JP3860373B2 - Production method of wooden flooring - Google Patents

Production method of wooden flooringDownload PDFInfo

- Publication number

- JP3860373B2 JP3860373B2JP37094199AJP37094199AJP3860373B2JP 3860373 B2JP3860373 B2JP 3860373B2JP 37094199 AJP37094199 AJP 37094199AJP 37094199 AJP37094199 AJP 37094199AJP 3860373 B2JP3860373 B2JP 3860373B2

- Authority

- JP

- Japan

- Prior art keywords

- groove

- decorative sheet

- substrate

- width

- grooves

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Floor Finish (AREA)

Description

Translated fromJapanese【0001】

【産業上の利用分野】

本発明は、住宅における建築用木質床材、特に、表面に化粧シートを貼着した木質床材の製造方法に関するものである。

【0002】

【従来の技術】

近年、無垢の天然木材を加工してなる床材や表面に化粧単板を貼着している木質床材に代わって、基板表面に樹脂フィルムや樹脂強化化粧紙などの化粧シートを貼着してなる木質床材が広く使用されている。基板表面に貼着される上記化粧シートは品質が一定であり、且つ印刷技術の向上や樹脂組成の改良によって、外観や耐久性も化粧単板とほとんど変わらなく、従って、良好な外観と強度的にも優れた化粧シート貼り木質床材を安価に且つ多量に生産し得るという利点を備えている。

【0003】

【発明が解決しようとする課題】

しかしながら、木質床材には通常、疑似目地となる溝が刻設されており、この溝加工は基板表面に化粧シートを貼着したのち、断面V字状の刃体を表面に押し付けることにより刻設されているため、溝部においては先鋭な刃先によって化粧シートが切断された構造となり、従って、深い溝を刻設すると、断面V字状の溝における両側溝壁面に基材の生地が露出して表面の化粧シートとの色合いが相違し、違和感を与えて商品価値が低下するという問題点があった。このため、比較的浅く且つ細い溝しか形成することができず、立体感や高級感に劣るものであった。

【0004】

さらに、化粧シートが基板表面から溝に沿って溝底に達するまで密着していても、溝底において切断されていると、施工後においてその切断した端部から化粧シートが剥離したり捲れが生じて外観を著しく損するばかりでなく、耐水性等の耐久性が低下して長期の使用に供することができなくなるという問題点がある。また、基板表面に上記溝を刻設したのち化粧シートを貼着した場合においては、図7に示すように、基板aの表面に刻設した溝bの溝底が鋭角な底面に刻設されているので、化粧シートcを溝b内に没入させても化粧シートcは厚みを有しているために溝底端にまで密着させることができず、浮き上がり状態となって立体感を著しく阻害すると共に均一な木質床材を得ることができないという問題点がある。

【0005】

本発明はこのような問題点に鑑みてなされたもので、その目的とするところは優れた外観を呈すると共に、立体感と高級感に富み、且つ剥離したりする虞れもなく長期の使用に耐えることができる木質床材を工業的に多量生産可能な製造方法を提供するにある。

【0006】

【課題を解決するための手段】

上記目的を達成するために、本発明の木質床材の製造方法は、木質板よりなる基板の表面に、溝底の幅が全長に亘って0.2mm以上で1.0mm未満の細幅の平坦な底面に形成されていると共に両側溝壁面をこの底面の両側端から基板表面に向かって溝幅が幅広くなる方向に傾斜した傾斜壁面に形成している溝を断面V字状の刃体によって刻設したのち、これらの溝の面を含めて基板の表面全面に接着剤を塗布し、しかるのち、この基板表面に厚みが上記溝の平坦な底面の幅寸法よりも薄い化粧シートを重ね合わせて貼着すると共に溝部を被覆している化粧シート部分を溝内に押し込んで該溝の両側溝壁面から上記平坦な底面に連続して密着させることを特徴とする。

【0007】

【作用】

基板表面に刻設した溝の底面は細幅の平坦な面に形成されてあり、この溝を設けている基板表面に化粧シートを貼着しているので、溝部を被覆する化粧シート部分を溝内に没入させることによって溝が深く且つ溝幅が広くても化粧シートが切断されることなく溝の傾斜壁面に全面的に貼着する。従って、溝の傾斜壁面に基板の生地面が露出することのない優れた外観を呈する化粧シート貼り木質床材を提供することができる。その上、溝の底面を細幅の平坦面に形成しているので、化粧シートが浮き上がることなく溝底面にまで確実に密着した構造となり、立体感と高級感に富んで商品価値が向上すると共に優れた耐久性を発揮して長期の使用に供することができる。

【0008】

また、上記木質床材の製造方法は、予め、溝底が全長に亘って細幅の平坦な面に形成している溝加工を施すものであるから、深くて幅広い一定の断面形状を有する溝を簡単且つ正確に刻設することができ、この溝加工後に、基板表面に化粧シートを貼着して溝部を被覆している化粧シート部分を溝内に没入させるので、溝の傾斜壁面に全面的に密着させることができると共に溝底が上記のように全長に亘って細幅の平坦な面に形成しているから、化粧シートが浮き上がることなく、また、破損する虞れもなく確実に溝底に密着し、均一にして優れた外観を呈する化粧シート貼り木質床材を安価に且つ多量に製造することができる。

【0009】

【実施例】

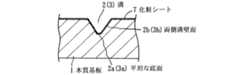

次に、本発明の具体的な実施の形態を図面について説明すると、図1において、1は厚さが12〜20mmの長方形状板材からなる木質床材の基板で、その表面に該基板1の長辺に平行な疑似目地を形成する溝(以下、縦溝という)2、2を幅方向に一定間隔毎に全長に亘って刻設していると共に隣接する縦溝2、2間、及び基板1の長辺と該長辺に隣り合う縦溝2間に基板1の長さ方向に所定間隔毎に疑似目地を形成する横溝3を刻設している。これらの縦溝2と横溝3とは、その溝底が細幅の平坦面をなした断面V字状に形成している。詳しくは、図2、図3に示すように、その溝底を幅0.2mm 以上で1.0mm 未満の細幅の平坦な底面2a、3aに形成していると共にこれらの底面2a、3aの両側端から基材1の表面に向かう両側溝壁面2b、3bは溝幅が徐々に幅広くなる傾斜壁面に形成されている。

【0010】

上記基板1としては上記溝2、3が刻設可能な木質板であればよく、例えば、合板、LVL(集成材)、パーティクルボード、MDF(中比重繊維板)またはこれらの積層板を用いることができる。また、上記縦溝2と横溝3の両側溝壁面2b、3bは、図2に示すように平坦な底面2a、3aの両側端から基板1の表面に向かって断面直線状に傾斜したV目地の傾斜壁面に形成しておいてもよく、図3に示すように平坦な底面2a、3aの両側縁から基板1の表面に向かって断面凸円弧状に湾曲したR目地の傾斜壁面に形成しておいてもよい。

【0011】

さらに、基板1の表面側における四方周端縁は、上記両側溝壁面2b、3bと同一形状に面取り加工されて傾斜端面4に形成されていると共に四方端面には雌雄実部5、6が形成されている。

【0012】

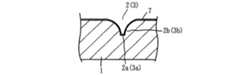

7は基板1の表面全面に貼着している化粧シートで、上記縦溝2及び横溝3に対しては、両側溝壁面2b、3bから平坦な底面2a、3aに連続して密着し、溝全面に貼着されている。このような化粧シート7としては、厚みが上記溝2、3の平坦な底面2a、3aの幅寸法よりも薄いシートであって、塩化ビニルやポリエチレン、ポリプロピレンなどの樹脂フィルム、或いは印刷紙を樹脂でコーティングまたは樹脂を含浸させてなる化粧シートを用いることができる。そして、基板1の表面全面にこの化粧シート7を貼着することによって木質床材Aを構成している。なお、印刷紙を用いる場合は、貼着後に減摩剤を添加した塗装を施すことが好ましい。

【0013】

このように構成した木質床材Aにおいて、基板1の表面に刻設している上記縦溝2及び横溝3の平坦な底面2a、3aの幅が0.2mm 未満であると、上記化粧シート7をその底面2a、3aまで没入させることが困難となって密着性が悪くなり、溝底から浮き上がってこれらの溝2、3によって形成される木質床材Aの疑似目地の深さが浅くなり、立体感を損なうばかりでなく、その浮き上がり部分から破損して化粧シートが捲り上がる虞れが生じる一方、底面幅が1.0mm 以上であると、疑似目地としての外観に違和感が生じて意匠的に不自然となるので、上述したように溝2、3の平坦な底面2a、3aの幅を0.2mm 以上で1.0mm 未満に形成している。

【0014】

次に、上記木質床材Aの製造方法を説明すると、図4に示すように、先端面が全長に亘って細幅の平坦面とした刃先12に形成している断面V字状の突条の刃体11を上記基板1の縦溝2と横溝3との刻設部位に対応して押圧板10の下面に突設してなる溝加工具を用いて、基板1の表面にこの押圧板10を押し付けることにより刃体11によって図5に示すように、基板1に上記平坦な底面2a、3aとこの底面2a、3aの両側端から基板1の表面に向かって傾斜してなる断面V字状の溝2、3を刻設する。なお、溝加工具としては、押圧板10に限らず、上記刃体11を突設しているロール体であってもよく、また、先端に刃体11を形成してなる軸体を回転させながら水平方向に移動させることによって溝加工を行ってもよい。

【0015】

こうして、基板1の表面に溝底が全長に亘って細幅の平坦な底面2a、3aに形成し且つ両側溝壁面2b、3bを底面2a、3aの両側端から斜め上方に傾斜した傾斜面に形成しているV字状の縦溝2と横溝3を刻設したのち、これらの溝2、3の面を含めて基板1の表面全面に接着剤を塗布し、しかるのち、上記化粧シート7を基板1上に重ね合わせてラッピング法又は曲面プレスにより化粧シート7を基板表面に貼着すると共に溝2、3を被覆している化粧シート部分を溝2、3内に押し込んで、両側溝壁面2b、3bから細幅の平坦な底面2a、3aに亘り全面的に密着させ、溝2、3に一体に貼着するものである。なお、基板1の表面に2枚の化粧シートを並べて全面的に貼着してもよいが、切れ目のない1枚の化粧シートを基板1の表面全面に貼着する方が、継目もなくて捲れが生じる虞れのないきれいな化粧面にすることができ、その上、作業の簡素化することができる。

【0016】

こうして製造された木質床材Aは、複数枚、床下地面上に互いに対向する雌雄実部5、6を係合させながら敷設して床を構成するものであり、互いに接合した木質床材A、Aはその傾斜端面4、4によって溝2、3と同一形状、同一大きさの目地が形成される。

【0017】

【発明の効果】

以上のように本発明によれば、表面に溝を刻設している基板の表面全面に化粧シートを貼着してなる木質床材であって、であって、上記基板表面に刻設した溝はその溝底を細幅の平坦な面に形成していると共に両側溝壁面を上記平坦な底面の両側端から基板表面に向かって溝幅が幅広くなる方向に傾斜した傾斜壁面に形成してあり、さらに、上記化粧シートは溝を刻設した後の基板表面全面に貼着され且つ溝に対してはその両側溝壁面から平坦な底面に連続して密着しているので、溝底部に基板の生地が露出しておらず、該基板の表面から溝の底面にまで化粧シートによって全面的に被覆された構造となり、美麗な外観を呈して商品価値を増大させることができる。

【0018】

さらに、基板表面に刻設した溝の底面は上記のように細幅の平坦な面に形成されているので、深い溝を刻設しても化粧シートをその溝底面にまで確実に密着させた構造とすることができ、従って、立体感と高級感に富んだ優れた木質床材を提供することができ、その上、溝はその溝底から両側溝壁面に切れ目なく化粧シートによって被覆されているので、耐水性、耐汚染性が向上すると共に化粧シートが剥離したり捲れたりする虞れもなく長期の使用に供することができる。

【0019】

また、本発明の木質床材の製造方法によれば、予め、溝底が全長に亘って細幅の平坦な面に形成された断面V字状の溝を刻設したのち、この基板表面全面に化粧シートを貼着すると共に溝部を被覆している化粧シート部分を溝内に没入させて該溝の両側溝壁面から上記平坦な底面に連続して密着させることを特徴とするものであるから、予め、基板表面に溝底が全長に亘って細幅の平坦な面に形成している溝加工を施すので、深くて幅広い一定の断面形状を有する溝を簡単且つ正確に刻設することができ、この溝加工後に、基板表面に化粧シートを貼着して溝部を被覆している化粧シート部分を溝内に押し込むので、溝の傾斜壁面に全面的に密着させることができると共に溝底が上記のように全長に亘って細幅の平坦な面に形成しているから、化粧シートが浮き上がることなく、また、破損する虞れもなく確実に且つ容易に溝底に密着させることができ、均一にして優れた外観を呈する化粧シート貼り木質床材を安価に且つ多量に製造することができる。

【図面の簡単な説明】

【図1】 木質床材の斜視図、

【図2】 その溝部分の拡大縦断面図、

【図3】 別な実施例を示す溝部分の拡大縦断面図、

【図4】 基板に溝加工を施す直前の簡略縦断面図、

【図5】 溝加工を施した後の簡略縦断面図、

【図6】 化粧シートを貼着した状態の一部の縦断面図、

【図7】 従来例を示す縦断面図。

【符号の説明】

1 木質基板

2、3 溝

2a、3a 平坦な底面

2b、3b 両側溝壁面

7 化粧シート

11 刃体

12 刃先[0001]

[Industrial application fields]

The present invention, for construction of residential wood flooring, particularly, to a method for manufacturinga wood flooring that attaching a decorative sheet to the surface.

[0002]

[Prior art]

In recent years, decorative sheets such as resin films and resin-reinforced decorative paper have been attached to the substrate surface, instead of flooring made of natural natural wood and wooden flooring with a decorative veneer on the surface. Wooden flooring is widely used. The decorative sheet adhered to the substrate surface has a constant quality, and the appearance and durability are almost the same as the decorative veneer due to the improvement of printing technology and resin composition. In addition, it has the advantage of being able to produce an excellent decorative sheet-attached wood floor material at low cost and in large quantities.

[0003]

[Problems to be solved by the invention]

However, the wooden floor material is usually provided with a groove serving as a pseudo joint, and this groove processing is performed by sticking a decorative sheet on the surface of the substrate and then pressing a blade having a V-shaped cross section on the surface. Therefore, the groove portion has a structure in which the decorative sheet is cut by a sharp cutting edge. Therefore, when a deep groove is formed, the base material fabric is exposed on both side groove wall surfaces of the V-shaped groove. There was a problem that the hue of the decorative sheet on the surface was different, giving a sense of incongruity and reducing the product value. For this reason, only a comparatively shallow and thin groove | channel can be formed, and it was inferior to a three-dimensional feeling and a high-class feeling.

[0004]

Furthermore, even if the decorative sheet is in close contact from the substrate surface until it reaches the groove bottom, if the decorative sheet is cut at the groove bottom, the decorative sheet is peeled off or curled after the cut ends. As a result, there is a problem that not only the appearance is remarkably impaired, but also durability such as water resistance is lowered and it cannot be used for a long time. Further, when the decorative sheet is pasted after the groove is engraved on the substrate surface, the groove bottom of the groove b engraved on the surface of the substrate a is engraved on an acute bottom surface as shown in FIG. Therefore, even if the decorative sheet c is immersed in the groove b, since the decorative sheet c has a thickness, the decorative sheet c cannot be brought into close contact with the bottom of the groove, and the three-dimensional effect is remarkably hindered by rising. However, there is a problem that a uniform wooden flooring cannot be obtained.

[0005]

The present invention has been made in view of such problems, and the object of the present invention is to provide an excellent appearance, rich in three-dimensionality and luxury, and can be used for a long time without fear of peeling off. An object of the present invention is to provide a production method capable of industrially mass-producing wood floor materialsthat can withstand.

[0006]

[Means for Solving the Problems]

In order to achieve the above object, amethod for producing a wood floor material according to the present invention provides a flat surface havinga narrow width of0.2 mmor more andlessthan1.0mmover theentire length of agroove bottom on the surface of a substrate made ofwood board.engraving the blade body a groove from both ends toward the substrate surfaceare formed in an inclined wall which is inclined widely made direction groove widthof the V-shaped cross section ofthe bottom of both side groove walls withare formed on thebottom surfaceAfter that, an adhesive is applied to the entire surface of the substrate including the surfaces of these grooves, and then a decorative sheet having athickness smaller than the width of the flat bottom surface of the groove islaminated and pasted on thesubstrate surface. The decorative sheet portion that is worn and covers the groove portion ispushed into the groove so as to be in close contact with the flat bottom surface from the both-side groove wall surfacesof the groove.

[0007]

[Action]

The bottom surface of the groove engraved on the substrate surface is formed as a narrow flat surface, and a decorative sheet is attached to the surface of the substrate provided with this groove. Even if the groove is deep and the groove width is wide, the decorative sheet is adhered to the inclined wall surface of the groove without being cut. Therefore, it is possible to provide a decorative sheet-attached wooden floor material that exhibits an excellent appearance without exposing the substrate surface to the inclined wall surface of the groove. In addition, since the bottom surface of the groove is formed on a narrow flat surface, the decorative sheet does not float up, and the structure firmly adheres to the bottom surface of the groove. It can be used for long-term use with excellent durability.

[0008]

In addition, since the above-mentioned method for producing a wooden floor material is a groove processing in which a groove bottom is formed in advance on a narrow flat surface over the entire length, a groove having a deep and wide constant cross-sectional shape. After this groove processing, the decorative sheet is attached to the substrate surface and the decorative sheet portion covering the groove is immersed in the groove. Since the bottom of the groove is formed on a flat and narrow surface over the entire length as described above, the decorative sheet does not float and there is no risk of breakage. It is possible to produce a large amount of a wooden flooring with a decorative sheet adhered to the bottom and uniform and exhibiting an excellent appearance at low cost.

[0009]

【Example】

Next, a specific embodiment of the present invention will be described with reference to the drawings. In FIG. 1,

[0010]

The

[0011]

Further, the peripheral edge of the four sides on the surface side of the

[0012]

[0013]

In the wooden flooring A thus configured, if the width of the flat bottom surfaces 2a and 3a of the

[0014]

Next, the manufacturing method of the wooden flooring A will be described. As shown in FIG. 4, the protrusion having a V-shaped cross section formed on the cutting edge 12 whose tip surface is a narrow flat surface over the entire length. The pressing plate is formed on the surface of the

[0015]

In this way, the groove bottom is formed on the surface of the

[0016]

The wooden flooring A manufactured in this way is constructed by laying a plurality of wooden flooring materials A and 6 on the floor base surface while engaging the male and female real parts 5 and 6 facing each other. In A, joints having the same shape and the same size as the

[0017]

【The invention's effect】

As described above, according to the present invention, there is a wooden floor material obtained by sticking a decorative sheet to the entire surface of a substrate having grooves formed on the surface thereof, which is engraved on the surface of the substrate. The groove has a groove bottom formed on a flat surface with a narrow width, and both side groove wall surfaces are formed on inclined wall surfaces inclined in a direction in which the groove width becomes wider from both side ends of the flat bottom surface toward the substrate surface. In addition, the decorative sheet is adhered to the entire surface of the substrate after the groove is engraved, and the groove is continuously adhered to the flat bottom surface from the groove wall surfaces on both sides of the groove. The fabric is not exposed, and the entire surface is covered with a decorative sheet from the surface of the substrate to the bottom surface of the groove, and the product value can be increased by providing a beautiful appearance.

[0018]

Furthermore, since the bottom surface of the groove engraved on the substrate surface is formed as a narrow flat surface as described above, the decorative sheet is securely adhered to the bottom surface of the groove even when a deep groove is engraved. Therefore, it is possible to provide an excellent wooden flooring material rich in three-dimensionality and luxury, and in addition, the groove is covered with a decorative sheet from the groove bottom to both sides of the groove wall without any breaks. Therefore, the water resistance and the stain resistance are improved, and the decorative sheet can be used for a long period of time without fear of peeling or dripping.

[0019]

Further, according to the method for producing a wood floor material of the present invention, after the groove bottom is previously engraved with a groove having a V-shaped cross section formed on a flat surface with a narrow width over the entire length, the entire surface of the substrate is formed. Since the decorative sheet portion is attached to the groove portion, the decorative sheet portion covering the groove portion is immersed in the groove, and is continuously adhered from the groove wall surfaces on both sides of the groove to the flat bottom surface. Since the groove bottom is formed on the substrate surface in advance so that the groove bottom is formed on a flat surface with a narrow width, it is possible to easily and accurately engrave a groove having a deep and wide constant cross-sectional shape. After the groove processing, the decorative sheet is pasted on the surface of the substrate and the decorative sheet portion covering the groove is pushed into the groove, so that the groove bottom can be closely adhered to the inclined wall surface of the groove. Since it is formed on a narrow flat surface over the entire length as described above A low-cost and large-scale production of a wooden flooring with a decorative sheet that can be reliably and easily adhered to the bottom of the groove without causing the decorative sheet to float or be damaged. can do.

[Brief description of the drawings]

FIG. 1 is a perspective view of a wooden flooring,

FIG. 2 is an enlarged longitudinal sectional view of the groove part,

FIG. 3 is an enlarged longitudinal sectional view of a groove portion showing another embodiment,

FIG. 4 is a simplified longitudinal sectional view just before grooving a substrate,

FIG. 5 is a simplified longitudinal sectional view after grooving,

FIG. 6 is a longitudinal sectional view of a part with a decorative sheet attached,

FIG. 7 is a longitudinal sectional view showing a conventional example.

[Explanation of symbols]

1

2a, 3a Flat bottom

2b, 3b Groove wall on both

11 Blade

12 cutting edge

Claims (1)

Translated fromJapanesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP37094199AJP3860373B2 (en) | 1999-12-27 | 1999-12-27 | Production method of wooden flooring |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP37094199AJP3860373B2 (en) | 1999-12-27 | 1999-12-27 | Production method of wooden flooring |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2001179710A JP2001179710A (en) | 2001-07-03 |

| JP3860373B2true JP3860373B2 (en) | 2006-12-20 |

Family

ID=18497861

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP37094199AExpired - Fee RelatedJP3860373B2 (en) | 1999-12-27 | 1999-12-27 | Production method of wooden flooring |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3860373B2 (en) |

Families Citing this family (34)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE0001325L (en) | 2000-04-10 | 2001-06-25 | Valinge Aluminium Ab | Locking systems for joining floorboards and floorboards provided with such locking systems and floors formed from such floorboards |

| US20020178674A1 (en) | 1993-05-10 | 2002-12-05 | Tony Pervan | System for joining a building board |

| US7121059B2 (en) | 1994-04-29 | 2006-10-17 | Valinge Innovation Ab | System for joining building panels |

| US7386963B2 (en) | 1998-06-03 | 2008-06-17 | Valinge Innovation Ab | Locking system and flooring board |

| JP4605844B2 (en)* | 2000-01-12 | 2011-01-05 | 大日本印刷株式会社 | Manufacturing method of decorative material for flooring |

| US6851241B2 (en) | 2001-01-12 | 2005-02-08 | Valinge Aluminium Ab | Floorboards and methods for production and installation thereof |

| US8028486B2 (en) | 2001-07-27 | 2011-10-04 | Valinge Innovation Ab | Floor panel with sealing means |

| US8250825B2 (en) | 2001-09-20 | 2012-08-28 | Välinge Innovation AB | Flooring and method for laying and manufacturing the same |

| SE525558C2 (en) | 2001-09-20 | 2005-03-08 | Vaelinge Innovation Ab | System for forming a floor covering, set of floorboards and method for manufacturing two different types of floorboards |

| SE525661C2 (en) | 2002-03-20 | 2005-03-29 | Vaelinge Innovation Ab | Floor boards decorative joint portion making system, has surface layer with underlying layer such that adjoining edge with surface has underlying layer parallel to horizontal plane |

| ATE467015T1 (en) | 2002-04-03 | 2010-05-15 | Vaelinge Innovation Ab | FLOOR PANEL WITH INTEGRATED CONNECTING MEANS AND METHOD FOR THE PRODUCTION THEREOF |

| SE525657C2 (en) | 2002-04-08 | 2005-03-29 | Vaelinge Innovation Ab | Flooring boards for floating floors made of at least two different layers of material and semi-finished products for the manufacture of floorboards |

| US8850769B2 (en) | 2002-04-15 | 2014-10-07 | Valinge Innovation Ab | Floorboards for floating floors |

| US7051486B2 (en) | 2002-04-15 | 2006-05-30 | Valinge Aluminium Ab | Mechanical locking system for floating floor |

| US7739849B2 (en) | 2002-04-22 | 2010-06-22 | Valinge Innovation Ab | Floorboards, flooring systems and methods for manufacturing and installation thereof |

| US7845140B2 (en) | 2003-03-06 | 2010-12-07 | Valinge Innovation Ab | Flooring and method for installation and manufacturing thereof |

| US7677001B2 (en) | 2003-03-06 | 2010-03-16 | Valinge Innovation Ab | Flooring systems and methods for installation |

| DE20311569U1 (en)* | 2003-07-25 | 2003-10-09 | ANDY Holzprodukte GmbH, 47441 Moers | laminate flooring |

| US7886497B2 (en) | 2003-12-02 | 2011-02-15 | Valinge Innovation Ab | Floorboard, system and method for forming a flooring, and a flooring formed thereof |

| US20050166516A1 (en) | 2004-01-13 | 2005-08-04 | Valinge Aluminium Ab | Floor covering and locking systems |

| US7516588B2 (en) | 2004-01-13 | 2009-04-14 | Valinge Aluminium Ab | Floor covering and locking systems |

| SE527570C2 (en) | 2004-10-05 | 2006-04-11 | Vaelinge Innovation Ab | Device and method for surface treatment of sheet-shaped material and floor board |

| US7454875B2 (en) | 2004-10-22 | 2008-11-25 | Valinge Aluminium Ab | Mechanical locking system for floor panels |

| US7841144B2 (en) | 2005-03-30 | 2010-11-30 | Valinge Innovation Ab | Mechanical locking system for panels and method of installing same |

| US8215078B2 (en) | 2005-02-15 | 2012-07-10 | Välinge Innovation Belgium BVBA | Building panel with compressed edges and method of making same |

| SI1691005T1 (en)* | 2005-02-15 | 2010-01-29 | Vaelinge Innovation Ab | Method to make a floorboard with compressed edges |

| JP4679206B2 (en)* | 2005-03-31 | 2011-04-27 | 大日本印刷株式会社 | Floor decorative material |

| US8061104B2 (en) | 2005-05-20 | 2011-11-22 | Valinge Innovation Ab | Mechanical locking system for floor panels |

| US20070175144A1 (en) | 2006-01-11 | 2007-08-02 | Valinge Innovation Ab | V-groove |

| US8323016B2 (en) | 2006-09-15 | 2012-12-04 | Valinge Innovation Belgium Bvba | Device and method for compressing an edge of a building panel and a building panel with compressed edges |

| BR112012013809B1 (en) | 2009-12-17 | 2019-07-30 | Välinge Innovation AB | METHOD FOR MANUFACTURING FLOOR PANELS |

| JP6210378B2 (en)* | 2014-02-07 | 2017-10-11 | パナソニックIpマネジメント株式会社 | Production method of wooden flooring |

| JP2016199951A (en)* | 2015-04-13 | 2016-12-01 | 株式会社アイエムアイ | Rustic floor material and manufacturing method thereof |

| JP7228437B2 (en)* | 2019-03-27 | 2023-02-24 | 大建工業株式会社 | wrapping veneer |

- 1999

- 1999-12-27JPJP37094199Apatent/JP3860373B2/ennot_activeExpired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2001179710A (en) | 2001-07-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3860373B2 (en) | Production method of wooden flooring | |

| JPH06307065A (en) | Decorated wood plate and its manufacture | |

| US20060174566A1 (en) | Process of making decorative flooring materials and decorative flooring material made by the process | |

| JPH02188204A (en) | Manufacture of decorative plate with groove | |

| JP6598842B2 (en) | Wrapping decorative board and method for producing the same | |

| JP2015016663A (en) | Decorative plate and method of manufacturing the decorative plate | |

| JP2001353706A (en) | Woody floor material and its manufacturing method | |

| JP4279273B2 (en) | Decorative material and method for producing flooring or upholstery using this decorative material | |

| KR100899402B1 (en) | Manufacturing method of door panels for furniture and door panels thereof | |

| JP3981562B2 (en) | Decorative plate manufacturing method | |

| JPH02188203A (en) | Manufacture of decorative plate with groove | |

| KR100775027B1 (en) | Two-Tone Processing of Furniture Doors | |

| JPH11333804A (en) | Grooved decorative laminate and manufacture thereof | |

| JP3703776B2 (en) | Decorative plate manufacturing method | |

| KR100530887B1 (en) | Two tone processing method of door | |

| CN100379932C (en) | Corner piece | |

| JP4007246B2 (en) | Decorative plate manufacturing method | |

| KR200184859Y1 (en) | The wood panel having three dimensional pattern | |

| JP3870096B2 (en) | Decorative plate manufacturing method | |

| JP3905792B2 (en) | Decorative plate manufacturing method | |

| JPS6259665B2 (en) | ||

| JPS58126149A (en) | Method of molding decorative gypsum board | |

| JPH04136359A (en) | Large waterproof panel | |

| JPH081859Y2 (en) | Narrow groove decorative board | |

| JPS6121138B2 (en) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination | Free format text:JAPANESE INTERMEDIATE CODE: A621 Effective date:20040805 | |

| A131 | Notification of reasons for refusal | Free format text:JAPANESE INTERMEDIATE CODE: A131 Effective date:20060523 | |

| A521 | Written amendment | Free format text:JAPANESE INTERMEDIATE CODE: A523 Effective date:20060721 | |

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) | Free format text:JAPANESE INTERMEDIATE CODE: A01 Effective date:20060822 | |

| A61 | First payment of annual fees (during grant procedure) | Free format text:JAPANESE INTERMEDIATE CODE: A61 Effective date:20060921 | |

| R150 | Certificate of patent or registration of utility model | Ref document number:3860373 Country of ref document:JP Free format text:JAPANESE INTERMEDIATE CODE: R150 Free format text:JAPANESE INTERMEDIATE CODE: R150 | |

| FPAY | Renewal fee payment (event date is renewal date of database) | Free format text:PAYMENT UNTIL: 20120929 Year of fee payment:6 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| FPAY | Renewal fee payment (event date is renewal date of database) | Free format text:PAYMENT UNTIL: 20150929 Year of fee payment:9 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| LAPS | Cancellation because of no payment of annual fees |