CN211515235U - Parcel sorting device - Google Patents

Parcel sorting deviceDownload PDFInfo

- Publication number

- CN211515235U CN211515235UCN201921785610.1UCN201921785610UCN211515235UCN 211515235 UCN211515235 UCN 211515235UCN 201921785610 UCN201921785610 UCN 201921785610UCN 211515235 UCN211515235 UCN 211515235U

- Authority

- CN

- China

- Prior art keywords

- conveying

- package

- section

- unit

- sorting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Sorting Of Articles (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本实用新型涉及机电领域,尤其涉及一种包裹分拣装置。The utility model relates to the electromechanical field, in particular to a parcel sorting device.

背景技术Background technique

目前,随着科技的发展,世界上各个国家对环境的保护愈来愈注重。由于工业生产和日常生活中,易产生较多的废旧资源,因此,如何处理废旧资源,实现回收利用,正成为当下以及未来的发展热点和解决的难点。At present, with the development of science and technology, countries in the world are paying more and more attention to environmental protection. Since industrial production and daily life are prone to generate more waste resources, how to deal with waste resources and realize recycling is becoming a current and future development hotspot and a difficult point to solve.

在日常生活用品中,电子产品的更新换代的速度愈来愈快,产生了大量废旧的电子产品,例如手机、平板电脑、笔记本电脑等。而电子产品通常都包含有大量的贵金属,如按照焚烧、掩埋等现有的垃圾处理方式处理,会对土壤以及地下水的环境造成严重的污染,且难以治理。因此,如何对电子产品进行分拣处理,将可重复利用的电子产品继续投放市场,或将对应对应的电子产品进行拆解处理,对应电子产品的回收利用至关重要。Among the daily necessities, the replacement speed of electronic products is getting faster and faster, resulting in a large number of waste electronic products, such as mobile phones, tablet computers, notebook computers, etc. Electronic products usually contain a large amount of precious metals, such as incineration, landfill and other existing garbage disposal methods will cause serious pollution to the soil and groundwater environment, and it is difficult to treat. Therefore, how to sort electronic products, continue to put reusable electronic products on the market, or disassemble the corresponding electronic products, the recycling of corresponding electronic products is very important.

通常,回收的产品都会通过用户或第三方进行打包形成包裹后,将包裹邮寄或运输至回收站点进行集中处理,然而由于包裹的种类和数量繁多,因此需要通过输送线将包裹输送至相应的多个处理工位进行拆包处理,由于部分包裹存在空包或投递错误的情况,一旦输送至相应的处理工位,易对拆包人员带来不必要的工作负担,降低了包裹的分拣效率。Usually, the recycled products are packaged by the user or a third party to form a package, and then the package is mailed or transported to the recycling site for centralized processing. However, due to the variety and quantity of the package, it needs to be conveyed through the conveyor line. One processing station is used for unpacking processing. Since some packages are empty or wrongly delivered, once they are transported to the corresponding processing station, it is easy to bring unnecessary workload to the unpacking personnel and reduce the sorting efficiency of the packages. .

此外,由于包裹上通常贴有包含包裹信息的标识码,当包裹被输送至相应的处理工位后,工作人员需要通过相应的读取装置读取标识码对应的包裹信息后,拆解包裹,并在产品上贴上与该包裹信息相匹配的产品标识码,以便于后续产品的分拣,然而由于人工在操作过程中,易出现失误,因此可能造成贴在产品上的标识码与对应的包裹信息不匹配的现象。In addition, since the package is usually affixed with an identification code containing the package information, when the package is transported to the corresponding processing station, the staff needs to read the package information corresponding to the identification code through the corresponding reading device, and then disassemble the package. And paste the product identification code that matches the package information on the product to facilitate the sorting of subsequent products. However, due to manual errors in the operation process, it may cause the identification code pasted on the product to match the corresponding one. The phenomenon that the package information does not match.

因此,如何提供一种结构简单的包裹分拣装置,可以在对包裹分拣前,方便地获取包裹的包裹信息和重量信息,以利于后续的分拣,提高包裹的分拣效率,降低工作人员的工作负担。Therefore, how to provide a package sorting device with a simple structure, which can conveniently obtain the package information and weight information of the package before sorting the package, so as to facilitate the subsequent sorting, improve the sorting efficiency of the package, and reduce the number of staff work load.

实用新型内容Utility model content

针对上述现有技术的缺点或不足,本实用新型要解决的技术问题是如何提供一种结构简单的包裹分拣装置,可以在对包裹分拣前,方便地获取包裹的包裹信息和重量信息,以利于后续的分拣,提高包裹的分拣效率,降低工作人员的工作负担。In view of the above-mentioned shortcomings or deficiencies of the prior art, the technical problem to be solved by the present invention is how to provide a package sorting device with a simple structure, which can conveniently obtain the package information and weight information of the package before sorting the package, In order to facilitate subsequent sorting, improve the sorting efficiency of packages, and reduce the workload of staff.

为解决上述技术问题,本实用新型提供了一种包裹分拣装置,其包括:用于输送包裹的输送线、控制装置;所述输送线包括:多个依次相接且用于独立输送包裹的输送单元;各输送单元均与所述控制装置通讯连接,其中,所述输送线包括:包裹输送主段;In order to solve the above technical problems, the utility model provides a package sorting device, which includes: a conveying line and a control device for conveying packages; the conveying line includes: a plurality of sequentially connected and used for independently conveying packages. a conveying unit; each conveying unit is connected in communication with the control device, wherein the conveying line includes: a main section of package conveying;

所述包裹输送主段具有至少一个包裹分配区段;the package delivery main section has at least one package distribution section;

所述包裹分配区段包括:沿所述包裹输送主段的传送方向先后设置的监测单元和多个分拣单元;The package distribution section includes: a monitoring unit and a plurality of sorting units sequentially arranged along the conveying direction of the main package conveying section;

读取装置,与所述控制装置通讯连接,用于在所述包裹到达所述监测单元时,读取与所述包裹相匹配的包裹信息,并发送所述包裹信息至所述控制装置;a reading device, connected in communication with the control device, for reading the package information matching the package when the package arrives at the monitoring unit, and sending the package information to the control device;

其中,所述监测单元与所述控制装置通讯连接,其设置于相邻的两个输送单元之间,用于在所述包裹通过时,检测所述包裹的重量信息,并将所述重量信息发送至所述控制装置。Wherein, the monitoring unit is connected in communication with the control device, and is arranged between two adjacent conveying units, for detecting the weight information of the package when the package passes through, and converting the weight information sent to the control device.

进一步作为优选地,所述监测单元包括:第一监测子单元,用于在所述包裹通过时,通过所述读取装置读取所述包裹信息;第二监测子单元,其两端分别与所述第一监测子单元和输送单元相接,用于在所述包裹通过时,检测所述包裹的重量信息,并将所述重量信息发送至所述控制装置。Further preferably, the monitoring unit includes: a first monitoring sub-unit for reading the package information through the reading device when the package passes through; a second monitoring sub-unit, two ends of which are respectively connected to The first monitoring sub-unit is connected to the conveying unit, and is used for detecting the weight information of the package when the package passes, and sending the weight information to the control device.

进一步作为优选地,所述监测单元还包括:监测传感器,设置于所述第一监测子单元上,与所述控制装置通讯连接,用于在检测到所述包裹时,向所述控制装置发送感应信号;其中,所述包裹在被所述监测传感器检测时,所述包裹位于所述读取装置的读取区域。Further preferably, the monitoring unit further comprises: a monitoring sensor, which is arranged on the first monitoring sub-unit and is connected in communication with the control device, and is used to send a message to the control device when the package is detected. Induction signal; wherein, when the package is detected by the monitoring sensor, the package is located in the reading area of the reading device.

进一步作为优选地,所述第一监测子单元包括:用于与所述包裹接触并施加输送力的传送带体、用于旋转支撑所述传送带体的框架;所述第二监测子单元包括:用于与所述包裹接触并施加输送力的传送体、用于旋转支撑所述传送体的支撑架、设置于传送体下方的重量传感器。Further preferably, the first monitoring subunit includes: a conveyor belt body for contacting the package and applying a conveying force, and a frame for rotatably supporting the conveyor belt body; the second monitoring subunit includes: using On the conveying body which is in contact with the package and exerts the conveying force, the supporting frame for rotatably supporting the conveying body, and the weight sensor arranged under the conveying body.

进一步作为优选地,所述读取装置包括:用于读取所述包裹的标识码所对应的包裹信息的扫码器、用于固定所述扫码器的扫码支架。Further preferably, the reading device includes: a code scanner for reading package information corresponding to the identification code of the package, and a code scanning bracket for fixing the code scanner.

进一步作为优选地,所述分拣单元包括:多个间隔设置且用于对产品施加输送力的输送辊、相对输送辊伸出没入且用于对输送辊施加输送力的分拣部件、用于旋转支撑输送辊的支撑部件、用于控制所述分拣部件的升降高度的升降机构;其中,所述输送辊和分拣部件对所述产品施加的输送力的方向不同;升降机构用于使所述分拣部件从输送辊之间伸出和没入。Further preferably, the sorting unit comprises: a plurality of conveying rollers arranged at intervals and used for applying conveying force to the products, a sorting part protruding and submerged relative to the conveying rollers and used for applying conveying force to the conveying rollers; A support member that rotates and supports the conveying roller, and a lifting mechanism for controlling the lifting height of the sorting member; wherein, the direction of the conveying force exerted by the conveying roller and the sorting member on the product is different; the lifting mechanism is used to make The sorting elements protrude and submerge between the conveying rollers.

进一步作为优选地,所述分拣部件为可转动的转子;所述转子包括:转子本体、用于固定所述转子本体并设置于所述支撑部件上的转子支座;其中,所述转子本体的转轴的轴向与所述输送辊的轴向呈夹角设置;其中,与所述包裹处理段相衔接一侧的转子的转速比背离所述包裹处理段相衔接一侧的转子的转速慢。Further preferably, the sorting component is a rotatable rotor; the rotor includes: a rotor body, a rotor support for fixing the rotor body and arranged on the support member; wherein, the rotor body The axial direction of the rotating shaft is arranged at an angle with the axial direction of the conveying roller; wherein, the rotational speed of the rotor on the side connected to the wrapping processing section is slower than the rotational speed of the rotor on the side facing away from the wrapping processing section. .

进一步作为优选地,所述输送线还包括:Further preferably, the conveying line also includes:

至少两个收货段,与所述包裹输送主段相连,用于接收投递的包裹并输送至所述包裹输送主段;at least two receiving sections, connected to the main package conveying section, for receiving the delivered packages and conveying them to the main package conveying section;

与各分拣单元相衔接的包裹处理段;The parcel processing section connected with each sorting unit;

所述包裹输送主段包括:与各收货段相连的包裹接收区段、用于连接相邻的两个包裹接收区段的包裹传送区段。The package conveying main section includes: a package receiving section connected with each receiving section, and a package conveying section for connecting two adjacent package receiving sections.

进一步作为优选地,所述包裹接收区段包括:至少一个第一输送单元,且所述第一输送单元包括:多个用于对所述产品施加输送力且沿所述第一输送单元的输送方向间隔设置的输送辊体、用于旋转支撑所述输送辊体的框架;Further preferably, the package receiving section includes: at least one first conveying unit, and the first conveying unit includes: a plurality of conveying units for applying conveying force to the product and along the first conveying unit conveying roller bodies arranged at intervals in the direction, and a frame for rotatably supporting the conveying roller bodies;

所述包裹传送区段包括:至少一个第二输送单元;所述第二输送单元包括:用于对所述产品施加输送力的传送带体、用于旋转支撑所述传送带体的框座部件。The package conveying section includes: at least one second conveying unit; the second conveying unit includes: a conveying belt body for applying conveying force to the product, and a frame base part for rotatably supporting the conveying belt body.

进一步作为优选地,所述包裹输送主段被划分为具有所述包裹接收区段和所述包裹传送区段的第一包裹输送主段、与所述第一包裹输送主段相连的第二包裹输送主段;Further preferably, the main parcel conveying section is divided into a first main parcel conveying section having the parcel receiving section and the parcel conveying section, and a second parcel conveying main section connected to the first parcel conveying section conveying the main section;

其中,所述第二包裹输送主段至少具有一个包裹分配区段,且所述第二包裹输送主段的头端与所述第一包裹输送主段相连,尾端与异常区域相连;其中,所述控制装置用于根据所述重量信息判断包裹的重量大于预设的重量后,控制所述分拣单元将所述包裹分拣至对应的包裹处理段,否则将所述包裹继续传送至所述异常区域。Wherein, the second package conveying main section has at least one package distribution section, and the head end of the second package conveying main section is connected with the first package conveying main section, and the tail end is connected with the abnormal area; wherein, The control device is configured to control the sorting unit to sort the package to the corresponding package processing section after judging that the weight of the package is greater than the preset weight according to the weight information, otherwise the package will continue to be delivered to the corresponding package processing section. the exception area.

进一步作为优选地,所述包裹输送主段的输送路径为U形;所述第二包裹输送主段包括:多个依次相接的所述第一输送单元和第三输送单元;其中,所述第三输送单元包括:多个间隔设置且用于对包裹施加输送力的锥形输送辊,且各锥形输送辊呈弧形分布。Further preferably, the conveying path of the package conveying main section is U-shaped; the second package conveying main section includes: a plurality of the first conveying unit and the third conveying unit connected in sequence; wherein, the The third conveying unit includes: a plurality of conical conveying rollers arranged at intervals and used for applying conveying force to the package, and each conical conveying roller is distributed in an arc shape.

进一步作为优选地,所述输送单元的输送路径包括:直线输送路径和/或弧线输送路径。Further preferably, the conveying path of the conveying unit includes: a straight conveying path and/or an arc conveying path.

与现有技术相比,本申请能够提供一种结构简单的包裹分拣装置,在对包裹分拣前,方便地获取包裹的包裹信息和重量信息,以利于后续的分拣。Compared with the prior art, the present application can provide a package sorting device with a simple structure, which can conveniently obtain the package information and weight information of the package before sorting the package, so as to facilitate the subsequent sorting.

附图说明Description of drawings

通过阅读参照以下附图所作的对非限制性实施例所作的详细描述,本申请的其它特征、目的和优点将会变得更明显:Other features, objects and advantages of the present application will become more apparent by reading the detailed description of non-limiting embodiments made with reference to the following drawings:

图1:本实用新型第一实施例中包裹分拣装置的输送流程图;Fig. 1: The conveying flow chart of the parcel sorting device in the first embodiment of the present invention;

图2:本实用新型第一实施例中包裹分拣装置的具体结构示意图;Figure 2: a schematic diagram of the specific structure of the package sorting device in the first embodiment of the present invention;

图3:图2中D所示的局部放大示意图;Fig. 3: The partial enlarged schematic diagram shown in D in Fig. 2;

图4:本实用新型第一实施例中监测单元的具体结构示意图;Fig. 4: the concrete structure schematic diagram of the monitoring unit in the first embodiment of the present utility model;

图5:本实用新型第一实施例中第一输送单元的结构示意图;Figure 5: a schematic structural diagram of the first conveying unit in the first embodiment of the present invention;

图6:本实用新型第一实施例中第二输送单元的结构示意图;Figure 6: a schematic structural diagram of the second conveying unit in the first embodiment of the present invention;

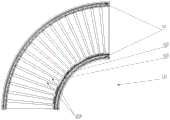

图7:本实用新型第一实施例中第三输送单元的结构示意图;Figure 7: a schematic structural diagram of the third conveying unit in the first embodiment of the present invention;

图8:本实用新型第一实施例中第一输送单元和多个相连的第三输送单元相接时的局部立体结构示意图;Fig. 8: In the first embodiment of the present utility model, the partial three-dimensional structure schematic diagram when the first conveying unit is connected with a plurality of connected third conveying units;

图9:本实用新型第一实施例中分拣单元的内部结构示意图;Fig. 9: The internal structure schematic diagram of the sorting unit in the first embodiment of the present invention;

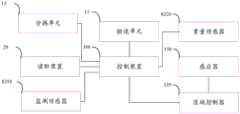

图10:本实用新型第一实施例中包裹分拣装置的电路模块框图;Figure 10: a block diagram of a circuit module of the parcel sorting device in the first embodiment of the present invention;

附图标记说明:Description of reference numbers:

输送单元11;

第一输送单元11a、框架111、输送辊体113、契型带115、感应器118、单元控制器119;The

第二输送单元11b、传送带体112、框部件114;The

传送皮带1121、主传送辊1122、从传送辊1123;

第三输送单元11c、锥形输送辊116、框体117;The

分拣单元13、输送辊131、转子132、转子本体1321、转子支座1322、驱动辊1323、支撑部件135;

升降机构134、框座部件1342、驱动部件1343、升降电机1344;

环形槽136a、环形槽136b、环形槽136c、环形槽136d;

卷带137a、卷带137b、卷带137c、卷带137d;

读取装置28、扫码器281、扫码支架282;The

包裹输送主段8、收货段9、包裹处理段10;The main

第一包裹输送主段81、包裹接收区段811、包裹传送区段812、第二包裹输送主段82;The first package conveying

监测单元82a;monitoring

第一监测子单元821、第一监测子单元822;a

传送带体8211、传送皮带82111、主传送辊82112、从传送辊82113、监测传感器8210、框架8215;

传送体8221、支撑架8222、重量传感器8220。

具体实施方式Detailed ways

以下将结合附图对本实用新型的构思、具体结构及产生的技术效果作进一步说明,以充分地了解本实用新型的目的、特征和效果。The concept, specific structure and technical effects of the present utility model will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, characteristics and effects of the present utility model.

实施例一Example 1

如图1至图10所示,本实用新型的第一实施例提供了一种包裹分拣装置,用于输送并分拣回收的废旧产品,其主要是由输送线1和控制装置 101等构成。As shown in FIG. 1 to FIG. 10 , the first embodiment of the present invention provides a package sorting device for conveying and sorting recycled waste products, which is mainly composed of a conveying line 1 and a

其中,输送线由多个依次相接用于独立输送包裹的输送单元11构成,且各输送单元11均与控制装置101通讯连接。在此需要说明的是,本实施例中的相接可以理解为相互连接,或者呈一定的间隔相接设置。Wherein, the conveying line is composed of a plurality of conveying

输送线包括一包裹输送主段8,且包裹输送主段8具有至少一个包裹分配区段,例如:该输送线可被划分出一由各输送单元11(如图1所示的带单向箭头的格子区段)依次相接构成的包裹输送主段8,且包裹输送主段8的某一区段还可以再被划分为一包裹分配区段。其中,需要说明的是,本实施例中的输送单元11的输送路径可以为直线输送路径,其具体结构可参照图5 所示的第一输送单元11a的结构或图6所示的第二输送单元11b的结构,输送单元11的输送路径也可以为弧形输送路径,其具体结构可参照图7所示的第三输送单元11c的结构。The conveying line includes a main

如图1所示,包裹分配区段沿包裹输送主段8的传送方向先后设置有监测单元82a和多个分拣单元13,且监测单元82a和各分拣单元13的相对两端分别在包裹分配区段内与对应的输送单元11相接。其中,本实施例中的包裹输送主段8的传送方向为构成包裹输送主段8的各输送单元11相接形成的主传送方向。As shown in FIG. 1 , the parcel distribution section is provided with a

如图2和图4所示,本实施例中的包裹分拣装置还包括:与控制装置101 通讯连接的读取装置28,用于在包裹到达监测单元82a时,读取与包裹相匹配的包裹信息,并发送包裹信息至控制装置101。As shown in FIG. 2 and FIG. 4 , the package sorting device in this embodiment also includes: a reading

其中,监测单元82a与控制装置101通讯连接,其设置于相邻的两个输送单元11之间,用于在包裹通过时,检测包裹的重量信息,并将重量信息发送至控制装置101。Wherein, the

通过上述内容可知:包裹分拣装置中的输送线是由多个用于独立输送包裹且与控制装置101通讯连接的输送单元等构成,并且输送线包括一具有包裹分配区段的包裹输送主段,且具有沿包裹输送主段的传送方向先后设置的监测单元82a和多个分拣单元13。并且由于包裹分拣装置还具有一读取装置28。因此,当未分拣的包裹到达监测单元上时,可通过读取装置 28读取包裹的包裹信息,并同时将检测到的包裹的重量信息发送至控制装置101,以使得控制装置101可根据重量信息和包裹信息,控制分拣单元 13对与该包裹信息相匹配的包裹进行分拣或对包裹信息进行校对匹配。It can be seen from the above content that the conveying line in the package sorting device is composed of a plurality of conveying units for independently conveying packages and communicating with the

具体地,在本实施例中,如图1和图2所示,监测单元82a可以由第一监测子单元821和第二监测子单元822等构成。其中,第一监测子单元821,用于在包裹通过时,通过读取装置28读取包裹信息;第二监测子单元822,其两端分别与第一监测子单元821和输送单元11相接,用于在包裹通过时,检测包裹的重量信息,并将重量信息发送至控制装置。通过该分别设置的第一监测子单元821和第二监测子单元822,获取包裹对应的包裹信息和重量信息,有利于第二监测子单元822精准测量包裹的重量信息,避免受外界的干扰。此外,通过独立设置的方式,有利于输送线的装配。值得一提的是,本实施例的监测单元也仅可以由第二监测子单元822单独所构成,其可设置于读取装置28的下方。Specifically, in this embodiment, as shown in FIG. 1 and FIG. 2 , the

进一步作为优选地,如图4所示,监测单元82a还包括:监测传感器8210,设置于第一监测子单元821上,与控制装置101通讯连接,用于在检测到包裹时,向控制装置101发送感应信号。其中,包裹在被监测传感器检测时,包裹位于读取装置的读取区域。因此,当包裹从第一监测子单元 821上被监测传感器8210检测后,控制装置101接收到感应信号后,控制装置101向读取装置28发送读取信号,以实时准确读取与包裹相匹配的包裹信息,例如通过读取包裹上贴有的标识码、条形码等获取包裹信息,起到节电,节约资源,提升读取装置寿命的作用。在此需要说明的是,该监测传感器的设置高度低于包裹的高度,以便于感应包裹。其中,监测传感器8210优选为光电传感器,以在感应到包裹时,快速触发读取装置28,从而便于读取装置在包裹运行状态,即动态下读取包裹所对应的包裹信息。Further preferably, as shown in FIG. 4 , the

进一步作为优选地,如图4所示,本实施例中的第一监测子单元821 主要是由用于与包裹接触并施加输送力的传送带体8211、用于旋转支撑传送带体8211的框架8215等构成。第二监测子单元822可以由用于与包裹接触并施加输送力的传送体8221、用于旋转支撑传送体8221的支撑架8222、设置于传送体8221下方的重量传感器8220等构成。由于监测单元的传送主体是由传送带体8211构成,因此可避免包裹在传送时出现上下晃动而不利于读取装置的读取。Further preferably, as shown in FIG. 4 , the

同时,由于重量传感器8220设置于第二监测子单元822的传送体8222 的底部,因此可在不影响包裹动态传送的同时,还可以检测包裹的重量信息,以匹配包裹的包裹信息,有利于提高分拣效率。At the same time, since the

另外,需要说明的是,如图4所示,本实施例中的传送带体8211和传送体8222均可以由传送皮带82111、用于带动传送皮带转动的主传送辊 82112、与传送辊相配合的从传送辊82113、用于驱动主传送辊82112转动且与控制装置通讯连接的传送电机等构成等构成,且主传送辊82112和从传送辊82113可旋转地设置于的框架8215上,在此不作赘述。In addition, it should be noted that, as shown in FIG. 4 , the

进一步作为优选地,如图4所示,读取装置28可以由用于读取包裹的标识码所对应的包裹信息的扫码器281、用于固定扫码器281的扫码支架282等构成,以便于读取包裹上的包裹信息。其中,扫码支架281可以是单独设置的,也可以设置在监测单元的框架上,并且,扫码器281悬挂于扫码支架282 上,用于对贴在包裹顶部的标识码进行扫码读取,当包裹被输送至监测单元上时,包裹顶部的标识码被读取装置读取对应的包裹信息。在此,需要值得一提是,该监测传感器8210,可以设置于监测单元82a的框架8125的相对两侧或一侧,也可以设置在单独设置的支架上,例如扫码支架281上,本实施例仅以监测传感器8210为设置于监测单元的框架8215的相对两侧的光电传感器为例作说明,在此不作赘述。Further preferably, as shown in FIG. 4 , the

具体地,如图2所示,输送线主要是由至少两个与包裹输送主段8相连的收货段9、与各收货段9相连的包裹输送主段、与包裹输送主段8中各分拣单元13相衔接的包裹处理段10等构成。其中,收货段9用于接收投递的包裹并输送至包裹输送主段。并且,包裹输送主段8可以由与各收货段9相连的包裹接收区段811、用于连接相邻的两个包裹接收区段811的包裹传送区段812等构成。Specifically, as shown in FIG. 2 , the conveying line is mainly composed of at least two receiving

由上述内容可知:本实施例中分拣装置的输送线主要是由至少两个收货段9、包裹输送主段8和包裹处理段10构成,因此可通过包裹接收区段811 接收不同种类和重量的包裹,并且,通过包裹传送区段812将从各收货段9 接收的包裹通过包裹传送区段812进行传送,并在包裹输送主段8上逐步依次序排列汇集,然后依次通过包裹分配区段内的监测单元82a后,被包裹分配区段内的各分拣单元13进行分拣,因此可避免在未进行包裹投递的情况下由人工进行拆包时产生的漏拆或信息匹配错误的现象。It can be seen from the above that the conveying line of the sorting device in this embodiment is mainly composed of at least two receiving

详细地,如图4所示,本实施例中的输送单元11可以根据输送路径的不同划分为不同的输送单元,当输送单元的输送路径为直线输送路径时,为直线输送单元,其中,直线输送单元可分为两种。In detail, as shown in FIG. 4 , the conveying

如图5所示,当直线输送单元为第一输送单元11a,其主要由用于与包裹接触并施加输送力的输送辊体113、用于可旋转地支撑输送辊体113的框架111等构成。其中,输送辊体113优选为多个沿第一输送单元11a的输送方向间隔设置的辊子。并且,各输送辊体113平行设置于两个框架111 之间,且输送辊体113为直立筒状的辊子。如图5所示,本实施例中的输送单元11a仅以八个辊子113a、113b、113c、113d、113e、113f、113g为例作输送辊体113,沿如图5中A所示的方向输送产品为例说明。As shown in FIG. 5 , when the linear conveying unit is the first conveying

如图6所示,当直线输送单元为第二输送单元11b,其主要是由用于对包裹施加输送力的传送带体112、用于旋转支撑传送带体112的框部件114 等构成。As shown in FIG. 6 , when the linear conveying unit is the second conveying

如图7所示,当输送单元11的输送路径为弧线输送路径时,为弧线输送单元时,即第三输送单元11c,该第三输送单元11c主要是由多个间隔设置且用于对包裹施加输送力的锥形输送辊116、用于旋转支撑锥形输送辊116 的框体117等构成,其中,各锥形输送辊16呈弧形分布于两个框体117之间。其中,该框体117为弧形框体。As shown in FIG. 7 , when the conveying path of the conveying

在此,需要说明的是,本实施例中的框架111、框部件114和框体117 可以为独立设置的框体结构,也可以是一体成型的框体结构,如沿输送路径设计带有直线区段和弧形区段的框板,如图2所示,本实施例优选为一体成型的框体为例作说明,在此不作具体的赘述。Here, it should be noted that the

并且,第一输送单元11a中至少有一输送辊体113为可提供动力的驱动辊子,例如内置电机的驱动辊子,或外置驱动装置驱动的驱动辊子。并且,其他输送辊体113为通过契型带115与驱动辊子相连的从动辊子,从而当驱动辊子转动时,其他从动辊子跟随转动,以保证辊子之间的转动步调一致,同时减少辊子的数量,以节约成本。此外,本实施例中可提供动力的驱动辊子和其他的从动辊子13可以采用相同的部件,也可以采用不同的部件,在此不作赘述。作为优选的方式,本实施例中的第一输送单元 11a采用一个输送辊体113为驱动辊子,其他的输送辊体113为从动辊子,且相邻的两个输送辊体113均通过一契型带115连接,从而实现传动。Moreover, at least one conveying

同理,第三输送单元11a中至少有一锥形输送辊116为可提供动力的驱动辊子,例如内置电机的驱动辊子,或外置驱动装置驱动的辊子。并且,其他锥形输送辊116为通过契型带115与驱动辊子相连的从动辊。作为优选的方式,本实施例中的第二输送单元11b采用一个输送辊体116为驱动辊子,其他的输送辊体113为从动辊子,且相邻的两个输送辊体113均通过一契型带115连接,从而实现传动。Similarly, at least one tapered conveying

如图6所示,当输送单元11为第二输送单元11b,即由传送带体112 构成时,传送带体112可以由传送皮带1211、用于带动传送皮带转动的主传送辊1212、与传送辊相配合的从传送辊1213、用于旋转支撑主传送辊1212 和从传送辊1213的框部件114、设置用于驱动主传送辊1212转动且与控制装置通讯连接的传送电机等构成。As shown in FIG. 6, when the conveying

如图1和图2所示,包裹接收区段811主要是由一个第一输送单元11a 构成。包裹传送区段812主要是由一个第二输送单元11b构成。As shown in FIGS. 1 and 2, the

由于包裹接收区段811采用由多个平行设置的输送辊体113构成的第一输送单元11a与收货段9相连,因此可使得包裹从收货段9移动至包裹接收区段811时,可避免出现晃动而导致包裹的摆动幅度过大,以致于出现包裹无序排列的现象,同时在相邻的收货段9之间采用由传送带体构成的第二输送单元传输包裹,可实现平稳的过渡传送,且不易造成对包裹的摆动,而传送带体无须使用多个输送辊体进行传输,可节约生产成本,适用于相邻的两个收货段9之间距离较大的输送线中。Since the

另外,值得一提的是,如图1所示,本实施例中收货段9和包裹处理段 10均仅以三个为例作说明,而对收货段9和包裹处理段10的数量不作具体的限定和说明。In addition, it is worth mentioning that, as shown in FIG. 1 , in this embodiment, only three receiving

另外,值得一提的是,如图1和图2所示,本实施例中的包裹输送主段可被划分为具有包裹接收区段811和包裹传送区段812的第一包裹输送主段81、与第一包裹输送主段81相连的第二包裹输送主段82。其中,第二包裹输送主段82至少具有一个包裹分配区段,且第二包裹输送主段82的头端与第一包裹输送主段81相连,尾端与异常区域相连。其中,控制装置101用于在根据重量信息判断包裹的重量大于预设的重量后,根据包裹信息控制分拣单元13将包裹分拣至对应的包裹处理段10,否则将包裹继续传送至异常区域。例如:当包裹的重量小于预设的重量,或扫描失败而无法读取包裹信息等情况,均会未经分拣处理,直接传送至异常区域。In addition, it is worth mentioning that, as shown in FIG. 1 and FIG. 2 , the main package conveying section in this embodiment can be divided into a first main

在此,值得一提的是,本实施例中的包裹输送主段优选具有一个包裹分配区段,并仅以此为例作说明,而不对包裹分配区段的具体数量作限定和赘述。Here, it is worth mentioning that the main package conveying section in this embodiment preferably has one package distribution section, which is only used as an example for illustration, and the specific number of the package distribution sections is not limited or described in detail.

由上可知:通过将包裹输送主段8分成两段,可以在第一包裹输送主段81 内将收货段9接收的包裹进行汇总,然后依次序输送至第二包裹输送主段82 的包裹分配区段进行分配,以避免有部分包裹从收货段9移动至第一包裹输送主段81后,无法被输送至包裹分配区段进行分配,并且在包裹分配区域内未分配的包裹,可在通过包裹分配区段后,被输送至异常区域进行集中处理。It can be seen from the above: by dividing the main

另外,需要说明的是,本实施例中采用平均分配的方式,将位于第二包裹输送主段82上的包裹在通过包裹分配区段时,被各分拣单元13平均分配至对应的包裹处理段,以提高分拣效率。In addition, it should be noted that in this embodiment, the method of equal distribution is adopted, and the packages located on the second main

另外,如图1、图2和图8所示,本实施例中的输送单元的输送路径可以为直线输送路径和/或弧线输送路径,以满足实际的输送线的设计和装配需求,简化结构,例如将包裹输送主段8的输送路径设计为U形。因此,使得包裹输送主段8的相对两端,即U形的相对两端可分别设置收货段9和包裹处理段10,有利于优化空间布局,提升空间的利用率。并且,本实施例中的第二包裹输送主段82可以由多个依次相接的所述第一输送单元11a和第三输送单元11c所构成,以满足实际的设计和装配需求。另外,值得一提的是本实施中的收货段9和包裹处理段10也可以根据实际需求,为多个依次相接的所述第一输送单元11a、第二输送单元11b和/或第三输送单元11c等组合所构成。并且,各收货段9之间相互平行,且等距设置。各包裹处理段10之间相互平行,且等距设置。In addition, as shown in FIG. 1 , FIG. 2 and FIG. 8 , the conveying path of the conveying unit in this embodiment can be a straight conveying path and/or an arc conveying path, so as to meet the actual design and assembly requirements of the conveying line and simplify the Structure, for example, the conveying path of the parcel conveying

另外,如图9所示,本实施例中的分拣单元13可以由多个平行间隔设置且用于对包裹施加输送力的输送辊131、相对输送辊131伸出没入且用于对包裹施加输送力的分拣部件、用于旋转支撑输送辊131的支撑部件 135、用于控制分拣部件的升降高度的升降机构等构成。其中,输送辊131 和分拣部件对包裹施加的输送力的方向不同;升降机构用于使分拣部件从输送辊131之间伸出和没入。当分拣部件在升降机构的控制下从输送辊 131之间伸出时,由于分拣部件的施加的输送力的方向与输送辊131的输送方向不一致,因此可使得包裹的传送方向产生改变,而沿着分拣部件施加输送力的方向移动包裹,实现自动分拣。In addition, as shown in FIG. 9 , the sorting

如图3和图9所示,详细地,本实施例中的分拣部件优选为转子132,且转子132以相对于输送辊131的传送方向倾斜的状态设置。其中,该转子132可自带动力,也可通过相应驱动辊、设置在驱动辊132c上的带轮、卷挂在带轮和转子132之间的卷带137驱动转子132的转动。As shown in FIGS. 3 and 9 , in detail, the sorting member in this embodiment is preferably a

其中,如图3和图9所示,转子132,即转子本体1321的转轴的轴向平行于包裹处理段10中相衔接的输送单元中的输送辊体113的轴向,以使得包裹在与转子132接触后,其沿输送辊体113的输送方向传送。并且,分拣单元与包裹处理段10相邻的一侧的转子的转速要比远离包裹处理段 10一侧的转子转速慢,在每一列的转子132的排列方向上形成速度差,从而当包裹通过输送辊131上方时,在各转子132的驱动下,产生路径的改变,朝向包裹处理段10移动,进而完成分拣。Among them, as shown in FIG. 3 and FIG. 9 , the axial direction of the

并且,当包裹分配段的输送方向与包裹处理段10的输送方向不一致时,作为优选的方式,转子132沿输送辊131的轴向设置的数量从接收包裹的输送一侧的输送单元朝向输出包裹的一侧逐渐减小,以构成三角区域的布局设置,从而利于包裹的转向,降低转子的数量,节约成本。显然,本实施例中的转子132沿输送辊131的轴向设置的数量从接收包裹的输送一侧的输送单元朝向输出包裹的一侧也可以是保持不变的,即转子132呈矩阵式分布。Also, when the conveying direction of the parcel distribution section is inconsistent with the conveying direction of the

如图3和图9所示,作为优选的方式,本实施例中各转子132的转子本体1321通过转子支座1322设置于输送辊131的上方,驱动辊1323通过支撑部件135设置于输送辊131的下方;转子支座1322设置于支撑部件135上。并且驱动辊1323沿其轴向开设有不同深度的环形槽136,如图 10中所示的环形槽136a、环形槽136b、环形槽136c、环形槽136d,分别套设有卷带137a、卷带137b、卷带137c和卷带137d,且各卷带137均套设于对应的转子本体1321上,因此,使得各卷带137在同一驱动辊1323 的驱动下,由于环形槽的深度不同,使得单位时间内,各卷带137a~137d 的传动速度不同,从而使得驱动的转子132的转速不同。在本实施例中,驱动辊1323上各环形槽的深度沿其轴向,从一端至另一端逐渐变深,其中,环形槽136a的深度最深,环形槽136d的深度最浅,因此套设在环形槽136a上的卷带137a的速度较慢,而环形槽136d上的卷带137d的速度较快,从而使得对应驱动的转子在驱动辊1323的轴向上具有速度差。因此,如图2所示,当包裹通过输送辊131上方时,分拣单元13与包裹处理段10相邻的一侧的转子本体1321的转速要比远离包裹处理段10一侧的转子本体1321转速慢,从而使得包裹在各转子本体1321的驱动下,朝向包裹处理段10移动,完成分拣。As shown in FIG. 3 and FIG. 9 , as a preferred method, in this embodiment, the

此外,需要说明的是,本实施例也可以采用在驱动辊1323上沿其轴向套设不同直径大小的带轮(图中未标示),且各带轮的直径大小从一驱动辊1323的一端至另一端逐渐变小,以使得上述与包裹处理段10相邻的一侧的转子132的转速要比远离包裹处理段10一侧的转子132转速慢的目的,在此不作赘述。In addition, it should be noted that, in this embodiment, pulleys with different diameters (not marked in the figure) can also be sleeved on the driving

另外,如图9所示,本实施例的升降机构134还包括:框座部件1342、设置在框座部件1342上的升降电机1344、与升降电机1344转动连接的驱动部件1343,且驱动部件1343与支撑部件135相连。当升降电机1344 运转时,驱动部件1343可驱动支撑部件135的上升或下降,以使得转子可伸出或没入输送辊131之间,并相对水平方向倾斜设置。其中,作为优选的方式,本实施例中的升降电机优选为内置电机的辊体、驱动部件1343 优选为凸轮。显然,本实施例中的升降机构还可以采用齿轮结构、连杆结构和蜗杆传动结构等其他的现有结构,以实现转子132的升降。其中,本实施例的支撑部件135和框座部件1342均可优选采用框架结构,且支撑部件135可以是独立设置的框架,也可以为与包裹输送主段中其他输送单元的框架111为一体结构。In addition, as shown in FIG. 9 , the

由上可知:通过多个输送辊131组成一个独立的输送体独立输送包裹,可以使得输送单元11在平稳输送包裹的同时,根据输送辊体113的数量和间隔距离控制各输送单元11的输送间隔。It can be seen from the above that a plurality of conveying

此外,需要说明的是,本实施例中的输送辊131也可以采用传送带体 112来代替对包裹进出输送。In addition, it should be noted that the conveying

另外,如图5和图10所示,输送单元11还包括:与控制装置通讯连接并用于独立控制输送体输送的单元控制器119、与单元控制器119通讯连接的感应器118。其中,输送单元11中的输送体可以为第一输送单元 11a内的多个输送辊体113、第二输送单元11b内的传送带体11或第三输送单元11a内的多个锥形输送辊116中的任意一种或其组合。以实现输送单元11对包裹的独立输送的控制,即使得一个输送单元11停止输送包裹时,不影响其他的输送单元11对在先或在后输送的包裹的输送,从而提高了分拣和输送效率。In addition, as shown in FIG. 5 and FIG. 10 , the conveying

此外,单元控制器119还用于根据感应器118检测输送单元11内是否有包裹通过,生成相应的位置信息并发送至控制装置101,以使得控制装置101根据位置信息确定包裹的输送路径,从而便于控制装置101确定并控制包裹的输送路径。此外,当感应器118未检测到输送单元11上有包裹传输时,单元控制器119可根据感应器118在设定的时间内发送的信号次数或未发送的信号次数等方式,控制输送辊体113停止传送,以避免输送单元11作无用的输送,节约能源。In addition, the

并且,作为优选的方式,本实施例中的感应器118均设置于输送单元 11的输送方向的末端,以便于输送单元11上的任意位置投放产品后,均可被感应器118感应。Moreover, as a preferred way, the

当任意一输送单元11的感应器118在设定的间隔内持续感应产品,例如该输送单元11上在输送一产品的同时,接收另一个投放的产品时,控制装置101控制与该输送单元11相邻且在后输送产品的输送单元11停止输送,直至感应器118在设定的间隔内未感应到产品后,即控制装置101 判断该输送单元11未输送产品时,控制相邻且在后输送产品的输送单元 11继续传送产品,以避免造成堵塞或漏检的现象。When the

同理,当任意一输送单元11出现故障而停止运行时,控制装置101 控制与该输送单元11相邻且在后输送产品的输送单元11停止运行的输送,直至该输送单元11重新运行且感应器118在设定的间隔内未感应到产品时,控制与该输送单元11相邻且在后输送产品的输送单元11重新运行。Similarly, when any one of the conveying

并且,当任意一输送单元11在设定的时间内未检测到产品而停止运行时,若与该输送单元11相邻且在后输送产品的输送单元11上的感应器 118感应到产品后,该输送单元11重新运行,以避免造成堵塞,保障产品的顺利输送和分拣。Moreover, when any conveying

另外,需要说明的是,本实施例中的感应器118优选为对射型的光电传感器,其发射端和接收端均分别设置于框架111的一侧。显然,本实施例中的感应器也可以为其他类型的传感器,如红外传感器、激光传感器、微波传感器等其他现有的可实现检测包裹的传感器。In addition, it should be noted that the

并且,作为优选的方式,本实施例中的感应器118均设置于输送单元 11的输送方向的末端,以便于输送单元11上的任意位置投放包裹后,均可被感应器118感应,从而避免出现漏检的现象。Moreover, as a preferred way, the

另外,需要说明的是,作为优选的方式,本实施例中的控制装置101 可以为一个或多个与各输送单元、监测单元、各分拣单元和读取装置通讯连接的PCL(ProgrammableLogic Controller,可编程逻辑控制器)控制器,与PCL控制器通讯连接的控制主机,例如工控机等。In addition, it should be noted that, as a preferred manner, the

以上实施例仅用以说明本实用新型的技术方案而非限定,仅仅参照较佳实施例对本实用新型进行了详细说明。本领域的普通技术人员应当理解,可以对本实用新型的技术方案进行修改或等同替换,而不脱离本实用新型技术方案的精神和范围,均应涵盖在本实用新型的权利要求范围。The above embodiments are only used to illustrate the technical solutions of the present invention and are not intended to limit the present invention. The present invention is only described in detail with reference to the preferred embodiments. It should be understood by those of ordinary skill in the art that the technical solutions of the present invention can be modified or equivalently replaced without departing from the spirit and scope of the technical solutions of the present invention, and should be included in the scope of the claims of the present invention.

Claims (12)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921785610.1UCN211515235U (en) | 2019-10-22 | 2019-10-22 | Parcel sorting device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921785610.1UCN211515235U (en) | 2019-10-22 | 2019-10-22 | Parcel sorting device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN211515235Utrue CN211515235U (en) | 2020-09-18 |

Family

ID=72462012

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201921785610.1UActiveCN211515235U (en) | 2019-10-22 | 2019-10-22 | Parcel sorting device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN211515235U (en) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11798250B2 (en) | 2019-02-18 | 2023-10-24 | Ecoatm, Llc | Neural network based physical condition evaluation of electronic devices, and associated systems and methods |

| US11843206B2 (en) | 2019-02-12 | 2023-12-12 | Ecoatm, Llc | Connector carrier for electronic device kiosk |

| US11922467B2 (en) | 2020-08-17 | 2024-03-05 | ecoATM, Inc. | Evaluating an electronic device using optical character recognition |

| US11989710B2 (en) | 2018-12-19 | 2024-05-21 | Ecoatm, Llc | Systems and methods for vending and/or purchasing mobile phones and other electronic devices |

| US12033454B2 (en) | 2020-08-17 | 2024-07-09 | Ecoatm, Llc | Kiosk for evaluating and purchasing used electronic devices |

| US12271929B2 (en) | 2020-08-17 | 2025-04-08 | Ecoatm Llc | Evaluating an electronic device using a wireless charger |

| US12300059B2 (en) | 2019-02-12 | 2025-05-13 | Ecoatm, Llc | Kiosk for evaluating and purchasing used electronic devices |

| US12321965B2 (en) | 2020-08-25 | 2025-06-03 | Ecoatm, Llc | Evaluating and recycling electronic devices |

| US12322259B2 (en) | 2018-12-19 | 2025-06-03 | Ecoatm, Llc | Systems and methods for vending and/or purchasing mobile phones and other electronic devices |

| US12380420B2 (en) | 2019-12-18 | 2025-08-05 | Ecoatm, Llc | Systems and methods for vending and/or purchasing mobile phones and other electronic devices |

- 2019

- 2019-10-22CNCN201921785610.1Upatent/CN211515235U/enactiveActive

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11989710B2 (en) | 2018-12-19 | 2024-05-21 | Ecoatm, Llc | Systems and methods for vending and/or purchasing mobile phones and other electronic devices |

| US12322259B2 (en) | 2018-12-19 | 2025-06-03 | Ecoatm, Llc | Systems and methods for vending and/or purchasing mobile phones and other electronic devices |

| US11843206B2 (en) | 2019-02-12 | 2023-12-12 | Ecoatm, Llc | Connector carrier for electronic device kiosk |

| US12300059B2 (en) | 2019-02-12 | 2025-05-13 | Ecoatm, Llc | Kiosk for evaluating and purchasing used electronic devices |

| US11798250B2 (en) | 2019-02-18 | 2023-10-24 | Ecoatm, Llc | Neural network based physical condition evaluation of electronic devices, and associated systems and methods |

| US12223684B2 (en) | 2019-02-18 | 2025-02-11 | Ecoatm, Llc | Neural network based physical condition evaluation of electronic devices, and associated systems and methods |

| US12380420B2 (en) | 2019-12-18 | 2025-08-05 | Ecoatm, Llc | Systems and methods for vending and/or purchasing mobile phones and other electronic devices |

| US11922467B2 (en) | 2020-08-17 | 2024-03-05 | ecoATM, Inc. | Evaluating an electronic device using optical character recognition |

| US12033454B2 (en) | 2020-08-17 | 2024-07-09 | Ecoatm, Llc | Kiosk for evaluating and purchasing used electronic devices |

| US12271929B2 (en) | 2020-08-17 | 2025-04-08 | Ecoatm Llc | Evaluating an electronic device using a wireless charger |

| US12321965B2 (en) | 2020-08-25 | 2025-06-03 | Ecoatm, Llc | Evaluating and recycling electronic devices |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN211515235U (en) | Parcel sorting device | |

| CN110976302B (en) | Sorting device, sorting and recycling equipment, sorting and recycling system and control method thereof | |

| CN103508192B (en) | Feeding system and use this feeding system solar components conveying Fabricating machinery | |

| CN206454918U (en) | Flow goods sorting equipment and system | |

| CN203392318U (en) | Intermittent online weighing roller conveyor | |

| CN103086142B (en) | Bottle cap automatic cap-arranging device | |

| CN103231898B (en) | Lateral embark and disembark device | |

| CN206032581U (en) | Rotary type automatic feeding device | |

| CN104944116A (en) | Detection system used for detecting thickness of coal layer on belt conveyor | |

| CN201757907U (en) | Portable smart card automatic sorting device | |

| CN203728124U (en) | Automatic conveyor | |

| CN105502170A (en) | Heavy comprehensive lifting transfer device in logistics network intermediate link | |

| CN107324006A (en) | Automatically plate overlapping transmitting device is fallen | |

| CN210176022U (en) | Light guide plate swing receiving agencies | |

| CN208165981U (en) | A kind of wisdom logistics goods sorting equipment | |

| CN103920652A (en) | Weighing-sorting system | |

| CN204528554U (en) | Double belt Weighing feeder | |

| CN207158213U (en) | Automatically plate overlapping transmitting device is fallen | |

| CN215363192U (en) | Closed-angle bridge type weight checking machine enabling product to go up slope conveniently | |

| CN201777437U (en) | Online weight detector for product package | |

| CN206535769U (en) | A kind of new carrot classification collating unit | |

| CN216026313U (en) | Automatic AG glass nonconforming article sorting device of count | |

| CN214651721U (en) | An intelligent conveying device based on the honeycomb conveying module as the main body | |

| CN214502592U (en) | Mechanical type charge level indicator | |

| CN201140178Y (en) | Full-automatic sortation system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CP01 | Change in the name or title of a patent holder | ||

| CP01 | Change in the name or title of a patent holder | Address after:Room 1101-1103, No. 433, Songhu Road, Yangpu District, Shanghai Patentee after:Shanghai wanwansheng Environmental Protection Technology Group Co.,Ltd. Address before:Room 1101-1103, No. 433, Songhu Road, Yangpu District, Shanghai Patentee before:SHANGHAI YUEYI NETWORK INFORMATION TECHNOLOGY Co.,Ltd. | |

| CP03 | Change of name, title or address | ||

| CP03 | Change of name, title or address | Address after:Room 1101-1103, No. 433, Songhu Road, Yangpu District, Shanghai Patentee after:Shanghai Wanwu Xinsheng Information Technology Group Co.,Ltd. Country or region after:China Address before:Room 1101-1103, No. 433, Songhu Road, Yangpu District, Shanghai Patentee before:Shanghai wanwansheng Environmental Protection Technology Group Co.,Ltd. Country or region before:China |