CN201952992U - Building thermal insulation pavement construction - Google Patents

Building thermal insulation pavement constructionDownload PDFInfo

- Publication number

- CN201952992U CN201952992UCN2010206704782UCN201020670478UCN201952992UCN 201952992 UCN201952992 UCN 201952992UCN 2010206704782 UCN2010206704782 UCN 2010206704782UCN 201020670478 UCN201020670478 UCN 201020670478UCN 201952992 UCN201952992 UCN 201952992U

- Authority

- CN

- China

- Prior art keywords

- heat insulation

- building

- insulating board

- board

- building floor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000009413insulationMethods0.000titleclaimsabstractdescription119

- 238000010276constructionMethods0.000titledescription9

- 239000000463materialSubstances0.000claimsdescription8

- 239000004568cementSubstances0.000claimsdescription5

- 238000005054agglomerationMethods0.000claims1

- 230000002776aggregationEffects0.000claims1

- 230000015572biosynthetic processEffects0.000claims1

- 230000000694effectsEffects0.000description10

- 238000000034methodMethods0.000description9

- 125000006850spacer groupChemical group0.000description9

- VYPSYNLAJGMNEJ-UHFFFAOYSA-NSilicium dioxideChemical compoundO=[Si]=OVYPSYNLAJGMNEJ-UHFFFAOYSA-N0.000description8

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description6

- 230000009286beneficial effectEffects0.000description5

- 230000008569processEffects0.000description4

- 239000004576sandSubstances0.000description4

- 238000010586diagramMethods0.000description3

- 230000017525heat dissipationEffects0.000description3

- 230000008439repair processEffects0.000description3

- 239000011347resinSubstances0.000description3

- 229920005989resinPolymers0.000description3

- 239000004115Sodium SilicateSubstances0.000description2

- 230000003796beautyEffects0.000description2

- 239000011083cement mortarSubstances0.000description2

- 239000000919ceramicSubstances0.000description2

- 239000004927claySubstances0.000description2

- 230000003631expected effectEffects0.000description2

- 239000010433feldsparSubstances0.000description2

- 239000011521glassSubstances0.000description2

- 230000005855radiationEffects0.000description2

- 239000000377silicon dioxideSubstances0.000description2

- 238000005245sinteringMethods0.000description2

- NTHWMYGWWRZVTN-UHFFFAOYSA-Nsodium silicateChemical compound[Na+].[Na+].[O-][Si]([O-])=ONTHWMYGWWRZVTN-UHFFFAOYSA-N0.000description2

- 229910052911sodium silicateInorganic materials0.000description2

- 239000000454talcSubstances0.000description2

- 229910052623talcInorganic materials0.000description2

- 239000011449brickSubstances0.000description1

- 230000008859changeEffects0.000description1

- 238000004049embossingMethods0.000description1

- 230000006872improvementEffects0.000description1

- 230000008595infiltrationEffects0.000description1

- 238000001764infiltrationMethods0.000description1

- 239000012466permeateSubstances0.000description1

- 238000010792warmingMethods0.000description1

Images

Landscapes

- Road Paving Structures (AREA)

- Floor Finish (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本实用新型有关一种建筑物的隔热构造,特别是指一种可供自由调整隔热板与建筑物楼层板间距,以及更换隔热板或将隔热板回收重复使用的建筑物隔热铺面构造。The utility model relates to a heat insulation structure of a building, in particular to a building heat insulation structure that can freely adjust the distance between a heat insulation board and a building floor board, replace a heat insulation board or recycle a heat insulation board for reuse. Pavement construction.

背景技术Background technique

中国台湾省地处亚热带区域,加上受到全球暖化的影响,使得地球环境每年平均气温持续上升,尤其到了夏天经常处于30℃以上高温,目前最普及的混凝土平顶建筑,最容易吸收和蓄积强烈的太阳辐射热,顶楼地板的下层楼室内空间不但白天酷热难熬,甚至于到了夜晚,由于屋顶板面仍然不断释放出蓄积的辐射热,致使热气漫留顶层楼室内,影响居住的舒适性,故根本防热之道即作屋顶隔热处理,以阻绝热的传导和辐射。Taiwan Province of China is located in the subtropical region, coupled with the impact of global warming, the annual average temperature of the earth's environment continues to rise, especially in summer, often at a high temperature above 30°C. At present, the most popular concrete flat-roof buildings are the easiest to absorb and accumulate. Intense solar radiant heat, the indoor space on the lower floor of the top floor is not only extremely hot in the daytime, but even at night, because the roof slabs still continuously release the accumulated radiant heat, the hot air permeates the interior of the top floor, affecting the comfort of living. Therefore, the fundamental way to prevent heat is to insulate the roof to prevent heat conduction and radiation.

其次,一般的建筑物顶楼楼板为接受雨水及光照的承接面,故多涂布有PU材质的防水层,复于该防水层上再设置一隔热层,制成隔热层的材质种类众多,较常见者诸如磨石隔热砖、PS材质隔热层等等,当隔热层铺设完成后,需以水泥砂浆加以固定;藉此,构成屋顶的防水隔热铺面结构。Secondly, the top floor of a general building is the receiving surface for receiving rainwater and light, so it is often coated with a waterproof layer made of PU material, and a heat insulation layer is placed on the waterproof layer. There are many types of materials for the heat insulation layer. , the more common ones, such as terrazzo heat insulation bricks, PS material heat insulation layer, etc., after the heat insulation layer is laid, it needs to be fixed with cement mortar; thereby, the waterproof and heat insulation pavement structure of the roof is formed.

上述习用建筑物隔热铺面结构虽可达预期功效,但是由于该结构施工上必须要经过繁杂程序,且易因施工人员手法及用料比例的不同,而使施工后的质量较不稳定;再者,由于该防水层、隔热层以水泥砂浆黏着固接,因此当屋顶经过一段时间的风吹日晒雨淋之后,容易产生龟裂或是浮凸现象,导致防水或隔热的预期效果降低或丧失。Although the above-mentioned conventional building heat insulation pavement structure can achieve the expected effect, but because the construction of the structure must go through complicated procedures, and it is easy to cause the quality after construction to be unstable due to the different methods of construction personnel and the proportion of materials used; Or, since the waterproof layer and heat insulation layer are fixed with cement mortar, when the roof is exposed to wind, sun, and rain for a period of time, cracks or embossments are likely to occur, resulting in the expected effect of waterproof or heat insulation. reduced or lost.

再者,由于上述习用建筑物隔热铺面结构虽然在刚完工时紧密附着于建筑物楼层板,但若日后遇有龟裂、浮凸现象,或是漏水的情况发生时,非常不容易让渗入的水气散发,更无法作局部的维修则必须将原始的整体结构加以除去,再重新进行施工,显然无法符合实际所需,而有改善的必要。Furthermore, although the above-mentioned conventional building heat insulation pavement structure is closely attached to the building floor slab when it is just completed, it is very difficult to allow infiltration if cracks, embossing, or water leakage occur in the future. If it is impossible to make local repairs, the original overall structure must be removed and then re-constructed. Obviously, it cannot meet the actual needs, and there is a need for improvement.

实用新型内容Utility model content

本实用新型所解决的技术问题即在提供一种可供自由调整隔热板与建筑物楼层板间距,以及更换隔热板或将隔热板回收重复使用的建筑物隔热铺面构造。The technical problem solved by the utility model is to provide a building heat insulation pavement structure that can freely adjust the distance between the heat insulation board and the building floor board, and replace the heat insulation board or recycle the heat insulation board for reuse.

本实用新型的技术方案为:一种建筑物隔热铺面构造,包括有:复数组间隔座,由预定数量脚架为一组的方式配设于建筑物楼层板相对于各隔热板所覆盖的区域处;复数隔热板,各隔热板具有预定的轮廓外型及预定的规格尺寸;以及各隔热板直接放置于脚架上的方式铺设于建筑物楼层板上方,并与建筑物楼层保持预定的间距。The technical scheme of the utility model is: a building heat insulation pavement structure, including: a plurality of sets of spacer seats, which are arranged in a group of a predetermined number of tripods on the floor of the building and covered by the heat insulation boards. a plurality of heat insulation boards, each heat insulation board has a predetermined outline shape and a predetermined size; Floors maintain predetermined spacing.

其中,各脚架由至少两个垫块相叠置黏固而成。Wherein, each tripod is formed by stacking at least two pads and sticking them together.

各脚架固设于建筑物楼层板上。Each tripod is fixed on the floor board of the building.

各隔热板的表面具有一经烧结作用而形成的磁化层。The surface of each heat shield has a magnetized layer formed by sintering.

各隔热板周缘设有至少一凹口。At least one notch is provided on the periphery of each heat insulation board.

各隔热板亦由轻质骨材以水泥、树脂胶结材胶结成型。Each heat insulation board is also formed by cementing and resin cementing materials with lightweight aggregates.

各隔热板于至少一导角处形成一导角,以当隔热板相互抵靠铺设时,以由相临的隔热板形成一缺口。Each heat insulation board forms a chamfer at at least one chamfer, so that when the heat insulation boards are laid against each other, a gap is formed by the adjacent heat insulation boards.

本实用新型的有益效果为:本实用新型的建筑物隔热铺面构造,在建筑物楼层板之上铺设有复数隔热板,以及在各数隔热板与建筑物楼层板之间设有间隔座;其中,各间隔座由预定数量脚架为一组的方式配设于建筑物楼层板相对于各隔热板所覆盖的区域处,各隔热板直接放置于脚架上的方式铺设于建筑物楼层板上方,并与建筑物楼层保持预定之间距。The beneficial effects of the utility model are: the building heat insulation pavement structure of the utility model is provided with a plurality of heat insulation boards on the building floor boards, and an interval is provided between each number of heat insulation boards and the building floor boards. Seats; wherein, each spacer seat is arranged in a group with a predetermined number of tripods on the floor of the building relative to the area covered by each heat insulation board, and each heat insulation board is laid directly on the tripod. Above the building floor slab, and keep a predetermined distance from the building floor.

据以,可在施作时,利用简单改变脚架高度的方式,即可达到调整隔热板与建筑物楼层板间距的目的;以及,当隔热板遇有毁损时,不需要使用任何工具即可将损坏的隔热板更换;尤其,当欲改变隔热铺面的位置,或欲将隔热铺面移除时,所回收的隔热板因不会在移除过程中遭受破坏,故有利于隔热板的重复使用。Therefore, the purpose of adjusting the distance between the heat insulation board and the building floor board can be achieved by simply changing the height of the tripod during construction; and when the heat insulation board is damaged, no tools are required The damaged heat insulation board can be replaced; especially, when the position of the heat insulation pavement is to be changed, or the heat insulation pavement is to be removed, the recovered heat insulation board will not be damaged during the removal process, so there is It is beneficial to the repeated use of the insulation board.

本实用新型的建筑物隔热铺面构造于实施时,所述各脚架由可以由至少两个垫块相叠置黏固而成,以方便施工人员依实际的需求立即改变各脚架的高度。When implementing the building heat insulation pavement structure of the present utility model, each foot frame can be formed by stacking and sticking at least two pads, so that the construction personnel can immediately change the height of each foot frame according to actual needs. .

本实用新型的建筑物隔热铺面构造于实施时,所述各脚架固设于建筑物楼层板上,以增加整体建筑物隔热铺面构造的稳定度及可靠度。When the building heat insulation pavement structure of the present invention is implemented, each of the tripods is fixed on the building floor to increase the stability and reliability of the overall building heat insulation pavement structure.

本实用新型的建筑物隔热铺面构造于实施时,所述各隔热板表面具有一经烧结作用而形成的磁化层,以增加隔热板的美观及耐用度。When the heat insulation pavement structure of a building of the utility model is implemented, the surface of each heat insulation board has a magnetized layer formed by sintering to increase the appearance and durability of the heat insulation board.

本实用新型的建筑物隔热铺面构造于实施时,所述各隔热板由30~54%的黏土、30~54%的长石、5~10%的硅沙、1~3%的滑石、5~10%的回收陶沙、5~10%的回收玻璃,以及8~15%的硅酸钠烧结而成。When the heat insulation pavement structure of the utility model is implemented, each heat insulation board is composed of 30-54% clay, 30-54% feldspar, 5-10% silica sand, and 1-3% talc. , 5~10% recycled ceramic sand, 5~10% recycled glass, and 8~15% sodium silicate sintered.

本实用新型另一实施例的隔热板亦可以由粗、细的轻质骨材以水泥、树脂等胶结材胶结成型,同样可达隔热板的美观及耐用度。The heat insulation board in another embodiment of the present invention can also be made of thick and thin lightweight aggregates with cement, resin and other cementing materials, which can also achieve the beauty and durability of the heat insulation board.

本实用新型的建筑物隔热铺面构造于实施时,所述各隔热板周缘设有至少一凹口,以方便隔热板的铺设或移除,并可使铺设完成的建筑物隔热铺面构造具有较佳的排热效果。When the building heat insulation pavement structure of the utility model is implemented, at least one notch is provided on the periphery of each heat insulation board to facilitate the laying or removal of the heat insulation board, and to make the completed building heat insulation pavement The structure has better heat dissipation effect.

与前揭习用建筑物隔热构造相较,本实用新型的建筑物隔热铺面构造相对具有方便施工、方便修善,以及隔热效果较为显著等优点;尤其,当隔热板遇有毁损时,仅需要使用简易工具例如:勾取杆,藉由勾取杆朝向凹口勾取,即可将损坏的隔热板更换,以及当欲改变隔热铺面的位置,或欲将隔热铺面移除时,所回收的隔热板因不会在移除过程中遭受破坏,故有利于隔热板的重复使用。Compared with the heat insulation structure of buildings previously disclosed, the heat insulation pavement structure of the building of the utility model has the advantages of convenient construction, convenient repair, and remarkable heat insulation effect; especially, when the heat insulation board is damaged, Only need to use simple tools such as: hook rod, by hooking the rod towards the notch, the damaged heat insulation board can be replaced, and when the position of the heat insulation pavement is to be changed, or the heat insulation pavement is to be removed , the recovered insulation board will not be damaged during the removal process, so it is beneficial to the reuse of the insulation board.

附图说明Description of drawings

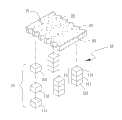

图1为本实用新型一较佳实施例的隔热铺面构造立体图。Fig. 1 is a perspective view of a heat-insulating pavement structure in a preferred embodiment of the present invention.

图2为本实用新型的隔热铺面构造侧视图。Fig. 2 is a side view of the heat insulation pavement structure of the present invention.

图3为本实用新型的隔热板铺设方式示意图。Fig. 3 is a schematic diagram of the laying method of the heat insulation board of the present invention.

图4为本实用新型的隔热板铺设导角结构示意图。Fig. 4 is a structural schematic diagram of laying chamfers of heat insulation boards of the present invention.

图号说明:10间隔座;11脚架;111垫块;20隔热板;21磁化层;22凹口;23导角;30建筑物楼层板;40缺口。 Description of drawing number: 10 spacer seat; 11 tripod; 111 spacer; 20 heat shield; 21 magnetized layer; 22 notch; 23 guide angle; 30 building floor plate; the

具体实施方式Detailed ways

如图1本实用新型一较佳实施例的隔热铺面构造立体图、图2本实用新型的隔热铺面构造侧视图、图3本实用新型的隔热板铺设方式示意图所示,本实用新型的建筑物隔热铺面构造,包括有:复数组间隔座10,由预定数量脚架11为一组的方式配设于建筑物楼层板30相对于各隔热板20所覆盖的区域处;于实施时,各脚架11可以由一个垫块111或如图所示的至少两个垫块111利用水泥加以相叠置黏固而成,以符合实际的高度,而且各脚架11同样可利用水泥固定在建筑物楼层板30上,以增加间隔座10的稳定性。As shown in Fig. 1 the perspective view of the thermal insulation pavement structure of a preferred embodiment of the utility model, the side view of the thermal insulation pavement structure of Fig. 2 the utility model, and the schematic diagram of the laying method of the thermal insulation board of the utility model in Fig. 3, the utility model The heat insulation pavement structure of the building includes: a plurality of groups of

复数隔热板20,分别设于各组间隔座10的脚架11上,各隔热板20直接放置于脚架11上的方式铺设于建筑物楼层板30上方,并与建筑物楼层30保持预定的间距;以及,各隔热板20具有预定的轮廓外型及预定的规格尺寸,使得以相互拼靠成一连续的铺面。A plurality of

据以,本实用新型的建筑物隔热铺面构造在施作时,只需利用简单改变脚架11高度的方式,即可达到调整隔热板20与建筑物楼层板30间距的目的,并藉以让各隔热板20的板面得以平齐;再者,各隔热板20可在间隔座10的作用下,与建筑物楼层板30保持一适当之间距,除可增加隔热效果的外,更可做为一暂存时的集水空间,使得以提升各隔热板20板面的排水速度,以维持于隔热板20上行走、活动的安全。Accordingly, when the building heat-insulating pavement structure of the present utility model is being applied, the purpose of adjusting the distance between the heat-insulating

由于本实用新型中的隔热板20以直接放置于脚架11上的方式铺设于筑物楼层板30,因此,当隔热板20遇有毁损时,仅需要使用简易工具例如:勾取杆(图未示),藉由勾取杆朝向凹口22勾取,即可将损坏的隔热板20更换;尤其,当欲改变隔热铺面的位置,或欲将隔热铺面移除时,所回收的隔热板20因不会在移除过程中遭受破坏,故有利于隔热板20的重复使用。Since the

具体而言,本实用新型的建筑物隔热铺面构造主要利用隔热板20阻挡阳光直射在建筑物楼层板30上,减少建筑物受太阳辐射热的影响,进而达到降低室内温度的效果。Specifically, the building heat insulation pavement structure of the utility model mainly uses the

特别是,本实用新型的建筑物隔热铺面构造于实施时,所述各隔热板20可以由30~54%的黏土、30~54%的长石、5~10%的硅沙、1~3%的滑石、5~10%的回收陶沙、5~10%的回收玻璃,以及8~15%的硅酸钠烧结而成,并使隔热板20表面可进一步具有一经烧结作用而形成的磁化层21,以增加隔热板20的美观及耐用度。In particular, when the building heat insulation pavement structure of the present invention is implemented, each

本实用新型另一实施例的隔热板20亦可以由粗、细的轻质骨材以水泥、树脂等胶结材胶结成型,同样可达隔热板20的美观及耐用度。The

以及本实用新型中的隔热板20可进一步在其周缘设有至少一凹口22,除可供做为手指伸入隔热板20周缘,以方便隔热板的铺设或移除的设计之外,并可使铺设完成的建筑物隔热铺面构造具有可供隔热铺面下方气流通往隔热铺面上方的通道,因此可藉以获致较佳的排热效果,更可加速隔热铺面下方水气散发的速度,以降低建筑物楼层板渗水的机率。And the

再者,如图4所示,本实用新型的隔热板20可于至少一导角处形成一导角23,以当隔热板20相互抵靠铺设时,以由相临的隔热板20形成一缺口40,同样可藉以获致较佳的排热效果,更可加速隔热铺面下方水气散发的速度,以降低建筑物楼层板渗水的机率。Furthermore, as shown in FIG. 4, the

与前揭习用建筑物隔热构造相较,本实用新型的建筑物隔热铺面构造相对具有方便施工、方便修善,以及隔热效果较为显著等优点;尤其,当隔热板遇有毁损时,仅需要使用简易工具例如:勾取杆(图未示),藉由勾取杆朝向凹口22勾取,即可将损坏的隔热板更换,以及当欲改变隔热铺面的位置,或欲将隔热铺面移除时,所回收的隔热板因不会在移除过程中遭受破坏,故有利于隔热板的重复使用。Compared with the heat insulation structure of buildings previously disclosed, the heat insulation pavement structure of the building of the utility model has the advantages of convenient construction, convenient repair, and remarkable heat insulation effect; especially, when the heat insulation board is damaged, Only need to use a simple tool such as: a hook rod (not shown in the figure), by hooking the rod towards the

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010206704782UCN201952992U (en) | 2010-12-21 | 2010-12-21 | Building thermal insulation pavement construction |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010206704782UCN201952992U (en) | 2010-12-21 | 2010-12-21 | Building thermal insulation pavement construction |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN201952992Utrue CN201952992U (en) | 2011-08-31 |

Family

ID=44497111

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2010206704782UExpired - Fee RelatedCN201952992U (en) | 2010-12-21 | 2010-12-21 | Building thermal insulation pavement construction |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN201952992U (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104929324A (en)* | 2015-04-22 | 2015-09-23 | 浙江建设职业技术学院 | Temperature control waterproof roof |

| CN106401090A (en)* | 2015-07-31 | 2017-02-15 | 骆重光 | Waterproof and heat-insulating roof structure |

| TWI783775B (en)* | 2021-11-10 | 2022-11-11 | 辛文佐 | Detachable, recyclable, environmentally friendly heat insulation structure and construction method of roof truss |

- 2010

- 2010-12-21CNCN2010206704782Upatent/CN201952992U/ennot_activeExpired - Fee Related

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104929324A (en)* | 2015-04-22 | 2015-09-23 | 浙江建设职业技术学院 | Temperature control waterproof roof |

| CN106401090A (en)* | 2015-07-31 | 2017-02-15 | 骆重光 | Waterproof and heat-insulating roof structure |

| TWI783775B (en)* | 2021-11-10 | 2022-11-11 | 辛文佐 | Detachable, recyclable, environmentally friendly heat insulation structure and construction method of roof truss |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN107313573B (en) | Quick-heating energy-saving wet floor heating structure and construction method thereof | |

| CN106760245A (en) | A kind of anastrophe energy-saving roofing system and its construction method | |

| CN110409756A (en) | A kind of the flooring heat insulating and sound insulating system and its installation method of low cost | |

| KR101079646B1 (en) | Internal and external insulation construction method of building using formwork composite panel | |

| CN205369827U (en) | Ground that gypsum base was laid from levelling mortar warms up ground structure | |

| CN201952992U (en) | Building thermal insulation pavement construction | |

| CN202755547U (en) | Inverted type waterproof roof | |

| CN210563183U (en) | Dry-method floor heating system for overhead ground | |

| CN206267349U (en) | A building structure that prevents the thermal bridge effect on the wall surface and prevents moisture on the ground | |

| CN208039733U (en) | A kind of floor heating floor structure | |

| CN202066097U (en) | Module type floor heating structure | |

| CN205224517U (en) | Ceramic tile type ground structure | |

| CN101699173A (en) | Light and thin composite hot water heating floor | |

| CN218562885U (en) | Gypsum-based fabricated floor module and floor system | |

| CN208088760U (en) | A kind of thin type ground heating ground structure | |

| CN2464825Y (en) | Integral pouring polyphenyl thermal-insulating composite wall | |

| CN211526526U (en) | Ground heating structure | |

| TWM405459U (en) | Thermal insulation pavement structure for building | |

| CN207863355U (en) | A kind of composite building decorating wall | |

| CN201507982U (en) | A light and thin composite hot water heating floor | |

| CN221590249U (en) | Ground heating ground structure paved by gypsum-based self-leveling mortar | |

| CN204754084U (en) | Prefabricated board that warms up that can splice integratedly and floor heating structure who constitutes thereof | |

| CN103469976B (en) | A kind of roof heat insulation method | |

| CN205637369U (en) | Roofing insulation construction | |

| CN213841068U (en) | Novel module warms up simple and easy dry process of assembled |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20110831 Termination date:20151221 | |

| EXPY | Termination of patent right or utility model |