CN201637149U - Spiral pulsating heat pipe solar water heater - Google Patents

Spiral pulsating heat pipe solar water heaterDownload PDFInfo

- Publication number

- CN201637149U CN201637149UCN2010201723240UCN201020172324UCN201637149UCN 201637149 UCN201637149 UCN 201637149UCN 2010201723240 UCN2010201723240 UCN 2010201723240UCN 201020172324 UCN201020172324 UCN 201020172324UCN 201637149 UCN201637149 UCN 201637149U

- Authority

- CN

- China

- Prior art keywords

- heat pipe

- spiral

- glass tube

- pulsating heat

- vacuum glass

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000titleclaimsabstractdescription69

- 239000011521glassSubstances0.000claimsabstractdescription34

- 238000001704evaporationMethods0.000claimsabstractdescription16

- 238000009833condensationMethods0.000claimsabstractdescription14

- 230000005494condensationEffects0.000claimsabstractdescription14

- 230000008020evaporationEffects0.000claimsabstractdescription13

- 230000010349pulsationEffects0.000claimsdescription9

- 238000009413insulationMethods0.000claimsdescription2

- 239000007788liquidSubstances0.000abstractdescription11

- 238000012546transferMethods0.000abstractdescription11

- 238000000034methodMethods0.000abstractdescription9

- 230000000694effectsEffects0.000abstractdescription5

- 230000010355oscillationEffects0.000abstractdescription5

- 238000005728strengtheningMethods0.000abstract1

- 238000004134energy conservationMethods0.000description6

- 238000011161developmentMethods0.000description3

- 238000010438heat treatmentMethods0.000description3

- 239000002184metalSubstances0.000description3

- 229910052751metalInorganic materials0.000description3

- 238000009834vaporizationMethods0.000description3

- 230000008016vaporizationEffects0.000description3

- CSCPPACGZOOCGX-UHFFFAOYSA-NAcetoneChemical compoundCC(C)=OCSCPPACGZOOCGX-UHFFFAOYSA-N0.000description2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000description2

- 238000010521absorption reactionMethods0.000description2

- 230000007812deficiencyEffects0.000description2

- 238000005265energy consumptionMethods0.000description2

- 239000012530fluidSubstances0.000description2

- RYGMFSIKBFXOCR-UHFFFAOYSA-NCopperChemical compound[Cu]RYGMFSIKBFXOCR-UHFFFAOYSA-N0.000description1

- 230000009286beneficial effectEffects0.000description1

- 239000004566building materialSubstances0.000description1

- 229910052802copperInorganic materials0.000description1

- 239000010949copperSubstances0.000description1

- 230000007547defectEffects0.000description1

- 238000010586diagramMethods0.000description1

- 239000012153distilled waterSubstances0.000description1

- 230000005484gravityEffects0.000description1

- 238000009434installationMethods0.000description1

- 230000007774longtermEffects0.000description1

- 238000004806packaging method and processMethods0.000description1

- 238000012545processingMethods0.000description1

- 230000005855radiationEffects0.000description1

- 238000011160researchMethods0.000description1

- 238000007789sealingMethods0.000description1

- 229910001220stainless steelInorganic materials0.000description1

- 239000010935stainless steelSubstances0.000description1

Images

Classifications

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D15/00—Heat-exchange apparatus with the intermediate heat-transfer medium in closed tubes passing into or through the conduit walls ; Heat-exchange apparatus employing intermediate heat-transfer medium or bodies

- F28D15/02—Heat-exchange apparatus with the intermediate heat-transfer medium in closed tubes passing into or through the conduit walls ; Heat-exchange apparatus employing intermediate heat-transfer medium or bodies in which the medium condenses and evaporates, e.g. heat pipes

- F28D15/0266—Heat-exchange apparatus with the intermediate heat-transfer medium in closed tubes passing into or through the conduit walls ; Heat-exchange apparatus employing intermediate heat-transfer medium or bodies in which the medium condenses and evaporates, e.g. heat pipes with separate evaporating and condensing chambers connected by at least one conduit; Loop-type heat pipes; with multiple or common evaporating or condensing chambers

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24S—SOLAR HEAT COLLECTORS; SOLAR HEAT SYSTEMS

- F24S10/00—Solar heat collectors using working fluids

- F24S10/90—Solar heat collectors using working fluids using internal thermosiphonic circulation

- F24S10/95—Solar heat collectors using working fluids using internal thermosiphonic circulation having evaporator sections and condenser sections, e.g. heat pipes

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/40—Solar thermal energy, e.g. solar towers

- Y02E10/44—Heat exchange systems

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Sustainable Energy (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Heat-Pump Type And Storage Water Heaters (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本实用新型属于太阳能热利用及传热、传质技术领域,特别涉及一种螺旋脉动热管太阳能热水器。The utility model belongs to the technical field of solar heat utilization, heat transfer and mass transfer, in particular to a spiral pulsating heat pipe solar water heater.

背景技术Background technique

建筑节能是我国三大重点节能领域之一。在我国已有的4×1010m2建筑中,有99%属于高耗能建筑。即使是新建建筑,仍有95%以上为高耗能建筑,我国单位建筑耗能比同等气候条件下的发达国家高2~3倍。因此,建筑节能是我国“节能、减排”工作重要组成部分,开展建筑节能具有重要的现实意义和长远意义。开展建筑节能,除了要开发节能的建筑材料外,很重要的一个方面是要大力开发利用可再生能源。太阳能是在建筑节能中可以发挥显著作用的可再生能源。我国地处阳光充沛的亚热带地区,地域辽阔,太阳能年辐射总量超过5MJ/m2,年日照时数超过2200小时的地区占国土面积的2/3,属太阳能资源丰富的国家之一。为此,研究开发高效的太阳能集热装置具有重要的意义。Building energy conservation is one of the three key energy conservation areas in my country. Among the existing 4×1010 m2 buildings in our country, 99% are high energy consumption buildings. Even for new buildings, more than 95% of them are high-energy-consuming buildings. The energy consumption per unit of building in my country is 2-3 times higher than that of developed countries under the same climatic conditions. Therefore, building energy conservation is an important part of my country's "energy saving and emission reduction" work, and the development of building energy conservation has important practical and long-term significance. To carry out building energy conservation, in addition to the development of energy-saving building materials, a very important aspect is to vigorously develop and utilize renewable energy. Solar energy is a renewable energy that can play a significant role in building energy conservation. China is located in a sunny subtropical region with a vast territory. The total annual solar radiation exceeds 5MJ/m2 , and the area with annual sunshine hours exceeding 2200 hours accounts for 2/3 of the country's land area. It is one of the countries with abundant solar energy resources. For this reason, it is of great significance to research and develop efficient solar thermal collectors.

脉动热管PHP(Pulsating Heat Pipe)又可称为自激振荡流热管SEMOHP(Self-Exciting Mode Oscillating-Flow Heat Pipe)、振荡流热管OFHP(Oscillating-Flow Heat Pipe)或振荡热管OHP(Oscillating Heat Pipe)是1994年日本学者Akachi发明的。它是将直径小于5mm的金属管弯曲成由若干直管和若干弯头组成的形状,在真空条件下封装一定质量工作液体。由于管径足够小,管内工作介质在毛细力等因素的作用下,形成交替分布的气塞和液柱。按其循环系统的不同,可分为首尾连成闭合回路的回路型和首尾端不相连的非回路型两种。当脉动热管一端加热段受热时,管内液体受热蒸发膨胀,向另一端冷凝段运动,并被冷凝放出汽化潜热,重新变为液态,致使在冷热端之间产生很大的压差。由于气-液柱塞交错分布,导致管内产生强烈的往复振荡运动。脉动热管的脉动频率远远高于传统热管内的气-液闭合循环频率,同时,其工作介质与热管壁面间的换热过程也因受到剧烈脉动的作用而大大强化。另外,脉动热管还具有结构简单,不需要毛细芯,有利于降低成本;加热位置和加热方式不受限制(常用的重力热管必须底部加热);可以随意弯曲,适用范围广;以及管径小,重量轻,易于实现微型化和启动迅速等突出优点。但现有技术脉动热管还未开发应用于太阳能热水器方面。所以目前的太阳能热水器具有管径大、重量比较重、结构复杂、热启动慢、成本高等缺点和不足。Pulsating Heat Pipe PHP (Pulsating Heat Pipe) can also be called SEMOHP (Self-Exciting Mode Oscillating-Flow Heat Pipe), OFHP (Oscillating-Flow Heat Pipe) or OHP (Oscillating Heat Pipe) It was invented by Japanese scholar Akachi in 1994. It bends a metal tube with a diameter of less than 5mm into a shape consisting of several straight tubes and several elbows, and encapsulates a certain quality of working liquid under vacuum conditions. Because the pipe diameter is small enough, the working medium in the pipe forms alternately distributed gas plugs and liquid columns under the action of factors such as capillary force. According to the different circulatory systems, it can be divided into two types: the loop type with the end connected into a closed loop and the non-loop type with the end not connected. When the heating section at one end of the pulsating heat pipe is heated, the liquid in the tube is heated, evaporates and expands, moves to the condensation section at the other end, and is condensed to release the latent heat of vaporization, and becomes liquid again, resulting in a large pressure difference between the hot and cold ends. Due to the staggered distribution of gas-liquid plungers, strong reciprocating oscillations are generated in the tube. The pulsation frequency of the pulsating heat pipe is much higher than the gas-liquid closed cycle frequency in the traditional heat pipe. At the same time, the heat exchange process between the working medium and the wall of the heat pipe is also greatly enhanced by the violent pulsation. In addition, the pulsating heat pipe also has a simple structure and does not require a capillary core, which is beneficial to reduce costs; the heating position and heating method are not limited (the commonly used gravity heat pipe must be heated at the bottom); it can be bent at will and has a wide range of applications; and the pipe diameter is small, It has outstanding advantages such as light weight, easy miniaturization and rapid start-up. But the prior art pulsating heat pipe has not yet been developed and applied to solar water heaters. Therefore, current solar water heaters have the disadvantages and deficiencies such as large pipe diameter, relatively heavy weight, complex structure, slow thermal start-up, and high cost.

发明内容Contents of the invention

针对现有技术的不足和缺陷,本实用新型提供一种结构简单、集热效果好的螺旋脉动热管太阳能热水器。Aiming at the deficiencies and defects of the prior art, the utility model provides a spiral pulsating heat pipe solar water heater with simple structure and good heat collection effect.

本实用新型是这样设计的:一种螺旋脉动热管太阳能热水器,其特征在于,包括水箱、冷凝段、盖板、蒸发段、真空玻璃管,其中真空玻璃管和水箱中设有螺旋脉动热管,螺旋脉动热管分冷凝段和蒸发段,所述冷凝段位于水箱内,蒸发段位于真空玻璃管内,所述水箱和真空玻璃管通过盖板相连接,所述的水箱设有进口和出口,所述的盖板和水箱通过胶垫密封,所述的盖板和真空玻璃管通过胶圈密封,所述的水箱主体外加保温层,所述的螺旋脉动热管是内径小于5mm的金属管。The utility model is designed in this way: a spiral pulsating heat pipe solar water heater is characterized in that it includes a water tank, a condensation section, a cover plate, an evaporation section, and a vacuum glass tube, wherein the vacuum glass tube and the water tank are provided with a spiral pulsating heat pipe, a spiral The pulsating heat pipe is divided into a condensation section and an evaporation section. The condensation section is located in the water tank, and the evaporation section is located in the vacuum glass tube. The water tank and the vacuum glass tube are connected through a cover plate. The water tank is provided with an inlet and an outlet. The cover plate and the water tank are sealed by a rubber gasket, the cover plate and the vacuum glass tube are sealed by a rubber ring, the main body of the water tank is provided with an insulation layer, and the spiral pulsating heat pipe is a metal pipe with an inner diameter of less than 5mm.

本实用新型的脉动热管由内径小于5mm的相应直管段和螺旋管段组成封闭回路,为了更好地吸收太阳能,整个螺旋脉动热管太阳能热水器倾斜一定的角度,工作时除了具有传统的真空玻璃管太阳能热水器的吸热方式外,由于真空玻璃管与水箱内的水存在温差,真空玻璃管内的水使得脉动热管蒸发段内的工质蒸发膨胀,向冷凝段运动,并被冷凝放出汽化潜热,重新变为液态,致使在蒸发段和冷凝段之间很大压差的作用下,产生强烈的往复振荡运动,在脉动热管内工质显热和潜热的共同作用下,使得螺旋脉动热管太阳能热水器与传统的真空玻璃管太阳能热水器相比,集热效果明显得到提高。由于脉动热管的螺旋弹性结构,工作时管内工质的振荡也强化了脉动热管与热水器内水的对流传热过程。另外,由于脉动热管的双向传热特性,某种程度上还可以防止冬季寒冷夜晚真空玻璃管被冻裂。所以本实用新型具有结构简单、集热效果佳、热启动快、加工成本低等优点,便于实施开发利用。The pulsating heat pipe of the utility model is composed of a corresponding straight pipe section and a spiral pipe section with an inner diameter of less than 5mm to form a closed circuit. In order to better absorb solar energy, the whole spiral pulsating heat pipe solar water heater is inclined at a certain angle. In addition to the heat absorption method, due to the temperature difference between the vacuum glass tube and the water in the water tank, the water in the vacuum glass tube causes the working medium in the evaporation section of the pulsating heat pipe to evaporate and expand, and moves to the condensation section, where it is condensed to release the latent heat of vaporization and becomes Liquid state, resulting in a strong reciprocating oscillation movement under the action of a large pressure difference between the evaporation section and the condensation section. Compared with the vacuum glass tube solar water heater, the heat collection effect is obviously improved. Due to the helical elastic structure of the pulsating heat pipe, the oscillation of the working medium in the tube also strengthens the convective heat transfer process between the pulsating heat pipe and the water in the water heater during operation. In addition, due to the two-way heat transfer characteristics of the pulsating heat pipe, it can also prevent the vacuum glass tube from being frozen and cracked in the cold winter night to some extent. Therefore, the utility model has the advantages of simple structure, good heat collection effect, fast heat start, low processing cost, etc., and is convenient for implementation, development and utilization.

附图说明Description of drawings

下面结合附图说明及具体实施方式对本实用新型作进一步说明。The utility model will be further described below in conjunction with the accompanying drawings and specific embodiments.

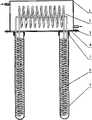

图1为螺旋脉动热管太阳能热水器结构示意图。Figure 1 is a structural schematic diagram of a spiral pulsating heat pipe solar water heater.

图2为螺旋脉动热管太阳能热水器结构左视图。Fig. 2 is the left view of the structure of the spiral pulsating heat pipe solar water heater.

图中1为水箱、2为冷凝段、3为胶垫、4为盖板、5胶圈、6为蒸发段、7为真空玻璃管。In the figure, 1 is a water tank, 2 is a condensation section, 3 is a rubber pad, 4 is a cover plate, 5 is an apron, 6 is an evaporation section, and 7 is a vacuum glass tube.

具体实施方式Detailed ways

本实用新型涉及一种螺旋脉动热管太阳能热水器,如图1所示,属于太阳能热利用及传热、传质领域。包括水箱1、冷凝段2、盖板4、蒸发段6、真空玻璃管7,真空玻璃管7和水箱1中设有螺旋脉动热管,螺旋脉动热管由内径小于5mm的相应直管段和螺旋管段组成封闭回路,螺旋脉动热管由内径小于5mm的金属铜或不锈钢材料,管内真空状态下充入占整个管容积50%~70%的工质(蒸馏水、乙醇或丙酮等),工质在管内会形成交替分布的液柱和气塞。螺旋脉动热管分冷凝段2和蒸发段6,螺旋脉动热管蒸发段6位于真空玻璃管7内,冷凝段2位于水箱1内;水箱1与真空玻璃管7联通并充满水;水箱设有进口和出口,盖板4和水箱1通过胶垫3密封,盖板4和真空玻璃管7通过胶圈5密封。The utility model relates to a spiral pulsating heat pipe solar water heater, as shown in Fig. 1, belonging to the field of solar heat utilization, heat transfer and mass transfer. Including water tank 1,

为了更好地吸收太阳能,整个螺旋脉动热管太阳能热水器倾斜一定的角度,工作时除了具有传统的真空玻璃管太阳能热水器的吸热方式外,由于真空玻璃管7与水箱1内的水存在温差,真空玻璃管7内的水使得脉动热管蒸发段6内的工质蒸发膨胀,向冷凝段2运动,并被冷凝放出汽化潜热,重新变为液态,致使在蒸发段6和冷凝段2之间很大压差的作用下,产生强烈的往复振荡运动,在脉动热管内工质显热和潜热的共同作用下,使得螺旋脉动热管太阳能热水器与传统的真空玻璃管太阳能热水器相比,集热效果明显得到提高。由于脉动热管的螺旋弹性结构,工作时管内工质的振荡也强化了脉动热管与热水器内水的对流传热过程。另外,由于脉动热管的双向传热特性,某种程度上还可以防止冬季寒冷夜晚真空玻璃管被冻裂。In order to better absorb solar energy, the entire spiral pulsating heat pipe solar water heater is tilted at a certain angle. In addition to the heat absorption method of the traditional vacuum glass tube solar water heater during operation, due to the temperature difference between the vacuum glass tube 7 and the water in the water tank 1, the vacuum The water in the glass tube 7 causes the working medium in the evaporating section 6 of the pulsating heat pipe to evaporate and expand, and moves to the

为了便于脉动热管的安装,水箱主体由水箱1和盖板4组成,其间用胶垫3密封,并设进、出口,工作时水箱主体外加保温。盖板4上孔数取决于真空玻璃管7的数量,脉动热管根据真空玻璃管7的数量做成图1所示的结构,经过抽真空、灌液、封装等程序后,放入热水器内。真空玻璃管7与盖板4装配时加入胶圈5以保证真空玻璃管的端部和径向的密封性能。螺旋脉动热管太阳能热水器正常工作时,可另加支架和托板,以保证热水器倾斜一定的角度以及真空玻璃管的稳固。In order to facilitate the installation of the pulsating heat pipe, the main body of the water tank is composed of a water tank 1 and a

Claims (6)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010201723240UCN201637149U (en) | 2010-04-28 | 2010-04-28 | Spiral pulsating heat pipe solar water heater |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010201723240UCN201637149U (en) | 2010-04-28 | 2010-04-28 | Spiral pulsating heat pipe solar water heater |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN201637149Utrue CN201637149U (en) | 2010-11-17 |

Family

ID=43081646

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2010201723240UExpired - Fee RelatedCN201637149U (en) | 2010-04-28 | 2010-04-28 | Spiral pulsating heat pipe solar water heater |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN201637149U (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103776288A (en)* | 2014-01-15 | 2014-05-07 | 桂林电子科技大学 | Pulsating heat pipe |

| CN105651090A (en)* | 2016-02-20 | 2016-06-08 | 内蒙古博特科技有限责任公司 | Novel nano pulse heat superconducting device of three-dimensional spiral condensation structure |

| CN105737402A (en)* | 2016-02-20 | 2016-07-06 | 内蒙古博特科技有限责任公司 | Three-dimensional nano-pulsed heat superconducting CPC medium-high-temperature solar heat collector |

| CN106321381A (en)* | 2016-08-31 | 2017-01-11 | 北京建筑大学 | Organic Rankine cycle power-generation device and flow control method for heat collecting liquid |

| CN109367355A (en)* | 2018-10-15 | 2019-02-22 | 江苏东方电热器制造有限公司 | A kind of new-energy automobile PTC electric heater |

| CN110579026A (en)* | 2019-08-02 | 2019-12-17 | 广东工业大学 | A line-focused pulsating heat pipe vacuum heat collection device |

| CN110579027A (en)* | 2019-08-20 | 2019-12-17 | 广东工业大学 | A solar vacuum heat collector based on rolled flat pulsating heat pipe |

- 2010

- 2010-04-28CNCN2010201723240Upatent/CN201637149U/ennot_activeExpired - Fee Related

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103776288A (en)* | 2014-01-15 | 2014-05-07 | 桂林电子科技大学 | Pulsating heat pipe |

| CN103776288B (en)* | 2014-01-15 | 2016-01-13 | 桂林电子科技大学 | A pulsating heat pipe |

| CN105651090A (en)* | 2016-02-20 | 2016-06-08 | 内蒙古博特科技有限责任公司 | Novel nano pulse heat superconducting device of three-dimensional spiral condensation structure |

| CN105737402A (en)* | 2016-02-20 | 2016-07-06 | 内蒙古博特科技有限责任公司 | Three-dimensional nano-pulsed heat superconducting CPC medium-high-temperature solar heat collector |

| CN105651090B (en)* | 2016-02-20 | 2017-09-01 | 内蒙古博特科技有限责任公司 | Novel three-dimensional spiral condensation structure nanometer pulsation thermal superconducting device |

| CN106321381A (en)* | 2016-08-31 | 2017-01-11 | 北京建筑大学 | Organic Rankine cycle power-generation device and flow control method for heat collecting liquid |

| CN106321381B (en)* | 2016-08-31 | 2018-10-12 | 北京建筑大学 | The flow control method of Organic Rankine Cycle power generator and thermal-arrest liquid |

| CN109367355A (en)* | 2018-10-15 | 2019-02-22 | 江苏东方电热器制造有限公司 | A kind of new-energy automobile PTC electric heater |

| CN110579026A (en)* | 2019-08-02 | 2019-12-17 | 广东工业大学 | A line-focused pulsating heat pipe vacuum heat collection device |

| CN110579027A (en)* | 2019-08-20 | 2019-12-17 | 广东工业大学 | A solar vacuum heat collector based on rolled flat pulsating heat pipe |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN201637149U (en) | Spiral pulsating heat pipe solar water heater | |

| CN104279770B (en) | Solar medium-high temperature loop heat pipe steam generator | |

| CN203323422U (en) | Building integrated energy storage type solar gravity assisted heat pipe and heat pump heating supply system | |

| CN103245085B (en) | A kind of accumulating type solar oscillating heat pipe heat pump heat distribution system and method thereof | |

| CN102087053B (en) | Solar flat plate collector capable of exchanging heat through micro-channel | |

| CN104501455B (en) | Combined heating and cooling solar-assisted heat pump system | |

| CN201363922Y (en) | Heat tube tank type solar collector | |

| CN103335415B (en) | A kind of phase-change thermal storage solar water heater strengthening heat absorption | |

| CN103912999B (en) | A kind of phase-change thermal storage solar water heater with new radiator structure | |

| CN101408353A (en) | Hot pipe type solar heat collector | |

| CN100447522C (en) | A solar vacuum glass heat collecting tube using an oscillating flow heat pipe as a heat-absorbing inner tube | |

| CN201897329U (en) | Superconduction flat-plate solar collector | |

| CN101387447B (en) | Graphite filled vacuum glass tube closed-loop capillary solar collector tube | |

| CN204128219U (en) | A kind of solar energy phase transition heat accumulation heating plant | |

| CN202955901U (en) | Solar vacuum heat collection pipe capable of enlarging absorption area and improving compressive capacity | |

| CN203269609U (en) | Solar seawater desalination device | |

| CN203099981U (en) | Wall-mounted type flat-plate solar heating device of power-driven separating type heat pipe | |

| CN207230959U (en) | Air source heat pump equipped with solar energy heating structure | |

| CN204535158U (en) | A kind of for solar water heater new heat pipe defroster | |

| CN201764721U (en) | Wall-mounted solar water heater for heating and bathing | |

| CN204313527U (en) | Changes in temperature alliance solar-assisted heat pump system | |

| CN204830537U (en) | Heat pipe vacuum tubular solar energy collection parts | |

| CN209763519U (en) | Horizontal drop heat conduction pipe for solar water heater | |

| CN208871881U (en) | Flat Oscillating Flow Heat Pipe Solar Collector | |

| CN101737966A (en) | Vacuum-tube heat-pipe combined high-temperature high-pressure steam solar heater |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20101117 Termination date:20110428 |