JP2009095368A - Puncture needle for epidural anesthesia and method for producing the same - Google Patents

Puncture needle for epidural anesthesia and method for producing the sameDownload PDFInfo

- Publication number

- JP2009095368A JP2009095368AJP2007266730AJP2007266730AJP2009095368AJP 2009095368 AJP2009095368 AJP 2009095368AJP 2007266730 AJP2007266730 AJP 2007266730AJP 2007266730 AJP2007266730 AJP 2007266730AJP 2009095368 AJP2009095368 AJP 2009095368A

- Authority

- JP

- Japan

- Prior art keywords

- puncture needle

- needle

- puncture

- tip

- rough

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Landscapes

- Infusion, Injection, And Reservoir Apparatuses (AREA)

Abstract

Translated fromJapaneseDescription

Translated fromJapanese本発明は、硬膜外麻酔を行うための穿刺針、及びその製造方法に関する。 The present invention relates to a puncture needle for performing epidural anesthesia and a method for producing the same.

硬膜外麻酔用穿刺針は、例えば下記特許文献1に開示されている。従来のこの種の硬膜外麻酔用穿刺針を図4に示す。同図において、硬膜外麻酔用穿刺針11は、筒状の本体12の先端部12aが上向きに屈曲し、その先端の刃面13は上向きの傾斜面となっている。これは、術者が穿刺針からカテーテルを挿入する場合、任意の方向にカテーテルを走行させやすくするためである。先端面13の角度αは通常12〜19°程度である。穿刺針の外表面は、全体が鏡面となっている。この穿刺針11を脊椎の間から硬膜外腔に穿刺し、その後穿刺針の内部を通してカテーテルを硬膜外腔に挿入し、該カテーテルから麻酔薬を注入する。硬膜外腔への針の穿刺は、骨に一度刃先をあて、その後椎間の隙間を探してから硬膜外腔へ針先端を挿入する穿刺方法(ウォーク・イン・タップ法)などがある。

針先端を硬膜外腔へ挿入する場合、針先が硬膜外腔の外側の黄靱帯を穿刺するときに穿刺抵抗が増大し、術者は黄靱帯を穿刺していることを認識する。しかし、その穿刺抵抗の増大が明確でない場合、術者が、針先が黄靱帯を貫通したことが分からずに針を深く入れすぎ、人体組織を傷つけてしまうおそれがある。 When the needle tip is inserted into the epidural space, the puncture resistance increases when the needle tip punctures the ligamentum outside the epidural space, and the operator recognizes that the ligament has been punctured. However, if the increase in puncture resistance is not clear, the surgeon may not know that the needle has penetrated the ligamentum flavum, and may insert the needle too deeply, damaging human tissue.

従来、穿刺抵抗の調整は、先端面の角度αや針先角度βを調節することで行っていた。特に針先角度βを大きくすると穿刺抵抗が増すが、患者の苦痛が大きくなり、穿刺部分の組織のダメージも大きくなるので、これにより穿刺抵抗を大きくするには限界があった。 Conventionally, adjustment of puncture resistance has been performed by adjusting the angle α of the tip surface and the needle tip angle β. In particular, when the needle tip angle β is increased, the puncture resistance is increased. However, the pain of the patient is increased, and the tissue damage at the puncture portion is also increased, so that there is a limit to increase the puncture resistance.

本発明は、穿刺部分の組織のダメージを最小限に留めながら、黄靱帯を貫通するときの穿刺抵抗を増大させ、術者が、針先端が黄靱帯を通過して硬膜外腔に進入したことを容易に認識できるようにすることを課題としてなされたものである。 The present invention increases puncture resistance when penetrating the ligamentum flavum while minimizing tissue damage at the puncture site, and the operator enters the epidural space through the ligamentum flavum. It was made as a subject to make it easy to recognize this.

本発明は、先端部が上向きに屈曲し、先端の刃面が上向きの傾斜面となっている硬膜外麻酔用穿刺針において、その先端部に表面が粗面となっている領域を有することを特徴とする硬膜外麻酔用穿刺針である。

先端部表面に粗面領域を設けることで、黄靱帯を穿刺、貫通するときの穿刺抵抗が増大するので、針先端部が硬膜外腔に達したことをより明確に知ることができ、針を深く入れすぎて人体組織を傷つけてしまうおそれがなくなる。In the puncture needle for epidural anesthesia in which the tip is bent upward and the blade surface of the tip is an upward inclined surface, the tip has a region having a rough surface at the tip. Is a puncture needle for epidural anesthesia.

By providing a rough surface area on the tip surface, the puncture resistance when puncturing and penetrating the ligamentum flavum increases, so that the tip of the needle has reached the epidural space more clearly. There is no risk of damaging human tissue due to excessive insertion.

粗面の表面粗さは、Ra(JIS B 0601)で0.5〜5.0μmが適当である。Raが0.5μmより小さいと、穿刺抵抗を増大させる効果が十分でなく、5.0μmより大きいと穿刺部分の組織を傷つける可能性がある。なお、通常の麻酔針(粗面を有さないもの)の表面粗さはRaで0.09μmである。 The surface roughness of the rough surface is suitably 0.5 to 5.0 μm in Ra (JIS B 0601). If Ra is smaller than 0.5 μm, the effect of increasing the puncture resistance is not sufficient, and if it is larger than 5.0 μm, the tissue at the puncture portion may be damaged. Note that the surface roughness of a normal anesthetic needle (without a rough surface) is 0.09 μm in Ra.

針の最先端部に表面が粗面となっていない領域を設けることができる。粗面の領域は、最先端部の表面が粗面となっていない領域の後側に設ける。このようにすることで、針を皮膚に差し込むときの抵抗が少なくなり、滑らかに差し込むことができる。表面が粗面となっていない領域の軸方向長さは0.5〜1.5mmが適当である。0.5mmより短いと、針を皮膚に差し込むときの抵抗が少なくなる効果が不十分であり、1.5mmよりも長いと、黄靱帯を穿刺するときの穿刺抵抗が増大する効果が不十分となる。 An area where the surface is not rough can be provided at the most distal end of the needle. The rough surface region is provided on the rear side of the region where the surface of the most advanced portion is not rough. By doing so, the resistance when inserting the needle into the skin is reduced, and the needle can be inserted smoothly. The axial length of the region where the surface is not rough is suitably 0.5 to 1.5 mm. If shorter than 0.5 mm, the effect of reducing resistance when the needle is inserted into the skin is insufficient, and if longer than 1.5 mm, the effect of increasing puncture resistance when puncturing the ligamentum is insufficient. Become.

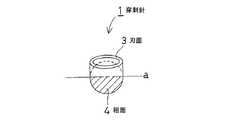

表面が粗面となっている領域は、軸芯を通る水平面よりも下側の表面に形成することが望ましい。粗面領域を軸芯を通る水平面よりも上側に設けないことで、粗面による組織の損傷を最小限にすることができる。黄靱帯を穿刺するときの穿刺抵抗の増大は、主に、水平面よりも下側の粗面の作用によるので、このようにしても、黄靱帯を穿刺するときの穿刺抵抗の増大効果はほとんど変わらない。

ただし、粗面の領域の境目を完全に軸芯を通る水平面とすることは技術的に困難であるので、上下方向にそれぞれ0.1mm(針の外径の10%)程度の誤差は許容される。It is desirable to form the region having a rough surface on the surface below the horizontal plane passing through the axis. By not providing the rough surface region above the horizontal plane passing through the axis, tissue damage due to the rough surface can be minimized. The increase in puncture resistance when puncturing the ligament is mainly due to the action of a rough surface below the horizontal plane, so the effect of increasing the puncture resistance when puncturing the ligament is almost unchanged. Absent.

However, since it is technically difficult to make the boundary of the rough surface area completely a horizontal plane passing through the axis, an error of about 0.1 mm (10% of the outer diameter of the needle) is allowed in the vertical direction. The

表面が粗面となっている領域の後端の位置は、針先端から軸芯方向に2.5〜4.5mm後方であることが望ましい。2.5mmよりも短いと、黄靱帯を穿刺するときの穿刺抵抗の増大効果が不十分であり、4.5mmより長くしても黄靱帯を穿刺するときの穿刺抵抗がさらに増大することはなく、逆に、組織をいたずらに傷つけるおそれがある。 The position of the rear end of the region where the surface is rough is preferably 2.5 to 4.5 mm rearward from the tip of the needle in the axial direction. If it is shorter than 2.5 mm, the effect of increasing the puncture resistance when puncturing the ligamentum flavum is insufficient, and even if it is longer than 4.5 mm, the puncture resistance when puncturing the ligamentum flavum does not increase further. On the contrary, there is a risk of damaging the tissue.

また本発明は、前記本発明の穿刺針の製造方法であって、前記粗面を、サンドブラスト加工によって形成したことを特徴とする硬膜外麻酔用穿刺針の製造方法である。

粗面は、レーザー加工などによっても形成することができるが、サンドブラスト加工が最も容易で、多数の針を並べて同時に粗面加工することができる。粗面としない部分は、マスキングを行えばよい。The present invention also relates to a method for manufacturing a puncture needle for epidural anesthesia according to the present invention, wherein the rough surface is formed by sandblasting.

The rough surface can be formed by laser processing or the like, but sandblasting is the easiest, and a large number of needles can be arranged and roughed simultaneously. Masking may be performed on the portion not roughened.

サンドブラスト加工で、吹き付ける研磨材は任意であるが、特に、平均粒径40〜55μmのアルミナ粒子、平均粒径50〜65μmのガラスビーズ、平均粒径50〜65μmのカーボンランダムが適している。これらの研磨材の2種以上を混合して用いてもよい。 Abrasives to be blown in the sand blasting are arbitrary, but alumina particles having an average particle diameter of 40 to 55 μm, glass beads having an average particle diameter of 50 to 65 μm, and carbon random having an average particle diameter of 50 to 65 μm are particularly suitable. Two or more kinds of these abrasives may be mixed and used.

本発明の硬膜外麻酔用穿刺針は、黄靱帯を穿刺、貫通するときの穿刺抵抗が増大するので、針先端部が硬膜外腔に進入したことをより明確に知ることができ、針を深く入れすぎて人体組織を傷つけてしまうおそれがなくなる。 The puncture needle for epidural anesthesia according to the present invention increases the puncture resistance when puncturing and penetrating the ligamentum flavum, so that the needle tip has entered the epidural space more clearly. There is no risk of damaging human tissue due to excessive insertion.

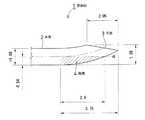

図1は実施例の硬膜外麻酔用穿刺針1の側面図、図2は正面図である。穿刺針1は、直径1.08mmの管状の本体2の先端部が上向きに屈曲し、その先端の刃面3は上向きの傾斜面となっている。刃面の長さ(軸方向)は2.05mmである。本体2の軸芯を通る水平面aよりも下側の表面には粗面4が形成されている。図1、2においては、粗面の領域を斜線で示している。最先端部には、粗面となっていない領域を有し、その軸方向長さは0.85mmである。粗面4となっている領域の後端位置は、針先端から軸芯方向に3.75mm後方である。粗面となっている領域の表面粗さはRaで1.5μm、粗面以外の領域の表面粗さはRaで0.09μmである。 1 is a side view of a puncture needle 1 for epidural anesthesia according to an embodiment, and FIG. 2 is a front view. In the puncture needle 1, the tip of a tubular body 2 having a diameter of 1.08 mm is bent upward, and the blade surface 3 at the tip is an upward inclined surface. The length (axial direction) of the blade surface is 2.05 mm. A rough surface 4 is formed on the surface below the horizontal plane a passing through the axis of the main body 2. 1 and 2, the rough surface area is indicated by diagonal lines. The most advanced portion has an area that is not rough, and its axial length is 0.85 mm. The rear end position of the region that is the rough surface 4 is 3.75 mm behind the needle tip in the axial direction. The surface roughness of the roughened region is 1.5 μm in Ra, and the surface roughness of the region other than the rough surface is 0.09 μm in Ra.

穿刺針1は、通常の粗面を有しない穿刺針を作成した後、その多数の穿刺針を並列に並べ、粗面以外の領域(最先端部及び根元よりの部分)をマスキングシートでマスキングし、平均粒径50μmのアルミナ粒子で10秒間ブラスト加工して製造した。 For the puncture needle 1, after creating a normal puncture needle having no rough surface, the many puncture needles are arranged in parallel, and areas other than the rough surface (the most advanced portion and the portion from the root) are masked with a masking sheet. And blasting with alumina particles having an average particle size of 50 μm for 10 seconds.

実施例の穿刺針1と、穿刺針1と同じ形状で粗面が形成されていないことだけが異なる比較例の穿刺針を各5本用意し、厚さ0.05mmのポリウレタンフィルムを穿刺した。このフィルムは、人の黄靱帯と同じ程度の硬さ及び弾力を有するように作られたものである。フィルムを穿刺したときの実施例の穿刺抵抗を表1に、比較例の穿刺抵抗を表2に示す。なお、穿刺抵抗の単位はgfである。

表1、2において、第1ピークは、穿刺針先端がフィルムを貫通する瞬間の穿刺抵抗値、第2ピークは、穿刺針の刃面3の後端がフィルムを通過する瞬間の穿刺抵抗値である。穿刺針の前進量(ストローク)と穿刺抵抗の関係は図3に示すようになっている。穿刺針を前進させると共に穿刺抵抗が増大し、穿刺針先端がフィルムを貫通する瞬間に第1ピークとなる。その後、一旦穿刺抵抗は急激に減少するが、さらに穿刺針を前進させると、穿刺抵抗は徐々に増加し、穿刺針の刃面3の後端がフィルムを通過する瞬間に、穿刺抵抗が最大である第2ピークとなる。その後、穿刺抵抗は急激に減少する。

術者は、穿刺抵抗が最大となる第2ピークの穿刺抵抗により、穿刺針先端部が黄靱帯を完全に突き抜け、硬膜外腔に達したことを知る。実施例は比較例に較べて平均で約45%、第2ピークの穿刺抵抗が大きくなっているので、比較例に較べて、術者は穿刺針先端部が黄靱帯を完全に突き抜け、硬膜外腔に達したことを明確に知ることができる。In Tables 1 and 2, the first peak is the puncture resistance value at the moment when the tip of the puncture needle penetrates the film, and the second peak is the puncture resistance value at the moment when the rear end of the blade surface 3 of the puncture needle passes through the film. is there. The relationship between the advancement amount (stroke) of the puncture needle and the puncture resistance is as shown in FIG. As the puncture needle is advanced, the puncture resistance increases, and the first peak is reached at the moment when the tip of the puncture needle penetrates the film. After that, once the puncture resistance suddenly decreases, the puncture resistance gradually increases when the puncture needle is further advanced, and the puncture resistance reaches the maximum at the moment when the rear end of the blade surface 3 of the puncture needle passes through the film. It becomes a certain second peak. Thereafter, the puncture resistance decreases rapidly.

The operator knows that the tip of the puncture needle has completely penetrated the ligamentum flavum and reached the epidural space by the puncture resistance of the second peak that maximizes the puncture resistance. Since the average of the example is about 45% compared to the comparative example and the puncture resistance of the second peak is larger, the surgeon completely penetrates the ligamentum flavum than the comparative example, and the dura mater You can clearly know that you have reached the outer space.

1 穿刺針

2 本体

3 刃面

4 粗面

11 穿刺針

12 本体

13 刃面DESCRIPTION OF SYMBOLS 1 Puncture needle 2 Main body 3 Blade surface 4 Rough surface 11 Puncture needle 12 Main body 13 Blade surface

Claims (8)

Translated fromJapaneseThe hard sand according to claim 7, wherein the abrasive for sandblasting is alumina particles having an average particle diameter of 40 to 55 μm, and / or glass beads having an average particle diameter of 50 to 65 μm, and / or carbon random having an average particle diameter of 50 to 65 μm. A method for producing a puncture needle for epimembrane anesthesia.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007266730AJP4598041B2 (en) | 2007-10-12 | 2007-10-12 | Puncture needle for epidural anesthesia |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007266730AJP4598041B2 (en) | 2007-10-12 | 2007-10-12 | Puncture needle for epidural anesthesia |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2009095368Atrue JP2009095368A (en) | 2009-05-07 |

| JP4598041B2 JP4598041B2 (en) | 2010-12-15 |

Family

ID=40698961

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007266730AActiveJP4598041B2 (en) | 2007-10-12 | 2007-10-12 | Puncture needle for epidural anesthesia |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4598041B2 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014167756A1 (en) | 2013-04-08 | 2014-10-16 | オリンパス株式会社 | Injection needle |

| CN107569258A (en)* | 2017-09-29 | 2018-01-12 | 上海长海医院 | A kind of puncture needle |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07514A (en)* | 1993-04-16 | 1995-01-06 | Wilhelm Waskoenig | Needle such as epidural needle, etc. |

| WO2002004051A1 (en)* | 2000-07-06 | 2002-01-17 | Dr. Japan Co., Ltd. | Spinal anesthetic needle |

| JP2004208971A (en)* | 2002-12-27 | 2004-07-29 | Terumo Corp | Needle assembly |

| JP2005323898A (en)* | 2004-05-17 | 2005-11-24 | Medical Support:Kk | Injection needle and its manufacturing method |

| JP2006223653A (en)* | 2005-02-18 | 2006-08-31 | Nihon Medi Physics Co Ltd | Puncture needle and double sword needle using the same, radiopharmaceutical injection device and radiopharmaceutical administration device |

- 2007

- 2007-10-12JPJP2007266730Apatent/JP4598041B2/enactiveActive

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07514A (en)* | 1993-04-16 | 1995-01-06 | Wilhelm Waskoenig | Needle such as epidural needle, etc. |

| WO2002004051A1 (en)* | 2000-07-06 | 2002-01-17 | Dr. Japan Co., Ltd. | Spinal anesthetic needle |

| JP2004208971A (en)* | 2002-12-27 | 2004-07-29 | Terumo Corp | Needle assembly |

| JP2005323898A (en)* | 2004-05-17 | 2005-11-24 | Medical Support:Kk | Injection needle and its manufacturing method |

| JP2006223653A (en)* | 2005-02-18 | 2006-08-31 | Nihon Medi Physics Co Ltd | Puncture needle and double sword needle using the same, radiopharmaceutical injection device and radiopharmaceutical administration device |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014167756A1 (en) | 2013-04-08 | 2014-10-16 | オリンパス株式会社 | Injection needle |

| JP2014200551A (en)* | 2013-04-08 | 2014-10-27 | オリンパス株式会社 | Puncture needle |

| CN107569258A (en)* | 2017-09-29 | 2018-01-12 | 上海长海医院 | A kind of puncture needle |

Also Published As

| Publication number | Publication date |

|---|---|

| JP4598041B2 (en) | 2010-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3595551B1 (en) | An implant needle | |

| US20170245883A1 (en) | Dilator | |

| JP6222495B2 (en) | Biopuncture needle and method for producing the same | |

| CA2712011A1 (en) | Dilator | |

| CN101181653A (en) | Trocar | |

| WO2013104642A1 (en) | Port cannula for puncturing port catheters | |

| US10639070B2 (en) | Implant needle and method for production | |

| US20140236104A1 (en) | Punch-reducing cannula | |

| JP4598041B2 (en) | Puncture needle for epidural anesthesia | |

| CN207640475U (en) | Intervertebral foramen expands the device of forming in a kind of operation of foramen intervertebrale lens | |

| JP4443996B2 (en) | Spinal anesthesia needle | |

| KR102681663B1 (en) | Cannula manufacturing method using seamless steel pipe | |

| JP2005211268A (en) | Peridural needle | |

| WO2014054156A1 (en) | Stylet for medical needle and medical needle | |

| JP2008029575A (en) | Injection needle for spinal anesthesia and its manufacturing method | |

| JP4051010B2 (en) | Medical hollow needle and method for producing the same | |

| JP6384909B2 (en) | Dental implant drill | |

| JP2004208971A (en) | Needle assembly | |

| JPH10328302A (en) | Needle | |

| CN106456211A (en) | Medical injection needle and manufacturing method therefor | |

| CN215079357U (en) | A depth-limiting epidural puncture needle | |

| CN102935026A (en) | Super-bore-diameter stab knife | |

| CN207693643U (en) | deep fascia cutter | |

| CN104586546A (en) | Screwed type fusion apparatus among cervical vertebra zygopophysis joints and supporting cutter of fusion apparatus | |

| JP5083948B2 (en) | Puncture needle for epidural anesthesia |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A977 | Report on retrieval | Free format text:JAPANESE INTERMEDIATE CODE: A971007 Effective date:20100603 | |

| A131 | Notification of reasons for refusal | Free format text:JAPANESE INTERMEDIATE CODE: A131 Effective date:20100629 | |

| A521 | Request for written amendment filed | Free format text:JAPANESE INTERMEDIATE CODE: A523 Effective date:20100804 | |

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) | Free format text:JAPANESE INTERMEDIATE CODE: A01 Effective date:20100914 | |

| A01 | Written decision to grant a patent or to grant a registration (utility model) | Free format text:JAPANESE INTERMEDIATE CODE: A01 | |

| A61 | First payment of annual fees (during grant procedure) | Free format text:JAPANESE INTERMEDIATE CODE: A61 Effective date:20100922 | |

| R150 | Certificate of patent or registration of utility model | Ref document number:4598041 Country of ref document:JP Free format text:JAPANESE INTERMEDIATE CODE: R150 Free format text:JAPANESE INTERMEDIATE CODE: R150 | |

| FPAY | Renewal fee payment (event date is renewal date of database) | Free format text:PAYMENT UNTIL: 20131001 Year of fee payment:3 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 |