KR20120033091A - Apparatus and method for removing carbon - Google Patents

Apparatus and method for removing carbonDownload PDFInfo

- Publication number

- KR20120033091A KR20120033091AKR1020100094690AKR20100094690AKR20120033091AKR 20120033091 AKR20120033091 AKR 20120033091AKR 1020100094690 AKR1020100094690 AKR 1020100094690AKR 20100094690 AKR20100094690 AKR 20100094690AKR 20120033091 AKR20120033091 AKR 20120033091A

- Authority

- KR

- South Korea

- Prior art keywords

- carbon

- oxygen concentration

- riser

- change

- bleeder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10B—DESTRUCTIVE DISTILLATION OF CARBONACEOUS MATERIALS FOR PRODUCTION OF GAS, COKE, TAR, OR SIMILAR MATERIALS

- C10B43/00—Preventing or removing incrustations

- C10B43/02—Removing incrustations

- C10B43/10—Removing incrustations by burning out

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10B—DESTRUCTIVE DISTILLATION OF CARBONACEOUS MATERIALS FOR PRODUCTION OF GAS, COKE, TAR, OR SIMILAR MATERIALS

- C10B27/00—Arrangements for withdrawal of the distillation gases

- C10B27/04—Arrangements for withdrawal of the distillation gases during the charging operation of the oven

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10B—DESTRUCTIVE DISTILLATION OF CARBONACEOUS MATERIALS FOR PRODUCTION OF GAS, COKE, TAR, OR SIMILAR MATERIALS

- C10B41/00—Safety devices, e.g. signalling or controlling devices for use in the discharge of coke

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Coke Industry (AREA)

Abstract

Translated fromKoreanDescription

Translated fromKorean본 발명은 카본 제거 방법 및 그 장치에 관한 것이다. 보다 상세하게는, 세라믹 히터를 이용하여 코크스 상승관 내 카본을 제거하는 방법 및 그 장치에 관한 것이다.The present invention relates to a method for removing carbon and a device thereof. More specifically, the present invention relates to a method and apparatus for removing carbon in a coke riser using a ceramic heater.

제철산업에서는 코크스를 산화철을 환원시키는 환원제로 사용하고 있다. 이러한, 코크스는 코크스 오븐(Coke Oven)에서 1100℃이상의 고온에서 석탄을 건류하여 제조한다.In the steel industry, coke is used as a reducing agent to reduce iron oxide. Such coke is produced by distilling coal at a high temperature of 1100 ° C. or higher in a coke oven.

코크스 오븐은 탄화실에 장입되는 석탄을 간접가열하여 코크스를 제조하는 설비이다. 석탄은 장입차에 의해 탄화실에 장입되며, 석탄의 장입과정에서 발생되는 다량의 가스와 분진은 상승관을 통하여 배출된다.The coke oven is a facility for manufacturing coke by indirectly heating coal charged in a carbonization chamber. Coal is charged to the carbonization chamber by a charging car, and a large amount of gas and dust generated during the charging process of the coal is discharged through the riser.

코크스 제조과정에서는 석탄 내 포함된 휘발성 탄소성분이 열분해 되어, 코크스 오븐의 노벽 및 상승관에 카본의 형태로 부착되게 된다. 여기서, 카본은 탄소 약83%와 수소 약2%로 구성되어 있다. 즉, 카본은 탄화수소의 연소현상에서 국소적인 산소부족으로 생성되는 그을음(soot)과 매우 유사한 성질을 가지고 있다.In the coke manufacturing process, volatile carbon components contained in coal are thermally decomposed and attached to the furnace wall and the riser of the coke oven in the form of carbon. Here, carbon is composed of about 83% carbon and about 2% hydrogen. In other words, carbon has properties very similar to soot produced by local oxygen deficiency in hydrocarbon combustion.

본 발명은 세라믹 히터를 이용하여 상승관 내 카본을 제거하는 방법 및 그 장치를 제공하는 것을 목적으로 한다.An object of the present invention is to provide a method and apparatus for removing carbon in a riser using a ceramic heater.

상기 과제를 해결하기 위한 본 발명의 일 실시예에 따른, 카본 제거 장치는Carbon removal device according to an embodiment of the present invention for solving the above problems is

상승관 내부의 산소 농도를 감지하는 산소센서; 상기 산소 농도의 변화를 검출하는 농도 변화 검출부; 상기 상승관 내부에 위치하는 발열부; 및 상기 산소 농도의 변화가 기준치 이상인 경우, 상기 발열부를 특정 온도로 승온하여 상기 상승관 내 위치하는 카본을 제거하는 제어부를 포함한다.An oxygen sensor for sensing oxygen concentration inside the riser; A concentration change detector for detecting a change in the oxygen concentration; A heating unit located inside the riser; And a control unit for removing the carbon located in the riser by raising the heat generating unit to a specific temperature when the change of the oxygen concentration is equal to or more than a reference value.

상기 과제를 해결하기 위한 본 발명의 다른 실시예에 따른, 카본 제거 방법은Carbon removal method according to another embodiment of the present invention for solving the above problems is

산소센서에 의해 상승관 내부의 산소 농도를 감지하는 단계; 농도 변화 검출부에 의해 상기 산소 농도의 변화를 검출하는 단계; 및 제어부에 의해 상기 산소 농도의 변화가 기준치 이상인 경우, 발열부를 특정 온도로 승온하여 상기 상승관 내 위치하는 카본을 제거하는 단계를 포함한다.Detecting an oxygen concentration inside the riser by an oxygen sensor; Detecting a change in the oxygen concentration by a concentration change detector; And removing, by the control unit, the carbon located in the riser by raising the heat generating unit to a specific temperature when the change in the oxygen concentration is equal to or more than a reference value.

본 발명의 카본 제거 방법 및 그 장치에 의하면, 건류 시 코크스 상승관에 부착되는 카본을 효율적으로 제거하여 코크스 공정시 발생하는 부생가스를 화성정제 공정으로 원활하게 이송시킬 수 있다.According to the carbon removal method and apparatus of the present invention, the carbon adhering to the coke rising pipe during dry distillation can be efficiently removed, and the by-product gas generated during the coke process can be smoothly transferred to the chemical conversion process.

또한 본 발명의 카본 제거 방법 및 그 장치에 의하면 카본을 효율적으로 제거함으로써, 코크스 공정시 발생하는 부생가스를 이송시켜 부생가스의 안정적 생산 및 코크스 조업의 안정성을 확보할 수 있다.In addition, according to the carbon removal method and apparatus of the present invention, by efficiently removing carbon, by-product gas generated during the coke process can be transferred to ensure stable production of the by-product gas and stability of coke operation.

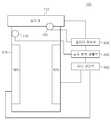

도 1은 본 발명의 실시예에 따른 카본 제거 장치가 적용된 환경을 개략적으로 나타내는 도면이다.

도 2는 본 발명의 실시예에 따른 카본 제거 장치를 나타내는 구성도이다.

도 3은 본 발명의 실시예에 따른 카본 제거 방법을 나타내는 흐름도이다.1 is a view schematically showing an environment to which a carbon removal device according to an embodiment of the present invention is applied.

2 is a block diagram showing a carbon removal device according to an embodiment of the present invention.

3 is a flowchart illustrating a carbon removal method according to an embodiment of the present invention.

본 발명을 첨부된 도면을 참조하여 상세히 설명하면 다음과 같다. 여기서, 반복되는 설명, 본 발명의 요지를 불필요하게 흐릴 수 있는 공지 기능, 및 구성에 대한 상세한 설명은 생략한다. 본 발명의 실시형태는 당 업계에서 평균적인 지식을 가진 자에게 본 발명을 보다 완전하게 설명하기 위해서 제공되는 것이다. 따라서, 도면에서의 요소들의 형상 및 크기 등은 보다 명확한 설명을 위해 과장될 수 있다.

Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. Here, the repeated description, well-known functions and configurations that may unnecessarily obscure the subject matter of the present invention, and detailed description of the configuration will be omitted. Embodiments of the present invention are provided to more completely describe the present invention to those skilled in the art. Accordingly, the shape and size of elements in the drawings may be exaggerated for clarity.

이하에서는, 본 발명의 실시예에 따른 카본 제거 방법 및 그 장치에 대하여 첨부한 도면을 참고로 하여 상세히 설명한다.Hereinafter, a carbon removal method and an apparatus thereof according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

도 1은 본 발명의 실시예에 따른 카본 제거 장치가 적용된 환경을 개략적으로 나타내는 도면이다. 또한, 도 2는 본 발명의 실시예에 따른 카본 제거 장치를 나타내는 구성도이다.1 is a view schematically showing an environment to which a carbon removal device according to an embodiment of the present invention is applied. 2 is a block diagram showing a carbon removal device according to an embodiment of the present invention.

도 1을 참고하면, 코코스 로는 탄화실(10), 탄화실 측면에 배치된 연소실(20) 및 탄화실(10)과 연소실(20)을 지지하는 축열실(21)을 포함한다. 각 연소실(20)은 복수개의 소연소실로 구분되며, 각 소연소실 내로 연료 가스 및 공기가 공급된다.Referring to FIG. 1, the cocos furnace includes a

탄화실(10)에는 탄장입구(11)를 통해 석탄이 장입되며, 연소실(20)의 각 소연소실에는 열원인 열료 가스와 혼합물을 연소시키는 버너(도시되지 않음)가 장착되어 있으며, 이 버너의 작동에 따라 열이 발생된다. 이와 같이, 소연소실에서 발생된 열이 탄화실(10) 내로 공급되어 석탄을 건류시킴으로써 코크스가 제조된다.In the

이처럼, 코크스 제조과정에서는 석탄 내 포함된 휘발성 탄소성분이 열분해 되어, 코코스 로의 노벽 및 상승관(30)에 카본의 형태로 부착되게 된다. 이처럼, 부착된 카본은 건류가 지속될수록 발생 또는 성장하여 내벽에 손상을 가할 뿐만 아니라, 상승관(30)을 통하여 화성공장으로 이송되는 가스의 흐름을 방해되고, 이처럼 가스의 흐름이 방해받는 경우, 작은 폭발이 야기된다.As such, in the process of producing coke, volatile carbon components contained in coal are thermally decomposed to be attached to the furnace wall and the

본 발명의 실시예에 따른, 카본 제거 장치(100)는 탄화실(10) 상부의 상승관(20) 내에 위치하여, 세라믹 히터를 이용하여 부착된 카본을 제거한다. 여기서, 카본 제거 장치(100)는 상승관(20) 내 카본 부착이 많이 발생하는 구역에 위치한다.

According to an embodiment of the present invention, the

도 2를 참고하면, 카본 제거 장치(100)는 블리더(bleeder)(110), 압전센서(120), 블리더 제어부(130), 산소센서(140), 농도 변화 검출부(150), 히터 제어부(160) 및 발열부(이하 "히터"라고 함)(170)를 포함한다.Referring to FIG. 2, the

블리더(110)는 상승관(20) 윗 부분에 위치하며, 개방되어 있는 경우에 카본 제거 작업 중에 발생되는 비산분진을 방출하고, 닫혀있는 경우에 대기의 유입을 차단한다.The

압전센서(120)는 블리더(110)의 개폐를 감지한다.The

블리더 제어부(130)는 압전센서(120)의 감지 결과를 이용하여 블리더(110)의 위치를 파악한다. 또한, 블리더 제어부(130)는 탄화실(10) 내에 석탄이 장입하는 경우에 탄화실(10)을 제어하는 특정 제어장치(도시하지 않음)로부터 장입 신호를 전달받아, 장입 신호에 대응하게 블리더(110)를 개방시킨다.The

산소센서(140)는 상승관(20) 내부의 산소 농도를 감지한다. 여기서, 산소센서(140)는 블리더(110)의 개폐를 압전센서(120)가 감지하지 못할 경우를 대비하여 장착한다.The

농도 변화 검출부(150)는 산소센서(140)의 감지 결과 즉, 산소 농도를 설정 시간 내지 실시간으로 전달받아, 산소 농도의 변화를 검출한다.The concentration

일반적으로, 건류시에는 산소 농도가 3%이하이며, 블리더(110)가 개방되는 경우, 상승관(20)으로 대기가 유입되므로 산소 농도가 급격히 증가한다. 이때, 농도 변화 검출부(150)는 산소 농도가 기준치 이상으로 증가되는 것을 검출할 수 있다.In general, oxygen concentration is 3% or less during dry distillation, and when the

히터 제어부(160)는 농도 변화 검출부(150)에서 검출한 농도 변화가 기준치 예를 들어, 5% 이상인 경우, 히터(170)를 550~600℃로 승온시킨다. 또한, 히터 제어부(160)는 농도 변화가 5% 이하가 되는 경우, 히터(170)의 동작을 종료시킨다.When the concentration change detected by the concentration

히터(170)는 Ni-Cr열선과 세라믹으로 구성되어 있으며, 히터 제어부(160)의 제어에 대응하게 승온하여 카본을 제거한다. 여기서, 카본은 산소 농도가 5%이상, 온도 550℃이상에서 완전연소 즉, 제거된다.

The

다음, 카본 제거 장치가 카본을 제거하는 방법을 도 3을 참조하여 상세하게 설명한다.Next, the method for removing the carbon by the carbon removal apparatus will be described in detail with reference to FIG. 3.

도 3은 본 발명의 실시예에 따른 카본 제거 방법을 나타내는 흐름도이다.3 is a flowchart illustrating a carbon removal method according to an embodiment of the present invention.

먼저, 본 발명의 실시예에 따른 카본 제거 장치(100)는 상승관(30) 내에 위치하며, 이에 한정되지 않는다. 또한, 상승관(30) 내 부착된 카본은 산소 농도가 5%이상, 온도 550℃이상에서 완전연소 즉, 제거된다.First, the

도 3을 참고하면, 카본 제거 장치(100)는 상승관(20) 윗 부분에 위치하는 블리더(110)의 위치를 압전센서(120)를 이용하여 감지한다(S310).Referring to FIG. 3, the

카본 제거 장치(100)는 블리더(110)가 개방되어 있는지를 판단한다(S320).The

블리더(110)가가 개방되어 있는 경우, 카본 제거 장치(100)는 산소센서(140)를 이용하여 산소 농도를 감지하여, 산소 농도에 변화가 발생하는지 판단한다(S330).When the

산소 농도에 변화가 발생한 경우, 카본 제거 장치(100)는 히터(170)의 전원을 키고(S340), 550~600℃까지 승온시킨다(S350).When a change occurs in the oxygen concentration, the

카본 제거 장치(100)는 상승관(30) 내 산소 농도가 5%이상, 온도 550℃이상으로 제어하여 카본을 연소시킨다(S360).The

카본을 모두 연소하여 제거한 경우, 카본 제거 장치(100)는 탄화실(10)을 제어하는 특정 제어장치(도시하지 않음)로부터 탄화실(10) 내에 석탄이 장입 완료되었다는 장입완료 신호를 전달받는다(S370).When all of the carbon is burned and removed, the

다음, 카본 제거 장치(100)는 장입완료 신호에 대응하게 히터(170)의 동작을 종료시키고(S380), 블리더(110)를 닫는다(S390).Next, the

이로써, 본 발명은 카본을 효율적으로 제거함으로써, 코크스 공정시 발생하는 부생가스를 이송시켜 부생가스의 안정적 생산 및 코크스 조업의 안정성을 확보할 수 있다.

As a result, the present invention can efficiently remove the carbon, thereby transporting the by-product gas generated during the coke process to ensure the stable production of the by-product gas and the stability of the coke operation.

이상에서와 같이 도면과 명세서에서 최적의 실시예가 개시되었다. 여기서 특정한 용어들이 사용되었으나, 이는 단지 본 발명을 설명하기 위한 목적에서 사용된 것이지 의미 한정이나 특허청구범위에 기재된 본 발명의 범위를 제한하기 위하여 사용된 것은 아니다. 그러므로, 본 기술 분야의 통상의 지식을 가진자라면 이로부터 다양한 변형 및 균등한 타 실시예가 가능하다는 점을 이해할 것이다. 따라서, 본 발명의 진정한 기술적 보호범위는 첨부된 특허청구범위의 기술적 사상에 의해 정해져야 할 것이다.

As described above, the best embodiment has been disclosed in the drawings and the specification. Although specific terms have been used herein, they are used only for the purpose of describing the present invention and are not used to limit the scope of the present invention as defined in the meaning or claims. Therefore, those skilled in the art will understand that various modifications and equivalent other embodiments are possible from this. Therefore, the true technical protection scope of the present invention will be defined by the technical spirit of the appended claims.

10: 탄화실20: 연소실

30: 상승관100: 카본 제거 장치

110: 블리더120: 압전센서

130: 블리더 제어부140: 산소센서

150: 농도 변화 검출부160: 히터 제어부

170: 히터10: carbonization chamber 20: combustion chamber

30: riser 100: carbon removal device

110: bleeder 120: piezoelectric sensor

130: bleeder control unit 140: oxygen sensor

150: concentration change detection unit 160: heater control unit

170: heater

Claims (10)

Translated fromKorean상기 산소 농도의 변화를 검출하는 농도 변화 검출부;

상기 상승관 내부에 위치하는 발열부; 및

상기 산소 농도의 변화가 기준치 이상인 경우, 상기 발열부를 특정 온도로 승온하여 상기 상승관 내 위치하는 카본을 제거하는 제어부

를 포함하는 카본 제거 장치.An oxygen sensor for sensing oxygen concentration inside the riser;

A concentration change detector for detecting a change in the oxygen concentration;

A heating unit located inside the riser; And

When the change in the oxygen concentration is greater than or equal to the reference value, the control unit for removing the carbon located in the riser by raising the heating portion to a specific temperature

Carbon removal device comprising a.

상기 제어부는

상기 산소 농도가 5% 이상인 경우, 상기 발열부를 550~600℃로 승온하는 카본 제거 장치.The method according to claim 1,

The control unit

The carbon removal apparatus which heats up the said heat generating part to 550-600 degreeC when the said oxygen concentration is 5% or more.

상기 발열부는

Ni-Cr열선과 세라믹 히터를 포함하는 카본 제거 장치.The method according to claim 1,

The heating portion

Carbon removal device comprising Ni-Cr heating wire and ceramic heater.

상기 상승관의 블리더의 개폐를 감지하는 압전센서; 및

탄화실 내에 석탄이 장입되는 경우, 상기 블리더를 개방시키는 블리더 제어부를 더 포함하는 것을 특징으로 하는 카본 제거 장치.The method according to claim 1,

Piezoelectric sensor for detecting the opening and closing of the bleeder of the riser; And

And a bleeder control unit which opens the bleeder when the coal is charged into the carbonization chamber.

상기 농도 변화 검출부는

상기 블리더가 개방되어 있는 경우에 상기 산소 농도의 변화를 검출하는 것을 특징으로 하는 카본 제거 장치.The method of claim 4,

The concentration change detection unit

Detecting a change in the oxygen concentration when the bleeder is open.

상기 제어부는

상기 상승관 내 위치하는 카본을 제거한 후, 상기 발열부의 동작을 중지시키는 카본 제거 장치.The method according to claim 1,

The control unit

After removing the carbon located in the riser, the carbon removal device for stopping the operation of the heat generating portion.

농도 변화 검출부에 의해 상기 산소 농도의 변화를 검출하는 단계; 및

제어부에 의해 상기 산소 농도의 변화가 기준치 이상인 경우, 발열부를 특정 온도로 승온하여 상기 상승관 내 위치하는 카본을 제거하는 단계

를 포함하는 카본 제거 방법.Detecting an oxygen concentration inside the riser by an oxygen sensor;

Detecting a change in the oxygen concentration by a concentration change detector; And

If the change in the oxygen concentration by the control unit more than the reference value, the step of heating the heating unit to a specific temperature to remove the carbon located in the riser

Carbon removal method comprising a.

상기 카본을 제거하는 단계는

상기 산소 농도가 5% 이상인 경우, 상기 발열부를 550~600℃로 승온하는 것을 특징으로 하는 카본 제거 방법.The method according to claim 7,

Removing the carbon

When the oxygen concentration is 5% or more, the carbon removal method characterized in that the heating portion is heated to 550 ~ 600 ℃.

상기 산소 농도의 변화를 검출하는 단계는

압전센서에 의해 상기 상승관의 블리더의 개폐를 감지하는 단계;

탄화실 내에 석탄이 장입되는 경우, 블리더 제어부에 의해 상기 블리더를 개방시키는 단계,

상기 블리더가 개방되어 있는 경우에 상기 산소 농도의 변화를 검출하는 단계

를 더 포함하는 카본 제거 방법.The method according to claim 7,

Detecting the change in oxygen concentration is

Detecting opening and closing of a bleeder of the riser by a piezoelectric sensor;

When coal is charged in the carbonization chamber, opening the bleeder by a bleeder control unit;

Detecting a change in oxygen concentration when the bleeder is open

Carbon removal method comprising more.

상기 발열부는 Ni-Cr열선과 세라믹 히터를 포함하는 것을 특징으로 하는 카본 제거 방법.

The method according to claim 7,

The heat generating unit carbon removal method characterized in that it comprises a Ni-Cr heating wire and a ceramic heater.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020100094690AKR101149142B1 (en) | 2010-09-29 | 2010-09-29 | Apparatus and method for removing carbon |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020100094690AKR101149142B1 (en) | 2010-09-29 | 2010-09-29 | Apparatus and method for removing carbon |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20120033091Atrue KR20120033091A (en) | 2012-04-06 |

| KR101149142B1 KR101149142B1 (en) | 2012-05-25 |

Family

ID=46135992

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020100094690AExpired - Fee RelatedKR101149142B1 (en) | 2010-09-29 | 2010-09-29 | Apparatus and method for removing carbon |

Country Status (1)

| Country | Link |

|---|---|

| KR (1) | KR101149142B1 (en) |

Cited By (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111167795A (en)* | 2018-11-13 | 2020-05-19 | 现代自动车株式会社 | Apparatus and method for removing carbon from oxygen sensor |

| WO2020140079A1 (en)* | 2018-12-28 | 2020-07-02 | Suncoke Technology And Development Llc | Decarbonizatign of coke ovens, and associated systems and methods |

| US10968395B2 (en) | 2014-12-31 | 2021-04-06 | Suncoke Technology And Development Llc | Multi-modal beds of coking material |

| US10968393B2 (en) | 2014-09-15 | 2021-04-06 | Suncoke Technology And Development Llc | Coke ovens having monolith component construction |

| US11008518B2 (en) | 2018-12-28 | 2021-05-18 | Suncoke Technology And Development Llc | Coke plant tunnel repair and flexible joints |

| US11008517B2 (en) | 2012-12-28 | 2021-05-18 | Suncoke Technology And Development Llc | Non-perpendicular connections between coke oven uptakes and a hot common tunnel, and associated systems and methods |

| US11053444B2 (en) | 2014-08-28 | 2021-07-06 | Suncoke Technology And Development Llc | Method and system for optimizing coke plant operation and output |

| US11071935B2 (en) | 2018-12-28 | 2021-07-27 | Suncoke Technology And Development Llc | Particulate detection for industrial facilities, and associated systems and methods |

| US11098252B2 (en) | 2018-12-28 | 2021-08-24 | Suncoke Technology And Development Llc | Spring-loaded heat recovery oven system and method |

| US11117087B2 (en) | 2012-12-28 | 2021-09-14 | Suncoke Technology And Development Llc | Systems and methods for removing mercury from emissions |

| US11214739B2 (en) | 2015-12-28 | 2022-01-04 | Suncoke Technology And Development Llc | Method and system for dynamically charging a coke oven |

| US11261381B2 (en) | 2018-12-28 | 2022-03-01 | Suncoke Technology And Development Llc | Heat recovery oven foundation |

| US11359146B2 (en) | 2013-12-31 | 2022-06-14 | Suncoke Technology And Development Llc | Methods for decarbonizing coking ovens, and associated systems and devices |

| US11359145B2 (en) | 2012-12-28 | 2022-06-14 | Suncoke Technology And Development Llc | Systems and methods for maintaining a hot car in a coke plant |

| US11395989B2 (en) | 2018-12-31 | 2022-07-26 | Suncoke Technology And Development Llc | Methods and systems for providing corrosion resistant surfaces in contaminant treatment systems |

| US11441077B2 (en) | 2012-08-17 | 2022-09-13 | Suncoke Technology And Development Llc | Coke plant including exhaust gas sharing |

| US11486572B2 (en) | 2018-12-31 | 2022-11-01 | Suncoke Technology And Development Llc | Systems and methods for Utilizing flue gas |

| US11508230B2 (en) | 2016-06-03 | 2022-11-22 | Suncoke Technology And Development Llc | Methods and systems for automatically generating a remedial action in an industrial facility |

| US11692138B2 (en) | 2012-08-17 | 2023-07-04 | Suncoke Technology And Development Llc | Automatic draft control system for coke plants |

| US11746296B2 (en) | 2013-03-15 | 2023-09-05 | Suncoke Technology And Development Llc | Methods and systems for improved quench tower design |

| US11760937B2 (en) | 2018-12-28 | 2023-09-19 | Suncoke Technology And Development Llc | Oven uptakes |

| US11767482B2 (en) | 2020-05-03 | 2023-09-26 | Suncoke Technology And Development Llc | High-quality coke products |

| US11788012B2 (en) | 2015-01-02 | 2023-10-17 | Suncoke Technology And Development Llc | Integrated coke plant automation and optimization using advanced control and optimization techniques |

| US11845898B2 (en) | 2017-05-23 | 2023-12-19 | Suncoke Technology And Development Llc | System and method for repairing a coke oven |

| US11851724B2 (en) | 2021-11-04 | 2023-12-26 | Suncoke Technology And Development Llc. | Foundry coke products, and associated systems, devices, and methods |

| US11939526B2 (en) | 2012-12-28 | 2024-03-26 | Suncoke Technology And Development Llc | Vent stack lids and associated systems and methods |

| US11946108B2 (en) | 2021-11-04 | 2024-04-02 | Suncoke Technology And Development Llc | Foundry coke products and associated processing methods via cupolas |

| US12110458B2 (en) | 2022-11-04 | 2024-10-08 | Suncoke Technology And Development Llc | Coal blends, foundry coke products, and associated systems, devices, and methods |

| US12227699B2 (en) | 2019-12-26 | 2025-02-18 | Suncoke Technology And Development Llc | Oven health optimization systems and methods |

| US12325828B2 (en) | 2012-12-28 | 2025-06-10 | Suncoke Technology And Development Llc | Exhaust flow modifier, duct intersection incorporating the same, and methods therefor |

| US12410369B2 (en) | 2023-11-21 | 2025-09-09 | Suncoke Technology And Development Llc | Flat push hot car for foundry coke and associated systems and methods |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2854493B2 (en)* | 1993-03-01 | 1999-02-03 | 住友金属工業株式会社 | Coke oven riser cleaning method and apparatus |

| JPH10310773A (en)* | 1997-05-13 | 1998-11-24 | Nippon Steel Corp | Method for removing carbon adhering to coke oven riser and coke oven riser |

| JP2000273459A (en)* | 1999-03-25 | 2000-10-03 | Sumitomo Metal Ind Ltd | Method and apparatus for removing carbon adhering to the upper part of coke oven carbonization chamber |

| KR200355147Y1 (en)* | 2004-04-09 | 2004-07-02 | 정재곤 | Apparatus for removing the carbon attatched on the inside of the ascension pipe in the coke oven |

- 2010

- 2010-09-29KRKR1020100094690Apatent/KR101149142B1/ennot_activeExpired - Fee Related

Cited By (52)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11441077B2 (en) | 2012-08-17 | 2022-09-13 | Suncoke Technology And Development Llc | Coke plant including exhaust gas sharing |

| US11692138B2 (en) | 2012-08-17 | 2023-07-04 | Suncoke Technology And Development Llc | Automatic draft control system for coke plants |

| US12195671B2 (en) | 2012-08-17 | 2025-01-14 | Suncoke Technology And Development Llc | Automatic draft control system for coke plants |

| US11008517B2 (en) | 2012-12-28 | 2021-05-18 | Suncoke Technology And Development Llc | Non-perpendicular connections between coke oven uptakes and a hot common tunnel, and associated systems and methods |

| US11845037B2 (en) | 2012-12-28 | 2023-12-19 | Suncoke Technology And Development Llc | Systems and methods for removing mercury from emissions |

| US11359145B2 (en) | 2012-12-28 | 2022-06-14 | Suncoke Technology And Development Llc | Systems and methods for maintaining a hot car in a coke plant |

| US11117087B2 (en) | 2012-12-28 | 2021-09-14 | Suncoke Technology And Development Llc | Systems and methods for removing mercury from emissions |

| US11939526B2 (en) | 2012-12-28 | 2024-03-26 | Suncoke Technology And Development Llc | Vent stack lids and associated systems and methods |

| US12325828B2 (en) | 2012-12-28 | 2025-06-10 | Suncoke Technology And Development Llc | Exhaust flow modifier, duct intersection incorporating the same, and methods therefor |

| US11746296B2 (en) | 2013-03-15 | 2023-09-05 | Suncoke Technology And Development Llc | Methods and systems for improved quench tower design |

| US11359146B2 (en) | 2013-12-31 | 2022-06-14 | Suncoke Technology And Development Llc | Methods for decarbonizing coking ovens, and associated systems and devices |

| US11053444B2 (en) | 2014-08-28 | 2021-07-06 | Suncoke Technology And Development Llc | Method and system for optimizing coke plant operation and output |

| US10968393B2 (en) | 2014-09-15 | 2021-04-06 | Suncoke Technology And Development Llc | Coke ovens having monolith component construction |

| US11795400B2 (en) | 2014-09-15 | 2023-10-24 | Suncoke Technology And Development Llc | Coke ovens having monolith component construction |

| US10975310B2 (en) | 2014-12-31 | 2021-04-13 | Suncoke Technology And Development Llc | Multi-modal beds of coking material |

| US10975311B2 (en) | 2014-12-31 | 2021-04-13 | Suncoke Technology And Development Llc | Multi-modal beds of coking material |

| US10968395B2 (en) | 2014-12-31 | 2021-04-06 | Suncoke Technology And Development Llc | Multi-modal beds of coking material |

| US12338394B2 (en) | 2014-12-31 | 2025-06-24 | Suncoke Technology And Development Llc | Multi-modal beds of coking material |

| US11788012B2 (en) | 2015-01-02 | 2023-10-17 | Suncoke Technology And Development Llc | Integrated coke plant automation and optimization using advanced control and optimization techniques |

| US11214739B2 (en) | 2015-12-28 | 2022-01-04 | Suncoke Technology And Development Llc | Method and system for dynamically charging a coke oven |

| US12190701B2 (en) | 2016-06-03 | 2025-01-07 | Suncoke Technology And Development Llc | Methods and systems for automatically generating a remedial action in an industrial facility |

| US11508230B2 (en) | 2016-06-03 | 2022-11-22 | Suncoke Technology And Development Llc | Methods and systems for automatically generating a remedial action in an industrial facility |

| US11845898B2 (en) | 2017-05-23 | 2023-12-19 | Suncoke Technology And Development Llc | System and method for repairing a coke oven |

| CN111167795A (en)* | 2018-11-13 | 2020-05-19 | 现代自动车株式会社 | Apparatus and method for removing carbon from oxygen sensor |

| US11193069B2 (en) | 2018-12-28 | 2021-12-07 | Suncoke Technology And Development Llc | Coke plant tunnel repair and anchor distribution |

| US11680208B2 (en) | 2018-12-28 | 2023-06-20 | Suncoke Technology And Development Llc | Spring-loaded heat recovery oven system and method |

| US11643602B2 (en) | 2018-12-28 | 2023-05-09 | Suncoke Technology And Development Llc | Decarbonization of coke ovens, and associated systems and methods |

| US11597881B2 (en) | 2018-12-28 | 2023-03-07 | Suncoke Technology And Development Llc | Coke plant tunnel repair and flexible joints |

| US11760937B2 (en) | 2018-12-28 | 2023-09-19 | Suncoke Technology And Development Llc | Oven uptakes |

| WO2020140079A1 (en)* | 2018-12-28 | 2020-07-02 | Suncoke Technology And Development Llc | Decarbonizatign of coke ovens, and associated systems and methods |

| US11505747B2 (en) | 2018-12-28 | 2022-11-22 | Suncoke Technology And Development Llc | Coke plant tunnel repair and anchor distribution |

| US12060525B2 (en) | 2018-12-28 | 2024-08-13 | Suncoke Technology And Development Llc | Systems for treating a surface of a coke plant sole flue |

| US11008518B2 (en) | 2018-12-28 | 2021-05-18 | Suncoke Technology And Development Llc | Coke plant tunnel repair and flexible joints |

| US11845897B2 (en) | 2018-12-28 | 2023-12-19 | Suncoke Technology And Development Llc | Heat recovery oven foundation |

| US12305119B2 (en) | 2018-12-28 | 2025-05-20 | Suncoke Technology And Development Llc | Decarbonization of coke ovens and associated systems and methods |

| US11365355B2 (en) | 2018-12-28 | 2022-06-21 | Suncoke Technology And Development Llc | Systems and methods for treating a surface of a coke plant |

| US11071935B2 (en) | 2018-12-28 | 2021-07-27 | Suncoke Technology And Development Llc | Particulate detection for industrial facilities, and associated systems and methods |

| US11261381B2 (en) | 2018-12-28 | 2022-03-01 | Suncoke Technology And Development Llc | Heat recovery oven foundation |

| US11098252B2 (en) | 2018-12-28 | 2021-08-24 | Suncoke Technology And Development Llc | Spring-loaded heat recovery oven system and method |

| US11486572B2 (en) | 2018-12-31 | 2022-11-01 | Suncoke Technology And Development Llc | Systems and methods for Utilizing flue gas |

| US11395989B2 (en) | 2018-12-31 | 2022-07-26 | Suncoke Technology And Development Llc | Methods and systems for providing corrosion resistant surfaces in contaminant treatment systems |

| US11819802B2 (en) | 2018-12-31 | 2023-11-21 | Suncoke Technology And Development Llc | Methods and systems for providing corrosion resistant surfaces in contaminant treatment systems |

| US12227699B2 (en) | 2019-12-26 | 2025-02-18 | Suncoke Technology And Development Llc | Oven health optimization systems and methods |

| US12215289B2 (en) | 2020-05-03 | 2025-02-04 | Suncoke Technology And Development Llc | High-quality coke products |

| US11767482B2 (en) | 2020-05-03 | 2023-09-26 | Suncoke Technology And Development Llc | High-quality coke products |

| US11946108B2 (en) | 2021-11-04 | 2024-04-02 | Suncoke Technology And Development Llc | Foundry coke products and associated processing methods via cupolas |

| US11851724B2 (en) | 2021-11-04 | 2023-12-26 | Suncoke Technology And Development Llc. | Foundry coke products, and associated systems, devices, and methods |

| US12319976B2 (en) | 2021-11-04 | 2025-06-03 | Suncoke Technology And Development Llc | Foundry coke products, and associated systems, devices, and methods |

| US12331367B2 (en) | 2021-11-04 | 2025-06-17 | Suncoke Technology And Development Llc | Foundry coke products, and associated systems, devices, and methods |

| US12110458B2 (en) | 2022-11-04 | 2024-10-08 | Suncoke Technology And Development Llc | Coal blends, foundry coke products, and associated systems, devices, and methods |

| US12286591B2 (en) | 2022-11-04 | 2025-04-29 | Suncoke Technology And Development Llc | Coal blends, foundry coke products, and associated systems, devices, and methods |

| US12410369B2 (en) | 2023-11-21 | 2025-09-09 | Suncoke Technology And Development Llc | Flat push hot car for foundry coke and associated systems and methods |

Also Published As

| Publication number | Publication date |

|---|---|

| KR101149142B1 (en) | 2012-05-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101149142B1 (en) | Apparatus and method for removing carbon | |

| US11021655B2 (en) | Decarbonization of coke ovens and associated systems and methods | |

| KR100797852B1 (en) | How to control the flow rate of exhaust gas | |

| KR101665066B1 (en) | Apparatus and Method for Manufacturing Sintered Ore | |

| JP6107382B2 (en) | Evaluation method of solid fuel | |

| EA201101637A1 (en) | METHOD OF OPERATION OF THE REGENERATIVE HEATER | |

| CN102563857A (en) | Process and device for heating gas by using a heat accumulation type heating furnace | |

| KR101175504B1 (en) | Testing Apparatus for Manufacturing Coke | |

| CN106546695A (en) | Dry dust collection method tests coal combustion rate device and method | |

| CN104197733B (en) | Regenerative cycles device in Gas heating furnace high-temperature burns carbon distribution device and technique | |

| CN102305803A (en) | Experiment device and method for studying blast furnace hearth and bottom carbon brick annular crack mechanism | |

| CN103206857A (en) | Method for operating environment-friendly energy-saving de-waxing kiln | |

| CN104583367A (en) | Temperature control device for coke oven and temperature control method for coke oven | |

| CN102778133A (en) | Air inlet system of trolley type gas heat treatment furnace | |

| KR20130021957A (en) | Fuel pre-heating apparatus | |

| CN104236285B (en) | Drying device and the drying means using the drying device | |

| KR101330703B1 (en) | Apparatus for increasing coke oven gas | |

| JP6252526B2 (en) | Coke oven operation method | |

| RU76912U1 (en) | CHARCOAL INSTALLATION | |

| JP2003003172A (en) | Coke reforming method | |

| KR101205070B1 (en) | Ascension pipe for Coke Oven | |

| KR101398263B1 (en) | Apparatus for removing the carbon attatched on the inside of the ascension pipe in carbonization chamber | |

| JP6018860B2 (en) | Waste gasification melting furnace startup method | |

| CN104944395A (en) | Yellow phosphorus furnace gas filtering system and method and filtering method | |

| JP2009179858A (en) | Pulverized coal blowing equipment damage prevention system and pulverized coal blowing equipment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| PA0109 | Patent application | St.27 status event code:A-0-1-A10-A12-nap-PA0109 | |

| PA0201 | Request for examination | St.27 status event code:A-1-2-D10-D11-exm-PA0201 | |

| D13-X000 | Search requested | St.27 status event code:A-1-2-D10-D13-srh-X000 | |

| D14-X000 | Search report completed | St.27 status event code:A-1-2-D10-D14-srh-X000 | |

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration | St.27 status event code:A-1-2-D10-D22-exm-PE0701 | |

| PG1501 | Laying open of application | St.27 status event code:A-1-1-Q10-Q12-nap-PG1501 | |

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment | St.27 status event code:A-2-4-F10-F11-exm-PR0701 | |

| PR1002 | Payment of registration fee | St.27 status event code:A-2-2-U10-U11-oth-PR1002 Fee payment year number:1 | |

| PG1601 | Publication of registration | St.27 status event code:A-4-4-Q10-Q13-nap-PG1601 | |

| PN2301 | Change of applicant | St.27 status event code:A-5-5-R10-R13-asn-PN2301 St.27 status event code:A-5-5-R10-R11-asn-PN2301 | |

| LAPS | Lapse due to unpaid annual fee | ||

| PC1903 | Unpaid annual fee | St.27 status event code:A-4-4-U10-U13-oth-PC1903 Not in force date:20150517 Payment event data comment text:Termination Category : DEFAULT_OF_REGISTRATION_FEE | |

| PC1903 | Unpaid annual fee | St.27 status event code:N-4-6-H10-H13-oth-PC1903 Ip right cessation event data comment text:Termination Category : DEFAULT_OF_REGISTRATION_FEE Not in force date:20150517 | |

| P22-X000 | Classification modified | St.27 status event code:A-4-4-P10-P22-nap-X000 | |

| P22-X000 | Classification modified | St.27 status event code:A-4-4-P10-P22-nap-X000 | |

| R18-X000 | Changes to party contact information recorded | St.27 status event code:A-5-5-R10-R18-oth-X000 | |

| PN2301 | Change of applicant | St.27 status event code:A-5-5-R10-R13-asn-PN2301 St.27 status event code:A-5-5-R10-R11-asn-PN2301 | |

| R18-X000 | Changes to party contact information recorded | St.27 status event code:A-5-5-R10-R18-oth-X000 | |

| PN2301 | Change of applicant | St.27 status event code:A-5-5-R10-R13-asn-PN2301 St.27 status event code:A-5-5-R10-R11-asn-PN2301 | |

| R18-X000 | Changes to party contact information recorded | St.27 status event code:A-5-5-R10-R18-oth-X000 | |

| R18-X000 | Changes to party contact information recorded | St.27 status event code:A-5-5-R10-R18-oth-X000 | |

| R18-X000 | Changes to party contact information recorded | St.27 status event code:A-5-5-R10-R18-oth-X000 | |

| PN2301 | Change of applicant | St.27 status event code:A-5-5-R10-R13-asn-PN2301 St.27 status event code:A-5-5-R10-R11-asn-PN2301 |