CN201924562U - Finger joint wood solid wood floor - Google Patents

Finger joint wood solid wood floorDownload PDFInfo

- Publication number

- CN201924562U CN201924562UCN2010206732301UCN201020673230UCN201924562UCN 201924562 UCN201924562 UCN 201924562UCN 2010206732301 UCN2010206732301 UCN 2010206732301UCN 201020673230 UCN201020673230 UCN 201020673230UCN 201924562 UCN201924562 UCN 201924562U

- Authority

- CN

- China

- Prior art keywords

- wear

- finger

- solid wood

- layer

- wood

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000002023woodSubstances0.000titleclaimsabstractdescription42

- 239000007787solidSubstances0.000titleclaimsabstractdescription27

- 210000001145finger jointAnatomy0.000titledescription4

- 240000004045Cassia javanicaSpecies0.000title1

- 239000000463materialSubstances0.000claimsabstractdescription25

- 239000000758substrateSubstances0.000claimsdescription5

- 238000009408flooringMethods0.000abstractdescription9

- 238000004519manufacturing processMethods0.000abstractdescription7

- 230000000694effectsEffects0.000abstractdescription3

- 238000005516engineering processMethods0.000abstractdescription3

- 239000002699waste materialSubstances0.000abstractdescription2

- 239000010410layerSubstances0.000description33

- 238000000034methodMethods0.000description9

- 238000010276constructionMethods0.000description2

- 238000003825pressingMethods0.000description2

- 238000004026adhesive bondingMethods0.000description1

- 238000005034decorationMethods0.000description1

- 230000007547defectEffects0.000description1

- 230000007613environmental effectEffects0.000description1

- 238000003912environmental pollutionMethods0.000description1

- 238000010438heat treatmentMethods0.000description1

- 238000009434installationMethods0.000description1

- 238000011900installation processMethods0.000description1

- 238000005304joiningMethods0.000description1

- 239000004922lacquerSubstances0.000description1

- 238000003475laminationMethods0.000description1

- 230000007774longtermEffects0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 238000000465mouldingMethods0.000description1

- 239000004745nonwoven fabricSubstances0.000description1

- 239000011241protective layerSubstances0.000description1

- 239000013589supplementSubstances0.000description1

- 238000004381surface treatmentMethods0.000description1

Images

Classifications

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A30/00—Adapting or protecting infrastructure or their operation

- Y02A30/60—Planning or developing urban green infrastructure

Landscapes

- Floor Finish (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本实用新型涉及木地板技术领域,尤其是涉及一种指接木实木地板。The utility model relates to the technical field of wood floors, in particular to a finger-jointed solid wood floor.

背景技术Background technique

随着人们的生活消费水平大幅度提高,健康、环保的木地板在目前的装饰装修中越来越受到人们的青睐。传统实木地板主要存在下述缺陷:1、实木地板表面不能加耐磨层,因为传统实木地板的基材材料是原木,没有经过加工处理,工艺上无法加耐磨层,即使加了耐磨层以后就会马上变形。2、实木地板底部无法设置平衡层,主要也是工艺上没有办法加工。实木地板的基材原木材质无法进行压贴工艺,这样,传统实木地板上是无法安装地暖之类的地热装置,防水效果也不好。3、实木地板表面的四周不能进行模压倒角处理,目前只在强化地板上实施过模压倒角。Along with people's living consumption level improves substantially, the wooden floor of health, environmental protection is more and more subject to people's favor in present decoration. The traditional solid wood floor mainly has the following defects: 1. The surface of the solid wood floor cannot be added with a wear-resistant layer, because the base material of the traditional solid wood floor is a log, which has not been processed, and the wear-resistant layer cannot be added in the process, even if the wear-resistant layer is added It will be deformed immediately in the future. 2. The bottom of the solid wood floor cannot be equipped with a balance layer, mainly because there is no way to process it in terms of technology. The raw wood material of the solid wood floor cannot be pressed and pasted. In this way, it is impossible to install geothermal devices such as floor heating on the traditional solid wood floor, and the waterproof effect is not good. 3. Molded chamfering cannot be performed around the surface of solid wood flooring. At present, molded chamfering is only implemented on laminate flooring.

为此,人们进行了长期的探索,提出了各种各样的解决方案。例如,中国专利文献公开了一种拼板和指接木棍[申请号:200720049193.5],包括利用短材料拼板和指接的棍体,实施时在棍体的表面均匀地贴敷有一层无纺布加木皮层。然后,在所有木皮的表面上涂敷有漆性保护层。在进行贴敷操作时,所述的木皮加无纺布与棍体间为粘连接。该方案用各种边角废料拼板指接加工制成,既经济又环保,大幅度提高了材料利用率,降低了生产成本,而且经指拼构成的木棍,不易变形,表面处理工艺简单,还可有效降低生产过程造成的环境污染。然而,上述方案仅将实木条拼接成木棍,并不能加工成板体。因此仍然无法解决现有技术存在的技术问题。For this reason, people have carried out long-term exploration, put forward various solutions. For example, the Chinese patent literature discloses a wooden stick for jigsaw puzzle and finger joint [Application No.: 200720049193.5], which includes a stick made of short materials for jigsaw puzzle and finger joint. Buga wood cortex. Then, a protective layer of lacquer is applied on the surface of all veneers. During the sticking operation, the wood veneer plus the non-woven fabric and the stick are bonded. This scheme is made by finger jointing of various edge scraps, which is economical and environmentally friendly. It greatly improves the utilization rate of materials and reduces production costs. Moreover, the wooden sticks formed by finger joints are not easy to deform, and the surface treatment process is simple. , It can also effectively reduce the environmental pollution caused by the production process. However, the above scheme only splices the solid wood strips into sticks, and cannot be processed into boards. Therefore still can't solve the technical problem that prior art exists.

发明内容Contents of the invention

本实用新型的目的是针对上述问题,提供一种设计合理,结构简单,性能稳定可靠,加工制造成本低的指接木实木地板。The purpose of this utility model is to solve the above problems and provide a finger-jointed solid wood floor with reasonable design, simple structure, stable and reliable performance, and low processing and manufacturing costs.

为达到上述目的,本实用新型采用了下列技术方案:本指接木实木地板,其特征在于,本地板包括由指接木制成的基材层,在基材层的一面复合有由耐磨材料制成的耐磨层,在基材层的另一面复合有由防水材料制成的平衡层。In order to achieve the above object, the utility model adopts the following technical solutions: the finger-jointed solid wood floor is characterized in that the floor includes a base material layer made of finger-joined wood, and one side of the base layer is compounded with a layer made of wear-resistant material. The wear-resistant layer is formed, and a balance layer made of waterproof material is compounded on the other side of the base layer.

指接木是由接木机器将一根根木头拼接在一起形成板材。具体工序是将中短建筑木材的梳齿,开榫,拼接。它是将建筑木材纵向胶合并接制成长尺寸规格料,以便提高木材利用率,降低成本,性能远远优于中密度板和大芯板。耐磨层压贴工艺是将耐磨纸压贴到地板的基材层表面。当然,这里的耐磨层不仅限耐磨纸,也可能是其他耐磨材料。平衡层用压贴工艺将防水材料压贴到基材层上,主要的作用是平衡层在安装过程中是直接安装在地面上的,加平衡层以后能起到防水作用,并且保证了地板在受潮和受热等情况下不容易变形。Finger-jointed lumber is made by splicing individual pieces of wood together to form a board. The specific process is to mortise, tenon and splice the comb teeth of short and medium construction timber. It is made of long-dimension materials by longitudinally gluing and joining construction timber, so as to improve timber utilization and reduce costs, and its performance is far superior to that of medium-density boards and large-core boards. The wear-resistant lamination process is to press and paste the wear-resistant paper to the surface of the substrate layer of the floor. Of course, the wear-resistant layer here is not limited to wear-resistant paper, and may also be other wear-resistant materials. The balance layer uses the pressing process to press the waterproof material onto the base layer. The main function is that the balance layer is directly installed on the ground during the installation process. After adding the balance layer, it can play a waterproof role and ensure that the floor is in It is not easy to deform under conditions such as moisture and heat.

在上述的指接木实木地板中,所述的指接木由实木木条压制而成。In the above-mentioned finger-joined wood solid wood floor, the finger-joined wood is pressed from solid wood strips.

现有的实木地板是无法设置模压倒角的,在上述的指接木实木地板中,所述的平衡层的周边设有模压倒角。Existing solid wood floors cannot be provided with molded chamfers. In the above-mentioned finger-jointed solid wood floors, molded chamfers are provided around the balance layer.

与现有的技术相比,本指接木实木地板的优点在于:1、设计合理,结构简单,易于加工制造,能够有效利用废弃材料,不仅节约了生产成本,在性能上也兼具强化地板和实木地板的优点。2、由于设置了耐磨层,有效提升了耐磨性,且当选用特定的耐磨材料时能够实现阻燃。3、由于设置了平衡层,有效提升了防水效果,应用范围广泛。Compared with the existing technology, the advantages of this finger-joined solid wood floor are: 1. Reasonable design, simple structure, easy processing and manufacturing, and effective use of waste materials, which not only saves production costs, but also has both laminated flooring and flooring in performance. Advantages of solid wood flooring. 2. Due to the installation of the wear-resistant layer, the wear resistance is effectively improved, and when a specific wear-resistant material is selected, flame retardancy can be achieved. 3. Due to the setting of the balance layer, the waterproof effect is effectively improved, and the application range is wide.

附图说明Description of drawings

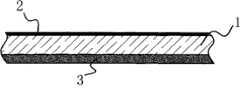

图1是本实用新型提供的剖视结构示意图。Fig. 1 is a schematic cross-sectional structure provided by the utility model.

图中,基材层1、耐磨层2、平衡层3。In the figure,

具体实施方式Detailed ways

如图1所示,本指接木实木地板包括由指接木制成的基材层1,在基材层1的一面复合有由耐磨材料制成的耐磨层2,在基材层1的另一面复合有由防水材料制成的平衡层3。指接木由实木木条压制而成。平衡层3的周边设有模压倒角。这里的耐磨层2和平衡层3均通过压贴工艺复合在基材层1上。As shown in Figure 1, the finger-jointed solid wood flooring comprises a

本文中所描述的具体实施例仅仅是对本实用新型精神作举例说明。本实用新型所属技术领域的技术人员可以对所描述的具体实施例做各种各样的修改或补充或采用类似的方式替代,但并不会偏离本实用新型的精神或者超越所附权利要求书所定义的范围。The specific embodiments described herein are only examples to illustrate the spirit of the present invention. Those skilled in the technical field to which the utility model belongs can make various modifications or supplements to the described specific embodiments or adopt similar methods to replace them, but they will not deviate from the spirit of the utility model or go beyond the appended claims defined range.

尽管本文较多地使用了基材层1、耐磨层2、平衡层3等术语,但并不排除使用其它术语的可能性。使用这些术语仅仅是为了更方便地描述和解释本实用新型的本质;把它们解释成任何一种附加的限制都是与本实用新型精神相违背的。Although terms such as

Claims (3)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010206732301UCN201924562U (en) | 2010-12-22 | 2010-12-22 | Finger joint wood solid wood floor |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010206732301UCN201924562U (en) | 2010-12-22 | 2010-12-22 | Finger joint wood solid wood floor |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN201924562Utrue CN201924562U (en) | 2011-08-10 |

Family

ID=44428421

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2010206732301UExpired - Fee RelatedCN201924562U (en) | 2010-12-22 | 2010-12-22 | Finger joint wood solid wood floor |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN201924562U (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102529290A (en)* | 2011-12-26 | 2012-07-04 | 广州易福诺木业有限公司 | Preparation method for decorative plate |

| CN103255900A (en)* | 2013-06-03 | 2013-08-21 | 德尔国际家居股份有限公司 | Multilayer finger joint waterproof solid wood floor |

- 2010

- 2010-12-22CNCN2010206732301Upatent/CN201924562U/ennot_activeExpired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102529290A (en)* | 2011-12-26 | 2012-07-04 | 广州易福诺木业有限公司 | Preparation method for decorative plate |

| CN103255900A (en)* | 2013-06-03 | 2013-08-21 | 德尔国际家居股份有限公司 | Multilayer finger joint waterproof solid wood floor |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN105014766B (en) | A kind of floor dash board and its manufacture method | |

| CN202627850U (en) | Environment-friendly energy-saving anti-deformation pure-solid-wood multilayer-board solid door | |

| CN201924562U (en) | Finger joint wood solid wood floor | |

| CN202414545U (en) | Container floorboard | |

| CN102294723A (en) | Non-degreased masson pine solid wood composite floor and production method thereof | |

| CN202248762U (en) | Solid wood composite floor | |

| CN201224977Y (en) | Sound-proof heat-insulation floor | |

| CN102225561A (en) | Equidirectional hardwood jointed board and manufacturing method thereof | |

| CN203317487U (en) | Novel composite board | |

| CN100419190C (en) | Solid wood composite floor board having vent hole structure on base material and its manufacturing method | |

| CN204343626U (en) | A kind of novel environment friendly waterproof wooden sandwich floor | |

| CN203557477U (en) | Low-carbon dampproof hipboard | |

| CN201824427U (en) | A composite floor substrate | |

| CN202718336U (en) | Cotton fiber composite plate | |

| CN206344257U (en) | A kind of low-carbon damp-proof blockboard | |

| CN204850896U (en) | Tide gate lagging | |

| CN205742889U (en) | Waterproof temperature resistance becomes composite bamboo timber floor | |

| CN204475772U (en) | A kind of multi-layer solid wood composite floor of epidermis anticracking | |

| CN205185442U (en) | Wood ecological plate | |

| CN201981759U (en) | Composite cork floor | |

| CN202220420U (en) | Waterproof composite floor | |

| CN202866242U (en) | Solid wood multi-layer composite floor | |

| CN206016116U (en) | A kind of Decorative bamboo sheet | |

| CN201833446U (en) | China fir plywood | |

| CN205466592U (en) | Regeneration wood indicates to connect multilayer composite sheet |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20110810 Termination date:20131222 |