JP3155022U - Display board having reflecting member - Google Patents

Display board having reflecting memberDownload PDFInfo

- Publication number

- JP3155022U JP3155022UJP2009005144UJP2009005144UJP3155022UJP 3155022 UJP3155022 UJP 3155022UJP 2009005144 UJP2009005144 UJP 2009005144UJP 2009005144 UJP2009005144 UJP 2009005144UJP 3155022 UJP3155022 UJP 3155022U

- Authority

- JP

- Japan

- Prior art keywords

- display

- reflective

- outer peripheral

- peripheral edge

- covered

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Devices For Indicating Variable Information By Combining Individual Elements (AREA)

- Illuminated Signs And Luminous Advertising (AREA)

Abstract

Translated fromJapaneseDescription

Translated fromJapanese本考案は、自然光とLEDの入射光による反射手段を備えた表示板に関するものである。 The present invention relates to a display panel provided with a reflection means by natural light and incident light of an LED.

本出願人が先に出願した表示板、即ち、透明合成樹脂基板の片面に、文字、記号、模様等を形成する溝を形成し、該溝底に透明アクリル樹脂からなる下地層を、また、薄い二枚の透明フィルムの間に着色したアルミ箔を挟んで細断し0.2メッシュ乃至0.5メッシュ程度とした光輝微細片と透明樹脂とを混合してなる中間層を下地層の表面に、さらに該中間層の表面に透明樹脂からなる押圧層を、それぞれ半乾き状態で順次積層して固化させてなる表示板、及び該表示板を表示板本体としてその裏面に更に着色合成樹脂板を接着した表示板(例えば、特許文献1参照。)が公知である。 A display panel previously filed by the present applicant, i.e., a groove for forming characters, symbols, patterns, etc. is formed on one side of a transparent synthetic resin substrate, and a base layer made of a transparent acrylic resin is formed on the bottom of the groove, The surface of the underlayer is an intermediate layer formed by mixing a fine resin piece and transparent resin, which are chopped by sandwiching a colored aluminum foil between two thin transparent films and having a thickness of about 0.2 mesh to 0.5 mesh. Further, a pressure plate made of a transparent resin is further laminated on the surface of the intermediate layer sequentially in a semi-dry state and solidified, and the display plate is used as a display plate main body, and a colored synthetic resin plate is further provided on the back surface thereof. A display panel (see, for example, Patent Document 1) to which is attached is known.

上記特許文献1に係る表示板は、金属光沢を有する反射面を持つ微小な細片(以下、光輝微細片という。)を樹脂層内に練り込む構成により、光線の当たり具合によって反射光の色彩が変化する模様を顕出するものであり、一定の効果が得られるものであった。 The display plate according to

しかしながら、反射光の色彩が変化する光輝微細片を備えているものの、蓄光塗料やバックライト等を使用せず自然光のみで使用するものであることから、十分に反射光を得ることが難しい点があり、反射光を得るために、極めて多量の光輝微細片を使用するものであった。

そして、現実的には、極めて多量の光輝微細片を使用した場合であっても、十分な反射光は得難いものであった。However, although it has bright fine pieces that change the color of the reflected light, it is used only with natural light without using a phosphorescent paint or backlight, so it is difficult to obtain enough reflected light. In order to obtain reflected light, an extremely large amount of bright fine pieces was used.

In reality, it is difficult to obtain sufficient reflected light even when a very large amount of bright fine pieces are used.

また、光輝微細片はその一つ一つが厚い樹脂内に囲まれるように練り込まれている構成であったことから、更に、十分な反射光を得ることが困難であった。 Moreover, since each of the bright fine pieces was kneaded so as to be surrounded by a thick resin, it was further difficult to obtain sufficient reflected light.

本考案は以上の事情に鑑みてなされたものであり、透明層と不透明層とが積層状態に形成された複層板に、第二反射部を形成し、これに第一反射部材を重合した表示板の外周縁の一部又は外周縁の全周囲からLED光を入射させることにより、自然光とLED光とで反射光の色彩が変化する光輝微細片がより一層輝きを増し、暗いところでも光輝微細片で形成した第二反射部の文字、図形、模様などの表示部分を自然光の反射光とLED光の入射光とが相俟って、より一層第二反射部を輝かせて、少量の光輝微細片で強力な反射光を得ることができる。

第二反射部はLED光の入射により非常に強い反射光を得ることができるため、自然光の弱い場所および夜間での使用が可能となり、室内、室外は勿論のこと、陳列表示板、道路標示、案内板、看板、広告宣伝用表示板、位牌・表札・墓石の文字表示板、さらに、床、壁、階段の案内表示などに使用することができる表示板を提供することを、考案が解決しようとする課題とするものである。The present invention has been made in view of the above circumstances, and a second reflecting portion is formed on a multilayer plate in which a transparent layer and an opaque layer are formed in a laminated state, and a first reflecting member is polymerized thereon. By making LED light incident from a part of the outer peripheral edge of the display panel or from the entire periphery of the outer peripheral edge, the glittering fine pieces in which the color of reflected light changes between natural light and LED light further increase in brightness, and even in dark places. The display part such as letters, figures, and patterns of the second reflecting part formed of fine pieces is combined with the reflected light of natural light and the incident light of LED light to make the second reflecting part further shine, and a small amount Strong reflected light can be obtained with the bright fine pieces.

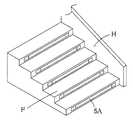

Since the second reflecting portion can obtain very strong reflected light by the incidence of LED light, it can be used in places where natural light is weak and at night, as well as indoors and outdoors, display display boards, road markings, The idea is to provide a display board that can be used for information boards, signboards, display boards for advertising, character display boards for ranks, nameplates, and tombstones, as well as information displays for floors, walls, and stairs. It is set as a subject.

本考案によれば、透明層10と不透明層11とが積層状態に形成された複層板1、該複層板1の不透明層11より透明層10にかけて透明層10の一部を残して後記の表示部分となる溝状の凹部13を切削形成し、該凹部13に反射面を有する複数の光輝微細片14が平均的且つ反射面の向きを不規則な状態に分散させて、これに着色塗料を塗布して光輝微細片14を固着させて文字、図形、模様などの表示部分12を有する第二反射部15を形成し、該第二反射部15を有する複層板1の裏面側に第一反射部材2を重合固着してなる表示基板Sを形成し、該表示基板Sの外周縁3の全周を反射テープ5で被覆しないで又は一部を残して反射テープ5で被覆し、外周縁3の反射テープ5で被覆していない箇所に複数個のLED4を配置して外周縁3の全体を被覆体5Aで被覆して該LED4に電気回路開閉装置を装備しなる表示板とすることを、課題を解決するための手段とする。 According to the present invention, a

本件考案によれば、表面側から光が入射することにより、表面側に近い第二反射部15により不規則な方向に反射され、さらに表示基板Sの外周縁3の遮蔽されていない部分からLEDの入射光により直線光と拡散状の光源が入射されるとともに、第二反射部に生じる隙間から更に内部へ入射した光はその一部が着色塗料層に吸収反射され、着色塗料層を更に透過した光は第一反射部材2により反射され、反射光の一部は着色された色の波長が外方へ出射されることによって、第二反射部15の不規則な乱反射と該第二反射部15の隙間からの反射光が有色となって得られる。一方、第二反射部15は平面的には分散状態にあるものの全体として凹部13の透明下地層上に位置する構成によって、透明下地層の平面上において、反射面の向きが不規則な状態で部分的に重合して平均的に分散していることから、全体として第二反射部15は密集して反射する。これらの反射と表示基板Sの外周縁3からのLED光による入射光とによる相乗効果、すなわち、表面側からの反射光とLED光の入射光とによって、第二反射部15が暗いところでも非常に強く、乱反射による不規則な強い反射光を有する文字、図形、模様などの表示部分12を得ることができるのである。 According to the present invention, when light is incident from the front surface side, the light is reflected in an irregular direction by the second reflecting

本考案は、第一反射部材2の反射と、第二反射部15の隙間から得られる有色の反射光と、さらに表示基板Sの外周縁3の複数個のLED4の入射光との相乗効果により、強い反射光が得られるため、日中は勿論、暗い場所又は夜間でもより鮮明に明るく見やすい表示板を安価に提供することができる。 The present invention is based on the synergistic effect of the reflection of the first reflecting

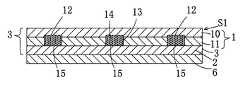

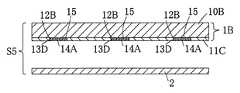

図1は本考案の透明層と不透明層からなる複層板の構成を示す拡大断面図、図2は本考案の実施例1に係る表示基板Sの拡大断面図、図3は本考案の実施例1に係る表示基板Sの平面図、図4は本考案の実施例1に係る表示基板にLEDを配備した表示板の平面図、図5は本考案の実施例1に係る図4のA−A線における拡大断面図、図6は本考案の実施例2の表示基板S1に支持板6を重合させた拡大断面図、図7は本考案の実施例2に係る表示基板S1の外周縁の一部を除き反射テープ5で遮蔽し、反射テープで遮蔽していない部分にLED光の電気回路開閉装置を装備して表面を除く外周縁及び底面を被覆体5Aで被覆した状態を示す拡大断面図、図8は本考案の実施例3に係る透明層と金箔不透明層が一体となっている複層板1Aと第一反射板2との構成関係を示す拡大断面図、図9は本考案の実施例3に係る図8の表示基板S2の拡大断面図、図10は本考案の表示基板S上にさらに内部に水または透明液体を封入した合成樹脂板19を重合してその外周縁にLEDを配置してその外周縁及び底面を被覆した状態の実施例4の拡大断面図、図11は本考案の実施例5を示す不透明合成樹脂板に貫通穴13Bで表示部分12を形成した構成拡大断面図、図12は本考案の実施例6の透明合成樹脂板と反射フィルムを積層した複層板1Bの拡大断面図、図13は実施例6の表示基板S4の構成拡大断面図、図14は本考案の実施例7に使用の一枚ものの透明合成樹脂板と反射フィルムを積層した複層板1Bの拡大断面図、図15は本考案の実施例7の表示基板S5の構成拡大断面図、図16は本考案の表示板を案内板に使用した正面図、図17は本考案の表示板を位牌に使用した状態の正面図、図18は本考案の表示板を階段に使用した斜視図、図19は本考案の表示板を廊下の床板に使用した斜視図である。 FIG. 1 is an enlarged cross-sectional view showing the structure of a multilayer board composed of a transparent layer and an opaque layer according to the present invention, FIG. 2 is an enlarged cross-sectional view of a display substrate S according to

本考案の実施例1に係る表示基板Sは、図1、図2の構成拡大断面図に示すように、厚さ2mm程度のアクリル樹脂透明板の裏面側に0.5mmの不透明の塗料層が形成されており、透明層10と不透明層11とを積層状態として有する複層板1に、不透明層11側より透明層10にかけて切削工具で溝状の凹部13を切削形成する。該凹部13は、溝状、有底穴状に適宜形成され、表示基板Sにおける文字、模様、記号等の輪郭を形成するものである。この凹部13に不規則な向きに反射面を有する複数の光輝微細片14を平均的に分散させ、これに着色塗料を塗布して光輝微細片14を固着させて文字、図形、模様などの表示部分12を有する第二反射部15を形成し、この凹部13側から厚さ0.5mm程度の反射アルミ板である第一反射部材2を順次重合固着した構成を備え、これら複層板1、第一反射部材2は、夫々周囲を接着剤、両面接着テープ等によって固着するとともに、該表示基板Sの外周縁3の全周を反射テープ5で被覆しないで又は一部を残して反射テープ5で被覆し、外周縁3の反射テープ5で遮蔽していない箇所に複数個のLED4を配置して外周縁3の全体を被覆体5Aで被覆して該LED4に電気回路開閉装置を装備してなる表示基板である。 The display substrate S according to the first embodiment of the present invention has an opaque paint layer of 0.5 mm on the back side of an acrylic resin transparent plate having a thickness of about 2 mm, as shown in the enlarged sectional views of FIGS. A groove-

ここで、図2に示すように、複層板1は、不透明層11側に開口して透明層10に底面を有する凹部13を形成し、該凹部13は溝状、有底穴状で、内部に光輝微細片14を分散して着色塗料又は透明ワニスの上澄み液を使用して凹部13に光輝微細片14を固着させて第二反射部15を形成している。 Here, as shown in FIG. 2, the

第二反射部15は複数の光輝微細片14からなるものであり、該光輝微細片14の反射面は、略六角形状で、反射面の幅が0.5mm前後程度の樹脂にアルミ箔を蒸着した微小な細片であり、また反射角度によって反射光の色が変化するホログラムチップと呼ばれるものである。本実施例に係る光輝微細片14は同程度の大きさのもののみを使用している。 The second reflecting

第二反射部15を構成する光輝微細片14は、略均一に凹部13の底面に平面上に散らばっており、部分的に光輝微細片14が相互に重なり合って、反射面の向きが不規則になっている。また、本実施例1に係る光輝微細片14は、略六角形の板状体として形成されている。 The bright

着色塗料は第二反射部15上に塗布されているが、着色塗料自体が第二反射部15を構成する光輝微細片14を安定固着させる働きをするものである。 The colored paint is applied on the second reflecting

以上の構成を有する複層板1と第一反射部材2は同形で、図4、図5に示すごとく第一反射部材2の反射面を残すように縁にのみ両面接着テープ又は接着剤を介して固着している。第一反射部材2のうち着色塗料を塗布した凹部13の対応する位置には、両面接着テープ又は接着剤層を設けず、第一反射部材2とは略当接状態とし、外周縁3の全周を反射テープ5で被覆しないで又は一部を残して反射テープ5で被覆し、外周縁3の反射テープ5で遮蔽していない箇所に複数個のLED4を配置して外周縁3の全体を被覆体5Aで被覆し、該LED4に電気回路開閉装置を装備して外周縁の遮蔽していない箇所にLED4の光を入射させて第二反射部15を構成する光輝微細片14を乱反射させることにより、より一層表示部分12の光輝微細片14を輝かせてより鮮明に表示部分12を表示させることができる。 The

また、被覆体5はゴム、合成樹脂板、合成樹脂フィルム、合板、布、紙で被覆してもよい。 The

尚、野外で使用するときは透明の柔らかい合成製樹脂製のフレキシブル基板を縦に帯状に使いその内部にLEDを封入した厚さ約4mm完全防水型の製品、商品名(Luci FLEX 株式会社コンテンツ製)を使用する。

あるいは野外で表示板として使用する場合は、太陽電池式LED発光体(発光ダイオード)は、一例としてシリコン単結晶型、3V、480mAを使用し、制御部には逆流防止回路、照度検出回路、発信回路、点灯回路、蓄電部には電気二重層コンデンサを使用し、LEDを点灯させるため電気回路開閉装置を使用した。In addition, when used outdoors, a product with a thickness of about 4mm, which is made of a transparent soft synthetic resin flexible substrate vertically and encapsulates LEDs inside it, is a product name (Luci FLEX Co., Ltd., content) ).

Or when using it as a display board in the outdoors, the solar cell type LED luminous body (light emitting diode) uses a silicon single crystal type, 3V, 480 mA as an example, and the control unit has a backflow prevention circuit, an illuminance detection circuit, a transmission An electric double layer capacitor was used for the circuit, lighting circuit, and power storage unit, and an electric circuit switching device was used to light the LED.

実施例2に係る考案によれば、図6、図7に示すごとく、透明層10と不透明層11とが積層状態に形成された複層板1、該複層板1の不透明層11より透明層10にかけて透明層10の一部を残して後記の表示部分12となる溝状の凹部13を切削形成し、該凹部13に反射面を有する光輝微細片14を分散させて、該光輝微細片14に着色塗料を塗布して光輝微細片14を固着させて文字、図形、模様などの表示部分12を有する第二反射部15を形成し、前記第二反射部15を有する複層板1の裏面側に第一反射部材2と支持板6を一体に重合固着して表示基板S1を形成し、該表示基板S1の外周縁3の全周を反射テープ5で被覆しないで又は一部を残して反射テープ5で被覆し、外周縁3の反射テープ5で遮蔽していない箇所に複数個のLED4を配置して外周縁3の全体を被覆体5Aで被覆して該LED4に電気回路開閉装置を装備してなる表示板である。

実施例2は第一反射部材2と支持板6を一体に重合固着しているため、第一反射部材2がアルミニウム板、反射金属板、金属箔蒸着反射フィルム、反射薄板、反射合成樹脂板で、これらの第一反射部材2からなる場合には衝撃に弱く支持板6で第一反射部材2を補強することができ、しかも薄い第一反射部材2で形成できるので軽量で強固な表示基板を提供することができる。According to the device according to the second embodiment, as shown in FIGS. 6 and 7, the

In Example 2, since the first reflecting

また、外周縁3の反射テープ5で被覆していない箇所に複数個のLED4を配置して被覆体5Aで表面以外を被覆した構成であるから、表示基板S1の外周縁3の一部を残して反射テープ5で遮蔽した場合は、遮蔽しない部分からLED光を入射させるので、入射した方向の反射テープ5と第一反射部材2が反射し、表示基板S1の表示部分12の輝きが増し、第二反射部15の表示部分12をより強く乱反射させることができる。 Moreover, since it is the structure which has arrange | positioned several LED4 in the location which is not coat | covered with the

実施例3に係る考案によれば、図9に示すごとく、透明層10と金箔不透明層11Bとが積層状態に形成された複層板1A、該複層板1Aの金箔不透明層11Bより透明層10にかけて透明層10の一部を残して後記の表示部分12となる溝状の凹部13を切削形成し、該凹部13に反射面を有する光輝微細片14を分散させて、該光輝微細片14に着色塗料を塗布して光輝微細片14を固着させて文字、図形、模様などの表示部分12を有する第二反射部15を形成し、前記第二反射部15を有する複層板1Aの裏面側に第一反射部材2を重合固着してなる表示基板S2を形成し、該表示基板S2の外周縁3の全周を反射テープ5で被覆しないで又は一部を残して反射テープ5で被覆し、外周縁3の反射テープ5で被覆していない箇所に複数個のLED4を配置して外周縁3の全体を被覆体5Aで被覆して該LED4に電気回路開閉装置を装備してなる表示板の構成である。

実施例3の複層板1Aの不透明層を金箔不透明層11Bで形成すれば、例えば、表示板を表札として使用する場合には表示基板の外周縁3からLED光を入射させることにより表示部分12の文字などが反射されて表札の文字の周囲を鮮明に浮かび上がらせることができる。さらに金箔不透明層11Bに焼き金箔を使用すれば、より豪奢な表札を提供することができる。

また、金箔不透明層11Bにさらに金箔を重合すれば金箔不透明層11Bから漏れる小さい隙間を塞ぎ、不透明さを増し、表面がきれいで完全な金箔不透明層とすることができる。

そしてこれらを室内灯のカバーに使用すれば、この金箔不透明層11B或いは焼き金箔不透明層11Dを有するやわらかい上品な輝きをかもし出し、室内インテリアなどとしも利用できるものである。According to the device according to the third embodiment, as shown in FIG. 9, a

If the opaque layer of the

Further, if a gold foil is further polymerized on the gold foil

If these are used for the cover of the indoor lamp, the gold foil

実施例4に係る考案によれば、図10に示すごとく、複層板の透明層又透明合成樹脂板上に、内部に透明液体又は水18を封入した透明液体入り合成樹脂板19を積層一体とした表示板からなる構成である。

前記表示基板の上に、内部に水18を封入した合成樹脂板19を重合して表示板の周囲からLED光を入射させたことから、入射光が透明層10を透過して水に対して屈折し、乱反射して第一反射部2へ届くため、自然光より強い反射光を得ることができ、また、第二反射部15が着色層を介して第一反射部材2に密集するように配置されることから、当該第二反射部15がより反射密集し、水との乱反射による不規則な、強い反射光を得ることができる。According to the device according to the fourth embodiment, as shown in FIG. 10, a

Since the

実施例5に係る考案によれば、図11に示すごとく、透明合成樹脂板10Aと不透明合成樹脂板11Aとからなり、不透明合成樹脂板11Aに後記の貫通穴13Bで文字、図形、模様などの表示部分12Aを形成して、透明合成樹脂板10Aと不透明合成樹脂板11Aを重合して該貫通穴13Bの文字、図形、模様などの表示部分12Aに反射面を有する光輝微細片14を分散させて該光輝微細片14に着色塗料を塗布し、着色塗料を乾燥させて、不透明合成樹脂板11A側に、第一反射部材2を固着して、表示基板S3を形成し、該表示基板S3の外周縁3を反射テープ5で被覆しないで又は外周縁3の一部を残して反射テープ5で被覆し、該外周部3の反射テープ5で遮蔽していない箇所に複数個のLED4を配置して外周縁3全体を被覆体5Aで被覆して該LED4に電気回路開閉装置を装備した表示板からなる構成である。

実施例5の透明合成樹脂板10Aと不透明合成樹脂板11Aを重合させる前に、不透明合成樹脂板11Aに予め貫通穴13Bで文字、図形、模様などの表示部分12Aを設け、透明合成樹脂板10Aと不透明合成樹脂板11Aを重合して該表示部分12Aに反射面を有する光輝微細片14を分散し、該部分に着色塗料を塗布し、着色塗料の乾燥後、不透明合成樹脂板11Aの裏面側に、第一反射部材2を固着して表示基板S3を形成し、該表示基板S3の外周縁3の全周を遮蔽しないで又は外周縁3の一部を残して遮蔽し、該外周部3の遮蔽していない箇所に複数個のLED4を配置して、該LED4に電気回路開閉装置を装備してなることを特徴とする表示板とすることで、請求項1に係る考案と比較して透明合成樹脂板10Aを切削しないで予め不透明合成樹脂板11Aに貫通穴13Bを形成したので、製造容易で、且つ低コストとすることができ、極めて生産効率を向上させることができる。According to the device according to the fifth embodiment, as shown in FIG. 11, the transparent

Before the transparent

実施例6に係る考案によれば、図12、図13に示すごとく、透明合成樹脂板10Bと反射フィルム11Cとが積層状態に形成された一枚ものの複層板1Bに、該複層板1Bの反射フィルム11C側より透明合成樹脂板10Bにかけて透明合成樹脂板10Bの一部を残して後記の表示部分12となる溝状の凹部13Cを切削形成し、該凹部13Cに反射面を有する光輝微細片14を分散させて、該光輝微細片14に着色塗料を塗布して光輝微細片14を固着させて文字、図形、模様などの表示部分12を有する第二反射部15を形成し、前記第二反射部15を有する複層板1Bの裏面側に第一反射部材2を重合固着してなる表示基板S4の外周縁3の全部を反射テープ5で被覆しないで又は一部を残して反射テープ5で被覆し、外周縁3の反射テープ5で遮蔽していない箇所に複数個のLED4を配置して外周縁3の全体を被覆体5Aで被覆して該LED4に電気回路開閉装置を装備してなる表示板の構成である。

前記第二反射部15を有する複層板1Bが一枚ものであるから加工が簡単で特に厚さを薄く形成できるので、使用用途が広い表示板が提供できる。According to the device according to the sixth embodiment, as shown in FIGS. 12 and 13, the

Since the

実施例7に係る考案によれば、図14、図15に示すごとく、透明合成樹脂板10Bと反射フィルム11Cとが積層状態に形成された一枚ものの複層板1Bに、複層板1Bの後記の表示部分12Bとなる反射フィルム面の一部を刃物または切削工具で削り取り、該削り取り凹部13Dを形成し、該削り取り凹部13Dに着色剤を混合した光輝微細片入りインキ14Aを印刷塗布して、前記の文字、図形、模様などの表示部分12Bを有する第二反射部15を形成し、前記第二反射部15を形成した複層板1Bの裏面側に第一反射部材2を重合固着して表示基板S5を形成し、表示基板S5の外周縁3の全部を反射テープ5で被覆しないで又は一部を残して反射テープ5で被覆し、外周縁3の反射テープ5で遮蔽していない箇所に複数個のLED4を配置して外周縁3の全体を被覆体5Aで被覆し、該LED4に電気回路開閉装置を装備してなる表示板の構成である。

外周縁からLED4を照射させて印刷により第二反射部15を形成することができるため、鮮明で微細な表現ができ、しかも量産が可能となり、より広範囲の表示板に応用することができる。

さらに、LED4に電気回路開閉装置を装備して外周縁をLEDで照射させることにより、乱反射の強い表示部を有する表示板が提供できるので、室内装飾、壁面にも応用できる製品を提供することができる。According to the device according to Example 7, as shown in FIG. 14 and FIG. 15, the transparent

Since the second reflecting

Furthermore, by providing an

実施例8の表示板の製造方法によれば、透明層10と不透明層11とが積層状態として形成される複層板1又は透明層10と金箔不透明層11Bとが積層状態として形成される複層板1Aを作成し、不透明層11又は金箔不透明層11Bより透明層10にかけて透明層10の一部を残して後記の表示部分12となる溝状の凹部13を切削形成し、該凹部13の底部に反射面を有する光輝微細片14を分散させ、該光輝微細片14に着色塗料を塗布乾燥させて光輝微細片14を前記凹部13に固着させた後、文字、図形、模様などの表示部分12を形成した第二反射部15を形成し、該第二反射部15側に第一反射部材2を重合固着して表示基板Sを形成し、

又は、透明層10と不透明層11とが積層状態として形成される複層板1又は透明層10と金箔不透明層11Bとが積層状態として形成される複層板1Aを作成し、不透明層11又は金箔不透明層11Bより透明層10にかけて透明層10の一部を残して後記の表示部分12となる溝状の凹部13を切削形成し、該凹部13の底部に反射面を有する光輝微細片14を分散させ、該光輝微細片14に着色塗料を塗布乾燥させて光輝微細片14を前記凹部13に固着させた後、文字、図形、模様などの表示部分12を形成した第二反射部15を形成し、該第二反射部15側に第一反射部材2と支持板6を重合固着して表示基板S1を形成し、

各表示基板S、S1の外周縁3の全周を反射テープ5で被覆しないで又は外周縁3の一部を残して反射テープ5で被覆し、該外周縁3の反射テープ5で被覆していない箇所に複数個のLED4を配置して表示基板の表面を除く全体を被覆体5Aで被覆し、該LED4に電気回路開閉装置を装備して外周縁よりLEDを照射させて第二反射部15を鮮明に表示することを特徴とする表示板の製造方法である。

外周縁3の反射テープ5で被覆していない箇所に複数個のLED4を配置して被覆体5Aで表面以外を被覆した構成であるから、各表示基板S又はS1の外周縁3の一部を残して反射テープ5で遮蔽した場合は、遮蔽しない部分からLED光を入射させるので、入射した方向の反射テープ5と第一反射部材2が反射し、各表示基板S又はS1の表示部分12の輝きが増し、第二反射部15の表示部分12をより強く乱反射させるものが提供できる。According to the manufacturing method of the display board of Example 8, the

Alternatively, a

The entire circumference of the outer

Since a plurality of

実施例9の表示板の製造方法によれば、透明合成樹脂板10Bと反射フィルム11Cとが積層状態に形成された一枚ものの複層板1Bに、該複層板1Bの反射フィルム11C側より透明合成樹脂板10Bにかけて透明合成樹脂板10Bの一部を残して後記の表示部分12となる溝状の凹部13Cを切削形成し、該凹部13Cに反射面を有する光輝微細片14を分散させ、該光輝微細片14に着色塗料を塗布して光輝微細片14を固着させて文字、図形、模様などの表示部分12を有する第二反射部15を形成し、前記第二反射部15を有する複層板1Bの裏面側に第一反射部材2を重合固着してなる表示基板S4を形成し、

又は、該複層板1Bの反射フィルム11Cの一部を刃物で削り取り、後記の表示部分12Bとなる反射フィルム面に削り取り凹部13D形成して、該削り取り凹部13Dに反射面を有する光輝微細片14と着色剤を混合した光輝微細片入りインキ14Aでスクリーン印刷又は捺染印刷により前記箇所に塗布して、該部分のインキを乾燥固着させた後、前記の文字、図形、模様などの表示部分12Bを有する第二反射部15を形成し、前記第二反射部15を形成した複層板1Bの裏面側に第一反射部材2を重合固着して表示基板S5を形成し、

各表示基板S4、S5の外周縁3の全部を反射テープ5で被覆しないで又は一部を残して反射テープ5で被覆し、外周縁3の反射テープ5で被覆していない箇所に複数個のLED4を配置して外周縁3の全体を被覆体5Aで被覆し、該LED4に電気回路開閉装置を装備して外周縁よりLEDを照射させて第二反射部15を鮮明に表示させることを特徴とする表示板の製造方法である。

溝状凹部13C又は削り取り凹部13Dに着色剤を混合した光輝微細片入りインキ14Aを印刷塗布して、前記の文字、図形、模様などの表示部分12Bを有する第二反射部15を形成したので、該第二反射部15を有する複層板1Bを量産することができ、安価で使用用途が広くなり、

第二反射部15の裏面側に第一反射部材2を重合固着して表示基板S5を形成し、該表示基板S5の外周縁3の全部を反射テープ5で被覆しないで又は一部を残して反射テープ5で被覆し、外周縁3の反射テープ5で被覆していない箇所に複数個のLED4を配置して外周縁3の全体を被覆体5Aで被覆し、該LED4に電気回路開閉装置を装備して外周縁をLEDで照射させることを特徴とする表示板を製造することができる。

また、位牌、墓石、壁面、床面などに埋め込み使用する場合は電池とLED発光体により点滅させるよう電気回路開閉装置を使用した。According to the manufacturing method of the display board of Example 9, the single-

Alternatively, a part of the

The entire outer

Since the

The first reflecting

In addition, an electric circuit switching device was used so that it was blinked by a battery and an LED illuminant when it was embedded in a pot, a tombstone, a wall surface, a floor surface or the like.

また、光輝微細片に着色塗料を混合させることにより更に透過した光は、第一反射部2により反射され、反射光の一部は外方へ着色された色の波長のみ出射されることによって、前記光輝微細片14の不規則な乱反射光と、第一反射部材2から着色塗料を介して反射され該光輝微細片14間の隙間から出射される有色の反射光とが得られる。 Further, the light further transmitted by mixing the colored fine paint with the glittering fine piece is reflected by the first reflecting

また、前記したように、着色塗料を第二反射部15の凹部13の内側であって、光輝微細片14の隙間から直接塗料の色が外部へ露呈し、塗料の色彩がより明瞭となり、視覚効果を良好とすることができるのである。 Further, as described above, the color paint is exposed to the inside of the

そして、更に、第ニ反射部15の光輝微細片14が平面的には分散状態にあるものの全体として凹部13の透明の下地に密集して位置する構成によって、透明層の凹部の透明下地の平面上において、反射面の向きが不規則な状態で、部分的に重合して、平均的に分散しているため、全体として光輝微細片14が密集して反射するのを、さらにその部分をLEDの入射光を反射させることにより、より一層明るい反射光が得られる。 Further, although the glittering

以上の作用による相乗効果によって、表面側からの光の入射によって、非常に強い輝きを有する乱反射と外周縁3からのLED4の入射光による不規則な反射光とで表示部分12により鮮明に輝かせることができるのである。 Due to the synergistic effect of the above action, the

また、光輝微細片14はその反射面が略六角形状片であることから、角部からの反射光が目に届くことで、円形状の光輝微細片14とした場合と比べて反射状態の輪郭がより鮮明となり、反射面の角のシャープな輪郭形状を有する反射光を得ることができる。

また、反射面が略六角形状片としたことによって、側面は六面の平坦面として併せて形成されることから、これらがLEDの入射光と独立した反射面として作用することにより、光輝微細片14自体の輝きを著しく向上させることができるのである。Moreover, since the reflective surface of the brilliant

In addition, since the reflecting surface is a substantially hexagonal piece, the side surface is formed as a six-sided flat surface, so that these act as a reflecting surface independent from the incident light of the LED, so that the bright fine piece The brightness of 14 itself can be remarkably improved.

次に、上記実施例1に係る表示基板Sの製造方法について説明する。

先ず、図1に示すように、アクリル樹脂透明板の裏面側に厚さ0.1mm未満程度の不透明のウレタン焼付塗装をしてなる複層板1の裏面側に、文字、模様、図形、記号等、所望の意匠を形成しておき、対応する溝を0.1乃至0.2mmの深さで形成する。(尚、図2では理解を容易とするために、ウレタン焼付塗装部分(即ち不透明層)の膜厚を大きくする等適宜厚さ比率を変更して表示している。)Next, a method for manufacturing the display substrate S according to Example 1 will be described.

First, as shown in FIG. 1, characters, patterns, figures and symbols are formed on the back side of a

次に、凹部13の底部に無色透明な透明ワニスの上澄み液を塗布して、その上から反射面を有する光輝微細片14を分散してその部分に着色塗料を塗布し、着色塗料の乾燥後、透明層10と不透明層11を形成する。第二反射部15の上部は略水平な平坦面として形成しておき、該平坦面に第二反射部15である光輝微細片14を、平均的に撒き、第二反射部15を形成する。 Next, a supernatant of a colorless and transparent transparent varnish is applied to the bottom of the

そして、当該光輝微細片14に対して着色剤を塗布し、着色塗料を塗布する。ここで、本実施例における着色剤は、和信塗料製のコンクステン(商品名)を使用し、塗布には刷毛を用いている。 And a coloring agent is apply | coated with respect to the said brightness | luminance

着色剤は、勿論一例として示したコンクステンに限らず、公知な種々の着色剤を使用することができるし、種々の色を配合使用することができる。

また、塗布方法についても、例えば、吹付け等、刷毛以外の種々の公知塗布手段を利用することができる。Of course, the colorant is not limited to the complex as shown as an example, and various known colorants can be used, and various colors can be used in combination.

Moreover, also about the coating method, various well-known coating means other than brushes, such as spraying, can be utilized, for example.

着色剤を乾燥させた後、複層板1の裏面側のうち、光輝微細片14を収納する凹部13の開口部(即ち、着色剤を塗布した部分)を除いて、両面接着テープまたは接着剤を介して、第一反射部材2であるアルミ板を重合固着する。 After drying the colorant, a double-sided adhesive tape or adhesive except for the opening of the recess 13 (that is, the part coated with the colorant) on the back side of the

次いで、支持板6を第一反射部材2であるアルミ板の裏面側へ接着剤を用いて接着し、複層板1、第一反射部材2及び支持板6の外周縁3の全周及び外周縁の一部を残して反射テープ5などで被覆し、被覆していない外周縁よりLED4の光を入射させて裏面側に露出する支持板6の全体に対して接着剤を用いて被覆体5Aで被覆して完成する。 Next, the

また、本考案における第一反射部材2は、上記実施例1及び実施例2においてアルミ板としたが、本考案はこれに限るものではなく、例えば鏡面を有する板状体等とすることもできるし、金属膜を蒸着により形成した軟質フィルム等とすることもできる。 Moreover, although the

更に、複層板若しくは透明板及び不透明板はいずれも必ずしも硬質である必要はなく、ナイロン、フッ素樹脂、ポリプロピレンの軟質の透明層若しくは軟質の透明板に、前記合成樹脂製のフィルム状の薄膜等のように軟質として形成した不透明層若しくは不透明板を積層することもできる。

そして、例えば前記したように第一反射部材を軟質フィルム等の反射部材として組み合せることによって、表示基板を軟質なものとして形成することができる。

尚、軟質とは弾性を有するもののみを示すのではなく、可撓性を有すればよい趣旨である。Furthermore, the multilayer board or the transparent board and the opaque board do not necessarily have to be hard, and the synthetic resin film-like thin film or the like is formed on a soft transparent layer or a soft transparent board of nylon, fluororesin, or polypropylene. As described above, an opaque layer or an opaque plate formed as a soft material can be laminated.

For example, as described above, the display substrate can be formed to be soft by combining the first reflective member as a reflective member such as a soft film.

Note that soft means not only an elastic material but also a flexible material.

以上に示した本考案に係る表示板は、LED光を使用することにより硬質、軟質を問わず、看板、装飾板や表札のほか、道路標識、車両のナンバープレート、夜間安全用反射板、夜間安全用反射テープ等としても使用することができるし、また、田畑等における鳥の駆除具等、風によってなびいて乱反射光による視覚上の効果を与えるものとして使用することもできる。 The above-mentioned display board according to the present invention uses LED light, regardless of whether it is hard or soft, in addition to signboards, decorative boards and nameplates, road signs, vehicle license plates, night safety reflectors, nighttime It can also be used as a safety reflective tape or the like, or it can be used as a bird extermination tool in a field or the like to give a visual effect by diffused light by flying with the wind.

1 複層板

1A 複層板

1B 複層板

2 第一反射部材

3 外周縁

4 LED

5 反射テープ

5A 被覆体

6 支持板

10 透明層

10A 透明合成樹脂板

10B 透明合成樹脂板

11 不透明層

11A 不透明合成樹脂板

11B 金箔不透明層

11C 反射フィルム

11D 焼き金箔不透明層

12 表示部分

12A 表示部分

12B 表示部分

13 凹部

13B 貫通穴

13C 凹部

13D 削り取り凹部

14 光輝微細片

14A 光輝微細片入りインキ

15 第二反射部

18 透明液体又は水

19 透明液体入り合成樹脂板

S 表示基板

S1 表示基板

S2 表示基板

S3 表示基板

S4 表示基板

S5 表示基板

F 踏み板

H 壁面

J 床板DESCRIPTION OF

DESCRIPTION OF

Claims (7)

Translated fromJapanesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009005144UJP3155022U (en) | 2009-07-23 | 2009-07-23 | Display board having reflecting member |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009005144UJP3155022U (en) | 2009-07-23 | 2009-07-23 | Display board having reflecting member |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006239655AContinuationJP2008064810A (en) | 2006-09-04 | 2006-09-04 | Display plate having reflection member, and manufacturing method thereof |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP3155022Utrue JP3155022U (en) | 2009-11-05 |

Family

ID=54859100

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009005144UExpired - Fee RelatedJP3155022U (en) | 2009-07-23 | 2009-07-23 | Display board having reflecting member |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3155022U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3189817U (en)* | 2014-01-20 | 2014-04-03 | 有限会社ティ・アール・ジィ | 棺 台 and 棺 carriage equipped with it |

- 2009

- 2009-07-23JPJP2009005144Upatent/JP3155022U/ennot_activeExpired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3189817U (en)* | 2014-01-20 | 2014-04-03 | 有限会社ティ・アール・ジィ | 棺 台 and 棺 carriage equipped with it |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202176982U (en) | Backlight module group used for appearance decoration | |

| CN209045104U (en) | Integrated light-emitting mark | |

| JP2004101712A (en) | Light transmissive colored film, light transmission masking film, and image display | |

| CN212528973U (en) | Optical leather | |

| JP2008064810A (en) | Display plate having reflection member, and manufacturing method thereof | |

| CN202966147U (en) | Luminous threshold pedal device | |

| CN105047101A (en) | Hidden display panel | |

| JP3155022U (en) | Display board having reflecting member | |

| KR20110003225A (en) | 3d stereoscopic advertising | |

| CN201761426U (en) | Flat type vehicle lighting pedal | |

| CN209358588U (en) | A kind of display module and cover sheet, touch screen | |

| JPWO2003075249A1 (en) | Display device and light source thereof | |

| JP2007101847A (en) | Display apparatus | |

| KR20130028242A (en) | Fluorescent reflective film and building exterior material including the same | |

| JP4551726B2 (en) | Display panel having reflecting member and method for manufacturing the same | |

| KR200433709Y1 (en) | Front-lit billboard | |

| JP5999520B2 (en) | Phosphorescent plate and method for manufacturing the same | |

| JP4870929B2 (en) | Surface emitting display method and surface emitting display device | |

| JP3136815U (en) | LED nameplate | |

| JP2005025004A (en) | Display board | |

| JP2012192828A (en) | Interior panel | |

| JP5149721B2 (en) | Decorative display board used by irradiating light, Buddhist tools and altars molded from the decorative display board | |

| JP6535893B2 (en) | Decorative wall material using relief | |

| JP7552982B2 (en) | Luminescent optical device and films for use in such luminescent optical device - Patents.com | |

| KR101213113B1 (en) | Signboard assembly to display cubic effect |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed | Free format text:JAPANESE INTERMEDIATE CODE: A523 Effective date:20090826 | |

| R150 | Certificate of patent or registration of utility model | Free format text:JAPANESE INTERMEDIATE CODE: R150 | |

| FPAY | Renewal fee payment (event date is renewal date of database) | Free format text:PAYMENT UNTIL: 20121014 Year of fee payment:3 | |

| FPAY | Renewal fee payment (event date is renewal date of database) | Free format text:PAYMENT UNTIL: 20131014 Year of fee payment:4 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| LAPS | Cancellation because of no payment of annual fees |