EP1508443B1 - Inkjet printer with electro-magnetically actuated ink plunger - Google Patents

Inkjet printer with electro-magnetically actuated ink plungerDownload PDFInfo

- Publication number

- EP1508443B1 EP1508443B1EP04024057AEP04024057AEP1508443B1EP 1508443 B1EP1508443 B1EP 1508443B1EP 04024057 AEP04024057 AEP 04024057AEP 04024057 AEP04024057 AEP 04024057AEP 1508443 B1EP1508443 B1EP 1508443B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- ink

- nozzle

- actuator

- plunger

- ink jet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000033001locomotionEffects0.000claimsabstractdescription42

- 239000012530fluidSubstances0.000claimsabstractdescription12

- 230000004913activationEffects0.000claimsabstractdescription11

- 238000004891communicationMethods0.000claimsabstractdescription3

- 238000010276constructionMethods0.000claimsdescription32

- 239000000696magnetic materialSubstances0.000claimsdescription8

- 230000005291magnetic effectEffects0.000abstractdescription54

- 238000007641inkjet printingMethods0.000abstractdescription17

- 239000000976inkSubstances0.000description284

- 238000004519manufacturing processMethods0.000description49

- 238000000034methodMethods0.000description46

- 239000000463materialSubstances0.000description31

- 230000007246mechanismEffects0.000description21

- 230000008901benefitEffects0.000description18

- 238000007639printingMethods0.000description16

- 230000008569processEffects0.000description16

- XUIMIQQOPSSXEZ-UHFFFAOYSA-NSiliconChemical compound[Si]XUIMIQQOPSSXEZ-UHFFFAOYSA-N0.000description13

- 238000005516engineering processMethods0.000description13

- 229920001343polytetrafluoroethylenePolymers0.000description13

- 239000004810polytetrafluoroethyleneSubstances0.000description13

- 229910052710siliconInorganic materials0.000description13

- 239000010703siliconSubstances0.000description13

- RYGMFSIKBFXOCR-UHFFFAOYSA-NCopperChemical compound[Cu]RYGMFSIKBFXOCR-UHFFFAOYSA-N0.000description12

- 229910052802copperInorganic materials0.000description12

- 239000010949copperSubstances0.000description12

- 230000035882stressEffects0.000description12

- 238000013461designMethods0.000description11

- 230000009467reductionEffects0.000description11

- 230000002441reversible effectEffects0.000description11

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N2-ButanoneChemical compoundCCC(C)=OZWEHNKRNPOVVGH-UHFFFAOYSA-N0.000description9

- 239000000049pigmentSubstances0.000description9

- 230000005684electric fieldEffects0.000description8

- 239000011521glassSubstances0.000description7

- 238000000926separation methodMethods0.000description7

- 239000000758substrateSubstances0.000description7

- 238000012546transferMethods0.000description7

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description7

- 235000009899Agrostemma githagoNutrition0.000description6

- ZOXJGFHDIHLPTG-UHFFFAOYSA-NBoronChemical compound[B]ZOXJGFHDIHLPTG-UHFFFAOYSA-N0.000description6

- XEEYBQQBJWHFJM-UHFFFAOYSA-NIronChemical compound[Fe]XEEYBQQBJWHFJM-UHFFFAOYSA-N0.000description6

- PXHVJJICTQNCMI-UHFFFAOYSA-NNickelChemical compound[Ni]PXHVJJICTQNCMI-UHFFFAOYSA-N0.000description6

- 229910052796boronInorganic materials0.000description6

- 238000001035dryingMethods0.000description6

- 230000005686electrostatic fieldEffects0.000description6

- 230000004907fluxEffects0.000description6

- 239000012943hotmeltSubstances0.000description6

- 229910001172neodymium magnetInorganic materials0.000description6

- 229910052581Si3N4Inorganic materials0.000description5

- 230000008859changeEffects0.000description5

- 239000000975dyeSubstances0.000description5

- 238000009713electroplatingMethods0.000description5

- 238000010304firingMethods0.000description5

- 238000012545processingMethods0.000description5

- HQVNEWCFYHHQES-UHFFFAOYSA-Nsilicon nitrideChemical compoundN12[Si]34N5[Si]62N3[Si]51N64HQVNEWCFYHHQES-UHFFFAOYSA-N0.000description5

- 240000000254Agrostemma githagoSpecies0.000description4

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000description4

- 229910052782aluminiumInorganic materials0.000description4

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000description4

- 230000003321amplificationEffects0.000description4

- 238000009835boilingMethods0.000description4

- -1carbon (DLC)Chemical compound0.000description4

- 229920001940conductive polymerPolymers0.000description4

- 230000008878couplingEffects0.000description4

- 238000010168coupling processMethods0.000description4

- 238000005859coupling reactionMethods0.000description4

- 238000000151depositionMethods0.000description4

- 238000010586diagramMethods0.000description4

- 238000005530etchingMethods0.000description4

- 239000011159matrix materialSubstances0.000description4

- 238000001465metallisationMethods0.000description4

- 238000003199nucleic acid amplification methodMethods0.000description4

- 239000003921oilSubstances0.000description4

- 239000002245particleSubstances0.000description4

- 229920000642polymerPolymers0.000description4

- 229910001285shape-memory alloyInorganic materials0.000description4

- 239000004094surface-active agentSubstances0.000description4

- 229910001030Iron–nickel alloyInorganic materials0.000description3

- QJVKUMXDEUEQLH-UHFFFAOYSA-N[B].[Fe].[Nd]Chemical compound[B].[Fe].[Nd]QJVKUMXDEUEQLH-UHFFFAOYSA-N0.000description3

- 230000015572biosynthetic processEffects0.000description3

- BTANRVKWQNVYAZ-UHFFFAOYSA-Nbutan-2-olChemical compoundCCC(C)OBTANRVKWQNVYAZ-UHFFFAOYSA-N0.000description3

- 230000015556catabolic processEffects0.000description3

- 239000013078crystalSubstances0.000description3

- 230000009977dual effectEffects0.000description3

- 229910052746lanthanumInorganic materials0.000description3

- FZLIPJUXYLNCLC-UHFFFAOYSA-Nlanthanum atomChemical compound[La]FZLIPJUXYLNCLC-UHFFFAOYSA-N0.000description3

- 229910000734martensiteInorganic materials0.000description3

- 239000012528membraneSubstances0.000description3

- 229910052751metalInorganic materials0.000description3

- 239000002184metalSubstances0.000description3

- 229910052759nickelInorganic materials0.000description3

- 235000021251pulsesNutrition0.000description3

- OKTJSMMVPCPJKN-UHFFFAOYSA-NCarbonChemical compound[C]OKTJSMMVPCPJKN-UHFFFAOYSA-N0.000description2

- 229910003321CoFeInorganic materials0.000description2

- 229910000640Fe alloyInorganic materials0.000description2

- 229910001329Terfenol-DInorganic materials0.000description2

- 229910010380TiNiInorganic materials0.000description2

- RTAQQCXQSZGOHL-UHFFFAOYSA-NTitaniumChemical compound[Ti]RTAQQCXQSZGOHL-UHFFFAOYSA-N0.000description2

- 244000178320Vaccaria pyramidataSpecies0.000description2

- 239000000853adhesiveSubstances0.000description2

- 230000001070adhesive effectEffects0.000description2

- 230000003115biocidal effectEffects0.000description2

- 239000003139biocideSubstances0.000description2

- KPLQYGBQNPPQGA-UHFFFAOYSA-Ncobalt samariumChemical compound[Co].[Sm]KPLQYGBQNPPQGA-UHFFFAOYSA-N0.000description2

- 239000003086colorantSubstances0.000description2

- 239000012141concentrateSubstances0.000description2

- 235000009508confectioneryNutrition0.000description2

- 230000008021depositionEffects0.000description2

- 238000005137deposition processMethods0.000description2

- 239000000428dustSubstances0.000description2

- 230000000694effectsEffects0.000description2

- 239000004744fabricSubstances0.000description2

- 239000000835fiberSubstances0.000description2

- 238000007710freezingMethods0.000description2

- 238000010438heat treatmentMethods0.000description2

- 239000003906humectantSubstances0.000description2

- 229910052742ironInorganic materials0.000description2

- 230000005389magnetismEffects0.000description2

- 230000005499meniscusEffects0.000description2

- 238000002715modification methodMethods0.000description2

- 239000002991molded plasticSubstances0.000description2

- 229910001000nickel titaniumInorganic materials0.000description2

- 238000007645offset printingMethods0.000description2

- 238000012856packingMethods0.000description2

- 238000002161passivationMethods0.000description2

- 229910052761rare earth metalInorganic materials0.000description2

- 150000002910rare earth metalsChemical class0.000description2

- 229910000938samarium–cobalt magnetInorganic materials0.000description2

- 239000004065semiconductorSubstances0.000description2

- 230000001360synchronised effectEffects0.000description2

- 230000009466transformationEffects0.000description2

- 230000001052transient effectEffects0.000description2

- 230000007704transitionEffects0.000description2

- 101100269850Caenorhabditis elegans mask-1 geneProteins0.000description1

- 241001164374CalyxSpecies0.000description1

- 229910001279Dy alloyInorganic materials0.000description1

- CWYNVVGOOAEACU-UHFFFAOYSA-NFe2+Chemical compound[Fe+2]CWYNVVGOOAEACU-UHFFFAOYSA-N0.000description1

- 239000004642PolyimideSubstances0.000description1

- 229910001117Tb alloyInorganic materials0.000description1

- ATJFFYVFTNAWJD-UHFFFAOYSA-NTinChemical compound[Sn]ATJFFYVFTNAWJD-UHFFFAOYSA-N0.000description1

- KGWWEXORQXHJJQ-UHFFFAOYSA-N[Fe].[Co].[Ni]Chemical compound[Fe].[Co].[Ni]KGWWEXORQXHJJQ-UHFFFAOYSA-N0.000description1

- 230000009471actionEffects0.000description1

- 239000012190activatorSubstances0.000description1

- 229910045601alloyInorganic materials0.000description1

- 239000000956alloySubstances0.000description1

- 238000004458analytical methodMethods0.000description1

- 238000003491arrayMethods0.000description1

- 239000011324beadSubstances0.000description1

- 230000000903blocking effectEffects0.000description1

- 229910052799carbonInorganic materials0.000description1

- 239000002041carbon nanotubeSubstances0.000description1

- 229910021393carbon nanotubeInorganic materials0.000description1

- 238000006243chemical reactionMethods0.000description1

- 238000004140cleaningMethods0.000description1

- 230000002860competitive effectEffects0.000description1

- 239000002322conducting polymerSubstances0.000description1

- 239000004020conductorSubstances0.000description1

- 230000007797corrosionEffects0.000description1

- 238000005260corrosionMethods0.000description1

- 238000005536corrosion preventionMethods0.000description1

- 238000013500data storageMethods0.000description1

- 230000007423decreaseEffects0.000description1

- 230000001419dependent effectEffects0.000description1

- 238000011161developmentMethods0.000description1

- 238000002059diagnostic imagingMethods0.000description1

- 229910003460diamondInorganic materials0.000description1

- 239000010432diamondSubstances0.000description1

- 238000009826distributionMethods0.000description1

- 239000002019doping agentSubstances0.000description1

- KBQHZAAAGSGFKK-UHFFFAOYSA-Ndysprosium atomChemical compound[Dy]KBQHZAAAGSGFKK-UHFFFAOYSA-N0.000description1

- 229920001971elastomerPolymers0.000description1

- 230000005611electricityEffects0.000description1

- 238000005323electroformingMethods0.000description1

- 230000008030eliminationEffects0.000description1

- 238000003379elimination reactionMethods0.000description1

- 230000008020evaporationEffects0.000description1

- 238000001704evaporationMethods0.000description1

- 239000003302ferromagnetic materialSubstances0.000description1

- 238000001914filtrationMethods0.000description1

- 229920005570flexible polymerPolymers0.000description1

- 230000008014freezingEffects0.000description1

- 230000017525heat dissipationEffects0.000description1

- 230000002209hydrophobic effectEffects0.000description1

- 238000003384imaging methodMethods0.000description1

- 230000006698inductionEffects0.000description1

- 239000007924injectionSubstances0.000description1

- 238000002347injectionMethods0.000description1

- 238000001746injection mouldingMethods0.000description1

- 238000009413insulationMethods0.000description1

- 239000012212insulatorSubstances0.000description1

- 230000010354integrationEffects0.000description1

- 230000003993interactionEffects0.000description1

- 238000000608laser ablationMethods0.000description1

- 238000007648laser printingMethods0.000description1

- 238000001459lithographyMethods0.000description1

- 230000007774longtermEffects0.000description1

- 238000003754machiningMethods0.000description1

- 229910001004magnetic alloyInorganic materials0.000description1

- 238000007567mass-production techniqueMethods0.000description1

- 230000008018meltingEffects0.000description1

- 238000002844meltingMethods0.000description1

- 150000002739metalsChemical class0.000description1

- VNWKTOKETHGBQD-UHFFFAOYSA-NmethaneChemical compoundCVNWKTOKETHGBQD-UHFFFAOYSA-N0.000description1

- 238000013508migrationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 238000012986modificationMethods0.000description1

- 229910021421monocrystalline siliconInorganic materials0.000description1

- 238000000465mouldingMethods0.000description1

- HLXZNVUGXRDIFK-UHFFFAOYSA-Nnickel titaniumChemical compound[Ti].[Ti].[Ti].[Ti].[Ti].[Ti].[Ti].[Ti].[Ti].[Ti].[Ti].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni].[Ni]HLXZNVUGXRDIFK-UHFFFAOYSA-N0.000description1

- 150000004767nitridesChemical class0.000description1

- 230000010355oscillationEffects0.000description1

- ZBSCCQXBYNSKPV-UHFFFAOYSA-Noxolead;oxomagnesium;2,4,5-trioxa-1$l^{5},3$l^{5}-diniobabicyclo[1.1.1]pentane 1,3-dioxideChemical compound[Mg]=O.[Pb]=O.[Pb]=O.[Pb]=O.O1[Nb]2(=O)O[Nb]1(=O)O2ZBSCCQXBYNSKPV-UHFFFAOYSA-N0.000description1

- 238000004806packaging method and processMethods0.000description1

- 239000004033plasticSubstances0.000description1

- 229920003023plasticPolymers0.000description1

- 229920002492poly(sulfone)Polymers0.000description1

- 229910021420polycrystalline siliconInorganic materials0.000description1

- 229920001690polydopaminePolymers0.000description1

- 229920001721polyimidePolymers0.000description1

- 229920005591polysiliconPolymers0.000description1

- 229920000123polythiophenePolymers0.000description1

- 238000012805post-processingMethods0.000description1

- 238000004080punchingMethods0.000description1

- 230000004044responseEffects0.000description1

- 239000000523sampleSubstances0.000description1

- 239000007787solidSubstances0.000description1

- 239000000243solutionSubstances0.000description1

- 239000002904solventSubstances0.000description1

- 239000012899standard injectionSubstances0.000description1

- 230000000638stimulationEffects0.000description1

- 238000000859sublimationMethods0.000description1

- 230000008022sublimationEffects0.000description1

- 239000000126substanceSubstances0.000description1

- 230000000153supplemental effectEffects0.000description1

- 229920003051synthetic elastomerPolymers0.000description1

- 238000012360testing methodMethods0.000description1

- 230000008646thermal stressEffects0.000description1

- 238000007514turningMethods0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J3/00—Typewriters or selective printing or marking mechanisms characterised by the purpose for which they are constructed

- B41J3/44—Typewriters or selective printing mechanisms having dual functions or combined with, or coupled to, apparatus performing other functions

- B41J3/445—Printers integrated in other types of apparatus, e.g. printers integrated in cameras

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/14—Structure thereof only for on-demand ink jet heads

- B41J2/14314—Structure of ink jet print heads with electrostatically actuated membrane

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/14—Structure thereof only for on-demand ink jet heads

- B41J2/14427—Structure of ink jet print heads with thermal bend detached actuators

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/1623—Manufacturing processes bonding and adhesion

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/1626—Manufacturing processes etching

- B41J2/1628—Manufacturing processes etching dry etching

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/1626—Manufacturing processes etching

- B41J2/1629—Manufacturing processes etching wet etching

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/1631—Manufacturing processes photolithography

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/1632—Manufacturing processes machining

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/1635—Manufacturing processes dividing the wafer into individual chips

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/1637—Manufacturing processes molding

- B41J2/1639—Manufacturing processes molding sacrificial molding

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/164—Manufacturing processes thin film formation

- B41J2/1642—Manufacturing processes thin film formation thin film formation by CVD [chemical vapor deposition]

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/164—Manufacturing processes thin film formation

- B41J2/1643—Manufacturing processes thin film formation thin film formation by plating

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/164—Manufacturing processes thin film formation

- B41J2/1645—Manufacturing processes thin film formation thin film formation by spincoating

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1621—Manufacturing processes

- B41J2/164—Manufacturing processes thin film formation

- B41J2/1646—Manufacturing processes thin film formation thin film formation by sputtering

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/135—Nozzles

- B41J2/16—Production of nozzles

- B41J2/1648—Production of print heads with thermal bend detached actuators

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/17—Ink jet characterised by ink handling

- B41J2/175—Ink supply systems ; Circuit parts therefor

- B41J2/17596—Ink pumps, ink valves

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/015—Ink jet characterised by the jet generation process

- B41J2/04—Ink jet characterised by the jet generation process generating single droplets or particles on demand

- B41J2002/041—Electromagnetic transducer

Definitions

- the present inventionrelates to the field of ink jet printing systems.

- US Patent 3596275 by Sweetalso discloses a process of a continuous ink jet printing including the step wherein the ink jet stream is modulated by a high frequency electro-static field so as to cause drop separation. This technique is still utilized by several manufacturers including Elmjet and Scitex (see also US Patent No. 3373437 by Sweet et al)

- Piezo-electric ink jet printersare also one form of commonly utilized ink jet printing device. Piezo-electric systems are disclosed by Kyser et. al. in US Patent No. 3946398 (1970) which utilises a diaphragm mode of operation, by Zolten in US Patent 3683212 (1970) which discloses a squeeze mode of operation of a piezo electric crystal, Stemme in US Patent No. 3747120 (1972) discloses a bend mode of piezo-electric operation, Howkins in US Patent No. 4459601 discloses a Piezo electric push mode actuation of the ink jet stream and Fischbeck in US 4584590 which discloses a sheer mode type of piezo-electric transducer element.

- Document JP-A-4126255shows an ink jet printhead with a plurality of nozzle arrangements each such arrangement comprising a plunger, and an electric coil located adjacent to the plunger and electrically connected to a nozzle activation signal wherein upon activation of the activation signal, said plunger is caused by said coil to move from an ink loaded position to an ink ejection position thereby causing the ejection of ink from said ink ejection port.

- the ink jet printing techniquesinclude those disclosed by Endo et al in GB 2007162 (1979) and Vaught et al in US Patent 4490728. Both the aforementioned references disclosed ink jet printing techniques rely upon the activation of an electrothermal actuator which results in the creation of a bubble in a constricted space, such as a nozzle, which thereby causes the ejection of ink from an aperture connected to the confined space onto a relevant print media.

- Printing devices utilising the electro-thermal actuatorare manufactured by manufacturers such as Canon and Hewlett Packard.

- a printing technologyshould have a number of desirable attributes. These include inexpensive construction and operation, high speed operation, safe and continuous long term operation etc. Each technology may have its own advantages and disadvantages in the areas of cost, speed, quality, reliability, power usage, simplicity of construction operation, durability and consumables.

- esoteric techniquesare also often utilized. These can include electroforming of nickel stage (Hewlett-Packard Journal, Vol. 36 no 5, pp33-37 (1985)), electro-discharge machining, laser ablation (U.S. Patent No. 5,208,604), micro-punching, etc.

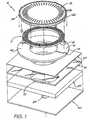

- Fig. 1there is illustrated an exploded perspective view illustrating the construction of a single ink jet nozzle 4 in accordance with the principles of the present invention.

- the nozzle 4operates on the principle of electro-mechanical energy conversion and comprises a solenoid 11 which is connected electrically at a first end 12 to a magnetic plate 13 which is in turn connected to a current source e.g. 14 utilized to activate the ink nozzle 4.

- the magnetic plate 13can be constructed from electrically conductive iron.

- a second magnetic plunger 15is also provided, again being constructed from soft magnetic iron. Upon energizing the solenoid 11, the plunger 15 is attracted to the fixed magnetic plate 13. The plunger thereby pushes against the ink within the nozzle 4 creating a high pressure zone in the nozzle chamber 17. This causes a movement of the ink in the nozzle chamber 17 and in a first design, subsequent ejection of an ink drop.

- a series of apertures e.g. 20is provided so that ink in the region of solenoid 11 is squirted out of the holes 20 in the top of the plunger 15 as it moves towards lower plate 13. This prevents ink trapped in the area of solenoid 11 from increasing the pressure on the plunger 15 and thereby increasing the magnetic forces needed to move the plunger 15.

- Fig. 2there is illustrated 30 a timing diagram of the plunger current control signal.

- the solenoid currentis activated 31 for the movement of the plunger and ejection of a drop from the ink nozzle.

- the current to the solenoidis turned off.

- a reverse currentis applied having approximately half the magnitude of the forward current.

- the reverse current 32causes the plunger to move backwards towards its original position.

- a series of torsional springs 22, 23(Fig. 1) also assists in the return of the plunger to its original position.

- a meniscus at the nozzle tipis formed with an approximately a concave hemispherical surface.

- the surface tensionwill exert a net forward force on the ink which will result in nozzle refilling.

- the repetition rate of the nozzle 4is therefore principally determined by the nozzle refill time which will be 100micro- seconds, depending on the device geometry, ink surface tension and the volume of the ejected drop.

- Fig. 3an important aspect of the operation of the eteetro-magnetically driven print nozzle will now be described.

- the plate 15Upon a current flowing through the coil 11, the plate 15 becomes strongly attracted to the plate 13.

- the plate 15experiences a downward force and begins movement towards the plate 13. This movement imparts a momentum to the ink within the nozzle chamber 17.

- the inkis subsequently ejected as hereinbefore described.

- the movement of the plate 15causes a build-up of pressure in the area 64 between the plate 15 and the coil 11. This build-up would normally result in a reduced effectiveness of the plate 15 in ejecting ink.

- the plate 15preferably includes a series of apertures e.g. 20 which allow for the flow of ink from the area 64 back into the ink chamber and thereby allow a reduction in the pressure in area 64. This results in an increased effectiveness in the operation of the plate 15.

- the apertures 20are of a teardrop shape increasing in diameter with increasing radial distance of the plunger.

- the aperture profilethereby providing minimal disturbance of the magnetic flux through the plunger while maintaining structural integrity of plunger 15.

- the current through coil 11is reversed resulting in a repulsion of the two plates 13, 15. Additionally, the torsional spring e.g. 23 acts to return the plate 15 to its initial position.

- a torsional spring e.g. 23has a number of substantial benefits including a compact layout, and the construction of the torsional spring from the same material and same processing steps as that of the plate 15.

- the top surface of plate 15does not include a series of apertures. Rather, the inner radial surface 25 of plate 15 comprises slots of substantially constant cross-sectional profile in fluid communication between the nozzle chamber 17 and the area 64 between plate 15 and the solenoid 11.

- the plate 15Upon activation of the coil 11, the plate 15 is attracted to the armature plate 13 and experiences a force directed towards plate 13.

- fluid in the area 64is compressed and experiences a higher pressure than its surrounds.

- the flow of fluidtakes place out of the slots in the inner radial surface 25 plate 15 into the nozzle chamber 17.

- the flow of fluid into chamber 17, in addition to the movement of the plate 15,causes the ejection of ink out of the ink nozzle port 24.

- the movement of the plate 15causes the torsional springs, for example 23, to be resiliently deformed.

- the coil 11is deactivated and a slight reverse current is applied.

- the reverse currentacts to repel the plate 15 from the armature plate 13.

- the torsional springs, for example 23,act as additional means to return the plate 15 to its initial or quiescent position.

- the nozzle apparatusis constructed from the following main parts including a nozzle tip 40 having an aperture 24 which can be constructed from boron doped silicon.

- the radius of the aperture 24 of the nozzle tipis an important determinant of drop velocity and drop size.

- CMOS silicon layer 42is provided upon which is fabricated all the data storage and driving circuitry 41 necessary for the operation of the nozzle 4.

- a nozzle chamber 17is also constructed.

- the nozzle chamber 17should be wide enough so that viscous drag from the chamber walls does not significantly increase the force required of the plunger. It should also be deep enough so that any air ingested through the nozzle port 24 when the plunger returns to its quiescent state does not extend to the plunger device. If it does, the ingested bubble may form a cylindrical surface instead of a hemispherical surface resulting in the nozzle not refilling properly.

- a CMOS dielectric and insulating layer containing various current paths parts for the current connection to the plunger deviceis also provided 44.

- a fixed plate of ferroelectric materialhaving two parts 13, 46.

- the two parts 13, 46are electrically insulated from one another.

- a solenoid 11is provided.

- Thiscan comprise a spiral coil of deposited copper.

- Preferably a single spiral layeris utilized to avoid fabrication difficulty and copper is used for a low resistivity and high electro-migration resistance.

- a plunger 15 of ferromagnetic materialis provided to maximize the magnetic form generated.

- the plunger 15 and fixed magnetic plate 13,46surround the solenoid 11 as a torus. Thus, little magnetic flux is lost and the flux is concentrated around the gap between the plunger 15 and the fix plate 13, 46.

- the gap between the fixed plate 13, 46 and the plunger 15is one of the most important "parts" of the print nozzle 4.

- the size of the gapwill strongly affect the magnetic force generated, and also limits the travel of the plunger 15.

- a small gapis desirable to achieve a strong magnetic force, but a large gap is desirable to allow longer plunger 15 to travel, and therefore allow smaller plunger radius to be utilized.

- the springs, e.g. 22, 23 for returning to the plunger 15 to its quiescent position after a drop has been ejectedare provided.

- the springs, e.g. 22, 23can be fabricated from the same material, and in the same processing steps, as the plunger 15.

- the springs, e.g. 22, 23act as torsional springs in their interaction with the plunger 15.

- passivation layerswhich may be silicon nitride (Si 3 N 4 ), diamond like carbon (DLC), or other chemically inert, highly impermeable layer.

- the passivation layersare especially important for device lifetime, as the active device will be immersed in the ink.

- the presently disclosed ink jet printing technologyis potentially suited to a wide range of printing system including: colour and monochrome office printers, short run digital printers, high speed digital printers, offset press supplemental printers, low cost scanning printers high speed pagewidth printers, notebook computers with inbuilt pagewidth printers, portable colour and monochrome printers, colour and monochrome copiers, colour and monochrome facsimile machines, combined printer, facsimile and copying machines, label printers, large format plotters, photograph copiers, printers for digital photographic "minilabs", video printers.

- the embodiments of the inventionuse an ink jet printer type device. Of course many different devices could be used. However presently popular ink jet printing technologies are unlikely to be suitable.

- thermal inkjetThe most significant problem with thermal inkjet is power consumption. This is approximately 100 times that required for high speed, and stems from the energy-inefficient means of drop ejection. This involves the rapid boiling of water to produce a vapor bubble which expels the ink. Water has a very high heat capacity, and must be superheated in thermal inkjet applications. This leads to an efficiency of around 0.02%, from electricity input to drop momentum (and increased surface area) out.

- piezoelectric inkjetThe most significant problem with piezoelectric inkjet is size and cost. Piezoelectric crystals have a very small deflection at reasonable drive voltages, and therefore require a large area for each nozzle. Also, each piezoelectric actuator must be connected to its drive circuit on a separate substrate. This is not a significant problem at the current limit of around 300 nozzles per print head, but is a major impediment to the fabrication of pagewide print heads with 19,200 nozzles.

- the inkjet technologies usedmeet the stringent requirements of in-camera digital color printing and other high quality, high speed, low cost printing applications.

- new inkjet technologieshave been created.

- the target featuresinclude:

- inkjet designs shown hereare suitable for a wide range of digital printing systems, from battery powered one-time use digital cameras, through to desktop and network printers, and through to commercial printing systems

- the print headis designed to be a monolithic 0.5 micron CMOS chip with MEMS post processing.

- the print headis 100 mm long, with a width which depends upon the inkjet type.

- the smallest print head designedis IJ38, which is 0.35 mm wide, giving a chip area of 35 square mm.

- the print headseach contain 19,200 nozzles plus data and control circuitry.

- Inkis supplied to the back of the print head by injection molded plastic ink channels.

- the moldingrequires 50 micron features, which can be created using a lithographically micromachined insert in a standard injection molding tool.

- Inkflows through holes etched through the wafer to the nozzle chambers fabricated on the front surface of the wafer.

- the print headis connected to the camera circuitry by tape automated bonding.

- Actuator mechanism(18 types) Basic operation mode (7 types) Auxiliary mechanism (8 types) Actuator amplification or modification method (17 types) Actuator motion (19 types) Nozzle refill method (4 types) Method of restricting back-flow through inlet (10 types) Nozzle clearing method (9 types) Nozzle plate construction (9 types) Drop ejection direction (5 types) Ink type (7 types)

- inkjet configurationscan readily be derived from these 45 examples by substituting alternative configurations along one or more of the 11 axes.

- Most of the IJ01 to IJ45 examplescan be made into inkjet print heads with characteristics superior to any currently available inkjet technology.

- Suitable applicationsinclude: Home printers, Office network printers, Short run digital printers, Commercial print systems. Fabric printers, Pocket printers, Internet WWW printers, Video printers, Medical imaging, Wide format printers, notebook PC printers. Fax machines, Industrial printing systems, Photocopiers, Photographic minilabs etc.

- Actuator mechanism(applied only to selected ink drops)

- Actuator MechanismDescription Advantages Disadvantages Examples Thermal bubble An electrothermal heater heats the ink to above boiling point, transferring significant heat to the aqueous ink. A bubble nucleates and quickly forms, expelling the ink. The efficiency of the process is low, with typically less than 0.05% of the electrical energy being transformed into kinetic energy of the drop.

- Perovskite materialssuch as tin modified lead lanthanum zirconate titanate (PLZSnT) exhibit large strains of up to 1% associated with the AFE to FE phase transition.

- ⁇ Low power consumption⁇ Many ink types can be used ⁇ Fast operation ( ⁇ 1 ⁇ s) ⁇ Relatively high longitudinal, strain ⁇ High efficiency ⁇ Electric field strength of around 3 V/ ⁇ m can be readily provided ⁇ Difficult to integrate with electronics ⁇ Unusual materials such as PLZSnT are required ⁇ Actuators require a large area ⁇ IJ04 Electrostatic plates Conductive plates are separated by a compressible or fluid dielectric (usually air).

- the conductive platesmay be in a comb or honeycomb structure, or stacked to increase the surface area and therefore the force.

- Low power consumption⁇ Many ink types can be used ⁇

- Fast operation⁇ Difficult to operate electrostatic devices in an aqueous environment ⁇

- the electrostatic actuatorwill normally need to be separated from the ink ⁇

- Very large area required to achieve high forces⁇

- High voltage drive transistorsmay be required ⁇

- Full pagewidth print headsare not competitive due to actuator size ⁇ IJ02, IJ04 Electrostatic pull on ink A strong electric field is applied to the ink, whereupon electrostatic attraction accelerates the ink towards the print medium.

- Examplesare: Samarium Cobalt (SaCo) and magnetic materials in the neodymium iron boron family (NdFeB, NdDyFeBNb, NdDyFeB, etc) ⁇ Low power consumption ⁇ Many ink types can be used ⁇ Fast operation ⁇ High efficiency ⁇ Easy extension from single nozzles to pagewidth print heads ⁇ Complex fabrication ⁇ Permanent magnetic material such as Neodymium Iron Boron (NdFeB) required.

- SaCoSamarium Cobalt

- NdDyFeBNbneodymium iron boron family

- NdDyFeBneodymium iron boron family

- NdFeBNeodymium Iron Boron

- the actuatorshould be pre-stressed to approx. 8 MPa.

- Many ink typescan be used ⁇ Fast operation ⁇ Easy extension from single nozzles to pagewidth print heads ⁇ High force is available ⁇ Force acts as a twisting motion ⁇ Unusual materials such as Terfenol-D are required ⁇ High local currents required ⁇ Copper metalization should be used for long electromigration lifetime and low resistivity ⁇ Pre-stressing may be required ⁇ Fischenbeck, USP 4,032,929 ⁇ IJ25 Surface tension reduction Ink under positive pressure is held in a nozzle by surface tension. The surface tension of the ink is reduced below the bubble threshold, causing the ink to egress from the nozzle.

- a viscosity reductioncan be achieved electrothermally with most inks, but special inks can be engineered for a 100:1 viscosity reduction, ⁇ Simple construction ⁇ No unusual materials required in fabrication ⁇ Easy extension from single nozzles to pagewidth print heads ⁇ Requires supplementary force to effect drop separation ⁇ Requires special ink viscosity properties ⁇ High speed is difficult to achieve ⁇ Requires oscillating ink pressure ⁇ A high temperature difference (typically 80 degrees) is required ⁇ Silverbrook, EP 0771 658 A2 and related patent applications Acoustic An acoustic wave is generated and focussed upon the drop ejection region.

- a heater fabricated from a conductive materialis incorporated.

- a 50 ⁇ m long PTFE bend actuator with polysilicon heater and 15 mW power inputcan provide 180 ⁇ N force and 10 ⁇ m deflection.

- Actuator motionsinclude: 1) Bend 2) Push 3) Buckle 4) Rotate ⁇ High force can be generated ⁇ PTFE is a candidate for low dielectric constant insulation in ULSI ⁇ Very low power consumption ⁇ Many ink types can be used ⁇ Simple planar fabrication ⁇ Small chip area required for each actuator ⁇ Fast operation ⁇ High efficiency ⁇ CMOS compatible voltages and currents ⁇ Easy extension from single nozzles to pagewidth print heads ⁇ Requires special material (e.g.

- PTFERequires a PTFE deposition process, which is not yet standard in ULSI fabs ⁇ PTFE deposition cannot be followed with high temperature (above 350 °C) processing ⁇ Pigmented inks may be infeasible, as pigment particles may jam the bend actuator ⁇ IJ09, IJ17, IJ18, IJ20 ⁇ IJ21, IJ22, IJ23, IJ24 ⁇ IJ27, IJ28, IJ29, IJ30 ⁇ IJ31, IJ42, IJ43, IJ44 Conductive polymer thermoelastic actuator A polymer with a high coefficient of thermal expansion (such as PTFE) is doped with conducting substances to increase its conductivity to about 3 orders of magnitude below that of copper.

- the conducting polymerexpands when resistively heated.

- conducting dopantsinclude: 1) Carbon nanotubes 2) Metal fibers 3) Conductive polymers such as doped polythiophene 4) Carbon granules ⁇ High force can be generated ⁇ Very low power consumption ⁇ Many ink types can be used ⁇ Simple planar fabrication ⁇ Small chip area required for each actuator ⁇ Fast operation ⁇ High efficiency ⁇ CMOS compatible voltages and currents ⁇ Easy extension from single nozzles to pagewidth print heads ⁇ Requires special materials development (High CTE conductive polymer) ⁇ Requires a PTFE deposition process, which is not yet standard in ULSI fabs ⁇ PTFE deposition cannot be followed with high temperature (above 350 °C) processing ⁇ Evaporation and CVD deposition techniques cannot be used ⁇ Pigmented inks may be infeasible, as pigment particles may jam the bend actuator ⁇ IJ24 Shape memory alloy A shape memory alloy such as TiNi (also known as Nitinol

- Linear Magnetic Actuator Linear magnetic actuatorsinclude the Linear Induction Actuator (LIA), Linear Permanent Magnet Synchronous Actuator (LPMSA), Linear Reluctance Synchronous Actuator (LRSA), Linear Switched Reluctance Actuator (LSRA), and the Linear Step

- Linear Magnetic actuatorscan be constructed with high thrust, long travel, and high efficiency using planar semiconductor fabrication techniques ⁇ Long actuator travel is available ⁇ Medium force is ⁇ Low voltage operation ⁇ Requires unusual semiconductor materials such as soft magnetic alloys (e.g. CoNiFe [1]) ⁇ Some varieties also require permanent magnetic materials such as Neodymium iron boron (NdFeB) ⁇ Requires complex multi-phase drive circuitry ⁇ High current operation ⁇ IJ12

- Actuatordirectly pushes Ink This is the simplest mode of operation: the actuator directly supplies sufficient kinetic energy to expel the drop. The drop must have a sufficient velocity to overcome the surface tension. ⁇ Simple operation ⁇ No external fields required ⁇ Satellite drops can be avoided if drop velocity is less than 4 m/s ⁇ Can be efficient, depending upon the actuator used ⁇ Drop repetition rate is usually limited to less than 10 KHz.

- Satellite dropsusually form if drop velocity is greater than 4.5 m/s ⁇

- the drops to be printedare selected by some manner (e.g.

- Very simple print head fabricationcan be used ⁇

- the drop selection meansdoes not need to provide the energy required to separate the drop from the nozzle ⁇

- Electrostatic field for small nozzle sizesis above air breakdown ⁇

- Electrostatic fieldmay attract dust ⁇

- Silverbrook, EP 0771 658 A2 and related patent applications⁇ Tone-Jet Magnetic pull on ink

- the drops to be printedare selected by some manner (e.g. thermally induced surface tension reduction of pressurized ink). Selected drops are separated from the ink in the nozzle by a strong magnetic field acting on the magnetic ink.

- Very simple print head fabricationcan be used ⁇

- the drop selection meansdoes not need to provide the energy required to separate the drop from the nozzle ⁇

- Requires magnetic ink⁇

- Ink colors other than blackare difficult ⁇

- Requires very high magnetic fields⁇

- Silverbrook, EP 0771 658 A2 and related patent applications ShutterThe actuator moves a shutter to block ink flow to the nozzle.

- the ink pressureis pulsed at a multiple of the drop ejection frequency.

- Actuators with small travelcan be used

- Actuators with small forcecan be used

- High speed (>50 KHz) operationcan be achieved

- Moving partsare required

- Requires ink pressure modulator⁇ Friction and wear must be considered

- Stictionis possible

- Pulsed magnetic pull on ink pusherA pulsed magnetic field attracts an 'ink pusher' at the drop ejection frequency.

- An actuatorcontrols a catch, which prevents the ink pusher from moving when a drop is not to be ejected.

- Extremely low energy operationis possible

- No heat dissipation problems⁇ Requires an external pulsed magnetic field

- Requires special materials for both the actuator and the ink pusher⁇ Complex construction ⁇ IJ10

- the ink pressure oscillationmay be achieved by vibrating the print head, or preferably by an actuator in the ink supply.

- ⁇ Oscillating ink pressurecan provide a refill pulse, allowing higher operating speed ⁇

- the actuatorsmay operate with much lower energy ⁇

- Acoustic lensescan be used to focus the sound on the nozzles ⁇

- Requires external ink pressure oscillator⁇

- Ink pressure phase and amplitudemust be carefully controlled ⁇ Acoustic reflections in the ink chamber must be designed for ⁇ Silverbrook, EP 0771 658 A2 and related patent applications ⁇ IJ08, IJ13, IJ15, IJ17 ⁇ IJ18, IJ19, IJ21 Media proximity The print head is placed in close proximity to the print medium.

- the actuatordirectly drives the drop ejection process.

- Operational simplicity⁇ Many actuator mechanisms have insufficient travel, or insufficient force, to efficiently drive the drop ejection process ⁇

- Thermal Bubble Inkjet⁇ IJ01, IJ02, IJ06, IJ07 ⁇ IJ16, IJ25, IJ26

- Differential expansion bend actuatorAn actuator material expands more on one side than on the other. The expansion may be thermal, piezoelectric, magnetostrictive, or other mechanism.

- the bend actuatorconverts a high force low travel actuator mechanism to high travel, lower force mechanism.

- Transient bend actuatorA trilayer bend actuator where the two outside layers are identical. This cancels bend due to ambient temperature and residual stress. The actuator only responds to transient heating of one side or the other.

- Actuator forcesmay not add linearly, reducing efficiency ⁇ IJ12, IJ13, IJ18, IJ20 ⁇ IJ22, IJ28, IJ42, IJ43 Linear Spring

- a linear springis used to transform a motion with small travel and high force into a longer travel, lower force motion.

- Matches low travel actuator with higher travel requirements⁇

- Non-contact method of motion transformation⁇ Requires print head area for the spring

- IJ15Reverse spring The actuator loads a spring. When the actuator is turned off, the spring releases. This can reverse the force/distance curve of the actuator to make it compatible with the force/time requirements of the drop ejection.

- the catcheither enables or disables movement of an ink pusher that is controlled In a bulk manner.

- Very low actuator energy⁇ Very small actuator size ⁇ Complex construction ⁇ Requires external force ⁇ Unsuitable for pigmented inks ⁇ IJ10 Buckle plate

- a buckle platecan be used to change a slow actuator into a fast motion. It can also convert a high force, low travel actuator into a high travel, medium force motion.

- Very fast movement achievable ⁇Must stay within elastic limits of the materials for long device life ⁇ High stresses involved ⁇ Generally high power requirement ⁇ S. Hirata et al, "An Ink-jet Head ", Proc. IEEE MEMS, Feb. 1996, pp 418-423.

- IJ18, IJ27 Tapered magnetic poleA tapered magnetic pole can increase travel at the expense of force.

- ⁇Linearizes the magnetic force/distance curve ⁇ Complex construction ⁇ IJ14 Lever A lever and fulcrum is used to transform a motion with small travel and high force into a motion with longer travel and lower force. The lever can also reverse the direction of travel.

- a small angular deflection of the actuatorresults in a rotation of the impeller vanes, which push the ink against stationary vanes and out of the nozzle.

- ⁇ High mechanical advantage⁇

- the ratio of force to travel of the actuatorcan be matched to the nozzle requirements by varying the number of impeller vanes ⁇

- Complex construction⁇

- Unsuitable for pigmented inks ⁇ IJ28 Acoustic lensA refractive or diffractive (e.g. zone plate) acoustic lens is used to concentrate sound waves.

- Actuator motion Description AdvantagesDisadvantages: Volume expansion

- the volume of the actuatorchanges, pushing the ink in all directions.

- ⁇ Simple construction in the case of thermal ink jet⁇ High energy is typically required to achieve volume expansion. This leads to thermal stress, cavitation, and kogation in thermal ink jet implementations ⁇ Hewlett-Packard Thermal Inkjet ⁇ Canon Bubblejet Linear, normal to chip surface

- the actuatormoves in a direction normal to the print head surface.

- the nozzleis typically in the line of movement.

- the effective area of the actuatorbecomes the membrane area ⁇ Fabrication complexity ⁇ Actuator size ⁇ Difficulty of integration in a VLSI process ⁇ 1982 Howkins USP 4,459,601 Rotary

- the actuatorcauses the rotation of some element, such a grill or impeller ⁇ Rotary levers may be used to increase travel ⁇ Small chip area requirements ⁇

- Device complexity ⁇May have friction at a pivot point ⁇ IJ05, IJ08, IJ13, IJ28 Bend The actuator bends when energized. This may be due to differential thermal expansion, piezoelectric expansion, magnetostriction, or other form of relative dimensional change. ⁇ A very small change in dimensions can be converted to a large motion.

- the actuator⁇ Requires the actuator to be made from at least two distinct layers, or to have a thermal difference across the actuator ⁇ 1970 Kyser et al USP 3,946,398 ⁇ 1973 Stemme USP 3,747,120 ⁇ IJ03, IJ09, IJ10, IJ19 ⁇ IJ23, IJ24, IJ25, U29 ⁇ IJ30, IJ31, IJ33, IJ34 ⁇ IJ35 Swivel

- the actuatorswivels around a central pivot. This motion is suitable where there are opposite forces applied to opposite sides of the paddle, e.g. Lorenz force.

- Nozzle refill methodDescription Advantages Disadvantages Examples Surface tension After the actuator is energized, it typically returns rapidly to its normal position. This rapid return sucks in air through the nozzle opening. The ink surface tension at the nozzle then exerts a small force restoring the meniscus to a minimum area.

- a filteris located between the ink inlet and the nozzle chamber.

- the filterhas a multitude of small holes or slots, restricting ink flow.

- the filteralso removes particles which may block the nozzle.

- ⁇ Additional advantage of ink filtration ⁇ Ink filtermay be fabricated with no additional process steps ⁇ Restricts refill rate ⁇ May result in complex construction ⁇ IJ04, IJ12, IJ24, IJ27 ⁇ IJ29, IJ30 Small inlet compared to nozzle The ink inlet channel to the nozzle chamber has a substantially smaller cross section than that of the nozzle, resulting in easier ink egress out of the nozzle than out of the inlet. ⁇ Design simplicity ⁇ Restricts refill rate ⁇ May result in a relatively large chip area ⁇ Only partially effective ⁇ IJ02, IJ37, IJ44 Inlet shutter A secondary actuator controls the position of a shutter, closing off the ink inlet when the main actuator is energized.

- Nozzle Clearing methodDescription Advantages Disadvantages Examples Normal nozzle firing All of the nozzles are fired periodically, before the ink has a chance to dry. When not in use the nozzles are sealed (capped) against air. The nozzle firing is usually performed during a special clearing cycle, after first moving the print head to a cleaning station.

- ⁇ A high nozzle clearing capabilitycan be achieved ⁇ May be implemented at very low cost in systems which already include acoustic actuators ⁇ High implementation cost if system does not already include an acoustic actuator ⁇ IJ08, IJ13, IJ15, IJ17 ⁇ IJ18, IJ19, IJ21 Nozzle clearing plate A microfabricated plate is pushed against the nozzles. The plate has a post for every nozzle.

- the bladeis usually fabricated from a flexible polymer, e.g. rubber or synthetic elastomer.

- ⁇ Effective for planar print head surfaces⁇ Low cost ⁇ Difficult to use if print head surface is non-planar or very fragile ⁇ Requires mechanical parts ⁇ Blade can wear out in high volume print systems ⁇ Many ink jet systems Separate Ink boiling heater A separate heater is provided at the nozzle although the normal drop e-ection mechanism does not require it. The heaters do not require individual drive circuits, as many nozzles can be cleared simultaneously, and no imaging is required.

- ⁇ Can be effective where other nozzle clearing methods cannot be used⁇ Can be implemented at no additional cost in some inkjet configurations ⁇ Fabrication complexity ⁇ Can be used with many IJ series ink jets

- Nozzle plate constructionDescription Advantages Disadvantages Examples Electroformed nickel A nozzle plate is separately fabricated from electroformed nickel, and bonded to the print head chip. ⁇ Fabrication simplicity ⁇ High temperatures and pressures are required to bond nozzle plate ⁇ Minimum thickness constraints ⁇ Differential thermal expansion ⁇ Hewlett Packard Thermal Inkjet Laser ablated or drilled polymer Individual nozzle holes are ablated by an intense UV laser in a nozzle plate, which is typically a polymer such as polyimide or polysulphone ⁇ No masks required ⁇ Can be quite fast ⁇ Some control over nozzle profile is possible ⁇ Equipment required is relatively low cost ⁇ Each hole must be individually formed ⁇ Special equipment required ⁇ Slow where there are many thousands of nozzles per print head ⁇ May produce thin burrs at exit holes ⁇ Canon Bubblejet ⁇ 1988 Sercel et al., SPIE, Vol.

- Nozzle chambersare etched in the front of the wafer, and the wafer is thinned from the back side. Nozzles are then etched in the etch stop layer.

- High accuracy ( ⁇ 1 ⁇ m)⁇ Monolithic ⁇ Low cost ⁇ No differential expansion ⁇ Requires long etch times ⁇ Requires a support wafer ⁇ IJ03, IJ05, IJ06, IJ07 ⁇ IJ08, IJ09, IJ10, IJ13 ⁇ IJ14, IJ15, IJ16, IJ19 ⁇ IJ21, IJ23, IJ25, IJ26 No nozzle plate Various methods have been tried to eliminate the nozzles entirely, to prevent nozzle clogging.

- EdgeInk flow is along the surface of the chip, and ink drops are ejected from the chip edge.

- Simple construction⁇ No silicon etching required ⁇ Good heat sinking via substrate ⁇ Mechanically strong ⁇ Ease of chip handing ⁇ Nozzles limited to edge ⁇ High resolution is difficult ⁇

- Fast color printingrequires one print head per color ⁇ Canon Bubblejet 1979 Endo et al GB patent 2,007,162 ⁇ Xerox heater-in-pit 1990 Hawkins et al USP 4,899,181 ⁇ Tone-jet Surface ('roof shooter') Ink flow is along the surface of the chip, and ink drops are ejected from the chip surface, normal to the plane of the chip.

- Suitable for piezoelectric print headsrequire several thousand connections to drive circuits ⁇ Cannot be manufactured in standard CMOS fabs ⁇ Complex assembly required ⁇ Epson Stylus ⁇ Tektronix hot melt piezoelectric ink jets

- Aqueous, dye Water based inkwhich typically contains: water, dye, surfactant, humectant, and biocide.

- Modern ink dyeshave high water-fastness, light fastness ⁇ Environmentally friendly ⁇ No odor ⁇ Slow drying ⁇ Corrosive ⁇ Bleeds on paper ⁇ May strikethrough ⁇ Cockles paper ⁇

- Most existing inkjets⁇ All IJ series ink jets ⁇ Silverbrook, EP 0771 658 A2 and related patent applications

- Aqueous, pigment Water based inkwhich typically contains: water, pigment, surfactant, humectant, and biocide. Pigments have an advantage in reduced bleed, wicking and strikethrough.

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Particle Formation And Scattering Control In Inkjet Printers (AREA)

- Ink Jet (AREA)

Abstract

Description

- The present invention relates to the field of ink jet printing systems.

- Many different types of printing have been invented, a large number of which are presently in use. The known forms of print have a variety of methods for marking the print media with a relevant marking media. Commonly used forms of printing include offset printing, laser printing and copying devices, dot matrix type impact printers, thermal paper printers, film recorders, thermal wax printers, dye sublimation printers and ink jet printers both of the drop on demand and continuous flow type. Each type of printer has its own advantages and problems when considering cost, speed, quality, reliability, simplicity of construction and operation etc.

- In recent years, the field of ink jet printing, wherein each individual pixel of ink is derived from one or more ink nozzles has become increasingly popular primarily due to its inexpensive and versatile nature.

- Many different techniques of ink jet printing have been invented. For a survey of the field. reference is made to an article by J Moore, "Non-Impact Printing: Introduction and Historical Perspective", Output Hard Copy Devices, Editors R Dubeck and S Sherr, pages 207-220 (1988).

- Ink jet printers themselves come in many different types. The utilisation of a continuous stream ink in ink jet printing appears to date back to at least 1929 wherein US Patent No. 1941001 by Hansell discloses a simple form of continuous stream electro-static inkjet printing.

- US Patent 3596275 by Sweet also discloses a process of a continuous ink jet printing including the step wherein the ink jet stream is modulated by a high frequency electro-static field so as to cause drop separation. This technique is still utilized by several manufacturers including Elmjet and Scitex (see also US Patent No. 3373437 by Sweet et al)

- Piezo-electric ink jet printers are also one form of commonly utilized ink jet printing device. Piezo-electric systems are disclosed by Kyser et. al. in US Patent No. 3946398 (1970) which utilises a diaphragm mode of operation, by Zolten in US Patent 3683212 (1970) which discloses a squeeze mode of operation of a piezo electric crystal, Stemme in US Patent No. 3747120 (1972) discloses a bend mode of piezo-electric operation, Howkins in US Patent No. 4459601 discloses a Piezo electric push mode actuation of the ink jet stream and Fischbeck in US 4584590 which discloses a sheer mode type of piezo-electric transducer element.

- Document JP-A-4126255 shows an ink jet printhead with a plurality of nozzle arrangements each such arrangement comprising a plunger, and an electric coil located adjacent to the plunger and electrically connected to a nozzle activation signal wherein upon activation of the activation signal, said plunger is caused by said coil to move from an ink loaded position to an ink ejection position thereby causing the ejection of ink from said ink ejection port.

- Recently, thermal ink jet printing has become an extremely popular form of ink jet printing. The ink jet printing techniques include those disclosed by Endo et al in GB 2007162 (1979) and Vaught et al in US Patent 4490728. Both the aforementioned references disclosed ink jet printing techniques rely upon the activation of an electrothermal actuator which results in the creation of a bubble in a constricted space, such as a nozzle, which thereby causes the ejection of ink from an aperture connected to the confined space onto a relevant print media. Printing devices utilising the electro-thermal actuator are manufactured by manufacturers such as Canon and Hewlett Packard.

- As can be seen from the foregoing, many different types of printing technologies are available. Ideally, a printing technology should have a number of desirable attributes. These include inexpensive construction and operation, high speed operation, safe and continuous long term operation etc. Each technology may have its own advantages and disadvantages in the areas of cost, speed, quality, reliability, power usage, simplicity of construction operation, durability and consumables.

- Many inkjet printing mechanisms are known. Unfortunately, in mass production techniques, the production of ink jet heads is quite difficult. For example, often, the orifice or nozzle plate is constructed separately from the ink supply and ink ejection mechanism and bonded to the mechanism at a later stage (Hewlett-Packard Journal, Vol. 36 no 5, pp33-37 (1985)). These separate material processing steps required in handling such precision devices often adds a substantially expense in manufacturing.

- Additionally, side shooting ink jet technologies (U.S. Patent No. 4,899,181) are often used but again, this limit the amount of mass production throughput given any particular capital investment.

- Additionally, more esoteric techniques are also often utilized. These can include electroforming of nickel stage (Hewlett-Packard Journal, Vol. 36 no 5, pp33-37 (1985)), electro-discharge machining, laser ablation (U.S. Patent No. 5,208,604), micro-punching, etc.

- The utilisation of the above techniques is likely to add substantial expense to the mass production of ink jet print heads and therefore add substantially to their final cost.

- It would therefore be desirable if an efficient system for the mass production of ink jet print heads could be developed.

- It is an object of the present invention to provide for an ink jet printing mechanism having a series of ink ejection nozzles, with the nozzles including an internal selective actuator mechanism activated on a nozzle by nozzle basis by the placement of a field around said nozzles. Accordingly the invention provides a printhead according to claim 1. Advantageous embodiments are provided in the dependent claims.

- Notwithstanding any other forms which may fall within the scope of the present invention, preferred forms of the invention will now be described, by way of example only, with reference to the accompanying drawings in which:

- Fig. 1 is an exploded perspective view illustrating the construction of a single ink jet nozzle in accordance with an embodiment of the present invention;

- Fig. 2 is a timing diagram illustrating the operation of an embodiment;

- Fig. 3 is a cross-seedonat top view of a single ink nozzle constructed in accordance with an embodiment of the present invention;

- Fig. 4 provides a legend of the materials indicated in Fig. 5 to Fig. 21;

- Fig. 5 to Fig. 21 illustrate sectional views of the manufacturing steps in one form of construction of an ink jet printhead nozzle;

- In Fig. 1, there is illustrated an exploded perspective view illustrating the construction of a single

ink jet nozzle 4 in accordance with the principles of the present invention. - The

nozzle 4 operates on the principle of electro-mechanical energy conversion and comprises asolenoid 11 which is connected electrically at afirst end 12 to amagnetic plate 13 which is in turn connected to a current source e.g. 14 utilized to activate theink nozzle 4. Themagnetic plate 13 can be constructed from electrically conductive iron. - A second

magnetic plunger 15 is also provided, again being constructed from soft magnetic iron. Upon energizing thesolenoid 11, theplunger 15 is attracted to the fixedmagnetic plate 13. The plunger thereby pushes against the ink within thenozzle 4 creating a high pressure zone in thenozzle chamber 17. This causes a movement of the ink in thenozzle chamber 17 and in a first design, subsequent ejection of an ink drop. A series of apertures e.g. 20 is provided so that ink in the region ofsolenoid 11 is squirted out of the holes 20 in the top of theplunger 15 as it moves towardslower plate 13. This prevents ink trapped in the area ofsolenoid 11 from increasing the pressure on theplunger 15 and thereby increasing the magnetic forces needed to move theplunger 15. - Referring now to Fig. 2, there is illustrated 30 a timing diagram of the plunger current control signal. Initially, the solenoid current is activated 31 for the movement of the plunger and ejection of a drop from the ink nozzle. After approximately 2 micro-seconds, the current to the solenoid is turned off. At the same time or at a slightly

later time 32, a reverse current is applied having approximately half the magnitude of the forward current. As the plunger has a residual magnetism, thereverse current 32 causes the plunger to move backwards towards its original position. A series oftorsional springs 22, 23 (Fig. 1) also assists in the return of the plunger to its original position. The reverse current is turned off before the magnetism of theplunger 15 is reversed which would otherwise result in the plunger being attracted to the fixed plate again. Returning to Fig. I, the forced return of theplunger 15 to its quiescent position results in a low pressure in thechamber 17. This can cause ink to begin flowing from theoutlet nozzle 24 inwards and also ingests air to thechamber 17. The forward velocity of the drop and the backward velocity of the ink in thechamber 17 are resolved by the ink drop breaking off around thenozzle 24. The ink drop then continues to travel toward the recording medium under its own momentum. The nozzle refills due to the surface tension of the ink at thenozzle tip 24. Shortly after the time of drop break off, a meniscus at the nozzle tip is formed with an approximately a concave hemispherical surface. The surface tension will exert a net forward force on the ink which will result in nozzle refilling. The repetition rate of thenozzle 4 is therefore principally determined by the nozzle refill time which will be 100micro- seconds, depending on the device geometry, ink surface tension and the volume of the ejected drop. - Turning now to Fig. 3, an important aspect of the operation of the eteetro-magnetically driven print nozzle will now be described. Upon a current flowing through the

coil 11, theplate 15 becomes strongly attracted to theplate 13. Theplate 15 experiences a downward force and begins movement towards theplate 13. This movement imparts a momentum to the ink within thenozzle chamber 17. The ink is subsequently ejected as hereinbefore described. Unfortunately, the movement of theplate 15 causes a build-up of pressure in thearea 64 between theplate 15 and thecoil 11. This build-up would normally result in a reduced effectiveness of theplate 15 in ejecting ink. - However, in a first design the

plate 15 preferably includes a series of apertures e.g. 20 which allow for the flow of ink from thearea 64 back into the ink chamber and thereby allow a reduction in the pressure inarea 64. This results in an increased effectiveness in the operation of theplate 15. - Preferably, the apertures 20 are of a teardrop shape increasing in diameter with increasing radial distance of the plunger. The aperture profile thereby providing minimal disturbance of the magnetic flux through the plunger while maintaining structural integrity of

plunger 15. - After the

plunger 15 has reached its end position, the current throughcoil 11 is reversed resulting in a repulsion of the twoplates plate 15 to its initial position. - The use of a torsional spring e.g. 23 has a number of substantial benefits including a compact layout, and the construction of the torsional spring from the same material and same processing steps as that of the

plate 15. - In an alternative design, the top surface of

plate 15 does not include a series of apertures. Rather, the inner radial surface 25 ofplate 15 comprises slots of substantially constant cross-sectional profile in fluid communication between thenozzle chamber 17 and thearea 64 betweenplate 15 and thesolenoid 11. Upon activation of thecoil 11, theplate 15 is attracted to thearmature plate 13 and experiences a force directed towardsplate 13. As a result of the movement, fluid in thearea 64 is compressed and experiences a higher pressure than its surrounds. As a result, the flow of fluid takes place out of the slots in the inner radial surface 25plate 15 into thenozzle chamber 17. The flow of fluid intochamber 17, in addition to the movement of theplate 15, causes the ejection of ink out of theink nozzle port 24. Again, the movement of theplate 15 causes the torsional springs, for example 23, to be resiliently deformed. Upon completion of the movement of theplate 15, thecoil 11 is deactivated and a slight reverse current is applied. The reverse current acts to repel theplate 15 from thearmature plate 13. The torsional springs, for example 23, act as additional means to return theplate 15 to its initial or quiescent position. - Returning now to Fig. 1, the nozzle apparatus is constructed from the following main parts including a

nozzle tip 40 having anaperture 24 which can be constructed from boron doped silicon. The radius of theaperture 24 of the nozzle tip is an important determinant of drop velocity and drop size. - Next, a