KR20200070030A - Triboelectric Smart stent - Google Patents

Triboelectric Smart stentDownload PDFInfo

- Publication number

- KR20200070030A KR20200070030AKR1020180157690AKR20180157690AKR20200070030AKR 20200070030 AKR20200070030 AKR 20200070030AKR 1020180157690 AKR1020180157690 AKR 1020180157690AKR 20180157690 AKR20180157690 AKR 20180157690AKR 20200070030 AKR20200070030 AKR 20200070030A

- Authority

- KR

- South Korea

- Prior art keywords

- stent

- pdms

- attached

- pressure

- triboelectricity

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 239000004205dimethyl polysiloxaneSubstances0.000claimsabstractdescription42

- 235000013870dimethyl polysiloxaneNutrition0.000claimsabstractdescription42

- CXQXSVUQTKDNFP-UHFFFAOYSA-NoctamethyltrisiloxaneChemical compoundC[Si](C)(C)O[Si](C)(C)O[Si](C)(C)CCXQXSVUQTKDNFP-UHFFFAOYSA-N0.000claimsabstractdescription42

- 238000004987plasma desorption mass spectroscopyMethods0.000claimsabstractdescription42

- 229920000435poly(dimethylsiloxane)Polymers0.000claimsabstractdescription42

- 230000005611electricityEffects0.000claimsabstractdescription33

- OKTJSMMVPCPJKN-UHFFFAOYSA-NCarbonChemical compound[C]OKTJSMMVPCPJKN-UHFFFAOYSA-N0.000claimsabstractdescription30

- 229910021389grapheneInorganic materials0.000claimsabstractdescription30

- 210000004204blood vesselAnatomy0.000claimsabstractdescription20

- 229910052751metalInorganic materials0.000claimsabstractdescription19

- 239000002184metalSubstances0.000claimsabstractdescription19

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000claimsabstractdescription11

- 230000003746surface roughnessEffects0.000claimsabstractdescription10

- 239000003990capacitorSubstances0.000claimsabstractdescription9

- 239000000843powderSubstances0.000claimsabstractdescription9

- 239000011248coating agentSubstances0.000claimsabstractdescription8

- 238000000576coating methodMethods0.000claimsabstractdescription8

- 238000000034methodMethods0.000claimsabstractdescription8

- 230000000968intestinal effectEffects0.000claimsabstractdescription7

- 238000010438heat treatmentMethods0.000claimsdescription6

- 230000036772blood pressureEffects0.000abstractdescription9

- 239000000126substanceSubstances0.000abstractdescription6

- 210000002429large intestineAnatomy0.000abstractdescription3

- 230000000694effectsEffects0.000abstract1

- 210000000936intestineAnatomy0.000description2

- 238000010586diagramMethods0.000description1

- 239000000203mixtureSubstances0.000description1

- 230000002792vascularEffects0.000description1

Images

Classifications

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F2/00—Filters implantable into blood vessels; Prostheses, i.e. artificial substitutes or replacements for parts of the body; Appliances for connecting them with the body; Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/82—Devices providing patency to, or preventing collapsing of, tubular structures of the body, e.g. stents

- A61F2/86—Stents in a form characterised by the wire-like elements; Stents in the form characterised by a net-like or mesh-like structure

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B5/00—Measuring for diagnostic purposes; Identification of persons

- A61B5/02—Detecting, measuring or recording for evaluating the cardiovascular system, e.g. pulse, heart rate, blood pressure or blood flow

- A61B5/021—Measuring pressure in heart or blood vessels

- A61B5/0215—Measuring pressure in heart or blood vessels by means inserted into the body

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B5/00—Measuring for diagnostic purposes; Identification of persons

- A61B5/68—Arrangements of detecting, measuring or recording means, e.g. sensors, in relation to patient

- A61B5/6846—Arrangements of detecting, measuring or recording means, e.g. sensors, in relation to patient specially adapted to be brought in contact with an internal body part, i.e. invasive

- A61B5/6847—Arrangements of detecting, measuring or recording means, e.g. sensors, in relation to patient specially adapted to be brought in contact with an internal body part, i.e. invasive mounted on an invasive device

- A61B5/6862—Stents

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B5/00—Measuring for diagnostic purposes; Identification of persons

- A61B5/68—Arrangements of detecting, measuring or recording means, e.g. sensors, in relation to patient

- A61B5/6846—Arrangements of detecting, measuring or recording means, e.g. sensors, in relation to patient specially adapted to be brought in contact with an internal body part, i.e. invasive

- A61B5/6867—Arrangements of detecting, measuring or recording means, e.g. sensors, in relation to patient specially adapted to be brought in contact with an internal body part, i.e. invasive specially adapted to be attached or implanted in a specific body part

- A61B5/6876—Blood vessel

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L31/00—Materials for other surgical articles, e.g. stents, stent-grafts, shunts, surgical drapes, guide wires, materials for adhesion prevention, occluding devices, surgical gloves, tissue fixation devices

- A61L31/02—Inorganic materials

- A61L31/022—Metals or alloys

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02N—ELECTRIC MACHINES NOT OTHERWISE PROVIDED FOR

- H02N1/00—Electrostatic generators or motors using a solid moving electrostatic charge carrier

- H02N1/04—Friction generators

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B2560/00—Constructional details of operational features of apparatus; Accessories for medical measuring apparatus

- A61B2560/02—Operational features

- A61B2560/0204—Operational features of power management

- A61B2560/0214—Operational features of power management of power generation or supply

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B2562/00—Details of sensors; Constructional details of sensor housings or probes; Accessories for sensors

- A61B2562/02—Details of sensors specially adapted for in-vivo measurements

- A61B2562/0247—Pressure sensors

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Veterinary Medicine (AREA)

- Vascular Medicine (AREA)

- Public Health (AREA)

- General Health & Medical Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- Engineering & Computer Science (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Surgery (AREA)

- Molecular Biology (AREA)

- Cardiology (AREA)

- Pathology (AREA)

- Biophysics (AREA)

- Physics & Mathematics (AREA)

- Medical Informatics (AREA)

- Oral & Maxillofacial Surgery (AREA)

- Physiology (AREA)

- Transplantation (AREA)

- Chemical & Material Sciences (AREA)

- Inorganic Chemistry (AREA)

- Epidemiology (AREA)

- Materials For Medical Uses (AREA)

- Media Introduction/Drainage Providing Device (AREA)

Abstract

Translated fromKoreanDescription

Translated fromKorean본 발명은 마찰전기를 이용한 스마트 스텐트에 관한 것으로서,The present invention relates to a smart stent using triboelectricity,

더욱 상세하게는 스텐트에 있어서,More specifically, in the stent,

혈관 및 장내벽에 부착할 수 있게 원통모양으로 제작한 스텐트, TENG에 이물질이 닿지 않게 할 수 있게 생체적합한 코팅, Graphene PDMS와 접촉하여 마찰전기를 발생할 수 있게 두께1mm아래로 제작한 알루미늄 금속, 체내에 있는 둥근모양을한 혈관내벽, 생성된 TENG의 마찰전기로 체내의 압력을 측정 할 수 있게 스텐트에 부착한 압력센서, 휘스톤 브릿지에서 정류된 직류전류를 저장할 수 있게 회로에 부착한 캐패시터, TENG에서 발생한 교류전류를 직류전류로 바꿔줄 수 있게 회로에 부착한 휘스톤 브릿지, 금속과 접촉하여 마찰전기를 생성 할 수 있게 Sylgard184A와 Sylgard184B용액을 10:1로 섞어 PDMS를 제작하고 그 PDMS가 굳기전 Graphene가루를 2wt%첨가하여 원심분리기에서 2000rpm으로 5분간 섞은후 진공 오븐을 이용하여 21kpa에서 1시간동안 기포를 제거하고 70도에서 2시간동안 가열하여 굳혀서 유연하게 제작한 Graphene PDMS, 금속과의 접촉면을 늘려 마찰전기 생성량을 증가시킬 수 있도록 굳히는 과정에서 사포를 이용한 표면조도로 구성 하여서,A stent made in a cylindrical shape to be attached to blood vessels and intestinal walls, a biocompatible coating to prevent foreign substances from coming into contact with TENG, and an aluminum metal manufactured under a thickness of 1 mm to generate friction electricity by contact with Graphene PDMS, in the body The inner wall of the blood vessel in a round shape, the pressure sensor attached to the stent to measure the pressure in the body with the generated TENG's friction electricity, the capacitor attached to the circuit to store the rectified DC current in the Wheatstone bridge, TENG The Wheatstone bridge attached to the circuit so that the alternating current generated in the DC current can be converted into a DC current, and the PDMS is prepared by mixing Sylgard184A and Sylgard184B solutions with 10:1 to generate triboelectricity by contact with metal. Graphene PDMS was added to 2 wt% and mixed for 5 minutes at 2000 rpm in a centrifuge, then air bubbles were removed for 1 hour at 21 kpa using a vacuum oven, and heated and hardened for 2 hours at 70°C. In the process of hardening to increase the amount of friction electricity generated by increasing the

대장내에서 발생하는 연동, 분절 운동이나 혈관에서 발생하는 미세한 진동을 동력으로 하여 스텐트에 부착된 TENG에서 마찰전기를 얻을 수 있고 그 전기로 인해 내부 압력센서를 구동하여 혈압 및 체내의 압력을 체외에서 측정가능하도록 함을 목적으로 한 것이다.By using interlocking in the large intestine, segmental movement, or microscopic vibrations generated in blood vessels, triboelectricity can be obtained from the TENG attached to the stent, and the electricity drives the internal pressure sensor to monitor blood pressure and internal pressure. The purpose is to make it measurable.

일반적으로 스텐트는 혈관 및 장내에 삽입되어 혈관내벽 형상을 유지할 수 있게 고정하는 것이다.Generally, the stent is inserted into a blood vessel and an intestine to fix the inner wall of the blood vessel.

상기한 바와 같이 스텐트는 스텐트로 구성된 것이다.As described above, the stent is composed of a stent.

이상과 같은 스텐트는 카테터를 이용하여 장내 및 혈관 안쪽에 삽입되어 내벽의 크기에 맞게 고정하는 것이다.The stent as described above is inserted into the intestine and inside the blood vessel using a catheter and fixed to the size of the inner wall.

그러나 상기한 바와 같은 종래의 스텐트는 스텐트에 압력센서를 부착하여 혈압 및 체내의 압력을 측정할수 있는 문제점이 있었다.However, the conventional stent as described above has a problem in that a pressure sensor is attached to the stent to measure blood pressure and pressure in the body.

이에 본 발명은 종래의 스텐트가 스텐트에 압력센서를 부착하여 혈압 및 체내의 압력을 측정할수 있는 문제점을 해결하기 위한 것이다.Accordingly, the present invention is to solve the problem that a conventional stent can attach a pressure sensor to the stent to measure blood pressure and pressure in the body.

즉, 본 발명은 혈관 및 장내벽에 부착할 수 있게 원통모양으로 제작한 스텐트, TENG에 이물질이 닿지 않게 할 수 있게 생체적합한 코팅, Graphene PDMS와 접촉하여 마찰전기를 발생할 수 있게 두께1mm아래로 제작한 알루미늄 금속, 체내에 있는 둥근모양을한 혈관내벽, 생성된 TENG의 마찰전기로 체내의 압력을 측정 할 수 있게 스텐트에 부착한 압력센서, 휘스톤 브릿지에서 정류된 직류전류를 저장할 수 있게 회로에 부착한 캐패시터, TENG에서 발생한 교류전류를 직류전류로 바꿔줄 수 있게 회로에 부착한 휘스톤 브릿지, 금속과 접촉하여 마찰전기를 생성 할 수 있게 Sylgard184A와 Sylgard184B용액을 10:1로 섞어 PDMS를 제작하고 그 PDMS가 굳기전 Graphene가루를 2wt%첨가하여 원심분리기에서 2000rpm으로 5분간 섞은후 진공 오븐을 이용하여 21kpa에서 1시간동안 기포를 제거하고 70도에서 2시간동안 가열하여 굳혀서 유연하게 제작한 Graphene PDMS, 금속과의 접촉면을 늘려 마찰전기 생성량을 증가시킬 수 있도록 굳히는 과정에서 사포를 이용한 표면조도로 구성한 것이다.That is, the present invention is made of a stent made of a cylindrical shape to be attached to blood vessels and intestinal walls, a biocompatible coating to prevent foreign substances from contacting TENG, and a thickness of 1 mm or less to generate frictional electricity by contacting Graphene PDMS. One aluminum metal, inner wall of blood vessel inside the body, pressure sensor attached to the stent to measure the pressure in the body with the generated TENG's friction electricity, and circuit to store the DC current rectified by the Wheatstone Bridge. Attached capacitor, Wheatstone bridge attached to the circuit to convert AC current generated in TENG to DC current, and Sylgard184A and Sylgard184B solution mixed with 10:1 to produce friction electricity by contact with metal to produce PDMS. Graphene PDMS, which was flexibly produced by adding 2 wt% of Graphene powder before the PDMS was hardened, mixing at 2000 rpm for 5 minutes, removing air bubbles at 21 kpa for 1 hour using a vacuum oven, and heating at 70 degrees for 2 hours to harden. , It is composed of surface roughness using sandpaper in the process of hardening to increase the amount of friction electricity generated by increasing the contact surface with metal.

따라서 본 발명은 혈관 및 장내벽에 부착할 수 있게 원통모양으로 제작한 스텐트, TENG에 이물질이 닿지 않게 할 수 있게 생체적합한 코팅, Graphene PDMS와 접촉하여 마찰전기를 발생할 수 있게 두께1mm아래로 제작한 알루미늄 금속, 체내에 있는 둥근모양을한 혈관내벽, 생성된 TENG의 마찰전기로 체내의 압력을 측정 할 수 있게 스텐트에 부착한 압력센서, 휘스톤 브릿지에서 정류된 직류전류를 저장할 수 있게 회로에 부착한 캐패시터, TENG에서 발생한 교류전류를 직류전류로 바꿔줄 수 있게 회로에 부착한 휘스톤 브릿지, 금속과 접촉하여 마찰전기를 생성 할 수 있게 Sylgard184A와 Sylgard184B용액을 10:1로 섞어 PDMS를 제작하고 그 PDMS가 굳기전 Graphene가루를 2wt%첨가하여 원심분리기에서 2000rpm으로 5분간 섞은후 진공 오븐을 이용하여 21kpa에서 1시간동안 기포를 제거하고 70도에서 2시간동안 가열하여 굳혀서 유연하게 제작한 Graphene PDMS, 금속과의 접촉면을 늘려 마찰전기 생성량을 증가시킬 수 있도록 굳히는 과정에서 사포를 이용한 표면조도로 구성 함으로써, 대장내에서 발생하는 연동, 분절 운동이나 혈관에서 발생하는 미세한 진동을 동력으로 하여 스텐트에 부착된 TENG에서 마찰전기를 얻을 수 있고 그 전기로 인해 내부 압력센서를 구동하여 혈압 및 체내의 압력을 체외에서 측정가능하도록 한 효과를 갖는 것이다.Therefore, the present invention is a stent manufactured in a cylindrical shape to be attached to blood vessels and intestinal walls, a biocompatible coating to prevent foreign substances from contacting TENG, and a thickness of 1 mm or less to generate friction electricity by contacting Graphene PDMS. Aluminum metal, the inner wall of blood vessel inside the body, the pressure sensor attached to the stent to measure the pressure in the body with the generated TENG's friction electricity, attached to the circuit to store the rectified DC current from the Wheatstone Bridge A capacitor, a Wheatstone bridge attached to a circuit to convert AC current generated in TENG to DC current, and Sylgard184A and Sylgard184B solutions mixed with 10:1 to produce triboelectricity by making contact with metal to produce PDMS. Graphene PDMS, which was flexibly produced by adding 2 wt% of Graphene powder before PDMS hardening, mixing at 2000 rpm for 5 minutes, removing air bubbles at 21 kpa for 1 hour using a vacuum oven, and heating at 70 degrees for 2 hours to harden. It is composed of surface roughness using sandpaper in the process of hardening to increase the amount of frictional electricity generated by increasing the contact surface with metal. It is possible to obtain triboelectricity from TENG, and by doing so, the internal pressure sensor is driven to measure blood pressure and pressure in the body outside the body.

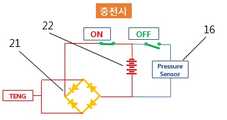

도 1: 회로 구성도1: Circuit diagram

도 2: 스텐트 구성도Figure 2: Stent configuration

즉, 본 발명은 혈관 및 장내벽에 부착할 수 있게 원통모양으로 제작한 (11)스텐트, TENG에 이물질이 닿지 않게 할 수 있게 생체적합한 (12)코팅, Graphene PDMS와 접촉하여 마찰전기를 발생할 수 있게 두께1mm아래로 제작한 (13)알루미늄 금속, 체내에 있는 둥근모양을한 (17)혈관내벽, 생성된 TENG의 마찰전기로 체내의 압력을 측정 할 수 있게 스텐트에 부착한 (16)압력센서, 휘스톤 브릿지에서 정류된 직류전류를 저장할 수 있게 회로에 부착한 (22)캐패시터, TENG에서 발생한 교류전류를 직류전류로 바꿔줄 수 있게 회로에 부착한 (21)휘스톤 브릿지, 금속과 접촉하여 마찰전기를 생성 할 수 있게 Sylgard184A와 Sylgard184B용액을 10:1로 섞어 PDMS를 제작하고 그 PDMS가 굳기전 Graphene가루를 2wt%첨가하여 원심분리기에서 2000rpm으로 5분간 섞은후 진공 오븐을 이용하여 21kpa에서 1시간동안 기포를 제거하고 70도에서 2시간동안 가열하여 굳혀서 유연하게 제작한 (14)Graphene PDMS, 금속과의 접촉면을 늘려 마찰전기 생성량을 증가시킬 수 있도록 굳히는 과정에서 사포를 이용한 (15)표면조도로 구성 된 것이다.In other words, the present invention is a (11) stent made of a cylindrical shape to be attached to blood vessels and intestinal walls, biocompatible (12) coating to prevent foreign substances from contacting TENG, and contact with Graphene PDMS to generate triboelectricity. (13) aluminum metal fabricated under a thickness of 1 mm, rounded shape in the body (17) blood vessel inner wall, attached to the stent to measure pressure in the body with the frictional electricity of the generated TENG (16) pressure sensor , A capacitor attached to the circuit to store the rectified DC current at the Wheatstone bridge (22), a capacitor attached to the circuit to convert the alternating current generated by TENG into a DC current (21) The Wheatstone bridge, in contact with metal To generate triboelectricity, Sylgard184A and Sylgard184B solutions were mixed with 10:1 to prepare PDMS, and 2 wt% of Graphene powder was added to the PDMS before the PDMS hardened, followed by mixing for 5 minutes at 2000 rpm in a centrifuge, and then using a vacuum oven at 21 kpa 1 (14)Graphene PDMS, which was softened by removing air bubbles for a period of time and heating at 70°C for 2 hours, to increase the amount of frictional electricity generated by increasing the contact surface with metal (MS) (15) Surface roughness using sandpaper It consists of.

여기서, (13)알루미늄 금속은 Graphene PDMS와 접촉하여 마찰전기를 발생할 수 있게 두께1mm아래로 제작한 것이다.Here, (13) aluminum metal is manufactured to a thickness of 1 mm or less so that friction electricity can be generated by contact with Graphene PDMS.

여기서, (16)압력센서는 생성된 TENG의 마찰전기로 체내의 압력을 측정 할 수 있게 스텐트에 부착한 것이다.Here, (16) the pressure sensor is attached to the stent so that the pressure in the body can be measured by the generated frictional electricity of TENG.

여기서, (14)Graphene PDMS은 금속과 접촉하여 마찰전기를 생성 할 수 있게 Sylgard184A와 Sylgard184B용액을 10:1로 섞어 PDMS를 제작하고 그 PDMS가 굳기전 Graphene가루를 2wt%첨가하여 원심분리기에서 2000rpm으로 5분간 섞은후 진공 오븐을 이용하여 21kpa에서 1시간동안 기포를 제거하고 70도에서 2시간동안 가열하여 굳혀서 유연하게 제작한 것이다.Here, (14) Graphene PDMS is made by mixing Sylgard184A and Sylgard184B solutions in a 10:1 ratio to generate triboelectricity by contact with metal to produce PDMS.The graphene powder is added 2 wt% before the PDMS hardens to 2000 rpm in a centrifuge. After mixing for 5 minutes, air bubbles were removed for 1 hour at 21 kpa using a vacuum oven, and then heated at 70 degrees for 2 hours to harden.

여기서, (15)표면조도는 금속과의 접촉면을 늘려 마찰전기 생성량을 증가시킬 수 있도록 굳히는 과정에서 사포를 이용한 것이다.Here, (15) surface roughness is to use sandpaper in the process of hardening to increase the amount of friction electricity generated by increasing the contact surface with the metal.

이하, 본 발명의 사용과정에 대하여 설명하면 다음과 같다.Hereinafter, the use process of the present invention will be described.

상기한 바와 같이 본 발명은 스텐트에 있어서 혈관 및 장내벽에 부착할 수 있게 원통모양으로 제작한 (11)스텐트, TENG에 이물질이 닿지 않게 할 수 있게 생체적합한 (12)코팅, Graphene PDMS와 접촉하여 마찰전기를 발생할 수 있게 두께1mm아래로 제작한 (13)알루미늄 금속, 체내에 있는 둥근모양을한 (17)혈관내벽, 생성된 TENG의 마찰전기로 체내의 압력을 측정 할 수 있게 스텐트에 부착한 (16)압력센서, 휘스톤 브릿지에서 정류된 직류전류를 저장할 수 있게 회로에 부착한 (22)캐패시터, TENG에서 발생한 교류전류를 직류전류로 바꿔줄 수 있게 회로에 부착한 (21)휘스톤 브릿지, 금속과 접촉하여 마찰전기를 생성 할 수 있게 Sylgard184A와 Sylgard184B용액을 10:1로 섞어 PDMS를 제작하고 그 PDMS가 굳기전 Graphene가루를 2wt%첨가하여 원심분리기에서 2000rpm으로 5분간 섞은후 진공 오븐을 이용하여 21kpa에서 1시간동안 기포를 제거하고 70도에서 2시간동안 가열하여 굳혀서 유연하게 제작한 (14)Graphene PDMS, 금속과의 접촉면을 늘려 마찰전기 생성량을 증가시킬 수 있도록 굳히는 과정에서 사포를 이용한 (15)표면조도로 구성된 본 발명을 적용하여 실시하게 되면, 스텐트에 압력센서를 부착하여 혈압 및 체내의 압력을 측정할수 있는 문제점을 해소하도록 한 것이다.As described above, the present invention provides (11) a stent manufactured in a cylindrical shape to be attached to a blood vessel and an intestinal wall in a stent, and biocompatible (12) coating to prevent foreign substances from contacting the TENG, in contact with Graphene PDMS. (13) Aluminum metal fabricated under a thickness of 1 mm to generate friction electricity, (17) an inner wall of the blood vessel, and attached to the stent to measure the pressure in the body with the friction electricity of the generated TENG. (16) Pressure sensor, attached to the circuit to store the rectified DC current from the Wheatstone bridge (22) Capacitor, attached to the circuit to convert the alternating current generated by TENG to DC current (21) , Sylgard184A and Sylgard184B solutions are mixed with 10:1 to produce friction electricity in contact with metal, PDMS is prepared, and 2 wt% of Graphene powder is added before the PDMS hardens, mixed at 2000 rpm for 5 minutes in a centrifuge and vacuum oven (14) Graphene PDMS fabricated flexibly by removing air bubbles at 21 kpa for 1 hour and heating at 70 degrees for 2 hours to increase the amount of friction electricity generated by increasing the contact surface with metal. (15) When applied to the present invention consisting of surface roughness, the pressure sensor is attached to the stent to solve the problem of measuring blood pressure and pressure in the body.

또한 본 발명의 실시에 있어, 두께1mm아래로 제작한 (13)알루미늄 금속으로 구성한 본 발명을 적용하여 실시하게 되면, Graphene PDMS와 접촉하여 마찰전기를 발생할 수 있게 될 것이다.In addition, in the practice of the present invention, if the present invention is made of (13) aluminum metal fabricated to a thickness of 1 mm or less, it will be possible to generate friction electricity in contact with Graphene PDMS.

또한 본 발명의 실시에 있어, 스텐트에 부착한 (16)압력센서로 구성한 본 발명을 적용하여 실시하게 되면, 생성된 TENG의 마찰전기로 체내의 압력을 측정 할 수 있게 될 것이다.In addition, in the practice of the present invention, if the present invention is constructed by applying the (16) pressure sensor attached to the stent, it will be possible to measure the pressure in the body with the generated frictional electricity of the TENG.

또한 본 발명의 실시에 있어, Sylgard184A와 Sylgard184B용액을 10:1로 섞어 PDMS를 제작하고 그 PDMS가 굳기전 Graphene가루를 2wt%첨가하여 원심분리기에서 2000rpm으로 5분간 섞은후 진공 오븐을 이용하여 21kpa에서 1시간동안 기포를 제거하고 70도에서 2시간동안 가열하여 굳혀서 유연하게 제작한 (14)Graphene PDMS으로 구성한 본 발명을 적용하여 실시하게 되면, 금속과 접촉하여 마찰전기를 생성 할 수 있게 될 것이다.In addition, in the practice of the present invention, a mixture of Sylgard184A and Sylgard184B is mixed in a 10:1 ratio to produce PDMS, 2 wt% of Graphene powder is added before the PDMS hardens, mixed at 2000 rpm for 5 minutes in a centrifuge, and then vacuumed at 21 kpa. If the present invention is constructed of (14)Graphene PDMS, which is flexible and manufactured by removing air bubbles for 1 hour and heating at 70 degrees for 2 hours, it will be able to generate friction electricity by contact with metal.

또한 본 발명의 실시에 있어, 굳히는 과정에서 사포를 이용한 (15)표면조도로 구성한 본 발명을 적용하여 실시하게 되면, 금속과의 접촉면을 늘려 마찰전기 생성량을 증가시킬 수 있도록 될 것이다.In addition, in the practice of the present invention, in the process of hardening, applying the present invention consisting of (15) surface roughness using sandpaper, the contact surface with the metal will be increased to increase the amount of frictional electricity generated.

11: 스텐트, 12: 코팅, 13: 알루미늄 금속, 17: 혈관내벽, 16: 압력센서, 22: 캐패시터, 21: 휘스톤 브릿지, 14: Graphene PDMS, 15: 표면조도11: Stent, 12: Coating, 13: Aluminum metal, 17: Vascular inner wall, 16: Pressure sensor, 22: Capacitor, 21: Wheatstone bridge, 14: Graphene PDMS, 15: Surface roughness

Claims (5)

Translated fromKorean혈관 및 장내벽에 부착할 수 있게 원통모양으로 제작한 (11)스텐트, TENG에 이물질이 닿지 않게 할 수 있게 생체적합한 (12)코팅, Graphene PDMS와 접촉하여 마찰전기를 발생할 수 있게 두께1mm아래로 제작한 (13)알루미늄 금속, 체내에 있는 둥근모양을한 (17)혈관내벽, 생성된 TENG의 마찰전기로 체내의 압력을 측정 할 수 있게 스텐트에 부착한 (16)압력센서, 휘스톤 브릿지에서 정류된 직류전류를 저장할 수 있게 회로에 부착한 (22)캐패시터, TENG에서 발생한 교류전류를 직류전류로 바꿔줄 수 있게 회로에 부착한 (21)휘스톤 브릿지, 금속과 접촉하여 마찰전기를 생성 할 수 있게 Sylgard184A와 Sylgard184B용액을 10:1로 섞어 PDMS를 제작하고 그 PDMS가 굳기전 Graphene가루를 2wt%첨가하여 원심분리기에서 2000rpm으로 5분간 섞은후 진공 오븐을 이용하여 21kpa에서 1시간동안 기포를 제거하고 70도에서 2시간동안 가열하여 굳혀서 유연하게 제작한 (14)Graphene PDMS, 금속과의 접촉면을 늘려 마찰전기 생성량을 증가시킬 수 있도록 굳히는 과정에서 사포를 이용한 (15)표면조도로 구성 된 것을 특징으로 하는 마찰전기를 이용한 스마트 스텐트.In the stent,

Cylindrical (11) stent made to be attached to blood vessels and intestinal walls, biocompatible (12) coating to prevent foreign matter from contacting TENG, and contact with Graphene PDMS to generate frictional electricity below 1 mm in thickness Manufactured by (13) aluminum metal, rounded in the body (17) blood vessel inner wall, generated by TENG's friction electricity (16) pressure sensor attached to the stent to measure pressure in the body, from the Wheatstone Bridge (22) Capacitor attached to the circuit to store the rectified DC current, (21) Wheatstone bridge attached to the circuit to convert the alternating current generated in TENG to DC current, to generate friction electricity by contact with metal To make the PDMS by mixing the Sylgard184A and Sylgard184B solutions at 10:1, the graphene powder was added 2 wt% before the PDMS hardened, mixed at 2000 rpm for 5 minutes in a centrifuge, and then the air bubbles were removed at 21 kpa for 1 hour using a vacuum oven. (14) Graphene PDMS, which was softened by heating for 2 hours at 70 degrees, and made to be flexible so as to increase the amount of frictional electricity generated by increasing the contact surface with metal (15) Surface roughness using sandpaper Smart stent using friction electricity.

(13)알루미늄 금속을 통하여 Graphene PDMS와 접촉하여 마찰전기를 발생할 수 있게 두께1mm아래로 제작함을 특징으로 하는 마찰전기를 이용한 스마트 스텐트.According to claim 1,

(13) Smart stent using triboelectricity, characterized in that it is manufactured below 1mm in thickness to generate triboelectricity by contacting Graphene PDMS through aluminum metal.

(16)압력센서를 통하여 생성된 TENG의 마찰전기로 체내의 압력을 측정 할 수 있게 스텐트에 부착함을 특징으로 하는 마찰전기를 이용한 스마트 스텐트.According to claim 1,

(16) Smart stent using triboelectricity, characterized in that it is attached to the stent so that the pressure in the body can be measured with triboelectricity generated by the pressure sensor.

(14)Graphene PDMS을 통하여 금속과 접촉하여 마찰전기를 생성 할 수 있게 Sylgard184A와 Sylgard184B용액을 10:1로 섞어 PDMS를 제작하고 그 PDMS가 굳기전 Graphene가루를 2wt%첨가하여 원심분리기에서 2000rpm으로 5분간 섞은후 진공 오븐을 이용하여 21kpa에서 1시간동안 기포를 제거하고 70도에서 2시간동안 가열하여 굳혀서 유연하게 제작함을 특징으로 하는 마찰전기를 이용한 스마트 스텐트.According to claim 1,

(14) The PDMS was prepared by mixing Sylgard184A and Sylgard184B solutions in a 10:1 ratio to generate triboelectricity by contacting the metal through graphene PDMS, and adding 2% by weight of Graphene powder before the PDMS hardened to 2000rpm in a centrifuge 5 After mixing for a minute, using a vacuum oven, air bubbles are removed at 21 kpa for 1 hour, and heated at 70 degrees for 2 hours to harden and softly produced.

(15)표면조도를 통하여 금속과의 접촉면을 늘려 마찰전기 생성량을 증가시킬 수 있도록 굳히는 과정에서 사포를 이용함을 특징으로 하는 마찰전기를 이용한 스마트 스텐트.According to claim 1,

(15) Smart stent using triboelectricity, characterized in that sandpaper is used in the process of hardening to increase the amount of triboelectricity by increasing the contact surface with metal through surface roughness.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020180157690AKR20200070030A (en) | 2018-12-08 | 2018-12-08 | Triboelectric Smart stent |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020180157690AKR20200070030A (en) | 2018-12-08 | 2018-12-08 | Triboelectric Smart stent |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20200070030Atrue KR20200070030A (en) | 2020-06-17 |

Family

ID=71405814

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020180157690AWithdrawnKR20200070030A (en) | 2018-12-08 | 2018-12-08 | Triboelectric Smart stent |

Country Status (1)

| Country | Link |

|---|---|

| KR (1) | KR20200070030A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20220304581A1 (en)* | 2020-06-24 | 2022-09-29 | Zhejiang University | Vasospasm monitoring device based on triboelectrification technology |

| WO2023163705A1 (en)* | 2022-02-24 | 2023-08-31 | Bard Peripheral Vascular, Inc. | Smart stent with triboelectric nano-generators (teng) to detect restenosis |

| CN120171720A (en)* | 2025-05-20 | 2025-06-20 | 中国石油大学(华东) | Underwater self-driving anti-biofouling device and method based on wave-current friction nano-power generation |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20180071414A (en) | 2012-03-16 | 2018-06-27 | 마이크로벤션, 인코포레이티드 | Stent and stent delivery device |

- 2018

- 2018-12-08KRKR1020180157690Apatent/KR20200070030A/ennot_activeWithdrawn

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20180071414A (en) | 2012-03-16 | 2018-06-27 | 마이크로벤션, 인코포레이티드 | Stent and stent delivery device |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20220304581A1 (en)* | 2020-06-24 | 2022-09-29 | Zhejiang University | Vasospasm monitoring device based on triboelectrification technology |

| US12251198B2 (en)* | 2020-06-24 | 2025-03-18 | Zhejiang University | Vasospasm monitoring device based on triboelectrification technology |

| WO2023163705A1 (en)* | 2022-02-24 | 2023-08-31 | Bard Peripheral Vascular, Inc. | Smart stent with triboelectric nano-generators (teng) to detect restenosis |

| CN120171720A (en)* | 2025-05-20 | 2025-06-20 | 中国石油大学(华东) | Underwater self-driving anti-biofouling device and method based on wave-current friction nano-power generation |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20200070030A (en) | Triboelectric Smart stent | |

| Li et al. | Recent developments in dopamine-based materials for cancer diagnosis and therapy | |

| Schmidlin et al. | Effect of different surface pre-treatments and luting materials on shear bond strength to PEEK | |

| Yang et al. | Durability of resin bonding to zirconia using products containing 10-methacryloyloxydecyl dihydrogen phosphate | |

| De La Isla et al. | Nanohybrid scratch resistant coatings for teeth and bone viscoelasticity manifested in tribology | |

| Manly | Adhesion in biological systems | |

| El Bahra et al. | Linear and volumetric dimensional changes of injection-molded PMMA denture base resins | |

| Makkar et al. | Development and properties of duplex MgF2/PCL coatings on biodegradable magnesium alloy for biomedical applications | |

| ATE538757T1 (en) | IN VIVO SENSOR AND METHOD FOR PRODUCING IT | |

| Reis et al. | Effect of relining, water storage and cyclic loading on the flexural strength of a denture base acrylic resin | |

| ATE518127T1 (en) | METHOD AND DEVICE FOR DETERMINING THE HARDNESS OF SEMI-SOLID MATERIALS | |

| Szabelski et al. | Analysis of the Effect of Component Ratio Imbalances on Selected Mechanical Properties of Seasoned, Medium Viscosity Bone Cements | |

| Yilmaz | Investigating the effect of chewing force and an abrasive medium on the wear resistance of composite materials by chewing simulation | |

| Liu et al. | Influence of glucose on corrosion fatigue and cytocompatibility of Mg–Zn–Zr–Y alloy | |

| Wang et al. | The effect of nitrogen plasma treatment on adhesive properties of PEEK | |

| Oh et al. | Surface forces apparatus and its applications for nanomechanics of underwater adhesives | |

| Feng et al. | Modal damping factor detected with an impulse-forced vibration method provides additional information on osseointegration during dental implant healing. | |

| Nicodemo et al. | Micro-hardness of acrylic resin utilized for provisional crowns: effect of different polymerization techniques and pH-cycling | |

| Eskandarizadeh et al. | The Effect of Aging on Nano-Hardness and Modulus of Elasticity of Four Types of Composites: An in-vitro Study. | |

| RU2636398C1 (en) | Method for dental restoration materials wear-resistance determination | |

| Kumar et al. | Evaluation and assessment of bonding of heat cure acrylic resin to cobalt-chromium alloy: Old ideas employing newer concepts | |

| Antonov et al. | Age dependent changes of arterial wall viscoelasticity | |

| Patel et al. | The effect of primer on bond strength of silicone prosthetic elastomer to polymethylmethacrylate: an in vitro study | |

| Vishwanath et al. | The effect of surface pretreatments on the bond strength of Soft denture lining materials to heat polymerized Polymethyl methacrylate (PMMA) denture base resin-an in vitro study | |

| Wang et al. | Effect of angular displacement amplitude on the torsional fretting corrosion behavior of CoCrMo alloy in different synovial fluid |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0109 | Patent application | Patent event code:PA01091R01D Comment text:Patent Application Patent event date:20181208 | |

| PG1501 | Laying open of application | ||

| PC1203 | Withdrawal of no request for examination |