KR20120008751A - Mulching Nonwoven Structure - Google Patents

Mulching Nonwoven StructureDownload PDFInfo

- Publication number

- KR20120008751A KR20120008751AKR1020100069788AKR20100069788AKR20120008751AKR 20120008751 AKR20120008751 AKR 20120008751AKR 1020100069788 AKR1020100069788 AKR 1020100069788AKR 20100069788 AKR20100069788 AKR 20100069788AKR 20120008751 AKR20120008751 AKR 20120008751A

- Authority

- KR

- South Korea

- Prior art keywords

- pet

- mulching

- nonwoven

- less

- nonwoven fabric

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 239000004745nonwoven fabricSubstances0.000claimsabstractdescription37

- 239000000203mixtureSubstances0.000claims1

- 239000007788liquidSubstances0.000abstractdescription8

- 239000003337fertilizerSubstances0.000abstractdescription7

- 230000035699permeabilityEffects0.000abstractdescription7

- 230000006750UV protectionEffects0.000abstractdescription2

- 239000004743PolypropyleneSubstances0.000description27

- 229920001155polypropylenePolymers0.000description27

- 239000004800polyvinyl chlorideSubstances0.000description15

- 229920000915polyvinyl chloridePolymers0.000description14

- 238000002834transmittanceMethods0.000description7

- 239000000463materialSubstances0.000description6

- 230000012010growthEffects0.000description5

- 238000000034methodMethods0.000description4

- 241000196324EmbryophytaSpecies0.000description3

- 238000009960cardingMethods0.000description3

- 230000000052comparative effectEffects0.000description3

- 230000000903blocking effectEffects0.000description2

- 239000010410layerSubstances0.000description2

- 239000002689soilSubstances0.000description2

- 238000001228spectrumMethods0.000description2

- 230000000475sunscreen effectEffects0.000description2

- 239000000516sunscreening agentSubstances0.000description2

- FAIFRACTBXWXGY-JTTXIWGLSA-NCOc1ccc2C[C@H]3N(C)CC[C@@]45[C@@H](Oc1c24)[C@@]1(OC)C=C[C@@]35C[C@@H]1[C@](C)(O)CCc1ccccc1Chemical compoundCOc1ccc2C[C@H]3N(C)CC[C@@]45[C@@H](Oc1c24)[C@@]1(OC)C=C[C@@]35C[C@@H]1[C@](C)(O)CCc1ccccc1FAIFRACTBXWXGY-JTTXIWGLSA-N0.000description1

- 239000012790adhesive layerSubstances0.000description1

- QVGXLLKOCUKJST-UHFFFAOYSA-Natomic oxygenChemical compound[O]QVGXLLKOCUKJST-UHFFFAOYSA-N0.000description1

- 239000002131composite materialSubstances0.000description1

- 238000007906compressionMethods0.000description1

- 238000010586diagramMethods0.000description1

- 238000009826distributionMethods0.000description1

- 230000007613environmental effectEffects0.000description1

- 230000001747exhibiting effectEffects0.000description1

- 239000002657fibrous materialSubstances0.000description1

- 230000004927fusionEffects0.000description1

- 238000003475laminationMethods0.000description1

- 238000004519manufacturing processMethods0.000description1

- 244000005700microbiomeSpecies0.000description1

- 229910052760oxygenInorganic materials0.000description1

- 239000001301oxygenSubstances0.000description1

- 230000029553photosynthesisEffects0.000description1

- 238000010672photosynthesisMethods0.000description1

- 230000008635plant growthEffects0.000description1

- -1polypropylenePolymers0.000description1

- 238000003825pressingMethods0.000description1

- 238000004611spectroscopical analysisMethods0.000description1

- 238000000870ultraviolet spectroscopyMethods0.000description1

- 125000000391vinyl groupChemical group[H]C([*])=C([H])[H]0.000description1

- 229920002554vinyl polymerPolymers0.000description1

Images

Classifications

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01G—HORTICULTURE; CULTIVATION OF VEGETABLES, FLOWERS, RICE, FRUIT, VINES, HOPS OR SEAWEED; FORESTRY; WATERING

- A01G13/00—Protection of plants

- A01G13/30—Ground coverings

- A01G13/35—Mulches, i.e. loose material

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01G—HORTICULTURE; CULTIVATION OF VEGETABLES, FLOWERS, RICE, FRUIT, VINES, HOPS OR SEAWEED; FORESTRY; WATERING

- A01G13/00—Protection of plants

- A01G13/30—Ground coverings

- A01G13/32—Mats; Nets; Sheets or films

- A01G13/33—Sheets or films

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/18—Manufacture of films or sheets

Landscapes

- Health & Medical Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Life Sciences & Earth Sciences (AREA)

- Environmental Sciences (AREA)

- Engineering & Computer Science (AREA)

- Toxicology (AREA)

- General Health & Medical Sciences (AREA)

- Materials Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Protection Of Plants (AREA)

Abstract

Translated fromKoreanDescription

Translated fromKorean본 발명은 우수한 액체 비료 투과성 및 자외선 차단성을 나타내는 멀칭용 부직포 구조체에 관한 것으로, 더욱 자세하게는 카딩에 의해 얻어지는 열융착 혹은 니들펀칭 부직포를 다공성 폴리비닐클로라이드(PVC) 접합 필름을 사이에 두고 합포하여 제조된 샌드위치형 부직포 구조체가 적용되어 높은 자외선 차단율을 제공하여 멀칭된 농토에서의 잡초 생장을 효과적으로 억제하며, 액체 비료의 투입이 가능하고, 높은 인장 강도를 보유하여 작물의 생장 기간 동안 찢김에 의한 파손을 방지할 수 있는 멀칭용 부직포 구조체에 관한 것이다.The present invention relates to a non-woven fabric structure for mulching exhibiting excellent liquid fertilizer permeability and UV-blocking properties, and more specifically, a heat-sealed or needle punched non-woven fabric obtained by carding is laminated with a porous polyvinyl chloride (PVC) bonding film interposed therebetween. The sandwich-type nonwoven fabric is applied to provide high UV-blocking rate, which effectively inhibits weed growth in mulched farmland, enables the introduction of liquid fertilizer, and retains high tensile strength. It relates to a non-woven fabric structure for mulching that can prevent.

여러 층의 부직포를 적층하거나 두꺼운 웹으로부터 성형하는 농업용 부직포는 기존 PVC 필름 제품에 비해 그 두께가 두터운 편인데, 경우에 따라 작물이 부직포를 토양으로 인식하여 잔뿌리를 뻗음으로써 가물이 발생하는 경우 쉽게 고사하는 문제점이 있다. (대한민국 특허등록 제 10-0248939호)Agricultural nonwoven fabrics that are laminated with multiple layers of non-woven fabric or formed from thick webs are thicker than conventional PVC film products.In some cases, crops recognize nonwovens as soil and stretch the fine roots, causing easy killing when fraud occurs. There is a problem. (Korean Patent Registration No. 10-0248939)

일반적인 농업용 부직포에 대한 실험 결과로부터 0.3mm 내지 0.6mm 두께의 부직포의 경우 가장 우수한 특성이 나타났으며, 뿌리의 들림 현상에 따른 고사를 방지하면서 적절한 공기 유통을 확보할 수 있다는 보고도 있다. (대한민국 특허등록 제 10-0562856호)From the test results for the general agricultural nonwoven fabrics showed that the non-woven fabric of the 0.3mm to 0.6mm thickness showed the most excellent characteristics, and it is also reported that it is possible to secure proper air circulation while preventing the death due to the lifting of the roots. (Korean Patent Registration No. 10-0562856)

부직포는 비닐 제품과 마찬가지로 산소공급량을 감소시킴으로써 미생물의 배양이 충분히 진행되지 않기 때문에 토양을 산성화시킨다는 보고도 있다. 또한 충분한 통기성이 보장되는 경우에도 태양광 차단이 미흡하여 일광에 의한 광합성을 통해 생장하는 잡초의 성장 억제가 용이하지 않다는 점도 문제로 지적된다. (대한민국 특허등록 제 20-0315780호)Non-woven fabrics, like vinyl products, have been reported to acidify soils by reducing the oxygen supply and not cultivating microorganisms sufficiently. In addition, it is pointed out that even when sufficient breathability is guaranteed, it is not easy to inhibit the growth of weeds growing through photosynthesis by sunlight due to insufficient solar blocking. (Korean Patent Registration No. 20-0315780)

멀칭용 재료로서 PVC 필름의 사용이 대표적인데, 이들 필름은 쉽게 파손되고 수거가 곤란하여 환경적인 문제점을 야기한다는 단점이 있으며, 이들 필름으로 멀칭된 토지에 액체 비료를 공급하는 것이 어려워 작물의 생장이 후반기에 더뎌지는 문제점이 있다.The use of PVC film as a material for mulching is typical, and these films have the disadvantage of being easily broken and difficult to collect, which causes environmental problems, and it is difficult to supply liquid fertilizer to the land mulched with these films, resulting in crop growth. There is a problem of slowing down in the second half.

최근 스펀본딩 폴리프로필렌(PP) 부직포를 적용한 멀칭용 부직포 제품이 시장에 발표되어 있으나, 스펀본드 부직포의 높은 제조 단가에 따른 고가의 제품으로 공급되고 있으며, PVC 필름에 비해 상대적으로 액체 비료의 투과성이 높기는 하지만, 식물의 생장 후기에 있어서의 성장이 더뎌지는 문제에 대해서는 충분한 해결책을 제시하지 못하고 있다.Recently, a mulching nonwoven product using spunbonded polypropylene (PP) nonwoven fabric has been announced on the market, but it is supplied as an expensive product due to the high manufacturing cost of the spunbond nonwoven fabric, and the permeability of liquid fertilizer is relatively higher than that of PVC film. Although high, it does not provide a sufficient solution to the problem of slow growth in later stages of plant growth.

합성 및 천연섬유 소재의 카딩공정에 의해 제조된 부직포 구조체의 적용성도 검토된 바 있으나, 자외선 차단율이 극히 낮아 멀칭재 하부에서의 잡초의 생장을 충분히 억제할 수 없다는 문제점이 있다.Although the applicability of the nonwoven fabric structure produced by the carding process of synthetic and natural fiber materials has also been examined, there is a problem in that the UV blocking rate is extremely low and the growth of weeds under the mulching material cannot be sufficiently suppressed.

본 발명자는 이제까지 멀칭용 소재의가 갖는 상기의 단점을 해결하고자 액체 비료의 투과도를 높이면서 자외선 투과도를 낮추기 위하여 다공성 PVC 필름을 카딩공정에 의해 제조된 부직포 사이에 위치하고 열압착하여 합포시키는 경우 자외선 차단성과 액체 비료 투과성이 우수한 멀칭용 부직포 구조체를 제조할 수 있음을 알고 본 발명을 완성하였다.In order to solve the above disadvantages of the material for mulching so far, the inventors placed a porous PVC film between non-woven fabrics prepared by a carding process to reduce UV transmittance while increasing the permeability of the liquid fertilizer to block UV rays. The present invention has been completed by knowing that it is possible to produce a non-woven fabric structure for mulching excellent in permeability and liquid fertilizer permeability.

이상의 실시예에서 볼 수 있는 바와 같이 본 발명에 의하여 제조된 멀칭용 부직포 구조체는 우수한 태양광 차단성을 가지며 접합 필름 상하의 부직포 층 두께가 0.6mm 이내로써 뿌리의 들림 현상에 따른 고사를 방지할 수 있을 뿐 아니라 다공성 접착층에 의한 통기성 및 액비 투과성을 확보할 수 있으므로 멀칭용 소재로 사용하기에 바람직하다.As can be seen in the above embodiment, the mulching nonwoven structure manufactured by the present invention has excellent sunscreen property and the nonwoven fabric layer thickness above and below the bonding film can be prevented from being killed due to the lifting phenomenon of the roots within 0.6 mm. In addition, it is preferable to use as a material for mulching because it can ensure the breathability and liquid ratio permeability by the porous adhesive layer.

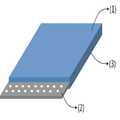

도 1은 다공성 PVC 접합 필름이 적용된 멀칭용 부직포 구조체의 모식도,

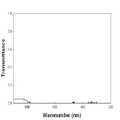

도 2는 제조된 멀칭용 부직포 구조체의 광투과도를 보인 자외선-가시광선 스펙트럼,

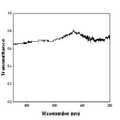

도 3은 PVC 접합 필름이 적용되지 않은 PP 부직포의 광투과도를 보인 자외선-가시광선 스펙트럼1 is a schematic view of a non-woven fabric structure for mulching applied porous PVC bonding film,

2 is an ultraviolet-visible light spectrum showing the light transmittance of the prepared mulching nonwoven structure,

3 is an ultraviolet-visible light spectrum showing the light transmittance of the PP nonwoven fabric not applied to the PVC bonding film

본 발명은 150 내지 400 g/m2의 PP, PE 및 PET로 구성된 두 장의 부직포 사이에 0.1 내지 2.0 mm의 다공성 PVC 필름을 열압착하여 합포하는 것을 특징으로 하는 멀칭용 부직포 구조체에 대한 것이다.The present invention relates to a non-woven fabric structure for mulching, characterized in that the thermo-compression bonding of the porous PVC film of 0.1 to 2.0 mm between the two non-woven fabric consisting of 150 to 400 g / m2 PP, PE and PET.

이하, 본 발명을 첨부된 도면을 참조하여 상세히 설명하면 다음과 같다.Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

도 1은 다공성 PVC 접합 필름이 적용된 멀칭용 부직포 구조체의 모식도를 보인 것으로, 합포 후 각 부직포 층 (1)과 (3)은 0.3 내지 0.6mm의 두께를 갖는 것이 바람직하다.Figure 1 shows a schematic diagram of the non-woven fabric for mulching to which the porous PVC bonding film is applied, it is preferable that each nonwoven layer (1) and (3) after the composite has a thickness of 0.3 to 0.6mm.

도 1에 있어 부직포의 합포에 사용되는 다공성 PVC 필름 (2)는 0.1 mm 이상의 두께를 갖는 것이 바람직하였는데, 그 이하의 두께에서는 부직포와의 합포 과정 중에 PVC 필름이 용융되어 자외선 차단을 위한 충분한 면적분포를 이루지 못하였으며, 2.0 mm 이상의 두께에서는 제조된 멀칭용 부직포 구조체의 두께 및 무게가 농업용으로 사용하기에 너무 무겁고 두꺼워 적합하지 않다.In FIG. 1, the

도 1에 있어 다공성 PVC 필름 (2)는 1 내지 5 mm의 홀 크기를 갖는 것이 바람직하였으며, 더욱 바람직하게는 1 내지 3 mm의 홀 크기가 적합하다.In Fig. 1, the

본 발명의 합포과정은 80 내지 150의 온도 범위에서 진행되었으며, 더욱 바람직하게는 100 내지 120의 온도 범위가 적합하다.The mixing process of the present invention was carried out in a temperature range of 80 to 150, more preferably a temperature range of 100 to 120 is suitable.

이하, 바람직한 실시예를 참조하여 본 발명을 더욱 상세하게 설명한다. 이하의 실시예들은 본 발명을 설명하기 위한 것으로, 이들 실시예에 의해 본 발명의 범위가 제한되는 것은 아니다.

Hereinafter, the present invention will be described in more detail with reference to preferred embodiments. The following examples are provided to illustrate the present invention, and the scope of the present invention is not limited by these examples.

실시예Example 1 One

200 g/m2의 PET 부직포 사이에 홀 크기 1mm 및 두께 0.8mm의 다공성 PVC 필름을 삽입하고 120에서 가압하여 열 융착함으로써 두 장의 부직포를 합포하였다. 획득한 멀칭용 부직포 구조체는 자외선-가시광선 분광분석을 통해 광투과도를 평가하였으며, 그 결과를 도 2에 보인다.

Two nonwoven fabrics were fabricated by inserting a porous PVC film having a hole size of 1 mm and a thickness of 0.8 mm between the 200 g / m2 PET nonwoven fabrics and pressing them at 120 to heat fusion. The obtained nonwoven fabric for mulching was evaluated for light transmittance through ultraviolet-visible light spectroscopy, the results are shown in FIG.

실시예Example 2~36 2 ~ 36

하기 표 1에 보인 바와 같은 조건을 사용하여 실시예 1에서와 마찬가지로 본 발명에 따라 멀칭용 부직포 구조체를 제조하였다.

According to the present invention as in Example 1 using the conditions as shown in Table 1 was prepared for the mulching nonwoven structure.

비교예Comparative example

200 g/m2의 PP 부직포 두 장을 120에서 가압하여 열 융착함으로써 합포하였다. 획득한 부직포 구조체는 자외선-가시광선 분광분석을 통해 광투과도를 평가하였으며, 그 결과를 도 3에 보인다.

Two 200 g / m2 PP nonwoven fabrics were pressurized at 120 to thermally fuse them. The obtained nonwoven fabric structure was evaluated for light transmittance through ultraviolet-visible spectroscopy, and the result is shown in FIG. 3.

비교예에서 보인 바와 같이 부직포 단독으로 사용된 경우에는 광 투과도가 70% 이상으로 효과적인 태양광 차단 효과를 기대할 수 없었으며, 이로부터 다공성 PVC 접합 필름이 태양광 차단에 영향이 크다는 것을 확인하였다.As shown in the comparative example, when the nonwoven fabric alone was used, the light transmittance of 70% or more was not expected to be effective, and from this, it was confirmed that the porous PVC bonding film had a great influence on the sunscreen.

해당사항 없음None

Claims (3)

Translated fromKoreanMulching non-woven fabric structure, characterized in that the porous PVC film is laminated between the two non-woven fabrics.

The nonwoven fabric for mulching according to claim 1, wherein the nonwoven fabric is 150 to 400 g / m2 of PP, PE, PET or a mixture thereof.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020100069788AKR20120008751A (en) | 2010-07-20 | 2010-07-20 | Mulching Nonwoven Structure |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020100069788AKR20120008751A (en) | 2010-07-20 | 2010-07-20 | Mulching Nonwoven Structure |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20120008751Atrue KR20120008751A (en) | 2012-02-01 |

Family

ID=45833724

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020100069788ACeasedKR20120008751A (en) | 2010-07-20 | 2010-07-20 | Mulching Nonwoven Structure |

Country Status (1)

| Country | Link |

|---|---|

| KR (1) | KR20120008751A (en) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9788576B2 (en) | 2013-12-30 | 2017-10-17 | Huizhou Kimree Technology Co., Ltd. Shenzhen | Electronic cigarette, and battery rod and atomizer |

| US10638792B2 (en) | 2013-03-15 | 2020-05-05 | Juul Labs, Inc. | Securely attaching cartridges for vaporizer devices |

| US10667560B2 (en) | 2013-12-23 | 2020-06-02 | Juul Labs, Inc. | Vaporizer apparatus |

| US10667561B2 (en) | 2013-11-12 | 2020-06-02 | Vmr Products Llc | Vaporizer |

| US10701975B2 (en) | 2013-12-23 | 2020-07-07 | Juul Labs, Inc. | Vaporization device systems and methods |

| US10709173B2 (en) | 2014-02-06 | 2020-07-14 | Juul Labs, Inc. | Vaporizer apparatus |

| US10865001B2 (en) | 2016-02-11 | 2020-12-15 | Juul Labs, Inc. | Fillable vaporizer cartridge and method of filling |

| US10912333B2 (en) | 2016-02-25 | 2021-02-09 | Juul Labs, Inc. | Vaporization device control systems and methods |

| US10986867B2 (en) | 2013-12-23 | 2021-04-27 | Juul Labs, Inc. | Vaporization device systems and methods |

| US11019685B2 (en) | 2014-02-06 | 2021-05-25 | Juul Labs, Inc. | Vaporization device systems and methods |

- 2010

- 2010-07-20KRKR1020100069788Apatent/KR20120008751A/ennot_activeCeased

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10638792B2 (en) | 2013-03-15 | 2020-05-05 | Juul Labs, Inc. | Securely attaching cartridges for vaporizer devices |

| US10667561B2 (en) | 2013-11-12 | 2020-06-02 | Vmr Products Llc | Vaporizer |

| US11134722B2 (en) | 2013-11-12 | 2021-10-05 | Vmr Products Llc | Vaporizer |

| US10986867B2 (en) | 2013-12-23 | 2021-04-27 | Juul Labs, Inc. | Vaporization device systems and methods |

| US10667560B2 (en) | 2013-12-23 | 2020-06-02 | Juul Labs, Inc. | Vaporizer apparatus |

| US10701975B2 (en) | 2013-12-23 | 2020-07-07 | Juul Labs, Inc. | Vaporization device systems and methods |

| US11752283B2 (en) | 2013-12-23 | 2023-09-12 | Juul Labs, Inc. | Vaporization device systems and methods |

| US9788576B2 (en) | 2013-12-30 | 2017-10-17 | Huizhou Kimree Technology Co., Ltd. Shenzhen | Electronic cigarette, and battery rod and atomizer |

| US11019685B2 (en) | 2014-02-06 | 2021-05-25 | Juul Labs, Inc. | Vaporization device systems and methods |

| US11452177B2 (en) | 2014-02-06 | 2022-09-20 | Juul Labs, Inc. | Vaporization device systems and methods |

| US10709173B2 (en) | 2014-02-06 | 2020-07-14 | Juul Labs, Inc. | Vaporizer apparatus |

| US10865001B2 (en) | 2016-02-11 | 2020-12-15 | Juul Labs, Inc. | Fillable vaporizer cartridge and method of filling |

| US10912333B2 (en) | 2016-02-25 | 2021-02-09 | Juul Labs, Inc. | Vaporization device control systems and methods |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20120008751A (en) | Mulching Nonwoven Structure | |

| US7708503B2 (en) | Extruded plastic netting for use in erosion control, mulch stabilization, and turf reinforcement | |

| JP5321871B2 (en) | Crop cultivation material and crop cultivation method using the same | |

| CN1149914C (en) | Improved agricultural mulch film and method of use thereof | |

| JP5863803B2 (en) | Agricultural coating | |

| KR101454576B1 (en) | Non-woven fabric for agriculture | |

| US20020124463A1 (en) | Landscape fabric with hydration dams | |

| KR100779925B1 (en) | Eco friendly grass mat | |

| KR101317628B1 (en) | Mat for preventing growing weeds | |

| KR102079226B1 (en) | Spunbond nonwoven fabric for mulching and method of preparing the same | |

| KR101863374B1 (en) | Nonwoven fabric having a soft property and preparing method thereof | |

| KR101778415B1 (en) | Covering material for agricultural use, and method for producing same | |

| KR101005548B1 (en) | Mulching Nonwoven Fabric | |

| KR101352535B1 (en) | Mat for preventing growing weeds and process for preparing thereof | |

| KR100742962B1 (en) | Multi-layered Polypropylene Spunbond Nonwoven Fabric for Mulching and its Manufacturing Method | |

| EP1372373B1 (en) | Weather-resistant film consisting of thermoplastic synthetic materials | |

| KR102503940B1 (en) | Expanable Fabric Pot | |

| CN106888871A (en) | A kind of cover layer and plant cultivation method | |

| JPS6344820A (en) | Protective sheet for directly protecting plant | |

| US20090133325A1 (en) | Cover for deflecting light and minimizing heat absorption by a body | |

| RU216686U1 (en) | MULCH FABRIC | |

| JP4717673B2 (en) | Water absorption / water retention sheet | |

| JP5505737B2 (en) | Crop cultivation material and crop cultivation method using the same | |

| RU216599U1 (en) | COVERING FABRIC | |

| RU216553U1 (en) | FOIL MULCH FABRIC |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| PA0109 | Patent application | Patent event code:PA01091R01D Comment text:Patent Application Patent event date:20100720 | |

| PA0201 | Request for examination | ||

| PG1501 | Laying open of application | ||

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection | Comment text:Notification of reason for refusal Patent event date:20120220 Patent event code:PE09021S01D | |

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent | Patent event date:20120516 Comment text:Decision to Refuse Application Patent event code:PE06012S01D Patent event date:20120220 Comment text:Notification of reason for refusal Patent event code:PE06011S01I |