CN202373787U - Encapsulated emission control cable component with five polytetrafluoroethylene powder pushed and extruded insulated wires - Google Patents

Encapsulated emission control cable component with five polytetrafluoroethylene powder pushed and extruded insulated wiresDownload PDFInfo

- Publication number

- CN202373787U CN202373787UCN2011204315322UCN201120431532UCN202373787UCN 202373787 UCN202373787 UCN 202373787UCN 2011204315322 UCN2011204315322 UCN 2011204315322UCN 201120431532 UCN201120431532 UCN 201120431532UCN 202373787 UCN202373787 UCN 202373787U

- Authority

- CN

- China

- Prior art keywords

- control cable

- polytetrafluoroethylene

- core

- insulated wire

- glue

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 229920001343polytetrafluoroethylenePolymers0.000titleclaimsabstractdescription34

- 239000004810polytetrafluoroethyleneSubstances0.000titleclaimsabstractdescription34

- 239000000843powderSubstances0.000titleclaimsabstractdescription33

- -1polytetrafluoroethylenePolymers0.000titleclaimsabstractdescription20

- 239000003292glueSubstances0.000claimsabstractdescription20

- 239000002184metalSubstances0.000claimsabstractdescription19

- 229910052751metalInorganic materials0.000claimsabstractdescription19

- 238000003032molecular dockingMethods0.000claimsabstractdescription5

- RYGMFSIKBFXOCR-UHFFFAOYSA-NCopperChemical group[Cu]RYGMFSIKBFXOCR-UHFFFAOYSA-N0.000claimsdescription6

- 229910052802copperInorganic materials0.000claimsdescription3

- 239000010949copperSubstances0.000claimsdescription3

- 238000000034methodMethods0.000claimsdescription3

- 230000004888barrier functionEffects0.000claims1

- 238000009954braidingMethods0.000claims1

- 238000009413insulationMethods0.000abstractdescription13

- 230000005672electromagnetic fieldEffects0.000abstractdescription2

- 239000012778molding materialSubstances0.000description4

- 238000010586diagramMethods0.000description3

- 239000004020conductorSubstances0.000description2

- 238000001125extrusionMethods0.000description2

- 239000000463materialSubstances0.000description2

- 238000003466weldingMethods0.000description2

- 230000000712assemblyEffects0.000description1

- 238000000429assemblyMethods0.000description1

- 230000009286beneficial effectEffects0.000description1

- 230000005540biological transmissionEffects0.000description1

- 239000003086colorantSubstances0.000description1

- 230000007123defenseEffects0.000description1

- 210000001503jointAnatomy0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

Images

Classifications

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A30/00—Adapting or protecting infrastructure or their operation

Landscapes

- Manufacturing Of Electric Cables (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域:Technical field:

本实用新型涉及电缆领域,尤其涉及一种带五根聚四氟乙烯粉料推挤绝缘线的灌胶式发控线缆组件。The utility model relates to the field of cables, in particular to a glue-filled hair control cable assembly with five polytetrafluoroethylene powder pushing insulated wires.

背景技术:Background technique:

发控线缆组件是我国某国防工程项目的一个重要组成部分,用于火箭弹发射。该项目开始研制时采用预埋穿线管方式,这种结构的致命缺点是气密性不能保证。后改用连接座加焊接线路的方式,而这种结构虽然保证了气密性,但是两线之间的绝缘电阻偏小,不能满足不小于20兆欧的技术要求。因此设想提供一种新型接插座组件来解决这一问题。The launch control cable assembly is an important part of a certain national defense project in my country, and is used for rocket launch. At the beginning of the development of this project, the method of pre-embedded threading pipe was adopted. The fatal disadvantage of this structure is that the airtightness cannot be guaranteed. Later, the connecting seat and welding line were used. Although this structure ensures airtightness, the insulation resistance between the two lines is too small to meet the technical requirements of not less than 20 megohms. Therefore it is conceived to provide a novel socket assembly to solve this problem.

实用新型内容:Utility model content:

本实用新型的目的就是提供带五根聚四氟乙烯粉料推挤绝缘线的灌胶式发控线缆组件,解决以往的发控线缆组件在气密性和绝缘电阻方面不能满足规定的技术要求的问题。The purpose of this utility model is to provide a glue-filled hair control cable assembly with five PTFE powder pushing insulated wires, so as to solve the problem that the previous hair control cable assemblies cannot meet the requirements in terms of air tightness and insulation resistance. technical requirements.

本实用新型采用的技术方案为:The technical scheme that the utility model adopts is:

带五根聚四氟乙烯粉料推挤绝缘线的灌胶式发控线缆组件:具有五根绞合在一起的聚四氟乙烯粉料推挤绝缘线,所述聚四氟乙烯粉料推挤绝缘线具有一线芯,线芯外包裹有聚四氟乙烯粉料推挤绝缘层;五根聚四氟乙烯粉料推挤绝缘线伸入接插座中,接插座上设置有凸台,接插座外包裹有金属屏蔽层。Glue-filled hair control cable assembly with five PTFE powder extruded insulated wires: it has five PTFE powder extruded insulated wires twisted together, the PTFE powder The push insulated wire has a core, and the wire core is wrapped with a PTFE powder push insulation layer; five PTFE powder push insulated wires extend into the socket, and the socket is provided with a boss. The socket is wrapped with a metal shielding layer.

所述线芯为镀银铜线芯,结构为19根直径为0.18㎜的镀银单丝绞合而成。The wire core is a silver-plated copper wire core, and its structure is twisted with 19 silver-plated monofilaments with a diameter of 0.18mm.

所述聚四氟乙烯粉料推挤绝缘层,是将聚四氟乙烯粉料经预成型模具做成管状成型料,放入料筒中,根据导体截面和绝缘外径的尺寸,选择不同的推挤模具,将料筒中的成型料推压挤出包裹在导电线芯上,再经高温烧结制成。The polytetrafluoroethylene powder pushing the insulating layer is to make the polytetrafluoroethylene powder into a tubular molding material through a preforming mold, put it into the barrel, and select different pushing materials according to the cross section of the conductor and the size of the outer diameter of the insulation. Extrusion die, which pushes and extrudes the molding material in the barrel to wrap it on the conductive wire core, and then sinters it at high temperature.

组件总长度2130㎜,其中带金属屏蔽层的长度有1900㎜,无金属屏蔽层的长度230㎜;所述金属屏蔽层,是由168根直径为0.10㎜的镀镍铜单丝编织而成的圆筒形外套。The total length of the components is 2130㎜, of which the length with metal shielding layer is 1900㎜, and the length without metal shielding layer is 230㎜; the metal shielding layer is braided by 168 nickel-plated copper monofilaments with a diameter of 0.10㎜ Cylindrical jacket.

所述接插座安装在离不带金属屏蔽层的一端170㎜处,接插座两端的五根聚四氟乙烯粉料推挤绝缘线的线芯与线芯之间分别一一焊接;接插座是通过灌胶模具,在对接点处灌入AB胶制成。The socket is installed at a distance of 170 mm from the end without metal shielding layer, and the five PTFE powders at both ends of the socket are pushed and welded one by one between the wire cores of the insulated wire; the socket is It is made by pouring AB glue into the butt joint through the glue filling mold.

与现有技术相比,本实用新型的有益效果在于:Compared with the prior art, the utility model has the beneficial effects of:

本实用新型通过将五根绝缘线绞合在一起,并在其外套装金属屏蔽层的结构,能够利用金属屏蔽体,把主串回路和被串回路隔开,使干扰电磁场减弱,有效减少回路间的相互干扰和外部干扰;组件接插座是采用导电线芯与导电线芯一一对接(焊接)的形式,通过灌胶模具,在对接点处灌入AB胶制成,有效的解决了以往发控线缆组件在气密性和绝缘电阻方面不能满足规定的技术要求的问题。经改进后的发控线缆组件任意两线间的绝缘电阻达500兆欧以上,远远高出绝缘电阻不小于20兆欧的技术要求。The utility model twists five insulated wires together and puts a metal shielding layer on its outer structure. The metal shielding body can be used to separate the main series circuit from the serial circuit, weaken the interference electromagnetic field, and effectively reduce the number of loops. Interference between each other and external interference; the socket of the component is made by butting (welding) the conductive wire core and the conductive wire core one by one, and it is made by pouring AB glue at the docking point through the glue filling mold, which effectively solves the problem in the past. The problem that the hair control cable assembly cannot meet the specified technical requirements in terms of air tightness and insulation resistance. The insulation resistance between any two wires of the improved transmission and control cable assembly is more than 500 megohms, which is far higher than the technical requirement that the insulation resistance is not less than 20 megohms.

附图说明:Description of drawings:

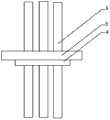

附图1为本实用新型电缆部分横截面示意图;

附图2为本实用新型组件横截面示意图;

附图3为本实用新型组件结构示意图。Accompanying drawing 3 is the schematic diagram of the assembly structure of the utility model.

具体实施方式:Detailed ways:

下面结合附图,通过实施例对本实用新型作进一步详细说明:Below in conjunction with accompanying drawing, the utility model is described in further detail by embodiment:

带五根聚四氟乙烯粉料推挤绝缘线的灌胶式发控线缆组件:具有五根绞合在一起的聚四氟乙烯粉料推挤绝缘线6,所述聚四氟乙烯粉料推挤绝缘线6具有一线芯1,线芯1外包裹有聚四氟乙烯粉料推挤绝缘层2;五根聚四氟乙烯粉料推挤绝缘电缆外包裹有金属屏蔽层3,线芯1为镀银铜线芯,结构为19根单丝绞合而成,聚四氟乙烯粉料推挤绝缘层2,是将聚四氟乙烯粉料经预成型模具做成管状成型料,放入料筒中,根据导体截面和绝缘外径的尺寸,选择不同的推挤模具,将料筒中的成型料推压挤出包裹在导电线芯上,再经高温烧结制成,金属屏蔽层3,是由168根直径为0.10㎜的镀镍铜单丝编织而成的圆筒形外套。灌胶式接插座5上设置有凸台4,灌胶式接插座5的两端面各连接五种颜色的聚四氟乙烯粉料推挤绝缘线6,每种颜色的绝缘线6的导电线芯一一对接,通过灌胶模具,在对接处灌入AB胶,去除模具,制成灌胶式接插座5。Glue-filled hair control cable assembly with five PTFE powder extruded insulated wires: five twisted PTFE powder extruded insulated

五根聚四氟乙烯粉料推挤绝缘线绞合成缆,总长度2130㎜,其中1900㎜带金属屏蔽层,另外230㎜不带金属屏蔽层。在离不带金属屏蔽层的一端170㎜处,将五根绝缘线截断,将其导电线芯与导电线芯一一对接(焊接)的形式,通过灌胶模具,在对接点处灌入AB胶。该结构既保证了产品的气密性,又使任意两线间的绝缘电阻达到500兆欧以上,远远高出绝缘电阻不小于20兆欧的技术要求。Five PTFE powder pushes insulated wires and twists them into a cable, with a total length of 2130mm, of which 1900mm has a metal shielding layer, and the other 230mm has no metal shielding layer. Cut off the five insulated wires at a distance of 170 mm from the end without the metal shielding layer, and connect (weld) the conductive wire cores to the conductive wire cores one by one, and pour AB at the docking point through the glue filling mold glue. This structure not only ensures the airtightness of the product, but also makes the insulation resistance between any two lines reach more than 500 megohm, which is far higher than the technical requirement that the insulation resistance is not less than 20 megohm.

上述实施例仅为本实用新型的较佳的实施方式,除此之外,本实用新型还可以有其他实现方式。需要说明的是,在没有脱离本实用新型构思的前提下,任何显而易见的改进和修饰均应落入本实用新型的保护范围之内。The above-mentioned embodiments are only preferred implementation modes of the present utility model, in addition, the present utility model may also have other implementation modes. It should be noted that any obvious improvements and modifications shall fall within the protection scope of the present utility model without departing from the concept of the utility model.

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011204315322UCN202373787U (en) | 2011-11-04 | 2011-11-04 | Encapsulated emission control cable component with five polytetrafluoroethylene powder pushed and extruded insulated wires |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011204315322UCN202373787U (en) | 2011-11-04 | 2011-11-04 | Encapsulated emission control cable component with five polytetrafluoroethylene powder pushed and extruded insulated wires |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202373787Utrue CN202373787U (en) | 2012-08-08 |

Family

ID=46597479

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2011204315322UExpired - Fee RelatedCN202373787U (en) | 2011-11-04 | 2011-11-04 | Encapsulated emission control cable component with five polytetrafluoroethylene powder pushed and extruded insulated wires |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202373787U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107610832A (en)* | 2017-09-19 | 2018-01-19 | 江苏亨通高压海缆有限公司 | Submarine cable with ultralow thermal resistance loss and preparation method thereof |

- 2011

- 2011-11-04CNCN2011204315322Upatent/CN202373787U/ennot_activeExpired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107610832A (en)* | 2017-09-19 | 2018-01-19 | 江苏亨通高压海缆有限公司 | Submarine cable with ultralow thermal resistance loss and preparation method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103219576B (en) | A kind of production technology of radio frequency coaxial-cable | |

| CN202373787U (en) | Encapsulated emission control cable component with five polytetrafluoroethylene powder pushed and extruded insulated wires | |

| CN103600482B (en) | A kind of tubular molding tool and prepare special-shaped conductor cable | |

| CN204732189U (en) | Flexible Teflon coaxial cable with PTFE sheath | |

| CN102280171B (en) | Three-core cable and manufacturing method thereof | |

| CN202150302U (en) | Anti-electromagnetic interference shielded cable | |

| CN202662348U (en) | Shielding flexible tensile cable | |

| CN202126869U (en) | High-voltage and ultrahigh-voltage alternating-current copper sleeve shielding submarine power cable | |

| CN115547552A (en) | Flat medium-voltage reel cable and manufacturing method thereof | |

| CN203521038U (en) | Data bus cable | |

| CN202307249U (en) | Polytetrafluoroethylene powder pushing insulated wire cable possessing sheath | |

| CN202373321U (en) | Polytetrafluoroethylene powder pushing insulated wire cable with metal shielding layer | |

| CN203312434U (en) | Radio frequency coaxial cable | |

| CN203056527U (en) | Cable traction head | |

| CN202373344U (en) | Cable with multiple polytetrafluoroethylene powder pushing insulation wires and metal shielding layer | |

| CN203056463U (en) | A new type of single-core high-voltage cable pulling head | |

| CN202495275U (en) | Copper cladded aluminum signal transmission cable | |

| CN113421719A (en) | Three-layer co-extrusion continuous extrusion production sleeve die device and method for medium-voltage cable | |

| CN206059614U (en) | A kind of semi flexible coaxial cable | |

| CN206236469U (en) | High pressure extrudes lead sheath power cable | |

| CN107464625A (en) | The pre- branch power cable of skyscraper aluminium alloy core | |

| CN110729080B (en) | Cable glue injection mold and process | |

| CN223193549U (en) | A dual-parallel cable supporting POE function | |

| CN203179580U (en) | A JE copper-core ethylene propylene rubber motor winding lead wire | |

| CN203192520U (en) | A thermoplastic elastomer sheathed power cable |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20120808 Termination date:20141104 | |

| EXPY | Termination of patent right or utility model |