分為兩個小輸送用鐵板部41a、41b。輸送用鐵板部由含有鐵氧體等磁性體成分的鋼板製成。In addition, the

蓋組件43包括蓋主體部45和活動蓋部48。活動蓋部48上具有捏手部50,透過按壓該捏手部50而將活動蓋部48打開。然後,維持活動蓋部48呈打開狀態。The

如第3圖所示,蓋組件43被安裝於容器主體40而構成藥劑排出部47。As shown in FIG. 3, the

接下來,對本實施方式之藥劑配發裝置1之功能進行說明。本實施方式之藥劑配發裝置1係將藥劑按照一次服用量一包一包地從藥劑容器30排出並輸送至下游側的包裝裝置6,然後按照一次服用量一包一包地進行包裝之裝置。Next, the function of the medicine dispensing device 1 of the present embodiment will be described. The medicine dispensing device 1 of the present embodiment is a device that discharges medicines from the

本實施方式之藥劑配發裝置1,在被保管於藥劑容器收容部3之藥劑容器30中預先收納有所需的散劑。In the medicine dispensing device 1 of the present embodiment, the

本實施方式之藥劑配發裝置1能夠自動地進行以下動作:即,根據處方選出藥劑容器之動作、從藥劑容器30按照一次服用量一包一包地排出藥劑之動作,以及藉由包裝裝置6對藥劑進行包裝之動作。The medicine dispensing device 1 of this embodiment can automatically perform the following actions: that is, the action of selecting a medicine container based on the prescription, the action of discharging the medicine from the

本實施方式之藥劑配發裝置1根據處方自動地選出藥劑容器30。具體而言,旋轉藥劑容器收容部3之滾筒組件7,從而使所需的藥劑容器30靠近容器移動裝置5。然後,藉由容器移動裝置5之手部18保持藥劑容器30,並使臂等動作而將該藥劑容器30移動至散劑投入料斗31的正上方。另外,使藥劑容器30保持呈水平姿勢。另外,藉由未圖示之裝置按壓活動蓋部48之捏手部50,而將活動蓋部48打開。The medicine dispensing device 1 of the present embodiment automatically selects the

然後,在藉由容器移動裝置5之手部18保持著藥劑容器30之狀態下,啟動激振組件22a、22b而使容器保持掌部21振動。其結果是,藥劑容器30中的散劑緩慢地移動,從藥劑容器30中排出並落入散劑投入料斗31之主料斗26中。另外,此時主料斗26之開閉板35處於關閉狀態,落下的藥劑積留在主料斗26中。Then, in a state where the

另外,在振動開始之後緊接著藉由容器移動裝置5之第一重量測量裝置25對藥劑容器30的重量進行測量。在此期間,對藥劑容器30的重量進行監視,在散劑之總落下量變為所需的重量時,停止振動容器保持掌部21。In addition, immediately after the vibration starts, the weight of the

即,藉由第一重量測量裝置25對作為排出藥劑之前之藥劑容器30重量之原重G進行測量,在從藥劑容器30一點一點地排出散劑時,藉由前述第一重量測量裝置25對藥劑容器30的重量進行監視。然後,在作為藥劑容器30目前重量之現重g與從原重G減去目標排出量後的值一致時或大致一致時,停止從藥劑容器30排出散劑。That is, the first

在本實施方式中,在總落下量變為一次服用量時停止振動容器保持掌部21。In this embodiment, the vibration

另外,在本實施方式中,在主料斗26中也設置有重量測量裝置(第二重量測量裝置36)。在本實施方式中,藉由第二重量測量裝置36對藥劑的排出量進行監視。In addition, in the present embodiment, a weight measurement device (second weight measurement device 36) is also provided in the

在本實施方式中,在停止從藥劑容器30排出散劑之階段,藉由第二重量測量裝置36確認藥劑的排出量,並且,以確認到藥劑的排出量相當於患者的一次服用量作為條件,打開主料斗26之開閉板35,使藥劑經由輔助料斗27而被導入包裝裝置6側。然後,藉由包裝裝置6對藥劑進行包裝。In this embodiment, at the stage when the powder medicine is stopped from the

在這之後,再次開始激振組件22a、22b的振動,使容器保持掌部21再次振動,重複上述的一系列工序,從藥劑容器30向主料斗26投入一次服用量的散劑,打開開閉板35將該散劑導入包裝裝置6側,藉由包裝裝置6對一次服用量的藥劑進行包裝。After that, start the vibration of the

在本實施方式之藥劑配發裝置1之情況下,藉由容器移動裝置5中所設置的排出結構,以一次服用量為單位從藥劑容器30定量地排出散劑後,藉由包裝裝置6按一次服用量一包一包地包裝藥劑。然後,當完成所需服數的藥劑包裝時,藉由未圖示之裝置使活動蓋部48之捏手部50恢復原位,從而關閉活動蓋部48。然後,容器移動裝置5進行動作,使藥劑容器30返回藥劑容器收容部3之滾筒組件7。In the case of the medicine dispensing device 1 of this embodiment, the discharging structure provided in the

本實施方式之藥劑配發裝置1,在容器移動裝置5之排出裝置中設有第一重量測量裝置25作為排出側計量結構,進而設有主料斗26,作為將從藥劑容器30排出的散劑暫時存留之臨時放置容器。另外,在作為臨時放置容器發揮作用的主料斗26中設有第二重量測量裝置36,作為接收側計量結構。而且,藉由排出裝置將藥劑從藥劑容器30中排出並臨時放置於臨時放置容器中,當作為臨時放置容器的主料斗26中積存有一次服用量的散劑時,將主料斗26內的散劑轉移至包裝裝置6中。在本實施方式之藥劑配發裝置1中,由於對藥劑進行兩次計量,因此裝於包裝內的散劑之量準確。In the medicine dispensing device 1 of this embodiment, the first

進而,在本實施方式之藥劑配發裝置1之情況下,當第一重量測量裝置25或第二重量測量裝置26中的一方因某些原因發生了故障時,能夠檢測到該情況。Furthermore, in the case of the medicine dispensing device 1 of the present embodiment, when one of the first

即,由於第一重量測量裝置25和第二重量測量裝置26的檢測重量應相同,因此,當兩者的檢測重量不一致時,可以認為是第一重量測量裝置25或第二重量測量裝置26中的一方發生了故障。That is, since the detection weights of the first

另外,本實施方式之藥劑配發裝置1由於不需要分配盤,因此能夠謀求裝置之小型化。In addition, since the medicine dispensing device 1 of the present embodiment does not require a dispensing tray, it is possible to reduce the size of the device.

在以上說明的實施方式中,散劑投入料斗31分為主料斗26和輔助料斗27,但是,也可以如第5圖所示之藥劑配發裝置51那樣設有將從藥劑容器30排出的藥劑暫時存留之臨時放置容器52,並在臨時放置容器52中設置重量測量裝置(第二重量測量裝置37)。In the embodiment described above, the

第5圖所示之藥劑配發裝置51中所採用的臨時放置容器52呈有底的杯狀。在藥劑配發裝置51中,臨時放置容器52的開口朝上,從而接收從藥劑容器30排出的藥劑。然後,使臨時放置容器52傾斜或翻轉而變為上下顛倒之姿勢,從而將散劑投入散劑投入料斗55中。The

其他構成與之前的實施方式相同。The other configuration is the same as the previous embodiment.

在本實施方式之藥劑配發裝置51中也對藥劑進行兩次計量,因此計量準確。另外,在本實施方式之藥劑配發裝置51中也不需要分配盤,因此能夠謀求裝置之小型化。In the

作為更簡單的構成,可以考慮第6圖所示結構之藥劑配發裝置56。As a simpler structure, a

第6圖所示之藥劑配發裝置56未設置第二重量測量裝置。而且,將散劑從藥劑容器30直接投入散劑投入料斗55中。The

即,在藉由容器移動裝置5之手部18保持著藥劑容器30之狀態下啟動激振組件22a、22b,使容器保持掌部21振動,而使散劑直接落入散劑投入料斗55中。That is, in a state in which the

而且,藉由第一重量測量裝置25對藥劑容器30的重量進行監視,當散劑的總落下量變為所需重量時,停止振動容器保持掌部21。Furthermore, the weight of the

其他構成與之前的實施方式相同。The other configuration is the same as the previous embodiment.

另外,也可以如第7圖所示之藥劑配發裝置60那樣,藉由容器移動裝置5之排出功能,將散劑從藥劑容器30投入分配盤61中。In addition, like the

藥劑配發裝置60同先前之藥劑配發裝置一樣,具有分配盤61和刮出裝置62。The

分配盤61同習知技術為盤狀的組件。分配盤61的頂面側設置有藥劑投入槽63。藥劑投入槽63也稱為“R槽”,剖面形狀為圓弧狀。The

刮出裝置62具有刮出用臂65和刮出結構66。透過使刮出用臂65昇降,而能夠使刮出結構66上下移動。The

在本實施方式之藥劑配發裝置60中,藉由容器移動裝置5之手部18保持藥劑容器30,並且使臂等動作而將藥劑容器30移動到分配盤61之藥劑投入槽63的正上方。In the

然後,在藉由容器移動裝置5之手部18保持著藥劑容器30之狀態下,啟動容器移動裝置5的激振組件22a、22b,使容器保持掌部21振動,從而使藥劑落下至分配盤61之藥劑投入槽63中。Then, while the

另外,在振動開始之後緊接著使分配盤61旋轉。而且,在振動開始之後緊接著對藥劑容器30的重量進行測量。在此期間,藉由第一重量測量裝置25對藥劑容器30的重量進行監視,當散劑之總落下量變為所需重量時,停止振動容器保持掌部21。在此,在本實施方式中,總落下量為多次服用量的合計量。當作為藥劑容器30目前重量之現重g與從原重G減去多次服用量的合計量後的值一致或大致一致時,停止從藥劑容器30中排出散劑。In addition, the

在這之後,停止旋轉分配盤61。然後,搖動刮出用臂65,使其前端側降下從而使刮出結構66下降,並使刮出結構66進入分配盤61之藥劑投入槽63內。After that, the rotation of the

接著,使分配盤61僅旋轉與分配個數對應之角度,將藥劑刮攏至刮攏板67。然後,旋轉刮攏板67,並且藉由刮出板68將藥劑撈起而將藥劑從分配盤61排出並投入散劑投入料斗77中。當藥劑在散劑投入料斗77中下落並被運送至包裝裝置6時,藉由包裝裝置6進行包裝。Next, the

依次重複該動作,將分配盤61內的藥劑全部排出,並分別藉由包裝裝置6包裝藥劑。This operation is repeated in order to discharge all the medicines in the

在以上說明的實施方式中,均在容器移動裝置5中設置有重量測量裝置(第一重量測量裝置25),但亦可根據其他位置的重量測量裝置的檢測值使激振組件22a、22b工作。In the above-described embodiments, the weight measurement device (first weight measurement device 25) is provided in the

第8圖所示之藥劑配發裝置70為第4圖所示之藥劑配發裝置1之變形,且在容器移動裝置5中未設置重量測量裝置(第一重量測量裝置25)。其他構成同第4圖所示之藥劑配發裝置1。The

在藥劑配發裝置70中,也是藉由容器移動裝置5之手部18保持藥劑容器30,並使臂等動作而將該藥劑容器30移動到散劑投入料斗31的正上方。然後,在藉由容器移動裝置5之手部18保持著藥劑容器30之狀態下,啟動激振組件22a、22b,使容器保持掌部21振動,從而使藥劑從藥劑容器30落下至散劑投入料斗31之主料斗26中。Also in the

另外,在振動開始之後緊接著藉由主料斗26側的第二重量測量裝置36對藥劑容器30的重量進行測量。In addition, immediately after the vibration starts, the weight of the

即,藉由主料斗26側的第二重量測量裝置36對積存於主料斗26內之藥劑的重量進行測量。然後,當積存於主料斗26內之藥劑的重量與從原重G減去目標排出量後的值一致或大致一致時,停止從藥劑容器30排出散劑。更具體而言,當達到患者的一次服用量時,使激振組件22a、22b停止,從而停止從藥劑容器30排出散劑。That is, the weight of the medicine stored in the

第9圖所示之藥劑配發裝置71為第5圖所示之藥劑配發裝置51之變形,且在容器移動裝置5中未設置重量測量裝置(第一重量測量裝置25)。其他構成同藥劑配發裝置51。The

另外,本發明亦可應用於本申請人開發之揭示於專利文獻2之藥劑配發裝置。In addition, the present invention can also be applied to the medicine dispensing device disclosed in

即,亦可如第10圖所示之藥劑配發裝置71那樣,在分配盤61的周圍設置容器載置裝置(容器設置臺)80。容器載置裝置80具有振動臺72。That is, like the

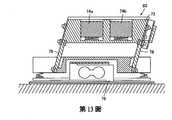

容器載置裝置80作為設置藥劑容器30用的容器設置臺而發揮作用。容器載置裝置80設有振動臺72,具有使散劑從藥劑容器30排出之排出結構。如第11圖、第12圖及第13圖所示,容器載置裝置80具有振動臺72和直接或間接地測量藥劑容器30的重量之重量測量裝置76。另外,設有未圖示之落下確認感測器。The

振動臺72設置有將藥劑容器30暫時固定於振動臺72之容器保持組件。容器保持組件具體為磁鐵74a、74b。在振動臺72的兩端以傾斜姿勢安裝有激振組件78。激振組件78具體為壓電元件。落下確認感測器例如為光電感測器,且是用於確認藥劑是否被從藥劑容器30排出之感測器。The vibrating table 72 is provided with a container holding assembly for temporarily fixing the

在本實施方式中,能夠將藥劑容器30載置於容器載置裝置80上,並透過使振動臺72振動而將藥劑從藥劑容器30中排出。另外,對於此時的藥劑容器30的重量變化,藉由重量測量裝置76進行檢測。In this embodiment, the

藥劑配發裝置71中採用的容器移動裝置83,如第10圖所示具有第一重量測量裝置25。另外,如第10圖所示,藥劑配發裝置71所採用的容器移動裝置83中無激振組件,而具有容器保持掌部21和第一重量測量裝置25。The

本實施方式之藥劑配發裝置71也是根據處方自動地選出藥劑容器30。然後,藉由容器移動裝置83之手部18保持藥劑容器30,使臂等動作而將藥劑容器30載置於容器載置裝置80上。The

另外,在藉由容器移動裝置83輸送藥劑容器30的期間,藉由容器移動裝置83之第一重量測量裝置25對藥劑容器30的重量進行測量,在分配動作完成後,再次對藉由手部保持的藥劑容器30的重量進行測量,並將藥劑容器30的重量之差與藉由重量測量裝置76測量的總排出量進行比較而進行雙重檢查,由此能夠確保秤量值的可靠性,進而能夠對各重量測量裝置的調整不良情況或故障進行檢測。In addition, while the

在本實施方式之藥劑配發裝置71之情況下,在將藥劑容器30載置於容器載置裝置80上之狀態下,使內裝於容器載置裝置80中的振動臺72振動。其結果是,藥劑容器30中的散劑緩慢地移動而被從藥劑容器30中排出並落入分配盤61中。In the case of the

另外,在振動開始之後緊接著使分配盤61旋轉。此外,在振動開始之後緊接著藉由容器載置裝置80之重量測量裝置76對藥劑容器30的重量進行測量。在此期間,對藥劑容器30的重量進行監視,當散劑之總排出量變為所需的重量時,停止振動振動臺72。In addition, the

之後的工序與先前技術相同,停止分配盤61的旋轉,使刮出結構66進入藥劑投入槽63內,然後使分配盤61僅旋轉與分配個數對應之角度,將藥劑刮攏至刮攏板67。然後,旋轉刮攏板67,並且藉由刮出板68將藥劑撈起而從分配盤61中排出藥劑,並將藥劑投入散劑投入料斗77中。當藥劑在散劑投入料斗77中下落並被輸送至包裝裝置6時,藉由包裝裝置6進行包裝。The subsequent steps are the same as the prior art. Stop the rotation of the

依次重複該動作,將分配盤61內的藥劑全部排出,並分別藉由包裝裝置6進行包裝。This action is repeated in order to discharge all the medicines in the

另外,也可以考慮第14圖所示之藥劑配發裝置81那樣的結構。In addition, a configuration like the

藥劑配發裝置81不具有分配盤,而是從載置於容器載置裝置(容器設置臺)80上的藥劑容器30中將藥劑直接投入包裝裝置6中。The

容器載置裝置80與上述的容器載置裝置相同,具有振動臺72。容器載置裝置80具有直接或間接地測量藥劑容器30的重量之重量測量裝置。The

藥劑配發裝置81中採用的容器移動裝置83如第14圖所示具有第一重量測量裝置25。即,藥劑配發裝置81中採用的容器移動裝置83具有容器保持掌部21和第一重量測量裝置(計量結構)25。容器移動裝置83中無激振組件。The

如第14圖(a)所示,本實施方式之藥劑配發裝置81也是根據處方自動地選出藥劑容器30。然後,藉由容器移動裝置83之手部18保持藥劑容器30,使臂等動作而將藥劑容器30載置於容器載置裝置80上。As shown in FIG. 14(a), the

另外,在藉由容器移動裝置83輸送藥劑容器30的期間,藉由容器移動裝置83之第一重量測量裝置25對藥劑容器30的重量進行測量。In addition, while the

在本實施方式之藥劑配發裝置81中,在將藥劑容器30載置於容器載置裝置80上之狀態下,使內裝於容器載置裝置80的振動臺72振動。其結果是,藥劑容器30中的散劑緩慢地移動而被從藥劑容器30中排出並落至包裝裝置6之散劑投入料斗77中(第14圖(b))。In the

而且,在此期間,藉由容器載置裝置80之重量測量裝置對藥劑容器30的重量進行監視,當散劑的排出量變為一次服用量時,停止振動振動臺72。During this period, the weight of the

對於已經投入包裝裝置6之散劑投入料斗77中的一次服用量之散劑,藉由包裝裝置6進行包裝。The one-time dosage of the powder that has been put into the

與此並行地,如第14圖(c)所示,藉由容器移動裝置83保持藥劑容器30,驅動容器移動裝置83而將藥劑容器30暫時從容器載置裝置(容器設置臺)80上移開。然後,藉由容器移動裝置83之第一重量測量裝置25再次對藥劑容器30的重量進行測量。In parallel with this, as shown in FIG. 14(c), the

再次測量後的藥劑容器30的重量相對於先前的測量值應只減少一次服用量的重量,當兩者之差與一次服用量的散劑的重量相比相差規定量以上時,進行規定的錯誤顯示。The weight of the

亦可對再次測量後的藥劑容器30的重量與容器載置裝置80之重量測量裝置的檢測重量進行比較。此時,兩者的重量應該相同,當兩者之差為規定值以上時,進行規定的錯誤顯示。It is also possible to compare the weight of the

在無異常的情況下,驅動容器移動裝置83再次將藥劑容器30載置於容器載置裝置80上。然後,重複前述的一系列動作,而將包裝有一次服用量散劑的包裝藥劑排出規定包數。If there is no abnormality, the

在以上所說明的實施方式中係透過振動使藥劑從藥劑容器30中排出,但也能夠採用藉由螺桿或葉片等使藥劑從藥劑容器中排出這一結構。該情況下,將螺桿等內裝於藥劑容器中,並從容器移動裝置5、83側對藥劑容器內的螺桿等傳遞動力。In the embodiment described above, the medicine is discharged from the

在上述各實施方式中,容器移動裝置5為機械手,但本發明並不限於該結構,亦可使X-Y工作臺或X-Y-Z工作臺等物件進行平面移動或立體地移動。In each of the above embodiments, the

另外,容器移動裝置亦可為使用傳送帶等的裝置。In addition, the container moving device may be a device using a conveyor belt or the like.

1、51、56、60、70、71、81‧‧‧藥劑配發裝置2‧‧‧框體3‧‧‧藥劑容器收容部5、83‧‧‧容器移動裝置6‧‧‧包裝裝置7‧‧‧滾筒組件8‧‧‧昇降結構10‧‧‧機械手11‧‧‧直線軌道12‧‧‧昇降臺13‧‧‧容器設置部15、16‧‧‧臂組件18‧‧‧手部21‧‧‧容器保持掌部22a、22b、78‧‧‧激振組件23‧‧‧主體部分24‧‧‧電磁鐵25、76‧‧‧重量測量裝置26‧‧‧主料斗27‧‧‧輔助料斗28‧‧‧分包紙30‧‧‧藥劑容器31‧‧‧散劑投入料斗32‧‧‧分包紙供給裝置33‧‧‧製袋裝置35‧‧‧開閉板36、37‧‧‧第二重量測量裝置38‧‧‧防振組件40‧‧‧容器主體41a、41b‧‧‧小輸送用鐵板部43‧‧‧蓋組件47‧‧‧藥劑排出部48‧‧‧活動蓋部50‧‧‧捏手部52‧‧‧臨時放置容器55‧‧‧散劑投入料斗61‧‧‧分配盤62‧‧‧刮出裝置63‧‧‧藥劑投入槽65‧‧‧刮出用臂66‧‧‧刮出結構67‧‧‧刮攏板68‧‧‧刮出板72‧‧‧振動臺74a、74b‧‧‧磁鐵77‧‧‧散劑投入料斗80‧‧‧容器載置裝置1, 51, 56, 60, 70, 71, 81‧‧‧

第1圖係本發明實施方式之藥劑配發裝置之概念圖。 第2圖係第1圖之藥劑配發裝置之移動裝置之立體圖。 第3圖係第1圖之藥劑配發裝置之藥劑容器之立體圖(a)以及剖視圖(b)。 第4圖係第1圖之藥劑配發裝置之主要部分之概念圖,其中,(a)係顯示從藥劑容器向包裝裝置之料斗排出藥劑之狀態,(b)係顯示打開料斗將藥劑投入包裝裝置之包裝紙內之狀態。 第5圖係本發明其他實施方式之主要部分之概念圖,其中,(a)係顯示從藥劑容器向臨時放置容器排出藥劑之狀態,(b)係顯示使臨時放置容器傾斜而將藥劑投入包裝裝置之包裝紙內之狀態。 第6圖係本發明另一實施方式之主要部分之概念圖,係顯示將藥劑從藥劑容器直接投入包裝裝置之包裝紙內之狀態。 第7圖係本發明又一實施方式之主要部分之概念圖。 第8圖係本發明又一實施方式之藥劑配發裝置之主要部分之概念圖,其中,(a)係顯示從藥劑容器向包裝裝置之料斗排出藥劑之狀態,(b)係顯示打開料斗將藥劑投入包裝裝置之包裝紙內之狀態。 第9圖係本發明又一實施方式之藥劑配發裝置之主要部分之概念圖,其中,(a)係顯示從藥劑容器向臨時放置容器排出藥劑之狀態,(b)係顯示使臨時放置容器傾斜而將藥劑投入包裝裝置之包裝紙內之狀態。 第10圖係本發明又一實施方式之藥劑配發裝置之主要部分之概念圖。 第11圖係第10圖之藥劑配發裝置中所採用之容器載置裝置之立體圖。 第12圖係第11圖之容器載置裝置之立體剖視圖。 第13圖係第11圖之容器載置裝置之剖視圖。 第14圖係本發明又一實施方式之藥劑配發裝置之主要部分之概念圖,其中,(a)係顯示藉由容器移動裝置使藥劑容器移動時之狀態,(b)係顯示將藥劑容器配置於容器載置裝置上而排出散劑時之狀態,(c)係顯示藉由容器移動裝置保持藥劑容器並再次計量藥劑容器之重量時之狀態。Figure 1 is a conceptual diagram of a medicine dispensing device according to an embodiment of the present invention. Figure 2 is a perspective view of the mobile device of the medicine dispensing device of Figure 1. Fig. 3 is a perspective view (a) and a cross-sectional view (b) of the medicine container of the medicine dispensing device of Fig. 1. Fig. 4 is a conceptual diagram of the main parts of the medicine dispensing device of Fig. 1, in which (a) shows the state of discharging medicine from the medicine container to the hopper of the packaging device, and (b) shows the opening of the hopper and putting the medicine into the packaging The state in the packaging paper of the device. Figure 5 is a conceptual diagram of the main parts of other embodiments of the present invention, in which (a) shows the state of discharging the medicine from the medicine container to the temporary storage container, and (b) shows the temporary storage container is tilted to put the medicine into the package The state in the packaging paper of the device. Fig. 6 is a conceptual diagram of the main part of another embodiment of the present invention, showing the state where the medicine is directly put into the packaging paper of the packaging device from the medicine container. Fig. 7 is a conceptual diagram of the main part of another embodiment of the present invention. Figure 8 is a conceptual diagram of the main parts of a medicine dispensing device according to another embodiment of the present invention, in which (a) shows the state of discharging medicine from the medicine container to the hopper of the packaging device, and (b) shows the opening of the hopper The state where the medicine is put into the packaging paper of the packaging device. Figure 9 is a conceptual diagram of the main parts of a medicine dispensing device according to another embodiment of the present invention, in which (a) shows the state of discharging medicine from the medicine container to the temporary storage container, and (b) shows the temporary storage container Tilt and put the medicine into the wrapping paper of the packaging device. Fig. 10 is a conceptual diagram of the main parts of a medicine dispensing device according to another embodiment of the present invention. Figure 11 is a perspective view of the container placement device used in the medicine dispensing device of Figure 10. Figure 12 is a perspective cross-sectional view of the container mounting device of Figure 11. Fig. 13 is a cross-sectional view of the container mounting device of Fig. 11. Figure 14 is a conceptual diagram of the main parts of a medicine dispensing device according to another embodiment of the present invention, in which (a) shows the state when the medicine container is moved by the container moving device, and (b) shows the medicine container The state of discharging the powder when it is arranged on the container mounting device, (c) shows the state when the medicine container is held by the container moving device and the weight of the medicine container is measured again.

1‧‧‧藥劑配發裝置1‧‧‧Pharmaceutical dispensing device

5‧‧‧容器移動裝置5‧‧‧Container moving device

6‧‧‧包裝裝置6‧‧‧Packaging device

10‧‧‧機械手10‧‧‧Robot

16‧‧‧第二臂組件16‧‧‧Second arm assembly

18‧‧‧手部18‧‧‧Hand

21‧‧‧容器保持掌部21‧‧‧Container holding palm

22a、22b‧‧‧激振組件22a, 22b‧‧‧Exciting components

23‧‧‧主體部分23‧‧‧Main part

24‧‧‧電磁鐵24‧‧‧Electromagnet

25‧‧‧重量測量裝置25‧‧‧Weight measuring device

26‧‧‧主料斗26‧‧‧Main Hopper

27‧‧‧輔助料斗27‧‧‧Auxiliary Hopper

28‧‧‧分包紙28‧‧‧Packing paper

30‧‧‧藥劑容器30‧‧‧Pharmacy Container

31‧‧‧散劑投入料斗31‧‧‧Powder into the hopper

32‧‧‧分包紙供給裝置32‧‧‧Packing paper supply device

33‧‧‧製袋裝置33‧‧‧Bag making device

35‧‧‧開閉板35‧‧‧Opening and closing plate

36‧‧‧第二重量測量裝置36‧‧‧Second weight measuring device

Claims (6)

Translated fromChineseApplications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015-159021 | 2015-08-11 | ||

| JP2015159021 | 2015-08-11 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| TW201707804A TW201707804A (en) | 2017-03-01 |

| TWI730974Btrue TWI730974B (en) | 2021-06-21 |

Family

ID=57984223

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| TW105124961ATWI730974B (en) | 2015-08-11 | 2016-08-05 | Medicine dispensing device |

Country Status (5)

| Country | Link |

|---|---|

| JP (5) | JP6094952B1 (en) |

| KR (1) | KR102531220B1 (en) |

| CN (1) | CN107847397A (en) |

| TW (1) | TWI730974B (en) |

| WO (1) | WO2017026431A1 (en) |

Families Citing this family (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TWI730974B (en)* | 2015-08-11 | 2021-06-21 | 日商湯山製作所有限公司 | Medicine dispensing device |

| WO2019026027A1 (en)* | 2017-08-04 | 2019-02-07 | 9958304 Canada Inc. (Ypc Technologies) | A system for automatically preparing meals according to a selected recipe and method for operating the same |

| JP7274236B2 (en)* | 2017-11-22 | 2023-05-16 | 株式会社タカゾノ | Powder Dispensing Device, Combination of Powder Dispensing Device and Packaging Device |

| JP6422606B1 (en)* | 2018-03-13 | 2018-11-14 | 株式会社トーショー | Powder container, powder discharge device, and powder dispenser |

| JP6945239B2 (en)* | 2018-03-13 | 2021-10-06 | 株式会社トーショー | Powder storage container, powder discharge device, and powder packaging machine |

| JP6418707B1 (en)* | 2018-03-27 | 2018-11-07 | 株式会社トーショー | Powder storage machine, powder storage container storage shelf of powder distribution machine, powder storage container of powder distribution machine |

| JP6945237B2 (en)* | 2018-05-25 | 2021-10-06 | 株式会社トーショー | Powder vibration transporter, powder packaging machine including powder vibration transporter |

| JP6406785B1 (en)* | 2018-07-03 | 2018-10-17 | 株式会社トーショー | Powder packing machine |

| JP6913951B2 (en)* | 2018-07-03 | 2021-08-04 | 株式会社トーショー | Powder packaging machine |

| JP2020039829A (en)* | 2018-09-13 | 2020-03-19 | 株式会社トーショー | Powder medicine dividing packaging system |

| JP6982842B2 (en)* | 2018-09-14 | 2021-12-17 | 株式会社トーショー | Powder storage container, powder discharger, and powder packaging machine |

| JP2019171004A (en)* | 2018-09-14 | 2019-10-10 | 株式会社トーショー | Powder medicine packing machine, powder medicine receiving container storage shelf of the same, powder medicine receiving container of the same |

| JP2020089681A (en)* | 2018-12-07 | 2020-06-11 | 株式会社タカゾノ | Medicine feeding device and medicine individually packaging device |

| JP7384384B2 (en)* | 2019-10-11 | 2023-11-21 | 株式会社タカゾノ | Pharmaceutical packaging device |

| JP2021108786A (en)* | 2020-01-07 | 2021-08-02 | 株式会社トーショー | Powder measuring device |

| JP6860246B1 (en)* | 2020-02-27 | 2021-04-14 | 株式会社トーショー | Powder packaging device |

| JP7412766B2 (en)* | 2020-07-15 | 2024-01-15 | 株式会社タカゾノ | Pharmaceutical packaging device |

| JP7466901B2 (en)* | 2020-08-04 | 2024-04-15 | 株式会社タカゾノ | Drug Delivery Device |

| JP7513260B2 (en)* | 2020-10-13 | 2024-07-09 | 株式会社タカゾノ | Drug Delivery Device |

| JP7575779B2 (en)* | 2021-02-24 | 2024-10-30 | 株式会社ヨシヤ | Packaging Equipment |

| JP7648152B2 (en)* | 2021-12-01 | 2025-03-18 | 株式会社タカゾノ | Drug delivery device and drug delivery method |

| JP7648154B2 (en)* | 2021-12-10 | 2025-03-18 | 株式会社タカゾノ | Drug Delivery Device |

| JP2023184142A (en)* | 2022-06-17 | 2023-12-28 | 株式会社タカゾノ | drug packaging equipment |

| JP2023184141A (en)* | 2022-06-17 | 2023-12-28 | 株式会社タカゾノ | drug packaging equipment |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0257505A (en)* | 1988-08-23 | 1990-02-27 | Tokyo Shokai:Kk | Automatic powder distributing and dividing apparatus |

| JPH05285198A (en)* | 1992-04-03 | 1993-11-02 | Tokyo Shokai:Kk | Powder medicine supply device |

| JP2002096802A (en)* | 2000-09-21 | 2002-04-02 | Ueda Avancer Corp | Method, apparatus and subdivision-packing apparatus for weighing-type fully automatic separation of powdered medicine |

| JP2013129451A (en)* | 2011-12-22 | 2013-07-04 | Hitachi Aloka Medical Ltd | Powder medicine dispensing device |

| WO2014046148A1 (en)* | 2012-09-19 | 2014-03-27 | 株式会社湯山製作所 | Drug feeder and drug dispensing device |

| JP2015000194A (en)* | 2013-06-17 | 2015-01-05 | システムエルエスアイ株式会社 | Medicine packaging device |

| TW201505912A (en)* | 2013-07-12 | 2015-02-16 | Yuyama Mfg Co Ltd | Drug dispenser and medicament dispensing device |

| WO2015076267A1 (en)* | 2013-11-22 | 2015-05-28 | 株式会社湯山製作所 | Drug dispensing device |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2802964B2 (en)* | 1990-11-22 | 1998-09-24 | 株式会社 東京商会 | Drug packaging machine |

| JPH0653145B2 (en)* | 1991-08-27 | 1994-07-20 | 株式会社東京商会 | Powder supply device |

| JPH0780043A (en) | 1993-09-11 | 1995-03-28 | Tokyo Shokai:Kk | Powder supplying machine |

| JPH11114021A (en)* | 1997-10-17 | 1999-04-27 | Tosho:Kk | Device for supplying powdered medicine |

| JP5978493B2 (en)* | 2011-08-03 | 2016-08-24 | システムエルエスアイ株式会社 | Drug packaging device |

| JP5382263B2 (en)* | 2011-11-11 | 2014-01-08 | 株式会社湯山製作所 | Drug dispensing apparatus and method for calculating remaining amount of drug |

| JP5620451B2 (en)* | 2012-10-11 | 2014-11-05 | スペクトリス株式会社 | Powder quantitative division apparatus and powder quantitative division method |

| JP5716879B1 (en)* | 2013-09-19 | 2015-05-13 | 株式会社湯山製作所 | Mixed injection device, mixed injection method |

| TWI730974B (en)* | 2015-08-11 | 2021-06-21 | 日商湯山製作所有限公司 | Medicine dispensing device |

- 2016

- 2016-08-05TWTW105124961Apatent/TWI730974B/enactive

- 2016-08-08WOPCT/JP2016/073247patent/WO2017026431A1/ennot_activeCeased

- 2016-08-08KRKR1020187003215Apatent/KR102531220B1/enactiveActive

- 2016-08-08JPJP2016557671Apatent/JP6094952B1/enactiveActive

- 2016-08-08CNCN201680045611.5Apatent/CN107847397A/enactivePending

- 2016-11-04JPJP2016216489Apatent/JP6924360B2/enactiveActive

- 2021

- 2021-04-02JPJP2021063266Apatent/JP7691728B2/enactiveActive

- 2021-04-28JPJP2021075843Apatent/JP7397497B2/enactiveActive

- 2023

- 2023-11-29JPJP2023201840Apatent/JP2024019250A/enactivePending

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0257505A (en)* | 1988-08-23 | 1990-02-27 | Tokyo Shokai:Kk | Automatic powder distributing and dividing apparatus |

| JPH05285198A (en)* | 1992-04-03 | 1993-11-02 | Tokyo Shokai:Kk | Powder medicine supply device |

| JP2002096802A (en)* | 2000-09-21 | 2002-04-02 | Ueda Avancer Corp | Method, apparatus and subdivision-packing apparatus for weighing-type fully automatic separation of powdered medicine |

| JP2013129451A (en)* | 2011-12-22 | 2013-07-04 | Hitachi Aloka Medical Ltd | Powder medicine dispensing device |

| WO2014046148A1 (en)* | 2012-09-19 | 2014-03-27 | 株式会社湯山製作所 | Drug feeder and drug dispensing device |

| JP2015000194A (en)* | 2013-06-17 | 2015-01-05 | システムエルエスアイ株式会社 | Medicine packaging device |

| TW201505912A (en)* | 2013-07-12 | 2015-02-16 | Yuyama Mfg Co Ltd | Drug dispenser and medicament dispensing device |

| WO2015076267A1 (en)* | 2013-11-22 | 2015-05-28 | 株式会社湯山製作所 | Drug dispensing device |

Also Published As

| Publication number | Publication date |

|---|---|

| JP7691728B2 (en) | 2025-06-12 |

| JP6094952B1 (en) | 2017-03-15 |

| TW201707804A (en) | 2017-03-01 |

| KR20180039056A (en) | 2018-04-17 |

| JP2021112579A (en) | 2021-08-05 |

| KR102531220B1 (en) | 2023-05-10 |

| JP2024019250A (en) | 2024-02-08 |

| JP6924360B2 (en) | 2021-08-25 |

| JP2021118894A (en) | 2021-08-12 |

| CN107847397A (en) | 2018-03-27 |

| JP2017056221A (en) | 2017-03-23 |

| WO2017026431A1 (en) | 2017-02-16 |

| JP7397497B2 (en) | 2023-12-13 |

| JPWO2017026431A1 (en) | 2017-08-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWI730974B (en) | Medicine dispensing device | |

| TWI613132B (en) | Drug feeder and dispensing device | |

| JP5788329B2 (en) | Apparatus and method for filling and inspecting capsules | |

| CN100473582C (en) | Packaging Machines and Measuring Machines | |

| JP2008264548A (en) | Method and machine for filling capsules or similar with at least one product, in particular pharmaceutical product in granules | |

| CN101288623B (en) | Granular formulation dispensing and controlling method and device using the method | |

| JP2002230513A (en) | Small article counting and feeding device | |

| JP7194893B2 (en) | powder weighing device | |

| JP2022040353A (en) | Powdered medicine weighing device and medicine dividing and packing system | |

| JP5620451B2 (en) | Powder quantitative division apparatus and powder quantitative division method | |

| ITMI20072177A1 (en) | PACKAGING MACHINE FOR PACKAGING FINE GRAIN PRODUCTS | |

| KR20110113866A (en) | Weighing Devices and Product Counters Having the Same | |

| ITBO20010156A1 (en) | APPARATUS AND PROCEDURE FOR FILLING CONTAINERS WITH POWDERED MATERIAL | |

| JP7315207B2 (en) | drug supply device | |

| TW202134140A (en) | Medicinal powder storage container, medicinal powder weighing device, and medicinal powder automatic packaging machine | |

| TW202138246A (en) | Powder packaging apparatus | |

| JP2023184141A (en) | drug packaging equipment | |

| JP2025081818A (en) | Drug dividing apparatus | |

| JP2022135702A (en) | Automatic powder and tablet packaging device | |

| JP2023184142A (en) | drug packaging equipment | |

| JP2022060860A (en) | Drug supply device |