CN218274596U - A dual-color temperature LED patch lamp bead structure - Google Patents

A dual-color temperature LED patch lamp bead structureDownload PDFInfo

- Publication number

- CN218274596U CN218274596UCN202222930775.1UCN202222930775UCN218274596UCN 218274596 UCN218274596 UCN 218274596UCN 202222930775 UCN202222930775 UCN 202222930775UCN 218274596 UCN218274596 UCN 218274596U

- Authority

- CN

- China

- Prior art keywords

- color temperature

- lamp bead

- color

- chip

- led

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000011324beadSubstances0.000titleclaimsabstractdescription49

- 239000003292glueSubstances0.000claimsabstractdescription16

- 239000012790adhesive layerSubstances0.000claimsdescription8

- 239000000203mixtureSubstances0.000claimsdescription6

- 239000010410layerSubstances0.000claimsdescription5

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000claimsdescription4

- 229910052782aluminiumInorganic materials0.000claimsdescription4

- 239000000758substrateSubstances0.000claimsdescription4

- 238000002156mixingMethods0.000abstractdescription8

- 239000000843powderSubstances0.000abstractdescription7

- 238000004519manufacturing processMethods0.000abstractdescription5

- 238000000576coating methodMethods0.000abstractdescription3

- 238000000034methodMethods0.000description8

- OAICVXFJPJFONN-UHFFFAOYSA-NPhosphorusChemical compound[P]OAICVXFJPJFONN-UHFFFAOYSA-N0.000description5

- 238000010586diagramMethods0.000description3

- 238000004806packaging method and processMethods0.000description3

- 238000002360preparation methodMethods0.000description3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-NSilicium dioxideChemical compoundO=[Si]=OVYPSYNLAJGMNEJ-UHFFFAOYSA-N0.000description2

- 238000005538encapsulationMethods0.000description2

- 239000007788liquidSubstances0.000description2

- 239000000463materialSubstances0.000description2

- 239000000741silica gelSubstances0.000description2

- 229910002027silica gelInorganic materials0.000description2

- 241001025261Neoraja caeruleaSpecies0.000description1

- 230000007812deficiencyEffects0.000description1

- 230000000694effectsEffects0.000description1

- 230000005611electricityEffects0.000description1

- 239000013072incoming materialSubstances0.000description1

- 230000001788irregularEffects0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 230000003287optical effectEffects0.000description1

- 238000001556precipitationMethods0.000description1

- 238000009877renderingMethods0.000description1

- 239000004065semiconductorSubstances0.000description1

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description1

- 238000003466weldingMethods0.000description1

Images

Landscapes

- Led Device Packages (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本实用新型涉及LED封装技术领域,特别涉及一种双色温LED贴片系列,双色温贴片模组系列,和双色温COB系列。The utility model relates to the technical field of LED packaging, in particular to a dual-color temperature LED patch series, a dual-color temperature patch module series, and a dual-color temperature COB series.

背景技术Background technique

LED封装是一个涉及到多学科如光学、热学、机械、电学、力学、材料及半导体等的技术。LED封装方法、材料、结构和工艺的选择主要由芯片结构、光电/机械特性、具体应用和成本等因素决定。随着智能化的发展,对灯光的亮度和色温的调节需求越来越多,于是双色温灯珠的需求越来越多,双色温灯珠也开始从简单调色功能经历“有”和“无”的发展,到追求给客户带来更好的客户体验感!不但要求更高的光效,更高显色指数,更好的光色品质等功能参数。同时要求光斑规则,混光均匀,调色过程中色温过度自然,丝滑等带来的良好体验感!LED packaging is a technology involving multiple disciplines such as optics, heat, mechanics, electricity, mechanics, materials and semiconductors. The selection of LED packaging method, material, structure and process is mainly determined by factors such as chip structure, photoelectric/mechanical characteristics, specific application and cost. With the development of intelligence, there are more and more requirements for the adjustment of the brightness and color temperature of the light, so the demand for dual-color temperature lamp beads is increasing, and the dual-color temperature lamp beads have also begun to experience "yes" and "" from the simple color adjustment function. From the development of "no" to the pursuit of bringing customers a better customer experience! Not only require higher light efficiency, higher color rendering index, better light color quality and other functional parameters. At the same time, it is required to have regular light spots, uniform light mixing, excessively natural color temperature and silky smoothness during the color adjustment process to bring a good sense of experience!

目前的双色产品,分为贴片系列和COB系列。贴片系列主要采用正装芯片,分别在具有两个碗杯的双色温支架中封装不同色温。产品成本低,但在适配光学透镜(反光杯)后混光不均。COB系列是采用倒装CSP芯片和倒装蓝光芯片交叉排布,再封装荧光粉胶。缺点是CSP成本高,CSP芯片色温受制于来料,制备定制双色温灯珠时,灵活性欠缺。The current two-color products are divided into patch series and COB series. The SMD series mainly uses front-mounted chips, which are packaged with different color temperatures in a dual-color temperature bracket with two bowls. The product cost is low, but the mixed light is uneven after the optical lens (reflector cup) is adapted. The COB series uses flip-chip CSP chips and flip-chip blue-ray chips to be arranged crosswise, and then encapsulated with phosphor glue. The disadvantage is that the cost of CSP is high, the color temperature of the CSP chip is subject to the incoming materials, and there is a lack of flexibility when manufacturing custom dual-color temperature lamp beads.

实用新型内容Utility model content

针对上述现有技术的不足,本实用新型的目的在于提供一种照明时光斑规则成型,双色混光均匀、混光效果好且便于生产的双色温LED贴片灯珠结构和制备方法,以解决现有技术中存在的光斑不规则、双色照明时混光不均匀、光斑不成型技术问题和CSP成本高,色温定制灵活欠缺的成本问题。In view of the deficiencies of the above-mentioned prior art, the purpose of this utility model is to provide a structure and a preparation method of a two-color temperature LED patch lamp bead that is regular in shape during lighting, has uniform two-color light mixing, good light mixing effect, and is easy to produce. In the existing technology, there are irregular light spots, uneven light mixing during two-color lighting, technical problems of unshaped light spots, high cost of CSP, and lack of flexibility in color temperature customization.

本实用新型是这样实现上述目的的:The utility model realizes above-mentioned purpose like this:

一种双色温LED贴片灯珠结构,包括贴片支架和固定在所述贴片支架上的第一色温芯片和第二色温芯片,三个或者三个以上所述第一色温芯片紧密排布成内圈正多边形环,形成中央发光区,所述内圈正多边形环电气连接组成第一色温电路,所述中央发光区中部形成有中央凹部区即碗杯状区;三个或三个以上所述第二色温芯片布置成外圈正多边形环,包围在所述中央发光区周围,所述外圈正多边形环电气连接组成第二色温电路,所述中央发光区敷设有荧光胶层。A two-color temperature LED patch lamp bead structure, including a patch bracket and a first color temperature chip and a second color temperature chip fixed on the patch bracket, three or more of the first color temperature chips are closely arranged Form an inner regular polygonal ring to form a central light-emitting area, the inner regular polygonal ring is electrically connected to form a first color temperature circuit, and a central concave area is formed in the middle of the central light-emitting area, that is, a bowl-cup-shaped area; three or more The second color temperature chip is arranged as an outer regular polygonal ring, surrounding the central light-emitting area. The outer regular polygonal ring is electrically connected to form a second color temperature circuit. The central light-emitting area is covered with a fluorescent glue layer.

进一步地,所述荧光胶层外敷设有封装胶层。Further, the fluorescent adhesive layer is coated with an encapsulation adhesive layer.

进一步地,所述贴片支架上设有焊盘,所述第一色温电路和所述第二色温电路电气连接至所述焊盘。Further, a pad is provided on the patch bracket, and the first color temperature circuit and the second color temperature circuit are electrically connected to the pad.

进一步地,所述第一色温芯片为LED倒装芯片、LED正装芯片或者这两种芯片混用。Further, the first color temperature chip is an LED flip-chip, an LED front-mount chip or a mixture of these two chips.

进一步地,所述第二色温芯片为LED倒装芯片、LED正装芯片或者这两种芯片混用。Further, the second color temperature chip is an LED flip-chip, an LED front-mount chip or a mixture of these two chips.

进一步地,将多个所述双色温LED贴片灯珠结构单元排列组合并连接在贴片模组支架上,形成双色贴片模组系列灯珠。Further, a plurality of the two-color temperature LED patch lamp bead structural units are arranged and combined and connected to the SMD module bracket to form a two-color SMD module series lamp bead.

进一步地,将多个所述双色温LED贴片灯珠结构单元排列组合并连接在COB铝基板上,形成双色COB系列灯珠。Further, a plurality of the two-color temperature LED patch lamp bead structural units are arranged and combined and connected on the COB aluminum substrate to form a two-color COB series lamp bead.

进一步地,所述双色COB系列灯珠使用LED正装芯片或者LED倒装芯片。Further, the two-color COB series lamp beads use LED front-mount chips or LED flip-chips.

本实用新型提供的一种双色温LED贴片灯珠结构,三个或者三个以上所述第一色温芯片布置使得排布的形状成规则的内圈正多边形环,形成中央发光区,中央发光区设置有中央凹部区即碗杯状区,三个或者三个以上所述第二色温芯片布置成外圈正多边形环,包围在所述中央发光区周围,内圈正多边形环电气连接组成第一色温电路,外圈正多边形环电气连接组成第二色温电路。制备第一色温荧光胶就是利用精密的设备在所述中央发光区敷设荧光胶层;使得敷设的荧光胶以中央凹部区为中心,进行覆粉工艺,水滴状液态荧光胶(硅胶和荧光粉混合物)置于“碗杯”中心,受力面均匀,表面张力较小,经过设备特别制程让其荧光胶沉淀,在荧光胶沉淀和固化过程中,荧光粉均匀覆盖在第一色温芯片表面,形态稳定,形状更加规整,烘烤后灯珠后色温测试稳定集中。制备第一色温芯片色温后贴片支架整体碗杯敷设第二色温荧光胶层。这样制备的双色贴片灯珠混光均匀,光斑形状方圆规则;色温集中度高;定制色温简便灵活;一次出货率高,成本降低;提升对市场需求的快速供应。The utility model provides a two-color temperature LED patch lamp bead structure. Three or more of the first color temperature chips are arranged so that the shape of the arrangement is a regular inner polygonal ring, forming a central light-emitting area, and the center emits light. The area is provided with a central concave area, that is, a bowl-shaped area, and three or more of the second color temperature chips are arranged in an outer regular polygonal ring, surrounding the central light-emitting area, and the inner regular polygonal ring is electrically connected to form a second The first color temperature circuit is electrically connected with the regular polygon ring on the outer circle to form the second color temperature circuit. The preparation of the first color temperature fluorescent glue is to use sophisticated equipment to lay a fluorescent glue layer in the central light-emitting area; so that the laid fluorescent glue is centered on the central concave area, and the powder coating process is carried out, and the liquid fluorescent glue (silica gel and phosphor powder mixture) ) is placed in the center of the "bowl", the force-bearing surface is uniform, and the surface tension is small. After the special process of the equipment, the fluorescent glue is precipitated. During the process of fluorescent glue precipitation and curing, the phosphor powder evenly covers the surface of the first color temperature chip. Stable, the shape is more regular, and the color temperature test of the lamp beads after baking is stable and concentrated. After preparing the color temperature of the chip with the first color temperature, lay the second color temperature fluorescent adhesive layer on the whole bowl cup of the patch bracket. The two-color SMD lamp beads prepared in this way have uniform light mixing, regular light spot shape, high concentration of color temperature, easy and flexible customization of color temperature, high one-time shipment rate and reduced cost, and rapid supply to market demand.

附图说明Description of drawings

为了更清楚地说明本实用新型具体实施方式或现有技术中的技术方案,下面将对具体实施方式或现有技术描述中所需要使用的附图作简单说明:In order to more clearly illustrate the specific embodiment of the utility model or the technical solution in the prior art, the accompanying drawings that need to be used in the description of the specific embodiment or the prior art will be briefly described below:

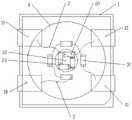

图1为本实用新型双色温LED贴片灯珠结构的结构示意图;Fig. 1 is a structural schematic diagram of the structure of the dual-color temperature LED patch lamp bead of the present invention;

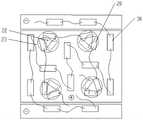

图2为双色贴片模组系列灯珠结构示意图,将双色温LED贴片灯珠结构当做一个单元,将多个所述双色温LED贴片灯珠结构单元排列组合在贴片模组支架上,形成双色贴片模组系列灯珠;Figure 2 is a schematic diagram of the structure of the two-color SMD module series lamp beads. The two-color temperature LED SMD lamp bead structure is regarded as a unit, and a plurality of the two-color temperature LED SMD lamp bead structural units are arranged and combined on the SMD module bracket , forming two-color SMD module series lamp beads;

图3为双色COB系列灯珠结构示意图,将双色温LED贴片灯珠结构当做一个单元,将多个所述双色温LED贴片灯珠结构单元排列组合在COB铝基板上,形成双色COB系列灯珠。Figure 3 is a schematic diagram of the structure of the two-color COB series lamp bead. The two-color temperature LED SMD lamp bead structure is regarded as a unit, and multiple structural units of the two-color temperature LED SMD lamp bead are arranged and combined on the COB aluminum substrate to form a two-color COB series. Lamp beads.

上述图中,1、贴片支架,10、焊盘,2、第一色温电路,20、第一色温芯片,22、中央凹部区即碗杯状区,23、荧光胶层,3、第二色温电路,30、第二色温芯片,4、封装胶层。In the above figure, 1. SMD support, 10. Welding pad, 2. First color temperature circuit, 20. First color temperature chip, 22. The central concave area is the bowl-shaped area, 23. The fluorescent adhesive layer, 3. The second Color temperature circuit, 30, second color temperature chip, 4, encapsulation adhesive layer.

具体实施方式detailed description

下面结合附图对本实用新型的技术方案的实施例进行清楚、完整的描述。在此需要说明的是,对于这些实施方式的说明用于帮助理解本实用新型,但并不构成对本实用新型的限定。此外,下面所描述的本实用新型各个实施方式中所涉及的技术特征只要彼此之间未构成冲突就可以相互组合。The embodiments of the technical solutions of the present utility model are clearly and completely described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these implementations are used to help understand the utility model, but are not intended to limit the utility model. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute conflicts with each other.

参照图1,以四个第一色温芯片为例,本实施例中,一种双色温LED贴片灯珠结构,包括贴片支架1和固定在所述贴片支架1上的第一色温芯片20和第二色温芯片30,四个所述第一色温芯片20紧密排布成内圈正多边形环,形成中央发光区,所述内圈正多边形环电气连接组成第一色温电路2,所述中央发光区中部形成有中央凹部区即碗杯状区22;四个所述第二色温芯片30布置成外圈正多边形环,包围在所述中央发光区周围,所述外圈正多边形环电气连接组成第二色温电路3,所述中央发光区敷设有荧光胶层23。Referring to Figure 1, taking four first color temperature chips as an example, in this embodiment, a dual-color temperature LED patch lamp bead structure includes a patch bracket 1 and a first color temperature chip fixed on the patch bracket 1 20 and the second

四个所述第一色温芯片布置使得排布的形状成规则的内圈正多边形环,形成中央发光区,所述中央发光区设置有中央凹部区即碗杯状区,四个所述第二色温芯片布置成外圈正多边形环,包围在所述中央发光区周围,电气连接组成第二色温电路,制备第一色温荧光胶就是利用精密的设备在所述中央发光区敷设荧光胶层;使得敷设的荧光胶以中央凹部区为中心,进行覆粉工艺,水滴状液态荧光胶(硅胶和荧光粉混合物)置于“碗杯”中心,受力面均匀,表面张力较小,经过设备特别制程让其荧光胶沉淀,固化过程后,荧光粉均匀覆盖在第一色温芯片表面,形态稳定,形状更加规整,烘烤后灯珠后色温测试稳定集中。制备第一色温芯片色温后贴片支架整体碗杯敷设第二色温荧光胶层。这样制备的双色贴片灯珠混光均匀,光斑形状方圆规则;色温集中度高;定制色温简便灵活;一次出货率高,成本降低;提升对市场需求的快速供应。The four first color temperature chips are arranged so that the shape of the arrangement is a regular inner regular polygonal ring, forming a central light-emitting area. The central light-emitting area is provided with a central concave area, that is, a bowl-shaped area, and the four second The color temperature chips are arranged in an outer regular polygonal ring, surrounded by the central light-emitting area, and electrically connected to form a second color temperature circuit. The preparation of the first color temperature fluorescent glue is to use sophisticated equipment to lay a fluorescent glue layer on the central light-emitting area; so that The fluorescent glue laid is centered on the central concave area, and the powder coating process is carried out. The liquid fluorescent glue (a mixture of silica gel and phosphor powder) in the form of water droplets is placed in the center of the "bowl". The force surface is uniform and the surface tension is small. After special equipment manufacturing Allow the fluorescent glue to settle, and after the curing process, the phosphor powder evenly covers the surface of the first color temperature chip, the shape is stable and the shape is more regular, and the color temperature test of the lamp beads after baking is stable and concentrated. After preparing the color temperature of the chip with the first color temperature, lay the second color temperature fluorescent adhesive layer on the whole bowl cup of the patch bracket. The two-color SMD lamp beads prepared in this way have uniform light mixing, regular light spot shape, high concentration of color temperature, easy and flexible customization of color temperature, high one-time shipment rate and reduced cost, and rapid supply to market demand.

参照图2,以三个第一色温芯片为例,本实施例中,与前一实施例相比,根据芯片的电压等要求,采用三个第一色温芯片,形成内圈正多边形环;另外,本实施例将将双色温LED贴片灯珠结构当做一个单元,将多个所述双色温LED贴片灯珠结构单元排列组合在贴片模组支架上,形成双色贴片模组系列灯珠。具有混光均匀、光斑规则的特点,且工艺简单,生产效率高。Referring to Fig. 2, taking three first color temperature chips as an example, in this embodiment, compared with the previous embodiment, according to the requirements such as chip voltage, three first color temperature chips are used to form an inner regular polygonal ring; In this embodiment, the two-color temperature LED patch lamp bead structure is regarded as a unit, and a plurality of the two-color temperature LED patch lamp bead structural units are arranged and combined on the SMD module bracket to form a two-color SMD module series lamp beads. It has the characteristics of uniform light mixing and regular light spots, and the process is simple and the production efficiency is high.

参照图3,以四个第一色温芯片为例,将双色温LED贴片灯珠结构当做一个单元,将多个所述双色温LED贴片灯珠结构单元排列组合在COB铝基板上,形成双色COB系列灯珠。作为优选方案,所述双色COB系列灯珠使用LED正装芯片或者LED倒装芯片。Referring to Figure 3, taking the four first color temperature chips as an example, the two-color temperature LED chip bead structure is regarded as a unit, and a plurality of the two-color temperature LED chip bead structure units are arranged and combined on the COB aluminum substrate to form Two-color COB series lamp beads. As a preferred solution, the two-color COB series lamp beads use LED front-mount chips or LED flip-chips.

根据以上实施例,可以根据实际需要采用更多个第一色温芯片例如五个等构成内圈正多边形环,形成中央发光区;可以根据实际需要采用多个第二色温芯片例如三个、四个、五个等构成外圈正多边形环,包围在中央发光区周围。依据双色温灯珠的电性特点,为使第一色温和第二色温芯片的电压要求大致相同,内圈和外圈的芯片型号可以不同,内圈和外圈的芯片数量可以不等,内圈和外圈的芯片排布方式有少许调整这些都视为合理要求,视为未脱离本实用新型精神和范围。According to the above embodiments, more first color temperature chips, such as five, can be used according to actual needs to form an inner regular polygonal ring to form a central light-emitting area; multiple second color temperature chips, such as three or four, can be used according to actual needs , five, etc. form an outer regular polygonal ring, which surrounds the central light-emitting area. According to the electrical characteristics of the two-color temperature lamp bead, in order to make the voltage requirements of the first color temperature and the second color temperature chip roughly the same, the chip models of the inner ring and the outer ring can be different, and the number of chips in the inner ring and the outer ring can be different. Some adjustments to the arrangement of chips in the ring and the outer ring are regarded as reasonable requirements, and are regarded as not departing from the spirit and scope of the present utility model.

以上显示和描述了本实用新型的基本原理和主要特征以及本实用新型的优点,本行业的技术人员应该了解,本实用新型不受上述实施例的限制,在不脱离本实用新型精神和范围的前提下,本实用新型还会有各种变型和改进,这些变型和改进都落入要求保护的本实用新型范围内。The basic principles and main features of the present utility model and the advantages of the present utility model have been shown and described above. Those skilled in the art should understand that the present utility model is not limited by the above-mentioned embodiments, without departing from the spirit and scope of the present utility model. Under the premise, the utility model also has various modifications and improvements, and these variations and improvements all fall within the scope of the utility model claimed.

Claims (8)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202222930775.1UCN218274596U (en) | 2022-11-04 | 2022-11-04 | A dual-color temperature LED patch lamp bead structure |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202222930775.1UCN218274596U (en) | 2022-11-04 | 2022-11-04 | A dual-color temperature LED patch lamp bead structure |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN218274596Utrue CN218274596U (en) | 2023-01-10 |

Family

ID=84754526

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202222930775.1UActiveCN218274596U (en) | 2022-11-04 | 2022-11-04 | A dual-color temperature LED patch lamp bead structure |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN218274596U (en) |

- 2022

- 2022-11-04CNCN202222930775.1Upatent/CN218274596U/enactiveActive

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWI387135B (en) | Light emitting device and method of manufacturing same | |

| CN104253194A (en) | Structure and method for packaging of chip-size white LED (light emitting diode) | |

| CN103904197A (en) | LED lamp filament piece, manufacturing method of LED lamp filament piece and LED lamp filament piece bulb | |

| CN102623621A (en) | Packaging process for light-emitting diode (LED) with fluorescent glue film and LED packaging | |

| CN102891242A (en) | LED packaging device | |

| CN106505138B (en) | LED packaging structure and preparation method thereof | |

| CN109585632A (en) | High-power long-distance fluorescent powder type white light LEDs cooling encapsulation | |

| CN105355757A (en) | Integrated light engine packaging method | |

| CN207353289U (en) | A kind of LED encapsulation structure and automobile dimming-distance lighting system for improving light efficiency | |

| CN218274596U (en) | A dual-color temperature LED patch lamp bead structure | |

| CN215266294U (en) | Novel paster lamp pearl structure | |

| EP4016649A1 (en) | Light-emitting device and manufacturing method, and display screen and lighting equipment comprising said light-emitting device | |

| CN104576900A (en) | Packaging method of LED chip | |

| CN113471179A (en) | Color temperature adjustable COB LED light source and manufacturing method thereof | |

| CN209016051U (en) | A kind of integrated LED encapsulating structure using WLP | |

| CN205896749U (en) | Full -angle light -emitting LED bulb lamp | |

| CN203883042U (en) | White LED packaging structure capable of reducing color temperature drifting | |

| CN111244077A (en) | Double-color temperature COB light source and manufacturing method thereof | |

| CN211929486U (en) | Lens type full-color LED packaging device | |

| CN102969308A (en) | LED (light-emitting diode) lamp structure and packaging method thereof | |

| CN105047796B (en) | Full-ambient-light L ED light source and preparation method thereof | |

| CN202930428U (en) | LED lamp structure | |

| CN207993893U (en) | A kind of novel colour mixture packaging technology lamp | |

| CN208460792U (en) | A kind of full-color stage lighting light source of novel RGBW type | |

| CN220604689U (en) | Novel double-color temperature LED patch lamp bead structure |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |