CN217921447U - Seam beautifying agent vacuum stirring and canning all-in-one machine - Google Patents

Seam beautifying agent vacuum stirring and canning all-in-one machineDownload PDFInfo

- Publication number

- CN217921447U CN217921447UCN202221943161.0UCN202221943161UCN217921447UCN 217921447 UCN217921447 UCN 217921447UCN 202221943161 UCN202221943161 UCN 202221943161UCN 217921447 UCN217921447 UCN 217921447U

- Authority

- CN

- China

- Prior art keywords

- tank

- upper cover

- tank body

- gas pipeline

- frame

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Vacuum Packaging (AREA)

Abstract

Description

Translated fromChinese技术领域:Technical field:

本实用新型涉及灌装设备制造技术领域,具体的说是一种能够完成流体搅拌、多余气体排空、流体分装的美缝剂真空搅拌罐装一体机。The utility model relates to the technical field of filling equipment manufacturing, in particular to an all-in-one vacuum mixing and filling machine for beautifying agent that can complete fluid stirring, excess gas emptying, and fluid packaging.

背景技术:Background technique:

现有美缝剂的分装或灌装设备体积较大,主要适用于美缝剂生产厂商和经销商,适配大容积反应釜。美缝剂在使用过程中需要分装到体积较小的管体或袋体内,由于美缝剂为具有一定流动性的膏状,在分装的过程中流体内混入空气,导致打入分装管或分装袋内的美缝剂含有大量气泡,不但会导致分装管内容量不足,还会造成施工缺陷,且现阶段尚无能够持续完成多管分装的此类装置。The existing beautifying agent subpackaging or filling equipment is relatively large in size, which is mainly suitable for beautifying agent manufacturers and distributors, and is suitable for large-volume reactors. The beautifying agent needs to be packed into smaller tubes or bags during use. Since the beautifying agent is a paste with a certain fluidity, air is mixed into the fluid during the dispensing process, causing it to enter the dispensing tube Or the beautifying agent in the subpackaging bag contains a large number of air bubbles, which will not only lead to insufficient capacity in the subpackaging tube, but also cause construction defects, and there is no such device that can continuously complete multi-tube subpackaging at this stage.

发明内容:Invention content:

本实用新型针对现有技术中存在的缺点和不足,提出了一种结构合理、操作简便,能够完成待分装流体搅拌、多余气体排空、连续分装的美缝剂灌装装置。Aiming at the shortcomings and deficiencies in the prior art, the utility model proposes a beautifying agent filling device with reasonable structure and simple operation, which can complete the stirring of the fluid to be filled, the emptying of excess gas, and continuous filling.

本实用新型通过以下措施达到:The utility model reaches through the following measures:

一种美缝剂真空搅拌罐装一体机,设有机架,其特征在于,机架上设有流体搅拌组件和分装组件,所述流体搅拌组件包括罐体、上盖体、搅拌器、搅拌电动机、真空泵以及气体管路,罐体上端敞口,罐体底部设有灌装通道,灌装通道上设有单向阀;上盖体用于密封罐体的上端口,搅拌电动机位于上盖体上侧且驱动位于上盖体下侧的搅拌器伸入罐体内运转,上盖体上还开设排气通道,排气通道与气体管路连通,真空泵与气体管路相连;所述分装组件包括用于推挤罐体内容物沿灌装通道排出的推挤圆盘,推挤圆盘的上端与螺杆下端相连,螺杆与机架上的螺母座相连,螺杆的上端设有手轮。An all-in-one vacuum mixing and filling machine for beautifying agent, which is provided with a frame, is characterized in that, the frame is provided with a fluid stirring assembly and a packaging assembly, and the fluid stirring assembly includes a tank body, an upper cover, an agitator, Stirring motor, vacuum pump and gas pipeline, the upper end of the tank is open, the bottom of the tank is provided with a filling channel, and a one-way valve is provided on the filling channel; the upper cover is used to seal the upper port of the tank, and the stirring motor is located on the upper The upper side of the cover body drives the agitator located on the lower side of the upper cover body to extend into the tank to run, and an exhaust channel is also set on the upper cover body, the exhaust channel is connected with the gas pipeline, and the vacuum pump is connected with the gas pipeline; The filling assembly includes a pushing disc for pushing the contents of the tank to be discharged along the filling channel. The upper end of the pushing disc is connected with the lower end of the screw, and the screw is connected with the nut seat on the frame. The upper end of the screw is equipped with a hand wheel. .

本实用新型中搅拌电动机采用减速电动机,带有减速箱。The stirring motor in the utility model adopts a deceleration motor with a reduction box.

本实用新型所述气体管路上设有气压计,用于检测当前罐体内气压值,保证多余气体被尽量排空。The gas pipeline of the utility model is provided with a barometer, which is used to detect the current air pressure value in the tank to ensure that the excess gas is emptied as much as possible.

本实用新型所述机架上设有与罐体外壁相配合的卡扣,具体地说,机架上对称设置用于与挂扣相配合的挂钩,罐体两侧外壁分别设有锁紧挂扣,使用时通过将挂扣与挂钩挂接并扣紧,完成罐体与机架的固定,进一步,所述机架上对应上盖体的两侧设有卡扣,在对应推挤圆盘的两侧也设有卡扣。The frame of the utility model is provided with buckles matching with the outer wall of the tank, specifically, the frame is symmetrically provided with hooks for matching with the buckles, and the outer walls on both sides of the tank body are respectively provided with locking hooks. Buckle, when in use, the fixing of the tank body and the frame is completed by hooking the buckle with the hook and fastening it. Further, the frame is provided with buckles on both sides corresponding to the upper cover, and the corresponding pushing disc There are also buckles on both sides.

本实用新型所述上盖体外侧设有胶圈,用于与罐体内壁完成密封;所述推挤圆盘的周面上开设凹槽,并设有胶圈,用于提高推挤圆盘在灌装时的推挤可靠性,避免物料沿推挤圆盘与罐体内壁之间的缝隙溢出。The outer side of the upper cover of the utility model is provided with an apron, which is used to complete the sealing with the inner wall of the tank; grooves are provided on the peripheral surface of the pushing disc, and an apron is provided, which is used to improve the pressure of the pushing disc. The reliability of pushing during filling prevents the material from overflowing along the gap between the pushing disc and the inner wall of the tank.

本实用新型在使用时,现将待灌装物料由罐体的上端口倒入罐体内,将罐体提升至机架上的流体搅拌组件下方,使罐体的上端口与上盖体相配合,封闭罐体,然后利用卡扣将罐体固定在机架上,此时开启搅拌电动机,使搅拌电动机带动搅拌器对罐体内的物料进行搅拌,并开启真空泵,将物料搅拌后释放的多余气体排出,其中气体管路上设置的气压计能够使操作者实时获取罐体内气压情况,当罐体内气压接近0或负压,说明物料内的气泡被充分排出,可以进行灌装,此时解开卡扣,卸开上盖体与罐体,将罐体移至所述分装组件下方,并利用此处卡扣完成罐体与机架的固定,此时,分装组件中的推挤圆盘与罐体同轴设置,通过操作螺杆上端的手轮,可以调整推挤圆盘的高度,当推挤圆盘伸入罐体内,并持续下移,能够推动罐体内的物料沿罐体底部的灌装通道送出,灌装通道输出端提前连接分装管或分装袋,由于灌装通道内设有单向阀,可以防止在搅拌过程中物料外溢。When the utility model is in use, the material to be filled is now poured into the tank body from the upper port of the tank body, and the tank body is lifted to the bottom of the fluid stirring assembly on the frame, so that the upper port of the tank body matches the upper cover body , close the tank, and then fix the tank on the frame with buckles. At this time, turn on the stirring motor, so that the stirring motor drives the stirrer to stir the materials in the tank, and turn on the vacuum pump to remove the excess gas released after stirring the materials. Discharging, the air pressure gauge installed on the gas pipeline can enable the operator to obtain the air pressure inside the tank in real time. When the air pressure inside the tank is close to 0 or negative pressure, it means that the air bubbles in the material have been fully discharged and can be filled. At this time, the card is released. buckle, remove the upper cover and the tank body, move the tank body to the bottom of the sub-package assembly, and use the buckle here to complete the fixation of the tank body and the frame. At this time, the pushing disc in the sub-package assembly It is set coaxially with the tank body, and the height of the pushing disc can be adjusted by operating the handwheel at the upper end of the screw rod. When the pushing disc extends into the tank and continues to move down, it can push the material in the tank along the bottom of the tank. The filling channel is sent out, and the output end of the filling channel is connected to the sub-packaging pipe or sub-packaging bag in advance. Since there is a one-way valve in the filling channel, it can prevent the material from overflowing during the mixing process.

本实用新型与现有技术相比,通过简便的操作,有效排除了物料内的多余气体,保证了物料质量,具有结构合理、操作简便、分装效率高等显著的优点。Compared with the prior art, the utility model effectively eliminates excess gas in the material through simple operation, ensures the quality of the material, and has the remarkable advantages of reasonable structure, convenient operation and high packaging efficiency.

附图说明:Description of drawings:

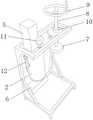

附图1是本实用新型的结构示意图。Accompanying

附图2是本实用新型中流体搅拌组件局部结构示意图。

附图标记:机架1、罐体2、上盖体3、搅拌器4、搅拌电动机5、真空泵6、推挤圆盘7、螺杆8、手轮9、螺母座10、气压计11、卡扣12。Reference signs:

具体实施方式:Detailed ways:

下面结合附图和实施例,对本实用新型做进一步的说明。Below in conjunction with accompanying drawing and embodiment, the utility model is described further.

实施例1:Example 1:

本例提供了一种美缝剂真空搅拌罐装一体机,设有机架1,机架1上并排设置流体搅拌组件和分装组件,所述流体搅拌组件包括罐体2、上盖体3、搅拌器4、搅拌电动机5、真空泵6以及气体管路,罐体2上端敞口,罐体2底部设有灌装通道,灌装通道上设有单向阀;上盖体3用于密封罐体2的上端口,搅拌电动机5位于上盖体3上侧且驱动位于上盖体3下侧的搅拌器4伸入罐体2内运转,上盖体3上还开设排气通道,排气通道与气体管路连通,真空泵6与气体管路相连;所述分装组件为螺杆式推进分装组件,设置在流体搅拌组件一侧,包括用于推挤罐体内容物沿灌装通道排出的推挤圆盘7,推挤圆盘7的上端与螺杆8下端相连,螺杆8与机架1上的螺母座10相连,螺杆8的上端设有手轮9;如附图1所示,本例所述气体管路上设有气压计11,用于检测当前罐体2内气压值,保证多余气体被尽量排空;This example provides an all-in-one vacuum mixing and filling machine for beautifying agent, which is provided with a

如附图1所示,所述机架1上设有与罐体2外壁相配合的卡扣12,具体地说,机架1上对称设置用于与挂扣相配合的挂钩,罐体2两侧外壁分别设有锁紧挂扣,使用时通过将挂扣与挂钩挂接并扣紧,完成罐体2与机架1的固定,进一步,所述机架1上对应上盖体3的两侧设有卡扣,在对应推挤圆盘7的两侧也设有卡扣;As shown in accompanying

本例中所述上盖体3的外周面设有胶圈,用于与罐体2内壁完成密封;所述推挤圆盘7的周面上开设凹槽,并设有胶圈,用于提高推挤圆盘在灌装时的推挤可靠性,避免物料沿推挤圆盘7与罐体2内壁之间的缝隙溢出。In this example, the outer peripheral surface of the

在工作时,现将待灌装物料由罐体的上端口倒入罐体内,将罐体提升至机架上的流体搅拌组件下方,使罐体的上端口与上盖体相配合,封闭罐体,然后利用卡扣将罐体固定在机架上,此时开启搅拌电动机,使搅拌电动机带动搅拌器对罐体内的物料进行搅拌,并开启真空泵,将物料搅拌后释放的多余气体排出,其中气体管路上设置的气压计能够使操作者实时获取罐体内气压情况,当罐体内气压接近0或负压,说明物料内的气泡被充分排出,可以进行灌装,此时解开卡扣,卸开上盖体与罐体,将罐体移至所述分装组件下方,并利用此处卡扣完成罐体与机架的固定,此时,分装组件中的推挤圆盘与罐体同轴设置,通过操作螺杆上端的手轮,可以调整推挤圆盘的高度,当推挤圆盘伸入罐体内,并持续下移,能够推动罐体内的物料沿罐体底部的灌装通道送出,灌装通道输出端提前连接分装管或分装袋,由于灌装通道内设有单向阀,可以防止在搅拌过程中物料外溢。When working, now pour the material to be filled into the tank from the upper port of the tank, lift the tank to the bottom of the fluid stirring assembly on the frame, make the upper port of the tank match the upper cover, and close the tank body, and then fix the tank body on the frame with buckles, turn on the stirring motor at this time, let the stirring motor drive the stirrer to stir the materials in the tank body, and turn on the vacuum pump to discharge the excess gas released after the materials are stirred, among which The air pressure gauge installed on the gas pipeline can enable the operator to obtain the air pressure inside the tank in real time. When the air pressure in the tank is close to 0 or negative pressure, it means that the air bubbles in the material have been fully discharged and can be filled. At this time, unfasten the buckle and unload Open the upper cover and the tank, move the tank to the bottom of the sub-packaging assembly, and use the buckle here to complete the fixing of the tank and the frame. At this time, the pushing disc and the tank in the sub-packing assembly Coaxial setting, by operating the hand wheel on the upper end of the screw, the height of the pushing disc can be adjusted. When the pushing disc extends into the tank and continues to move down, it can push the material in the tank along the filling channel at the bottom of the tank. Sending out, the output end of the filling channel is connected to the sub-packaging pipe or sub-packaging bag in advance. Since the filling channel is equipped with a one-way valve, it can prevent the material from overflowing during the mixing process.

本实用新型与现有技术相比,通过简便的操作,有效排除了物料内的多余气体,保证了物料质量,具有结构合理、操作简便、分装效率高等显著的优点。Compared with the prior art, the utility model effectively eliminates excess gas in the material through simple operation, ensures the quality of the material, and has the remarkable advantages of reasonable structure, convenient operation and high packaging efficiency.

Claims (4)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202221943161.0UCN217921447U (en) | 2022-07-25 | 2022-07-25 | Seam beautifying agent vacuum stirring and canning all-in-one machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202221943161.0UCN217921447U (en) | 2022-07-25 | 2022-07-25 | Seam beautifying agent vacuum stirring and canning all-in-one machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN217921447Utrue CN217921447U (en) | 2022-11-29 |

Family

ID=84148527

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202221943161.0UExpired - Fee RelatedCN217921447U (en) | 2022-07-25 | 2022-07-25 | Seam beautifying agent vacuum stirring and canning all-in-one machine |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN217921447U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115947285A (en)* | 2023-01-10 | 2023-04-11 | 上海靓钻建筑装饰有限公司 | A method and device for press-fitting beautifying agent |

- 2022

- 2022-07-25CNCN202221943161.0Upatent/CN217921447U/ennot_activeExpired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115947285A (en)* | 2023-01-10 | 2023-04-11 | 上海靓钻建筑装饰有限公司 | A method and device for press-fitting beautifying agent |

| CN116139726A (en)* | 2023-01-10 | 2023-05-23 | 上海靓钻建筑装饰有限公司 | A kind of beautifying agent coloring machine |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN217921447U (en) | Seam beautifying agent vacuum stirring and canning all-in-one machine | |

| CN107051321A (en) | Agitator tank | |

| CN115490022A (en) | Ton bag residual sufficient material pouring device and feeding equipment | |

| CN207385400U (en) | A kind of liquid adjuvants filling apparatus | |

| CN206980589U (en) | A drug raw material batching device | |

| CN206050235U (en) | Packed glue quantitative filling device | |

| CN115593671A (en) | A fully automatic sauce quantitative discharge machine | |

| CN213832995U (en) | Powder turnover barrel | |

| CN205932555U (en) | Aluminite powder holding vessel | |

| CN214744990U (en) | A fine chemical liquid material conveying device | |

| CN211659952U (en) | Discharging device of reaction kettle | |

| CN113526141A (en) | High-efficient accurate material transmission system | |

| CN209451696U (en) | A mobile material preparation and feeding integrated device | |

| CN210593447U (en) | Powder material transport tank | |

| CN209852613U (en) | Efficient vacuum filling machine | |

| CN222099538U (en) | Filling machine with leak-proof structure | |

| CN221025526U (en) | Product intermediate tank for unsaturated polyester resin | |

| CN220564289U (en) | A quantitative discharging machine for sauce production | |

| CN222219369U (en) | A kind of auxiliary material powder extraction and distribution device | |

| CN222753083U (en) | Solvent-free compound machine glue mixing mechanism | |

| CN222885601U (en) | Isolated air stirring dissolving device and solution preparation transferring device | |

| CN217320982U (en) | Quantitative micro-irrigation machine edge sealing device | |

| CN223116671U (en) | A bottom flushing degassing packaging machine | |

| CN218807972U (en) | Movable sending tank | |

| CN211281772U (en) | Vacuum quantitative filling machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20221129 | |

| CF01 | Termination of patent right due to non-payment of annual fee |