CN202132647U - Pre-socket induction heating welding plastic fastening pipe fittings - Google Patents

Pre-socket induction heating welding plastic fastening pipe fittingsDownload PDFInfo

- Publication number

- CN202132647U CN202132647UCN201120138204UCN201120138204UCN202132647UCN 202132647 UCN202132647 UCN 202132647UCN 201120138204 UCN201120138204 UCN 201120138204UCN 201120138204 UCN201120138204 UCN 201120138204UCN 202132647 UCN202132647 UCN 202132647U

- Authority

- CN

- China

- Prior art keywords

- plastic

- fastening

- layer

- composite pipe

- socket

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000004033plasticSubstances0.000titleclaimsabstractdescription137

- 230000006698inductionEffects0.000titleclaimsabstractdescription36

- 238000010438heat treatmentMethods0.000titleclaimsabstractdescription34

- 238000003466weldingMethods0.000titleclaimsdescription26

- 239000002131composite materialSubstances0.000claimsabstractdescription115

- 239000012943hotmeltSubstances0.000claimsabstractdescription7

- 239000002184metalSubstances0.000claimsdescription39

- 239000003292glueSubstances0.000claimsdescription3

- 238000002844meltingMethods0.000claimsdescription3

- 230000008018meltingEffects0.000claimsdescription3

- 238000002347injectionMethods0.000claimsdescription2

- 239000007924injectionSubstances0.000claimsdescription2

- 230000004927fusionEffects0.000abstractdescription4

- 238000009434installationMethods0.000abstractdescription4

- 239000010410layerSubstances0.000description86

- 239000007769metal materialSubstances0.000description6

- 238000005516engineering processMethods0.000description5

- 238000007789sealingMethods0.000description5

- 239000004831Hot glueSubstances0.000description4

- 230000005674electromagnetic inductionEffects0.000description4

- 238000000034methodMethods0.000description3

- 238000001125extrusionMethods0.000description2

- 238000001746injection mouldingMethods0.000description2

- 229920001169thermoplasticPolymers0.000description2

- 239000004416thermosoftening plasticSubstances0.000description2

- 238000003723SmeltingMethods0.000description1

- 230000003044adaptive effectEffects0.000description1

- 230000006835compressionEffects0.000description1

- 238000007906compressionMethods0.000description1

- 230000007547defectEffects0.000description1

- 238000010586diagramMethods0.000description1

- 238000005485electric heatingMethods0.000description1

- 239000000463materialSubstances0.000description1

- 239000000155meltSubstances0.000description1

- 239000002905metal composite materialSubstances0.000description1

- CJRQAPHWCGEATR-UHFFFAOYSA-Nn-methyl-n-prop-2-ynylbutan-2-amineChemical compoundCCC(C)N(C)CC#CCJRQAPHWCGEATR-UHFFFAOYSA-N0.000description1

- 230000035515penetrationEffects0.000description1

- 239000000523sampleSubstances0.000description1

- 239000002344surface layerSubstances0.000description1

Images

Landscapes

- Lining Or Joining Of Plastics Or The Like (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本实用新型涉及一种管道连接管件,特别涉及一种采用电磁感应加热技术用于“金属-塑料”或“塑料-金属”复合管的安装用管件。 The utility model relates to a pipe connecting pipe fitting, in particular to a pipe fitting for installation of a "metal-plastic" or "plastic-metal" composite pipe using electromagnetic induction heating technology. the

背景技术Background technique

现有技术中,对于采用热塑性塑料挤塑塑料挤塑成型的塑料金属复合管,在管件的安装上,一般采用机械连接及热熔连接方式,对于热熔连接方式一般采用热熔模头加热或电热熔加热,令热塑性塑料熔化并熔成一体。本实用新型技术采用技术成熟的电磁感应加热技术,间接加热塑料使之熔融并熔为一体。电磁感应加热技术,是目前对金属材料的加热效率最高、速度最快,且低耗环保。它已经广泛应用于各行各业对金属材料的热加工、热处理、热装配及焊接、熔炼等工艺中。它不但可以对工件整体加热,还能对工件局部的针对性加热;可实现工件的深层透热,也可只对其表面、表层集中加热;不但可对金属材料直接加热,也可对非金属材料进行间接式加热。 In the prior art, for plastic-metal composite pipes formed by thermoplastic extrusion plastic extrusion, mechanical connection and hot-melt connection are generally used for the installation of pipe fittings, and hot-melt die head heating or hot-melt connection is generally used for hot-melt connection. Electric heating melts the thermoplastic and fuses it into one. The technology of the utility model adopts the electromagnetic induction heating technology with mature technology, and indirectly heats the plastic to melt and fuse it into one. Electromagnetic induction heating technology is currently the most efficient and fastest heating of metal materials, and it is low-consumption and environmentally friendly. It has been widely used in thermal processing, heat treatment, thermal assembly, welding and smelting of metal materials in various industries. It can not only heat the workpiece as a whole, but also heat the parts of the workpiece in a targeted manner; it can realize the deep heat penetration of the workpiece, and it can also only heat the surface and surface layer; it can not only directly heat metal materials, but also non-metallic materials. The material is heated indirectly. the

实用新型内容Utility model content

本实用新型的目的是公开一种预承插感应加热熔接塑料紧固式管件,以解决现有技术中的紧固管件适用性差的缺陷。 The purpose of the utility model is to disclose a pre-socket induction heating and welding plastic fastening type pipe fitting to solve the defect of poor applicability of the fastening pipe fittings in the prior art. the

本实用新型所述的预承插感应加热熔接塑料紧固式管件,包括塑料连接件、塑料套、辅助紧固件和紧固螺帽,塑料套与待热熔紧固的复合管管口套装适配形成复合套,塑料连接件包括至少一个连接端,各连接端通过塑料连接件内的通道彼此连通,在每个连接端自中央向外端依次设有凸块和紧固接触面,凸块向外端的方向设有突出部,突出部与紧固接触面之间的凹进空间与复合套的套口适配,在凸块上设有紧固外螺纹,可套装在复合管上的辅助紧固件设置在塑料连接件与紧固螺帽之间,在 紧固螺帽的内表面设有可与紧固外螺纹适配的螺帽内螺纹,紧固螺帽通过螺帽内螺纹与紧固外螺纹的螺接与辅助紧固件、塑料连接件夹装成一体。 The pre-socket induction heating welding plastic fastening type pipe fitting described in the utility model includes plastic connectors, plastic sleeves, auxiliary fasteners and fastening nuts, and the plastic sleeve is set with the nozzle of the composite pipe to be fastened by hot melting Adapted to form a composite sleeve, the plastic connecting piece includes at least one connecting end, each connecting end communicates with each other through a channel in the plastic connecting piece, and each connecting end is sequentially provided with a bump and a fastening contact surface from the center to the outer end, and the convex There is a protruding part in the direction of the outer end of the block, and the recessed space between the protruding part and the fastening contact surface is adapted to the socket of the composite sleeve, and the protruding block is provided with a fastening external thread, which can be set on the composite pipe. The auxiliary fastener is arranged between the plastic connector and the fastening nut, and the inner surface of the fastening nut is provided with a nut internal thread that can be adapted to the fastening external thread, and the fastening nut passes through the nut internal thread The screw connection with fastening external thread is integrated with auxiliary fasteners and plastic connectors. the

其中,复合管包括最内层和最外层,最内层和最外层分别为金属层和塑料层;或者,最内层和最外层分别为塑料层和金属层。 Wherein, the composite pipe includes an innermost layer and an outermost layer, and the innermost layer and the outermost layer are respectively a metal layer and a plastic layer; or, the innermost layer and the outermost layer are respectively a plastic layer and a metal layer. the

其中,塑料套包括套层和套头,当复合管的最内层和最外层分别为金属层和塑料层时,套层套装在复合管的内层,当复合管的最内层和最外层分别为塑料层和金属层时,套层套装在复合管的外层,套层与复合管的金属层相叠装,套头与复合管的管口套接适配。 Among them, the plastic sleeve includes a sleeve layer and a sleeve head. When the innermost layer and the outermost layer of the composite pipe are respectively a metal layer and a plastic layer, the sleeve layer is set on the inner layer of the composite pipe. When the innermost layer and the outermost layer of the composite pipe are When the layers are respectively a plastic layer and a metal layer, the sleeve layer is set on the outer layer of the composite pipe, the sleeve layer is stacked with the metal layer of the composite pipe, and the sleeve head is socketed and adapted to the nozzle of the composite pipe. the

其中,当复合管的最内层和最外层分别为金属层和塑料层时,套头向复合管的外部呈与复合管中心轴线垂直的方向凸出设置,当复合管的最内层和最外层分别为塑料层和金属层时,套头向复合管的内部呈与复合管中心轴线垂直的方向凹进设置,套头与复合管的管口相抵接。 Wherein, when the innermost layer and the outermost layer of the composite pipe are respectively a metal layer and a plastic layer, the collar protrudes to the outside of the composite pipe in a direction perpendicular to the central axis of the composite pipe. When the innermost layer and the outermost layer of the composite pipe When the outer layer is a plastic layer and a metal layer respectively, the sleeve head is recessed into the interior of the composite pipe in a direction perpendicular to the central axis of the composite pipe, and the sleeve head abuts against the mouth of the composite pipe. the

其中,紧固螺帽由塑料或金属制成。 Wherein, the fastening nut is made of plastic or metal. the

其中,辅助紧固件由橡胶或塑料制成。 Wherein, the auxiliary fastener is made of rubber or plastic. the

其中,还包括防水紧固橡胶圈,防水紧固橡胶圈夹装于塑料连接件、辅助紧固件之间。 Among them, the waterproof fastening rubber ring is also included, and the waterproof fastening rubber ring is sandwiched between the plastic connecting piece and the auxiliary fastening piece. the

其中,还包括辅助紧固圆环,辅助紧固圆环夹装于防水紧固橡胶圈、辅助紧固件之间。 Wherein, the auxiliary fastening ring is also included, and the auxiliary fastening ring is sandwiched between the waterproof fastening rubber ring and the auxiliary fastening piece. the

其中,塑料套由与复合管的金属层适配的热熔胶或塑料注塑成型。 Wherein, the plastic sleeve is formed by injection molding of hot-melt adhesive or plastic adapted to the metal layer of the composite pipe. the

本实用新型的预承插感应加热熔接塑料紧固式管件,可以适用于多种复合管的使用情景,连接牢固,抗压力性强,密封性好,使用方便,特别对于内径较大的复合管,其紧固尤其牢固、密封性尤其良好、抗压力性尤其强,即使在复合管内部压力较大的情况下,连接管件仍能保证连接的可靠性。 The pre-socket induction heating welding plastic fastening type pipe fitting of the utility model can be applied to a variety of composite pipe usage scenarios, with firm connection, strong pressure resistance, good sealing performance, and convenient use, especially for composite pipes with larger inner diameters. , the fastening is particularly firm, the sealing performance is particularly good, and the pressure resistance is particularly strong. Even under the condition of high internal pressure of the composite pipe, the connecting pipe fittings can still ensure the reliability of the connection. the

附图说明Description of drawings

图1是本实用新型预承插感应加热熔接塑料紧固式管件的第一立体分解图; Fig. 1 is the first three-dimensional exploded view of the pre-socket induction heating welding plastic fastening type pipe fitting of the present utility model;

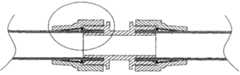

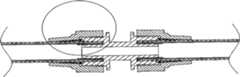

图2是本实用新型预承插感应加热熔接塑料紧固式管件的第一主视 图; Fig. 2 is the first front view of the pre-socket induction heating welding plastic fastening type pipe fitting of the present utility model;

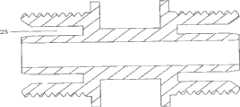

图3是图2中A-A截面的剖面图; Fig. 3 is the sectional view of A-A section in Fig. 2;

图4是本实用新型预承插感应加热熔接塑料紧固式管件的第一组装分解图; Fig. 4 is the first assembly and exploded view of the pre-socket induction heating welding plastic fastening pipe fitting of the utility model;

图5是本实用新型预承插感应加热熔接塑料紧固式管件的第一组装完成图; Fig. 5 is the first assembled drawing of the pre-socket induction heating welding plastic fastening type pipe fitting of the utility model;

图6为图5中圆圈部分的局部放大图; Figure 6 is a partially enlarged view of the circle part in Figure 5;

图7是本实用新型预承插感应加热熔接塑料紧固式管件的经过扩口的复合管的第一剖面图; Fig. 7 is the first cross-sectional view of the flared composite pipe of the pre-socket induction heating fusion plastic fastening pipe fitting of the present invention;

图8是本实用新型预承插感应加热熔接塑料紧固式管件的第二立体分解图; Fig. 8 is the second three-dimensional exploded view of the pre-socket induction heating welding plastic fastening type pipe fitting of the present invention;

图9是本实用新型预承插感应加热熔接塑料紧固式管件的第二主视图; Fig. 9 is the second front view of the pre-socket induction heating welding plastic fastening type pipe fitting of the utility model;

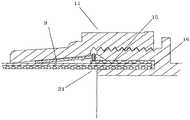

图10是图9中A-A截面的剖面图; Fig. 10 is the sectional view of A-A section among Fig. 9;

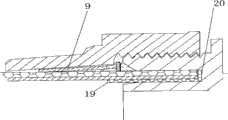

图11是本实用新型预承插感应加热熔接塑料紧固式管件的第二组装分解图; Fig. 11 is the second assembled and exploded view of the pre-socket induction heating and welding plastic fastening pipe fittings of the present invention;

图12是本实用新型预承插感应加热熔接塑料紧固式管件的第二组装完成图; Fig. 12 is the second assembled drawing of the pre-socket induction heating and welding plastic fastening pipe fittings of the utility model;

图13为图12中圆圈部分的局部放大图; Figure 13 is a partial enlarged view of the circle part in Figure 12;

图14是本实用新型预承插感应加热熔接塑料紧固式管件的经过扩口的复合管的第二剖面图; Fig. 14 is the second sectional view of the flared composite pipe of the pre-socket induction heating fusion plastic fastening pipe fitting of the present invention;

图15是本实用新型塑料连接件的结构示意图。 Fig. 15 is a schematic structural view of the plastic connector of the present invention. the

结合附图在其上标记以下附图标记: The following reference signs are marked thereon in conjunction with the accompanying drawings:

1-塑料连接件,2-凸块,3-紧固外螺纹,4-突出部,5-紧固接触面,7-防水紧固橡胶圈,8-辅助紧固圆环,9-辅助紧固件,10-螺帽内螺纹,11-紧固螺帽,12-螺帽管口,13-第一复合管,14-第一塑料套,15-第一套层,16-第一套头,17-第二复合管,18-第二塑料套,19-第二套层,20-第二套头,21-复合套,22-金属层,23-塑料层,24-通道,25-凹进空间。 1-plastic connector, 2-bump, 3-fastening external thread, 4-protrusion, 5-fastening contact surface, 7-waterproof fastening rubber ring, 8-auxiliary fastening ring, 9-auxiliary fastening Firmware, 10-nut internal thread, 11-fastening nut, 12-nut nozzle, 13-first composite pipe, 14-first plastic sleeve, 15-first sleeve layer, 16-first sleeve head , 17-the second composite pipe, 18-the second plastic sleeve, 19-the second sleeve layer, 20-the second sleeve head, 21-composite sleeve, 22-metal layer, 23-plastic layer, 24-channel, 25-concave into space. the

具体实施方式Detailed ways

下面结合附图,对本实用新型的几个具体实施方式进行详细描述,但应当理解本实用新型的保护范围并不受具体实施方式的限制。 Several specific embodiments of the present utility model will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present utility model is not limited by the specific embodiments. the

如图1-图15所示,本实施例的预承插感应加热熔接塑料紧固式管件包括塑料连接件1、塑料套、辅助紧固件9和紧固螺帽11,塑料套与待熔融紧固的复合管相互套装,塑料套与复合管套装后形成复合套21,塑料连接件1包括两个连接端,各连接端通过塑料连接件1内的通道24彼此连通,在每个连接端自中央向外端依次设有凸块2和紧固接触面5,凸块2向外端的方向设有突出部4,突出部4与紧固接触面5之间的凹进空间25与复合套21适配连接,紧固接触面5、突出部4与复合套21的接触面形成预承插感应加热熔接塑料紧固式管件的熔接表面,在凸块2上设有紧固外螺纹3,可套装在复合管上的辅助紧固件9设置在塑料连接件1与紧固螺帽11之间,在紧固螺帽11的内表面设有可与紧固外螺纹3适配的螺帽内螺纹10,紧固螺帽11通过螺帽内螺纹10与紧固外螺纹3的螺接与辅助紧固件9、塑料连接件1夹装成一体。 As shown in Figures 1-15, the pre-socket induction heating and welding plastic fastening pipe fittings of this embodiment include plastic connectors 1, plastic sleeves,

需要说明的是,如果将预承插感应加热熔接塑料紧固式管件用于连接两根复合管,其连接方式将包括两个连接端,如本实施例所示;如果预承插感应加热熔接塑料紧固式管件用于连接一根复合管的尾端,预承插感应加热熔接塑料紧固式管件将只包括一个连接端,与复合管相连。 It should be noted that if the pre-socket induction heating and welding plastic fastening pipe fittings are used to connect two composite pipes, the connection method will include two connection ends, as shown in this embodiment; if the pre-socket induction heating and welding Plastic fastening fittings are used to connect the ends of a composite pipe, and pre-socketed induction heating and welding plastic fastening fittings will only include one connection end, which is connected to the composite pipe. the

其中,如图1-图7所示,第一复合管13包括最外层和最内层,最外层为金属层22,最内层为塑料层23,图7为第一复合管13经过扩口处理后的示意图,同样也包括最外层的金属层22和最内层的塑料层23。同样,如图8-图14所示,第二复合管17也包括金属层和塑料层,不过第二复合管17的最外层是塑料层,最内层是金属层。 Wherein, as shown in Figures 1-7, the first

之所以说是最外层和最内层,是因为本申请适用于多种复合管,即不仅适用于由金属和塑料组成的两层复合结构,还适用于中间设有热熔胶粘接层的三层复合结构等。 The reason why it is said to be the outermost layer and the innermost layer is that this application is applicable to a variety of composite pipes, that is, it is not only applicable to a two-layer composite structure composed of metal and plastic, but also suitable for a hot-melt adhesive layer in the middle The three-layer composite structure, etc. the

优选地,塑料套包括套层和套头,如图4所示,第一塑料套14包括第一套层15和第一套头16,第一塑料套14与“金属-塑料”结构的第一复合管13相适配,第一塑料套14的第一套层15叠装在第一复合管 13外层的金属层22的外端,第一套头16尺寸与第一复合管13的管口的厚度相适配,第一套头16向第一复合管13管口的内部凹进设置,第一套头16设置在与第一复合管13的中心轴线垂直的方向,第一套头16与第一复合管13的管口的头端相抵接,第一塑料套14将第一复合管13套装在其内,第一塑料套14与第一复合管13套装后形成复合套21,复合套21与突出部4和紧固接触面5之间的凹进空间25相互适配。 Preferably, the plastic sleeve includes a sleeve layer and a sleeve head. As shown in FIG. 4 , the first

当然,为满足“塑料-金属”结构的第二复合管17的连接要求,塑料套还可以采用图8-图13中所示的第二塑料套18,第二塑料套18包括第二套层19和第二套头20,由于第二复合管17的内层是金属层,外层是塑料层,第二套层19压装在第二复合管17的内层金属层的内部,相应的,第二套头20向外呈与第二复合管17的中心轴线垂直的方向凸出设置,第二套头20的尺寸与第二复合管17的厚度相适配,第二套头20与第二复合管18的管口头端相抵接,第二塑料套18套装在第二复合管17内部,同理,第二塑料套18与第二复合管17套装成复合套后夹装在塑料连接件1的凹进空间25内,方便后面的熔接。 Of course, in order to meet the connection requirements of the second

优选地,第一塑料套14由热熔胶或塑料注塑成型,该热熔胶或者塑料与第一复合管13的金属层22所采用的金属材料相适配;第二塑料套18也由热熔胶或塑料注塑成型,相应的,此时采用的热熔胶或者塑料与第二复合管17的金属层采用的金属材料相适配。 Preferably, the first

优选地,紧固螺帽11由塑料或金属制成。 Preferably, the

优选地,辅助紧固件9可以由橡胶制成,也可以由塑料制成。 Preferably, the

其中,预承插感应加热熔接塑料紧固式管件还包括防水紧固橡胶圈7和辅助紧固圆环8,其自内向外依次夹装在塑料连接件1、辅助紧固件9之间。 Among them, the pre-socket induction heating welding plastic fastening pipe fitting also includes a waterproof fastening rubber ring 7 and an

在本实用新型的预承插感应加热熔接塑料紧固式管件中,在紧固螺帽11的尾端设有螺帽管口12,螺帽管口12与辅助紧固件9的外表面适配,螺帽管口12的最大内径小于辅助紧固件9的最大外径。紧固螺帽11的内径自外向内依次增大,辅助紧固件9的外径自外向内依次增大。紧固螺帽11的内径依次增大的倾斜角度为1-10度,辅助紧固件9的外径依次增大的倾斜角度为1-10度。 In the pre-socket induction heating welding plastic fastening type pipe fitting of the present utility model, a

本实施例的预承插感应加热熔接塑料紧固式管件在使用时,先将第一塑料套14、紧固螺帽11、辅助紧固件9、辅助紧固圆环8、防水紧固橡胶圈7依次插装入第一复合管13的管口,首先将第一复合管13的管口插装进突出部4与紧固接触面5之间的凹进空间25,然后将第一塑料套14插装进突出部4与紧固接触面5之间的凹进空间25,第一塑料套14的第一套层15便处于第一复合管13的外层金属层22的外层,第一塑料套14与第一复合管13套装形成复合套21,将电磁感应器探头设置在紧固接触面5、突出部4与复合套21的接触面上,电磁感应发生装置通电工作时,电磁感应器产生的中高频电磁振荡波能够使第一复合管13的金属层22加热,金属层22受热能够使与金属层22相接触的塑料层23、第一套头16和第一套层15熔融,塑料层23和第一塑料套14在塑料连接件1的凹进空间25内熔融,进而使第一复合管13与第一塑料套14的连接更加牢固,真正形成复合套21这个整体,同时整个复合套21与塑料连接件1熔接。通过上述步骤,复合套21将第一复合管13紧密套装,尤其是第一套头16的设置,避免了凹进空间25内部的连接死角,密封性更好。 When the pre-socket induction heating and welding plastic fastening type pipe fitting of this embodiment is used, the first plastic sleeve 14, the fastening nut 11, the auxiliary fastener 9, the auxiliary fastening ring 8, the waterproof fastening rubber The ring 7 is sequentially inserted into the mouth of the first composite pipe 13, first the nozzle of the first composite pipe 13 is inserted into the recessed space 25 between the protrusion 4 and the fastening contact surface 5, and then the first plastic The sleeve 14 is inserted into the recessed space 25 between the protruding part 4 and the fastening contact surface 5, and the first sleeve layer 15 of the first plastic sleeve 14 is in the outer layer of the outer metal layer 22 of the first composite pipe 13, The first plastic sleeve 14 is set with the first composite pipe 13 to form a composite sleeve 21, and the electromagnetic inductor probe is arranged on the contact surface of the fastening contact surface 5, the protrusion 4 and the composite sleeve 21, and when the electromagnetic induction generating device is powered on, The medium and high frequency electromagnetic oscillating waves produced by the electromagnetic inductor can heat the metal layer 22 of the first composite pipe 13, and the heating of the metal layer 22 can make the plastic layer 23, the first sleeve head 16 and the first sleeve layer 15 in contact with the metal layer 22 melting, the plastic layer 23 and the first plastic sleeve 14 are melted in the recessed space 25 of the plastic connector 1, thereby making the connection between the first composite pipe 13 and the first plastic sleeve 14 more firm, and truly forming the composite sleeve 21 as a whole, At the same time, the entire composite sleeve 21 is welded to the plastic connector 1 . Through the above steps, the

为进一步固定连接,将紧固螺帽11向塑料连接件1的方向压紧,紧固螺帽11的螺帽内螺纹10咬合紧固外螺纹3,将辅助紧固件9、辅助紧固圆环8、防水紧固橡胶圈7紧紧的向塑料连接件1的方向挤压,从而将复合管与预承插感应加热熔接塑料紧固式管件牢牢固定。 In order to further fix the connection, the

如图8-图14所示,对于“塑料-金属”结构的第二复合管17,管件的结构和原理都是一样的,所不同的是,由于第二塑料套18要与第二复合管17配合使用,第二套层19需套装在内层金属层的内部,所以在将第二塑料套18、紧固螺帽11、辅助紧固件9、辅助紧固圆环8、防水紧固橡胶圈7依次插装入第二复合管17的管口后,应首先插装第二塑料套18进入突出部4与紧固接触面5之间的凹进空间25,然后将第二复合管17的管口插装进突出部4与紧固接触面5之间的凹进空间25,此时,第二复合管17将第二塑料套18套装在管口内部,第二套层19与第二复合管17的内层金属层紧密连接,第二套头20与第二复合管17抵接后接入凹进空间25内部的缝隙,然后通过上面阐述的原理和过程将第二复合管 17与预承插感应加热熔接塑料紧固式管件牢牢固定。 As shown in Figures 8-14, for the second

此外,本领域技术人员应该可以想到,由于本申请的紧固式管件的尺寸限制,不可能满足所有复合管连接的需要,但可以通过扩口、压缩等技术处理后使用本申请的紧固式管件将复合管连通;或者说,本申请的紧固式管件不仅适用于一般复合管的连接,还适用于如图7和图14所示的扩口管等管件的连通。 In addition, those skilled in the art should be able to imagine that due to the size limitation of the fastened pipe fittings of the present application, it is impossible to meet the needs of all composite pipe connections, but the fastened pipe fittings of the present application can be used after processing by flaring, compression, etc. The pipe fittings connect the composite pipes; in other words, the fastening pipe fittings of the present application are not only suitable for the connection of general composite pipes, but also suitable for the connection of pipe fittings such as flared pipes as shown in Figure 7 and Figure 14 . the

本实用新型的预承插感应加热熔接塑料紧固式管件,可以适用于多种复合管的使用情景,连接牢固,抗压力性强,密封性好,使用方便,尤其是对于内径较小或较大的复合管,其紧固尤其牢固、密封性尤其良好、抗压力性尤其强,即使在复合管内部压力较大的情况下,连接管件仍能保证连接的可靠性。 The pre-socket induction heating and welding plastic fastening pipe fittings of the utility model can be applied to a variety of composite pipe use scenarios, with firm connection, strong pressure resistance, good sealing performance, and convenient use, especially for small or relatively Large composite pipes are particularly firm in fastening, good in sealing performance, and strong in pressure resistance. Even when the internal pressure of the composite pipe is high, the connecting pipe fittings can still ensure the reliability of the connection. the

以上公开的仅为本实用新型的几个具体实施例,但是,本实用新型并非局限于此,任何本领域的技术人员能思之的变化都应落入本实用新型的保护范围。 The above disclosures are only a few specific embodiments of the utility model, but the utility model is not limited thereto, and any changes conceivable by those skilled in the art should fall within the protection scope of the utility model. the

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201120138204UCN202132647U (en) | 2011-05-04 | 2011-05-04 | Pre-socket induction heating welding plastic fastening pipe fittings |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201120138204UCN202132647U (en) | 2011-05-04 | 2011-05-04 | Pre-socket induction heating welding plastic fastening pipe fittings |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202132647Utrue CN202132647U (en) | 2012-02-01 |

Family

ID=45521414

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201120138204UExpired - Fee RelatedCN202132647U (en) | 2011-05-04 | 2011-05-04 | Pre-socket induction heating welding plastic fastening pipe fittings |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202132647U (en) |

Cited By (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102720911A (en)* | 2012-04-20 | 2012-10-10 | 杨蒙 | Medium and high frequency electromagnetic induction heating welding steel-plastic composite pipe connection kit |

| CN105465643A (en)* | 2014-09-28 | 2016-04-06 | 嘉兴山蒲照明电器有限公司 | LED Straight Tube Light |

| CN105697903A (en)* | 2016-04-12 | 2016-06-22 | 镇江市神龙电器管件有限公司 | Pipe connector |

| CN106870838A (en)* | 2015-12-10 | 2017-06-20 | 靳宏杰 | A kind of connection method for moulding aluminium composite heating radiator using plastic whorl interface |

| US10487991B2 (en) | 2015-03-10 | 2019-11-26 | Jiaxing Super Lighting Electronic Appliance Co., Ltd. | LED tube lamp |

| US10514134B2 (en) | 2014-12-05 | 2019-12-24 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US10624160B2 (en) | 2014-09-28 | 2020-04-14 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US10619833B2 (en) | 2016-03-17 | 2020-04-14 | Zhejiang Super Lighting Electric Appliance Co., Ltd | Curved LED tubular lamp |

| US10634337B2 (en) | 2014-12-05 | 2020-04-28 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp with heat dissipation of power supply in end cap |

| US10670197B2 (en) | 2014-09-28 | 2020-06-02 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US10876690B2 (en) | 2015-09-02 | 2020-12-29 | Jiaxing Super Lighting Electric Appliance Co., Ltd. | LED tube lamp |

| US10897801B2 (en) | 2014-09-28 | 2021-01-19 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US11131431B2 (en) | 2014-09-28 | 2021-09-28 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US12085263B2 (en) | 2014-09-28 | 2024-09-10 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US12264789B2 (en) | 2014-12-05 | 2025-04-01 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

- 2011

- 2011-05-04CNCN201120138204Upatent/CN202132647U/ennot_activeExpired - Fee Related

Cited By (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102720911A (en)* | 2012-04-20 | 2012-10-10 | 杨蒙 | Medium and high frequency electromagnetic induction heating welding steel-plastic composite pipe connection kit |

| US12085263B2 (en) | 2014-09-28 | 2024-09-10 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US12372209B2 (en) | 2014-09-28 | 2025-07-29 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US10897801B2 (en) | 2014-09-28 | 2021-01-19 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| CN105465643B (en)* | 2014-09-28 | 2019-08-23 | 嘉兴山蒲照明电器有限公司 | LED straight lamp |

| US11686457B2 (en) | 2014-09-28 | 2023-06-27 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| CN105465643A (en)* | 2014-09-28 | 2016-04-06 | 嘉兴山蒲照明电器有限公司 | LED Straight Tube Light |

| US10624160B2 (en) | 2014-09-28 | 2020-04-14 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US11649934B2 (en) | 2014-09-28 | 2023-05-16 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US11519567B2 (en) | 2014-09-28 | 2022-12-06 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US10670197B2 (en) | 2014-09-28 | 2020-06-02 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US11131431B2 (en) | 2014-09-28 | 2021-09-28 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US11112068B2 (en) | 2014-09-28 | 2021-09-07 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US10514134B2 (en) | 2014-12-05 | 2019-12-24 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US10830397B2 (en) | 2014-12-05 | 2020-11-10 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US10634337B2 (en) | 2014-12-05 | 2020-04-28 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp with heat dissipation of power supply in end cap |

| US11906115B2 (en) | 2014-12-05 | 2024-02-20 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US12264789B2 (en) | 2014-12-05 | 2025-04-01 | Jiaxing Super Lighting Electric Appliance Co., Ltd | LED tube lamp |

| US10890300B2 (en) | 2015-03-10 | 2021-01-12 | Jiaxing Super Lighting Electric Appliance Co., Ltd. | LED tube lamp |

| US11226073B2 (en) | 2015-03-10 | 2022-01-18 | Jiaxing Super Lighting Electric Appliance Co., Ltd. | Led tube lamp |

| US10487991B2 (en) | 2015-03-10 | 2019-11-26 | Jiaxing Super Lighting Electronic Appliance Co., Ltd. | LED tube lamp |

| US11698170B2 (en) | 2015-03-10 | 2023-07-11 | Jiaxing Super Lighting Electric Appliance Co., Ltd. | LED tube lamp |

| US10876690B2 (en) | 2015-09-02 | 2020-12-29 | Jiaxing Super Lighting Electric Appliance Co., Ltd. | LED tube lamp |

| CN106870838A (en)* | 2015-12-10 | 2017-06-20 | 靳宏杰 | A kind of connection method for moulding aluminium composite heating radiator using plastic whorl interface |

| US10619833B2 (en) | 2016-03-17 | 2020-04-14 | Zhejiang Super Lighting Electric Appliance Co., Ltd | Curved LED tubular lamp |

| CN105697903A (en)* | 2016-04-12 | 2016-06-22 | 镇江市神龙电器管件有限公司 | Pipe connector |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202132647U (en) | Pre-socket induction heating welding plastic fastening pipe fittings | |

| CN102720901A (en) | Electromagnetic induction welding steel-plastic composite pipe connection kit | |

| US20060214418A1 (en) | Arrangement with a tubular element | |

| WO2010121339A1 (en) | Method for the highly-thick thermal coating of joints by using electrofusion in pipes used for conducting fluids, made of steel tubes externally coated with polyolefins | |

| US20100012304A1 (en) | Plastic heat exchanger and method of manufacturing the same | |

| CN202546113U (en) | Electromagnetic induction welding steel-plastic composite pipe fittings | |

| CN1774595B (en) | Plastic tube joint | |

| US20130133829A1 (en) | Internal electrofusion ring coupler | |

| CN102313107B (en) | Wire rope enhanced thermoplastic composite pipe heating type buckling and pressing joint and connection method | |

| CN202065563U (en) | Pre-socket induction heating fusion plastic pipe fittings | |

| CN202546053U (en) | Electromagnetic induction welding steel-plastic composite pipe fastening connection pipe fittings | |

| JP5576049B2 (en) | Corrugated tube manufacturing method | |

| CN102338254A (en) | Pre-socket induction heating fusion plastic pipe fittings | |

| CN203131296U (en) | Multi-seal pipe fittings that can observe the welding effect | |

| KR101923883B1 (en) | Air Intake Hose and Method Thereof | |

| CN202100881U (en) | Straight joint with metal sleeve | |

| CN215258379U (en) | Novel hollow wall winding pipe | |

| CN210950283U (en) | Plastic-coated metal pipeline system | |

| CN102720911A (en) | Medium and high frequency electromagnetic induction heating welding steel-plastic composite pipe connection kit | |

| CN203453693U (en) | Thermal welding pipe joint with heating zone | |

| CN202338724U (en) | Connecting piece of PE multiple unit tube and PE multiple unit tube employing same | |

| CN202992500U (en) | Composite tube connecting part | |

| CN110715126A (en) | Plastic-coated metal pipeline system | |

| CN222776332U (en) | Sealing structure for sealing end of electric heating pipe | |

| CN215335111U (en) | Electromagnetic four-side hot-melting connecting structure of PSP steel-plastic composite pressure pipe |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20120201 Termination date:20140504 |