CN211585861U - A kind of blast furnace water slag environmental protection whitening device - Google Patents

A kind of blast furnace water slag environmental protection whitening deviceDownload PDFInfo

- Publication number

- CN211585861U CN211585861UCN201922361765.9UCN201922361765UCN211585861UCN 211585861 UCN211585861 UCN 211585861UCN 201922361765 UCN201922361765 UCN 201922361765UCN 211585861 UCN211585861 UCN 211585861U

- Authority

- CN

- China

- Prior art keywords

- whitening

- water

- steam

- blast furnace

- granulation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000titleclaimsabstractdescription148

- 230000002087whitening effectEffects0.000titleclaimsabstractdescription104

- 239000002893slagSubstances0.000titleclaimsabstractdescription60

- 230000007613environmental effectEffects0.000titleclaimsabstractdescription23

- 239000007921spraySubstances0.000claimsabstractdescription71

- 238000005469granulationMethods0.000claimsabstractdescription52

- 230000003179granulationEffects0.000claimsabstractdescription52

- 239000000463materialSubstances0.000claimsabstractdescription18

- 238000009833condensationMethods0.000claimsabstractdescription17

- 230000005494condensationEffects0.000claimsabstractdescription17

- 238000002347injectionMethods0.000claimsabstractdescription16

- 239000007924injectionSubstances0.000claimsabstractdescription16

- 239000002245particleSubstances0.000claimsdescription5

- 238000000034methodMethods0.000abstractdescription15

- 238000001914filtrationMethods0.000abstractdescription7

- 230000000694effectsEffects0.000abstractdescription4

- 229910052717sulfurInorganic materials0.000description31

- 239000011593sulfurSubstances0.000description31

- NINIDFKCEFEMDL-UHFFFAOYSA-NSulfurChemical compound[S]NINIDFKCEFEMDL-UHFFFAOYSA-N0.000description30

- 239000007789gasSubstances0.000description7

- XEEYBQQBJWHFJM-UHFFFAOYSA-NIronChemical compound[Fe]XEEYBQQBJWHFJM-UHFFFAOYSA-N0.000description4

- 238000004061bleachingMethods0.000description4

- 238000011010flushing procedureMethods0.000description4

- 239000000203mixtureSubstances0.000description4

- 238000011084recoveryMethods0.000description4

- 238000011001backwashingMethods0.000description3

- 239000000243solutionSubstances0.000description3

- UGFAIRIUMAVXCW-UHFFFAOYSA-NCarbon monoxideChemical compound[O+]#[C-]UGFAIRIUMAVXCW-UHFFFAOYSA-N0.000description2

- 238000003723SmeltingMethods0.000description2

- 238000001816coolingMethods0.000description2

- 238000010586diagramMethods0.000description2

- 239000003546flue gasSubstances0.000description2

- 229910052742ironInorganic materials0.000description2

- 239000007788liquidSubstances0.000description2

- 238000004064recyclingMethods0.000description2

- 239000000779smokeSubstances0.000description2

- 238000005406washingMethods0.000description2

- 229910000831SteelInorganic materials0.000description1

- 238000010276constructionMethods0.000description1

- 238000005260corrosionMethods0.000description1

- 230000007797corrosionEffects0.000description1

- 230000008030eliminationEffects0.000description1

- 238000003379elimination reactionMethods0.000description1

- 238000005516engineering processMethods0.000description1

- 239000006260foamSubstances0.000description1

- 239000008187granular materialSubstances0.000description1

- 238000004519manufacturing processMethods0.000description1

- 239000002184metalSubstances0.000description1

- 229910052751metalInorganic materials0.000description1

- 239000003595mistSubstances0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 238000001556precipitationMethods0.000description1

- 238000010791quenchingMethods0.000description1

- 230000000171quenching effectEffects0.000description1

- 239000007787solidSubstances0.000description1

- 239000010959steelSubstances0.000description1

- 150000003463sulfurChemical class0.000description1

- 230000009466transformationEffects0.000description1

Images

Landscapes

- Waste-Gas Treatment And Other Accessory Devices For Furnaces (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本实用新型涉及金属冶炼设备领域,具体的是一种高炉水渣环保消白装置。The utility model relates to the field of metal smelting equipment, in particular to a blast furnace water slag environmental protection whitening device.

背景技术Background technique

高炉冶炼时会产生高温液态熔渣(1350℃-1500℃),国内每年生产铁水7亿吨,产生高温液态熔渣2.5亿吨。国内外通常采用沉淀过滤法(常称底滤法)水渣工艺对熔渣进行粒化处理。在高炉炉前进行水力冲渣,用水淬将熔渣击碎后,变成渣水混合物(常称水渣),水渣经冲渣沟进入过滤池,液态水经过滤池内的过滤层过滤后循环使用,过滤池内留下固态渣粒,然后通过桥式抓斗起重机对渣粒进行抓取、装车外运。High temperature liquid slag (1350℃-1500℃) will be produced during blast furnace smelting. The annual domestic production of molten iron is 700 million tons, and 250 million tons of high temperature liquid slag is produced. At home and abroad, precipitation filtration method (often called bottom filtration method) water slag process is usually used to granulate molten slag. Hydraulic slag flushing is carried out in front of the blast furnace, and the molten slag is crushed by water quenching and becomes a mixture of slag and water (often called water slag). After recycling, solid slag particles are left in the filter tank, and then the slag particles are grabbed by bridge-type grab cranes, loaded into trucks and shipped out.

水渣工艺对熔渣进行粒化处理的过程中会产生大量含硫蒸汽(约60℃-100℃),水渣蒸汽具有腐蚀性,在散发过程中污染周边环境,腐蚀周围的设备,同时由于过滤池距高炉的距离很近,因此散发的蒸汽也会对高炉设备造成一定的腐蚀。The water slag process will produce a large amount of sulfur-containing steam (about 60℃-100℃) in the process of granulating the molten slag. The water slag steam is corrosive, pollutes the surrounding environment and corrodes the surrounding equipment during the emission process The distance between the filter tank and the blast furnace is very close, so the steam emitted will also cause certain corrosion to the blast furnace equipment.

随着我国环保形势的越来越严峻,钢铁企业对水渣工艺的蒸汽消白技术的需求越来有强烈。国内外已经进行多年的相关研究,希望消除冲渣蒸汽,实现蒸汽消白。例如,中国专利CN 107815514 A,公开日期2018年3月20日,公开了一种《冲渣水蒸汽回收与消白雾的设备及回收方法》,该专利首先采用喷雾降温的方式实现蒸汽回收,然后利用热风炉烟气升温蒸汽防止产生白烟。采用该专利的方法能够有效减少部分蒸汽排放,利用热风炉烟气升温蒸汽能够防止产生白烟,但最终还是有部分蒸汽排入大气,即未能实现真正彻底的消白。With the increasingly severe environmental protection situation in my country, iron and steel enterprises have an increasingly strong demand for steam whitening technology of water slag process. Relevant research has been carried out for many years at home and abroad, hoping to eliminate the slag flushing steam and realize the steam whitening. For example, Chinese patent CN 107815514 A, published on March 20, 2018, discloses a kind of "equipment and recovery method for slag flushing water vapor recovery and white mist elimination", which first adopts the method of spray cooling to realize steam recovery, Then use the hot blast stove flue gas to heat up the steam to prevent the generation of white smoke. The method of this patent can effectively reduce part of the steam emission, and the use of hot blast stove flue gas to heat up the steam can prevent the generation of white smoke, but in the end, part of the steam is still discharged into the atmosphere, that is, true and complete whitening cannot be achieved.

实用新型内容Utility model content

为了实现真正彻底的消白,本实用新型提供了一种高炉水渣环保消白装置,该高炉水渣环保消白装置充分利用底滤法工艺中的滤料,在蒸汽消白过程中把未被冷凝喷淋装置凝结的小部分蒸汽引至消白池的底部,不但实现了彻底的蒸汽消白处理,而且先用蒸汽对滤料进行反冲洗、再用水对滤料进行反冲洗,能够提高对滤料的反冲洗效率、提高滤料活性,避免滤料易板结、使用寿命短的问题。In order to achieve truly complete whitening, the utility model provides an environmental protection whitening device for blast furnace water slag. A small part of the steam condensed by the condensing spray device is led to the bottom of the whitening tank, which not only realizes the complete steam whitening treatment, but also backwash the filter material with steam and then backwash the filter material with water, which can improve the efficiency of the filter. The backwashing efficiency of the filter material is improved, the activity of the filter material is improved, and the problems of easy hardening and short service life of the filter material are avoided.

本实用新型解决其技术问题所采用的技术方案是:一种高炉水渣环保消白装置,包括粒化消白塔和消白池,粒化消白塔的下部设有高炉熔渣入口和粒化器,粒化消白塔内含有上下设置的冷凝喷淋装置和喷淋水收集斗,粒化消白塔的上部设有蒸汽出口和注气口,消白池内设有过滤层和过滤管,蒸汽出口通过蒸汽输送管线与过滤管连接,蒸汽输送管线上依次设有除沫器和蒸汽风机。The technical scheme adopted by the utility model to solve the technical problem is as follows: a blast furnace water slag environmental protection whitening device includes a granulation and whitening tower and a whitening pool, and the lower part of the granulation and whitening tower is provided with a blast furnace slag inlet and a granulator. There are condensing spray devices and spray water collection buckets arranged up and down in the granulation and whitening tower. The upper part of the granulating and whitening tower is provided with a steam outlet and a gas injection port. The outlet is connected with the filter pipe through a steam conveying line, and a demister and a steam fan are arranged on the steam conveying line in turn.

蒸汽出口、注气口、冷凝喷淋装置、喷淋水收集斗、高炉熔渣入口和粒化器从上向下依次排列,注气口外连接有空气风机,通过注气口能够向粒化消白塔的上端内注入空气。The steam outlet, the gas injection port, the condensation spray device, the spray water collection bucket, the blast furnace slag inlet and the granulator are arranged in order from top to bottom. An air fan is connected to the outside of the gas injection port. Air is injected into the upper end.

喷淋水收集斗含有内筒斗、外筒斗和收集水管道,内筒斗套设于外筒斗内,内筒斗与外筒斗之间形成环形通道,外筒斗含有外斗体和内挡环,外斗体的下端与内挡环的下端之间通过环形连接板连接,外斗体与内挡环之间形成环形集水槽。The spray water collection bucket includes an inner bucket, an outer bucket and a collection water pipeline. The inner bucket is sleeved in the outer bucket, and an annular channel is formed between the inner bucket and the outer bucket. The outer bucket contains the outer bucket and the outer bucket. For the inner baffle ring, the lower end of the outer bucket body and the lower end of the inner baffle ring are connected by an annular connecting plate, and an annular water collecting groove is formed between the outer bucket body and the inner baffle ring.

内筒斗的上端高于外筒斗的上端,内筒斗的下端与外筒斗的下端齐平,内筒斗的上下两端均为开放状态,外斗体的上下两端均为开放状态,收集水管道呈水平状态,内筒斗的下端和外筒斗的下端均与收集水管道连接,内筒斗的内部与收集水管道的内部连通,所述环形连接板内设有排水通孔,环形集水槽通过排水通孔与收集水管道的内部连通。The upper end of the inner barrel is higher than the upper end of the outer barrel, the lower end of the inner barrel is flush with the lower end of the outer barrel, the upper and lower ends of the inner barrel are open, and the upper and lower ends of the outer barrel are open. , the water collection pipe is in a horizontal state, the lower end of the inner barrel and the lower end of the outer barrel are connected with the water collection pipe, the interior of the inner barrel is communicated with the interior of the water collection pipe, and the annular connecting plate is provided with a drainage through hole , the annular water collecting tank is communicated with the interior of the collecting water pipe through the drainage through hole.

内筒斗的上端外径小于粒化消白塔的内径,内筒斗的下端外径小于内挡环的内径,外斗体的上端外径等于粒化消白塔的内径,外斗体的下端与内挡环的下端齐平,收集水管道的一端位于粒化消白塔外,收集水管道的外径小于内挡环的内径。The outer diameter of the upper end of the inner barrel is smaller than the inner diameter of the granulation and whitening tower, the outer diameter of the lower end of the inner barrel is smaller than the inner diameter of the inner baffle ring, and the outer diameter of the upper end of the outer bucket is equal to the inner diameter of the granulation and whitening tower. The lower end is flush with the lower end of the inner baffle ring, one end of the collecting water pipe is located outside the granulation and whitening tower, and the outer diameter of the collecting water pipe is smaller than the inner diameter of the inner baffle ring.

粒化消白塔的侧壁上设有喷淋水入口、收集水出口和蒸汽返回口,通过喷淋水入口能够向冷凝喷淋装置供应喷淋水,通过收集水出口能够将喷淋水收集斗收集到的水排出,蒸汽返回口位于喷淋水收集斗的下方,蒸汽输送管线通过蒸汽返回管线与蒸汽返回口连接。The side wall of the granulation and whitening tower is provided with a spray water inlet, a collection water outlet and a steam return port. The spray water can be supplied to the condensation spray device through the spray water inlet, and the spray water can be collected through the collection water outlet. The water collected by the bucket is discharged, the steam return port is located below the spray water collection bucket, and the steam conveying line is connected with the steam return port through the steam return line.

冷凝喷淋装置含有至少一层高压雾化喷嘴。The condensation spray device contains at least one layer of high pressure atomizing nozzles.

过滤管位于过滤层内或过滤层以下。The filter tube is located in or below the filter layer.

过滤层含有粒径从上向下逐渐变大的滤料。The filter layer contains filter material whose particle size gradually increases from top to bottom.

消白池的上端面高于过滤层的上表面。The upper end surface of the whitening pool is higher than the upper surface of the filter layer.

1、本实用新型能够充分利用冷凝喷淋装置和底滤法工艺中的滤料实现彻底的蒸汽消白处理。1. The utility model can make full use of the condensing spray device and the filter material in the bottom filtration process to achieve complete steam whitening treatment.

2、本实用新型可以对冲渣粒化过程中的蒸汽实现全部回收,实现水资源的循环利用。2. The utility model can realize all the recovery of steam in the process of flushing slag granulation and realize the recycling of water resources.

3、本实用新型能够提高对滤料的反冲洗效率、提高滤料活性,避免滤料易板结、使用寿命短的问题。3. The utility model can improve the backwashing efficiency of the filter material, improve the activity of the filter material, and avoid the problems that the filter material is easy to harden and the service life is short.

4、本实用新型不但适用于高炉新建工程,而且适用于现有高炉水渣系统的环保改造。4. The utility model is not only suitable for new construction of blast furnaces, but also for environmental protection transformation of existing blast furnace water slag systems.

附图说明Description of drawings

构成本申请的一部分的说明书附图用来提供对本实用新型的进一步理解,本实用新型的示意性实施例及其说明用于解释本实用新型,并不构成对本实用新型的不当限定。The accompanying drawings forming a part of the present application are used to provide further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention and do not constitute an improper limitation of the present invention.

图1是本实用新型所述高炉水渣环保消白装置的结构示意图。Figure 1 is a schematic structural diagram of the blast furnace water slag environmental protection whitening device according to the present invention.

图2是图1中沿A-A方向的剖视图。FIG. 2 is a cross-sectional view taken along the A-A direction in FIG. 1 .

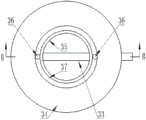

图3是粒化消白塔在喷淋水收集斗部位的示意图。Figure 3 is a schematic diagram of the part of the granulation and whitening tower in the spray water collection bucket.

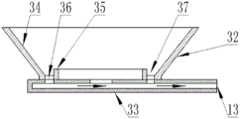

图4是外斗体和收集水管道的俯视图。Figure 4 is a top view of the outer bucket and the collection water conduit.

图5是图4中沿B-B方向的剖视图。FIG. 5 is a cross-sectional view taken along the direction B-B in FIG. 4 .

1、粒化器;2、粒化消白塔;3、喷淋水收集斗;4、冷凝喷淋装置;5、蒸汽风机;6、消白池;7、过滤层;8、过滤管;9、高炉熔渣入口;10、蒸汽出口;11、蒸汽输送管线;12、喷淋水入口;13、收集水出口;14、除沫器;15、空气风机;16、注气口;17、蒸汽返回口;18、蒸汽返回管线;19、阀门;1. Granulator; 2. Granulation and whitening tower; 3. Spray water collection bucket; 4. Condensing spray device; 5. Steam fan; 6. Whitening pool; 7. Filter layer; 8. Filter tube; 9 , blast furnace slag inlet; 10, steam outlet; 11, steam conveying pipeline; 12, spray water inlet; 13, collecting water outlet; 14, demister; 15, air fan; 16, gas injection port; 17, steam return port; 18, steam return line; 19, valve;

31、内筒斗;32、外筒斗;33、收集水管道;34、外斗体;35、内挡环;36、排水通孔;37、环形集水槽;38、冷凝水与喷淋水;39、含硫蒸汽。31. Inner barrel; 32. Outer barrel; 33. Water collection pipe; 34. Outer barrel; 35. Inner baffle ring; 36. Drainage through hole; ; 39. Sulfur-containing steam.

具体实施方式Detailed ways

需要说明的是,在不冲突的情况下,本申请中的实施例及实施例中的特征可以相互组合。下面将参考附图并结合实施例来详细说明本实用新型。It should be noted that the embodiments in the present application and the features of the embodiments may be combined with each other in the case of no conflict. The present utility model will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

一种高炉水渣环保消白装置,包括粒化消白塔2和消白池6,粒化消白塔2的下部设有高炉熔渣入口9和粒化器1,粒化消白塔2内含有上下设置的冷凝喷淋装置4和喷淋水收集斗3,粒化消白塔2的上部设有蒸汽出口10和注气口16,消白池6内设有过滤层7和过滤管8,蒸汽出口10通过蒸汽输送管线11与过滤管8连接,蒸汽输送管线11上依次设有除沫器14和蒸汽风机5,如图1所示。A blast furnace water slag environmental protection whitening device, comprising a

蒸汽出口10通过蒸汽输送管线11与过滤管8连接,未被凝结的剩余部分含硫蒸汽将从蒸汽出口10排出经过除沫器14除沫后通过蒸汽输送管线11进入过滤管8内,即把未被冷凝喷淋装置凝结的小部分蒸汽引至消白池的底部内。这样,不但实现了彻底的蒸汽消白处理,而且先用蒸汽对滤料进行反冲洗、再用水对滤料进行反冲洗,能够提高对滤料的反冲洗效率、提高滤料活性,避免滤料易板结、使用寿命短的问题。The

在本实施例中,高炉熔渣入口9与粒化器1上下对应设置,蒸汽出口10、注气口16、冷凝喷淋装置4、喷淋水收集斗3、高炉熔渣入口9和粒化器1从上向下依次排列,注气口16外连接有空气风机15,通过注气口16能够向粒化消白塔2的上端内注入空气,通过调节空气流入量可以调节粒化消白塔2顶部的负压值。In this embodiment, the blast

在本实施例中,粒化消白塔2的侧壁上还设有喷淋水入口12、收集水出口13和蒸汽返回口17,蒸汽输送管线11通过蒸汽返回管线18与蒸汽返回口17连接。通过注气口16和空气风机15能够向粒化消白塔2的上端内注入空气,通过调节空气的注入量可以调节粒化消白塔2顶部的负压值。通过喷淋水入口12能够向冷凝喷淋装置4供应喷淋水,通过收集水出口13能够将喷淋水收集斗3收集到的水排出。In this embodiment, a

蒸汽返回口17位于喷淋水收集斗3的下方,蒸汽输送管线11内的蒸汽可以通过蒸汽返回管线18返回至粒化消白塔2内,重新喷淋冷凝。即该含硫蒸汽中的剩余部分可以进入消白池6的过滤管8内,或者该含硫蒸汽中的剩余部分也可以进入粒化消白塔2内,蒸汽输送管线11和蒸汽返回管线18上均设有阀门19,以控制蒸汽输送管线11内含硫蒸汽的流向。The

喷淋水收集斗3可以为现有技术中的产品,或者,在本实用新型中,喷淋水收集斗3含有内筒斗31、外筒斗32和收集水管道33,内筒斗31套设于外筒斗32内,内筒斗31与外筒斗32之间形成环形通道。内筒斗31的轴线、外筒斗32的轴线和粒化消白塔2的轴线重合。内筒斗31为顶端朝下底端朝上的圆锥筒形结构,外筒斗32含有外斗体34和内挡环35,内挡环35套设于外斗体34的下端内,内挡环35的轴线与外斗体34的轴线重合,外斗体34为顶端朝下底端朝上的圆锥筒形结构,外斗体34的下端与内挡环35的下端之间通过环形连接板密封连接,外斗体34与内挡环35之间形成环形集水槽37。The spray

内筒斗31的上端高于外筒斗32的上端,内筒斗31的下端与外筒斗32的下端齐平。内筒斗31的上下两端均为开放状态,外斗体34的上下两端均为开放状态,收集水管道33呈水平状态,内筒斗31的下端和外筒斗32的下端均与收集水管道33连接,内筒斗31的内部与收集水管道33的内部连通,所述环形连接板内设有排水通孔36,环形集水槽37通过排水通孔36与收集水管道33的内部连通。The upper end of the

内筒斗31的上端外径小于粒化消白塔2的内径,内筒斗31的上端与粒化消白塔2的内表面之间形成环形空间。内筒斗31的下端外径小于内挡环35的内径,外斗体34的上端外径等于粒化消白塔2的内径,外斗体34与粒化消白塔2连接固定,外斗体34的下端与内挡环35的下端齐平,即内筒斗31的下端、外斗体34的下端和内挡环35的下端齐平。收集水管道33的一端位于粒化消白塔2外,收集水管道33的外径小于内挡环35的内径,收集水管道33的一端为收集水出口13,如图1至图5所示。The outer diameter of the upper end of the

使用时,含硫蒸汽39向上移动并依次穿过内挡环35的下端、所述环形通道以及所述环形空间,大部分的含硫蒸汽在雾化喷淋水的作用下成为冷凝水。该冷凝水与喷淋水38的一部分落入内筒斗31的下端,然后进入收集水管道33并从收集水出口13排出。该冷凝水与喷淋水38的另一部分落入外筒斗32下端的环形集水槽37,然后进入收集水管道33并从收集水出口13排出,如图3所示。In use, the sulfur-containing

在本实施例中,冷凝喷淋装置4含有至少一层高压雾化喷嘴,冷凝喷淋装置4能够喷淋冷水以使高温含硫蒸汽冷凝形成冷凝水,该冷凝水将汇集于喷淋水收集斗3的收集区域内。蒸汽出口10位于粒化消白塔2的顶部,蒸汽输送管线11上设有除沫器14和蒸汽风机5,蒸汽风机5用于使从蒸汽出口10排出的剩余含硫蒸汽通过蒸汽输送管线11进入过滤管8内或返回至粒化消白塔2内。In this embodiment, the

在本实施例中,过滤管8的管壁上多个过滤通孔,剩余含硫蒸汽进入过滤管8后经过该过滤通孔后可以进入过滤层7内,如图2所示。消白池6的构造与现有过滤池的构造的基本相同,过滤管8位于过滤层7内或过滤层7以下,优选过滤管8位于过滤层7的下部,过滤层7内含有粒径从上向下逐渐变大的滤料。In this embodiment, there are a plurality of filter through holes on the pipe wall of the

下面介绍该高炉水渣环保消白装置的工作过程。The working process of the blast furnace water slag environmental protection whitening device is described below.

高温熔渣(1350℃-1500℃)从高炉熔渣入口9进入粒化消白塔2,大量高速粒化水(约40℃-45℃)在粒化器1喷出进入粒化消白塔2,该高温熔渣在粒化水的作用下完成粒化,并形成渣水混合物以及大量的含硫蒸汽(约80℃-100℃)。The high temperature slag (1350℃-1500℃) enters the granulation and whitening

冲渣水从粒化消白塔2的下部的冲渣水入口进入粒化消白塔2,将该渣水混合物从粒化消白塔2的下部的水渣出口冲出粒化消白塔2外。该含硫蒸汽在蒸汽风机5的作用下,在粒化消白塔2内部向上运动。The slag washing water enters the granulation and

冷凝喷淋装置4喷出喷淋水(约40℃-45℃)后在粒化消白塔2内部形成雾化状态,雾化的喷淋水均匀布满粒化消白塔2内部空间。该含硫蒸汽向上穿过喷淋水收集斗3进入雾化水区域,大部分的含硫蒸汽在雾化喷淋水的作用下成为冷凝水,该冷凝水与喷淋水一起落入冷凝喷淋装置4下方的喷淋水收集斗3。喷淋水收集斗3收集到的水(即上述冷凝水和喷淋水)从收集水出口13排出粒化消白塔2后可以送至冷却塔。After the

蒸汽风机5将未被雾化喷淋水的凝结的剩余部分的含硫蒸汽引入蒸汽输送管线11,该含硫蒸汽中的剩余部分进入除沫器14除沫,通过注气口16和空气风机15能够向粒化消白塔2的上端内注入空气,通过调节空气流入量可以调节粒化塔顶部的负压值。The

经过除沫处理的所述含硫蒸汽中的剩余部分通过蒸汽输送管线11进入过滤管8内,或经过除沫处理的所述含硫蒸汽中的剩余部分依次通过蒸汽输送管线11和蒸汽返回管线18进入粒化消白塔2的下部内。The remaining part of the sulfur-containing steam that has undergone the defoaming treatment enters the

进入过滤管8内的所述剩余部分的含硫蒸汽从过滤管8的过滤通孔排出向上进入消白池6的过滤层7,所述剩余部分的含硫蒸汽向上移动对过滤层7的滤料进行反冲洗,消白池6内含有沉积水,该沉积水的水面通常位于过滤层7的上表面和消白池6的上端面之间,所述剩余部分的含硫蒸汽从过滤管8的过滤通孔排出进入消白池6后,该沉积水将全部吸收所述剩余部分的含硫蒸汽,从而实现真正彻底的消白。The remaining part of the sulfur-containing steam entering the

下面介绍一种高炉熔渣底滤法消白方法,所述高炉熔渣底滤法消白方法采用了上述的高炉水渣环保消白装置,所述高炉熔渣底滤法消白方法包括以下步骤:A method for eliminating whitening by bottom filtration of blast furnace slag is introduced below. The method for eliminating whitening by bottom filtering of blast furnace slag adopts the above-mentioned blast furnace water slag environmental protection whitening device, and the method for eliminating whitening by bottom filtering of blast furnace slag includes the following: step:

步骤1:高温熔渣(1350℃-1500℃)与粒化水(约40℃-45℃)相遇后产生渣水混合物以及大量的含硫蒸汽(约80℃-100℃);Step 1: After the high temperature molten slag (1350℃-1500℃) meets the granulated water (about 40℃-45℃), a mixture of slag and water and a large amount of sulfur-containing steam (about 80℃-100℃) are generated;

步骤2:所述含硫蒸汽向上运动,冷凝喷淋装置4喷出喷淋水(约40℃-45℃)喷淋所述含硫蒸汽,该含硫蒸汽中的大部分在该喷淋水的作用下成为冷凝水;Step 2: The sulfur-containing steam moves upward, and the

步骤3:该含硫蒸汽中的剩余部分进入除沫器14除沫;Step 3: The remaining part of the sulfur-containing steam enters the

步骤4:该含硫蒸汽中的剩余部分进入消白池6(消白池6内含有沉积水)的过滤管8内或该含硫蒸汽中的剩余部分进入粒化消白塔2的下部内;Step 4: the remainder in this sulfur-containing steam enters the

步骤5:该含硫蒸汽中的剩余部分从过滤管8排出并向上进入消白池6的过滤层7。Step 5: The remaining part of the sulfur-containing steam is discharged from the

以上所述,仅为本实用新型的具体实施例,不能以其限定实用新型实施的范围,所以其等同组件的置换,或依本实用新型专利保护范围所作的等同变化与修饰,都应仍属于本专利涵盖的范畴。另外,本实用新型中的技术特征与技术特征之间、技术特征与技术方案、技术方案与技术方案之间均可以自由组合使用。The above descriptions are only specific examples of the present invention, and cannot limit the scope of implementation of the present invention. Therefore, the replacement of the equivalent components thereof, or the equivalent changes and modifications made according to the scope of the patent protection of the present invention, shall still belong to the scope of the present invention. Scope covered by this patent. In addition, technical features and technical features, technical features and technical solutions, and technical solutions and technical solutions in the present invention can be freely combined and used.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201922361765.9UCN211585861U (en) | 2019-12-25 | 2019-12-25 | A kind of blast furnace water slag environmental protection whitening device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201922361765.9UCN211585861U (en) | 2019-12-25 | 2019-12-25 | A kind of blast furnace water slag environmental protection whitening device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN211585861Utrue CN211585861U (en) | 2020-09-29 |

Family

ID=72595468

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201922361765.9UActiveCN211585861U (en) | 2019-12-25 | 2019-12-25 | A kind of blast furnace water slag environmental protection whitening device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN211585861U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110975499A (en)* | 2019-12-25 | 2020-04-10 | 中冶京诚工程技术有限公司 | Environment-friendly white-removing device for blast furnace granulated slag |

- 2019

- 2019-12-25CNCN201922361765.9Upatent/CN211585861U/enactiveActive

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110975499A (en)* | 2019-12-25 | 2020-04-10 | 中冶京诚工程技术有限公司 | Environment-friendly white-removing device for blast furnace granulated slag |

| CN110975499B (en)* | 2019-12-25 | 2024-02-02 | 中冶京诚工程技术有限公司 | Environment-friendly white removing device for granulated slag of blast furnace |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109457070B (en) | A steam dewhitening and heat energy recovery system for blast furnace water slag process | |

| CN101265039A (en) | An environment-friendly bottom filtration blast furnace slag treatment equipment and treatment method | |

| CN205635660U (en) | Metallurgical liquid high temperature sludge shrend processing system | |

| CN208678740U (en) | Waste gas produced device when a kind of processing melting waste aluminum | |

| CN109457069B (en) | Energy-saving and white-eliminating system for blast furnace slag granulation | |

| CN211585861U (en) | A kind of blast furnace water slag environmental protection whitening device | |

| CN109439817B (en) | Energy-saving and white-eliminating equipment for granulating blast furnace slag | |

| CN200996021Y (en) | Environmental-protecting blast-furnace cinder treating system | |

| CN110975497B (en) | Method for eliminating white matter of blast furnace slag bottom filtering system | |

| CN211471465U (en) | White device that disappears of blast furnace water sediment system | |

| CN211585860U (en) | Environment-friendly white-removing system for blast furnace granulated slag | |

| CN209292374U (en) | Energy-saving white-removing system for blast furnace slag granulation | |

| CN211471466U (en) | White system disappears at bottom of blast furnace slag | |

| CN110975499B (en) | Environment-friendly white removing device for granulated slag of blast furnace | |

| CN205235573U (en) | Waste water cyclic utilization system is handled to intermediate frequency furnace flue gas | |

| CN204602789U (en) | A kind of plasma fusion cracking industrial sludge system | |

| CN201046376Y (en) | A flue gas dust collector | |

| CN209352936U (en) | Energy-saving white-removing equipment for blast furnace slag granulation | |

| CN212440087U (en) | Spray drying device containing salt mother liquor | |

| CN110975496B (en) | Environment-friendly white removing system for granulated slag of blast furnace | |

| CN111004880B (en) | White device of blast furnace grain slag system that disappears | |

| CN211471464U (en) | Steam condensate water collection device and chimney | |

| CN201632175U (en) | Tail gas treatment device | |

| CN206069798U (en) | Drop a hint during a kind of u gas gasification furnace driving and parking water washing dedust device | |

| CN109457068B (en) | Energy-saving and whitening treatment system for blast furnace granulated slag process |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |