JP2015100624A - Cooker - Google Patents

CookerDownload PDFInfo

- Publication number

- JP2015100624A JP2015100624AJP2013245171AJP2013245171AJP2015100624AJP 2015100624 AJP2015100624 AJP 2015100624AJP 2013245171 AJP2013245171 AJP 2013245171AJP 2013245171 AJP2013245171 AJP 2013245171AJP 2015100624 AJP2015100624 AJP 2015100624A

- Authority

- JP

- Japan

- Prior art keywords

- lid

- inner lid

- pan

- locking

- disposed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000010411cookingMethods0.000claimsdescription48

- 230000001105regulatory effectEffects0.000claimsdescription30

- 239000004615ingredientSubstances0.000claimsdescription4

- 239000000463materialSubstances0.000abstractdescription3

- 230000007246mechanismEffects0.000description18

- 241000209094OryzaSpecies0.000description14

- 235000007164Oryza sativaNutrition0.000description14

- 238000010992refluxMethods0.000description14

- 235000009566riceNutrition0.000description14

- 238000011144upstream manufacturingMethods0.000description13

- 238000012856packingMethods0.000description9

- 230000002093peripheral effectEffects0.000description7

- 230000003014reinforcing effectEffects0.000description7

- 239000011347resinSubstances0.000description7

- 229920005989resinPolymers0.000description7

- 239000002184metalSubstances0.000description6

- 238000005192partitionMethods0.000description5

- 238000007789sealingMethods0.000description5

- 238000010438heat treatmentMethods0.000description4

- 238000003780insertionMethods0.000description4

- 230000037431insertionEffects0.000description4

- 238000001514detection methodMethods0.000description3

- 239000011344liquid materialSubstances0.000description3

- 230000002265preventionEffects0.000description2

- 229910000897Babbitt (metal)Inorganic materials0.000description1

- 125000002066L-histidyl groupChemical group[H]N1C([H])=NC(C([H])([H])[C@](C(=O)[*])([H])N([H])[H])=C1[H]0.000description1

- 238000007599dischargingMethods0.000description1

- 230000005674electromagnetic inductionEffects0.000description1

- 239000000835fiberSubstances0.000description1

- 230000006698inductionEffects0.000description1

- 239000007769metal materialSubstances0.000description1

- 238000009423ventilationMethods0.000description1

Images

Landscapes

- Cookers (AREA)

Abstract

Description

Translated fromJapanese本発明は、調理器に関する。 The present invention relates to a cooking device.

調理器の1つである炊飯器は、鍋を着脱可能に収容する炊飯器本体と、炊飯器本体に回動可能に接続部で接続した蓋体とを備える。蓋体には、鍋内の排気を外部へ排出する排気通路が形成されている。また、蓋体には、鍋の上端開口を閉塞する内蓋が配設されている。内蓋には、鍋内に連通する排気孔が形成され、この内蓋と蓋体との間が排気通路の一部(上流側)を構成する。 A rice cooker, which is one of the cookers, includes a rice cooker body that detachably accommodates a pan, and a lid that is pivotally connected to the rice cooker body by a connecting portion. An exhaust passage for discharging the exhaust in the pan to the outside is formed in the lid. Moreover, the inner cover which obstruct | occludes the upper end opening of a pan is arrange | positioned at the cover body. An exhaust hole communicating with the inside of the pan is formed in the inner lid, and a portion (upstream side) of the exhaust passage is formed between the inner lid and the lid body.

特許文献1には、排気通路を構成する蓋体の下面および内蓋の上面を清掃可能とするために、蓋体に対して内蓋を着脱可能とした炊飯器が記載されている。この炊飯器は、蓋体に内蓋を装着していない状態で、炊飯器本体に対して蓋体を閉じることができないようにして、誤使用を防止している。蓋体の内蓋を装着する内蓋装着部には、蓋体の接続部側に内蓋を引っ掛けて係止する係止受部が設けられている。また、係止受部と逆の先端側には、内蓋を係止する係止部材がスライド可能に配設されている。この係止部材は、内蓋の装着により係止受部が蓋体から外向きに突出し、この係止受部に炊飯器本体のロック部材が係止される。内蓋の未装着状態では係止受部が蓋体内に没入し、係止受部に炊飯器本体のロック部材が係止できなくなる。その結果、炊飯器本体に対して蓋体を閉じた状態に維持できない。 Patent Document 1 describes a rice cooker in which an inner lid can be attached to and detached from a lid body so that the lower surface of the lid body and the upper surface of the inner lid can be cleaned. This rice cooker prevents misuse by preventing the lid body from being closed with respect to the rice cooker body when the lid is not fitted with an inner lid. The inner lid mounting portion for mounting the inner lid of the lid body is provided with a latch receiving portion for hooking and locking the inner lid on the connection portion side of the lid body. In addition, a locking member that locks the inner lid is slidably disposed on the tip side opposite to the locking receiving portion. In this locking member, when the inner lid is mounted, the locking receiving portion protrudes outward from the lid body, and the locking member of the rice cooker body is locked to the locking receiving portion. When the inner lid is not attached, the latch receiving portion is immersed in the lid body, and the lock member of the rice cooker body cannot be locked to the latch receiving portion. As a result, the lid cannot be kept closed with respect to the rice cooker body.

特許文献2には、蓋体の接続部に設けたダンパ機構により、蓋体をスムーズ(ゆっくり)に開閉できるようにした炊飯器が記載されている。ダンパ機構は、蓋体を開放方向に付勢するヒンジスプリングと、接続部に摺接するブレーキ部とを備え、摺接に伴う摩擦によりヒンジスプリングの付勢力に抗して制動力が作用するようにしている。制動力は開放角度が大きくなるに従って大きくなり、最大開放角度で最大となる。 Patent Document 2 describes a rice cooker in which a lid can be opened and closed smoothly (slowly) by a damper mechanism provided at a connection portion of the lid. The damper mechanism includes a hinge spring that urges the lid in the opening direction and a brake portion that slidably contacts the connecting portion, and a braking force acts against the urging force of the hinge spring due to friction caused by the slidable contact. ing. The braking force increases as the opening angle increases and becomes maximum at the maximum opening angle.

特許文献1の内蓋未装着防止機能と特許文献2のダンパ機能とは、1つの蓋体に両方が採用されることが多い。しかし、特許文献1の内蓋未装着防止機能は、ユーザが蓋体を閉じる際、炊飯器本体に対して蓋体を回動させ、ロックできないことで内蓋を装着し忘れていることを気付くことが多い。また、特許文献2のダンパ機能は、蓋体の制動力が蓋体の重量に大きな関連があり、重たいほど制動力が弱くなり、軽いほど制動力が強くなる。そのため、内蓋の重量が重い蓋体の場合、ロックできないことで内蓋の未装着を気付き、蓋体から手を離すと、勢いよく蓋体が開放するという不都合がある。この問題は、内蓋の重量が重くなるに従って顕著に現れ、最悪の場合には蓋体の接続部の破損に繋がる。 Both the inner lid non-mounting prevention function of Patent Document 1 and the damper function of Patent Document 2 are often employed in one lid. However, when the user closes the lid body, the inner lid non-mounting prevention function of Patent Document 1 turns out that the lid body is rotated with respect to the rice cooker body, and the user cannot forget to attach the inner lid because it cannot be locked. There are many cases. In addition, the damper function of Patent Document 2 has a large relationship between the braking force of the lid body and the weight of the lid body. The heavier the braking force, the weaker the braking force and the lighter the braking force. Therefore, when the weight of the inner lid is heavy, there is an inconvenience that when the lid is noticed that the inner lid is not attached because the inner lid cannot be locked and the hand is released from the lid, the lid is vigorously opened. This problem becomes more prominent as the weight of the inner lid becomes heavier, and in the worst case, it leads to breakage of the connecting portion of the lid.

本発明は、内蓋の装着し忘れを直ぐに認識できるようにして、誤使用および破損を確実に防止できる調理器を提供することを課題とする。 It is an object of the present invention to provide a cooking device that can immediately recognize that a user has forgotten to wear the inner lid and can reliably prevent misuse and damage.

前記課題を解決するため、本発明の調理器は、食材を収容する上端開口の鍋と、前記鍋の上部を覆う蓋体と、前記蓋体の前記鍋と対向する面に着脱可能に配設され、前記鍋の上端開口を閉塞する内蓋と、前記蓋体に前記内蓋が装着された状態で前記鍋を閉塞する方向に前記蓋体を移動可能とし、前記蓋体に前記内蓋が装着されていない状態で前記鍋を閉塞する方向に前記蓋体を移動不可能とする蓋規制部材と、を備える構成としている。具体的には、前記鍋を配設し、前記蓋体が回動可能に接続部で接続される調理器本体を備え、前記蓋規制部材は、前記蓋体内に配設され、前記内蓋が装着されていない状態で前記接続部に係止することにより前記蓋体を回動不可能にしている。 In order to solve the above-mentioned problem, the cooking device of the present invention is detachably disposed on a pan having an upper end opening for containing ingredients, a lid covering the top of the pan, and a surface of the lid facing the pan. An inner lid that closes the upper end opening of the pan, and the lid is movable in a direction in which the pan is closed while the inner lid is attached to the lid, and the inner lid is attached to the lid. And a lid regulating member that prevents the lid from moving in the direction of closing the pan in a state where it is not attached. Specifically, the pan is provided, and the cooker main body is connected to the lid by a connecting portion so that the lid is rotatable, the lid regulating member is arranged in the lid, and the inner lid is The lid is made non-rotatable by being locked to the connecting portion when not attached.

この調理器は、蓋体に内蓋を装着していない状態の場合、蓋規制部材によって蓋体を閉塞する方向に移動できないようにするため、ユーザに対して内蓋の装着し忘れを直ぐに認識させることができる。言い換えれば、蓋体を調理器本体に対する閉塞する位置まで移動させることができない。よって、蓋体に内蓋を装着するために、ユーザが蓋体から手を離しても、ヒンジスプリングの付勢力によって蓋体が勢いよく開放することはない。即ち、内蓋を装着しなければ蓋体を移動させることができないため、蓋体の安定した開閉を実現できる。そのため、蓋体の破損を防止できるとともに、内蓋の未装着状態で使用するという誤使用を確実に防止できる。 This cooker immediately recognizes that the user has forgotten to attach the inner lid to prevent the lid from moving in the direction of closing the lid by the lid regulating member when the inner lid is not attached to the lid. Can be made. In other words, the lid cannot be moved to a position where it closes with respect to the cooker body. Therefore, even if the user removes his / her hand from the lid in order to attach the inner lid to the lid, the lid does not open vigorously due to the biasing force of the hinge spring. That is, since the lid cannot be moved unless the inner lid is attached, the lid can be stably opened and closed. Therefore, it is possible to prevent the lid from being damaged, and to reliably prevent misuse of using the lid without the inner lid attached.

前記蓋規制部材は、前記蓋体の前記内蓋を装着する内蓋装着部に前記内蓋が装着されていない状態で、前記内蓋装着部に突出する干渉部と前記接続部に係止する係止部とを備え、前記内蓋装着部に前記内蓋が装着されることにより、前記干渉部が前記蓋体内の側に後退することにより前記接続部との係止が解除される。この場合、前記内蓋装着部は、前記接続部側に前記内蓋を引っ掛けて係止する係止受部を備え、前記蓋規制部材は、前記係止受部内に突出するように配設されている。このようにすれば、蓋規制部材を有する規制機構の簡素化を図ることができる。 The lid regulating member is engaged with the interference portion protruding from the inner lid mounting portion and the connecting portion in a state where the inner lid is not mounted on the inner lid mounting portion on which the inner lid of the lid is mounted. When the inner lid is mounted on the inner lid mounting portion, the interference portion is retracted toward the inside of the lid body, and the locking with the connection portion is released. In this case, the inner lid mounting portion includes a latch receiving portion that hooks and locks the inner lid on the connection portion side, and the lid regulating member is disposed so as to protrude into the latch receiving portion. ing. If it does in this way, simplification of the control mechanism which has a lid control member can be aimed at.

本発明の調理器では、蓋体に内蓋を装着していない場合、蓋体を閉塞する方向に移動できないため、ユーザに内蓋の装着し忘れを直ぐに認識させることができる。また、ヒンジスプリングの付勢力によって蓋体が勢いよく開放することはないため、蓋体の破損を防止できるとともに、内蓋の未装着状態で使用するという誤使用を確実に防止できる。 In the cooker according to the present invention, when the inner lid is not attached to the lid, the user cannot recognize that the user has forgotten to attach the inner lid because the lid cannot be moved in the closing direction. In addition, since the lid body does not open vigorously by the biasing force of the hinge spring, it is possible to prevent the lid body from being damaged, and to reliably prevent misuse when used without the inner lid attached.

以下、本発明の実施の形態を図面を参照して説明する。 Hereinafter, embodiments of the present invention will be described with reference to the drawings.

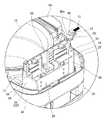

図1および図2は、本発明の実施形態に係る調理器10を示す。この調理器10は、調理物である食材を収容する調理鍋(鍋)11と、調理鍋11を着脱可能に収容する調理器本体15と、調理器本体15に開閉可能に配設した蓋体31とを備える。蓋体31は、閉じた状態で調理鍋11に対向する下面側に着脱可能に配設される内蓋セット(内蓋)66を備える。本実施形態では、内蓋セット66の未装着状態で蓋体31を閉塞する方向に移動できないようにして、内蓋セット66の装着し忘れを直ぐに認識させ、誤使用およびヒンジ接続部(接続部)24の破損を防止する。 1 and 2 show a

図2に示すように、調理鍋11は、上端開口の有底円筒状をなし、熱伝導率が高い金属製母材の外面に電磁誘導によって加熱される金属材層を有する。この調理鍋11の鍋外周壁12の上端開口には、径方向外向きに突出するフランジ部13が形成されている。フランジ部13の径方向の対向位置には、一対の鍋取手14が取り付けられている。この鍋取手14は樹脂製であり、調理器本体15の外壁である胴体16より外方に突出する寸法で形成されている。 As shown in FIG. 2, the

図1および図2に示すように、調理器本体15は、有底筒状の胴体16と、胴体16の上端開口を覆う肩体18とを有する本体外装体を備える。胴体16には、横方向の両側に位置するように、鍋取手14の下部を覆う下側把持部17が設けられている。肩体18は樹脂製であり、胴体16の上端開口に嵌合される。この肩体18には、下側把持部17の上側に位置し、鍋取手14と隙間をあけて位置する上側把持部19が水平方向外向きに突設されている。肩体18の正面側(前方側)には操作パネル部20が形成されている。操作パネル部20の背面側(後方側)には、蓋体31によって覆われる凹部21が形成されている。凹部21の中央には、調理鍋11を着脱可能に収容する鍋収容部22が形成されている。凹部21には、鍋収容部22の正面側に蓋体31をロックするためのロック孔23が設けられている。また、凹部21には、鍋収容部22の背面側に蓋体31をヒンジピン41によって回動可能に接続するヒンジ接続部24が形成されている。 As shown in FIGS. 1 and 2, the cooker

図3および図4に示すように、ヒンジ接続部24は、平面視凹字形状をなす隔壁部25と、ヒンジピン41を装着する軸受け金具28とを備える。隔壁部25は、鍋収容部22側に位置し、左右の幅方向に延びる端壁26を備える。この端壁26の上端は、蓋体31の回動(開放)を略90度で停止させるストッパの役割を兼ねる。この端壁26の一側(図4中右側)上端の背面側は、後述する蓋規制部材47が離脱可能に係止する係止受部26aを構成する。隔壁部25は、端壁26の両側下部から背面側へ突出する側壁27,27を備える。この側壁27,27は、下板32およびヒンジ接続部24を補強する補強リブの役割を兼ねる。軸受け金具28は、端壁26の背面側にネジ止めにより固定される。この軸受け金具28は、側壁27,27に沿って上向きに延びる一対のブラケット部29,29を備え、このブラケット部29の上端にヒンジピン41を装着する軸孔30が形成されている。 As shown in FIGS. 3 and 4, the

鍋収容部22と胴体16との間の内部には、鍋収容部22に収容した調理鍋11の加熱手段である誘導加熱コイル(図示せず)が配設されている。また、鍋収容部22には、調理鍋11の温度を検出する第1温度検出部材である鍋温度センサ(図示せず)が、鍋収容部22を貫通して調理鍋11の底に接触するように配設されている。 An induction heating coil (not shown) that is a heating means of the

図1および図5に示すように、蓋体31は、調理器本体15のヒンジ接続部24に回動可能に取り付けられ、調理鍋11の上端開口を含む調理器本体15の凹部21の上部を覆う。この蓋体31は、閉塞した状態で調理器本体15の上部を覆う下板32と、下板32の上部を覆う上板34とを有する蓋外装体を備える。下板32は樹脂製であり、鍋収容部22を含む凹部21の上方を覆う平面視形状の板材である。下板32の上部には金属製の補強板33が配設されている。上板34は樹脂製であり、下板32に上側から被せてネジ止めにより固定される下端開口のカバーである。この上板34の表面には装飾カバー35が配設されている。また、上板34の外周部には、鍋取手14の外周部を覆う取手カバー36が水平方向外向きに突設されている。 As shown in FIGS. 1 and 5, the

下板32の正面側には、調理器本体15のロック孔23にロックされるロック部材37が回動可能に配設されている。上板34には、ロック部材37を回動させて、ロック孔23との係合を解除するための操作部材38が配設されている。また、補強板33を含む下板32の背面側には、調理器本体15のヒンジ接続部24に回動可能に接続される一対の蓋体側接続部39,39が形成されている。これら蓋体側接続部39,39間に軸受け金具28のブラケット部29を配置し、ブラケット部29,29間にヒンジスプリング(付勢部材)40を配置して、ヒンジピン41を貫通させて配設する。この状態で、軸受け金具28を調理器本体15のヒンジ接続部24にネジ止めして固定することにより、調理器本体15に対して蓋体31が回動可能に装着される。 On the front side of the

図1および図2に示すように、蓋体31において、調理鍋11と対向する下板(面)32には、内蓋セット66を着脱可能に装着する内蓋装着部42が設けられている。この内蓋装着部42は、内蓋セット66の外形と略同一形状で上向きに隆起した第1配設部43と、後述する上側カバー部材68の外形と略同一形状で更に上向きに隆起した第2配設部44とを備える。第1配設部43には、蓋体側接続部39側に内蓋セット66を引っ掛けて係止する第1係止受部(係止受部)45,45が設けられている。また、第1配設部43には、蓋体側接続部39と逆側に位置する先端に、内蓋セット66の蓋係止部材75を離脱可能に係止する第2係止受部46が設けられている。 As shown in FIGS. 1 and 2, in the

第1係止受部45,45の一方(図2中左側)には、内蓋装着部42に内蓋セット66が装着された場合に蓋体31を閉塞する方向に回動可能とし、内蓋装着部42に内蓋セット66が装着されていない場合に蓋体31を閉塞する方向に回動不可能とする、蓋規制部材47が配設されている。この蓋規制部材47は、蓋体31内に位置するように、下板32上に移動可能に配設される。 One of the first

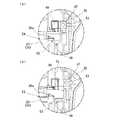

図4および図6に示すように、蓋規制部材47は、内蓋装着部42の第1係止受部45内に幅方向の外側から突出可能な干渉部48を備える。この干渉部48は、内蓋セット66の差込方向に沿って、内蓋装着部42の幅方向の外側から内側へ傾斜するテーパ面49を備える。干渉部48の逆側端部には、付勢スプリング51を位置決めする位置決め凸部50が設けられている。図3に示すように、位置決め突起を設けた干渉部48の逆側端と下板32との間には付勢スプリング(付勢部材)51が配設され、この付勢スプリング51によって干渉部48が第1係止受部45内に突出した進出位置に付勢される。蓋規制部材47の移動(進退)方向である干渉部48と位置決め凸部50との間には、移動方向に対して直交方向背面側に突出する連結部52が設けられている。 As shown in FIGS. 4 and 6, the

蓋規制部材47は、調理器本体15のヒンジ接続部24(端壁26)の係止受部26aに係止可能なヒンジ係止部(係止部)53を備える。このヒンジ係止部53は所定肉厚の板状であり、連結部52に連結するための連結片54と、ヒンジ係止部53をヒンジ接続部24に対して剛性が高い縁側で係止させるための連続部55とを備える。連結片54は、ヒンジ接続部24側である下向きに突出している。連続部55は、連結部52の下側に折り込まれている。この連続部55の縁に略L字形状をなすように折り曲げたヒンジ係止部53が形成される。このヒンジ係止部53は、調理器本体15に対して蓋体31を略90度開放させた状態で、ヒンジ接続部24の端壁26に対して背面側に係止する。 The

蓋規制部材47は、図7(A)に示す内蓋セット66の未装着状態(進出位置)で、内蓋装着部42に内蓋セット66が装着されると、内蓋装着部42内に突出した干渉部48が内蓋セット66に押圧される。これにより、図7(B)に示すように、付勢スプリング51の付勢力に抗して、干渉部48が蓋体31内に没入した後退位置に移動する。その結果、ヒンジ係止部53が調理器本体15のヒンジ接続部24に係止した状態から、係止が解除された状態になる。また、図7(B)に示す内蓋セット66の装着状態(後退位置)で、内蓋装着部42から内蓋セット66が取り外されると、図7(A)に示すように、付勢スプリング51の付勢力によって後退位置から進出位置へ移動される。その結果、ヒンジ係止部53が調理器本体15のヒンジ接続部24の係止受部26aに係止した状態になる。 When the inner lid set 66 is attached to the inner

本実施形態のヒンジ係止部53には、蓋体31の開放方向前側の縁に、基端側から先端側へ向けて開放方向後向きに傾斜するガイド縁部56が設けられている。このガイド縁部56は、調理器本体15に対して蓋体31が90度未満の開放状態で内蓋セット66が取り外されると、ヒンジスプリング40による開放方向の付勢力で、端壁26の正面側に当接する。そして、蓋規制部材47を付勢スプリング51の付勢力に抗して進出位置から後退位置に移動させた後、端壁26の背面側を越えることで、付勢スプリング51の付勢力で係止するように構成している。 The

図1および図2に示すように、蓋体31には、調理鍋11内と外部とを連通させ、調理鍋11内の排気(蒸気)を外部へ排出するための排気通路65,70が形成されている。そのうち、下流側排気通路65は蓋体31に設けられ、上流側排気通路70は内蓋セット66に設けられている。 As shown in FIGS. 1 and 2, the

具体的には、下板32には、第2配設部44の蓋体側接続部39側に、下流側排気通路65の入口である接続口57が設けられている。図1および図5に示すように、上板34には、接続口57の上部に位置するように、蒸気口ユニット60を着脱可能に配設する蒸気口ユニット配設部58が設けられている。この蒸気口ユニット配設部58には、接続口57上に位置するように挿通孔59が設けられている。接続口57と挿通孔59との間と、接続口57の内蓋セット66側には、パッキンが配設されている。蒸気口ユニット60は、有底円筒状の下容器61と、平面視矩形状の上カバー63とを備える。下容器61には、挿通孔59に差し込まれる円筒状の接続筒部62が設けられている。上カバー63には、蒸気を外部へ放出するための排出口64が設けられている。そして、下板32の接続口57から蒸気口ユニット60の排出口64までの流路が下流側排気通路65を構成する。 Specifically, the

図1および図2に示すように、蓋体31の内蓋装着部42には、調理鍋11の上端開口を閉塞する内蓋セット66が着脱可能に配設される。この内蓋セット66は、図8および図9に示すように、調理鍋11を閉塞する内蓋本体67と、内蓋本体67の上面側に着脱可能に装着される上側カバー部材68と、内蓋本体67の下面側に着脱可能に装着される下側カバー部材69とを備える。そして、内蓋本体67と上側カバー部材68との間に、下流側排気通路65に連通し、液状物を収容する空間の役割を兼ねる上流側排気通路70が形成(画定)される。 As shown in FIGS. 1 and 2, an inner lid set 66 that closes the upper end opening of the

内蓋本体67は、受け皿形状をなす金属製の閉塞板71を備える。閉塞板71の外周部には、調理鍋11の上端開口の内周面に密着されるシール部材72が配設される。このシール部材72は、閉塞板71の外周部に樹脂製の枠体73を配設することにより、これらの間に挟み込んで装着される。 The

枠体73には、蓋体31の内蓋装着部42の第1係止受部45に係止される一対の係止部74,74が、後方外向きに突出するように設けられている。この係止部74が蓋規制部材47の干渉部48に当接することにより、蓋規制部材47を進出位置から後退位置へ移動される。係止部74,74間の径方向の対向位置には、蓋体31のヒンジ接続部24と逆側に位置する第2係止受部46に離脱可能に係止される蓋係止部材75が配設されている。この蓋係止部材75は、径方向にスライド可能に配設され、図示しないスプリング(付勢部材)によって外向きに付勢されている。 The

また、内蓋本体67には、上側カバー部材68を着脱可能に装着するための一対の上カバー係止受部76A,76Bが、枠体73の径方向に対向する位置に上向きに突出するように設けられている。また、内蓋本体67には、下側カバー部材69を係止する一対の下カバー係止受部77が枠体73の径方向に対向する位置に設けられている。なお、ヒンジ接続部24側に位置する下カバー係止受部77は図示していない。 The

上側カバー部材68は、内蓋本体67の上部を覆うように開放可能に取り付けられ、内蓋本体67との間に液状物を収容する空間の役割を兼ねる上流側排気通路70を形成する。この上側カバー部材68は、受け皿形状をなす閉塞板71の内側に嵌合される下端開口の筒形状である。上側カバー部材68の天壁78は、閉塞板71に対して所定間隔(例えば約31.9mm)をもって位置する。また、上側カバー部材68の下端には、閉塞板71に圧接されて内蓋本体67と上側カバー部材68とを密閉するシール部材79が配設されている。 The

上側カバー部材68には、内蓋本体67に対して離脱可能に係止する第1および第2係止部材80,81がスライド可能に配設されている。上カバー係止受部76Aに係止される第1係止部材80は、図示しないスプリング(付勢部材)によって径方向外向きに付勢されている。上カバー係止受部76Bに係止される第2係止部材81は、上側カバー部材68を内蓋本体67から取り外すための開放操作部82を備え、図示しないスプリング(付勢部材)によって径方向外向きに付勢されている。 The

上側カバー部材68を内蓋本体67に装着することにより、上流側排気通路70が形成される。内蓋本体67には後述する調圧弁99が配設され、この調圧弁99の連通孔102が上流側排気通路70の入口を構成する。上側カバー部材68の天壁78には、蓋体31の下流側排気通路65の接続口57に対応するように接続口83が設けられ、この接続口83が上流側排気通路70の出口を構成する。下流側排気通路65の接続口57と上流側排気通路70の接続口83とは、パッキンによって密閉される。 By attaching the

下側カバー部材69は、内蓋本体67に対して調理鍋11内を臨む側に着脱可能に配設される。そして、調理(装着)時には、調理鍋11を臨む連通孔102が食材の繊維や崩れ落ちた食材片等によって目詰まりすることを防止する。この下側カバー部材69は、多数の通気孔を形成した金属製の下側カバー本体84と、下側カバー本体84の外周部を囲むカバーリング85とを備える。 The

カバーリング85には、内蓋本体67の下カバー係止受部77に係止される係止部86,87が設けられている。第1係止部86は一対の突片からなり、第2係止部87はスライド可能に配設した係止部材88に設けられている。係止部材88は、内蓋本体67から取り外すための取外操作部89を備え、図示しないスプリング(付勢部材)によって径方向外向きに付勢されている。 The

本実施形態の調理器10は、調理鍋11内を大気圧より高い圧力に昇圧するための密閉機構と、上流側排気通路70内に流入した液状物を調理鍋11に還流させるための還流機構と、を搭載している。密閉機構は、内蓋本体67に配設した2個の開閉弁98,99と、下板32に配設した2組の駆動機構と、を備える。還流機構は、内蓋本体67に配設した2個の開閉弁100,101と、下板32に配設した1組の駆動機構および内蓋本体67に配設した1組の駆動機構と、を備える。また、蓋体31には、調理鍋11内の圧力を検出する圧力検出部材である圧力センサ93が配設されるとともに、上流側排気通路70内の蒸気温度を検出する第2温度検出部材である蓋温度センサ94が配設される。4個の開閉弁98〜101と、圧力センサ93のダクト97により、内蓋セット66の重量が重くなっている。 The

具体的には、図5に示すように、下板32の第2配設部44の上部には、内蓋セット66の開閉弁98〜100を開閉駆動するための駆動手段としてソレノイド90がそれぞれ配設されている。ソレノイド90のロッドには、水平方向の移動を垂直方向の移動(駆動力)に変換するためのカム部材91が配設され、その下部に図示しない駆動部材が配設されている。また、下板32には、駆動部材を進退可能とする開口部が設けられ、各開口部にパッキン92が配設されている。また、下板32の第2配設部44の上部には、圧力センサ93および蓋温度センサ94が配設されている。下板32には、各センサ93,94の下部に開口部が設けられ、各開口部に筒状パッキン95が配設されている。 Specifically, as shown in FIG. 5,

図8および図9に示すように、内蓋本体67には、樹脂製のベース部材96が配設されている。このベース部材96には、圧力センサ93の下部に位置するように、調理鍋11内に連通するダクト97が形成されている。また、ベース部材96には、下板32上に配設した3個のソレノイド90によってそれぞれ開閉駆動される、安全弁98、調圧弁99および電動式還流弁100が配設されている。また、接続口83の下部に位置するように、連動式還流弁101が配設されている。 As shown in FIGS. 8 and 9, a

電動式の開閉弁98〜100は、調理鍋11内に連通する連通孔102と、この連通孔102を開放可能に密閉する弁体103とを備える。弁体103の上部には、駆動部材の駆動力を受ける作動受部材104が配設されている。弁体103と作動受部材104との間には、弁体103を連通孔102側へ向けて付勢する図示しないスプリング(付勢部材)が配設されている。安全弁98および調圧弁99の弁体103は連通孔102を上方から密閉し、電動式還流弁100の弁体103は連通孔102を下方から密閉する点で相違する。連動式還流弁101は、調理鍋11内に連通する還流孔105と、この還流孔105を開放可能に上方から密閉する弁体106とを備える。弁体106は、還流孔105を通して調理鍋11内の側へ突出する作動受部107を備える。 The electric on-off

上側カバー部材68には、電動式の開閉弁98〜100に対応する開口部が設けられ、各開口部にパッキン108が配設されている。また、圧力センサ93に対応する開口部が設けられ、この開口部にダクト97に圧接される筒状パッキン109が配設されている。また、筒状パッキン109の横に、いずれの機構とも対応しない開口部が設けられ、この開口部に上流側排気通路70内を透視可能な透明樹脂からなる窓部110が配設されている。また、蓋温度センサ94に対応する開口部111が設けられている。各パッキン108,109は、金属製の補強カバー112によって天壁78との間に挟み込んだ状態で位置決めされる。補強カバー112には、開口部111との対応位置を除く、各パッキン108,109および窓部110との対応位置に開口部113が設けられている。なお、蓋温度センサ94は、金属製の補強カバー112の開口部113の対応部分に接触し、この補強カバー112を介して上流側排気通路70の温度を検出する。 The

連動式還流弁101を開閉するための弁開閉部材114は、内蓋本体67の調理鍋11内を臨む下面に配設されている。この弁開閉部材114は、連動式還流弁101の下部に位置するように、内蓋本体67の開閉部材カバー115内に配設されている。弁開閉部材114は、蓋体31を閉じることにより調理鍋11の鍋外周壁12に当接して後退した後退位置、および、蓋体31の開放により進出した進出位置の間を移動可能であり、図示しないスプリング(付勢部材)により進出位置へ付勢されている。また、弁開閉部材114には、進出位置で弁体106を上向きに移動させて還流孔105を開放し、後退位置で弁体106を下向きに移動させて還流孔105を密閉するためのカム部116が設けられている。 A valve opening / closing

また、本実施形態の内蓋セット66は、下側カバー部材69を装着していない状態では、調理器本体15に対して蓋体31を閉じることができないようにするための干渉部材117が更に配設されている。この干渉部材117は、蓋体31の先端側に位置するように、内蓋本体67の枠体73に設けた干渉部材カバー118内に配設されている。この干渉部材カバー118のヒンジ接続部24側に、一方の下カバー係止受部77が形成されている。干渉部材117は、下側カバー部材69の装着により調理鍋11に干渉しない後退位置、および、下側カバーの取り外しにより調理鍋11に干渉するように進出した進出位置の間を移動可能であり、図示しないスプリング(付勢部材)により進出位置へ付勢されている。なお、下側カバー部材69は、内蓋本体67への装着により干渉部材117を後退位置へ移動させる押圧部119を備える。 Further, the inner lid set 66 of the present embodiment further includes an

このように構成した内蓋セット66は、4個の開閉弁98〜101、連動式還流弁101を開閉させるための弁開閉部材114、下側カバー部材69の未装着状態では蓋体31を閉じることができないようにするための干渉部材117など、多数の機構を配設しているため、重量が重い。この内蓋セット66を装着した蓋体31は、複数の駆動機構の重量も従来の炊飯器等と比較すると、遥かに重い。そのため、操作部材38の操作により蓋体31を開放するには、ヒンジスプリング40による開放方向の付勢力は、大きく設定される。逆に、蓋体31が勢いよく開放することを防止するダンパ機構(図示せず)の制動力は、極めて小さく設定される。そのため、蓋体31に内蓋セット66を装着していない状態では、重量が大幅に軽くなるため、ヒンジスプリング40の付勢力によって勢いよく蓋体31がする。 The inner lid set 66 configured in this manner closes the

しかし、本実施形態の調理器10には、蓋体31から内蓋セット66を取り外すと、調理器本体15のヒンジ接続部24に係止する蓋規制部材47を蓋体31に設けているため、内蓋セット66の未装着状態では蓋体31を閉塞する方向に回動させることができない。そのため、内蓋セット66の装着し忘れをユーザに直ぐに認識させることができる。また、蓋体31を調理器本体15に対する閉塞する位置まで回動させることができない。よって、ヒンジスプリング40の付勢力によって蓋体31が勢いよく開放することはない。即ち、内蓋セット66を装着しなければ蓋体31を回動できないため、安定した開閉を実現できる。そのため、蓋体31の破損を防止できるとともに、内蓋セット66の未装着状態で使用するという誤使用を確実に防止できる。 However, in the

また、蓋規制部材47は、内蓋セット66の取り外しおよび装着により進退し、ヒンジ係止部53が調理器本体15のヒンジ接続部24に係脱する構成であるため、蓋規制部材47を有する規制機構の簡素化を図ることができる。また、ヒンジ係止部53には、蓋体31の開放方向前側の縁にガイド縁部56を設け、ヒンジ係止部53がヒンジ接続部24に係止不可能な位置で内蓋セット66が取り外されても、ヒンジスプリング40の付勢力で蓋体31を開放させ、ヒンジ接続部24にヒンジ係止部53を係止可能としているため、利便性を向上できる。 The

なお、本発明の調理器10は、前記実施形態の構成に限定されず、種々の変更が可能である。 In addition, the

例えば、前記実施形態では、調理器本体15に対して蓋体31を90度回動させた状態で、ヒンジ係止部53がヒンジ接続部24に係止するようにしたが、ヒンジ係止部53が係止する開放角度は希望に応じて変更が可能である。また、ヒンジ接続部24の隔壁部25に2以上の係止段部を設け、2以上の開放角度で係止できるようにしてもよい。また、前記実施形態では、蓋体31を調理器本体15に対して回動可能に接続したが、スライド可能に配設して開閉可能に構成してもよい。また、蓋規制部材47は、スライド移動可能に配設した1個の部品により構成したが、リンク機構等を用いてヒンジ接続部24に係止する構成としてもよい。 For example, in the embodiment, the

本発明は、蓋体31から内蓋セット66を取り外すと、調理器本体15に対して蓋体31を閉塞する方向に移動できないようにする蓋規制部材47を設ける構成が特徴である。そのため、種々の食材を調理可能な調理器10に限られず、飯米の炊飯のみが可能な炊飯器でも適用可能である。また、蓋体31の開放速度を規制するダンパ機構を搭載しない機器であってもよい。また、加熱手段を有する調理器本体15を設ける構成に限らず、調理鍋11に蓋体31を開閉可能に配設し、家庭の台所の既存のコンロを加熱手段として用いる調理鍋11にも適用可能である。 The present invention is characterized in that a

10…調理器

11…調理鍋(鍋)

15…調理器本体

16…胴体

18…肩体

22…鍋収容部

24…ヒンジ接続部(接続部)

25…隔壁部

28…軸受け金具

30…軸孔

31…蓋体

32…下板

34…上板

39…蓋体側接続部

40…ヒンジスプリング

41…ヒンジピン

42…内蓋装着部

45…第1係止受部(係止受部)

46…第2係止受部

47…蓋規制部材

48…干渉部

53…ヒンジ係止部(係止部)

66…内蓋セット(内蓋)

67…内蓋本体

68…上側カバー部材

69…下側カバー部材

70…上流側排気通路

74…係止部

75…蓋係止部材10 ...

DESCRIPTION OF

25 ...

46 ... second

66 ... Inner lid set (inner lid)

67 ...

Claims (4)

Translated fromJapanese前記鍋の上部を覆う蓋体と、

前記蓋体の前記鍋と対向する面に着脱可能に配設され、前記鍋の上端開口を閉塞する内蓋と、

前記蓋体に前記内蓋が装着された状態で前記鍋を閉塞する方向に前記蓋体を移動可能とし、前記蓋体に前記内蓋が装着されていない状態で前記鍋を閉塞する方向に前記蓋体を移動不可能とする蓋規制部材と、

を備えることを特徴とする調理器。A pan with an upper end opening to accommodate ingredients;

A lid covering the top of the pan;

An inner lid that is detachably disposed on a surface of the lid facing the pan, and closes an upper end opening of the pan;

The lid can be moved in a direction to close the pan in a state where the inner lid is attached to the lid, and the pan is closed in a direction in which the inner lid is not attached to the lid. A lid regulating member that makes the lid impossible to move;

A cooking device comprising:

前記蓋規制部材は、前記蓋体内に配設され、前記内蓋が装着されていない状態で前記接続部に係止することにより前記蓋体を回動不可能にすることを特徴とする請求項1に記載の調理器。The pan is disposed, and the lid includes a cooker body that is pivotally connected by a connection portion,

The lid regulating member is disposed in the lid body, and locks the lid body in a state where the inner lid is not attached, thereby making the lid body non-rotatable. 1. The cooker according to 1.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013245171AJP6067546B2 (en) | 2013-11-27 | 2013-11-27 | Cooking device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013245171AJP6067546B2 (en) | 2013-11-27 | 2013-11-27 | Cooking device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2015100624Atrue JP2015100624A (en) | 2015-06-04 |

| JP6067546B2 JP6067546B2 (en) | 2017-01-25 |

Family

ID=53376854

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013245171AActiveJP6067546B2 (en) | 2013-11-27 | 2013-11-27 | Cooking device |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP6067546B2 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2017202062A (en)* | 2016-05-10 | 2017-11-16 | 象印マホービン株式会社 | Cooking device |

| JP2018143332A (en)* | 2017-03-02 | 2018-09-20 | 三菱電機株式会社 | rice cooker |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5826414U (en)* | 1981-08-12 | 1983-02-19 | 株式会社東芝 | Cooking device |

| JP2000023834A (en)* | 1998-07-13 | 2000-01-25 | Mitsubishi Electric Corp | rice cooker |

| JP2011156216A (en)* | 2010-02-02 | 2011-08-18 | Sharp Corp | Electric rice cooker |

- 2013

- 2013-11-27JPJP2013245171Apatent/JP6067546B2/enactiveActive

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5826414U (en)* | 1981-08-12 | 1983-02-19 | 株式会社東芝 | Cooking device |

| JP2000023834A (en)* | 1998-07-13 | 2000-01-25 | Mitsubishi Electric Corp | rice cooker |

| JP2011156216A (en)* | 2010-02-02 | 2011-08-18 | Sharp Corp | Electric rice cooker |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2017202062A (en)* | 2016-05-10 | 2017-11-16 | 象印マホービン株式会社 | Cooking device |

| JP2018143332A (en)* | 2017-03-02 | 2018-09-20 | 三菱電機株式会社 | rice cooker |

Also Published As

| Publication number | Publication date |

|---|---|

| JP6067546B2 (en) | 2017-01-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| AU2014319872B2 (en) | Pressure cooker | |

| JP5604382B2 (en) | rice cooker | |

| CN211795799U (en) | Cooking utensil | |

| JP2017015385A (en) | Cooking appliance | |

| JP6067546B2 (en) | Cooking device | |

| JP6018563B2 (en) | Cooking device | |

| JP6289414B2 (en) | Cooking device | |

| JP6067544B2 (en) | Cooking device | |

| JP4762931B2 (en) | rice cooker | |

| JP6548808B2 (en) | rice cooker | |

| US8919243B2 (en) | Cooking appliance | |

| CN210582222U (en) | Cooking utensil | |

| JP2015100625A (en) | Cooker | |

| JP6226856B2 (en) | Cooker | |

| JP3644451B2 (en) | rice cooker | |

| JP2015008798A (en) | Rice cooker | |

| JP2016202513A5 (en) | ||

| JP2015097578A (en) | Cooker | |

| JP6038762B2 (en) | Cooking device | |

| JP6483149B2 (en) | Warming pot | |

| CN113208439B (en) | Cooking utensils | |

| JP6615677B2 (en) | Cooker | |

| KR200389609Y1 (en) | Open close guide apparatus of pressure cover for steam-oven | |

| JP2025004320A (en) | Lever mechanism | |

| KR20080004693U (en) | Food Utensils |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination | Free format text:JAPANESE INTERMEDIATE CODE: A621 Effective date:20151109 | |

| A131 | Notification of reasons for refusal | Free format text:JAPANESE INTERMEDIATE CODE: A131 Effective date:20160830 | |

| A977 | Report on retrieval | Free format text:JAPANESE INTERMEDIATE CODE: A971007 Effective date:20160831 | |

| A521 | Request for written amendment filed | Free format text:JAPANESE INTERMEDIATE CODE: A523 Effective date:20160929 | |

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) | Free format text:JAPANESE INTERMEDIATE CODE: A01 Effective date:20161220 | |

| A61 | First payment of annual fees (during grant procedure) | Free format text:JAPANESE INTERMEDIATE CODE: A61 Effective date:20161221 | |

| R150 | Certificate of patent or registration of utility model | Ref document number:6067546 Country of ref document:JP Free format text:JAPANESE INTERMEDIATE CODE: R150 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 |