CN202366936U - Waste printed circuit board recovery and disposal system - Google Patents

Waste printed circuit board recovery and disposal systemDownload PDFInfo

- Publication number

- CN202366936U CN202366936UCN2011205262182UCN201120526218UCN202366936UCN 202366936 UCN202366936 UCN 202366936UCN 2011205262182 UCN2011205262182 UCN 2011205262182UCN 201120526218 UCN201120526218 UCN 201120526218UCN 202366936 UCN202366936 UCN 202366936U

- Authority

- CN

- China

- Prior art keywords

- crusher

- bag filter

- printed circuit

- circuit board

- vibrating screen

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000002699waste materialSubstances0.000titleclaimsabstractdescription28

- 238000011084recoveryMethods0.000titleabstractdescription7

- 238000004064recyclingMethods0.000claimsabstractdescription16

- 239000002184metalSubstances0.000abstractdescription9

- 229910052751metalInorganic materials0.000abstractdescription9

- 230000007547defectEffects0.000abstractdescription2

- 239000002910solid wasteSubstances0.000abstractdescription2

- 238000000034methodMethods0.000description10

- 239000000843powderSubstances0.000description10

- 238000000926separation methodMethods0.000description8

- 239000000428dustSubstances0.000description7

- 239000000463materialSubstances0.000description7

- 229910052755nonmetalInorganic materials0.000description5

- 238000005516engineering processMethods0.000description3

- 239000002923metal particleSubstances0.000description2

- 150000002739metalsChemical class0.000description2

- 238000000053physical methodMethods0.000description2

- 239000002994raw materialSubstances0.000description2

- 238000007664blowingMethods0.000description1

- 238000010586diagramMethods0.000description1

- 238000010494dissociation reactionMethods0.000description1

- 230000005593dissociationsEffects0.000description1

- 239000002245particleSubstances0.000description1

- 230000008929regenerationEffects0.000description1

- 238000011069regeneration methodMethods0.000description1

Images

Classifications

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/50—Reuse, recycling or recovery technologies

- Y02W30/82—Recycling of waste of electrical or electronic equipment [WEEE]

Landscapes

- Processing Of Solid Wastes (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本实用新型涉及工业固体废物控制及资源利用领域;尤其涉及一种废印刷电路板回收处理系统。The utility model relates to the fields of industrial solid waste control and resource utilization; in particular, it relates to a waste printed circuit board recycling and processing system.

背景技术Background technique

废印刷电路板中含有大量可回收利用的金属,拥有较高的资源回收利用价值,但是另一方面不当的处理方法工艺会在回收金属的同时对环境造成严重的二次污染。目前国内尚没有一套符合中国国情,处理能力和处理效率兼顾的废印刷电路板回收处理系统。Waste printed circuit boards contain a large amount of recyclable metals, which have high resource recycling value, but on the other hand, improper treatment methods will cause serious secondary pollution to the environment while recycling metals. At present, there is no waste printed circuit board recycling system in China that is in line with China's national conditions and has both processing capacity and processing efficiency.

浙江丰利粉碎设备有限公司开发的FXS废旧电子线路板回收处理成套设备,采用了物理法循环分离回收工艺、多层组合式涡轮粉碎解离和涡轮式超微分级技术、高压静电分离技术,对废旧线路板进行回收处理,该系统分离精度较高高,回收效率好,但是产量较低。The FXS waste electronic circuit board recycling and processing complete set of equipment developed by Zhejiang Fengli Crushing Equipment Co., Ltd. adopts the physical method cycle separation and recovery technology, multi-layer combined turbine crushing dissociation and turbine ultrafine classification technology, and high-voltage electrostatic separation technology. Waste circuit boards are recycled. This system has high separation precision and good recovery efficiency, but the output is low.

中国发明专利ZL200510023785.5于2007年5月2日公开了一种废旧印刷线路板的破碎及高压静电分离方法。该方法将废旧印刷线路板通过粉碎成一定大小的颗粒,采用高压静电方法进行金属颗粒和非金属颗粒的分离。Chinese invention patent ZL200510023785.5 disclosed a method of crushing and high-voltage electrostatic separation of waste printed circuit boards on May 2, 2007. In the method, waste printed circuit boards are crushed into particles of a certain size, and metal particles and non-metal particles are separated by a high-voltage electrostatic method.

现有技术处理废印刷电路板一般只是采用单级破碎和单辊高压静电分离,该方法处理量较低,金属粉末和非金属粉末分离率较低,难以兼顾处理量和分离效率。In the prior art, single-stage crushing and single-roller high-voltage electrostatic separation are generally used to process waste printed circuit boards. This method has a low processing capacity and a low separation rate of metal powder and non-metal powder. It is difficult to balance the processing capacity and separation efficiency.

实用新型内容Utility model content

基于现有废印刷电路板处理装置无法解决二次污染,处理量较低以及回收金属粉末效率较低的缺陷,本实用新型所要解决的技术问题是提供一种废印刷电路板回收处理系统。该系统不但能分离废印刷电路板中的金属粉末和非金属,而且二次污染较小,产量较高,实现了对废印刷电路板的资源化利用。Based on the defects that the existing waste printed circuit board processing device cannot solve the secondary pollution, the processing capacity is low and the recovery efficiency of metal powder is low, the technical problem to be solved by the utility model is to provide a waste printed circuit board recycling processing system. The system can not only separate metal powder and non-metal in waste printed circuit boards, but also has less secondary pollution and higher output, realizing resource utilization of waste printed circuit boards.

本实用新型为解决上述技术问题而采用的技术方案是:一种废印刷电路板回收处理系统,其创新点在于,该系统是密封的并处于负压之下,包括输送机、双层破碎机、细破机、振动筛、高压静电分离器、旋风分离器、袋式除尘器、螺旋送料器、斗式提升机,振动筛和高压静电分离器之间通过斗式提升机连接,双层破碎机和细破机之间以及细破机和振动筛之间通过螺旋送料器连接,双层破碎机顶端设有吸风口并接入袋式除尘器,细破机顶端设有吸风口并接入袋式除尘器,振动筛顶端设有吸风口并接入袋式除尘器,旋风分离器直接接入袋式除尘器。The technical scheme adopted by the utility model to solve the above-mentioned technical problems is: a waste printed circuit board recycling and processing system, the innovation of which is that the system is sealed and under negative pressure, including a conveyor, a double-layer crusher , fine crusher, vibrating screen, high-voltage electrostatic separator, cyclone separator, bag filter, screw feeder, bucket elevator, vibrating screen and high-voltage electrostatic separator are connected by bucket elevator, double-layer crushing The screw feeder is connected between the crusher and the fine crusher and between the fine crusher and the vibrating screen. The top of the double-layer crusher is provided with a suction port and connected to the bag filter, and the top of the fine crusher is provided with a suction port and connected to the Bag type dust collector, the top of the vibrating screen is provided with a suction port and connected to the bag type dust collector, and the cyclone separator is directly connected to the bag type dust collector.

上述双层破碎机最好选用锤式破碎机;除尘器最好选用脉冲袋式反吹除尘器;振动筛最好选用直线型振动筛;高压静电分离器最好选用六辊高压静电分离器。The above-mentioned double-layer crusher is best to use a hammer crusher; the dust collector is best to use a pulse bag type blowback dust collector; the vibrating screen is best to use a linear vibrating screen; the high-voltage electrostatic separator is best to use a six-roller high-voltage electrostatic separator.

相对于现有技术,本实用新型采用物理方法及全自动的方法对废印刷电路板进行破碎、细碎、振动、分离,整个系统密闭并处于负压状态,采用双层破碎机及细破机相结合提高处理能力,采用六辊高压静电分离器提高分离效率,采用旋风分离器及袋式除尘器防止二次污染。全过程处理能力高,回收效率高,无二次污染。Compared with the prior art, the utility model adopts physical methods and fully automatic methods to crush, finely crush, vibrate and separate waste printed circuit boards. The whole system is airtight and in a negative pressure state. Combined with the improvement of processing capacity, the six-roller high-voltage electrostatic separator is used to improve the separation efficiency, and the cyclone separator and bag filter are used to prevent secondary pollution. The whole process has high processing capacity, high recovery efficiency and no secondary pollution.

附图说明Description of drawings

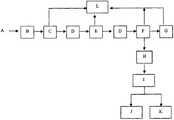

附图是本实用新型废印刷电路板回收处理工艺设备的联系图。The accompanying drawing is a connection diagram of waste printed circuit board recovery processing equipment of the utility model.

其中:A-原料,B-输送机,C-双层破碎机,D-螺旋送料器,E-细破机,F-振动筛,G-旋风分离器,H-斗式提升机,I-高压静电分离器,J-金属粉末,K-非金属粉末,L-脉冲袋式除尘器。Among them: A-raw material, B-conveyor, C-double-deck crusher, D-screw feeder, E-fine crusher, F-vibrating screen, G-cyclone separator, H-bucket elevator, I- High-voltage electrostatic separator, J-metal powder, K-non-metal powder, L-pulse bag filter.

具体实施方式Detailed ways

下面结合附图和实施例对本发明作进一步详细说明。The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

如附图所述,本实用新型一较佳实例提供的废印刷电路板回收处理系统,该系统是密封的并处于负压状态下,包括输送机B、双层破碎机C、螺旋送料器D、细破机E、振动筛F、旋风分离器G、斗式提升机H、高压静电分离器I和脉冲反吹袋式除尘器内L。双层破碎机C和细破机E之间、细破机E和振动筛F之间均通过螺旋送料器D连接,振动筛F和高压静电分离器I直接通过斗式提升机H连接,双层破碎机C、细破机E和旋风分离器G的顶端设有吸风口并接入脉冲袋式除尘器L。输送机B的作用是将物料送入系统设备;双层破碎机C的作用是将废印刷电路板进行初步破碎;细破机E的作用是将废印刷电路板进行进一步细破;螺旋送料器D的作用是将破碎后的物料送入系统设备;振动筛F的作用是将破碎后物料进行筛分,斗式提升机H的作用是将破碎后的物料送入高压静电分离器I;高压静电分离器H的作用是将金属粉末和非金属粉末进行分离;旋风分离器G的作用是进行系统除尘并收集在脉冲反吹袋式除尘器K中。As described in the accompanying drawings, a waste printed circuit board recycling system provided by a preferred example of the utility model, the system is sealed and under negative pressure, including a conveyor B, a double-layer crusher C, and a screw feeder D , Fine crusher E, vibrating screen F, cyclone separator G, bucket elevator H, high-voltage electrostatic separator I and pulse back-blowing bag filter L. The double-layer crusher C and the fine crusher E, between the fine crusher E and the vibrating screen F are connected through the screw feeder D, and the vibrating screen F and the high-voltage electrostatic separator I are directly connected through the bucket elevator H. The tops of layer crusher C, fine crusher E and cyclone separator G are provided with suction ports and connected to pulse bag filter L. The function of the conveyor B is to send materials into the system equipment; the function of the double-layer crusher C is to initially crush the waste printed circuit board; the function of the fine crusher E is to further finely crush the waste printed circuit board; the screw feeder The function of D is to send the crushed materials into the system equipment; the function of the vibrating screen F is to screen the crushed materials, and the function of the bucket elevator H is to send the crushed materials to the high-voltage electrostatic separator I; The role of the electrostatic separator H is to separate metal powder and non-metallic powder; the role of the cyclone separator G is to remove dust from the system and collect it in the pulse blowback bag filter K.

下面结合附图说明本实用新型的动作过程。The course of action of the present utility model is described below in conjunction with accompanying drawing.

如附图所示,原料废印刷电路板A首先通过输送机B传送入系统,进入双层破碎机C后反复锤打翻滚进行破碎;破碎的物料通过螺旋送料器D送入细破机E再进行破碎;破碎完的物料通过螺旋送料器D送入振动筛F;振动筛选后的物料通过斗式提升机H进行高压静电分离器I,最终获得金属粉末J和非金属粉末K,实现资源的再生。处理过程中产生的粉尘通过旋风分离器G收集入脉冲反吹袋式除尘器L,并最终委托有资质的处置单位焚烧处置。即本实用新型实现了对废印刷电路板的资源化,避免了对环境的污染。As shown in the attached figure, the raw material waste printed circuit board A is first conveyed into the system through the conveyor B, and after entering the double-layer crusher C, it is hammered and rolled repeatedly for crushing; the crushed material is sent to the fine crusher E through the screw feeder D and then crushing; the crushed material is sent to the vibrating screen F through the screw feeder D; the vibrating screened material is sent to the high-voltage electrostatic separator I through the bucket elevator H, and finally the metal powder J and the non-metal powder K are obtained to realize resource utilization. regeneration. The dust generated during the treatment process is collected by the cyclone separator G into the pulse blowback bag filter L, and finally entrusted to a qualified disposal unit for incineration. That is to say, the utility model realizes recycling of waste printed circuit boards and avoids pollution to the environment.

Claims (5)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011205262182UCN202366936U (en) | 2011-12-15 | 2011-12-15 | Waste printed circuit board recovery and disposal system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011205262182UCN202366936U (en) | 2011-12-15 | 2011-12-15 | Waste printed circuit board recovery and disposal system |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202366936Utrue CN202366936U (en) | 2012-08-08 |

Family

ID=46590660

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2011205262182UExpired - LifetimeCN202366936U (en) | 2011-12-15 | 2011-12-15 | Waste printed circuit board recovery and disposal system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202366936U (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102784794A (en)* | 2012-08-21 | 2012-11-21 | 中国科学院化学研究所 | Method for recycling circuit board |

| CN102962244A (en)* | 2012-12-07 | 2013-03-13 | 桑德环境资源股份有限公司 | Waste PCB (printed circuit board) crushing and sorting system |

| CN103084376A (en)* | 2013-01-28 | 2013-05-08 | 韩清洁 | Scrap copper wire material separation treatment system and corresponding separation process |

| CN103586254A (en)* | 2013-06-19 | 2014-02-19 | 上海细村粉体技术有限公司 | PCB (Printed circuit board) smashing recovery device and processing method thereof |

| CN105921493A (en)* | 2016-06-12 | 2016-09-07 | 上海绿澄环保科技有限公司 | Method and device of recycling and reusing scrapped circuit board |

- 2011

- 2011-12-15CNCN2011205262182Upatent/CN202366936U/ennot_activeExpired - Lifetime

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102784794A (en)* | 2012-08-21 | 2012-11-21 | 中国科学院化学研究所 | Method for recycling circuit board |

| CN102784794B (en)* | 2012-08-21 | 2014-07-30 | 中国科学院化学研究所 | Method for recycling circuit board |

| CN102962244A (en)* | 2012-12-07 | 2013-03-13 | 桑德环境资源股份有限公司 | Waste PCB (printed circuit board) crushing and sorting system |

| CN102962244B (en)* | 2012-12-07 | 2015-07-08 | 桑德环境资源股份有限公司 | Waste PCB (printed circuit board) crushing and sorting system |

| CN103084376A (en)* | 2013-01-28 | 2013-05-08 | 韩清洁 | Scrap copper wire material separation treatment system and corresponding separation process |

| CN103084376B (en)* | 2013-01-28 | 2015-11-25 | 韩清洁 | A kind of scrap copper wire material separation treatment system and corresponding separating technology |

| CN103586254A (en)* | 2013-06-19 | 2014-02-19 | 上海细村粉体技术有限公司 | PCB (Printed circuit board) smashing recovery device and processing method thereof |

| CN105921493A (en)* | 2016-06-12 | 2016-09-07 | 上海绿澄环保科技有限公司 | Method and device of recycling and reusing scrapped circuit board |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN105195313B (en) | The method that metal and combustible are reclaimed from domestic waste incineration residue | |

| CN101716553B (en) | Kiln slag processing technology of zinc volatilizing kiln | |

| CN202366936U (en) | Waste printed circuit board recovery and disposal system | |

| WO2018233382A1 (en) | Dry sorting and recycling process for valuable components in waste circuit boards | |

| CN112246389B (en) | System suitable for soft and hard classification treatment of decoration garbage and operation method | |

| CN105921484A (en) | Comprehensive utilization method of furnace slag in household garbage incineration power plant | |

| CN106140796A (en) | Useless lithium battery processing system and process technique | |

| CN202824089U (en) | Treatment equipment for circuit board of waste belt component | |

| CN105381866B (en) | Iron, the beneficiation method of carbon are extracted from furnace cloth bag dust-removing ash | |

| CN102279552A (en) | Method and device for recovering waste and old selenium drums | |

| CN203044321U (en) | Sorting and loading system of refractory brick raw materials | |

| Zhu et al. | Recovering copper from spent lithium ion battery by a mechanical separation process | |

| CN103586254A (en) | PCB (Printed circuit board) smashing recovery device and processing method thereof | |

| CN204396454U (en) | Dry type is separated useless circuit board production line | |

| CN203343159U (en) | PCB (printed circuit board) crushing recovery device | |

| CN205944325U (en) | Positive and negative pole piece processing system of lithium cell | |

| CN216499992U (en) | Waste incinerator slag treatment system | |

| CN106058359A (en) | Lithium batteries' positive and negative plate processing system and technology thereof | |

| CN213529043U (en) | System suitable for soft or hard classification of fitment rubbish | |

| CN209735768U (en) | Recycling system of waste circuit board | |

| CN206030304U (en) | A device is smashed to old and useless rubber for reclaimed rubber processes usefulness | |

| CN221514831U (en) | Lithium ore dry purification and tailing comprehensive utilization equipment | |

| CN218854558U (en) | Metal slag sorting system | |

| CN207787059U (en) | Copper-aluminum separation treatment system for particle wind power separator and lithium battery | |

| CN203343160U (en) | Recovery system of waste printed circuit board |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CX01 | Expiry of patent term | Granted publication date:20120808 | |

| CX01 | Expiry of patent term |