JP2006118088A - Muscle protection reinforced clothes - Google Patents

Muscle protection reinforced clothesDownload PDFInfo

- Publication number

- JP2006118088A JP2006118088AJP2004306771AJP2004306771AJP2006118088AJP 2006118088 AJP2006118088 AJP 2006118088AJP 2004306771 AJP2004306771 AJP 2004306771AJP 2004306771 AJP2004306771 AJP 2004306771AJP 2006118088 AJP2006118088 AJP 2006118088A

- Authority

- JP

- Japan

- Prior art keywords

- tightening

- main body

- elastic material

- clothing

- rubber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 210000003205muscleAnatomy0.000titleclaimsabstractdescription25

- 239000000463materialSubstances0.000claimsabstractdescription33

- 239000004744fabricSubstances0.000claimsabstractdescription22

- 229920001971elastomerPolymers0.000claimsabstractdescription19

- 238000007639printingMethods0.000claimsabstractdescription13

- 229920002379silicone rubberPolymers0.000claimsabstractdescription12

- 239000013013elastic materialSubstances0.000claimsdescription57

- 238000005728strengtheningMethods0.000claimsdescription18

- 230000003387muscularEffects0.000claimsdescription12

- 230000002787reinforcementEffects0.000claimsdescription5

- 238000005516engineering processMethods0.000abstractdescription7

- 238000004519manufacturing processMethods0.000abstractdescription5

- 230000000452restraining effectEffects0.000abstract6

- 239000004945silicone rubberSubstances0.000abstract1

- 239000000839emulsionSubstances0.000description10

- 210000003141lower extremityAnatomy0.000description9

- 238000007650screen-printingMethods0.000description8

- 238000000034methodMethods0.000description6

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description4

- XTXRWKRVRITETP-UHFFFAOYSA-NVinyl acetateChemical compoundCC(=O)OC=CXTXRWKRVRITETP-UHFFFAOYSA-N0.000description3

- 238000001723curingMethods0.000description3

- 238000010438heat treatmentMethods0.000description3

- 210000000629knee jointAnatomy0.000description3

- 239000002994raw materialSubstances0.000description3

- 238000005406washingMethods0.000description3

- SMZOUWXMTYCWNB-UHFFFAOYSA-N2-(2-methoxy-5-methylphenyl)ethanamineChemical compoundCOC1=CC=C(C)C=C1CCNSMZOUWXMTYCWNB-UHFFFAOYSA-N0.000description2

- NIXOWILDQLNWCW-UHFFFAOYSA-N2-Propenoic acidNatural productsOC(=O)C=CNIXOWILDQLNWCW-UHFFFAOYSA-N0.000description2

- 239000000853adhesiveSubstances0.000description2

- 230000001070adhesive effectEffects0.000description2

- 210000003423ankleAnatomy0.000description2

- 210000002310elbow jointAnatomy0.000description2

- 238000004049embossingMethods0.000description2

- 239000000835fiberSubstances0.000description2

- 238000011084recoveryMethods0.000description2

- 238000009958sewingMethods0.000description2

- 229920000459Nitrile rubberPolymers0.000description1

- 239000004952PolyamideSubstances0.000description1

- 229920006311Urethane elastomerPolymers0.000description1

- 238000005299abrasionMethods0.000description1

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000description1

- 229910052782aluminiumInorganic materials0.000description1

- 210000000544articulatio talocruralisAnatomy0.000description1

- 229920005549butyl rubberPolymers0.000description1

- 238000006243chemical reactionMethods0.000description1

- 239000003795chemical substances by applicationSubstances0.000description1

- 239000011248coating agentSubstances0.000description1

- 238000000576coating methodMethods0.000description1

- 238000006482condensation reactionMethods0.000description1

- 229920001577copolymerPolymers0.000description1

- 238000005520cutting processMethods0.000description1

- 238000013007heat curingMethods0.000description1

- 210000003127kneeAnatomy0.000description1

- 230000007257malfunctionEffects0.000description1

- 239000000203mixtureSubstances0.000description1

- 230000002093peripheral effectEffects0.000description1

- 239000000049pigmentSubstances0.000description1

- 229920002647polyamidePolymers0.000description1

- 229920000728polyesterPolymers0.000description1

- 229920006149polyester-amide block copolymerPolymers0.000description1

- 229920002635polyurethanePolymers0.000description1

- 239000004814polyurethaneSubstances0.000description1

- 239000011347resinSubstances0.000description1

- 229920005989resinPolymers0.000description1

- 230000000475sunscreen effectEffects0.000description1

- 239000000516sunscreening agentSubstances0.000description1

- 239000004094surface-active agentSubstances0.000description1

- 210000002435tendonAnatomy0.000description1

- 210000000689upper legAnatomy0.000description1

Images

Landscapes

- Professional, Industrial, Or Sporting Protective Garments (AREA)

Abstract

Description

Translated fromJapanese本発明は、体に密着して着用される筒状の衣料本体から主として成る衣料であって、衣料本体に被着された緊締用伸縮素材により着用者の筋肉を保護し強化する筋肉保護強化衣料に関する。 The present invention is a garment mainly composed of a cylindrical garment body that is worn in close contact with the body, and protects and strengthens the wearer's muscles with a stretchable elastic material attached to the garment body. About.

従来、この種の筋肉保護強化衣料は、例えば下記の特許文献1に記載されたものが知られている。前記文献開示の筋肉保護強化衣料を図5に示す。図示の筋肉保護強化衣料はトレーナ下衣52であり、股上部55および左右の下肢部56,56を有するタイツ状に縫製された衣料本体Cと、衣料本体C表面の、体表を緊締しようとする所定位置に重ね合せて縫い付けられた緊締用伸縮素材とからなっている。衣料本体Cは伸縮性生地で構成されている。緊締用伸縮素材としては、衣料本体Cとは別の伸縮性生地57,58、またはゴム入り生地が使用され、それぞれの布縁部分59が衣料本体Cに縫い付けられている。縫い付けの替わりに接着剤で貼り合わせたものも知られている。かかるトレーナ下衣52は、衣料本体Cが着用者の体にぴったりとフィットした状態で緊締用伸縮素材が筋肉を締め付けて保護したり強化するようになっている。このような筋肉保護強化衣料は、スポーツ用においては筋肉の強化を主目的とし、リハビリテーション用においては筋肉の保護を主目的として使用されている。 Conventionally, as for this kind of muscular protection reinforcement clothing, what was indicated in the following

前記したように、従来の筋肉保護強化衣料(トレーナ下衣52)では、伸縮性生地からなる衣料本体Cと伸縮性生地57,58やゴム入り生地といったように、伸縮性を有する生地同士を所定位置に位置決めして縫い合わさなければならない。すなわち、一方の生地を固定して他方の生地を縫い付ける作業が必要となるため、縫い付け作業に慎重を期さなければならないことから、作業に多大な手間と時間がかかるうえ熟練を要し、大量生産に不向きであった。これは接着剤を用いた貼り付け作業による場合も同様である。また、緊締用伸縮素材の形状を変更する場合は緊締用伸縮素材の裁断用型紙を作り直さなければならず、デザイン変更の自由度が小さかった。また、緊締用伸縮素材が小さい場合は縫い付けできないこともある。 As described above, in the conventional muscular protection strengthening garment (trainer lower garment 52), the cloth body C made of a stretchable cloth, the

本発明は、上記した従来の問題点に鑑みてなされたものであって、衣料本体に緊締用伸縮素材を被着する作業に手間と時間がかからず大量生産向きの筋肉保護強化衣料の提供を目的とする。 The present invention has been made in view of the above-described conventional problems, and provides a muscular protection-strengthened garment suitable for mass production without requiring labor and time for attaching a stretchable elastic material to the garment body. With the goal.

上記目的を達成するために、本発明に係る筋肉保護強化衣料は、伸縮性生地からなる衣料本体の所定位置に緊締用伸縮素材が被着された衣料であって、緊締用伸縮素材が、印刷により衣料本体に被着されたゴム質材料で構成されているものである。 In order to achieve the above object, the muscular protection strengthening garment according to the present invention is a garment in which an elastic material for tightening is attached to a predetermined position of a clothing body made of an elastic fabric, and the elastic material for tightening is printed. It is comprised with the rubber-like material adhere | attached on the clothing main body by.

また、前記構成において、ゴム質材料がシリコンゴムで構成されているものである。 Further, in the above configuration, the rubber material is made of silicon rubber.

そして、前記した各構成において、緊締用伸縮素材が衣料本体外面の所定位置に被着されており、緊締用伸縮素材が透明ないし半透明になっているものである。 In each of the above-described configurations, the elastic material for tightening is attached to a predetermined position on the outer surface of the clothing body, and the elastic material for tightening is transparent or translucent.

本発明に係る筋肉保護強化衣料によれば、ゴム質材料製の緊締用伸縮素材が印刷により衣料本体に被着されるので、緊締用伸縮素材の被着作業が手間をかけずに短時間に行なえて、筋肉保護強化衣料を大量に生産することができる。また、近年の画像処理技術や印刷技術などの向上により、複雑なデザインパターンの緊締用伸縮素材であっても鮮明に印刷でき、デザイン変更も容易である。 According to the muscular protection strengthening garment according to the present invention, the elastic material for tightening made of rubber material is attached to the clothing main body by printing, so that the work for attaching the elastic material for tightening can be done in a short time without trouble. In addition, it is possible to produce a large amount of clothing for strengthening muscle protection. In addition, with recent improvements in image processing technology and printing technology, it is possible to print clearly even for elastic materials for tightening with complex design patterns, and design changes are easy.

また、ゴム質材料がシリコンゴムで構成されている場合、シリコンゴム製のゴム質材料は広い温度範囲で良好な弾性を保ち、耐熱性、耐水性、耐磨耗性、洗濯堅牢性に富み、人体無害である。また、強く引っ張ってもヒビ割れや断裂を生じにくい。 In addition, when the rubber material is made of silicon rubber, the rubber material made of silicon rubber maintains good elasticity over a wide temperature range, and is rich in heat resistance, water resistance, wear resistance, and washing fastness, It is harmless to the human body. Moreover, even if it pulls strongly, it is hard to produce a crack and a tear.

そして、衣料本体の外面に対し透明ないし半透明の緊締用伸縮素材を被着する場合は、緊締用伸縮素材を透して衣料本体の外面を視認することができる。これにより、衣料本体そのもの、或いは衣料本体の外面に描かれている模様や文字を外部から見ることができる。 When a transparent or translucent tightening elastic material is attached to the outer surface of the clothing body, the outer surface of the clothing body can be visually recognized through the tightening elastic material. Thereby, the clothing main body itself or the pattern and character currently drawn on the outer surface of the clothing main body can be seen from the outside.

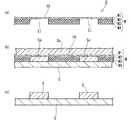

本発明の最良の実施形態を図面に基づいて説明する。尚、以下に述べる実施形態は本発明を具体化した一例に過ぎず、本発明の技術的範囲を限定するものでない。ここに、図1は本発明の一実施形態に係る筋肉保護強化衣料に用いる生地を展開した状態を示す平面図、図2は図1におけるA−A線矢視断面図である。

各図において、この実施形態に係る筋肉保護強化衣料の衣料本体Cは伸縮性生地で構成されている。衣料本体Cの表面には緊締用伸縮素材Sが被着されている。衣料本体Cの伸縮性生地は、例えばポリウレタン、ポリエステル、ポリアミドの混紡糸で編成された伸縮性を有する生地である。緊締用伸縮素材Sは、常温でゴム弾性、すなわち伸ばすと2倍以上に伸び、外力を取り除くとほぼ元に復元する性質を有するゴム質材料で構成されており、この例ではシリコンゴムを使用してある。The best mode for carrying out the present invention will be described with reference to the drawings. The embodiment described below is merely an example embodying the present invention, and does not limit the technical scope of the present invention. Here, FIG. 1 is a plan view showing a developed state of the fabric used in the muscle protection strengthening garment according to one embodiment of the present invention, and FIG. 2 is a cross-sectional view taken along line AA in FIG.

In each figure, the clothing main body C of the muscle protection strengthening clothing according to this embodiment is made of a stretchable fabric. An elastic material S for tightening is attached to the surface of the clothing main body C. The stretchable fabric of the clothing main body C is a stretchable fabric knitted with, for example, a blended yarn of polyurethane, polyester, and polyamide. The elastic material S for tightening is composed of a rubber material that has rubber elasticity at room temperature, that is, stretches more than twice when stretched, and restores to its original state when the external force is removed. In this example, silicon rubber is used. It is.

図1および図2に示した衣料本体Cの伸縮性生地は、後述するトレーナ上衣1の袖部4(図4参照)に使用される布地を平たく展開した状態で示してある。この衣料本体Cの布地には略V字状に屈折した形容の緊締用伸縮素材S1〜S7が、図1の手前から順に適宜間隔で配置されている。かかる緊締用伸縮素材S1〜S7の所定配置により、袖部4用のパターンP1が形成される。 The stretchable fabric of the garment body C shown in FIGS. 1 and 2 is shown in a state where a fabric used for a sleeve portion 4 (see FIG. 4) of a trainer

ここで、前記した緊締用伸縮素材Sを衣料本体Cに被着する例を図3に示す。この例ではシルクスクリーン印刷用のスクリーン版Bが用いられる。まず、アルミニウム周枠(図示省略)の枠内に紗10を張り、紗10の片面に感光乳剤を塗布し、塗布した感光乳剤の層M1を加熱してその表面を硬化させ、更に、硬化した乳剤層表面への感光乳剤の塗布、および、塗布した乳剤層表面の加熱硬化を繰り返して、4層に積層した乳剤層M1,M2,M3,M4から成る厚型版Mを得た。その後の十分な加熱により硬化した厚型版Mの厚さは約400μmであった。尚、厚型版Mの厚さを50〜700μm程度にしておくと、緊締力が十分に強く、しかも洗濯堅牢度の高い緊締用伸縮素材Sが得られる。乳剤層の積層数は、要求される厚型版Mの厚さに応じて選定すればよい。 Here, FIG. 3 shows an example in which the elastic material S for tightening described above is attached to the clothing main body C. FIG. In this example, a screen plate B for silk screen printing is used. First, a

この例で用いた紗10は目開き1200メッシュでポリエステル微細繊維製である。また、感光乳剤としては例えば酢酸ビニル・アクリル酸系エマルジョンを用いた。この酢酸ビニル・アクリル酸系エマルジョンは、酢酸ビニル・アクリル酸エステル共重合体および汎用感光性樹脂の混合物45〜55重量部を少量の界面活性剤により水45〜55重量部中に分散させたものである。

次に、パターンP1(後述のP2〜P5も同様)に対応した遮光パターンが描かれているフィルムで厚型版Mの表面を被い、紫外線を照射して厚型版Mの遮光パターン以外の部分を硬化させる。スクリーン版Bを水洗すると、遮光パターンで被われていた遮光部分が洗い流されて、図3(a)に示すような緊締用伸縮素材Sを印刷用の版孔11が厚型版Mに形成される。The

Next, the surface of the thick plate M is covered with a film on which a light-shielding pattern corresponding to the pattern P1 (the same applies to P2 to P5 described later) is drawn, and irradiated with ultraviolet rays, other than the light-shielding pattern of the thick plate M. Harden the part. When the screen plate B is washed with water, the light-shielding portion covered with the light-shielding pattern is washed away, and the elastic plate S for tightening as shown in FIG. The

この実施形態では、スクリーン版Bに使用される印刷インクの代わりに、未硬化のシリコンゴム原料を用いた。ここでは、未硬化シリコンゴム原料(硬化反応機構が付加型である信越化学工業社製の製品名KE−1300T)100gに、硬化剤(信越化学工業社製のCAT−1300(製品名)、またはCLA−4(製品名))10gを混練して、ペースト状物を調製した。尚、未硬化シリコンゴム原料として、硬化反応機構が縮合型のものを用いても構わない。

そして、厚型版Mを下側に配したスクリーン版Bを衣料本体Cの上におき(同図(b))、前記のように調製したペースト状物Saをスクリーン版B上に供給しスクイーズ(図示省略)で展ばすと、ペースト状物Saが紗10を透過して版孔11,11内に充填される。版孔11,11内のペースト状物Saは衣料本体Cの繊維間に入り込んで衣料本体Cに密着する。

その後、スクリーン版Bを衣料本体Cから引き離すと、版孔11内のペースト状物Saを伴った衣料本体Cが現われる。この衣料本体Cは加熱炉(図示省略)で例えば130℃、3分間加熱されることにより、ペースト状物Saが硬化して、同図(c)のようにシリコンゴムから成るほぼ透明な緊締用伸縮素材S,Sとなる。但し、ペースト状物Saの硬化に要する加熱温度および時間は前記に限定されない。In this embodiment, an uncured silicon rubber raw material was used in place of the printing ink used for the screen plate B. Here, the curing agent (CAT-1300 (product name) manufactured by Shin-Etsu Chemical Co., Ltd.), or 100 g of uncured silicon rubber raw material (product name KE-1300T manufactured by Shin-Etsu Chemical Co., Ltd., which has an addition type curing reaction mechanism), or CLA-4 (product name)) 10 g was kneaded to prepare a paste. As the uncured silicon rubber raw material, a material having a condensation reaction mechanism may be used.

Then, the screen plate B with the thick plate M placed on the lower side is placed on the clothing body C ((b) in the figure), and the paste material Sa prepared as described above is supplied onto the screen plate B and squeezed. When unfolded (not shown), the paste-like material Sa passes through the

Thereafter, when the screen plate B is pulled away from the clothing main body C, the clothing main body C accompanied by the paste-like material Sa in the plate hole 11 appears. The clothing body C is heated in a heating furnace (not shown), for example, at 130 ° C. for 3 minutes, so that the paste-like material Sa is cured, and as shown in FIG. Elastic material S, S. However, the heating temperature and time required for curing the paste-like material Sa are not limited to the above.

上記した緊締用伸縮素材Sを有する衣料本体Cを用いて、図4に示すようなトレーナ上衣(筋肉保護強化衣料の例)1およびトレーナ下衣(筋肉保護強化衣料の例)2が縫製される。トレーナ上衣1は胴部3と左右の袖部4,4からなり、トレーナ下衣2は股上部5と左右の下肢部6,6からなっている。

トレーナ上衣1の袖部4,4には、既述したパターンP1,P1の緊締用伸縮素材Sがそれぞれスクリーン印刷により被着されている。トレーナ下衣2の股上部5の履き口には全周にわたるパターンP2の緊締用伸縮素材Sがスクリーン印刷により被着され、下肢部6,6の大腿部分にはパターンP3,P3の緊締用伸縮素材Sがそれぞれスクリーン印刷により被着されている。下肢部6,6の膝上下部分にはパターンP4,P4の緊締用伸縮素材Sがそれぞれスクリーン印刷により被着され、下肢部6,6の裾部分にはパターンP5,P5の緊締用伸縮素材Sがそれぞれスクリーン印刷により被着されている。

尚、緊締用伸縮素材Sが被着される衣料本体Cの所定位置とは、衣料本体Cが着用者の体にぴったりフィットした状態で所望の筋肉を締め付けて保護したり強化することのできる部位であり、本実施形態では図1〜図4に示したパターンP1〜P5の位置である。但し、本発明は前記のパターンP1〜P5の位置に限定されず、例えば従来技術のトレーナ下衣52(図5参照)に用いた、広い面積の伸縮性生地57,58に替えて、これらを取り除いた位置にゴム質材料を印刷で被着しても構わない。A trainer upper garment (an example of muscle protection strengthening clothing) 1 and a trainer lower garment (an example of muscle protection strengthening clothing) 2 as shown in FIG. 4 are sewn using the clothing body C having the elastic material S for tightening described above. . The trainer

The elastic members S for tightening the patterns P1 and P1 described above are attached to the

In addition, the predetermined position of the clothing main body C to which the elastic material S for tightening is attached is a portion where the desired muscle can be tightened to be protected or strengthened in a state in which the clothing main body C fits the wearer's body. In this embodiment, the positions of the patterns P1 to P5 shown in FIGS. However, the present invention is not limited to the positions of the patterns P1 to P5. For example, instead of the

上記した構成のトレーナ上衣1およびトレーナ下衣2を着用すれば、各衣料本体C,Cが着用者の上半身と下半身を包んでそれぞれにフィットする。そして、トレーナ上衣1の袖部4の緊締用伸縮素材S(P1)がその被蔽位置周りの筋肉を素材長手方向に締め付けて強化する。トレーナ下衣2の股上部5の緊締用伸縮素材S(P2)はトレーナ下衣2を腰で止めるゴム紐の役割を果たす。下肢部6上部の緊締用伸縮素材S(P3)はその被蔽位置周りの筋肉を素材長手方向に締め付けて強化する。下肢部6中央の緊締用伸縮素材S(P4)は膝関節あるいは膝関節周りの筋や腱を保護し、膝関節周りの筋肉を強化する。下肢部6下端の緊締用伸縮素材S(P5)は下肢部6の先端を足首に止めるゴム紐の役割を果たしている。尚、図示は省略するが、トレーナ上衣1の袖部4の衣料本体Cの肘に対面する位置(所定位置)に緊締用伸縮素材Sを配置することにより、肘関節を保護し肘関節周りの筋肉を強化できる。これにより、野球投手やテニス選手が罹りやすい肘の故障を未然に防いだり、故障になった場合でも回復を早めることができる。 If the trainer

そして、トレーナ上衣1およびトレーナ下衣2は、シリコンゴム製の緊締用伸縮素材Sがスクリーン印刷によって衣料本体Cに被着されるので、衣料本体Cへの緊締用伸縮素材Sの被着作業を手間をかけずに短時間で行なうことができ、大量生産に好適である。また、近年の画像処理技術、スクリーン版製作技術、およびゴム質材料品質などの向上化により、緊締用伸縮素材Sのパターン形状が複雑であったり細かい場合でも確実かつ鮮明に被着することができる。加えて、印刷パターンは画像処理技術により容易に変更できるため、印刷パターンのデザイン変更の自由度が格段に大きくなる。 In the trainer

また、緊締用伸縮素材Sを構成するシリコンゴムは広い温度範囲で良好な弾性を保ち、耐熱性、耐水性、耐磨耗性、洗濯堅牢性に富み、人体無害である。また、強く引っ張ってもほとんどヒビ割れや断裂を生じない。そして、緊締用伸縮素材Sを透明に構成したことにより、衣料本体Cの表面に描かれている模様や文字を緊締用伸縮素材Sを透して外部から視認することができる。これにより、例えば野球用のアンダーシャツの袖外面に袖の地色とは異なる色の模様などを表わすことが禁止されているような場合に、その袖外面に緊締用伸縮素材を被着したとしても、緊締用伸縮素材を透して袖の地色が表れるので、忌憚なく緊締用伸縮素材を用いることができる。あるいは、プロスポーツ用のユニフォームのようにスポンサーの商標(文字や図形)が外面に表わされているユニフォームにおいて、スポンサー商標が表わされている部分と緊締用伸縮素材を被着する部分とが重複した場合でも、外部から緊締用伸縮素材を透してスポンサー商標を見ることができるのである。 Further, the silicon rubber constituting the elastic material S for tightening maintains good elasticity in a wide temperature range, is rich in heat resistance, water resistance, abrasion resistance, washing fastness, and is harmless to the human body. Moreover, even if it pulls strongly, it does not produce a crack and tear. And since the elastic material S for fastening is comprised transparently, the pattern and the character currently drawn on the surface of the clothing main body C can be visually recognized from the exterior through the elastic material S for fastening. As a result, for example, when it is prohibited to represent a pattern of a color different from the sleeve ground color on the sleeve outer surface of a baseball undershirt, the elastic material for tightening is attached to the outer surface of the sleeve. However, since the ground color of the sleeve appears through the elastic material for tightening, the elastic material for tightening can be used without any hesitation. Alternatively, in a uniform in which a sponsor's trademark (characters or figures) is represented on the outer surface, such as a professional sports uniform, a portion where the sponsor trademark is represented and a portion to which an elastic material for tightening is attached Even if they overlap, the sponsor trademark can be seen from the outside through the elastic material for tightening.

尚、上記の実施形態では、衣料本体Cの外面だけに緊締用伸縮素材Sを印刷で被着した例を示したが、本発明はそれに限定されるものでなく、例えば緊締用伸縮素材Sを衣料本体Cの内面だけに、あるいは、外面および内面の双方背中合わせの位置に印刷で被着しても構わない。そして、緊締用伸縮素材を構成するゴム質材料としては、上述したシリコンゴムに替えて、例えば、ブチルゴム、ニトリルブチルゴム、ウレタンゴムなどを使用することも可能である。

また、緊締用伸縮素材を衣料本体に印刷する方法としては、既述したシルクスクリーン印刷法に替えて、例えば汎用の型押しウェルダー法を利用して印刷することも可能である。この型押しウェルダー法は、印刷パターンに対応して金型に形成された型穴から加熱溶融したゴム質材料を押し出して衣料本体上に被着させるものである。また、本発明では、半透明のゴム質材料や、染料や顔料などを添加して着色したゴム質材料を用いることもできる。

そして、本発明の筋肉保護強化衣料は、上記したトレーナ上衣およびトレーナ下衣以外にも、例えばタイツ、パンティストッキング、靴下、日よけ用長手袋、身体各部位用のサポータ、スポーツ用または日用のアンダーシャツなど、身体に密着して着用される衣料に適用可能である。尚、靴下の足首部分に本発明の緊締用伸縮素材を被着しておけば、足首関節の故障を防いだり故障の回復を早めることができる。In the above-described embodiment, an example in which the elastic material for tightening S is attached only to the outer surface of the clothing main body C by printing is shown. However, the present invention is not limited thereto, and for example, the elastic material for tightening S You may apply | coat to only the inner surface of the clothing main body C, or the back-to-back position of both the outer surface and the inner surface by printing. Further, as the rubber material constituting the elastic material for tightening, for example, butyl rubber, nitrile butyl rubber, urethane rubber or the like can be used instead of the above-described silicon rubber.

Further, as a method for printing the elastic material for tightening on the clothing body, for example, a general-purpose embossing welder method may be used instead of the silk screen printing method described above. In this embossing welder method, a rubber material heated and melted is extruded from a mold hole formed in a mold corresponding to a printing pattern, and is deposited on a clothing main body. In the present invention, a translucent rubber material, or a rubber material colored by adding a dye or a pigment can also be used.

And the muscle protection strengthening garment of the present invention is, for example, tights, pantyhose, socks, sunscreen gloves, supporters for body parts, sports or daily use in addition to the trainer upper garment and the trainer garment described above. It can be applied to clothing such as undershirts that are worn in close contact with the body. If the elastic material for tightening of the present invention is attached to the ankle portion of the sock, failure of the ankle joint can be prevented and recovery from the failure can be accelerated.

1 トレーナ上衣(筋肉保護強化衣料)

2 トレーナ下衣(筋肉保護強化衣料)

B スクリーン版

C 衣料本体

M 厚型版

P1〜P5 パターン

S,S1〜S7 緊締用伸縮素材1 Trainer upper garment (muscle protection strengthening clothing)

2 Trainer underwear (muscle protection strengthening clothing)

B Screen version C Clothing body M Thick plate P1-P5 Pattern S, S1-S7 Elastic material for tightening

Claims (3)

Translated fromJapanesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004306771AJP2006118088A (en) | 2004-10-21 | 2004-10-21 | Muscle protection reinforced clothes |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004306771AJP2006118088A (en) | 2004-10-21 | 2004-10-21 | Muscle protection reinforced clothes |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| JP2006118088Atrue JP2006118088A (en) | 2006-05-11 |

Family

ID=36536225

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004306771APendingJP2006118088A (en) | 2004-10-21 | 2004-10-21 | Muscle protection reinforced clothes |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2006118088A (en) |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102264252A (en)* | 2008-11-25 | 2011-11-30 | 耐克国际有限公司 | Clothing items that provide enhanced body position feedback |

| JP2013067941A (en)* | 2007-05-31 | 2013-04-18 | Nike Internatl Ltd | Article of apparel providing enhanced body position feedback |

| JP2013091881A (en)* | 2011-10-27 | 2013-05-16 | Mizuno Corp | Supporter |

| JP2013096025A (en)* | 2011-10-31 | 2013-05-20 | Asics Corp | Sports wear |

| KR101279535B1 (en) | 2012-08-21 | 2013-06-28 | 엠코르셋 주식회사 | Women's underwear with body correction |

| CN103874433A (en)* | 2011-10-11 | 2014-06-18 | 彪马欧洲公司 | Article of clothing |

| US8832863B2 (en) | 2011-12-27 | 2014-09-16 | Jae Young Yang | Sports taping tights |

| CN104041949A (en)* | 2013-03-14 | 2014-09-17 | 丰田通商株式会社 | Sports tights |

| JP2015158023A (en)* | 2014-02-24 | 2015-09-03 | 株式会社ワコール | clothing |

| JP5807674B2 (en)* | 2011-04-13 | 2015-11-10 | 株式会社ワコール | clothing |

| WO2016051469A1 (en)* | 2014-09-29 | 2016-04-07 | 株式会社ワコール | Garment with compression-generating sections |

| WO2016072482A1 (en)* | 2014-11-07 | 2016-05-12 | 株式会社Toscom | Supporter and method for manufacturing same |

| WO2021187831A1 (en)* | 2020-03-17 | 2021-09-23 | 주식회사 웨이브컴퍼니 | Adhesive silicone pattern material, and wear comprising same |

| CN114578646A (en)* | 2022-03-14 | 2022-06-03 | 万景忠 | Printing and bonding process for multiple fabrics |

- 2004

- 2004-10-21JPJP2004306771Apatent/JP2006118088A/enactivePending

Cited By (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013067941A (en)* | 2007-05-31 | 2013-04-18 | Nike Internatl Ltd | Article of apparel providing enhanced body position feedback |

| CN102264252B (en)* | 2008-11-25 | 2014-03-26 | 耐克国际有限公司 | Clothing items that provide enhanced body position feedback |

| CN102264252A (en)* | 2008-11-25 | 2011-11-30 | 耐克国际有限公司 | Clothing items that provide enhanced body position feedback |

| US10092048B2 (en) | 2011-04-13 | 2018-10-09 | Wacoal Corporation | Garment |

| JP5807674B2 (en)* | 2011-04-13 | 2015-11-10 | 株式会社ワコール | clothing |

| CN103874433A (en)* | 2011-10-11 | 2014-06-18 | 彪马欧洲公司 | Article of clothing |

| JP2014528522A (en)* | 2011-10-11 | 2014-10-27 | プーマ エス イーPuma Se | clothing |

| JP2013091881A (en)* | 2011-10-27 | 2013-05-16 | Mizuno Corp | Supporter |

| JP2013096025A (en)* | 2011-10-31 | 2013-05-20 | Asics Corp | Sports wear |

| US8832863B2 (en) | 2011-12-27 | 2014-09-16 | Jae Young Yang | Sports taping tights |

| KR101279535B1 (en) | 2012-08-21 | 2013-06-28 | 엠코르셋 주식회사 | Women's underwear with body correction |

| CN104041949B (en)* | 2013-03-14 | 2017-05-24 | 丰田通商株式会社 | sports leggings |

| CN104041949A (en)* | 2013-03-14 | 2014-09-17 | 丰田通商株式会社 | Sports tights |

| KR101556039B1 (en) | 2013-03-14 | 2015-09-25 | 토요타 쯔우쇼우 가부시키가이샤 | Athletic tights |

| JP2015158023A (en)* | 2014-02-24 | 2015-09-03 | 株式会社ワコール | clothing |

| CN107072327A (en)* | 2014-09-29 | 2017-08-18 | 株式会社华歌尔 | With the clothing for wearing pressing creation portion |

| WO2016051469A1 (en)* | 2014-09-29 | 2016-04-07 | 株式会社ワコール | Garment with compression-generating sections |

| CN107072335A (en)* | 2014-11-07 | 2017-08-18 | 有限公司特斯科姆 | Support member class and its manufacture method |

| JPWO2016072482A1 (en)* | 2014-11-07 | 2017-04-27 | 株式会社Toscom | Supporters and manufacturing method thereof |

| JP2018040104A (en)* | 2014-11-07 | 2018-03-15 | 株式会社Toscom | Supporter and manufacturing method thereof |

| WO2016072482A1 (en)* | 2014-11-07 | 2016-05-12 | 株式会社Toscom | Supporter and method for manufacturing same |

| CN107072335B (en)* | 2014-11-07 | 2019-10-22 | 有限公司特斯科姆 | Support and method for manufacturing the same |

| US10806193B2 (en) | 2014-11-07 | 2020-10-20 | Toscom Co., Ltd. | Supporter and method for manufacturing same |

| WO2021187831A1 (en)* | 2020-03-17 | 2021-09-23 | 주식회사 웨이브컴퍼니 | Adhesive silicone pattern material, and wear comprising same |

| EP3915416A4 (en)* | 2020-03-17 | 2022-11-02 | Wavecompany Co., Ltd. | Adhesive silicone pattern material, and wear comprising same |

| CN114578646A (en)* | 2022-03-14 | 2022-06-03 | 万景忠 | Printing and bonding process for multiple fabrics |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2006118088A (en) | Muscle protection reinforced clothes | |

| US8832863B2 (en) | Sports taping tights | |

| JP5807674B2 (en) | clothing | |

| CZ279766B6 (en) | Textile permeable for solar radiation | |

| JP2001214303A (en) | Sporting spats | |

| US9839247B2 (en) | Performance garment having a realistic visual effect of abraded denim | |

| US20190082751A1 (en) | Support garment or tape and method of making the same | |

| CN114745984A (en) | Garment with gripping elements | |

| JP4368364B2 (en) | Exercise spats | |

| US20230240398A1 (en) | Clothing | |

| US20100205710A1 (en) | Protective Sports Garment | |

| JP7393825B2 (en) | Textiles and supportive hot stamping materials for supporting human locomotor organs | |

| JP2005264394A (en) | Clothes and method for producing the same | |

| US11034126B2 (en) | Visually dynamic multi-layer elastomeric materials | |

| WO2025104298A1 (en) | Compression garment | |

| CN113619303A (en) | Silica gel material for protective clothing, preparation method thereof and protective sports equipment | |

| CA2836058C (en) | Shoulder stabilization shirt | |

| CN205962933U (en) | Elastic wearables with three-layer composite structure | |

| JP5161392B1 (en) | clothing | |

| JP4557632B2 (en) | Clothes | |

| JP2004057808A (en) | Under pants | |

| CN210869918U (en) | Moisture absorption sweat-discharging sports wear | |

| JP3016119U (en) | Underwear for underwear | |

| KR20170116000A (en) | Cool fabrics Socks method | |

| WO2021177172A1 (en) | Clothing |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A871 | Explanation of circumstances concerning accelerated examination | Free format text:JAPANESE INTERMEDIATE CODE: A871 Effective date:20060830 | |

| A975 | Report on accelerated examination | Free format text:JAPANESE INTERMEDIATE CODE: A971005 Effective date:20060915 | |

| A131 | Notification of reasons for refusal | Free format text:JAPANESE INTERMEDIATE CODE: A131 Effective date:20061003 | |

| A02 | Decision of refusal | Free format text:JAPANESE INTERMEDIATE CODE: A02 Effective date:20070306 |