CN210833444U - A three-dimensional online monitoring device for warpage deformation and defects of packaged modules - Google Patents

A three-dimensional online monitoring device for warpage deformation and defects of packaged modulesDownload PDFInfo

- Publication number

- CN210833444U CN210833444UCN201921739255.4UCN201921739255UCN210833444UCN 210833444 UCN210833444 UCN 210833444UCN 201921739255 UCN201921739255 UCN 201921739255UCN 210833444 UCN210833444 UCN 210833444U

- Authority

- CN

- China

- Prior art keywords

- module

- ray

- warpage

- defects

- monitoring

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000007547defectEffects0.000titleclaimsabstractdescription47

- 238000012806monitoring deviceMethods0.000titleclaimsabstractdescription15

- 238000012544monitoring processMethods0.000claimsabstractdescription50

- 238000004806packaging method and processMethods0.000claimsabstractdescription16

- 238000004458analytical methodMethods0.000claimsabstractdescription14

- 238000005259measurementMethods0.000claimsdescription20

- 238000007405data analysisMethods0.000claimsdescription9

- 238000013500data storageMethods0.000claimsdescription8

- 230000003287optical effectEffects0.000claimsdescription8

- 230000001360synchronised effectEffects0.000claimsdescription3

- 238000005538encapsulationMethods0.000claims1

- 238000009776industrial productionMethods0.000abstractdescription6

- 238000000034methodMethods0.000description15

- 238000005516engineering processMethods0.000description14

- 235000012431wafersNutrition0.000description14

- 230000008569processEffects0.000description10

- 238000001514detection methodMethods0.000description8

- 238000011161developmentMethods0.000description6

- 238000004519manufacturing processMethods0.000description6

- 230000006872improvementEffects0.000description5

- 239000000463materialSubstances0.000description4

- 239000004065semiconductorSubstances0.000description4

- 238000004891communicationMethods0.000description3

- 230000000694effectsEffects0.000description3

- 238000009825accumulationMethods0.000description2

- 238000010586diagramMethods0.000description2

- 238000007689inspectionMethods0.000description2

- 238000005305interferometryMethods0.000description2

- 239000004973liquid crystal related substanceSubstances0.000description2

- 239000007787solidSubstances0.000description2

- 238000012360testing methodMethods0.000description2

- 238000010521absorption reactionMethods0.000description1

- 230000009471actionEffects0.000description1

- 230000000712assemblyEffects0.000description1

- 238000000429assemblyMethods0.000description1

- 238000012512characterization methodMethods0.000description1

- 239000002131composite materialSubstances0.000description1

- 230000002950deficientEffects0.000description1

- 230000032798delaminationEffects0.000description1

- 238000006073displacement reactionMethods0.000description1

- 238000004100electronic packagingMethods0.000description1

- 238000013467fragmentationMethods0.000description1

- 238000006062fragmentation reactionMethods0.000description1

- 238000000691measurement methodMethods0.000description1

- 238000010339medical testMethods0.000description1

- 239000000203mixtureSubstances0.000description1

- 239000013307optical fiberSubstances0.000description1

- 239000005022packaging materialSubstances0.000description1

- 238000012536packaging technologyMethods0.000description1

- 238000012545processingMethods0.000description1

- 230000004044responseEffects0.000description1

- 230000000630rising effectEffects0.000description1

- 239000007921spraySubstances0.000description1

- 239000000758substrateSubstances0.000description1

- 238000003325tomographyMethods0.000description1

- 238000012876topographyMethods0.000description1

- 230000000007visual effectEffects0.000description1

- 238000003466weldingMethods0.000description1

Images

Landscapes

- Analysing Materials By The Use Of Radiation (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本实用新型涉及封装模块监测技术领域,尤其涉及一种封装模块翘曲变形及缺陷的三维在线监测装置。The utility model relates to the technical field of packaging module monitoring, in particular to a three-dimensional online monitoring device for warping deformation and defects of packaging modules.

背景技术Background technique

目前集成电路技术已渗透到工业及社会生活的各个领域,电子工业已成为当今第一大产业。从20世纪70年代以来,全球电子信息产业迅速发展。电子信息产业是在电子科学技术发展和应用的基础上发展起来的。电子信息产业的发展由于生产技术的提高和加工工艺的改进,集成电路差不多每三年就更新一代;大规模集成电路和计算机的大量生产和使用,光纤通信、数字化通信、卫星通信技术的兴起,使电子工业成为一个迅速崛起的高技术产业。电子工业的发展及其产品的广泛应用,对全球经济文化等方面产生了极其深刻的影响。而无论从科技或是经济发展的角度来看,半导体的重要性都是非常巨大的。At present, integrated circuit technology has penetrated into all fields of industry and social life, and the electronics industry has become the largest industry today. Since the 1970s, the global electronic information industry has developed rapidly. The electronic information industry is developed on the basis of the development and application of electronic science and technology. The development of the electronic information industry Due to the improvement of production technology and the improvement of processing technology, integrated circuits are replaced by a new generation almost every three years; the mass production and use of large-scale integrated circuits and computers, the rise of optical fiber communication, digital communication, and satellite communication technologies, Make the electronics industry a rapidly rising high-tech industry. The development of the electronics industry and the wide application of its products have had a profound impact on the global economy and culture. From the perspective of technology or economic development, the importance of semiconductors is very huge.

当今大部分的电子产品,如计算机、移动电话或是数字录音机当中的核心单元都和半导体有着极为密切的关联。电子器件的封装技术是制约集成电路发展的关键环节之一。电子器件在封装中由于各种材料(基底、粘结层、芯片及封装材料)的尺寸和材料性能的差异在较大温差作用下引起的翘曲问题已严重影响了电子器件的可靠性、焊接性能和成品率。因此,电子器件的翘曲问题已成为影响电子封装技术继续深入发展的一个重大障碍。Most of today's electronic products, such as computers, mobile phones or the core unit of digital recorders, are closely related to semiconductors. The packaging technology of electronic devices is one of the key links restricting the development of integrated circuits. The warpage problem caused by the difference in size and material properties of various materials (substrate, bonding layer, chip and packaging material) in the packaging of electronic devices under the action of large temperature difference has seriously affected the reliability and welding of electronic devices. performance and yield. Therefore, the warpage problem of electronic devices has become a major obstacle that affects the further development of electronic packaging technology.

在半导体工艺过程中,随着在晶圆表面形成各种材料层以及各种半导体器件结构,会对晶圆表面产生各种应力,使得晶圆在工艺过程中发生翘曲。最理想的状态下,晶圆不应发生翘曲的,即便无法完全平坦,在理想状态下,晶圆的翘曲也应当是边缘向晶圆正面方向翘起的且关于垂直晶圆的中轴线对称的碗状;而实际情况中,由于晶圆正面受到应力的不对称性,经常会造成晶圆各种形态的不对称的翘曲,导致晶圆容易发生翘曲缺陷导致部分芯片失效甚至发生碎片的情况。During the semiconductor process, as various material layers and various semiconductor device structures are formed on the surface of the wafer, various stresses will be generated on the surface of the wafer, causing the wafer to warp during the process. In the ideal state, the wafer should not be warped. Even if it cannot be completely flat, in the ideal state, the warpage of the wafer should be warped from the edge to the front of the wafer and perpendicular to the central axis of the wafer. Symmetrical bowl shape; in practice, due to the asymmetry of the stress on the front side of the wafer, it often causes asymmetric warpage of various forms of the wafer, which makes the wafer prone to warpage defects and causes some chips to fail or even occur. Fragmentation.

现有技术中,在工业生产中难以实现对于电子器件的封装模块的翘曲缺陷在线监测。翘曲变形的测量方法有许多,例如电子散斑干涉技术、阴影云纹、投影云纹及数字图像相关法(DIC)等。这些方法各自有其特定的测量精度及应用场景,同时其测量面积及测量范围也有所不同。电子散斑干涉技术因其昂贵的大功率激光器不适用于例如晶圆这类大面积翘曲变形的测量与监测。阴影云纹因其光路设置的问题同样不适用于大面积翘曲变形的测量与监测。而数字图像相关法因其需在样件表面喷一层具有特异性灰度的散斑而不适用于不能进行表面预处理的样件。投影云纹法是20世纪70年代发展起来的一种现代光学测量技术,多用于面内变形、离面位移、表面形貌的检测。凭借非接触、快速、全场测量、高分辨率、高精度的优势,投影云纹法被广泛应用于生物、医学检测、产品检测、逆向工程等众多领域。而投影云纹技术目前国内外均有成熟的设备产品,对于翘曲的测量精度较高,可达1.5微米的精度,但投影云纹技术因其自身原理的缘故,只能对物体表面进行测量,其基本不具有穿透能力,因而对于产品的内部缺陷的探测能力较弱。In the prior art, it is difficult to realize on-line monitoring of warpage defects of packaged modules of electronic devices in industrial production. There are many measurement methods for warping deformation, such as electronic speckle interferometry, shadow moiré, projection moiré and digital image correlation (DIC). Each of these methods has its specific measurement accuracy and application scenarios, and its measurement area and measurement range are also different. Electronic speckle interferometry is not suitable for the measurement and monitoring of large-area warpage deformation such as wafers because of its expensive high-power lasers. Shadow moiré is also not suitable for the measurement and monitoring of large-area warping deformation due to the problem of optical path setting. However, the digital image correlation method is not suitable for samples that cannot be pretreated because it needs to spray a layer of speckle with specific grayscale on the surface of the sample. The projection moiré method is a modern optical measurement technology developed in the 1970s, and is mostly used for the detection of in-plane deformation, off-plane displacement, and surface topography. With the advantages of non-contact, fast, full-field measurement, high resolution, and high precision, the projection moiré method is widely used in many fields such as biology, medical testing, product testing, and reverse engineering. The projection moiré technology currently has mature equipment and products at home and abroad. The measurement accuracy of warpage is high, up to 1.5 microns. However, due to its own principle, the projection moiré technology can only measure the surface of the object. , which basically does not have the ability to penetrate, so the ability to detect the internal defects of the product is weak.

此外,当前对于电子器件的封装模块的翘曲变形及缺陷,在工业生产过程中通常的只是在电子器件失效之后对其进行离线检测,该方法不但流程复杂、所需设备繁多,而且耗时较长、测试效果不佳,对于改善电子器件的生产工艺也助益不大。如何有效可靠地在线监测电子器件封装模块的翘曲状态,提供相应的监测装置,是目前工业生产中亟待解决的问题。In addition, for the current warpage deformation and defects of the packaging modules of electronic devices, in the industrial production process, only offline detection is usually performed after the electronic devices fail. It is long and the test effect is not good, and it is not helpful for improving the production process of electronic devices. How to effectively and reliably monitor the warpage state of the electronic device package module online and provide a corresponding monitoring device is an urgent problem to be solved in the current industrial production.

实用新型内容Utility model content

本申请实施例通过提供一种封装模块翘曲变形及缺陷的三维在线监测装置,解决了现有技术中无法对封装模块的翘曲变形及缺陷进行三维在线监测的问题。The embodiment of the present application solves the problem of inability to perform three-dimensional online monitoring of the warpage deformation and defects of the package module in the prior art by providing a three-dimensional online monitoring device for the warpage deformation and defects of the package module.

本申请实施例提供一种封装模块翘曲变形及缺陷的三维在线监测装置,包括:投影云纹模块、X射线模块、监测分析模块;An embodiment of the present application provides a three-dimensional online monitoring device for warpage deformation and defects of a packaged module, including: a projection moiré module, an X-ray module, and a monitoring and analysis module;

所述监测分析模块分别与所述投影云纹模块、所述X射线模块相连。The monitoring and analysis modules are respectively connected with the projection moiré module and the X-ray module.

优选的,所述投影云纹模块包括:CCD相机、光栅投影仪;Preferably, the projection moiré module includes: a CCD camera and a grating projector;

所述光栅投影仪用于投射光栅至待测封装模块样品表面;The grating projector is used to project the grating to the sample surface of the packaged module to be tested;

所述CCD相机用于对所述待测封装模块样品表面的光栅变化进行连续拍摄采集,获得第一翘曲信息。The CCD camera is used for continuously photographing and collecting the grating changes on the surface of the package module sample to be tested to obtain the first warpage information.

优选的,所述投影云纹模块还包括:同步触发器;Preferably, the projection moiré module further comprises: a synchronization trigger;

所述CCD相机为多个CCD相机组成的CCD相机阵列;所述CCD相机阵列与所述同步触发器连接;The CCD camera is a CCD camera array composed of multiple CCD cameras; the CCD camera array is connected with the synchronization trigger;

所述光栅投影仪为多个光栅投影仪组成的光栅投影仪阵列。The grating projector is a grating projector array composed of a plurality of grating projectors.

优选的,所述X射线模块包括:X射线管、X射线探测器;Preferably, the X-ray module includes: an X-ray tube and an X-ray detector;

所述X射线管用于发射X射线至待测封装模块样品;The X-ray tube is used for emitting X-rays to the packaged module sample to be tested;

所述X射线探测器用于接收待测封装模块样品经照射后的X射线强度数据,获得第二翘曲信息。The X-ray detector is used for receiving X-ray intensity data after irradiation of the packaged module sample to be tested, to obtain second warpage information.

优选的,所述X射线模块还包括:X光控制电路;Preferably, the X-ray module further comprises: an X-ray control circuit;

所述X光控制电路用于控制所述X射线管发射的X射线的强度。The X-ray control circuit is used to control the intensity of the X-rays emitted by the X-ray tube.

优选的,所述X射线管为多个X射线管组成的X射线管阵列;所述X射线探测器为多个X射线探测器组成的阵列式线性陈列探测器。Preferably, the X-ray tube is an X-ray tube array composed of a plurality of X-ray tubes; the X-ray detector is an array linear array detector composed of a plurality of X-ray detectors.

优选的,所述监测分析模块包括:数据存储装置、数据分析装置、监测显示装置。Preferably, the monitoring and analysis module includes: a data storage device, a data analysis device, and a monitoring and display device.

优选的,所述封装模块翘曲变形及缺陷的三维在线监测装置还包括:光学三维测量标定器;Preferably, the three-dimensional online monitoring device for warpage deformation and defects of the packaging module further comprises: an optical three-dimensional measurement calibrator;

所述光学三维测量标定器用于对相机进行内参、外参、高度标定。The optical three-dimensional measurement calibrator is used to calibrate internal parameters, external parameters and height of the camera.

优选的,所述封装模块翘曲变形及缺陷的三维在线监测装置还包括:平面安置台;Preferably, the three-dimensional online monitoring device for warping deformation and defects of the package module further comprises: a plane mounting table;

所述待测封装模块样品放置在所述平面安置台上;所述X射线管设置在所述平面安置台的上方或侧边。The packaged module sample to be tested is placed on the plane mounting table; the X-ray tube is arranged above or on the side of the plane mounting table.

本申请实施例中提供的一个或多个技术方案,至少具有如下技术效果或优点:One or more technical solutions provided in the embodiments of this application have at least the following technical effects or advantages:

在本申请实施例中,结合投影云纹和X射线实现对实际工业生产过程中的电子器件的封装模块的失效情况进行在线监测,改变了以往工业界对于失效产品离线检测的僵局。In the embodiment of the present application, the online monitoring of the failure of the packaging module of the electronic device in the actual industrial production process is realized in combination with the projection moiré and X-ray, which changes the previous deadlock in the industry for offline detection of failed products.

附图说明Description of drawings

为了更清楚地说明本实施例中的技术方案,下面将对实施例描述中所需要使用的附图作简单地介绍,显而易见地,下面描述中的附图是本实用新型的一个实施例,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to illustrate the technical solutions in this embodiment more clearly, the following briefly introduces the accompanying drawings used in the description of the embodiments. Obviously, the accompanying drawings in the following description are an embodiment of the present utility model. For those of ordinary skill in the art, other drawings can also be obtained from these drawings without any creative effort.

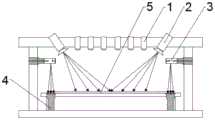

图1为本实用新型实施例1提供的一种封装模块翘曲变形及缺陷的三维在线监测装置的结构示意图;1 is a schematic structural diagram of a three-dimensional online monitoring device for warping deformation and defects of a package module provided in

图2为本实用新型实施例2提供的一种封装模块翘曲变形及缺陷的三维在线监测装置的结构示意图。FIG. 2 is a schematic structural diagram of a three-dimensional online monitoring device for warping deformation and defects of a package module provided by

其中,1-CCD相机、2-光栅投影仪、3-X射线管、4-X射线探测器、5-待测封装模块样品。Among them, 1-CCD camera, 2-grating projector, 3-X-ray tube, 4-X-ray detector, 5-package module sample to be tested.

具体实施方式Detailed ways

为了更好的理解上述技术方案,下面将结合说明书附图以及具体的实施方式对上述技术方案进行详细的说明。In order to better understand the above technical solutions, the above technical solutions will be described in detail below with reference to the accompanying drawings and specific embodiments.

实施例1:Example 1:

实施例1提供了一种封装模块翘曲变形及缺陷的三维在线监测装置,包括:投影云纹模块、X射线模块、监测分析模块;所述监测分析模块分别与所述投影云纹模块、所述X射线模块相连。

其中,如图1所示,所述投影云纹模块包括:CCD相机1、光栅投影仪2;所述光栅投影仪2用于投射光栅至待测封装模块样品5表面;所述CCD相机1用于对所述待测封装模块样品5表面的光栅变化进行连续拍摄采集,获得所述第一翘曲信息。Wherein, as shown in FIG. 1 , the projection moiré module includes: a

所述X射线模块包括:X射线管3、X射线探测器4;所述X射线管3用于发射X射线至待测封装模块样品5;所述X射线探测器4用于接收待测封装模块样品5经照射后的X射线强度数据,获得所述第二翘曲信息。The X-ray module includes: an

所述投影云纹模块用于获得待测封装模块样品的第一翘曲信息;所述X射线模块用于获得待测封装模块样品的第二翘曲信息;所述监测分析模块用于根据所述第一翘曲信息、所述第二翘曲信息获得监测结果信息。The projection moiré module is used to obtain the first warpage information of the packaged module sample to be tested; the X-ray module is used to obtain the second warpage information of the packaged module sample to be tested; the monitoring and analysis module is used to obtain the second warpage information of the packaged module sample to be tested; The first warpage information and the second warpage information are used to obtain monitoring result information.

所述监测分析模块包括:数据存储装置、数据分析装置、监测显示装置;所述数据存储装置用于存储来自所述投影云纹模块、所述X射线模块的信息,并传输至所述数据分析装置;所述数据分析装置用于根据所述第一翘曲信息获得翘曲变形信息,用于根据所述第二翘曲信息获得翘曲缺陷信息,用于根据所述翘曲变形信息和所述翘曲缺陷信息获得所述监测结果信息;所述监测显示装置用于对所述监测结果信息进行显示。The monitoring and analysis module includes: a data storage device, a data analysis device, and a monitoring and display device; the data storage device is used to store information from the projection moiré module and the X-ray module, and transmit it to the data analysis device device; the data analysis device is configured to obtain warpage deformation information according to the first warpage information, to obtain warpage defect information according to the second warpage information, and to obtain warpage deformation information according to the warpage deformation information and the The monitoring result information is obtained from the warpage defect information; and the monitoring display device is used for displaying the monitoring result information.

具体的,所述数据存储装置采用现有的数据存储器件即可,例如256G固态硬盘+惠普(HP)EX950 1T M.2NVMe PCle SSD固态硬盘X2;所述数据分析装置采用至强W2123处理器,P2000-5G显卡,(内部配置现有的Vic-3D软件);所述监测显示装置采用现有的显示器件即可,例如戴尔(DELL)2719HS微边框液晶显示器。Specifically, the data storage device may use an existing data storage device, such as a 256G solid state drive + Hewlett-Packard (HP) EX950 1T M.2NVMe PCle SSD solid state drive X2; the data analysis device uses a Xeon W2123 processor, P2000-5G graphics card, (the existing Vic-3D software is internally configured); the monitoring display device may use an existing display device, such as a Dell (DELL) 2719HS micro-frame liquid crystal display.

需要说明的是,本实用新型提供的是实现封装模块的翘曲变形及缺陷的三维在线监测的装置,是对现有监测装置的结构或组成进行的改进,不涉及具体的分析方法、软件的改进。It should be noted that the utility model provides a device for realizing three-dimensional online monitoring of the warpage deformation and defects of the package module, which is an improvement on the structure or composition of the existing monitoring device, and does not involve specific analysis methods and software. Improve.

由于投影云纹技术对于产品翘曲变形的测量具有较高的精度,因此可在线监测可能存在较大翘曲缺陷的大面积封装模块的翘曲变形测量的过程。由于X射线技术具有响应速度快、检测区域大、可在线监测某些难以接触或禁止接触的被测物体等特点,因此可在线监测大面积封装模块中可能存在较大翘曲缺陷的表征过程。将投影云纹技术与X射线技术进行结合,可进一步对工业生产中的电子器件的翘曲缺陷进行在线监测,提高翘曲缺陷监测的时效性,及时发现不合格的失效器件,为产品生产的工艺流程的质量提升提供有效的动态参考,从而提高电子器件的良品率,降低生产成本。Since the projection moiré technology has high accuracy for the measurement of product warpage deformation, the process of warpage deformation measurement of large-area packaged modules that may have large warpage defects can be monitored online. Because X-ray technology has the characteristics of fast response speed, large detection area, and online monitoring of some objects to be measured that are difficult or forbidden to be touched, it can monitor the characterization process of large warpage defects in large-area packaged modules online. The combination of projection moiré technology and X-ray technology can further monitor the warpage defects of electronic devices in industrial production online, improve the timeliness of warpage defect monitoring, and discover unqualified failed devices in time. The quality improvement of the process flow provides an effective dynamic reference, thereby improving the yield of electronic devices and reducing production costs.

实施例1以晶圆为例,所述X射线管3设置于待测封装模块样品5的检测区域的上方。Example 1 takes a wafer as an example, and the

优选的方案中,所述投影云纹模块还包括:同步触发器;所述CCD相机1为多个CCD相机组成的CCD相机阵列;所述CCD相机阵列与所述同步触发器连接;所述光栅投影仪2为多个光栅投影仪组成的光栅投影仪阵列。In a preferred solution, the projection moiré module further includes: a synchronization trigger; the

通过数据线将所述同步触发器和多台CCD相机分别连接起来,再将所述同步触发器与控制拍照和分析的工作站(即监测分析模块)连接起来。采用同步触发器是为了在拍照时保证多个CCD相机能够同时触发拍照,以保证在同一时刻拍出的照片能够在工作站中被合成一整张照片。The synchronization trigger and multiple CCD cameras are respectively connected through data lines, and then the synchronization trigger is connected with a workstation (ie, a monitoring and analysis module) that controls photographing and analysis. The synchronous trigger is used to ensure that multiple CCD cameras can trigger the photo at the same time, so as to ensure that the photos taken at the same time can be combined into a whole photo in the workstation.

采用CCD相机阵列可以实现对大面积的封装模块进行在线监测,可改善相机视场大小的限制。通过多个相机组成阵列来测量,例如16个CCD相机组阵列的视场为600*600mm,测量精度可达4微米,在240*240mm视场下精度可达1.5微米。通过本实用新型采用64、100、200乃至更多的相机组成阵列,理论上可以测量无限大的面积下的翘曲变形及缺陷。Using a CCD camera array can realize online monitoring of large-area packaged modules, which can improve the limitation of the field of view of the camera. It is measured by forming an array of multiple cameras. For example, the field of view of the 16 CCD camera group array is 600*600mm, and the measurement accuracy can reach 4 microns, and the accuracy can reach 1.5 microns under the 240*240mm field of view. By using 64, 100, 200 or even more cameras to form an array in the present invention, it is theoretically possible to measure warpage deformation and defects in an infinite area.

所述光栅投影仪2的个数的多少理论上取决于投影仪投出的光栅是否覆盖待测封装模块样品5的全部表面。为了实现理论上无限大的测量面积,通过增加所述光栅投影仪2的数量,即光栅投影仪阵列式组装可以实现大面积监测的目的。The number of the

所述X射线模块还可设置X光控制电路。所述X光控制电路用于控制所述X射线管发射的X射线的强度。具体的X光控制电路采用现有的常规控制电路即可。The X-ray module can also be provided with an X-ray control circuit. The X-ray control circuit is used to control the intensity of the X-rays emitted by the X-ray tube. The specific X-ray control circuit can use the existing conventional control circuit.

优选的方案中,所述X射线管3为多个X射线管组成的X射线管阵列;所述X射线探测器4为多个X射线探测器组成的阵列式线性陈列探测器。In a preferred solution, the

对大面积的封装模块进行在线监测时,单个X射线管3可能不能覆盖整个待检测区域,因此,采用X射线管阵列可实现大面积的覆盖。采用阵列式线性陈列探测器可实现对待测封装模块样品5缺陷部位的层扫。When performing online monitoring on a large-area packaged module, a

此外,还可采用高精度的光学三维测量标定器对相机进行内参、外参、高度标定,建立相机之间以及相机与待测封装模块样品5之间的空间坐标系。将所述待测封装模块样品5放置在平面安置台上。In addition, a high-precision optical three-dimensional measurement calibrator can also be used to calibrate the internal parameters, external parameters, and height of the cameras, and establish a spatial coordinate system between the cameras and between the cameras and the

实施例1中,(1)可以发射的光栅条纹投影面积为600mm×600mm,频率为50Hz,条纹密度为2-50线可调;(2)图像分辨率为6400万像素,相机帧率为75fps,帧频为6400万像素下采集帧频不低于10fps,视场不小于600mm×600mm,翘曲变形测量分辨率为4微米(600mm×600mm)。在在线监测翘曲缺陷过程中图像显示装置接收并读取X射线及投影云纹分析信息,并可根据实际状况选择不同的在线监测模式。In Example 1, (1) the projected area of the grating fringes that can be emitted is 600mm×600mm, the frequency is 50Hz, and the fringe density is adjustable from 2 to 50 lines; (2) the image resolution is 64 million pixels, and the camera frame rate is 75fps , the frame rate is 64 million pixels, the acquisition frame rate is not less than 10fps, the field of view is not less than 600mm × 600mm, and the warping deformation measurement resolution is 4 microns (600mm × 600mm). In the process of online monitoring of warpage defects, the image display device receives and reads X-ray and projection moiré analysis information, and can select different online monitoring modes according to the actual situation.

将所述X射线管3设置于待测封装模块样品5的检测区域的上方,是对于存在复合界面接触等截面存在较为复杂结构的封装模块的截面进行层扫,以此来构建截面方向上的翘曲变形及缺陷的三维模型,适用于在截面方向上易出现翘曲缺陷积累过多而产生截面方向上的断裂、裂缝等封装模块如晶圆等的检测过程中。The

实施例2:Example 2:

实施例2与实施例1的区别在于,实施例2将所述X射线管3设置于待测封装模块样品5的检测区域的侧面。The difference between

以晶圆为例,三维在线监测装置集成X射线模块及投影云纹模块,参看图2,装置主要的构成包括:2个及2个以上CCD相机1组成的阵列式CCD相机、2个及2个以上的光栅投影仪2、同步触发器、高精度光学三维测量标定器、平面安置台、2个及2个以上X射线管3组成的阵列式X射线管、2个及2个以上X射线探测器4组成的阵列式线性陈列探测器、X光控制电路、数据存储装置、数据分析装置、图像显示装置。Taking a wafer as an example, the three-dimensional online monitoring device integrates an X-ray module and a projection moiré module. Referring to Figure 2, the main components of the device include: an array CCD camera composed of two or

实施例2中,同样的,(1)可以发射的光栅条纹投影面积为600mm×600mm,频率为50Hz,条纹密度为2-50线可调;(2)图像分辨率为6400万像素,相机帧率为75fps,帧频为6400万像素下采集帧频不低于10fps,视场不小于600mm×600mm,翘曲变形测量分辨率为4微米(600mm×600mm)。在在线监测翘曲缺陷过程中图像显示装置接收并读取X射线及投影云纹分析信息,并可根据实际状况选择不同的在线监测模式。In Example 2, similarly, (1) the projected area of the grating fringes that can be emitted is 600mm×600mm, the frequency is 50Hz, and the fringe density is adjustable from 2 to 50 lines; (2) the image resolution is 64 million pixels, and the camera frame The frame rate is 75fps, the frame rate is not less than 10fps when the frame rate is 64 million pixels, the field of view is not less than 600mm × 600mm, and the warping deformation measurement resolution is 4 microns (600mm × 600mm). In the process of online monitoring of warpage defects, the image display device receives and reads X-ray and projection moiré analysis information, and can select different online monitoring modes according to the actual situation.

将所述X射线管3设置于待测封装模块样品5的检测区域的侧面,是大面积的封装模块进行平面方向上的层扫,以此来构建平面方向上的翘曲变形及缺陷的三维模型,适用于在平面方向上易出现翘曲缺陷积累过多而产生平面方向上分层、剥落、表面划痕等的大面积封装模块如液晶显示屏或手机屏幕总成等的检测过程中。The

本实用新型提供的装置实现三维在线监测的原理如下:投影云纹功能模块中,高速光栅投影仪投射出光栅至待测封装模块样品表面,阵列式CCD相机对样品表面的光栅变化进行连续拍摄采集,通过投影云纹分析软件(现有软件)对样品翘曲缺陷进行监测;X射线模块中,阵列式X射线管发射一定强度的X射线到样品上,使样品因自身材料厚度不同对X射线吸收程度的差异而形成不同的影像,通过X光控制电路设定合适的X射线强度,多次发射X射线进行多截面层扫,可建立样品翘曲缺陷的三维影像,然后通过阵列式线性陈列探测器将待测封装模块样品的三维翘曲变形及缺陷的X射线强度数据连续采集至数据分析装置中对样品的翘曲缺陷进行分析监测。X射线及投影云纹的数据均通过数据线输入到数据存储装置,再由其输出至数据分析装置和图像显示装置中,实现翘曲缺陷的可视化在线监测。通过这整套装置,达到对电子器件封装器件的翘曲变形及缺陷在线监测的目的。The principle of realizing three-dimensional online monitoring by the device provided by the utility model is as follows: in the projection moiré function module, a high-speed grating projector projects a grating on the sample surface of the package module to be tested, and an array CCD camera continuously captures and collects the grating changes on the sample surface. , and monitor the warpage defects of the sample through the projection moiré analysis software (existing software); in the X-ray module, the array X-ray tube emits a certain intensity of X-rays to the sample, so that the sample can respond to the X-ray due to the different thickness of its own material. The difference in absorption degree can form different images. The appropriate X-ray intensity is set through the X-ray control circuit, and the X-ray is emitted multiple times for multi-section tomography to establish a three-dimensional image of the warping defect of the sample. The detector continuously collects the X-ray intensity data of the three-dimensional warpage deformation and defects of the package module sample to be tested to the data analysis device to analyze and monitor the warpage defects of the sample. The data of X-ray and projection moiré are input to the data storage device through the data line, and then output to the data analysis device and image display device to realize the visual online monitoring of warpage defects. Through this whole set of devices, the purpose of online monitoring of warpage deformation and defects of electronic device packaging devices is achieved.

本实用新型实施例提供的一种封装模块翘曲变形及缺陷的三维在线监测装置至少包括如下技术效果:The three-dimensional online monitoring device for warping deformation and defects of a package module provided by the embodiment of the present invention includes at least the following technical effects:

(1)能够提高翘曲缺陷监测的时效性,及时发现不合格的失效器件。(1) The timeliness of warpage defect monitoring can be improved, and unqualified failed devices can be found in time.

(2)能够为产品生产的工艺流程的质量提升提供有效的动态参考,从而提高电子器件的良品率,降低生产成本。(2) It can provide an effective dynamic reference for the quality improvement of the technological process of product production, thereby improving the yield of electronic devices and reducing production costs.

最后所应说明的是,以上具体实施方式仅用以说明本实用新型的技术方案而非限制,尽管参照实例对本实用新型进行了详细说明,本领域的普通技术人员应当理解,可以对本实用新型的技术方案进行修改或者等同替换,而不脱离本实用新型技术方案的精神和范围,其均应涵盖在本实用新型的权利要求范围当中。Finally, it should be noted that the above specific embodiments are only used to illustrate the technical solutions of the present invention and not to limit them. Although the present invention has been described in detail with reference to examples, those of ordinary skill in the art should The technical solutions can be modified or equivalently replaced without departing from the spirit and scope of the technical solutions of the present invention, and they should all be included in the scope of the claims of the present invention.

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921739255.4UCN210833444U (en) | 2019-10-17 | 2019-10-17 | A three-dimensional online monitoring device for warpage deformation and defects of packaged modules |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201921739255.4UCN210833444U (en) | 2019-10-17 | 2019-10-17 | A three-dimensional online monitoring device for warpage deformation and defects of packaged modules |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN210833444Utrue CN210833444U (en) | 2020-06-23 |

Family

ID=71262070

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201921739255.4UActiveCN210833444U (en) | 2019-10-17 | 2019-10-17 | A three-dimensional online monitoring device for warpage deformation and defects of packaged modules |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN210833444U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110645904A (en)* | 2019-10-17 | 2020-01-03 | 武汉大学 | Three-dimensional online monitoring method and device for warpage deformation and defects of packaging module |

- 2019

- 2019-10-17CNCN201921739255.4Upatent/CN210833444U/enactiveActive

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110645904A (en)* | 2019-10-17 | 2020-01-03 | 武汉大学 | Three-dimensional online monitoring method and device for warpage deformation and defects of packaging module |

| WO2021073310A1 (en)* | 2019-10-17 | 2021-04-22 | 武汉大学 | Method and apparatus for three-dimensional on-line monitoring of warpage deformation and defect of encapsulation module |

| CN110645904B (en)* | 2019-10-17 | 2025-07-04 | 武汉大学 | A three-dimensional online monitoring method and device for packaging module warping deformation and defects |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110645903B (en) | A method and device for three-dimensional online monitoring of warpage deformation and defects of packaging modules | |

| TWI840585B (en) | Automated high-speed x-ray inspection method, computer-readable non-transitory storage media and electronic system | |

| CN102072700B (en) | Coplanarity measuring system based on projection Moire principle | |

| CN210719047U (en) | An online monitoring device for warpage deformation and defects of packaged modules | |

| CN110645904B (en) | A three-dimensional online monitoring method and device for packaging module warping deformation and defects | |

| CN110954007B (en) | Wafer inspection system and inspection method | |

| JP6277754B2 (en) | Quality control system and internal inspection device | |

| KR102786722B1 (en) | System and method for searching integrated circuits based on x-ray | |

| CN110645902B (en) | A method and device for online monitoring of warpage and defects of packaging modules | |

| CN210833444U (en) | A three-dimensional online monitoring device for warpage deformation and defects of packaged modules | |

| Zeng et al. | A full-field warpage characterization measurement method coupled with infrared information | |

| CN103438803B (en) | Computer vision technique accurately measures the method for Rectangular Parts size across visual field | |

| CN210833445U (en) | Packaging module warpage deformation and three-dimensional on-line monitoring device of defect | |

| CN102052907B (en) | A BGA Coplanarity Measuring System Based on Projection Mohr Principle | |

| JP3643722B2 (en) | X-ray inspection method and apparatus | |

| CN106910694A (en) | A kind of method and device of the integrated circuit devcie angularity of automatic detection | |

| KR101528200B1 (en) | An apparatus for three dimensional thermal image measurement and a method thereof | |

| JP2017015483A (en) | Electronic component conveying device and electronic component inspection device | |

| CN201844818U (en) | BGA (ball grid array) coplanarity measurement system based on projection Moire principle | |

| CN114441598B (en) | 3D stacked and packaged integrated circuit chip and failure positioning method and device thereof | |

| JP2017015479A (en) | Electronic component conveying device and electronic component inspection device | |

| TW202238299A (en) | Inspection system, inspection management device, inspection program creating method, and program | |

| CN206223684U (en) | Photomask detection device | |

| Hertl et al. | Innovative assessment of thermomechanical stress effects in electronics components and assemblies | |

| US11913772B2 (en) | Non-destructive gap metrology |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| GR01 | Patent grant | ||

| GR01 | Patent grant |