JP2007064557A - Cooling system - Google Patents

Cooling systemDownload PDFInfo

- Publication number

- JP2007064557A JP2007064557AJP2005251626AJP2005251626AJP2007064557AJP 2007064557 AJP2007064557 AJP 2007064557AJP 2005251626 AJP2005251626 AJP 2005251626AJP 2005251626 AJP2005251626 AJP 2005251626AJP 2007064557 AJP2007064557 AJP 2007064557A

- Authority

- JP

- Japan

- Prior art keywords

- cooled

- cooling element

- magnetic field

- coil

- cooling

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000001816coolingMethods0.000titleclaimsabstractdescription124

- 230000006698inductionEffects0.000claimsabstractdescription25

- 238000010521absorption reactionMethods0.000claimsdescription12

- NJPPVKZQTLUDBO-UHFFFAOYSA-NnovaluronChemical compoundC1=C(Cl)C(OC(F)(F)C(OC(F)(F)F)F)=CC=C1NC(=O)NC(=O)C1=C(F)C=CC=C1FNJPPVKZQTLUDBO-UHFFFAOYSA-N0.000claimsdescription9

- 230000005855radiationEffects0.000claimsdescription6

- 230000002093peripheral effectEffects0.000claimsdescription5

- 239000002470thermal conductorSubstances0.000claims1

- 238000010438heat treatmentMethods0.000abstractdescription15

- 230000005674electromagnetic inductionEffects0.000abstractdescription8

- 235000013361beverageNutrition0.000description19

- 230000017525heat dissipationEffects0.000description12

- 230000000694effectsEffects0.000description6

- 239000004065semiconductorSubstances0.000description6

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description6

- 238000010586diagramMethods0.000description5

- 239000011810insulating materialSubstances0.000description4

- 239000004020conductorSubstances0.000description2

- 239000003989dielectric materialSubstances0.000description2

- 239000006096absorbing agentSubstances0.000description1

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000description1

- 229910052782aluminiumInorganic materials0.000description1

- 239000003990capacitorSubstances0.000description1

- 230000005484gravityEffects0.000description1

- 238000009499grossingMethods0.000description1

- 238000009434installationMethods0.000description1

- 238000009413insulationMethods0.000description1

- 239000000696magnetic materialSubstances0.000description1

- 239000000463materialSubstances0.000description1

- 238000007789sealingMethods0.000description1

Images

Landscapes

- Induction Heating Cooking Devices (AREA)

- Devices That Are Associated With Refrigeration Equipment (AREA)

Abstract

Description

Translated fromJapanese本発明は、電子冷却装置によって容器部の被冷却物を冷却する冷却装置に関し、特に、電磁誘導機能を併用した冷却装置に関する。 The present invention relates to a cooling device that cools an object to be cooled by an electronic cooling device, and more particularly to a cooling device that uses an electromagnetic induction function.

食卓等で飲料物を適温で飲めるようにするために、筒状部を内筒と外筒とで構成し内筒を上下スライドできるようにし、筒状部の下部に配置したペルチェ素子等の電子温冷素子からに熱(冷熱又は温熱)が飲料物に全面から伝導するようにした温冷装置がある(特許文献1参照)。

この特許文献1のものは、ペルチェ素子へ流れる電流の向きを正方向と逆方向とに切り替えることによって、吸熱面と放熱面の位置を入れ替えて、飲料物を加温したり冷却したりするものである。この温冷装置は、容器に入れた飲料を筒状部に入れて、加温したり冷却したりするものであるが、この電子冷却部へ給電するためには電源コードが必要であり、温冷装置そのものの持ち運びに際しては、コンセントに対して電源コードの着脱が必要であり、面倒であり、この電源コードが邪魔である。 The thing of this

本発明は、このような点に鑑みて、電源コードを必要としない冷却装置を提供するために、飲料物等の被冷却物の冷却には、ペルチェ素子等の電子冷温素子を利用し、この電源としては、キッチンやダイニングなどの設備として普及している電磁誘導加熱装置を利用できる簡易型冷却装置を提供する。 In view of the above, the present invention uses an electronic cooling / heating element such as a Peltier element for cooling an object to be cooled such as a beverage in order to provide a cooling device that does not require a power cord. As a power source, a simple cooling device that can use an electromagnetic induction heating device that is widely used as a facility for kitchens and dining rooms is provided.

第1発明の冷却装置は、高周波誘導磁界発生コイルの磁界中に設置されたとき誘起電力を発生する受動側コイルを備え、この受動側コイルによって発生する電流から作られた直流によって作動する電子冷却素子を備え、この電子冷却素子の吸熱部によって被冷却物を冷却することを特徴とする。 A cooling device according to a first aspect of the present invention includes a passive side coil that generates an induced electric power when installed in a magnetic field of a high frequency induction magnetic field generating coil, and is operated by a direct current generated from a current generated by the passive side coil. An element is provided, and an object to be cooled is cooled by a heat absorption part of the electronic cooling element.

第2発明の冷却装置は、高周波誘導磁界発生コイルを備えた台座に着脱自在に載置される本体を備え、この本体は下部に作動部を備えその上部に被冷却物を収容する容器部を備え、前記作動部は、前記高周波誘導磁界発生コイルの磁界によって誘起電力を発生する受動側コイルと、この受動側コイルによって発生する電流に基づく直流によって作動する電子冷却素子を備え、この電子冷却素子の吸熱部によって前記容器部に収納した被冷却物を冷却することを特徴とする。 A cooling device according to a second aspect of the present invention includes a main body that is detachably mounted on a pedestal having a high-frequency induction magnetic field generating coil, and the main body includes an operating portion at a lower portion and a container portion for accommodating an object to be cooled at the upper portion. The actuating unit includes a passive side coil that generates an induced power by a magnetic field of the high-frequency induction magnetic field generating coil, and an electronic cooling element that operates by direct current based on a current generated by the passive side coil. The object to be cooled stored in the container part is cooled by the heat absorbing part.

第3発明の冷却装置は、高周波誘導磁界発生コイルを備えた台座に着脱自在に載置される本体を備え、この本体は下部に作動部を備えその上部に被冷却物を収容する容器部が着脱自在に載置され、前記作動部は、前記高周波誘導磁界発生コイルの磁界によって誘起電力を発生する受動側コイルと、この受動側コイルによって発生する電流に基づく直流によって作動する電子冷却素子を備え、この電子冷却素子の吸熱部によって前記容器部に収納した被冷却物を冷却することを特徴とする。 A cooling device according to a third aspect of the present invention includes a main body that is detachably mounted on a pedestal having a high-frequency induction magnetic field generating coil, and the main body includes an operating portion at a lower portion and a container portion for accommodating an object to be cooled at the upper portion. The actuating unit is detachably mounted, and the operating unit includes a passive side coil that generates an induced power by a magnetic field of the high-frequency induction magnetic field generating coil, and an electronic cooling element that is operated by a direct current based on a current generated by the passive side coil. The object to be cooled stored in the container portion is cooled by the heat absorbing portion of the electronic cooling element.

第4発明の冷却装置は、第2発明または第3発明において、前記作動部は、前記電子冷却素子の吸熱側を上面として前記容器部の底壁を冷却する位置に前記電子冷却素子を配置し、前記電子冷却素子の下面放熱側に熱良導体のヒートシンクを備え、このヒートシンクの下方に放熱用送風機が配置され、この放熱用送風機の下方には前記受動側コイルが配置され、前記放熱用送風機は前記直流によって作動することを特徴とする。 According to a fourth aspect of the present invention, there is provided the cooling device according to the second or third aspect of the invention, wherein the operating part is arranged with the electronic cooling element at a position for cooling the bottom wall of the container part with the heat absorption side of the electronic cooling element as an upper surface. The heat sink of the good heat conductor is provided on the heat radiation side of the lower surface of the electronic cooling element, the heat dissipation fan is disposed below the heat sink, the passive side coil is disposed below the heat dissipation fan, and the heat dissipation fan is It operates by the direct current.

第5発明の冷却装置は、第3発明又は第4発明のいずれかにおいて、前記作動部は、前記容器部の底部が着脱自在にセットされる上面開口の受け入れ部を備え、この受け入れ部の底部には前記電子冷却素子が吸熱側を上面として配置され、前記受け入れ部にセットされた前記容器部の底壁を冷却する位置に前記電子冷却素子を配置したことを特徴とする。 The cooling device according to a fifth aspect of the present invention is the cooling device of the third aspect or the fourth aspect, wherein the actuating portion includes a receiving portion having an upper surface opening in which a bottom portion of the container portion is detachably set, and a bottom portion of the receiving portion. The electronic cooling element is arranged with the heat absorption side as an upper surface, and the electronic cooling element is arranged at a position for cooling the bottom wall of the container part set in the receiving part.

第6発明の冷却装置は、第2発明乃至第5発明のいずれかにおいて、前記本体の周囲外面には、前記容器部に収納した被冷却物の温度表示部と作動中を点灯表示する表示部の少なくとも一方を備えたことを特徴とする。 A cooling device according to a sixth aspect of the present invention is the cooling device according to any one of the second to fifth aspects of the present invention, on the outer peripheral surface of the main body, a temperature display portion of the object to be cooled housed in the container portion and a display portion that lights and displays the operation It is characterized by having at least one of these.

第7発明の梱包装置は、第2発明乃至第6発明のいずれかにおいて、前記本体は、片手で持ち運び可能なコップ状をなすことを特徴とする。 According to a seventh aspect of the present invention, in any one of the second to sixth aspects, the main body has a cup shape that can be carried with one hand.

第1発明では、高周波誘導磁界発生コイルの磁界中に置いたとき発生する誘起電力によって、ペルチェ素子等の電子冷却素子が作動して、容器部の飲料物等の被冷却物の冷却が行われるため、電源コードを必要としない。このため、冷却装置の持ち運びが便利であると共に、キッチンやダイニングなどの設備として普及している電磁誘導加熱装置の利用範囲が拡大する。 In the first invention, an electronic cooling element such as a Peltier element is actuated by the induced power generated when placed in the magnetic field of the high frequency induction magnetic field generating coil, and the object to be cooled such as the beverage in the container portion is cooled. Therefore, no power cord is required. For this reason, it is convenient to carry the cooling device, and the range of use of the electromagnetic induction heating device that is widely used as facilities such as kitchens and dining areas is expanded.

第2発明は、第1発明の効果に加えて、高周波誘導磁界発生コイルを備えた台座に着脱自在に載置される本体が、下部の作動部と上部の被冷却物収容の容器部を備えることによって、冷却装置の重心が下がって安定した設置ができるものとなる。 In the second invention, in addition to the effects of the first invention, the main body detachably mounted on the pedestal having the high frequency induction magnetic field generating coil includes a lower operation part and an upper container part for receiving an object to be cooled. As a result, the center of gravity of the cooling device is lowered and stable installation can be achieved.

第3発明では、第1発明の効果に加えて、高周波誘導磁界発生コイルを備えた台座に着脱自在に載置される本体は、下部の作動部の上に被冷却物収容の容器部が着脱自在に載置される構成であるため、容器部を取り外して飲料等を容器部に入れたり、冷却された飲料等を他の容器に移したり等の作業がし易くなる。また、容器部を取り外して水洗いできるため、その場合、下部の作動部へ水が掛かることもなく安全である。 In the third invention, in addition to the effect of the first invention, the main body detachably mounted on the pedestal provided with the high frequency induction magnetic field generating coil has the container part for receiving the object to be cooled on the lower working part. Since it is configured to be freely placed, it is easy to perform operations such as removing the container part and putting a beverage or the like into the container part, or transferring the cooled beverage or the like to another container. Moreover, since the container part can be removed and washed with water, in this case, it is safe without water splashing on the lower working part.

第4発明では、第2発明または第3発明の効果に加えて、放熱用送風機への電力は、電子冷却素子への電力と同じ直流が利用されるため、本体を高周波誘導磁界発生コイルを備えた台座に載置することによって、電子冷却素子への給電と同時に給電できることとなり、放熱用送風機への電力供給の電源コードも不要であり、また、スイッチによるON−OFF制御も必要なく、使い勝手も便利なものとなる。 In the fourth invention, in addition to the effects of the second or third invention, since the same direct current as the power to the electronic cooling element is used as the power to the heat radiating fan, the main body is provided with a high frequency induction magnetic field generating coil. By mounting on the pedestal, power can be supplied at the same time as the power supply to the electronic cooling element, no power cord is required for power supply to the heat-dissipating blower, and there is no need for ON / OFF control by a switch. It will be convenient.

第5発明では、第3発明又は第4発明の効果に加えて、作動部は、容器部の底部が着脱自在にセットされる上面開口の受け入れ部を備えるため、容器部の着脱がし易く、使い勝手がよい。 In the fifth aspect of the invention, in addition to the effects of the third or fourth aspect of the invention, the actuating part is provided with a receiving part having an upper surface opening in which the bottom part of the container part is detachably set. Is good.

第6発明では、第2発明乃至第5発明の効果に加えて、容器部に収納した被冷却物が適温かの否かの見極めや、冷却装置が作動かを確認し易くなり便利である。また、表示部にLEDを採用すれば、電子冷却素子への電力と同じ直流を利用できるため、給電回路も簡素化される。 In the sixth aspect of the invention, in addition to the effects of the second to fifth aspects of the invention, it is easy to determine whether or not the object to be cooled stored in the container is at an appropriate temperature and to confirm whether the cooling device is operating. In addition, if an LED is used for the display unit, the same direct current as the electric power to the electronic cooling element can be used, so that the power feeding circuit is also simplified.

第7発明では、第2発明乃至第6発明の効果に加えて、本体が片手で持ち運び可能なコップ状であるため、持ち運びが便利であり、利用し易くなる。 In the seventh invention, in addition to the effects of the second to sixth inventions, since the main body is in a cup shape that can be carried with one hand, it is convenient to carry and easy to use.

本発明に係る冷却装置は、高周波誘導磁界発生コイルの磁界中に設置されたとき誘起電力を発生する受動側コイルを備え、この受動側コイルによって発生する電流から作られた直流によって作動する電子冷却素子を備え、この電子冷却素子の吸熱部によって被冷却物を冷却するものであり、本発明の実施例を以下に記載する。 The cooling device according to the present invention includes a passive-side coil that generates an induced power when installed in a magnetic field of a high-frequency induction magnetic field generating coil, and is operated by a direct current generated from a current generated by the passive-side coil. An element is provided, and an object to be cooled is cooled by a heat absorption part of the electronic cooling element. Examples of the present invention will be described below.

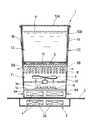

本発明の実施の形態について説明する。図1は冷却装置の縦断側面図、図2は電子冷却素子部分の拡大断面図、図3は電子冷却素子等への給電回路図である。 Embodiments of the present invention will be described. FIG. 1 is a longitudinal side view of a cooling device, FIG. 2 is an enlarged sectional view of an electronic cooling element portion, and FIG. 3 is a power supply circuit diagram for the electronic cooling element and the like.

図1において、本発明の冷却装置1は、電磁誘導加熱装置2を裏側に備えたキッチンの天板やダイニングテーブル板などを示す台座3に着脱自在に載置されるものであり、電磁誘導加熱装置2の高周波誘導磁界発生コイル2Aの磁界中に設置されたとき誘起電力を発生する受動側コイル4を備え、この受動側コイル4によって発生する電流から作られた直流によって作動する電子冷却素子5を備え、この電子冷却素子5の吸熱部5Aによって飲料等の被冷却物を冷却する。 In FIG. 1, a

これを具体的に説明する。図1において、冷却装置1は、高周波誘導磁界発生コイル2Aを備えた台座3に着脱自在に載置される本体10を備え、この本体10は、下部に作動部11を備え、その上部に飲料などの被冷却物Hを収容する上面開口の容器部12を備える。作動部11は、高周波誘導磁界発生コイル2Aの磁界によって誘起電力を発生する受動側コイル4と、この受動側コイル4によって発生する電流に基づく直流によって作動する電子冷却素子5を備え、この電子冷却素子5の吸熱部5Aによって容器部12に収納した被冷却物Hを冷却する。本体10は、上面開口の容器形状をなした被磁性体で形成され、図示の形態は全体として片手で持ち運び可能な大きさで上面開口のコップ形状をなす。本体10の周囲外面には、容器部12に収納した被冷却物Hの温度表示部18と、冷却装置1の作動中を点灯表示するLEDの表示部19を備えており、図では容器部12の周囲外面にこれらを設けた構成である。容器部12の上面開口には取り外し自在な蓋12Aを備えている。容器部12は、収納した被冷却物Hの温度保持のために断熱層12Bを備えた構成である。 This will be specifically described. In FIG. 1, a

図1に示すように、作動部11の内部には、下部から上方に向けて、受動側コイル4、支持部材13に支持した回路基板6、支持部材13に支持した放熱用送風機7、電子冷却素子5の放熱用ヒートシンク8、電子冷却素子5を順次配置した構成である。そして、受動側コイル4に対応した周囲面には、空気の取り入れ口9Aを形成し、放熱用ヒートシンク8に対応した周囲面には、空気の吐出口9Bを形成している。図2に示すように、電子冷却素子5の放熱部5Bは薄い電気絶縁材15を介して放熱用ヒートシンク8が組み合わされ、また、電子冷却素子5の吸熱部5Aは薄い電気絶縁材16を介して熱良導板17が組み合わされている。熱良導板17は容器部12の底板を形成するため、熱良導板17の周囲は、容器部12に収納した飲料等の被冷却物Hが漏れないように十分なシール構造になっている。 As shown in FIG. 1, inside the

図2に示すように、電子冷却素子5は、横方向にN型半導体とP型半導体が交互配列された状態で、隣り合うN型半導体とP型半導体の一端側が熱良導板で連結されて吸熱部5Aを構成し、他端側が熱良導板で連結されて放熱部5Bを構成する関係によって、全体としてN型半導体とP型半導体が直列状態に接続された周知の構成である。また、放熱用ヒートシンク8は、アルミニウム等のような熱良導体でもって多数の放熱フィン8Aを形成している。このような構成によって、電子冷却素子5の放熱部5Bの熱は、電気絶縁材15を介して放熱用ヒートシンク8によって放熱され、電子冷却素子5の吸熱部5Aは薄い電気絶縁材16を介して熱良導板17を冷却する。そして、熱良導板17の冷却によって、容器部12に収納した飲料等の被冷却物Hが冷却される。作動部11の内部の熱は、放熱用送風機7の運転によって、空気の取り入れ口9Aから吸い込んだ空気によって熱交換されて、空気の吐出口9Bから放出される。 As shown in FIG. 2, the

図3には電子冷却素子5等への給電回路図を示しており、これにおいて、交流電源20に接続された高周波誘導磁界発生コイル2Aと対峙する受動側コイル4に誘起される電力は、整流素子21Aで構成した整流回路21によって整流され、これが平滑コンデンサ22A、22Bによって平滑されて(+)(−)で示す直流となる。この直流によって電子冷却素子5、放熱用送風機7の直流電動機7A、及び表示部19のLEDが動作する。 FIG. 3 shows a power supply circuit diagram for the

このような構成であるため、受動側コイル4が高周波誘導磁界発生コイル2Aと対峙する位置に冷却装置1を載置して、電磁誘導加熱装置2の電源をONすることによって、交流電源20から高周波誘導磁界発生コイル2Aに電力が供給されて受動側コイル4に電力が誘起され、表示部19のLEDが点灯して動作中であることを表示する。これと共に、電子冷却素子5が動作して容器部12に収納した飲料等の被冷却物Hを冷却し、直流電動機7Aが始動して放熱用送風機7が運転される。このような動作によって、容器部12に収納した飲料等の被冷却物Hが冷却されるため、温度表示部18の温度を確認して、又は運転開始から適切な時間経過の後に、冷却装置1を取り上げれば、表示部19のLEDが消灯すると共に、電子冷却素子5と直流電動機7Aが運転停止状態となるため、その中の被冷却物Hをそのまま飲むことができるし、また他の容器に移し替えることができる。冷却装置1によって被冷却物Hを冷却しない場合は、電磁誘導加熱装置2の電源をOFFする。 Due to such a configuration, the

図4には本発明の実施例2の形態の冷却装置の縦断側面図を示している。実施例1と同様に部分は同一符号を付しており、上記の説明を援用するものとする。実施例1の形態と異なる部分は、本体10は、作動部11と容器部12が分離可能な構成であり、容器部12が作動部11の上部に着脱自在に載置された構成である。このため、作動部11は、高周波誘導磁界発生コイル2Aの磁界によって誘起電力を発生する受動側コイル4と、この受動側コイル4によって発生する電力に基づく直流によって作動する電子冷却素子5を備え、電子冷却素子5の吸熱部5Aの上面には、図2に示す構成と同様に薄い電気絶縁材16を介して熱良導板17を接合している。そして、作動部11は、容器部12の底部を受け入れるように、若干外方に広がった上面開口の受け口23を形成し、この受け口23の底面を熱良導板17が形成する構成である。また、容器部12の底面壁24は熱良導板で構成されている。電子冷却素子5等への給電回路図は図3と同様である。 FIG. 4 shows a longitudinal side view of the cooling device according to the second embodiment of the present invention. The parts are denoted by the same reference numerals as in the first embodiment, and the above description is incorporated. A different part from the form of Example 1 is that the

この構成によって、容器部12の底面壁24が熱良導板17に当接するように、容器部12の底部を受け口23に嵌め合わせて載置すれば、実施例1に記載したことと同様に、電子冷却素子5への通電に基づき、吸熱部5Aによって熱良導板17が冷却され、それによって容器部12の底面壁24が冷却され、容器部12に収納した被冷却物Hが冷却される。このため、容器部12を取り外して飲料等を容器部12に入れたり、冷却された飲料等を他の容器に移したり等の作業がし易くなる。また、容器部12を取り外して水洗いできるため、その場合、下部の作動部11へ水が掛かることもなく安全な冷却装置1となる。 With this configuration, if the bottom portion of the

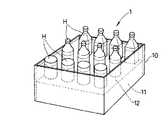

図5には実施例3の冷却装置の斜視図を示し、図6には図5の冷却装置の縦断側面図を示している。これらにおいて、実施例1と同様の機能部分は同一符号を付しており、上記の説明を援用するものとする。実施例1の形態と異なる部分は、本体10の形態が上面開口の矩形状等の箱型であり、実施例1と同様に、この本体10は、下部に作動部11を備え、その上部に飲料などの被冷却物Hを収容する上面開口の容器部12を備えるが、この作動部11内に取り付けられる受動側コイル4、電子冷却素子5、回路基板6、放熱用送風機7、放熱用ヒートシンク8の配置が若干異なり、放熱用送風機7によって、一側面に形成した空気の取り入れ口9Aから吸い込んだ空気は、他側面に形成した空気の吐出口9Bから放出される間に、受動側コイル4、電子冷却素子5、回路基板6を冷却する構成である。電子冷却素子5等への給電回路図は図3と同様である。 FIG. 5 shows a perspective view of the cooling device of Example 3, and FIG. 6 shows a longitudinal side view of the cooling device of FIG. In these, the same functional parts as those in the first embodiment are denoted by the same reference numerals, and the above description is incorporated. The part different from the form of the first embodiment is that the form of the

そして、実施例1同様に、電子冷却素子5の吸熱部5Aは薄い電気絶縁材16を介して熱良導板17が組み合わされており、容器部12は、その中に入れた水を熱良導板17によって冷却することによって、この水によってビン、缶、ペットボトル等の容器に入れた飲料の被冷却物Hを冷却するのに適する。また、容器部12によって、飲料以外の被冷却物Hの冷却を行うことも可能であり、その場合は、熱良導板17の上に被冷却物Hを載置すればよい。 As in the first embodiment, the

本発明は、高周波誘導磁界発生コイル2Aの磁界中に置いたとき発生する誘起電力によって、ペルチェ素子等の電子冷却素子が作動して、容器部の飲料物等の被冷却物の冷却が行われる冷却装置であるため、本体10の形態や内部構成は上記に限定されず、本発明の技術範囲において種々の構成に適用できる。 In the present invention, an electronic cooling element such as a Peltier element is actuated by induced electric power generated when placed in the magnetic field of the high-frequency induction magnetic

なお、上記冷却装置1の外面に露出するように、切り替えスイッチを設け、このスイッチによって、ペルチェ素子の電子冷却素子5に掛かる直流の(+)(−)の極性を逆にして印加するようにすれば、電子冷却素子5の上記吸熱部5Aが放熱部となり、上記放熱部5Bが吸熱部となるように切り替わる。このように切り替えれば、上記冷却装置1は加温装置となり、容器部12に収容した物品Hの加温が可能となるため、簡易型冷温装置を構成できる。 A changeover switch is provided so as to be exposed on the outer surface of the

1・・・・・冷却装置

2・・・・・電磁誘導加熱装置

2A・・・・高周波誘導磁界発生コイル

3・・・・・台座

4・・・・・受動側コイル

5・・・・・電子冷却素子

5A・・・・吸熱部

5B・・・・放熱部

6・・・・・回路基板

7・・・・・放熱用送風機

8・・・・・放熱用ヒートシンク

10・・・・本体

11・・・・作動部

12・・・・容器部

15・・・・電気絶縁材

16・・・・電気絶縁材

17・・・・熱良導板

18・・・・温度表示部

19・・・・動作表示部

20・・・・交流電源

21・・・・整流部

23・・・・上面開口の受け口

24・・・・容器部の熱良導板の底面壁DESCRIPTION OF

Claims (7)

Translated fromJapanesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005251626AJP4744242B2 (en) | 2005-08-31 | 2005-08-31 | Cooling system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005251626AJP4744242B2 (en) | 2005-08-31 | 2005-08-31 | Cooling system |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2007064557Atrue JP2007064557A (en) | 2007-03-15 |

| JP4744242B2 JP4744242B2 (en) | 2011-08-10 |

Family

ID=37926954

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005251626AExpired - Fee RelatedJP4744242B2 (en) | 2005-08-31 | 2005-08-31 | Cooling system |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4744242B2 (en) |

Cited By (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2008068850A1 (en)* | 2006-12-05 | 2008-06-12 | Kyushu Electric Power Co., Inc. | Cooling device for electromagnetic induction heating cooker |

| WO2009037783A1 (en) | 2007-09-21 | 2009-03-26 | Kyushu Electric Power Co., Inc. | Cooling apparatus for electromagnetic induction heating cooker |

| KR101014978B1 (en)* | 2008-09-23 | 2011-02-16 | 이진영 | Electric Supply Separation Thermoelectric Cooling System |

| WO2011003754A3 (en)* | 2009-07-08 | 2011-03-10 | BSH Bosch und Siemens Hausgeräte GmbH | Refrigeration device |

| JP2012210118A (en)* | 2011-03-30 | 2012-10-25 | Equos Research Co Ltd | Antenna |

| JP2013504740A (en)* | 2009-09-10 | 2013-02-07 | クアルコム,インコーポレイテッド | Wireless power for heating or cooling |

| JP2014504167A (en)* | 2010-11-02 | 2014-02-20 | ピアット テクノロジーズ、 インク. | Tableware and beverage dishes that can be heated or cooled safely in a dishwasher |

| CN103925768A (en)* | 2014-03-27 | 2014-07-16 | 陈永秘 | Beverage thermoelectric cooling device |

| JPWO2013051150A1 (en)* | 2011-10-07 | 2015-03-30 | トヨタ自動車株式会社 | Power receiving device, vehicle including the same, and power transmission system |

| JP2015220992A (en)* | 2014-05-14 | 2015-12-07 | 瀚率テクニクス株式會社 | Heating container |

| JP2017045675A (en)* | 2015-08-28 | 2017-03-02 | 株式会社Lixil | Temperature control system |

| US9782036B2 (en) | 2015-02-24 | 2017-10-10 | Ember Technologies, Inc. | Heated or cooled portable drinkware |

| US9801482B1 (en) | 2016-05-12 | 2017-10-31 | Ember Technologies, Inc. | Drinkware and plateware and active temperature control module for same |

| US9814331B2 (en) | 2010-11-02 | 2017-11-14 | Ember Technologies, Inc. | Heated or cooled dishware and drinkware |

| WO2017208339A1 (en)* | 2016-05-31 | 2017-12-07 | 三菱電機株式会社 | Cold storage device |

| JP2017537288A (en)* | 2014-09-16 | 2017-12-14 | フェローテック(ユーエスエー)コーポレイション | Integrated fluid heat exchanger and fluid heat exchange method |

| US9863695B2 (en) | 2016-05-02 | 2018-01-09 | Ember Technologies, Inc. | Heated or cooled drinkware |

| US10010213B2 (en) | 2010-11-02 | 2018-07-03 | Ember Technologies, Inc. | Heated or cooled dishware and drinkware and food containers |

| US10383476B2 (en) | 2016-09-29 | 2019-08-20 | Ember Technologies, Inc. | Heated or cooled drinkware |

| CN110300536A (en)* | 2017-02-28 | 2019-10-01 | 雀巢产品有限公司 | For in the cooling equipment of beverage for preparing cooling beverage with clock synchronization with beverage preparation machine |

| US10433672B2 (en) | 2018-01-31 | 2019-10-08 | Ember Technologies, Inc. | Actively heated or cooled infant bottle system |

| US10670323B2 (en) | 2018-04-19 | 2020-06-02 | Ember Technologies, Inc. | Portable cooler with active temperature control |

| WO2020240740A1 (en)* | 2019-05-29 | 2020-12-03 | 三菱電機株式会社 | Cooling device and cooking system |

| US10989466B2 (en) | 2019-01-11 | 2021-04-27 | Ember Technologies, Inc. | Portable cooler with active temperature control |

| US11118827B2 (en) | 2019-06-25 | 2021-09-14 | Ember Technologies, Inc. | Portable cooler |

| US11162716B2 (en) | 2019-06-25 | 2021-11-02 | Ember Technologies, Inc. | Portable cooler |

| KR20230023946A (en)* | 2021-08-11 | 2023-02-20 | 주식회사 델타써모 | A Subminiature Separate Air Conditioner Without Outdoor Unit |

| US11668508B2 (en) | 2019-06-25 | 2023-06-06 | Ember Technologies, Inc. | Portable cooler |

| US11950726B2 (en) | 2010-11-02 | 2024-04-09 | Ember Technologies, Inc. | Drinkware container with active temperature control |

| US12013157B2 (en) | 2020-04-03 | 2024-06-18 | Ember Lifesciences, Inc. | Portable cooler with active temperature control |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013100950A (en)* | 2011-11-09 | 2013-05-23 | Panasonic Corp | Cooling device |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04341790A (en)* | 1991-05-17 | 1992-11-27 | Mitsubishi Electric Home Appliance Co Ltd | High frequency induction heating cooker |

| JPH07269897A (en)* | 1994-03-31 | 1995-10-20 | Matsushita Electric Works Ltd | Cold air apparatus |

| JPH08838A (en)* | 1994-06-20 | 1996-01-09 | Taiyo Kogyo Kk | Vehicle toy of electromagnetic induction charging system |

| JPH1120535A (en)* | 1997-06-30 | 1999-01-26 | S I Electron:Kk | Cooling or warming device for automobile |

| JPH11270122A (en)* | 1998-03-24 | 1999-10-05 | Toyota Autom Loom Works Ltd | Storing device |

| JP2000301138A (en)* | 1999-04-21 | 2000-10-31 | Mitsubishi Rayon Co Ltd | Water purifier with cooling function |

| JP2001151278A (en)* | 1999-11-26 | 2001-06-05 | Sanyo Electric Co Ltd | Heating and cooling device |

| JP2001307302A (en)* | 2000-04-21 | 2001-11-02 | Fujitsu Ltd | Optical head for magneto-optical recording |

| JP2003086748A (en)* | 2001-09-13 | 2003-03-20 | Funai Electric Co Ltd | Radiator for cooling semiconductor device |

| JP2003287316A (en)* | 2002-03-28 | 2003-10-10 | Matsushita Refrig Co Ltd | Water feeder |

| JP2004079560A (en)* | 2002-08-09 | 2004-03-11 | Komatsu Electronics Inc | Methods of driving and controlling thermoelectric conversion element module |

| JP2005117987A (en)* | 2003-10-17 | 2005-05-12 | Thermogen Kk | Device for amplifying dna |

- 2005

- 2005-08-31JPJP2005251626Apatent/JP4744242B2/ennot_activeExpired - Fee Related

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04341790A (en)* | 1991-05-17 | 1992-11-27 | Mitsubishi Electric Home Appliance Co Ltd | High frequency induction heating cooker |

| JPH07269897A (en)* | 1994-03-31 | 1995-10-20 | Matsushita Electric Works Ltd | Cold air apparatus |

| JPH08838A (en)* | 1994-06-20 | 1996-01-09 | Taiyo Kogyo Kk | Vehicle toy of electromagnetic induction charging system |

| JPH1120535A (en)* | 1997-06-30 | 1999-01-26 | S I Electron:Kk | Cooling or warming device for automobile |

| JPH11270122A (en)* | 1998-03-24 | 1999-10-05 | Toyota Autom Loom Works Ltd | Storing device |

| JP2000301138A (en)* | 1999-04-21 | 2000-10-31 | Mitsubishi Rayon Co Ltd | Water purifier with cooling function |

| JP2001151278A (en)* | 1999-11-26 | 2001-06-05 | Sanyo Electric Co Ltd | Heating and cooling device |

| JP2001307302A (en)* | 2000-04-21 | 2001-11-02 | Fujitsu Ltd | Optical head for magneto-optical recording |

| JP2003086748A (en)* | 2001-09-13 | 2003-03-20 | Funai Electric Co Ltd | Radiator for cooling semiconductor device |

| JP2003287316A (en)* | 2002-03-28 | 2003-10-10 | Matsushita Refrig Co Ltd | Water feeder |

| JP2004079560A (en)* | 2002-08-09 | 2004-03-11 | Komatsu Electronics Inc | Methods of driving and controlling thermoelectric conversion element module |

| JP2005117987A (en)* | 2003-10-17 | 2005-05-12 | Thermogen Kk | Device for amplifying dna |

Cited By (73)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPWO2008068850A1 (en)* | 2006-12-05 | 2010-03-11 | 九州電力株式会社 | Cooling device for electromagnetic induction heating cooker |

| JP5030971B2 (en)* | 2006-12-05 | 2012-09-19 | 九州電力株式会社 | Cooling device for electromagnetic induction heating cooker |

| WO2008068850A1 (en)* | 2006-12-05 | 2008-06-12 | Kyushu Electric Power Co., Inc. | Cooling device for electromagnetic induction heating cooker |

| WO2009037783A1 (en) | 2007-09-21 | 2009-03-26 | Kyushu Electric Power Co., Inc. | Cooling apparatus for electromagnetic induction heating cooker |

| KR101014978B1 (en)* | 2008-09-23 | 2011-02-16 | 이진영 | Electric Supply Separation Thermoelectric Cooling System |

| WO2011003754A3 (en)* | 2009-07-08 | 2011-03-10 | BSH Bosch und Siemens Hausgeräte GmbH | Refrigeration device |

| JP2014224674A (en)* | 2009-09-10 | 2014-12-04 | クアルコム,インコーポレイテッド | Wireless power for heating or cooling |

| JP2013504740A (en)* | 2009-09-10 | 2013-02-07 | クアルコム,インコーポレイテッド | Wireless power for heating or cooling |

| US10743708B2 (en) | 2010-11-02 | 2020-08-18 | Ember Technologies, Inc. | Portable cooler container with active temperature control |

| US10188229B2 (en) | 2010-11-02 | 2019-01-29 | Ember Technologies, Inc. | Heated or cooled dishware and drinkware |

| JP2014504167A (en)* | 2010-11-02 | 2014-02-20 | ピアット テクノロジーズ、 インク. | Tableware and beverage dishes that can be heated or cooled safely in a dishwasher |

| US11771260B2 (en) | 2010-11-02 | 2023-10-03 | Ember Technologies, Inc. | Drinkware container with active temperature control |

| US11089891B2 (en) | 2010-11-02 | 2021-08-17 | Ember Technologies, Inc. | Portable cooler container with active temperature control |

| US11083332B2 (en) | 2010-11-02 | 2021-08-10 | Ember Technologies, Inc. | Portable cooler container with active temperature control |

| US11771261B2 (en) | 2010-11-02 | 2023-10-03 | Ember Technologies, Inc. | Drinkware container with active temperature control |

| US11950726B2 (en) | 2010-11-02 | 2024-04-09 | Ember Technologies, Inc. | Drinkware container with active temperature control |

| US12035843B2 (en) | 2010-11-02 | 2024-07-16 | Ember Technologies, Inc. | Dishware or serverware with active temperature control |

| US12185870B2 (en) | 2010-11-02 | 2025-01-07 | Ember Technologies, Inc. | Drinkware with active temperature control |

| US9814331B2 (en) | 2010-11-02 | 2017-11-14 | Ember Technologies, Inc. | Heated or cooled dishware and drinkware |

| US10010213B2 (en) | 2010-11-02 | 2018-07-03 | Ember Technologies, Inc. | Heated or cooled dishware and drinkware and food containers |

| US9974401B2 (en) | 2010-11-02 | 2018-05-22 | Ember Technologies, Inc. | Heated or cooled dishware and drinkware |

| JP2012210118A (en)* | 2011-03-30 | 2012-10-25 | Equos Research Co Ltd | Antenna |

| JPWO2013051150A1 (en)* | 2011-10-07 | 2015-03-30 | トヨタ自動車株式会社 | Power receiving device, vehicle including the same, and power transmission system |

| US9721722B2 (en) | 2011-10-07 | 2017-08-01 | Toyota Jidosha Kabushiki Kaisha | Power reception device, vehicle including power reception device, and power transfer system |

| US10876771B2 (en) | 2013-04-19 | 2020-12-29 | Ferrotec (USA) America | Integrated thermoelectric-powered fluid heat exchanger |

| CN103925768A (en)* | 2014-03-27 | 2014-07-16 | 陈永秘 | Beverage thermoelectric cooling device |

| JP2015220992A (en)* | 2014-05-14 | 2015-12-07 | 瀚率テクニクス株式會社 | Heating container |

| JP2017537288A (en)* | 2014-09-16 | 2017-12-14 | フェローテック(ユーエスエー)コーポレイション | Integrated fluid heat exchanger and fluid heat exchange method |

| US9782036B2 (en) | 2015-02-24 | 2017-10-10 | Ember Technologies, Inc. | Heated or cooled portable drinkware |

| US10098498B2 (en) | 2015-02-24 | 2018-10-16 | Ember Technologies, Inc. | Heated or cooled portable drinkware |

| US10413119B2 (en) | 2015-02-24 | 2019-09-17 | Ember Technologies, Inc. | Heated or cooled portable drinkware |

| JP2017045675A (en)* | 2015-08-28 | 2017-03-02 | 株式会社Lixil | Temperature control system |

| WO2017038153A1 (en)* | 2015-08-28 | 2017-03-09 | 株式会社Lixil | Temperature control system |

| US10995979B2 (en) | 2016-05-02 | 2021-05-04 | Ember Technologies, Inc. | Heated or cooled drinkware |

| US9863695B2 (en) | 2016-05-02 | 2018-01-09 | Ember Technologies, Inc. | Heated or cooled drinkware |

| US10182674B2 (en) | 2016-05-12 | 2019-01-22 | Ember Technologies, Inc. | Drinkware with active temperature control |

| US9801482B1 (en) | 2016-05-12 | 2017-10-31 | Ember Technologies, Inc. | Drinkware and plateware and active temperature control module for same |

| US11871860B2 (en) | 2016-05-12 | 2024-01-16 | Ember Technologies, Inc. | Drinkware with active temperature control |

| WO2017208339A1 (en)* | 2016-05-31 | 2017-12-07 | 三菱電機株式会社 | Cold storage device |

| JPWO2017208339A1 (en)* | 2016-05-31 | 2018-08-09 | 三菱電機株式会社 | Cooler |

| US10383476B2 (en) | 2016-09-29 | 2019-08-20 | Ember Technologies, Inc. | Heated or cooled drinkware |

| CN110300536A (en)* | 2017-02-28 | 2019-10-01 | 雀巢产品有限公司 | For in the cooling equipment of beverage for preparing cooling beverage with clock synchronization with beverage preparation machine |

| US11529020B2 (en) | 2017-02-28 | 2022-12-20 | Societe Des Produits Nestle S.A. | Beverage cooling device for preparing cooled beverage when paired with a beverage preparation machine |

| CN110300536B (en)* | 2017-02-28 | 2021-12-28 | 雀巢产品有限公司 | Beverage cooling device for preparing a cooled beverage when mated with a beverage preparation machine |

| US11395559B2 (en) | 2018-01-31 | 2022-07-26 | Ember Technologies, Inc. | Infant bottle system |

| US10433672B2 (en) | 2018-01-31 | 2019-10-08 | Ember Technologies, Inc. | Actively heated or cooled infant bottle system |

| US11517145B2 (en) | 2018-01-31 | 2022-12-06 | Ember Technologies, Inc. | Infant bottle system |

| US10941972B2 (en) | 2018-04-19 | 2021-03-09 | Ember Technologies, Inc. | Portable cooler with active temperature control |

| US11067327B2 (en) | 2018-04-19 | 2021-07-20 | Ember Technologies, Inc. | Portable cooler with active temperature control |

| US12410964B2 (en) | 2018-04-19 | 2025-09-09 | Yeti Coolers, Llc | Portable cooler with active temperature control |

| US10670323B2 (en) | 2018-04-19 | 2020-06-02 | Ember Technologies, Inc. | Portable cooler with active temperature control |

| US10852047B2 (en) | 2018-04-19 | 2020-12-01 | Ember Technologies, Inc. | Portable cooler with active temperature control |

| US11927382B2 (en) | 2018-04-19 | 2024-03-12 | Ember Technologies, Inc. | Portable cooler with active temperature control |

| US10989466B2 (en) | 2019-01-11 | 2021-04-27 | Ember Technologies, Inc. | Portable cooler with active temperature control |

| JP7112036B2 (en) | 2019-05-29 | 2022-08-03 | 三菱電機株式会社 | Cooling system and cooking system |

| JPWO2020240740A1 (en)* | 2019-05-29 | 2021-11-04 | 三菱電機株式会社 | Cooling device and cooking system |

| WO2020240740A1 (en)* | 2019-05-29 | 2020-12-03 | 三菱電機株式会社 | Cooling device and cooking system |

| US11668508B2 (en) | 2019-06-25 | 2023-06-06 | Ember Technologies, Inc. | Portable cooler |

| US12146706B1 (en) | 2019-06-25 | 2024-11-19 | Ember Technologies, Inc. | Portable cooler |

| US11719480B2 (en) | 2019-06-25 | 2023-08-08 | Ember Technologies, Inc. | Portable container |

| US11466919B2 (en) | 2019-06-25 | 2022-10-11 | Ember Technologies, Inc. | Portable cooler |

| US11365926B2 (en) | 2019-06-25 | 2022-06-21 | Ember Technologies, Inc. | Portable cooler |

| US12379145B2 (en) | 2019-06-25 | 2025-08-05 | Yeti Coolers, Llc | Portable container |

| US12372288B2 (en) | 2019-06-25 | 2025-07-29 | Yeti Coolers, Llc | Portable cooler |

| US11118827B2 (en) | 2019-06-25 | 2021-09-14 | Ember Technologies, Inc. | Portable cooler |

| US11162716B2 (en) | 2019-06-25 | 2021-11-02 | Ember Technologies, Inc. | Portable cooler |

| US12320584B2 (en) | 2019-06-25 | 2025-06-03 | Yeti Coolers, Llc | Portable cooler |

| US12331991B2 (en) | 2019-06-25 | 2025-06-17 | Yeti Coolers, Llc | Portable cooler |

| US12352493B2 (en) | 2019-06-25 | 2025-07-08 | Yeti Coolers, Llc | Portable container |

| US12366399B2 (en) | 2019-06-25 | 2025-07-22 | Yeti Coolers, Llc | Portable container |

| US12013157B2 (en) | 2020-04-03 | 2024-06-18 | Ember Lifesciences, Inc. | Portable cooler with active temperature control |

| KR20230023946A (en)* | 2021-08-11 | 2023-02-20 | 주식회사 델타써모 | A Subminiature Separate Air Conditioner Without Outdoor Unit |

| KR102548781B1 (en)* | 2021-08-11 | 2023-06-28 | 성순아 | A Subminiature Separate Air Conditioner Without Outdoor Unit |

Also Published As

| Publication number | Publication date |

|---|---|

| JP4744242B2 (en) | 2011-08-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4744242B2 (en) | Cooling system | |

| JP6403314B2 (en) | ELECTRIC INSULATION AND COOLING CONTAINER USING WIRELESS POWER TRANSFER, ELECTRIC INSULATION AND COOLING DEVICE USING THE SAME | |

| ES2560256T3 (en) | Induction heating cooker | |

| RU2012115333A (en) | MULTI-FUNCTION TOUCH COOLING HOLDER-HOLDER | |

| KR20120006993U (en) | cup having heating and cooling function | |

| JP6564281B2 (en) | Temperature control system | |

| WO2020008557A1 (en) | Table-type cooking device | |

| JP2014211247A (en) | Cooling device | |

| JP2009011574A (en) | Cooling device and body storage device using the same | |

| US11166595B2 (en) | Food processor | |

| JP2013100950A (en) | Cooling device | |

| JP2014134339A (en) | Cooling device | |

| CN207744983U (en) | A kind of automatic Washing cup of ultrasonic wave of wireless charging refrigeration | |

| JP2005063777A (en) | Electromagnetic induction heating cooker | |

| CN207940766U (en) | A kind of soy bean milk making machine | |

| WO2017077587A1 (en) | Portable cooling device | |

| KR101237861B1 (en) | Portable apparatus for supplying cool and hot drink | |

| CN209944876U (en) | Refrigerating device | |

| TWM509270U (en) | Stirring device of thermal energy conversion power generation | |

| KR200444959Y1 (en) | Desktop Cooling System Using Thermoelectric Module | |

| JP3928601B2 (en) | Induction heating cooker | |

| TWI607156B (en) | Ceiling fan controller cooling structure | |

| KR20100121092A (en) | Table type cooling apparatus of using thermoelectric module | |

| CN223261810U (en) | Magnetic radiator | |

| TWM511280U (en) | Cold and hot water bottle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination | Free format text:JAPANESE INTERMEDIATE CODE: A621 Effective date:20071122 | |

| A977 | Report on retrieval | Free format text:JAPANESE INTERMEDIATE CODE: A971007 Effective date:20091214 | |

| A131 | Notification of reasons for refusal | Free format text:JAPANESE INTERMEDIATE CODE: A131 Effective date:20100105 | |

| A521 | Request for written amendment filed | Free format text:JAPANESE INTERMEDIATE CODE: A523 Effective date:20100119 | |

| A131 | Notification of reasons for refusal | Free format text:JAPANESE INTERMEDIATE CODE: A131 Effective date:20100914 | |

| A521 | Request for written amendment filed | Free format text:JAPANESE INTERMEDIATE CODE: A523 Effective date:20101101 | |

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) | Free format text:JAPANESE INTERMEDIATE CODE: A01 Effective date:20110412 | |

| A61 | First payment of annual fees (during grant procedure) | Free format text:JAPANESE INTERMEDIATE CODE: A61 Effective date:20110510 | |

| FPAY | Renewal fee payment (event date is renewal date of database) | Free format text:PAYMENT UNTIL: 20140520 Year of fee payment:3 | |

| R151 | Written notification of patent or utility model registration | Ref document number:4744242 Country of ref document:JP Free format text:JAPANESE INTERMEDIATE CODE: R151 | |

| FPAY | Renewal fee payment (event date is renewal date of database) | Free format text:PAYMENT UNTIL: 20140520 Year of fee payment:3 | |

| S111 | Request for change of ownership or part of ownership | Free format text:JAPANESE INTERMEDIATE CODE: R313113 | |

| FPAY | Renewal fee payment (event date is renewal date of database) | Free format text:PAYMENT UNTIL: 20140520 Year of fee payment:3 | |

| R350 | Written notification of registration of transfer | Free format text:JAPANESE INTERMEDIATE CODE: R350 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| S531 | Written request for registration of change of domicile | Free format text:JAPANESE INTERMEDIATE CODE: R313531 | |

| S533 | Written request for registration of change of name | Free format text:JAPANESE INTERMEDIATE CODE: R313533 | |

| R350 | Written notification of registration of transfer | Free format text:JAPANESE INTERMEDIATE CODE: R350 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| S533 | Written request for registration of change of name | Free format text:JAPANESE INTERMEDIATE CODE: R313533 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R371 | Transfer withdrawn | Free format text:JAPANESE INTERMEDIATE CODE: R371 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| S531 | Written request for registration of change of domicile | Free format text:JAPANESE INTERMEDIATE CODE: R313531 | |

| S533 | Written request for registration of change of name | Free format text:JAPANESE INTERMEDIATE CODE: R313533 | |

| R350 | Written notification of registration of transfer | Free format text:JAPANESE INTERMEDIATE CODE: R350 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| R250 | Receipt of annual fees | Free format text:JAPANESE INTERMEDIATE CODE: R250 | |

| LAPS | Cancellation because of no payment of annual fees |