EP3512640B1 - Device and method for dynamic metering of sealing compounds - Google Patents

Device and method for dynamic metering of sealing compoundsDownload PDFInfo

- Publication number

- EP3512640B1 EP3512640B1EP17762112.5AEP17762112AEP3512640B1EP 3512640 B1EP3512640 B1EP 3512640B1EP 17762112 AEP17762112 AEP 17762112AEP 3512640 B1EP3512640 B1EP 3512640B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- sealant

- containers

- drive

- components

- component

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C11/00—Component parts, details or accessories not specifically provided for in groups B05C1/00 - B05C9/00

- B05C11/10—Storage, supply or control of liquid or other fluent material; Recovery of excess liquid or other fluent material

- B05C11/1036—Means for supplying a selected one of a plurality of liquids or other fluent materials, or several in selected proportions, to the applying apparatus

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F35/00—Accessories for mixers; Auxiliary operations or auxiliary devices; Parts or details of general application

- B01F35/71—Feed mechanisms

- B01F35/717—Feed mechanisms characterised by the means for feeding the components to the mixer

- B01F35/71775—Feed mechanisms characterised by the means for feeding the components to the mixer using helical screws

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F35/00—Accessories for mixers; Auxiliary operations or auxiliary devices; Parts or details of general application

- B01F35/80—Forming a predetermined ratio of the substances to be mixed

- B01F35/83—Forming a predetermined ratio of the substances to be mixed by controlling the ratio of two or more flows, e.g. using flow sensing or flow controlling devices

- B01F35/831—Forming a predetermined ratio of the substances to be mixed by controlling the ratio of two or more flows, e.g. using flow sensing or flow controlling devices using one or more pump or other dispensing mechanisms for feeding the flows in predetermined proportion, e.g. one of the pumps being driven by one of the flows

- B01F35/8311—Forming a predetermined ratio of the substances to be mixed by controlling the ratio of two or more flows, e.g. using flow sensing or flow controlling devices using one or more pump or other dispensing mechanisms for feeding the flows in predetermined proportion, e.g. one of the pumps being driven by one of the flows with means for controlling the motor driving the pumps or the other dispensing mechanisms

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F35/00—Accessories for mixers; Auxiliary operations or auxiliary devices; Parts or details of general application

- B01F35/80—Forming a predetermined ratio of the substances to be mixed

- B01F35/88—Forming a predetermined ratio of the substances to be mixed by feeding the materials batchwise

- B01F35/883—Forming a predetermined ratio of the substances to be mixed by feeding the materials batchwise using flow rate controls for feeding the substances

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C11/00—Component parts, details or accessories not specifically provided for in groups B05C1/00 - B05C9/00

- B05C11/10—Storage, supply or control of liquid or other fluent material; Recovery of excess liquid or other fluent material

- B05C11/1002—Means for controlling supply, i.e. flow or pressure, of liquid or other fluent material to the applying apparatus, e.g. valves

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C11/00—Component parts, details or accessories not specifically provided for in groups B05C1/00 - B05C9/00

- B05C11/10—Storage, supply or control of liquid or other fluent material; Recovery of excess liquid or other fluent material

- B05C11/1039—Recovery of excess liquid or other fluent material; Controlling means therefor

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C11/00—Component parts, details or accessories not specifically provided for in groups B05C1/00 - B05C9/00

- B05C11/10—Storage, supply or control of liquid or other fluent material; Recovery of excess liquid or other fluent material

- B05C11/1047—Apparatus or installations for supplying liquid or other fluent material comprising a buffer container or an accumulator between the supply source and the applicator

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C9/00—Apparatus or plant for applying liquid or other fluent material to surfaces by means not covered by any preceding group, or in which the means of applying the liquid or other fluent material is not important

- B05C9/06—Apparatus or plant for applying liquid or other fluent material to surfaces by means not covered by any preceding group, or in which the means of applying the liquid or other fluent material is not important for applying two different liquids or other fluent materials, or the same liquid or other fluent material twice, to the same side of the work

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C9/00—Apparatus or plant for applying liquid or other fluent material to surfaces by means not covered by any preceding group, or in which the means of applying the liquid or other fluent material is not important

- B05C9/08—Apparatus or plant for applying liquid or other fluent material to surfaces by means not covered by any preceding group, or in which the means of applying the liquid or other fluent material is not important for applying liquid or other fluent material and performing an auxiliary operation

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C5/00—Apparatus in which liquid or other fluent material is projected, poured or allowed to flow on to the surface of the work

- B05C5/02—Apparatus in which liquid or other fluent material is projected, poured or allowed to flow on to the surface of the work the liquid or other fluent material being discharged through an outlet orifice by pressure, e.g. from an outlet device in contact or almost in contact, with the work

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C5/00—Apparatus in which liquid or other fluent material is projected, poured or allowed to flow on to the surface of the work

- B05C5/02—Apparatus in which liquid or other fluent material is projected, poured or allowed to flow on to the surface of the work the liquid or other fluent material being discharged through an outlet orifice by pressure, e.g. from an outlet device in contact or almost in contact, with the work

- B05C5/0225—Apparatus in which liquid or other fluent material is projected, poured or allowed to flow on to the surface of the work the liquid or other fluent material being discharged through an outlet orifice by pressure, e.g. from an outlet device in contact or almost in contact, with the work characterised by flow controlling means, e.g. valves, located proximate the outlet

Definitions

- the present inventionrelates to a device for the dynamic dosing of sealing compound volumes and a corresponding method.

- Sealing compoundssuch as those used in aircraft and spacecraft are usually produced by mixing two components - base compound and hardener - in a mixing device and then cured on site, i.e. on the component to be coated. The latter can be done thermally and/or by actinic radiation.

- a device (1) for thisis in Fig. 1 shown:

- the components A and B (5a, 5b)are initially in separate reservoirs (2a, 2b).

- a suitable drive (3)preferably a servo drive, is controlled in such a way that the two components (A and B) (5a, 5b) are conveyed at a defined speed into a static mixing tube (7) and mixed with one another.

- the dosing speedi.e. the volume of sealing compound that is applied per unit of time

- the dosing speedmust be adjusted dynamically, i.e. depending on the point to be sealed. This is also referred to as dynamic dosing.

- U.S. 2011/253747 A1discloses a device for the dynamic dosing of sealing compounds, having two containers for sealing compound components, a first drive, which is connected to two devices, one of which can convey one of the sealing compound components out of its container, a drive controller, a mixing unit for mixing the components from the containers funded sealant components with an opening for applying the sealant to a component.

- this devicecannot be used to achieve adequate mixing quality and dosing accuracy independently of the dosing speed.

- the device (1) according to the invention for the dynamic dosing of sealing compoundshas two containers (2a, 2b) for sealing compound components, a first drive (3) which is connected to two devices (4a, 4b), one of which each controls one of the sealing compound components (5a , 5b) from its container (2a, 2b) (conveying devices), a drive controller (6), a mixing unit (7) for mixing the sealant components (5a, 5b) conveyed from the containers (2a, 2b) with an opening (8) for applying the sealing compound (9) to a component and, in addition, a compensating tank (10) with a compensating volume (11) and a second drive (12) which is connected to a piston (13) which is inserted into the compensating volume ( 11) of the expansion tank (10) is sufficient.

- the expansion tank (10)is connected to the mixing unit (7). Through this Connection is the expansion tank (10) filled and emptied.

- the first and the second drive (3, 12)can be dynamically controlled together by the drive controller (6).

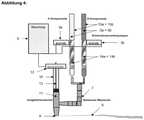

- a first such device (1) according to the inventionis in Fig. 2 as in Fig. 3 , a second in Fig. 4 shown, but these figures should not be understood as limiting.

- a “sealant”should always mean the mixture of two sealant components.

- the "first drive”can also consist of two separately controlled drive units (3a, 3b), of which the first is connected to the first and the second to the second of the two conveyor devices (4a, 4b) (cf. Fig. 4 ). According to a preferred embodiment, however, the first drive consists of a single drive unit (3) which is connected to the two conveyor devices (4a, 4b).

- the "two containers for sealing compound components”can be storage containers (2a, 2b), ie containers that can each be filled with a certain amount of sealing compound component (5a, 5b) and then sealed (cf. Fig. 2 and Fig. 3 ).

- the "two containers for sealant components"can be open containers (15a, 15b), ie containers that can each be continuously filled with a sealant component (5a, 5b) (cf. Fig. 4 ). In this way, an uninterrupted flow of sealant can be achieved (cf. Fig. 4 ).

- the “mixing unit”can be a static mixer, a dynamic mixer, or a combination of both.

- the first and/or second driveis preferably a servo drive, more preferably the first and the second drive are each a servo drive.

- the two conveying devicesare pistons, one of which reaches into one of the containers, which in this case are storage containers, and can push out the corresponding sealing compound component.

- the two conveying devicesare pumps which can draw the sealing compound components out of their containers by generating a vacuum.

- Screw eccentric pumps and scoop piston pumpsare particularly suitable for this.

- said containersare open containers (15a, 15b), which can each be continuously filled with a sealing compound component (5a, 5b) (cf. Fig. 4 ).

- the mixing unitis preferably a static mixer, in particular a static mixing tube.

- the expansion tankis preferably a plastic cartridge or a component that is easy to clean, particularly preferably a plastic cartridge, in particular one made of polyethylene (PE).

- PEpolyethylene

- the device (1)is a 2-component mixing and dosing system such as that manufactured by Hilger u. Kern (Mannheim, Germany), for example. These systems make it possible to convey, mix and dose sealant (9) consisting of 2 components (5a, 5b) from storage containers (2a, 2b) (cf. Fig. 2 and Fig. 3 ).

- the sealing compoundcan also be one which essentially only cures after exposure to actinic radiation, in particular to UV radiation.

- a sealanthas the advantage that its curing can be initiated in a controlled manner with a trigger (so-called SCOD : sealant curing on demand).

- the device according to the inventioncan comprise an integrated source for actinic radiation, in particular for UV radiation.

- the containers (2a, 2b) of the device (1) according to the inventionare each filled with a sealant component (5a, 5b) (components A and B or base material and hardener).

- the sealing compound components (5a, 5b)are then mixed in a mixing unit (7) and the resulting sealing compound (9) is applied to a component by the sealing compound components (5a, 5b) being removed from the containers (2a, 2b) are funded.

- a dosing speed below a critical value preset in the drive control (6)is achieved in that the conveying speed of the sealing compound components (5a, 5b) from the containers (2a, 2b) is reduced to the critical value of the dosing speed and the equalizing tank ( 10) is filled with sealant (9) by means of the second drive (12) in such a way that the speed at which the expansion tank (10) is filled corresponds to the difference between the critical and the realized value of the dosing speed.

- a dosing speed of, for example, 1 volume unit of sealant/time unitis achieved by reducing the conveying speed of the sealant components (5a, 5b) from the containers (2a, 2b) to 3 volume units of sealant/time unit. Unit of time lowered and the expansion tank (10) is filled at a rate of 2 volume units of sealant / unit of time.

- Fig. 2shows the device (1) according to the invention at a dosing rate above the critical value.

- the dosing rateis lower than the critical value, this is indicated by a reduction in the thickness of the bead of sealant (9).

- the compensating volume (11) of the compensating tank (10)is filled with sealing compound.

- the promotion of the sealing compound components from the containersis preferably stopped and the sealing compound is conveyed out of the expansion tank by means of the second drive until the sealing compound in the expansion tank is used up. This will help keep the reservoir empty enough to allow the reservoir to be refilled with sealant at a later date.

- the sealing compound componentscan then continue to be conveyed from the containers by means of the first drive and at the same time the sealing compound can be conveyed from the expansion tank by means of the second drive until the sealing compound in the expansion tank is used up. This makes it possible to increase the dosing speed beyond the maximum value that would be possible with the device without the expansion tank.

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

- Coating Apparatus (AREA)

- Accessories For Mixers (AREA)

- Sealing Material Composition (AREA)

- Medical Preparation Storing Or Oral Administration Devices (AREA)

- Basic Packing Technique (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

Description

Translated fromGermanDie vorliegende Erfindung betrifft eine Vorrichtung zur dynamischen Dosierung von Dichtmassevolumina sowie ein entsprechendes Verfahren.The present invention relates to a device for the dynamic dosing of sealing compound volumes and a corresponding method.

Dichtmassen wie sie beispielsweise bei Flug- und Raumfahrzeugen zum Einsatz kommen werden in der Regel durch Mischen zweier Komponenten - Grundmasse und Härter - in einer Mischvorrichtung erzeugt und anschließend vor Ort, d.h. auf dem zu beschichtenden Bauteil ausgehärtet. Letzteres kann thermisch und/oder durch aktinische Strahlung geschehen.Sealing compounds such as those used in aircraft and spacecraft are usually produced by mixing two components - base compound and hardener - in a mixing device and then cured on site, i.e. on the component to be coated. The latter can be done thermally and/or by actinic radiation.

Eine Vorrichtung (1) hierzu ist in

Bei der Abdichtung von Bauteilen mit komplizierter Geometrie muss die Dosiergeschwindigkeit, also das Dichtmassevolumen, welches pro Zeiteinheit aufgetragen wird, dynamisch, d.h. je nach gerade abzudichtender Stelle, angepasst werden. Man spricht auch von einer dynamischen Dosierung.When sealing components with a complicated geometry, the dosing speed, i.e. the volume of sealing compound that is applied per unit of time, must be adjusted dynamically, i.e. depending on the point to be sealed. This is also referred to as dynamic dosing.

Bei letzterer stellt sich allerdings das Problem, dass die Dosiergeschwindigkeit bei Verwendung von Statikmischern nicht beliebig erniedrigt werden kann, ohne dabei das Mischungsverhältnis und die Mischgüte negativ zu beeinflussen.With the latter, however, the problem arises that the dosing speed cannot be arbitrarily reduced when using static mixers without negatively influencing the mixing ratio and the mixing quality.

Dies ist vor allem darauf zurückzuführen, dass die Grundmassen-Komponente - beispielsweise eine solche auf Polysulfid-Basis - komprimierbar ist, während die Härter-Komponente keine Komprimierbarkeit aufweist, was mit abnehmender Dosiergeschwindigkeit zu einer im Vergleich zur Härter-Komponente immer weiter verzögerten Freisetzung der Grundmassen-Komponente aus ihrem Vorratsbehälter führt.This is mainly due to the fact that the base mass component - for example one based on polysulfide - is compressible, while the hardener component has no compressibility, which, with decreasing dosing rate, leads to an increasingly delayed release of the hardener component compared to the hardener component Basic mass component leads from its storage container.

Insbesondere bei geringsten Dosiergeschwindigkeiten wie sie für Punktdosierungen benötigt werden treten daher Probleme hinsichtlich eines veränderten Mischungsverhältnis sowie einer verminderten Mischgüte auf.Problems with regard to a changed mixing ratio and reduced mixing quality therefore arise, particularly at the lowest dosing speeds, such as are required for point dosing.

Wird die Fahrgeschwindigkeit einer Traverse mit der oben beschriebenen Vorrichtung erhöht, um einen geringeren Austrag pro Wegstrecke - also eine scheinbar niedrigere Dosiergeschwindigkeit - zu erreichen, geht dies bei komplizierten Geometrien jedoch zu Lasten der Dosiergenauigkeit.If the travel speed of a traverse is increased with the device described above in order to achieve a lower discharge per distance - ie an apparently lower dosing speed - this is at the expense of the dosing accuracy in the case of complicated geometries.

Daher war es die Aufgabe der vorliegenden Erfindung, eine Vorrichtung zur dynamischen Dosierung von Dichtmassen sowie ein entsprechendes Verfahren bereitzustellen, bei der bzw. bei dem unabhängig von der Dosiergeschwindigkeit - also auch bei niedrigen Dosiergeschwindigkeiten - eine hinreichende Mischgüte sowie Dosiergenauigkeit erreicht wird.It was therefore the object of the present invention to provide a device for the dynamic dosing of sealing compounds and a corresponding method in which adequate mixing quality and dosing accuracy are achieved independently of the dosing speed, ie even at low dosing speeds.

Diese Aufgabe wurde gelöst durch eine Vorrichtung nach Anspruch 1 sowie ein Verfahren nach Anspruch 10. Bevorzugte Ausführungsformen werden jeweils in den abhängigen Ansprüchen beschrieben.This object has been solved by an apparatus according to

Die erfindungsgemäße Vorrichtung (1) zur dynamischen Dosierung von Dichtmassen weist zwei Behälter (2a, 2b) für Dichtmassenkomponenten, einen ersten Antrieb (3), der mit zwei Einrichtungen (4a, 4b) verbunden ist, von denen jeweils eine eine der Dichtmassenkomponenten (5a, 5b) aus ihrem Behälter (2a, 2b) fördern kann (Fördereinrichtungen), eine Antriebssteuerung (6), eine Mischeinheit (7) für das Mischen der aus den Behältern (2a, 2b) geförderten Dichtmassenkomponenten (5a, 5b) mit einer Öffnung (8) für das Auftragen der Dichtmasse (9) auf ein Bauteil sowie zusätzlich einen Ausgleichsbehälter (10) mit einem Ausgleichsvolumen (11) und einen zweiten Antrieb (12), der mit einem Kolben (13) verbunden ist, der in das Ausgleichsvolumen (11) des Ausgleichsbehälter (10) reicht, auf.The device (1) according to the invention for the dynamic dosing of sealing compounds has two containers (2a, 2b) for sealing compound components, a first drive (3) which is connected to two devices (4a, 4b), one of which each controls one of the sealing compound components (5a , 5b) from its container (2a, 2b) (conveying devices), a drive controller (6), a mixing unit (7) for mixing the sealant components (5a, 5b) conveyed from the containers (2a, 2b) with an opening (8) for applying the sealing compound (9) to a component and, in addition, a compensating tank (10) with a compensating volume (11) and a second drive (12) which is connected to a piston (13) which is inserted into the compensating volume ( 11) of the expansion tank (10) is sufficient.

Dabei ist der Ausgleichsbehälter (10) mit der Mischeinheit (7) verbunden. Durch diese Verbindung wird der Ausgleichsbehälter (10) gefüllt und entleert. Der erste und der zweite Antrieb (3, 12) können gemeinsam durch die Antriebssteuerung (6) dynamisch gesteuert werden.The expansion tank (10) is connected to the mixing unit (7). Through this Connection is the expansion tank (10) filled and emptied. The first and the second drive (3, 12) can be dynamically controlled together by the drive controller (6).

Eine erste solche, erfindungsgemäße Vorrichtung (1) ist in

Unter einer "Dichtmasse" soll vorliegend stets die Mischung zweier Dichtmassenkomponenten gemeint sein.In the present case, a “sealant” should always mean the mixture of two sealant components.

Der "erste Antrieb" kann auch aus zwei separat zu steuernden Antriebseinheiten (3a, 3b) bestehen, von denen die erste mit der ersten und die zweite mit der zweiten der beiden Fördereinrichtungen (4a, 4b) verbunden ist (vgl.

Einerseits kann es sich bei den "zwei Behältern für Dichtmassenkomponenten" um Vorratsbehälter (2a, 2b) handeln, d.h. um Behälter, die jeweils mit einer bestimmten Menge an Dichtmassenkomponente (5a, 5b) befüllt und dann verschlossen werden können (vgl.

Andererseits kann es sich bei den "zwei Behältern für Dichtmassenkomponenten" um offene Behälter (15a, 15b) handeln, d.h. um Behälter, die jeweils kontinuierlich mit einer Dichtmassenkomponente (5a, 5b) befüllt werden können (vgl.

Bei der "Mischeinheit" kann es sich um einen Statikmischer, einen Dynamikmischer oder eine Kombination von beiden handeln.The "mixing unit" can be a static mixer, a dynamic mixer, or a combination of both.

Vorzugsweise handelt es sich bei dem ersten und/oder zweiten Antrieb um einen Servoantrieb, weiter bevorzugt ist der erste und der zweite Antrieb jeweils ein Servoantrieb.The first and/or second drive is preferably a servo drive, more preferably the first and the second drive are each a servo drive.

Gemäß einer ersten bevorzugten Ausführungsform handelt es sich bei den beiden Fördereinrichtungen um Kolben, von denen je einer in einen der Behälter, bei denen es sich in diesem Fall um Vorratsbehälter handelt, reicht und die entsprechende Dichtmassenkomponente herausschieben kann.According to a first preferred embodiment, the two conveying devices are pistons, one of which reaches into one of the containers, which in this case are storage containers, and can push out the corresponding sealing compound component.

Gemäß einer zweiten bevorzugten Ausführungsform handelt es sich bei den beiden Fördereinrichtungen um Pumpen, welche durch Erzeugen eines Vakuums die Dichtmassenkomponenten aus ihren Behältern ziehen können. Insbesondere sind hierfür Schneckenexzenterpumpen sowie Schöpfkolbenpumpen geeignet.According to a second preferred embodiment, the two conveying devices are pumps which can draw the sealing compound components out of their containers by generating a vacuum. Screw eccentric pumps and scoop piston pumps are particularly suitable for this.

Vor allem im Falle von Schneckenexzenterpumpen (14a, 14b) handelt es sich bei besagten Behältern um offene Behälter (15a, 15b), die jeweils kontinuierlich mit einer Dichtmassenkomponente (5a, 5b) befüllt werden können (vgl.

Bevorzugt handelt es sich bei der Mischeinheit um einen Statikmischer, insbesondere um ein statisches Mischrohr.The mixing unit is preferably a static mixer, in particular a static mixing tube.

Bei dem Ausgleichsbehälter handelt es sich bevorzugt um eine Kunststoffkartusche oder ein leicht zu reinigendes Bauteil, besonders bevorzugt um eine Kunststoffkartusche, insbesondere um eine solche aus Polyethylen (PE).The expansion tank is preferably a plastic cartridge or a component that is easy to clean, particularly preferably a plastic cartridge, in particular one made of polyethylene (PE).

Gemäß einer ersten besonders bevorzugten Ausführungsform ist die Vorrichtung (1) eine 2K Misch- und Dosieranlage wie sie beispielsweise von der Firma Hilger u. Kern (Mannheim, Deutschland) hergestellt wird. Diese Anlagen ermöglichen es, Dichtmasse (9) bestehend aus 2 Komponenten (5a, 5b) aus Vorratsbehältern (2a, 2b) zu fördern, zu mischen und zu dosieren (vgl.

Bei der Dichtmasse kann es sich auch um eine solche handeln, welche im Wesentlichen erst nach Bestrahlung mit aktinischer Strahlung, insbesondere mit UV Strahlung aushärtet. Eine solche Dichtmasse hat den Vorteil, dass ihre Aushärtung kontrolliert mit einem Trigger initiiert werden kann (sog. SCOD:sealant curingondemand). Die erfindungsgemäße Vorrichtung kann hierzu eine integrierte Quelle für aktinische Strahlung, insbesondere für UV-Strahlung umfassen.The sealing compound can also be one which essentially only cures after exposure to actinic radiation, in particular to UV radiation. Such a sealant has the advantagethat its curing can be initiated ina controlled manner with a trigger (so-calledSCOD : sealant curing on demand). For this purpose, the device according to the invention can comprise an integrated source for actinic radiation, in particular for UV radiation.

Bei dem erfindungsgemäßen Verfahren zur dynamischen Dosierung von Dichtmassen werden die Behälter (2a, 2b) der erfindungsgemäßen Vorrichtung (1) mit jeweils einer Dichtmassenkomponente (5a, 5b) befüllt (Komponenten A und B bzw. Grundmasse und Härter). Die Dichtmassenkomponenten (5a, 5b) werden dann in einer Mischeinheit (7) gemischt und die resultierende Dichtmasse (9) wird auf ein Bauteil aufgebracht, indem die Dichtmassenkomponenten (5a, 5b) mittels des ersten Antriebs (3) aus den Behältern (2a, 2b) gefördert werden.In the method according to the invention for the dynamic dosing of sealants, the containers (2a, 2b) of the device (1) according to the invention are each filled with a sealant component (5a, 5b) (components A and B or base material and hardener). The sealing compound components (5a, 5b) are then mixed in a mixing unit (7) and the resulting sealing compound (9) is applied to a component by the sealing compound components (5a, 5b) being removed from the containers (2a, 2b) are funded.

Dabei wird eine Dosiergeschwindigkeit unterhalb eines kritischen, in der Antriebssteuerung (6) voreingestellten Werts, dadurch realisiert, dass die Fördergeschwindigkeit der Dichtmassenkomponenten (5a, 5b) aus den Behältern (2a, 2b) auf den kritischen Wert der Dosiergeschwindigkeit erniedrigt wird und der Ausgleichsbehälter (10) mittels des zweiten Antriebs (12) so mit Dichtmasse (9) befüllt wird, dass die Geschwindigkeit, mit der der Ausgleichbehälter (10) befüllt wird, der Differenz des kritischen und des realisierten Wertes der Dosiergeschwindigkeit entspricht.A dosing speed below a critical value preset in the drive control (6) is achieved in that the conveying speed of the sealing compound components (5a, 5b) from the containers (2a, 2b) is reduced to the critical value of the dosing speed and the equalizing tank ( 10) is filled with sealant (9) by means of the second drive (12) in such a way that the speed at which the expansion tank (10) is filled corresponds to the difference between the critical and the realized value of the dosing speed.

Beträgt der kritische Wert der Dosiergeschwindigkeit beispielsweise 3 Volumeneinheiten Dichtmasse/Zeiteinheit, so wird eine Dosiergeschwindigkeit von beispielsweise 1 Volumeneinheit Dichtmasse/Zeiteinheit dadurch realisiert, dass die Fördergeschwindigkeit der Dichtmassenkomponenten (5a, 5b) aus den Behältern (2a, 2b) auf 3 Volumeneinheiten Dichtmasse/Zeiteinheit erniedrigt und der Ausgleichsbehälter (10) mit einer Geschwindigkeit von 2 Volumeneinheiten Dichtmasse/Zeiteinheit befüllt wird.If the critical value of the dosing speed is, for example, 3 volume units of sealant/time unit, a dosing speed of, for example, 1 volume unit of sealant/time unit is achieved by reducing the conveying speed of the sealant components (5a, 5b) from the containers (2a, 2b) to 3 volume units of sealant/time unit. Unit of time lowered and the expansion tank (10) is filled at a rate of 2 volume units of sealant / unit of time.

Im Falle des Wiederansteigens der Dosiergeschwindigkeit auf mindestens den kritischen Wert wird die Förderung der Dichtmassenkomponenten aus den Behältern vorzugsweise solange gestoppt und die Dichtmasse mittels des zweiten Antriebs aus dem Ausgleichsbehälter gefördert, bis die Dichtmasse im Ausgleichsbehälter aufgebraucht ist. Dies trägt dazu bei, den Ausgleichsbehälter leer genug zu halten, um zu einem späteren Zeitpunkt ein erneutes Befüllen des Ausgleichsbehälters mit Dichtmasse zu ermöglichen.If the dosing rate rises again to at least the critical value, the promotion of the sealing compound components from the containers is preferably stopped and the sealing compound is conveyed out of the expansion tank by means of the second drive until the sealing compound in the expansion tank is used up. This will help keep the reservoir empty enough to allow the reservoir to be refilled with sealant at a later date.

Alternativ kann dann aber auch weiterhin die Förderung der Dichtmassenkomponenten mittels des ersten Antriebs aus den Behältern erfolgen und gleichzeitig die Dichtmasse mittels des zweiten Antriebs aus dem Ausgleichsbehälter gefördert werden, bis die Dichtmasse im Ausgleichsbehälter aufgebraucht ist. Hierdurch ist eine Erhöhung der Dosiergeschwindigkeit über den Höchstwert hinaus möglich, der mit der Vorrichtung ohne den Ausgleichsbehälter möglich wäre.Alternatively, the sealing compound components can then continue to be conveyed from the containers by means of the first drive and at the same time the sealing compound can be conveyed from the expansion tank by means of the second drive until the sealing compound in the expansion tank is used up. This makes it possible to increase the dosing speed beyond the maximum value that would be possible with the device without the expansion tank.

Claims (13)

- An apparatus (1) for dynamic metering of sealants, comprisingtwo containers (2a, 2b) for sealant components,a first drive (3) which is connected to two devices (4a, 4b), each of which is able to convey one of the sealant components (5a, 5b) from its container (2a, 2b),a drive controller (6),a mixing unit (7) for mixing the sealant components (5a, 5b) conveyed from the containers (2a, 2b), having an opening (8) for applying the sealant (9) to a component,wherein the apparatus (1) additionally comprises a compensating container (10) with a compensating volume (11), anda second drive (12), which is connected to a piston (13) which reaches into the compensating volume (11) of the compensating container (10),where the compensating container (10) is connected to the mixing unit (7) and where the first and the second drive (3, 12) can be dynamically controlled jointly by the drive controller (6).

- The apparatus (1) according to claim 1,wherein the first and/or the second drive (3, 12) is in each case a servo drive.

- The apparatus (1) according to claim 1 or 2,wherein the two conveying devices (4a, 4b) are pistons, of which one each reaches into one of the containers (2a, 2b) for sealant components, and wherein the latter containers are reservoir containers.

- The apparatus (1) according to claim 1 or 2,wherein the two conveying devices are pumps, more particularly eccentric screw pumps (14a, 14b) or scoop piston pumps.

- The apparatus (1) according to claim 4,wherein the two conveying devices are eccentric screw pumps (14a, 14b) and the containers for sealant components are open containers (15a, 15b) which can each be filled continuously with a sealant component (5a, 5b) .

- The apparatus (1) according to any of the preceding claims,wherein the mixing unit (7) is a static mixer.

- The apparatus (1) according to any of the preceding claims,wherein the compensating container (10) is a plastic cartridge or a component that is easy to clean.

- The apparatus (1) according to any of the preceding claims,wherein the apparatus (1) is a 2-component mixing and metering system.

- The apparatus (1) according to any of the preceding claims,wherein it comprises an integrated source of actinic radiation.

- A method for dynamic metering of sealants,wherein the containers (2a, 2b) of the apparatus (1) according to any of the preceding claims are each filled with one sealant component (5a, 5b), wherein the sealant components (5a, 5b) are mixed in a mixing unit (7), and wherein the resultant sealant (9) is applied to a component, by conveying the sealant components (5a, 5b) from the containers (2a, 2b) by means of the first drive (3), where a metering rate below a critical value preset in the drive controller (6) is actualized by lowering the conveying rate of the sealant components (5a, 5b) from the containers (2a, 2b) to the critical value of the metering rate, and

filling the compensating container (10) with sealant (9) by means of the second drive (12) in such a way that the rate at which the compensating container (10) is filled corresponds to the difference between the critical value and the actualized value of the metering rate. - The method according to claim 10,wherein, in the event of the metering rate climbing again to at least the critical value, the conveying of the sealant components (5a, 5b) from the containers (2a, 2b) is halted, and the sealant (9) is conveyed from the compensating container (10) by means of the second drive (12), until the sealant (9) in the compensating container (10) is used up.

- The method according to claim 10,wherein, in the event of the metering rate climbing again to at least the critical value, the conveying of the sealant components (5a, 5b) from the containers (2a, 2b) by means of the first drive (3) and of the sealant (9) from the compensating container (10) by means of the second drive (12) takes place simultaneously until the sealant (9) in the compensating container (10) is used up.

- The method according to any of claims 10 to 12,wherein the sealant (9) is a sealant which cures substantially only after irradiation with actinic radiation.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102016217429 | 2016-09-13 | ||

| DE102016224655 | 2016-12-12 | ||

| PCT/EP2017/072215WO2018050482A1 (en) | 2016-09-13 | 2017-09-05 | Device and method for dynamic metering of sealing compounds |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3512640A1 EP3512640A1 (en) | 2019-07-24 |

| EP3512640B1true EP3512640B1 (en) | 2022-03-16 |

Family

ID=59799376

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP17762112.5AActiveEP3512640B1 (en) | 2016-09-13 | 2017-09-05 | Device and method for dynamic metering of sealing compounds |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US11059070B2 (en) |

| EP (1) | EP3512640B1 (en) |

| JP (1) | JP6999676B2 (en) |

| CN (1) | CN109789436B (en) |

| BR (1) | BR112019003551B1 (en) |

| CA (1) | CA3036589A1 (en) |

| WO (1) | WO2018050482A1 (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2021520991A (en)* | 2018-04-12 | 2021-08-26 | ノードソン コーポレーションNordson Corporation | Systems and methods for dispensing multi-component materials |

| MX2022007588A (en) | 2019-12-19 | 2022-07-19 | Chemetall Gmbh | Polyurea coating systems as sealants for the exterior of fuel tanks. |

| US20230018655A1 (en) | 2019-12-19 | 2023-01-19 | Construction Research & Technology Gmbh | Polyurea coating systems for construction waterproofing |

| DE102020128115A1 (en)* | 2020-10-26 | 2022-04-28 | Dürr Systems Ag | Application device for preferably partially boosted application |

Family Cites Families (34)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3224411A (en)* | 1961-09-18 | 1965-12-21 | Ford Motor Co | Apparatus for applying adhesive to a surface |

| US3390814A (en)* | 1965-09-24 | 1968-07-02 | Chem Dev Corp | Mixing device |

| US3401847A (en)* | 1967-04-03 | 1968-09-17 | Thermon Mfg Co | Pneumatically powered applicator |

| US3989228A (en)* | 1974-12-19 | 1976-11-02 | Products Research & Chemical Corporation | Mixing and dispensing apparatus |

| US4067479A (en)* | 1975-07-31 | 1978-01-10 | Products Research & Chemical Corporation | Two part material meter-mix dispenser apparatus |

| US4666430A (en)* | 1984-12-05 | 1987-05-19 | I-Flow Corporation | Infusion pump |

| US4995540A (en)* | 1987-12-07 | 1991-02-26 | Laurence Colin | Unit dosage dispenser for dental impression materials |

| FR2632891B1 (en)* | 1988-06-17 | 1990-10-19 | Saint Gobain Vitrage | IMPROVEMENT IN THE MANUFACTURE OF A CORD OF ORGANIC MATERIAL TO BE USED AS A JOINT AND INTERMEDIATE IN A MULTIPLE WINDOW |

| DE69022714T2 (en)* | 1990-02-22 | 1996-05-09 | Minnesota Mining & Mfg | Static mixing device. |

| US5064098A (en)* | 1990-02-23 | 1991-11-12 | Physical Systems, Inc. | Dual component dispenser gun |

| US5224629A (en)* | 1992-03-19 | 1993-07-06 | Hsich Rong Fuh | Control structure for a pneumatic sealant gun |

| US5478150A (en)* | 1994-01-24 | 1995-12-26 | Wilhelm A. Keller | Device for the continuous monitoring of the correct proportioning and mixing of at least two fluids |

| DE4412261C2 (en)* | 1994-04-09 | 1996-10-17 | Jonas Konrad H | Device for merging at least two flow media |

| JPH0998560A (en)* | 1995-09-29 | 1997-04-08 | Zexel Corp | Brushless motor |

| US5816445A (en)* | 1996-01-25 | 1998-10-06 | Stainless Steel Coatings, Inc. | Method of and apparatus for controlled dispensing of two-part bonding, casting and similar fluids and the like |

| US5979794A (en)* | 1997-05-13 | 1999-11-09 | Ingersoll-Rand Company | Two-part stream dispensing for high viscosity materials |

| DE19834444C2 (en)* | 1997-08-07 | 2003-04-30 | Lenhardt Maschinenbau | Machine for filling the edge joint of insulating glass panes with a sealing compound from two components |

| US6126401A (en)* | 1998-08-12 | 2000-10-03 | Computer Graphics Systems Development Corporation | Hybrid electric/hydraulic drive system |

| EP1000669B1 (en)* | 1998-11-09 | 2006-01-04 | Mixpac Systems AG | A system for the transfer of reactive resins components from a remote source to the point of application |

| TW509738B (en)* | 1999-03-25 | 2002-11-11 | Barmag Barmer Maschf | Lubrication apparatus and method of applying a lubricant |

| FR2791648B1 (en)* | 1999-04-02 | 2001-05-25 | Oreal | PORTABLE DISPENSER FOR THE PACKAGING AND DISPENSING OF COLORED COSMETICS |

| EP1197267A4 (en)* | 1999-05-21 | 2006-09-20 | Matsushita Electric Industrial Co Ltd | APPLICATION DEVICE FOR VISCOUS MATERIALS |

| JP2001149838A (en)* | 1999-11-30 | 2001-06-05 | Toyota Motor Corp | Apparatus for applying two-component mixed-curable sealing material and method for forming gasket in-situ |

| US6896152B2 (en)* | 2000-03-02 | 2005-05-24 | Graco Minnesota Inc. | Electronic plural component proportioner |

| US6540104B1 (en)* | 2000-06-30 | 2003-04-01 | Fanuc Robotics North America, Inc. | Integral pneumatic dispenser and method for controlling same |

| US6619508B2 (en)* | 2001-10-25 | 2003-09-16 | International Business Machines Corporation | Apparatus for dispensing a multiple-component substance from a multiple-barrel cartridge |

| DE202005005833U1 (en)* | 2005-02-25 | 2005-06-23 | Vosschemie Gmbh | Dispenser and mixer for two component reactive resin-fillers e.g. for repair of automobile bodywork |

| US7562792B2 (en)* | 2005-06-13 | 2009-07-21 | George Nisbet | Method and apparatus for metering a fluid mixture |

| US20070000947A1 (en)* | 2005-07-01 | 2007-01-04 | Lewis Russell H | Apparatus and methods for dispensing fluidic or viscous materials |

| US8197122B2 (en)* | 2008-04-24 | 2012-06-12 | Tyco Healthcare Group Lp | Dynamic mixing applicator |

| EP2191904A2 (en)* | 2008-12-01 | 2010-06-02 | Sturm Maschinenbau GmbH | Device and method for applying a multi-component mixture |

| EP2198949A1 (en)* | 2008-12-18 | 2010-06-23 | Sika Technology AG | Dispensing tool for multi-component substances |

| CN105385406B (en)* | 2015-12-08 | 2017-12-15 | 中国航空工业集团公司北京航空材料研究院 | A kind of room temperature vulcanization bi-component polysulfide ether sealant, its preparation and application |

| CN109476050A (en) | 2016-07-26 | 2019-03-15 | 凯密特尔有限责任公司 | Method and apparatus for filling sealing caps |

- 2017

- 2017-09-05WOPCT/EP2017/072215patent/WO2018050482A1/ennot_activeCeased

- 2017-09-05CNCN201780055980.7Apatent/CN109789436B/ennot_activeExpired - Fee Related

- 2017-09-05JPJP2019535447Apatent/JP6999676B2/ennot_activeExpired - Fee Related

- 2017-09-05CACA3036589Apatent/CA3036589A1/enactivePending

- 2017-09-05EPEP17762112.5Apatent/EP3512640B1/enactiveActive

- 2017-09-05BRBR112019003551-6Apatent/BR112019003551B1/ennot_activeIP Right Cessation

- 2017-09-05USUS16/332,919patent/US11059070B2/ennot_activeExpired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN109789436B (en) | 2021-07-09 |

| JP2019532813A (en) | 2019-11-14 |

| WO2018050482A1 (en) | 2018-03-22 |

| US11059070B2 (en) | 2021-07-13 |

| CN109789436A (en) | 2019-05-21 |

| BR112019003551B1 (en) | 2022-09-20 |

| US20190232330A1 (en) | 2019-08-01 |

| EP3512640A1 (en) | 2019-07-24 |

| JP6999676B2 (en) | 2022-02-04 |

| CA3036589A1 (en) | 2018-03-22 |

| BR112019003551A2 (en) | 2019-05-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3512640B1 (en) | Device and method for dynamic metering of sealing compounds | |

| EP3102503B1 (en) | Cartridge and method for producing a cartridge | |

| EP2440379B1 (en) | Method and device for preparing a paste-like compound for sealing an insulating glass pane | |

| DE2847906A1 (en) | METHOD AND SYSTEM FOR SUPPORTING A FIRST, IN PARTICULAR A FIRST, OF A SUBSIDIARY EXCAVATION | |

| EP2986394B1 (en) | Application nozzle | |

| DE202006014187U1 (en) | Device for mixing binder and hardener in machine for preparing filler, e.g. for automobile bodywork, comprises binder and hardener supply controlled so that small amount of hardener is pre-injected | |

| DE19708548A1 (en) | Multi=chamber tubular film cartridge, especially for two or more separate components | |

| EP1588757B1 (en) | Static mixer for production of curable mixtures from liquid components, and its use | |

| EP0853502B1 (en) | Method and device for metering viscous material | |

| AT517359B1 (en) | Device with intermittently provided liquid plastic component | |

| WO2017005803A1 (en) | 3d printing with a pasty, inhomogeneous printing material | |

| DE102021123434A1 (en) | Metering device and method for metered dispensing of a viscous thermal compound | |

| EP2198949A1 (en) | Dispensing tool for multi-component substances | |

| DE102018216152B4 (en) | Control and closure device for extruded plastically deformable material | |

| EP2868392A1 (en) | Sleeve, discharge device comprising the sleeve and method | |

| DE202007007037U1 (en) | Fluid e.g. hot melt adhesive, dispensing device, for foil or layer-shaped substrate e.g. label, has valve with rotatable body to selectively interrupt and release fluid flow, and nozzle arrangement communicating with supply channel | |

| EP2556934B1 (en) | Spraying device and process for analyzing a release mixture | |

| DE102010012466B4 (en) | Dosing device for a shear-sensitive adhesive and device for applying adhesive with such a dosing device | |

| EP0709144A1 (en) | Device for the dosed distribution of a viscous mass, particularly of adhesive sealant for the manufacture of insulating glass units | |

| DE202007004570U1 (en) | Mixing device for mixing of binding component and curing component to obtain a pasty or liquid mixed product, comprises inlet openings, discharge openings, and a mixing chamber arranged between the openings | |

| DE102018112966B4 (en) | Mixing nozzle, device with mixing nozzle for dispensing multi-component masses and use of the device | |

| DE9320072U1 (en) | Device for filling one or more casting molds with pourable liquid media | |

| DE102023136012A1 (en) | FLUID APPLICATOR WITH PROPORTIONAL VALVE | |

| DE2412249A1 (en) | DEVICE AND METHOD FOR MEASURING FLAVORING MATERIALS | |

| DE102021121588A1 (en) | Device for the exact dosing of a fluid, dosing system and method for the exact dosing of a fluid |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent | Free format text:STATUS: UNKNOWN | |

| STAA | Information on the status of an ep patent application or granted ep patent | Free format text:STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE | |

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase | Free format text:ORIGINAL CODE: 0009012 | |

| STAA | Information on the status of an ep patent application or granted ep patent | Free format text:STATUS: REQUEST FOR EXAMINATION WAS MADE | |

| 17P | Request for examination filed | Effective date:20190415 | |

| AK | Designated contracting states | Kind code of ref document:A1 Designated state(s):AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR | |

| AX | Request for extension of the european patent | Extension state:BA ME | |

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent | Free format text:ORIGINAL CODE: EPIDOSNIGR1 | |

| STAA | Information on the status of an ep patent application or granted ep patent | Free format text:STATUS: GRANT OF PATENT IS INTENDED | |

| INTG | Intention to grant announced | Effective date:20211117 | |

| GRAS | Grant fee paid | Free format text:ORIGINAL CODE: EPIDOSNIGR3 | |

| GRAA | (expected) grant | Free format text:ORIGINAL CODE: 0009210 | |

| STAA | Information on the status of an ep patent application or granted ep patent | Free format text:STATUS: THE PATENT HAS BEEN GRANTED | |

| AK | Designated contracting states | Kind code of ref document:B1 Designated state(s):AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR | |

| REG | Reference to a national code | Ref country code:GB Ref legal event code:FG4D Free format text:NOT ENGLISH | |

| REG | Reference to a national code | Ref country code:CH Ref legal event code:EP | |

| REG | Reference to a national code | Ref country code:DE Ref legal event code:R096 Ref document number:502017012791 Country of ref document:DE | |

| REG | Reference to a national code | Ref country code:IE Ref legal event code:FG4D Free format text:LANGUAGE OF EP DOCUMENT: GERMAN | |

| REG | Reference to a national code | Ref country code:AT Ref legal event code:REF Ref document number:1475506 Country of ref document:AT Kind code of ref document:T Effective date:20220415 | |

| REG | Reference to a national code | Ref country code:LT Ref legal event code:MG9D | |

| REG | Reference to a national code | Ref country code:NL Ref legal event code:MP Effective date:20220316 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:SE Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 Ref country code:RS Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 Ref country code:NO Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220616 Ref country code:LT Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 Ref country code:HR Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 Ref country code:BG Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220616 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:LV Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 Ref country code:GR Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220617 Ref country code:FI Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:NL Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:SM Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 Ref country code:SK Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 Ref country code:RO Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 Ref country code:PT Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220718 Ref country code:ES Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 Ref country code:EE Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 Ref country code:CZ Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:PL Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 Ref country code:IS Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220716 Ref country code:AL Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 | |

| REG | Reference to a national code | Ref country code:DE Ref legal event code:R097 Ref document number:502017012791 Country of ref document:DE | |

| PLBE | No opposition filed within time limit | Free format text:ORIGINAL CODE: 0009261 | |

| STAA | Information on the status of an ep patent application or granted ep patent | Free format text:STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:DK Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 | |

| 26N | No opposition filed | Effective date:20221219 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:SI Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:MC Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 | |

| REG | Reference to a national code | Ref country code:CH Ref legal event code:PL | |

| REG | Reference to a national code | Ref country code:BE Ref legal event code:MM Effective date:20220930 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:LU Free format text:LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date:20220905 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:LI Free format text:LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date:20220930 Ref country code:IT Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 Ref country code:IE Free format text:LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date:20220905 Ref country code:CH Free format text:LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date:20220930 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:BE Free format text:LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date:20220930 | |

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] | Ref country code:GB Payment date:20230926 Year of fee payment:7 | |

| REG | Reference to a national code | Ref country code:AT Ref legal event code:MM01 Ref document number:1475506 Country of ref document:AT Kind code of ref document:T Effective date:20220905 | |

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] | Ref country code:FR Payment date:20230926 Year of fee payment:7 Ref country code:DE Payment date:20230928 Year of fee payment:7 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:AT Free format text:LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date:20220905 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:HU Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date:20170905 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:CY Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:MK Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:MT Free format text:LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date:20220316 | |

| REG | Reference to a national code | Ref country code:DE Ref legal event code:R119 Ref document number:502017012791 Country of ref document:DE | |

| GBPC | Gb: european patent ceased through non-payment of renewal fee | Effective date:20240905 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:DE Free format text:LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date:20250401 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:GB Free format text:LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date:20240905 | |

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] | Ref country code:FR Free format text:LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date:20240930 |