EP2632696B1 - Process and apparatus for fabrication of three-dimensional objects - Google Patents

Process and apparatus for fabrication of three-dimensional objectsDownload PDFInfo

- Publication number

- EP2632696B1 EP2632696B1EP11781918.5AEP11781918AEP2632696B1EP 2632696 B1EP2632696 B1EP 2632696B1EP 11781918 AEP11781918 AEP 11781918AEP 2632696 B1EP2632696 B1EP 2632696B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- ink

- layer

- polymer

- dimensional

- certain embodiments

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000004519manufacturing processMethods0.000titleclaimsdescription52

- 238000000034methodMethods0.000titleclaimsdescription48

- 230000008569processEffects0.000titleclaimsdescription23

- 229920000642polymerPolymers0.000claimsdescription122

- 238000000151depositionMethods0.000claimsdescription45

- 239000000463materialSubstances0.000claimsdescription43

- 238000007639printingMethods0.000claimsdescription37

- 239000003054catalystSubstances0.000claimsdescription15

- KDLHZDBZIXYQEI-UHFFFAOYSA-NPalladiumChemical compound[Pd]KDLHZDBZIXYQEI-UHFFFAOYSA-N0.000claimsdescription12

- 238000001465metallisationMethods0.000claimsdescription10

- 239000004480active ingredientSubstances0.000claimsdescription9

- 239000000975dyeSubstances0.000claimsdescription7

- BQCADISMDOOEFD-UHFFFAOYSA-NSilverChemical compound[Ag]BQCADISMDOOEFD-UHFFFAOYSA-N0.000claimsdescription6

- 229910052763palladiumInorganic materials0.000claimsdescription6

- 239000000049pigmentSubstances0.000claimsdescription6

- BASFCYQUMIYNBI-UHFFFAOYSA-NplatinumChemical compound[Pt]BASFCYQUMIYNBI-UHFFFAOYSA-N0.000claimsdescription6

- 229910052709silverInorganic materials0.000claimsdescription6

- 239000004332silverSubstances0.000claimsdescription6

- KJTLSVCANCCWHF-UHFFFAOYSA-NRutheniumChemical compound[Ru]KJTLSVCANCCWHF-UHFFFAOYSA-N0.000claimsdescription3

- 229910017052cobaltInorganic materials0.000claimsdescription3

- 239000010941cobaltSubstances0.000claimsdescription3

- GUTLYIVDDKVIGB-UHFFFAOYSA-Ncobalt atomChemical compound[Co]GUTLYIVDDKVIGB-UHFFFAOYSA-N0.000claimsdescription3

- 229910052741iridiumInorganic materials0.000claimsdescription3

- GKOZUEZYRPOHIO-UHFFFAOYSA-Niridium atomChemical compound[Ir]GKOZUEZYRPOHIO-UHFFFAOYSA-N0.000claimsdescription3

- 229910052762osmiumInorganic materials0.000claimsdescription3

- SYQBFIAQOQZEGI-UHFFFAOYSA-Nosmium atomChemical compound[Os]SYQBFIAQOQZEGI-UHFFFAOYSA-N0.000claimsdescription3

- 229910052697platinumInorganic materials0.000claimsdescription3

- 229910052707rutheniumInorganic materials0.000claimsdescription3

- 230000005855radiationEffects0.000claims1

- 239000000976inkSubstances0.000description208

- 239000010410layerSubstances0.000description177

- XECAHXYUAAWDEL-UHFFFAOYSA-Nacrylonitrile butadiene styreneChemical compoundC=CC=C.C=CC#N.C=CC1=CC=CC=C1XECAHXYUAAWDEL-UHFFFAOYSA-N0.000description43

- 229920000122acrylonitrile butadiene styrenePolymers0.000description43

- 239000004676acrylonitrile butadiene styreneSubstances0.000description43

- 230000008021depositionEffects0.000description33

- 239000004615ingredientSubstances0.000description17

- 238000012360testing methodMethods0.000description16

- 229920001707polybutylene terephthalatePolymers0.000description13

- 230000003993interactionEffects0.000description11

- 229920005989resinPolymers0.000description11

- 239000011347resinSubstances0.000description11

- -1polybutylene terephthalatePolymers0.000description10

- WYURNTSHIVDZCO-UHFFFAOYSA-NTetrahydrofuranChemical compoundC1CCOC1WYURNTSHIVDZCO-UHFFFAOYSA-N0.000description8

- 239000011248coating agentSubstances0.000description8

- 238000000576coating methodMethods0.000description8

- 239000004922lacquerSubstances0.000description8

- 238000004113cell cultureMethods0.000description7

- 229920000747poly(lactic acid)Polymers0.000description7

- 238000010100freeform fabricationMethods0.000description6

- 239000007787solidSubstances0.000description6

- 239000000243solutionSubstances0.000description6

- 239000002904solventSubstances0.000description6

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description6

- 239000004952PolyamideSubstances0.000description5

- 239000007788liquidSubstances0.000description5

- 230000003287optical effectEffects0.000description5

- 229920002647polyamidePolymers0.000description5

- 229920000089Cyclic olefin copolymerPolymers0.000description4

- XEEYBQQBJWHFJM-UHFFFAOYSA-NIronChemical compound[Fe]XEEYBQQBJWHFJM-UHFFFAOYSA-N0.000description4

- 239000007864aqueous solutionSubstances0.000description4

- 238000005452bendingMethods0.000description4

- 230000008901benefitEffects0.000description4

- 210000004027cellAnatomy0.000description4

- 238000011960computer-aided designMethods0.000description4

- 238000004090dissolutionMethods0.000description4

- 239000004014plasticizerSubstances0.000description4

- 239000007921spraySubstances0.000description4

- YLQBMQCUIZJEEH-UHFFFAOYSA-NtetrahydrofuranNatural productsC=1C=COC=1YLQBMQCUIZJEEH-UHFFFAOYSA-N0.000description4

- 229920000106Liquid crystal polymerPolymers0.000description3

- 239000004977Liquid-crystal polymers (LCPs)Substances0.000description3

- 229920003171Poly (ethylene oxide)Polymers0.000description3

- 239000004696Poly ether ether ketoneSubstances0.000description3

- DNIAPMSPPWPWGF-UHFFFAOYSA-NPropylene glycolChemical compoundCC(O)CODNIAPMSPPWPWGF-UHFFFAOYSA-N0.000description3

- HEMHJVSKTPXQMS-UHFFFAOYSA-MSodium hydroxideChemical compound[OH-].[Na+]HEMHJVSKTPXQMS-UHFFFAOYSA-M0.000description3

- 239000004566building materialSubstances0.000description3

- 229920001577copolymerPolymers0.000description3

- 230000001965increasing effectEffects0.000description3

- 238000005495investment castingMethods0.000description3

- 229910052751metalInorganic materials0.000description3

- 239000002184metalSubstances0.000description3

- 238000007747platingMethods0.000description3

- 229920000058polyacrylatePolymers0.000description3

- 229920001610polycaprolactonePolymers0.000description3

- 229920000515polycarbonatePolymers0.000description3

- 239000004417polycarbonateSubstances0.000description3

- 229920000647polyepoxidePolymers0.000description3

- 229920000728polyesterPolymers0.000description3

- 229920002530polyetherether ketonePolymers0.000description3

- 229920000098polyolefinPolymers0.000description3

- 229920000915polyvinyl chloridePolymers0.000description3

- 239000004800polyvinyl chlorideSubstances0.000description3

- 239000004094surface-active agentSubstances0.000description3

- 229920002725thermoplastic elastomerPolymers0.000description3

- 230000001960triggered effectEffects0.000description3

- RZVAJINKPMORJF-UHFFFAOYSA-NAcetaminophenChemical compoundCC(=O)NC1=CC=C(O)C=C1RZVAJINKPMORJF-UHFFFAOYSA-N0.000description2

- 102000008186CollagenHuman genes0.000description2

- 108010035532CollagenProteins0.000description2

- RYGMFSIKBFXOCR-UHFFFAOYSA-NCopperChemical compound[Cu]RYGMFSIKBFXOCR-UHFFFAOYSA-N0.000description2

- 239000004641Diallyl-phthalateSubstances0.000description2

- 102000016942ElastinHuman genes0.000description2

- 108010014258ElastinProteins0.000description2

- LYCAIKOWRPUZTN-UHFFFAOYSA-NEthylene glycolChemical compoundOCCOLYCAIKOWRPUZTN-UHFFFAOYSA-N0.000description2

- WSFSSNUMVMOOMR-UHFFFAOYSA-NFormaldehydeChemical compoundO=CWSFSSNUMVMOOMR-UHFFFAOYSA-N0.000description2

- 102000006395GlobulinsHuman genes0.000description2

- 108010044091GlobulinsProteins0.000description2

- PXHVJJICTQNCMI-UHFFFAOYSA-NNickelChemical compound[Ni]PXHVJJICTQNCMI-UHFFFAOYSA-N0.000description2

- 239000004698PolyethyleneSubstances0.000description2

- 239000004642PolyimideSubstances0.000description2

- 239000004793PolystyreneSubstances0.000description2

- WCUXLLCKKVVCTQ-UHFFFAOYSA-MPotassium chlorideChemical compound[Cl-].[K+]WCUXLLCKKVVCTQ-UHFFFAOYSA-M0.000description2

- XUIMIQQOPSSXEZ-UHFFFAOYSA-NSiliconChemical compound[Si]XUIMIQQOPSSXEZ-UHFFFAOYSA-N0.000description2

- 239000008186active pharmaceutical agentSubstances0.000description2

- 239000003513alkaliSubstances0.000description2

- 230000003110anti-inflammatory effectEffects0.000description2

- 239000003146anticoagulant agentSubstances0.000description2

- 229940127219anticoagulant drugDrugs0.000description2

- 239000002246antineoplastic agentSubstances0.000description2

- 229920000249biocompatible polymerPolymers0.000description2

- 229920002988biodegradable polymerPolymers0.000description2

- 239000004621biodegradable polymerSubstances0.000description2

- QUDWYFHPNIMBFC-UHFFFAOYSA-Nbis(prop-2-enyl) benzene-1,2-dicarboxylateChemical compoundC=CCOC(=O)C1=CC=CC=C1C(=O)OCC=CQUDWYFHPNIMBFC-UHFFFAOYSA-N0.000description2

- 210000002449bone cellAnatomy0.000description2

- RJTANRZEWTUVMA-UHFFFAOYSA-Nboron;n-methylmethanamineChemical compound[B].CNCRJTANRZEWTUVMA-UHFFFAOYSA-N0.000description2

- 210000003321cartilage cellAnatomy0.000description2

- 230000003197catalytic effectEffects0.000description2

- 230000008859changeEffects0.000description2

- 229940044683chemotherapy drugDrugs0.000description2

- 229920001436collagenPolymers0.000description2

- 238000010276constructionMethods0.000description2

- 229910052802copperInorganic materials0.000description2

- 239000010949copperSubstances0.000description2

- 238000013461designMethods0.000description2

- 239000012153distilled waterSubstances0.000description2

- 238000001035dryingMethods0.000description2

- 229920002549elastinPolymers0.000description2

- 238000005516engineering processMethods0.000description2

- 239000003822epoxy resinSubstances0.000description2

- 238000005530etchingMethods0.000description2

- 238000011156evaluationMethods0.000description2

- LNEPOXFFQSENCJ-UHFFFAOYSA-NhaloperidolChemical compoundC1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1LNEPOXFFQSENCJ-UHFFFAOYSA-N0.000description2

- 239000000017hydrogelSubstances0.000description2

- 230000001506immunosuppresive effectEffects0.000description2

- 230000002401inhibitory effectEffects0.000description2

- 229910052742ironInorganic materials0.000description2

- 210000003292kidney cellAnatomy0.000description2

- 238000001459lithographyMethods0.000description2

- 210000005229liver cellAnatomy0.000description2

- 150000002689maleic acidsChemical class0.000description2

- 230000007246mechanismEffects0.000description2

- 239000000203mixtureSubstances0.000description2

- 210000000663muscle cellAnatomy0.000description2

- 210000002569neuronAnatomy0.000description2

- 210000000496pancreasAnatomy0.000description2

- 229920003023plasticPolymers0.000description2

- 239000004033plasticSubstances0.000description2

- 229920001306poly(lactide-co-caprolactone)Polymers0.000description2

- 229920002492poly(sulfone)Polymers0.000description2

- 239000004632polycaprolactoneSubstances0.000description2

- 229920001223polyethylene glycolPolymers0.000description2

- 229920000139polyethylene terephthalatePolymers0.000description2

- 229920001721polyimidePolymers0.000description2

- 239000013047polymeric layerSubstances0.000description2

- 229920002223polystyrenePolymers0.000description2

- 229920002635polyurethanePolymers0.000description2

- 239000004814polyurethaneSubstances0.000description2

- RUOJZAUFBMNUDX-UHFFFAOYSA-Npropylene carbonateChemical compoundCC1COC(=O)O1RUOJZAUFBMNUDX-UHFFFAOYSA-N0.000description2

- 150000003839saltsChemical class0.000description2

- 238000000110selective laser sinteringMethods0.000description2

- 239000010703siliconSubstances0.000description2

- 229910052710siliconInorganic materials0.000description2

- SQGYOTSLMSWVJD-UHFFFAOYSA-Nsilver(1+) nitrateChemical compound[Ag+].[O-]N(=O)=OSQGYOTSLMSWVJD-UHFFFAOYSA-N0.000description2

- 210000004927skin cellAnatomy0.000description2

- 210000001519tissueAnatomy0.000description2

- 2380000101463D printingMethods0.000description1

- HBTAOSGHCXUEKI-UHFFFAOYSA-N4-chloro-n,n-dimethyl-3-nitrobenzenesulfonamideChemical compoundCN(C)S(=O)(=O)C1=CC=C(Cl)C([N+]([O-])=O)=C1HBTAOSGHCXUEKI-UHFFFAOYSA-N0.000description1

- BSYNRYMUTXBXSQ-UHFFFAOYSA-NAspirinChemical compoundCC(=O)OC1=CC=CC=C1C(O)=OBSYNRYMUTXBXSQ-UHFFFAOYSA-N0.000description1

- 108010027612BatroxobinProteins0.000description1

- DKPFZGUDAPQIHT-UHFFFAOYSA-NButyl acetateNatural productsCCCCOC(C)=ODKPFZGUDAPQIHT-UHFFFAOYSA-N0.000description1

- PMATZTZNYRCHOR-CGLBZJNRSA-NCyclosporin AChemical compoundCC[C@@H]1NC(=O)[C@H]([C@H](O)[C@H](C)C\C=C\C)N(C)C(=O)[C@H](C(C)C)N(C)C(=O)[C@H](CC(C)C)N(C)C(=O)[C@H](CC(C)C)N(C)C(=O)[C@@H](C)NC(=O)[C@H](C)NC(=O)[C@H](CC(C)C)N(C)C(=O)[C@H](C(C)C)NC(=O)[C@H](CC(C)C)N(C)C(=O)CN(C)C1=OPMATZTZNYRCHOR-CGLBZJNRSA-N0.000description1

- 229930105110Cyclosporin ANatural products0.000description1

- 108010036949CyclosporineProteins0.000description1

- 239000004593EpoxySubstances0.000description1

- HKVAMNSJSFKALM-GKUWKFKPSA-NEverolimusChemical compoundC1C[C@@H](OCCO)[C@H](OC)C[C@@H]1C[C@@H](C)[C@H]1OC(=O)[C@@H]2CCCCN2C(=O)C(=O)[C@](O)(O2)[C@H](C)CC[C@H]2C[C@H](OC)/C(C)=C/C=C/C=C/[C@@H](C)C[C@@H](C)C(=O)[C@H](OC)[C@H](O)/C(C)=C/[C@@H](C)C(=O)C1HKVAMNSJSFKALM-GKUWKFKPSA-N0.000description1

- HTTJABKRGRZYRN-UHFFFAOYSA-NHeparinChemical compoundOC1C(NC(=O)C)C(O)OC(COS(O)(=O)=O)C1OC1C(OS(O)(=O)=O)C(O)C(OC2C(C(OS(O)(=O)=O)C(OC3C(C(O)C(O)C(O3)C(O)=O)OS(O)(=O)=O)C(CO)O2)NS(O)(=O)=O)C(C(O)=O)O1HTTJABKRGRZYRN-UHFFFAOYSA-N0.000description1

- 101000691618Homo sapiens Inactive phospholipase C-like protein 1Proteins0.000description1

- HEFNNWSXXWATRW-UHFFFAOYSA-NIbuprofenChemical compoundCC(C)CC1=CC=C(C(C)C(O)=O)C=C1HEFNNWSXXWATRW-UHFFFAOYSA-N0.000description1

- 102100026207Inactive phospholipase C-like protein 1Human genes0.000description1

- MGJKQDOBUOMPEZ-UHFFFAOYSA-NN,N'-dimethylureaChemical compoundCNC(=O)NCMGJKQDOBUOMPEZ-UHFFFAOYSA-N0.000description1

- SECXISVLQFMRJM-UHFFFAOYSA-NN-MethylpyrrolidoneChemical compoundCN1CCCC1=OSECXISVLQFMRJM-UHFFFAOYSA-N0.000description1

- 239000000020NitrocelluloseSubstances0.000description1

- 229930012538PaclitaxelNatural products0.000description1

- OFOBLEOULBTSOW-UHFFFAOYSA-NPropanedioic acidNatural productsOC(=O)CC(O)=OOFOBLEOULBTSOW-UHFFFAOYSA-N0.000description1

- QJJXYPPXXYFBGM-LFZNUXCKSA-NTacrolimusChemical compoundC1C[C@@H](O)[C@H](OC)C[C@@H]1\C=C(/C)[C@@H]1[C@H](C)[C@@H](O)CC(=O)[C@H](CC=C)/C=C(C)/C[C@H](C)C[C@H](OC)[C@H]([C@H](C[C@H]2C)OC)O[C@@]2(O)C(=O)C(=O)N2CCCC[C@H]2C(=O)O1QJJXYPPXXYFBGM-LFZNUXCKSA-N0.000description1

- NSOXQYCFHDMMGV-UHFFFAOYSA-NTetrakis(2-hydroxypropyl)ethylenediamineChemical compoundCC(O)CN(CC(C)O)CCN(CC(C)O)CC(C)ONSOXQYCFHDMMGV-UHFFFAOYSA-N0.000description1

- SLINHMUFWFWBMU-UHFFFAOYSA-NTriisopropanolamineChemical compoundCC(O)CN(CC(C)O)CC(C)OSLINHMUFWFWBMU-UHFFFAOYSA-N0.000description1

- 229920004890Triton X-100Polymers0.000description1

- 239000013504Triton X-100Substances0.000description1

- 239000006096absorbing agentSubstances0.000description1

- 229960001138acetylsalicylic acidDrugs0.000description1

- 150000001252acrylic acid derivativesChemical class0.000description1

- NIXOWILDQLNWCW-UHFFFAOYSA-Nacrylic acid groupChemical groupC(C=C)(=O)ONIXOWILDQLNWCW-UHFFFAOYSA-N0.000description1

- 239000000654additiveSubstances0.000description1

- 229930013930alkaloidNatural products0.000description1

- 150000001336alkenesChemical class0.000description1

- 229940100198alkylating agentDrugs0.000description1

- 239000002168alkylating agentSubstances0.000description1

- 230000000781anti-lymphocytic effectEffects0.000description1

- 230000000340anti-metaboliteEffects0.000description1

- 230000001494anti-thymocyte effectEffects0.000description1

- 229940100197antimetaboliteDrugs0.000description1

- 239000002256antimetaboliteSubstances0.000description1

- 239000004599antimicrobialSubstances0.000description1

- 230000004888barrier functionEffects0.000description1

- 229960002210batroxobinDrugs0.000description1

- JUPQTSLXMOCDHR-UHFFFAOYSA-Nbenzene-1,4-diol;bis(4-fluorophenyl)methanoneChemical compoundOC1=CC=C(O)C=C1.C1=CC(F)=CC=C1C(=O)C1=CC=C(F)C=C1JUPQTSLXMOCDHR-UHFFFAOYSA-N0.000description1

- 239000011230binding agentSubstances0.000description1

- 238000005266castingMethods0.000description1

- 229960001265ciclosporinDrugs0.000description1

- 239000003086colorantSubstances0.000description1

- 238000004040coloringMethods0.000description1

- 238000009500colour coatingMethods0.000description1

- JZCCFEFSEZPSOG-UHFFFAOYSA-Lcopper(II) sulfate pentahydrateChemical compoundO.O.O.O.O.[Cu+2].[O-]S([O-])(=O)=OJZCCFEFSEZPSOG-UHFFFAOYSA-L0.000description1

- 239000003246corticosteroidSubstances0.000description1

- 229960001334corticosteroidsDrugs0.000description1

- 239000013078crystalSubstances0.000description1

- 229930182912cyclosporinNatural products0.000description1

- 230000032798delaminationEffects0.000description1

- 229960001193diclofenac sodiumDrugs0.000description1

- 229940031578diisopropyl adipateDrugs0.000description1

- IRXRGVFLQOSHOH-UHFFFAOYSA-Ldipotassium;oxalateChemical compound[K+].[K+].[O-]C(=O)C([O-])=OIRXRGVFLQOSHOH-UHFFFAOYSA-L0.000description1

- 239000006185dispersionSubstances0.000description1

- 239000003534dna topoisomerase inhibitorSubstances0.000description1

- FBZANXDWQAVSTQ-UHFFFAOYSA-NdodecamethylpentasiloxaneChemical compoundC[Si](C)(C)O[Si](C)(C)O[Si](C)(C)O[Si](C)(C)O[Si](C)(C)CFBZANXDWQAVSTQ-UHFFFAOYSA-N0.000description1

- 229940087203dodecamethylpentasiloxaneDrugs0.000description1

- 230000002708enhancing effectEffects0.000description1

- 125000003700epoxy groupChemical group0.000description1

- 229960005167everolimusDrugs0.000description1

- 238000011049fillingMethods0.000description1

- KANJSNBRCNMZMV-ABRZTLGGSA-NfondaparinuxChemical compoundO[C@@H]1[C@@H](NS(O)(=O)=O)[C@@H](OC)O[C@H](COS(O)(=O)=O)[C@H]1O[C@H]1[C@H](OS(O)(=O)=O)[C@@H](O)[C@H](O[C@@H]2[C@@H]([C@@H](OS(O)(=O)=O)[C@H](O[C@H]3[C@@H]([C@@H](O)[C@H](O[C@@H]4[C@@H]([C@@H](O)[C@H](O)[C@@H](COS(O)(=O)=O)O4)NS(O)(=O)=O)[C@H](O3)C(O)=O)O)[C@@H](COS(O)(=O)=O)O2)NS(O)(=O)=O)[C@H](C(O)=O)O1KANJSNBRCNMZMV-ABRZTLGGSA-N0.000description1

- 229960001318fondaparinuxDrugs0.000description1

- 239000013538functional additiveSubstances0.000description1

- 230000004927fusionEffects0.000description1

- 229960002897heparinDrugs0.000description1

- 229920000669heparinPolymers0.000description1

- FUZZWVXGSFPDMH-UHFFFAOYSA-MhexanoateChemical compoundCCCCCC([O-])=OFUZZWVXGSFPDMH-UHFFFAOYSA-M0.000description1

- 239000001257hydrogenSubstances0.000description1

- 229910052739hydrogenInorganic materials0.000description1

- WGCNASOHLSPBMP-UHFFFAOYSA-NhydroxyacetaldehydeNatural productsOCC=OWGCNASOHLSPBMP-UHFFFAOYSA-N0.000description1

- 229960001680ibuprofenDrugs0.000description1

- VZCYOOQTPOCHFL-UPHRSURJSA-Nmaleic acidChemical compoundOC(=O)\C=C/C(O)=OVZCYOOQTPOCHFL-UPHRSURJSA-N0.000description1

- 239000011976maleic acidSubstances0.000description1

- 230000008018meltingEffects0.000description1

- 238000002844meltingMethods0.000description1

- 150000002734metacrylic acid derivativesChemical class0.000description1

- 150000002739metalsChemical class0.000description1

- XJRBAMWJDBPFIM-UHFFFAOYSA-Nmethyl vinyl etherChemical compoundCOC=CXJRBAMWJDBPFIM-UHFFFAOYSA-N0.000description1

- HPNSFSBZBAHARI-UHFFFAOYSA-Nmicophenolic acidNatural productsOC1=C(CC=C(C)CCC(O)=O)C(OC)=C(C)C2=C1C(=O)OC2HPNSFSBZBAHARI-UHFFFAOYSA-N0.000description1

- 229960000951mycophenolic acidDrugs0.000description1

- HPNSFSBZBAHARI-RUDMXATFSA-Nmycophenolic acidChemical compoundOC1=C(C\C=C(/C)CCC(O)=O)C(OC)=C(C)C2=C1C(=O)OC2HPNSFSBZBAHARI-RUDMXATFSA-N0.000description1

- 229910052759nickelInorganic materials0.000description1

- LGQLOGILCSXPEA-UHFFFAOYSA-Lnickel sulfateChemical compound[Ni+2].[O-]S([O-])(=O)=OLGQLOGILCSXPEA-UHFFFAOYSA-L0.000description1

- 229910000363nickel(II) sulfateInorganic materials0.000description1

- 229920001220nitrocellulosPolymers0.000description1

- 150000002894organic compoundsChemical class0.000description1

- 125000002524organometallic groupChemical group0.000description1

- 229960001592paclitaxelDrugs0.000description1

- 239000003973paintSubstances0.000description1

- YJVFFLUZDVXJQI-UHFFFAOYSA-Lpalladium(ii) acetateChemical compound[Pd+2].CC([O-])=O.CC([O-])=OYJVFFLUZDVXJQI-UHFFFAOYSA-L0.000description1

- 229960005489paracetamolDrugs0.000description1

- 230000000737periodic effectEffects0.000description1

- 229920000848poly(L-lactide-ε-caprolactone)Polymers0.000description1

- 229920001606poly(lactic acid-co-glycolic acid)Polymers0.000description1

- 229920001515polyalkylene glycolPolymers0.000description1

- 229920001451polypropylene glycolPolymers0.000description1

- 229920002451polyvinyl alcoholPolymers0.000description1

- 235000019422polyvinyl alcoholNutrition0.000description1

- 229920000036polyvinylpyrrolidonePolymers0.000description1

- 239000001267polyvinylpyrrolidoneSubstances0.000description1

- 235000013855polyvinylpyrrolidoneNutrition0.000description1

- 239000001103potassium chlorideSubstances0.000description1

- 235000011164potassium chlorideNutrition0.000description1

- 102000004196processed proteins & peptidesHuman genes0.000description1

- 108090000765processed proteins & peptidesProteins0.000description1

- 239000000047productSubstances0.000description1

- SCUZVMOVTVSBLE-UHFFFAOYSA-Nprop-2-enenitrile;styreneChemical compoundC=CC#N.C=CC1=CC=CC=C1SCUZVMOVTVSBLE-UHFFFAOYSA-N0.000description1

- 102000004169proteins and genesHuman genes0.000description1

- 108090000623proteins and genesProteins0.000description1

- ZAHRKKWIAAJSAO-UHFFFAOYSA-NrapamycinNatural productsCOCC(O)C(=C/C(C)C(=O)CC(OC(=O)C1CCCCN1C(=O)C(=O)C2(O)OC(CC(OC)C(=CC=CC=CC(C)CC(C)C(=O)C)C)CCC2C)C(C)CC3CCC(O)C(C3)OC)CZAHRKKWIAAJSAO-UHFFFAOYSA-N0.000description1

- 229920006395saturated elastomerPolymers0.000description1

- 238000006748scratchingMethods0.000description1

- 230000002393scratching effectEffects0.000description1

- 229910001961silver nitrateInorganic materials0.000description1

- 229960002930sirolimusDrugs0.000description1

- QFJCIRLUMZQUOT-HPLJOQBZSA-NsirolimusChemical compoundC1C[C@@H](O)[C@H](OC)C[C@@H]1C[C@@H](C)[C@H]1OC(=O)[C@@H]2CCCCN2C(=O)C(=O)[C@](O)(O2)[C@H](C)CC[C@H]2C[C@H](OC)/C(C)=C/C=C/C=C/[C@@H](C)C[C@@H](C)C(=O)[C@H](OC)[C@H](O)/C(C)=C/[C@@H](C)C(=O)C1QFJCIRLUMZQUOT-HPLJOQBZSA-N0.000description1

- 150000003384small moleculesChemical class0.000description1

- 239000001509sodium citrateSubstances0.000description1

- NLJMYIDDQXHKNR-UHFFFAOYSA-Ksodium citrateChemical compoundO.O.[Na+].[Na+].[Na+].[O-]C(=O)CC(O)(CC([O-])=O)C([O-])=ONLJMYIDDQXHKNR-UHFFFAOYSA-K0.000description1

- JGMJQSFLQWGYMQ-UHFFFAOYSA-Msodium;2,6-dichloro-n-phenylaniline;acetateChemical compound[Na+].CC([O-])=O.ClC1=CC=CC(Cl)=C1NC1=CC=CC=C1JGMJQSFLQWGYMQ-UHFFFAOYSA-M0.000description1

- 210000000130stem cellAnatomy0.000description1

- 229920000638styrene acrylonitrilePolymers0.000description1

- 239000000126substanceSubstances0.000description1

- 239000013589supplementSubstances0.000description1

- 229920001059synthetic polymerPolymers0.000description1

- 229960001967tacrolimusDrugs0.000description1

- QJJXYPPXXYFBGM-SHYZHZOCSA-NtacrolimusNatural productsCO[C@H]1C[C@H](CC[C@@H]1O)C=C(C)[C@H]2OC(=O)[C@H]3CCCCN3C(=O)C(=O)[C@@]4(O)O[C@@H]([C@H](C[C@H]4C)OC)[C@@H](C[C@H](C)CC(=C[C@@H](CC=C)C(=O)C[C@H](O)[C@H]2C)C)OCQJJXYPPXXYFBGM-SHYZHZOCSA-N0.000description1

- RCINICONZNJXQF-MZXODVADSA-NtaxolChemical compoundO([C@@H]1[C@@]2(C[C@@H](C(C)=C(C2(C)C)[C@H](C([C@]2(C)[C@@H](O)C[C@H]3OC[C@]3([C@H]21)OC(C)=O)=O)OC(=O)C)OC(=O)[C@H](O)[C@@H](NC(=O)C=1C=CC=CC=1)C=1C=CC=CC=1)O)C(=O)C1=CC=CC=C1RCINICONZNJXQF-MZXODVADSA-N0.000description1

- 238000010998test methodMethods0.000description1

- 229920001187thermosetting polymerPolymers0.000description1

- 229940044693topoisomerase inhibitorDrugs0.000description1

- VZCYOOQTPOCHFL-UHFFFAOYSA-Ntrans-butenedioic acidNatural productsOC(=O)C=CC(O)=OVZCYOOQTPOCHFL-UHFFFAOYSA-N0.000description1

- 238000013519translationMethods0.000description1

- 229960005080warfarinDrugs0.000description1

- PJVWKTKQMONHTI-UHFFFAOYSA-NwarfarinChemical compoundOC=1C2=CC=CC=C2OC(=O)C=1C(CC(=O)C)C1=CC=CC=C1PJVWKTKQMONHTI-UHFFFAOYSA-N0.000description1

- 229920003169water-soluble polymerPolymers0.000description1

- 238000009736wettingMethods0.000description1

- ZXIBCJHYVWYIKI-PZJWPPBQSA-NximelagatranChemical compoundC1([C@@H](NCC(=O)OCC)C(=O)N2[C@@H](CC2)C(=O)NCC=2C=CC(=CC=2)C(\N)=N\O)CCCCC1ZXIBCJHYVWYIKI-PZJWPPBQSA-N0.000description1

- 229960001522ximelagatranDrugs0.000description1

- CGTADGCBEXYWNE-JUKNQOCSSA-NzotarolimusChemical compoundN1([C@H]2CC[C@@H](C[C@@H](C)[C@H]3OC(=O)[C@@H]4CCCCN4C(=O)C(=O)[C@@]4(O)[C@H](C)CC[C@H](O4)C[C@@H](/C(C)=C/C=C/C=C/[C@@H](C)C[C@@H](C)C(=O)[C@H](OC)[C@H](O)/C(C)=C/[C@@H](C)C(=O)C3)OC)C[C@H]2OC)C=NN=N1CGTADGCBEXYWNE-JUKNQOCSSA-N0.000description1

- 229950009819zotarolimusDrugs0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y10/00—Processes of additive manufacturing

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C67/00—Shaping techniques not covered by groups B29C39/00 - B29C65/00, B29C70/00 or B29C73/00

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/10—Processes of additive manufacturing

- B29C64/106—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C35/00—Heating, cooling or curing, e.g. crosslinking or vulcanising; Apparatus therefor

- B29C35/02—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould

- B29C35/08—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation

- B29C35/0805—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation using electromagnetic radiation

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C37/00—Component parts, details, accessories or auxiliary operations, not covered by group B29C33/00 or B29C35/00

- B29C37/0067—Using separating agents during or after moulding; Applying separating agents on preforms or articles, e.g. to prevent sticking to each other

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/10—Processes of additive manufacturing

- B29C64/106—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material

- B29C64/112—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material using individual droplets, e.g. from jetting heads

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/10—Processes of additive manufacturing

- B29C64/106—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material

- B29C64/118—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material using filamentary material being melted, e.g. fused deposition modelling [FDM]

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/10—Processes of additive manufacturing

- B29C64/106—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material

- B29C64/124—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material using layers of liquid which are selectively solidified

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/10—Processes of additive manufacturing

- B29C64/106—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material

- B29C64/124—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material using layers of liquid which are selectively solidified

- B29C64/129—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material using layers of liquid which are selectively solidified characterised by the energy source therefor, e.g. by global irradiation combined with a mask

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/10—Processes of additive manufacturing

- B29C64/106—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material

- B29C64/124—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material using layers of liquid which are selectively solidified

- B29C64/129—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material using layers of liquid which are selectively solidified characterised by the energy source therefor, e.g. by global irradiation combined with a mask

- B29C64/135—Processes of additive manufacturing using only liquids or viscous materials, e.g. depositing a continuous bead of viscous material using layers of liquid which are selectively solidified characterised by the energy source therefor, e.g. by global irradiation combined with a mask the energy source being concentrated, e.g. scanning lasers or focused light sources

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/10—Processes of additive manufacturing

- B29C64/165—Processes of additive manufacturing using a combination of solid and fluid materials, e.g. a powder selectively bound by a liquid binder, catalyst, inhibitor or energy absorber

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C64/00—Additive manufacturing, i.e. manufacturing of three-dimensional [3D] objects by additive deposition, additive agglomeration or additive layering, e.g. by 3D printing, stereolithography or selective laser sintering

- B29C64/40—Structures for supporting 3D objects during manufacture and intended to be sacrificed after completion thereof

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y30/00—Apparatus for additive manufacturing; Details thereof or accessories therefor

- B—PERFORMING OPERATIONS; TRANSPORTING

- B33—ADDITIVE MANUFACTURING TECHNOLOGY

- B33Y—ADDITIVE MANUFACTURING, i.e. MANUFACTURING OF THREE-DIMENSIONAL [3-D] OBJECTS BY ADDITIVE DEPOSITION, ADDITIVE AGGLOMERATION OR ADDITIVE LAYERING, e.g. BY 3-D PRINTING, STEREOLITHOGRAPHY OR SELECTIVE LASER SINTERING

- B33Y70/00—Materials specially adapted for additive manufacturing

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C35/00—Heating, cooling or curing, e.g. crosslinking or vulcanising; Apparatus therefor

- B29C35/02—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould

- B29C35/08—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation

- B29C35/0805—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation using electromagnetic radiation

- B29C2035/0822—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation using electromagnetic radiation using IR radiation

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C35/00—Heating, cooling or curing, e.g. crosslinking or vulcanising; Apparatus therefor

- B29C35/02—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould

- B29C35/08—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation

- B29C35/0805—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation using electromagnetic radiation

- B29C2035/0827—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation using electromagnetic radiation using UV radiation

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C35/00—Heating, cooling or curing, e.g. crosslinking or vulcanising; Apparatus therefor

- B29C35/02—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould

- B29C35/08—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation

- B29C35/0805—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation using electromagnetic radiation

- B29C2035/0855—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation using electromagnetic radiation using microwave

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C35/00—Heating, cooling or curing, e.g. crosslinking or vulcanising; Apparatus therefor

- B29C35/02—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould

- B29C35/08—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation

- B29C35/0805—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation using electromagnetic radiation

- B29C2035/0861—Heating or curing, e.g. crosslinking or vulcanizing during moulding, e.g. in a mould by wave energy or particle radiation using electromagnetic radiation using radio frequency

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2071/00—Use of polyethers, e.g. PEEK, i.e. polyether-etherketone or PEK, i.e. polyetherketone or derivatives thereof, as moulding material

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2073/00—Use of other polymers having oxygen as the only hetero atom in the main chain, as moulding material

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2075/00—Use of PU, i.e. polyureas or polyurethanes or derivatives thereof, as moulding material

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2995/00—Properties of moulding materials, reinforcements, fillers, preformed parts or moulds

- B29K2995/0018—Properties of moulding materials, reinforcements, fillers, preformed parts or moulds having particular optical properties, e.g. fluorescent or phosphorescent

- B29K2995/002—Coloured

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24802—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.]

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24802—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.]

- Y10T428/24893—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.] including particulate material

- Y10T428/24901—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.] including particulate material including coloring matter

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24802—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.]

- Y10T428/24917—Discontinuous or differential coating, impregnation or bond [e.g., artwork, printing, retouched photograph, etc.] including metal layer

Definitions

- This disclosurerelates to a method and apparatus for fabricating three-dimensional objects from polymer-based material.

- this inventionrelates to a three-dimensional fabrication apparatus having a print head and ink delivery system.

- CADComputer Aided Design

- layer manufacturingwhich entails building an object on a layer-by- layer and point-by-point basis.

- Examples of commercially available solid freeform fabrication systemsinclude stereo lithography, selective laser sintering, laminated object manufacturing, and fused deposition modeling.

- Other examples of solid freeform fabrication systemsare known to those of skill in the art.

- Forming objects automatically in three dimensionsis useful in verifying CAD databases, assessing aesthetics, checking ergonomics of design, aiding in tool and fixture design, creating conceptual models and sales/marketing tools, generating patterns for investment casting, reducing or eliminating engineering changes in production, and providing small production runs.

- US 6 165 406 Adiscloses a freeform fabrication process and apparatus for making a colorful 3-D object.

- the processincludes (1) operating a multiple-channel droplet deposition device for supplying and, on demand, ejecting droplets of multiple liquid compositions containing a solidifiable baseline body-building material and different colorants; (2) providing a support platform a distance from this deposition device to receive the droplets therefrom; and (3) during the droplet ejecting process, moving the deposition device and the platform relative to one another in an X-Y plane and in a Z direction orthogonal to the X-Y plane so that the droplets are deposited to form multiple layers to build a colorful 3-D object.

- US 2010/195122 A1discloses a method for printing a painted three-dimensional object. Each layer of the object is printed so that only the external circumference of the layer contains colored material.

- US 2004/251574 A1discloses a method for producing an object formed through solid freeform fabrication includes dispensing a binder on successive layers of build material with a single first dispensing member; and coloring the successive layers with at least one second dispensing member, where the second dispensing member over-dispenses the first dispensing member.

- US 2007/108664 A1discloses a process for chemically etching a stereolithography resin involves chemically etching a shaped object of the resin at a temperature in a range of from about 20°C to about 30°C for a time of from about 30 seconds to about 60 seconds with a saturated aqueous solution of permanganate.

- EP 1 925 428 A1discloses a method and system for making a partially coated product having at least one coated area and at least one non-coated area.

- WO 98/09798discloses the features of the preamble of claim 1.

- aspects of the inventionare directed to fabrication of three-dimensional objects.

- the three-dimensional objectsmay have high-resolution color.

- the present inventionprovides a three-dimensional fabrication method comprising: (a) depositing a first polymer layer; (b) printing a first ink layer on to the first polymer layer; (c) depositing a second polymer layer on to the first ink layer; (d) printing a second ink layer on to the second polymer layer; and (e) repeating steps (a)-(d) to form a three-dimensional object, wherein at least one of the first and second ink layers includes an ink comprising electroless metallization catalysts.

- the first and the second ink layermay each include a plurality of ink layers.

- the first and second polymer layermay each include a plurality of polymer layers.

- forming at least one of the first and second ink layersmay include utilizing an ink further comprising at least one of pigments, dyes, and catalysts.

- the electroless metallization catalystsmay be selected from the group including palladium, ruthenium, platinum, silver, osmium, iridium, and cobalt.

- the electroless metallization catalystis palladium or silver.

- forming at least one of the first and second ink layersincludes utilizing a color ink.

- At least one of the first and second ink layersis deposited along a circumferential edge of at least one of the first and second polymer layers. In certain embodiments forming at least one of the first and second ink layers may include utilizing an ink that is selected based on its solubility parameter in relation to a polymer solubility parameter.

- forming at least one of the first and second polymer layersincludes utilizing a polymeric material selected from acrylonitrile butadiene styrene, polyacrylates, polyolefins, cyclic olefin polymers and copolymers, polycarbonates, polyamides, polyimides, polyethylene and polybutylene terephthalate, liquid crystal polymer resins, poly ether ether ketone, thermoplastic elastomers, polystyrenes, polyvinyl chloride, polysulfones, polyurethanes, polyamides, polyesters, epoxy resins, silicon resin, a diallyl phthalate resin, a cellulosic plastic, a rosin-modified maleic acid resin, copolymers thereof, collagen, elastin, hydrogels, xerogels, polycaprolactone, poly(D,L-lactide-co-glycolide), polylactide, poly(lactide-co-caprolact

- a support structureis formed adjacent to the three-dimensional object during the fabrication process.

- the support structuremay be removed from the three-dimensional object.

- a releasable ink layermay be printed between the three-dimensional object and the support structure.

- forming the support structuremay include utilizing a polymeric material that is similar to a polymeric material used to form the three-dimensional object.

- the polymeric materialmay be a water soluble, solvent soluble, or alkali soluble polymer.

- the support structurehas an external ink layer that includes at least one ingredient that is soluble in a polymeric material included in the support structure.

- the at least one ingredientaccelerates dissolution of the polymeric material of the support structure, or in alternative embodiments, the at least one ingredient causes the external ink layer to dissolve prior to the dissolution of the polymeric material of the support structure.

- an overcoat layeris applied to at least one of the first and second ink layers.

- the overcoat layeris a lacquer, in some embodiments the overcoat layer is applied to the three-dimensional object.

- the overcoat layeris a translucent or transparent polymeric material.

- at least one of the first and second ink layersis treated with a heat source, an energy source, or combinations thereof.

- the heat sourcemay be selected from the group having conventional, conduction, radiant, and combinations thereof.

- the energy sourcemay be an electromagnetic energy source.

- the electromagnetic energy sourcemay be selected from the group having infrared, near infrared, visible, ultraviolet, radiofrequency, microwave, and combinations thereof.

- the printing of at least one of the first or second ink layersforms a target pattern that may be used to optical!' align a three-dimensional printing apparatus.

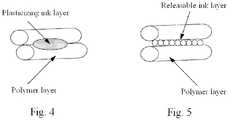

- At least one of the first and second ink layersincludes a releasable ink or a plasticizing ink.

- forming a first portion of at least one of the first and second ink layersincludes utilizing a first ink and a second portion of at least one of the first and second ink layers is formed utilizing a second ink.

- the first inkis a plasticizing ink and the second ink is a plasticizing ink with a higher concentration of plasticizer than the first ink.

- the first ink and the second inkprovide different surface properties between the first portion and the second portion of the ink layer.

- forming at least one of the first and second ink layersincludes utilizing a plasticizing ink creating a smooth surface on the three-dimensional object. In certain embodiments forming at least one of the first and second ink layers includes utilizing an ink comprising at least one ingredient that is soluble in the first and second polymer layer. In certain embodiments forming at least one of the first and second ink layers includes utilizing an ink comprising an active ingredient.

- the active ingredientmay be a pharmaceutical ingredient including an anti-inflammatory ingredient, an ingredient inhibiting neointimal growth, an anticoagulant, an antibody, an immunosuppressive ingredient, chemotherapeutic drugs, or combinations thereof. In alternative embodiments the active ingredient may be a cell culture including stem cells, cartilage cells, bone cells, muscle cells, skin cells, pancreas cells, kidney cells, liver cells, nerve cells, or combinations thereof.

- a three-dimensional fabrication apparatusincluding: (a) a polymer deposition apparatus; and (b) a printing apparatus including a print head and ink delivery system.

- the printing apparatusmay be attached to the polymer deposition apparatus.

- the polymer deposition apparatusincludes an extruder and the print head and ink delivery system is attached to the extruder.

- the polymer deposition apparatusincludes an extruder and the print head and ink delivery system is attached to the polymer deposition apparatus separate from the extruder.

- the polymer deposition apparatusis selected from the group having a fusion deposition modeling apparatus, a laminated object manufacturing apparatus, and a photopolymer three-dimensional deposition apparatus.

- the print head and ink delivery systemincludes a print head selected from the group including a thermal print head, a piezo print head, a MEMS print head, and an electrostatic print head.

- the print head and ink delivery systemincludes a print head selected from the group having a plotter-style single nozzle unit, a continuous ink jet, and a drop-on demand system.

- a method for selecting an ink for three-dimensional fabrication of a three-dimensional objectincluding: (a) selecting a polymer; (b) calculating the polymer's Hansen solubility parameter; (c) selecting an ink; (d) calculating the ink's Hansen solubility parameter; (e) comparing the polymer's Hansen solubility parameter to the ink's Hansen solubility parameter to determine if the ink would be a releasable ink or a plasticizing ink; and (f) utilizing the polymer and the ink to form a three-dimensional object by three-dimensional fabrication.

- a methodincluding (a) depositing a first polymer layer to form a three-dimensional object; (b) printing an ink layer on to the three-dimensional object to form a shell.

- the three-dimensional fabrication methodfurther includes depositing at least one second polymer layer on to the shell.

- the second polymer layeris formed utilizing a translucent or transparent polymeric material.

- the present inventionprovides a method for fabricating a three- dimensional object.

- three-dimensional fabricationis used to refer to the method of building a three-dimensional object layer-by-layer.

- Three-dimensional fabricationrefers to the combination of depositing at least one layer of a polymer and printing at least one layer of an ink to form a three-dimensional object.

- a "layer"is formed by a single pass of a deposition apparatus or a printing apparatus.

- the at least one polymer layer and at least one ink layermay be deposited and printed in any order.

- multiple polymer layersmay be deposited prior to an ink layer being printed.

- the polymer and ink layersmay alternate by individual or multiple layers.

- Various deposition methodsare known in the art, including, but not limited to, fused deposition modeling, laminated object manufacturing, stereo lithography, and selective laser sintering.

- the inventionmay be performed with a three-dimensional deposition apparatus, such as that used for fused deposition modeling, including an extruder assembly that dispenses a polymer.

- the polymerforms a three-dimensional object in a layer-by-layer process on a build platform.

- the extruder assemblymay be stationary, or may allow for movement in the XY axes, for movement in the X axis or Y axis only, and/or for rotational or angular movements.

- the build platformgenerally has indexed movement options in the Z axis.

- each movement in the Z axismay correspond to a specific layer thickness for the manufacture of a three-dimensional object.

- the build platformmay allow for optional movement in the XY axes, for movement in the X axis or Y axis only, and/or for rotational or angular movements.

- Extruder assembly 12dispenses polymer 14 onto build platform 18, in a layer-by-layer process, to form three-dimensional object 16. Once three-dimensional object 16 is completed it may be removed from build platform 18 and a new project may begin.

- a three-dimensional fabrication apparatusincludes a deposition apparatus and a printing apparatus.

- the deposition apparatusmay be similar to that used for fused deposition examples.

- the deposition apparatusincludes an extruder assembly that dispenses a polymer.

- the polymerforms a three-dimensional object in a layer-by- layer process on a build platform.

- the printing apparatusincludes a print head and ink delivery system for depositing various inks during production of any three-dimensional objects using the three-dimensional fabrication apparatus.

- the extruder headmay be stationary, or may allow for movement in the XY axes, for movement in the X axis or Y axis only, and/or for rotational or angular movements.

- the build platformgenerally has indexed movement options in the Z axis. Additionally, in certain examples the build platform may allow for optional movement in the XY axes, for movement in the X axis or Y axis only, and/or for rotational or angular movements.

- the print head and ink delivery systemmay deposit inks in a layer-by-layer fashion.

- the inksmay be color inks and/or functional inks.

- the print head and ink delivery systemmay be stationary, or in alternative embodiments, may allow for movement in the XY axes, for movement in the X axis or Y axis only, and/or for rotational or angular movements.

- the printing of the inksmay be triggered by an optical limit switch or a linear encoder.

- a schematic of a three-dimensional fabrication apparatusincluding a deposition apparatus similar to that used for fused deposition modeling and a printing apparatus having a print head and ink delivery system, is provided in Figure 2 .

- a three-dimensional fabrication apparatusincludes extruder assembly 32 that dispenses polymer 34, in a layer-by-layer process, to form three-dimensional object 36 on build platform 38.

- the fabrication apparatusincludes print head and ink delivery system 40, which dispenses ink on three-dimensional object 36, in a layer- by-layer process, during the build process.

- the printing apparatus having the print head and ink delivery systemis attached to the same mechanism as the deposition apparatus having the extruder, such that it travels with the deposition apparatus.

- the printing apparatusis attached to an independent moving or stationary mechanism that is attached to the three-dimensional fabrication apparatus.

- the printing apparatusis aligned with the deposition apparatus, but not attached to the deposition apparatus.

- the printing apparatusincludes a print head(s) that may be, for example, a piezoelectric print head, a thermal print head, a MEMS print head, an electrostatic print head, or combinations thereof.

- the printing apparatusincludes a print head that may be a plotter type single nozzle unit, a continuous ink jet, or a drop on demand system.

- the print head of the printing apparatusmay be positioned at any angle within the range of +45 to -45 degrees relative to the extruder of the deposition apparatus.

- printing apparatusis paired with any solid freeform fabrication apparatus that builds three-dimensional polymer objects by utilizing a layer-by-layer build process.

- apparatusesinclude a laminated object manufacturing apparatus or a three-dimensional photopolymer apparatus.

- the inventionprovides a three-dimensional fabrication method including depositing a first polymer layer, printing a first ink layer on to the first polymer layer, depositing a second polymer layer on to the first ink layer, and printing a second ink layer on to the second polymer layer.

- the fabrication processmay be repeated until a completed three-dimensional object is formed.

- the first and second polymer layermay each include a plurality of polymer layers.

- the plurality of polymer layers forming a first (or second) polymer layerneed not all be formed of the same polymer, but may include one or more distinct polymers.

- the first and second ink layermay each include a plurality of ink layers.

- the plurality of ink layers forming a first (or second) ink layerneed not all be formed of the same ink, but may include one or more distinct inks.

- the polymer layers and ink layersmay be deposited in varying number and in varying order when fabricating a three- dimensional object. Further, the polymer layers and/or the ink layers need not extend completely over the previously deposited layer. In some instances, an ink layer may be deposited only over a portion of the previously deposited polymer (or ink) layer. For example, an ink layer may be encapsulated between two surrounding polymer layers. In certain embodiments the printing or depositing of one layer onto another may cause the two layers to bind to one another.

- an ink layer printed between two polymer layersmay have at least one ingredient that is soluble in the polymeric material of the two polymer layers and causes a bond to form between the two polymer layers in binding to one another.

- an ink layermay be printed on a completed three-dimensional object to form a coating.

- the coatingmay act as a shell having a thickness of, for example, 0.01-5 mm.

- an overcoat layermay be applied to an ink layer.

- the overcoat layermay be a lacquer, and in alternative embodiments, may be a translucent or transparent polymer.

- an ink layermay be printed along the perimeter edge of a polymer layer.

- the ink layerincludes an ink that diffuses into the perimeter edge of the polymer layer.

- the perimeter ink layermay be printed on a polymer where the polymer includes a transparent or translucent polymeric material.

- the perimeter ink layer printed on a transparent or translucent polymermay create an optical illusion such that it appears the ink layer extends into the polymer layer.

- an additional polymeric layermay be applied to the perimeter of the ink layer, thereby providing protection from delamination or scratching, where the polymeric material may include a transparent or translucent polymeric material.

- the three-dimensional fabrication methodmay be utilized in certain embodiments to optically align the three-dimensional fabrication apparatus.

- an ink layer patternsuch as, for example, a target pattern, is printed on one or several layers of a sacrificial three-dimensional object or innocuously printed on any three-dimensional object.

- the ink layer patternis scanned with an optical sensor and the results of an optical alignment test are used to position the print head and ink jet delivery system as well as the extruder relative to the three-dimensional object.

- a layer of polymermay be deposited fully prior to a layer of ink being printed onto the layer of polymer.

- a layer of inkmay be printed onto the same layer of polymer.

- a first portion of at least one ink layermay include a first ink and a second portion of the at least one ink layer may include a second ink.

- a first portion of at least one polymer layermay include a first polymeric material and a second portion of the at least one polymeric layer may include a second polymeric material.

- FIG. 3A schematic of a three-dimensional fabrication process is provided in Figure 3 .

- An ink layeris formed on a polymer layer by having print head and ink delivery system 54 deposit ink droplets 52, optionally including dyes or pigments, onto polymer 56.

- Ink droplets 52form interaction area 58 where the ink contacts polymer 56.

- a support structureis formed adjacent to, or attached to, a three-dimensional object during the three-dimensional fabrication process.

- the three-dimensional apparatusis formed from a polymeric material.

- the deposition apparatusis used to form the support structure.

- a second deposition apparatusis used to form the support structure.

- the support structureis removable from the three-dimensional object.

- a releasable ink layeris printed between the three-dimensional object and the support structure, in some embodiments the releasable ink layer may be printed on the three-dimensional object only at the location where the support structure is attached. In certain embodiments the support structure may be broken into smaller pieces for removal.

- a polymeric material of the support structureis similar to, or in some embodiments is the same as, a polymeric material used to form the three- dimensional object.

- the support structure and/or the three-dimensional objectmay be formed of one or more polymeric materials.

- the support structuremay include a polymeric material that is a water soluble, solvent soluble, or alkali soluble polymer, such as, for example water soluble wax, polyethylene oxide and glycol-based polymers, polyvinyl pyrrolidone-based polymers, methyl vinyl ether, or maleic acid-based polymers.

- the support structuremay have an external ink layer.

- the external ink layerhas at least one ingredient that is soluble in a polymeric material included in the support structure.

- the at least one ingredient in the polymeric materialmay accelerate dissolution of the polymeric material.

- the at least one ingredientmay be, for example, low molecular weight compounds, such as, polyethylene glycols, polypropylene glycols, polyalkylene glycols, or polyethylene oxide.

- the at least one ingredient in the polymeric materialcauses the external ink layer to dissolve prior to the dissolution of the polymeric material of the support structure.

- the at least one ingredientmay be, for example, salts such as potassium chloride, potassium oxalate, or sodium citrate, low molecular weight water soluble polymers such as polyvinyl alcohols, or polyethylene oxides or water soluble organic compounds such as dimethyl urea, or propylene glycol.

- saltssuch as potassium chloride, potassium oxalate, or sodium citrate

- low molecular weight water soluble polymerssuch as polyvinyl alcohols, or polyethylene oxides or water soluble organic compounds such as dimethyl urea, or propylene glycol.

- At least one of the polymer layersmay include a polymeric material, such as, for example, acrylonitrile butadiene styrene (“ABS”), polyacrylates, polyolefins, cyclic olefin polymers and copolymers, polycarbonates, polyamides, polyimides, polyethylene and polybutylene terephthalate, liquid crystal polymer resins ("LCP”), polyether ether ketone (“PEEK”), thermoplastic elastomers (“TPE”), polystyrenes, polyvinyl chloride, polysulfones, polyacrylates, polyurethanes, polyamides, polyesters, polyolefins, epoxy resins, silicon resin, a diallyl phthalate resin, a cellulosic plastic, a rosin-modified maleic acid resin, copolymers thereof, any- other macromolecular structure, and combinations thereof.

- ABSacrylonitrile butadiene styrene

- the polymeris acrylonitrile butadiene styrene.

- the polymer layermay include a biocompatible or biodegradable polymeric material, such as, for example, collagen, elastin, hydrogels, xerogels, proteins, peptides, or a combination of any of them.

- the polymer layermay include a synthetic polymer, such as, for example, polycaprolactone ("PCL”), poly(D,L-lactide-co-glycolide) (“PLGA”), polylactide (“PLA”), poly(lactide-co-caprolactone) (“PLCL”), or a combination of any of them.

- the first polymer layeris wetted by application of the first ink layer.

- the ink of the first ink layeris a plasticizing or soluble ink that may be diffused into the first polymer layer(s).

- the polymer and ink layersmay be treated with plasma or corona discharge, in some embodiments the layers may be treated by passing the source of the discharge above the surface of the layers at, for example, a 1-5 mm distance.

- the print head and ink delivery system of the printing apparatusprints an ink layer.

- at least one of the ink layersincludes an ink having, for example, dyes, pigments, and/or catalysts.

- the inkis a color ink.

- the catalystsmay be electroless metallization catalysts.

- the electroless metallizationmay be, for example, a salt, or an organometallic complex of palladium, ruthenium, platinum, silver, osmium, iridium, or cobalt. In some embodiments other metals of Groups 8, 9, 10, and 11 of the Chemical Periodic Table are within the scope of this invention.

- the inkmay include an electroless metallization catalyst that is silver or palladium.

- the ink, the polymeric material, or both the ink and the polymeric materialmay include an active ingredient.

- the active ingredientmay be, for example, an active pharmaceutical ingredient or a cell culture.

- an active pharmaceutical ingredientmay be, for example, an anti-inflammatory ingredient, such as, for example, corticosteroids, diclofenac sodium, aspirin, ibuprofen, or acetaminophen; an ingredient inhibiting neointimal growth, such as, for example, everolimus, paclitaxel, or zotarolimus; an anticoagulant, such as, warfarin, heparin, fondaparinux, ximelagatran, or batroxobin; an immunosuppressive ingredient, such as, for example, cyclosporin, tacrolimus, sirolimus, or mycophenolic acid; an antibody, such as, for example, monoclonal anti-IL-2R ⁇ receptor antibodies, polyclonal anti-T-cell antibodies, anti

- a cell culturemay include, for example, stern cells, cartilage cells, bone cells, muscle cells, skin cells, pancreas cells, kidney cells, liver cells, nerve cells, or a combination of any of them.

- a cell culturemay be a live cell culture.

- a single ink or polymer layer having an active ingredientmay be printed/deposited.

- a number of ink or polymer layersmay be printed in a row. It is currently understood that by varying the number of ink or polymer layers having an active ingredient, the concentration and/or amount of the active ingredient on the three-dimensional object may be varied.

- an ink layeris formed utilizing an ink including a cell culture on a polymer layer formed utilizing a biocompatible or biodegradable polymer.

- an ink layer formed utilizing an ink including a cell culturemay form live tissue on a biocompatible or biodegradable polymer. In certain embodiments the live tissue will correspond to the type of cells in the ceil culture.

- the inkmay have a viscosity within the range of 10 -3 Pa ⁇ s to 2x10 -1 Pa ⁇ s (1 to 150 cps), within the range of 10 -3 Pa ⁇ s to 5x10 -2 Pa ⁇ s (1 to 50 cps), or within the range of 10 -3 Pa ⁇ s to 2x10 -2 Pa ⁇ s (1 to 22 cps), at a temperature of 25°C.

- the inkmay have a surface tension within the range of 0.018 - 0.072 N/m (18 to 72 dynes/cm), within the range of 0.02 - 0.04 N/m (20 to 40 dynes/cm), or within the range of 0.022 - 0.033 N/m (22 to 33 dynes/cm), at a temperature of 25°C.

- the inkmay be individually selected based on the solubility parameter of the ink and the solubility parameter of the polymer of the three- dimensional object.

- solubility parametersalso known as Hildebrand solubility parameters ( ⁇ ) and Hansen solubility parameters

- ⁇the energy of dispersion bonds

- ⁇ pdipole-dipole intermolecular force

- ⁇ hhydrogen bonding

- the Hansen solubility parameters of the two materialsmay be used to determine if one material will dissolve in the other, such as a polymer into a solvent or an ink.

- a value called an interaction radius (Ro)is given to the material to be dissolved.

- the interaction radius of the material to be dissolved, such as a polymermay define a sphere in Hansen space. If the second material, such as an ink, is within the sphere defined by the interaction radius then the polymer may be considered to dissolve into the ink.

- D(I-P)is the distance between the ink and the center of the polymer solubility sphere

- ⁇ x iis the Hansen component (as defined above) for an ink

- ⁇ xpis the Hansen component (as defined above) for the polymer.

- a specific inkmay be selected based on its solubility interaction with the specific polymer utilized for the three-dimensional object.

- the solubility of the ink in the polymermay be enhanced by utilizing heat or energy sources.

- enhanced solubility in the inkprovides additional benefits, including, for example, enhancing the drying characteristics of the ink.

- the heat sourcemay be, for example, conventional heat, conduction, radiant, or combinations thereof.

- the heat or energy sourceis applied after the three-dimensional object is fabricated.

- the heat or energy sourceis applied during fabrication of the three-dimensional object.

- the energy sourcemay be an electromagnetic energy source.

- the electromagnetic energy sourcemay be, for example, infrared, near infrared, visible, radiofrequency, microwave, or combinations thereof.

- many polymers and inksare transparent in the visible to infrared range, but in certain embodiments the polymer may be supplemented with pigments, dyes, or electroless metallization catalysts that may absorb energy in the same range, thus increasing process efficiency.

- various infrared, near infrared, visible energy, microwave, or radiofrequency absorbersmay be used to supplement the ink.

- the inkmay have a solubility parameter that falls within the radius of interaction, as defined by Equation 2. Inks that have a solubility parameter that fall within the radius of interaction are referred to here as plasticizing inks.

- a plasticizing inkmay be utilized to provide a color coating or shell, to deliver a functional coating, or to improve surface quality of a three- dimensional polymer object.

- the plasticizing inkfurther includes functional additives including, for example, electroless metallization or other catalysts, antimicrobial agents, or release additives.

- the plasticizing inkprovides a coating to a three-dimensional polymer object that may be cured.

- the coatingis a UV curable coating.

- the curable coatingmay create a smoother surface on the three-dimensional polymer object by filling in any gaps in an untreated surface of the object.

- three-dimensional polymer objectsformed with a polymer and a plasticizing ink by the method according to the invention, may be used to produce models for investment casting, also known as lost-wax casting. It is currently understood that in certain embodiments the plasticizing ink allows for a cleaner burnout process during the casting.

- a first portion of at least one of the ink is layersis formed utilizing a plasticizing ink and a second portion of the ink layer is formed utilizing a second plasticizing ink that has a higher concentration of plasticizer than the first ink.

- a difference in the amount of plasticizer in two different inkscan cause a different in the surface or material properties of the ink layer.

- a three-dimensional object formed utilizing a plasticizing ink having a high concentration of plasticizermay exhibit an increased flexibility as compared to a three-dimensional object formed utilizing an ink that is not a plasticizing ink.

- a plasticizing inkcreates a smooth surface on a three- dimensional object. It is currently understood that the plasticizing ink dissolves a portion of the surface of a polymer layer thereby creating a smoother surface.

- the print head and ink delivery systemincludes an ink that has a solubility parameter that falls outside the radius of interaction, as defined by Equation 2.

- Inks that have a solubility parameter that fall outside the radius of interactionare referred to here as releasing inks.

- releasing inksmay be utilized to aid in releasing a support structure from a three-dimensional polymer object.

- releasing inksmay provide a shell on a three-dimensional object.

- the releasing inksmay further include, for example, dyes, pigments, or catalysts to be utilized in forming the shell.

- the shellmay be a color shell.

- a fixing liquidmay be any liquid or solution with a solubility parameter within the radius of interaction as defined by Equation 2.

- the fixing process of the color shell on the three-dimensional objectmay be accelerated by application of, for example, heat, light, or electromagnetic energy.

- any volatile componentsmay be evaporated with or without a vacuum.

- an ink utilized in the three-dimensional fabrication methodmay have a low binding affinity to the specific polymer that is being utilized to form a three-dimensional object thereby resulting in low adhesion of the ink to the polymer.